John Wood Commercial ANED User Manual

COMMERCIAL

GAS WATER HEATER

INSTALLATION, OPERATING

AND MAINTENANCE INSTRUCTION MANUAL

- Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

- WHAT TO DO IF YOU SMELL GAS

- Do not try to light any appliance.

- Do not touch any electrical switch; do

not use any phone in your building.

- Immediately call your gas supplier from

a neighbor’s phone. Follow the gas

supplier’s instructions.

- If you cannot reach your gas supplier,

call the fire department.

- Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

WARNING: If the information in these

instructions is not followed exactly, a

fire or explosion may result causing

property damage, personal injury or

death.

READ THESE INSTRUCTIONS THOROUGHLY BEFORE STARTING

AND RETAIN THESE INSTRUCTIONS IN A SAFE LOCATION

FOR FUTURE REFERENCE

71781

IMPORTANT

FOR THE INSTALLER AND USER OF

THIS GAS FIRED WATER HEATER

These instructions have been written for the proper

installation and safe operation of this water heater. The

installation must conform with one or more of the following as applicable:

Canadian Installation:

1. The latest edition of CAN/CGA B149.

2. Public Utility and/or local Codes

U.S. Installation:

1. Public Utility and/or local Codes

2. The latest edition of the National Fuel Gas Code

ANSI Z 223.1/NFPA 54

WARNING

This water heater must be installed strictly in accordance

with the detailed instructions enclosed and local building

codes. It must be installed with a proper temperature and

pressure relief valve which may release water in normal operation. It is also possible that connections to the water heater,

or the water heater itself may develop leaks. IT IS THERE-

FORE IMPERATIVE that the water heater be installed so that

any water is directed to an adequate drain in such a way that

it cannot damage the building, furniture, carpeting or other

property subject to water damage. THE COMPANY CANNOT

BE HELD RESPONSIBLE for damage caused by water from

the water heater, pressure relief valve or related fittings where

adequate provision to drain such water has not been made.

Closets without drains and carpeted areas are examples of

unsuitable locations for any water heater.

The warranty on this water heater is in effect only when

the heater is installed and operated in accordance with

these instructions. The manufacturer of this heater will

not be liable for any damage resulting from failure to

comply with these instructions.

IMPORTANT: Before starting the installation read

the rating plate on the heater. The gas listed must be

the same as the gas supplied to the premises. A

heater designed for Natural Gas must only be

hooked up to a natural gas supply, and likewise, a

heater designed for Propane Gas must only be

hooked up to propane.

DO NOT PROCEED UNLESS GAS TYPE OF

HEATER AND GAS SUPPLY HAVE BEEN

IDENTIFIED TO BE THE SAME.

LOCATION

Location selected should be as close to the stack or chimney

as practical and as centralized with the piping system as possible. Heater should be located in an area not subject to

freezing temperatures.

The water heater should be located so that the controls and

drain are easily accessible. The heater should be located in

an area where leakage of the tank or connections will not

result in damage to the area adjacent to the water heater or

to lower floors of the structure. When such locations cannot

be provided, it is recommended that a suitable drain pan be

installed under the heater. Such pans should be a maximum

2” deep and have a minimum length and width at least two

inches greater than the diameter of the water heater and

should be piped to an adequate drain. The pan must not

restrict combustion air flow.

Under no circumstances is the manufacturer to be held liable

for any water damage in connection with this water heater.

The water heater must be level on the floor surface.

Any enclosure surrounding the installation must allow an adequate supply of ventilation and combustion air to the water

heater. Otherwise sufficient air must be drawn from outside

the enclosure. Air may be drawn into the enclosure through an

opening. The opening shall have a free area of 1 square inch

per thousand BTU’s and be located below 18 inches and

above 6 inches as measured to the floor.

Chemical vapour corrosion can occur anywhere that flue

gases are carrying cleaning solvents, refrigerants, pool chemicals, chlorine salts. The location of the water heater should

not be near any of these chemicals.

Minimum clearances from the water heater and venting

arrangement to combustible materials are: ( See also Fig. 1

and 2).

Electronic Ignition Model -G65

3 inches from sides

3 inches from back

6 inches above vent pipe

Electronic Ignition Models - (all others)

6 inches from sides

6 inches from back

6 inches above vent pipe

Standing Pilot Models

6 inches from sides

6 inches from back

6 inches above vent pipe

Page 1

CAUTION: When this heater is installed directly on

carpeting, carpeting must be protected by a metal

or wood panel beneath the appliance, extending

beyond the full width and depth of the appliance by

at least 3 inches in any direction. If the appliance is

installed in an alcove, the entire floor must be

covered by the panel. Failure to heed this warning

may result in fire hazard.

