E.C.M. Issue - 707668

Print date - 05.10.2011

Maintenance

Section

VT551

Twin Engined

Suction Sweeper

With Mk II CANview Software

Stage 3a VM Engine

Part No 02634-1-M

Revision Level 02

Pneumatic System

Page Issue Levels

Scheduled Maintenance

Hydraulic System

Electrical System

Water System

11

Wearing Items

Remove and Refit Procedures

Fault Diagnosis

Service Tools

Warranty

Health and Safety

7

P

8

9

10

12

13

14

15

16

17

All Copyright and rights are the property of Johnston Sweepers Ltd

VT551 - Maintenance

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue Levels

CHAPTER

P

Page Issue Levels

Description

This chapter lists each page in the Maintenance section, it’s issue level and

whether it has changed since the previous revision level. Changed pages are

indicated by the letter ‘C’ in the changed column, and new pages by the letter

‘N’.

P1

VT551 - Maintenance

Section Revision Level 02

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue LevelsP2

P Chapter - Page Issue Levels

Page Issue Changed Page Issue Changed

P1 02 C P2 02 C

P3 02 C P4 02 C

7 Chapter - Scheduled Maintenance

Page Issue Changed Page Issue Changed

7:1 01 7:2 01

7:3 01 7:4 01

7:5 02 C 7:6 01

7:7 01 7:8 01

8 Chapter - Hydraulic System

Page Issue Changed Page Issue Changed

8:1 01 8:2 01

8:3 02 C 8:4 01

8:5 01 8:6 01

8:7 01 8:8 01

8:9 01 8:10 01

8:11 01 8:12 01

9 Chapter - Electrical System

Page Issue Changed Page Issue Changed

9:1 01 9:2 01

9:3 01 9:4 01

9:5 01 9:6 01

9:7 01 9:8 01

9:9 02 C 9:10 02 C

9:11 02 C 9:12 02 C

9:13 02 C 9:14 02 C

9:15 02 C 9:16 02 C

9:17 02 C 9:18 02 C

9:19 02 C 9:20 02 C

Section Revision Level 02

VT551 - Maintenance

All Copyright and rights are the property of Johnston Sweepers Ltd

10 Chapter - Water System

Page Issue Changed Page Issue Changed

10:1 01 10:2 01

10:3 01 10:4 01

10:5 01 10:6 01

10:7 01 10:8 01

10:9 01 10:10 01

10:11 01 10:12 01

10:13 01 10:14 01

11 Chapter - Pneumatic System

Page Issue Changed Page Issue Changed

11:1 01 11:2 01

11:3 01 11:4 01

11:5 01 11:6 01

11:7 01 11:8 01

11:9 01 11:10 01

12 Chapter - Wearing Items

Page Issue Changed Page Issue Changed

12:1 01 12:2 01

12:3 01 12:4 01

12:5 01 12:6 01

12:7 01 12:8 01

13 Chapter - Remove and Refit Procedures

Page Issue Changed Page Issue Changed

13:1 01 13:2 01

13:3 01 13:4 01

13:5 01 13:6 01

13.7 01 13.8 01

14 Chapter - Fault Diagnosis

Page Issue Changed Page Issue Changed

14:1 01 14:2 01

14:3 01 14:4 01

14:5 01 14:6 01

14:7 01 14:8 01

Page Issue Levels P3Section Revision Level 02

VT551 - Maintenance

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue LevelsP4 Section Revision Level 01

VT551 - Maintenance

15 Chapter - Service Tools

Page Issue Changed Page Issue Changed

15:1 01 15:2 01

16 Chapter - Warranty

Page Issue Changed Page Issue Changed

16:1 01 16:2 01

16:3 01 16:4 01

17 Chapter - Health and Safety

Page Issue Changed Page Issue Changed

17:1 01 17:2 01

17:3 01 17:4 01

17:5 01 17:6 01

17:7 01 17:8 01

All Copyright and rights are the property of Johnston Sweepers Ltd

Chapter - Scheduled Maintenance

CHAPTER

7

Scheduled Maintenance

7:1

Table of Contents

Section Page

Introduction

Regular Maintenance 7 : 2

Security of Sweeping Equipment 7 : 3

Circuit Diagrams

Fluid Finder 7 : 4

Diagram Index 7 : 5

Auxiliary Engine

Fuel System Bleeding 7 : 6

Hydraulics

Hydraulic Oil Reservoir 7 : 7

Pneumatics

Filter Regulator Unit 7 : 8

Page Issue 01

VT551 - Maintenance

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01Chapter - Scheduled Maintenance7:2

VT551 - Maintenance

INTRODUCTION

REGULAR MAINTENANCE

It is impossible to over emphasise the importance of regular maintenance, inspection and running

adjustments to maintain efficiency and obtain trouble free service from the machine.