Page 2

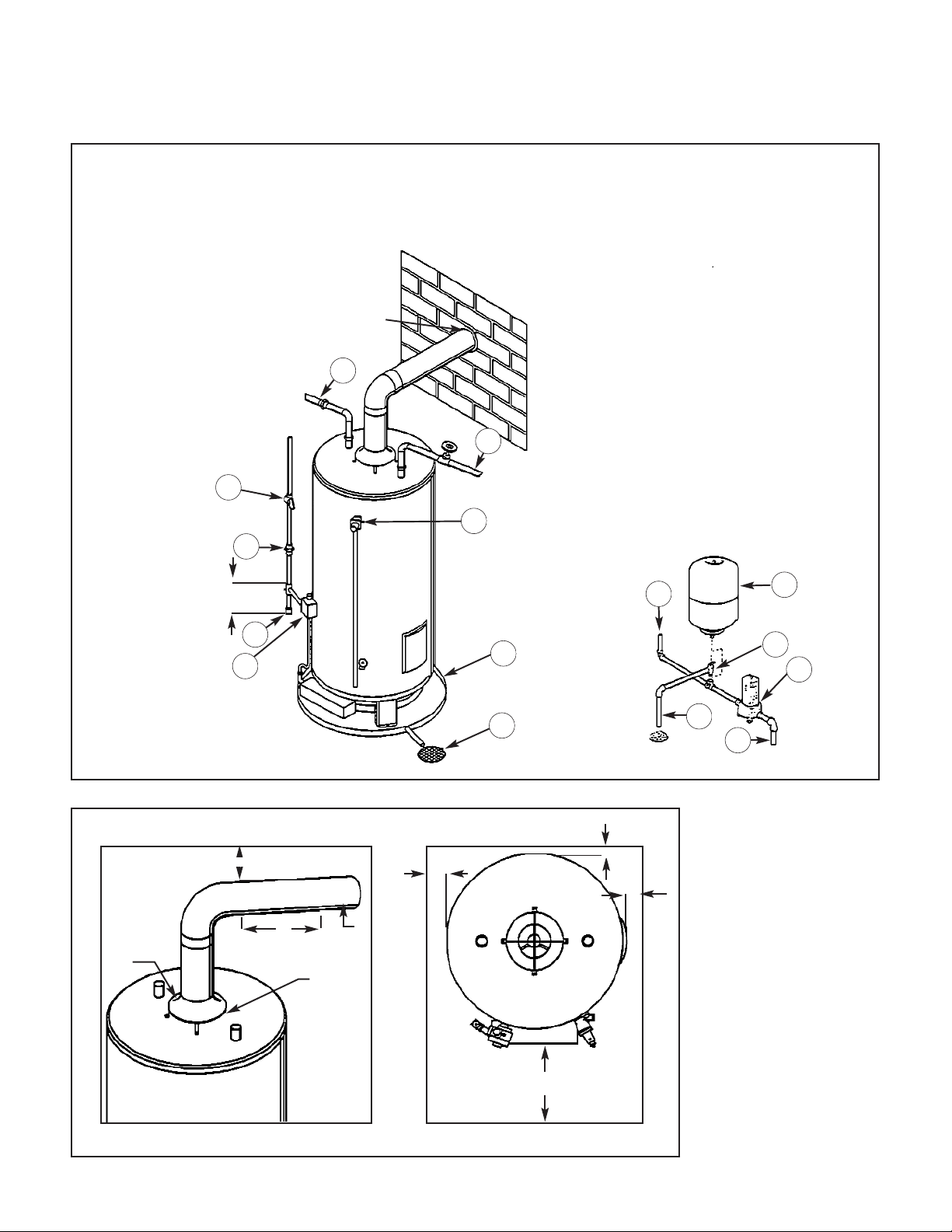

Figure 1

1. Cold water inlet

2. Hot water outlet

3. Gas supply manual shut-off valve

4. Sediment trap

5. Union - ground joint type

6. Gas control

7. Temperature & pressure relief valve

8. Floor drain

9. Drain pan (if used)

Figure 3

Location of pressure relief and/or expansion tank if a

check valve or pressure reducing valve is in the cold

water supply to the house.

Use option 1 or 2 as convenient. If pressure relief

valve is used, select one with a setting 25 psi. below

rating at tank.

10. Water supply to meter

11. Water supply to home

12. Water meter with backflow preventer

13. Overflow

14. Pressure relief valve

15. Expansion tank

seal tightly

11

15

14

12

13

10

8

9

7

1

2

3

5

4

6

6”

Figure 2

12

6

1/4

SHEET METAL

SCREWS

3”

3”

3”

MAINTAIN 26”

FOR ACCESS

Option 1

Option 2

DRAFT

HOOD

WATER PIPING

Pipes and fittings should be installed in compliance with the

installation drawing. Makes sure the dip tube is in the cold

water fitting and water connections are made correctly.

Have the installer show you where the water shut-off valve for

the water heater has been installed so that you know where

and how to shut the water off. It is recommended that such a

valve be located in close proximity to the cold water inlet of

the water heater. (See installation drawing, Figure 3).

Connect the cold water supply to the fitting marked “COLD”

the hot water outlet to the fitting marked “HOT”. Do not apply

heat to either of these fittings. It is imperative that no heat

be applied to these fittings as they contain a non-metallic

tube. When marking these connections, always use a good

grade of pipe joint compound and be certain that all fittings

are drawn up tight.

After piping has been installed, allow tank to fill up with water

and check connections for leaks. To ensure complete filling of

the tank, allow air to exit by opening the nearest hot water

faucet until a constant flow of water is obtained.

Check your area for water hardness. Hard water conditions

can shorten tank life or cause excessive maintenance. When

hard water conditions exist water softening is the best answer

to protect both the water heater and the appliances using hot

water.

Pressure Build-up in a Water System

During the heating cycle of the water heater, the water

expands, creating a pressure build-up in the water system. The water supply meter may contain a check valve or

back-flow preventer, creating a closed water system. A

method of controlling thermal expansion would then be

required. Contact the water supplier or local plumbing

inspector for instructions to control the situation.

A temperature and pressure relief valve must be installed

on the water heater (150 p.s.i maximum pressure setting.

See Temperature and Pressure Relief Valve, below.)

Should the relief valve discharge water, a potentially

dangerous situation may be indicated and must be investigated. Have the operation of the heater checked by a

qualified service person.

Temperature and Pressure Relief Valve

For protection against excessive pressure and/or

temperatures, a temperature and pressure relief valve must

be installed in the opening marked “T&P VALVE” - a design

certified by a nationally recognized testing laboratory that

maintains periodic inspection of production of listed equipment

or materials, as meeting the requirements of Relief Valves and

Automatic Gas Shutoff Devices for Hot Water Supply

Systems, ANSI Z 21.22 - latest edition. Pressure rating of the

valve must not exceed the working pressure shown on the rating plate of the water heater. The discharge capacity must

be equal to or greater than the input to the water heater.

Water heaters intended to be shipped to Canadian

destinations may have the temperature and pressure relief

valve factory installed. Any replacement valve must meet the

latest edition of CAN 1-4.4, the Standard for “Temperature,

Pressure, Temperature and Pressure Relief Valves and

Vacuum Relief Valves.”

Relief valve piping must terminate 6 inches above a floor

drain or external to the building. Do not thread, cap or plug the

end of this discharge line. Be certain that no contact is made

with any live electrical part. Do not connect discharge line

directly to drain. See figure 3. To prevent bodily injury, hazard

to life or damage to property, the relief valve must be allowed

to discharge water in the event of excessive temperature or

pressure developing in the water heater. The function of the

temperature and pressure relief valve is to discharge water in

quantities should circumstances demand. If the discharge

pipe is not directed to a drain as shown in Figure 3 or other

suitable means, the water flow may cause property damage.

The discharge line:

1. Shall not be reduced by a coupling or any other restriction;

2. Must not be plugged, or blocked;

3. Must be of material capable of withstanding 210

o

F,

without distortion;

4. Must be installed so as to allow complete drainage of

both the temperature and pressure relief valve and discharge lines;

5. Must terminate at an adequate drain; and

6. Must not have any valve installed between the relief

valve and the water heater.

Page 3

Failure to install and maintain a new,

properly listed temperature and

pressure relief valve will release the

manufacturer from any claims which may result

from excessive temperature or water pressure.

WARNING:

Do not attempt to operate this water heater

with the cold water inlet valve close.

Manually operate temperature and pressure

relief valve at least once a year. Standing

clear of the outlet, (discharge water will be

hot), lift and release the lever handle on the

temperature and pressure relief valve to

make sure the valve operates freely.

NEVER OPERATE THE HEATER IF IT IS NOT

COMPLETELY FILLED WITH WATER. TO

MAKE SURE THE HEATER IS FILLED, OPEN

THE HOT FAUCET OF TAP UNTIL A FULL

FLOW OF WATER IS VISIBLE WITH NO AIR

ESCAPING.

The installation of this appliance must conform to

applicable local codes and local authorities having

jurisdictions.

Install the gas piping as indicated in Figure 2. Use only new

pipe and fittings with sound, clean-cut pipe thread. Sealing

compound must conform to the applicable code for pipe

sealing compound approved for use with natural gas and

propane. It is important to have a readily accessible manual shut-off valve in the gas line supplying the heater, close

to the heater. A drip leg must be installed ahead of the gas

control valve to help trap sediments and foreign material.

A ground-joint union must be installed ahead of the gas

valve to permit easy removal of the unit.

Pipe sizing and the number of fittings used must conform to

the National Fuel Gas Code, Natural Gas Installation Code

B.149.1 or Propane Gas Installation Code B149.2.

The appliance and its gas connection must be leak tested

before placing the appliance in operation.

All leak testing must be done with soapy water solution.