Attention is drawn to the recommendation in the Auxiliary Engine Handbook relating to the post delivery

check over.

The maintenance schedule specified are for average operating conditions. Under particularly dry and

dusty conditions, it is essential that more frequent attention is given to:

1 Air cleaner servicing.

2 Engine oil changes.

3 Fluid oil changes.

4 Gearbox oil changes.

5 Hydraulic oil changes.

Attention to the servicing of air cleaners fitted to both auxiliary and vehicle engines is of vital importance

as clean air is essential for the proper functioning and ultimate life of an engine. Badly serviced air

cleaners can allow dust particles to be directly induced into the internal working surfaces with a resulting

rapid increase in engine wear and eventually complete failure. This also applies to any air leaks occurring

between the air cleaner and the engine inlet manifold. See separate instructions for Air Cleaner Servicing.

It is important that the following Safety Precautions are observed when working on the machine.

Ensure the machine is standing on firm, level ground and there are no obstructions above or

to the rear before raising the body.

Ensure the safety prop is used at all times when working under the body.

Ensure operators are fully conversant with the controls and operation.

Isolate the air in the filter regulator unit before working on any pneumatically operated or

controlled equipment.

Disconnect or isolate the vehicle battery when working on the electrical system.

Ensure the auxiliary engine is switched off once the channel brush has been lowered for

adjustment.

Be aware of the safety instructions relative to the suction fan given in the equipment

maintenance notes.

Keep hands, loose clothing, hair etc. well clear of moving parts.

Do not climb on the engine walkways unnecessarily or approach the fan inlet whilst the

engine is running.

Do not grasp any part of the engine or exhaust system without first ascertaining whether it

has cooled sufficiently to avoid scalding.

Do not use ill-fitting tools such as spanners that may slip and cause injury.

Use approved safety platforms/gantries when working above ground level. Get a

second person to check periodically when only one person is working on access

equipment or inside the body.

The use of ‘needle stick gloves’ is recommended when changing brushes, using the

wanderhose/Littasnatch and when cleaning out the machine.

Safety Precautions

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01

Chapter - Scheduled Maintenance

7:3

VT551 - Maintenance

95MA. 024

ALTERNATIVE END MOUNTING POSITIONS

(HARDWARE AS PREFERED POSITIONS ie. ‘C’ and ‘D’)

‘A’ = M12 Standard ‘B’ = M12 Grade 10.9 ‘C’ = M14 Grade 10.9

‘D’ = M12, M14 Grade depending on chassis10.9 or M16 Standard

Torque Settings

M12 Standard = 95 Nm (70 lbf/ft)

M12 Grade10.9 = 135 Nm M16 = 235 Nm

M14 Grade 10.9 = 215 Nm (160 lbf/ft)

(100 lbf/ft) Standard (150 lbf/ft)

C

C

C

C

C

AA

D

D

D

D

CC

A

A

SECURITY OF SWEEPING EQUIPMENT

It is necessary to check every six months the security of various components as part of the maintenance

programme.

These fixings are detailed on the illustration below.