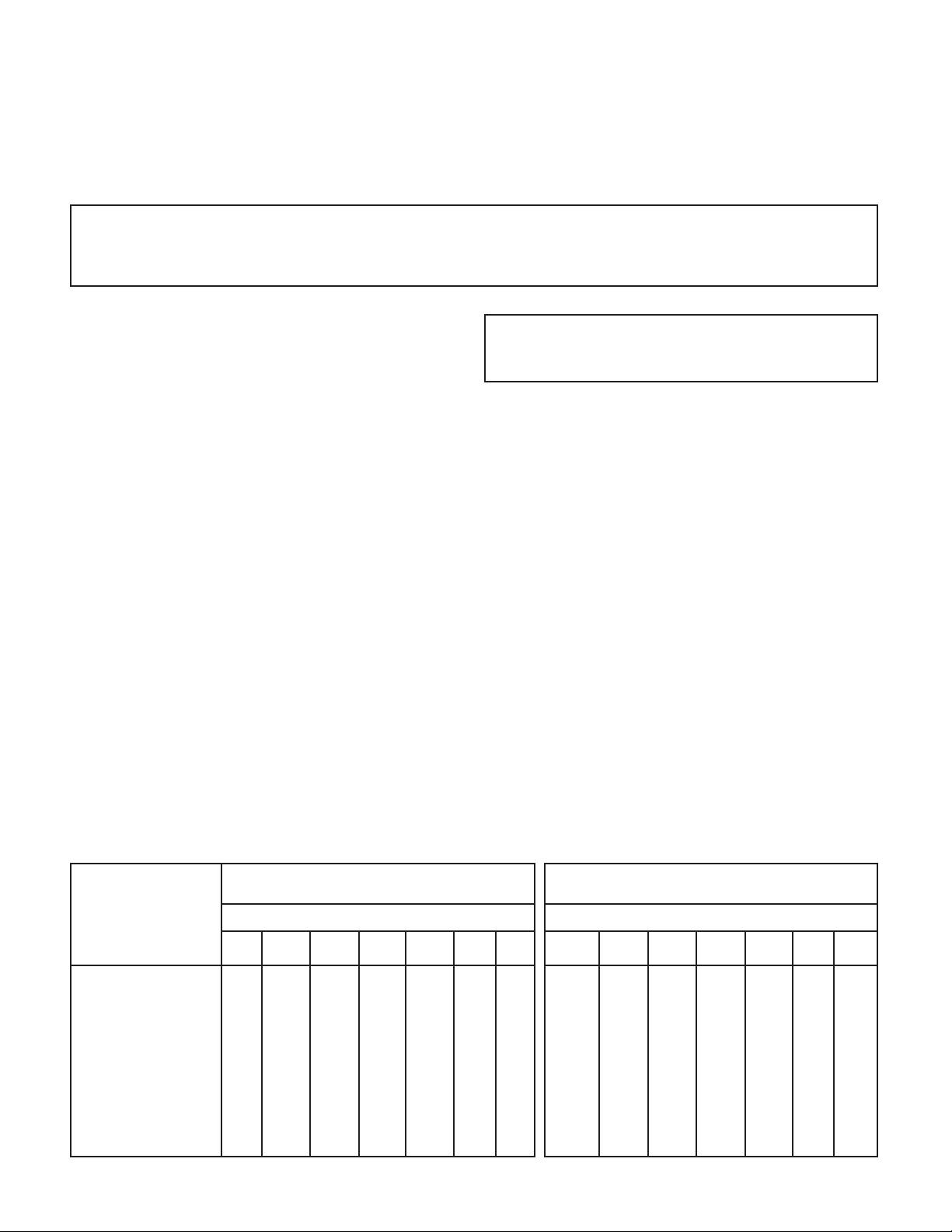

Table I

Gas Supply Line Sizes (Inches)

(Based on pressure drop of 0.3 inches water column)

Correct Gas Pipe Size for Heaters Operating on:

The maximum inlet gas pressure to the appliance must not

exceed the gas pressure marked on the rating plate: 10.5”

W.C. for natural gas and 13” W.C. for propane gas.

The minimum supply pressure for the purpose of input

adjustment is 1” above manifold pressure. The appliance

and its individual shut-off valve must be disconnected from

the gas supply piping system during any pressure testing of

that system at test pressures in excess of 1/2 psig (3.5 kPa)

The appliance must be isolated from the gas supply piping

system by closing its individual manual shut-off valve during

any pressure testing of the gas supply piping system at

least pressures equal to or, less then 1/2 psig(3.5kPA)

The input rating of the appliance should be checked against

the actual input and the manifold pressure adjusted to give

the correct input. In no case should the input exceed the

rated input. Overfiring and damage to the appliance will

result. High altitude installations require an input check

since overfiring is more likely.

Page 4

IMPORTANT: GAS SUPPLY

HAVE YOU CHECKED THE GAS SUPPLIED AND COMPARED IT WITH THE GAS MARKED

ON THE RATING PLATE? SEE ALSO WARNING ON PAGE 1.

GAS CONNECTIONS

NEVER USE A MATCH OR OPEN FLAME

TO TEST FOR GAS LEAKS.

A FIRE OR EXPLOSION COULD RESULT.

RATE

BTU

INPUT

NATURAL GAS

Specific gravity 0.6

DISTANCE TO METER IN FEET

PROPANE

Specific gravity 1.53

DISTANCE TO METER IN FEET

30

1/2

3/4

3/4

1

1

1-1/4

1-1/4

1-1/4

1-1/2

1-1/2

60

3/4

1

1

1-1/4

1-1/4

1-1/4

1-1/2

1-1/2

2

2

90

3/4

1

1

1-1/4

1-1/4

1-1/4

1-1/2

2

2

2

120

3/4

1

1-1/4

1-1/4

1-1/4

1-1/2

1-1/2

2

2

2

150

1

1-1/4

1-1/4

1-1/4

1-1/4

1-1/2

2

2

2

3

180

1

1-1/4

1-1/4

1-1/4

1-1/2

1-1/2

2

2

2

3

210

1

1-1/4

1-1/4

1-1/4

1-1/2

1-1/2

2

2

2

3

58,000

95,000

150,000

200,000

250,000

300,000

400,000

500,000

600,000

750,000

30

1/2

3/4

3/4

3/4

1

1

1-1/4

1-1/4

1-1/4

1-1/4

60

1/2

3/4

3/4

1

1

1-1/4

1-1/4

1-1/4

1-1/2

1-1/2

90

1/2

3/4

1

1

1

1-1/4

1-1/4

1-1/4

1-1/2

2

120

1/2

1

1

1-1/4

1-1/4

1-1/4

1-1/4

1-1/2

1-1/2

2

150

1/2

1

1

1-1/4

1-1/4

1-1/4

1-1/2

1-1/2

2

2

180

1/2

1

1

1-1/4

1-1/4

1-1/4

1-1/2

1-1/2

2

2

210

1/2

1

1-1/4

1-1/4

1-1/4

1-1/4

1-1/2

1-1/2

2

2

INPUT

BTU/HR.

58,000

90,000

135,000

160,000

180,000

200,000

225,000

270,000

315,000

360,000

NATURAL GAS

1000 BTU/CU. FT.

62 SEC.

40 SEC.

27 SEC.

22 SEC.

20 SEC.

18 SEC.

16 SEC.

13 SEC.

12 SEC.

10 SEC.

PROPANE

2500 BTU/CU. FT.

155 SEC.

100 SEC.

67 SEC.

56 SEC.

50 SEC.

45 SEC.

40 SEC.

33 SEC.

29 SEC.

25 SEC.

Table II

No. of seconds required to consume 1 cu. ft. of gas.

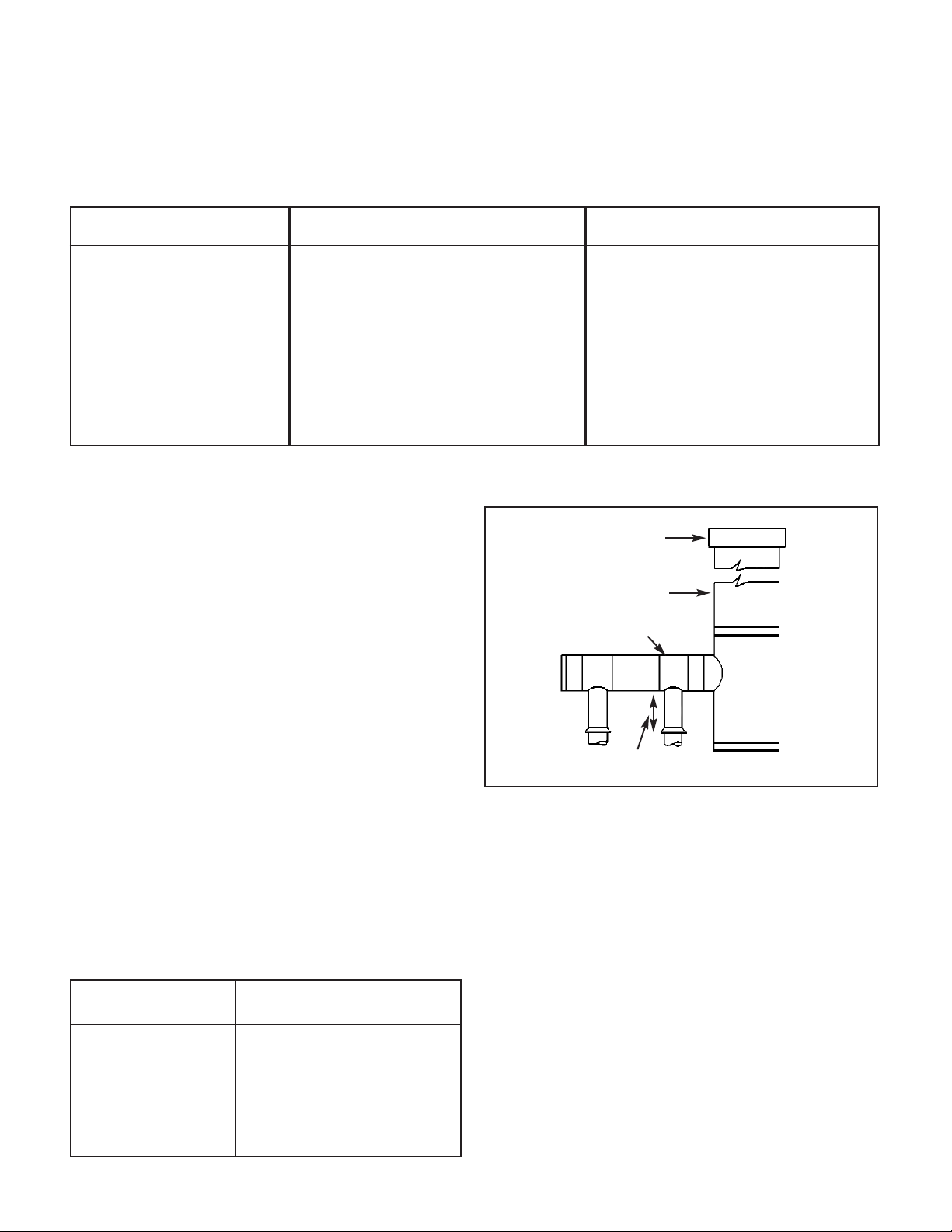

VENTING

To carry off the products of combustion, a vent pipe must be

attached to the drafthood of the heater and connected to a

chimney vent of adequate height and area. Venting

connections should be made in accordance with all codes

and ordinances which apply.

Ensure that the vent pipe is securely fastened to the draft hood

and that the draft hood is properly attached to the heater. For a

single heater installation the vent pipe must be sized no smaller than the flue size of the heater. Horizontal runs of vent pipe

should be installed with a rise of at least 1/4” per foot of length.

The vertical connector rise of vent pipe above the draft hood,

before any fittings, should be as great as possible.

When more then one heater is installed and the vents are

combined, the area of the horizontal manifold and common

vent should be at least equal to the area of the largest single

vent, plus 50% of the area of all other vents joining it (see

Vent Size Chart below) (For example, to combine two 6” vents

with a 5” vent, the area of the combined vent would be equal

to 28 + 28/2+20/2 equals 52 square inches - use a minimum

9 inch common vent and manifold). Units with larger inputs

must be vented below others. When using a common vent

connector, it shall be at the highest practical level.

The chimney vent must be extended at least two feet higher

than any obstruction located within 10 feet.

Where a back draft exists, the cause must be determined and

corrected. A flue cap on the chimney vent may correct the situation. However, if the back draft cannot be corrected, if long

horizontal vent pipe runs are necessary, or if a suitable flue

cannot be obtained, a mechanical exhaust may be required to

ensure proper venting and combustion.

Some local codes prohibit connecting a gas heater to a flue or

chimney with coal or oil fired equipment. Therefore, these

connections should be avoided. However, where a separate

chimney is not available, the flue pipe from the water heater

should enter the common flue or chimney at a point ABOVE

the flue pipe from the coal or oil fired equipment.

Improper venting may result in poor combustion, sooting and

serious damage to the heater.

DIA.

IN.

5

6

7

8

9

AREA

SQ. IN.

20

28

38

50

64

DIA.

IN.

10

12

14

16

AREA

SQ. IN.

79

113

154

201

VENT TOP

OR CAP

COMMON

CHIMNEY VENT

MANIFOLD

CONNECTOR

RISE

VENT

CONNECTOR

TEE

CAPPED

Page 5

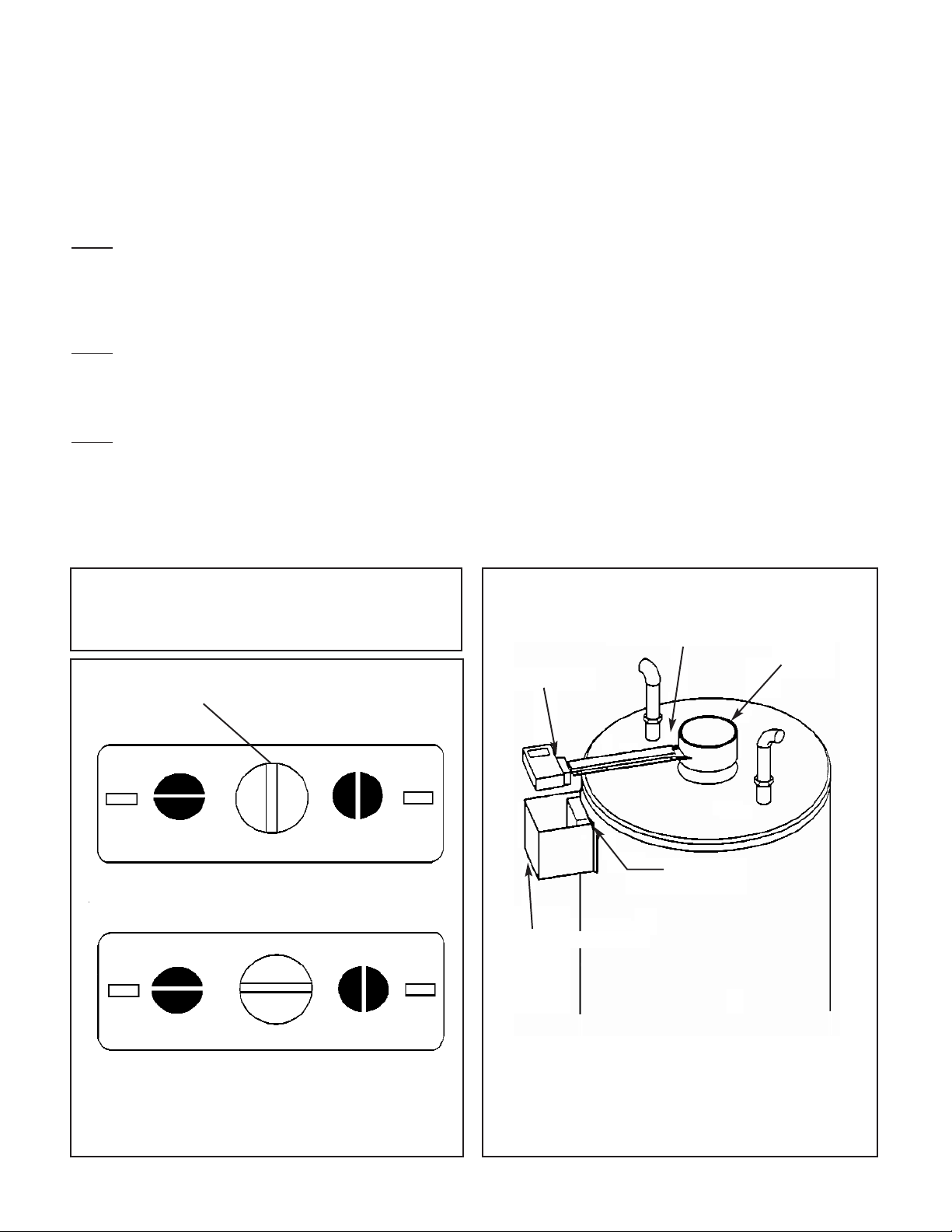

FLUE DAMPER

Flue Damper Installation

For Models equipped with a flue damper, the following instructions

must be followed. It is recommended to leave a minimum 24”

clearance from the actuator side of the flue damper for service

access.

S

tep 1:

Place flue damper on top pan into flue collector. The rail support

must be screwed to the top pan. The three pre-drilled holes on the

casing top must align with the three holes on the rail support. The

rail support must fit flush with the casing top.

S

tep 2:

Install the draft hood which is supplied with the heater in the carton

to the heater top. Fasten the draft hood with the four sheet metal

screws supplied.

S

tep 3:

Remove junction box cover plugs. Remove flue damper cover. The

wiring harness provided plugs into the four plug female molex connector (use strain relief connector provided). Molex plugs mate

together one way only.

To manually set the damper in the open position, see diagram below.

Flue Damper Venting

The vent pipe (flue pipe) must be installed without restriction

or reduction in size. Slope the horizontal run upwards to the

chimney at least 1/4” per foot. Fasten all joints with sheet

metal screws. (See Figure 4)

Venting must be inspected every three months for blockage

and problems due to age of the vent piping.

Damper Position Indicator

The damper position indicator can be found on the flue collar

of the flue damper. (See Figure 4).

Heater Wiring

Follow local codes for all electrical work. To reduce risk of

shock or possible electrocution, the heater must be electrically grounded in accordance with local codes or, in the absence

of local codes, with the National Electrical Code, ANSI /

NFPA 70.

If any of the original wiring must be replaced use only type

105

o

C thermoplastic or equivalent.

NOTE: THE FLUE DAMPER MUST BE IN THE OPEN

POSITION WHEN APPLIANCE, PILOT AND OR MAIN

BURNERS ARE ON. THIS SHOULD BE CHECKED BY

THE INSTALLER BEFORE LEAVING.

DAMPER SHAFT POSITION

“OPEN” POSITION

“CLOSED” POSITION

CLOSED

OPEN

CLOSED

OPEN

Figure 4

COLD

HOT

MOUNTING SCREWS (4)

DAMPER

POSITION

INDICATOR

JUNCTION BOX

JUNCTION BOX COVER

VENT DAMPER

Page 6

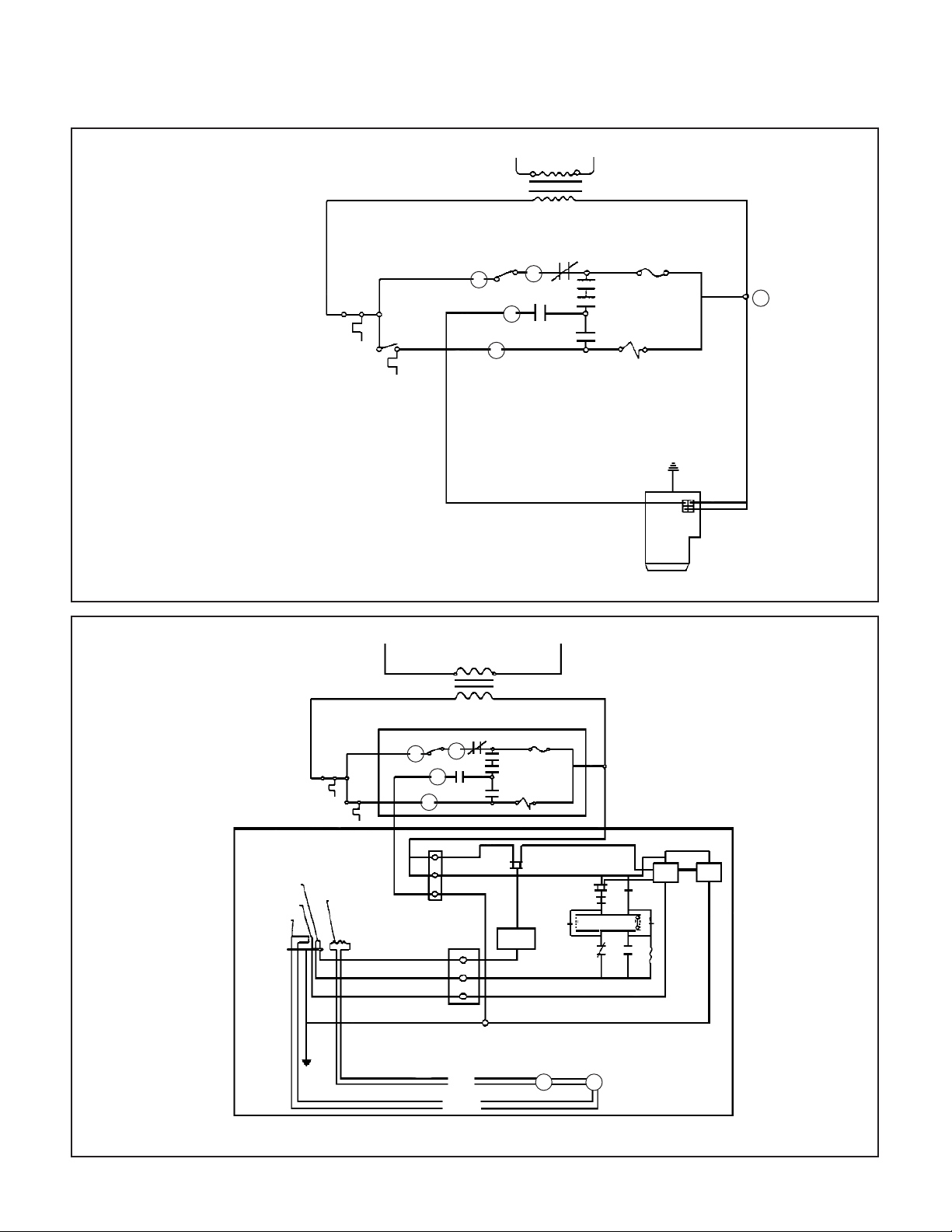

Connection Diagram

Appliance in Standby Condition

The motor is energized during appliance thermostat “off” cycle.

The flue damper is the “closed” position.

Circuit diagram is as shown.

SL VENT DAMPER

128 VAC

24 V

R1 (N.C.)

R2 (N.O.)

SS2 (N.O.)

E.S. (N.O.)

(N.O.)

SS1

E.C.O.

TH.ST

VALV E

GNO

2

M

1

3

4

Schematic - Valve and Ignition Module

VALVE AND IGNITION MODULE

SL VENT DAMPER

R2 (N.O.)

SS2 (N.O.)

E.S. (N.O.)

128V

NEUTRAL

H

24V

E.C.O

TH.ST

(N.O.)

R1 (N.C.)

HV PV

N.S.I.

ONO

N.S.I.

RELAY

DRIVE

PLANE

SENSOR

TRIAC

24 DC

POWER

SUPPLY

DUAL VALVE

OUT

PILOT

ONO

HSI

FLAME SENSING

PILOT BURNER

BURNER

2

M

3

4

X

X

Page 7

Loading...

Loading...