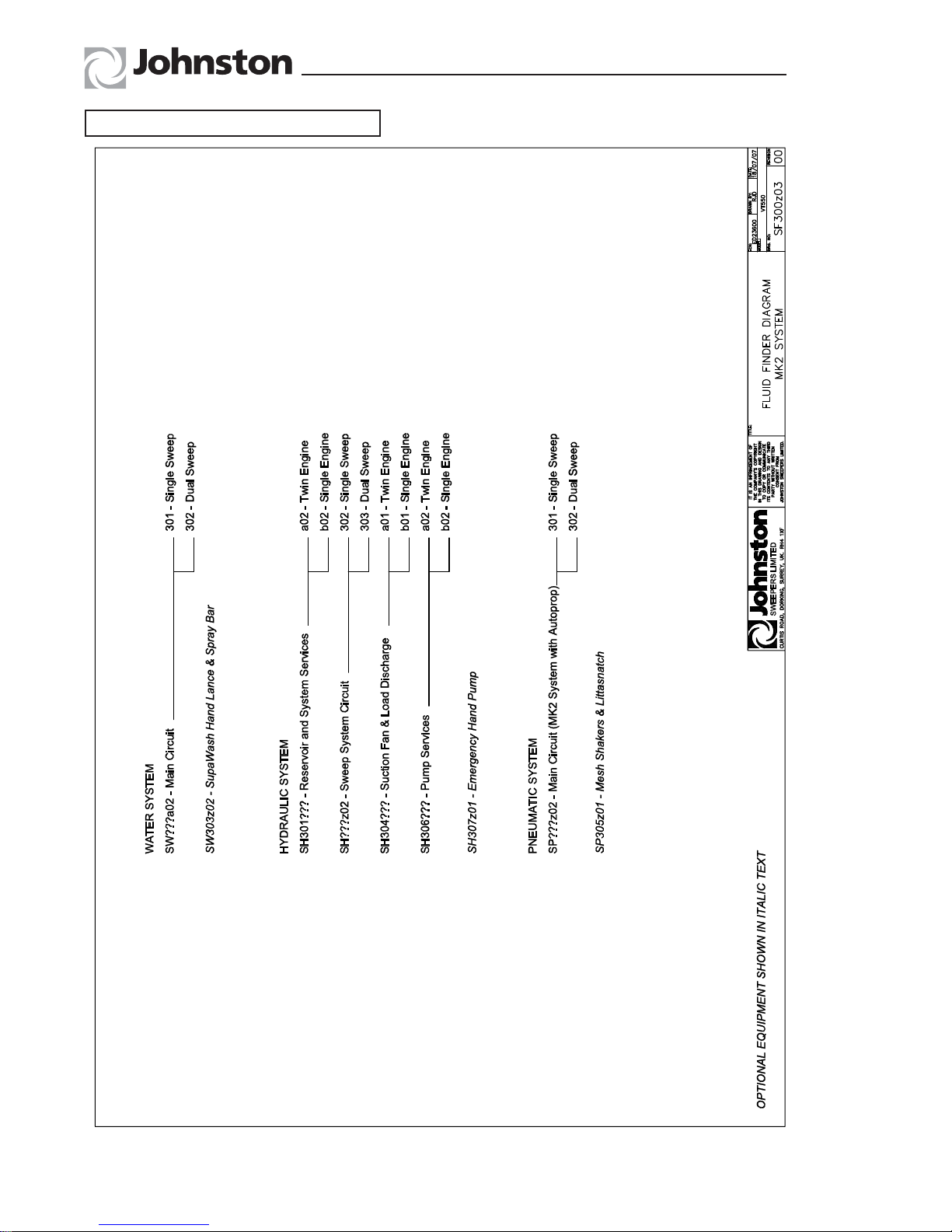

CIRCUIT DIAGRAMS

A chart can be found overleaf to assist in finding the circuit diagram required.

The actual circuit diagrams will be found in the appropriate chapter.

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01Chapter - Scheduled Maintenance7:4

VT551 - Maintenance

Fluid Finder - Diagram SF300z03

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 02

Chapter - Scheduled Maintenance

7:5

VT551 - Maintenance

Diagram Index - SE300z01

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01

Chapter - Scheduled Maintenance

7:6

VT551 - Maintenance

Please refer to the Operator’s Guide, Chapter 6, for the Routine Maintenance Schedules.

The following items are not covered in the Operator’s Guide.

MAINTENANCE AND ADJUSTMENT INSTRUCTIONS

AUXILIARY ENGINE - FUEL SYSTEM BLEEDING

Please refer to the Auxiliary Engine Handbook for information.

THROTTLE SETTINGS

The engine tick-over speed is adjustable and is set by the tick-over screw on the injector pump. The

engine maximum speed is controlled by the CANbus system and is not adjustable. The relevant speeds

are given in the chart below.

ENGINE

TYPE

JOHNSTON

PART NO.

IDLE

SPEED

Rev/min

MAXIMUM

FLIGHT SPEED

(Off Load)

Rev/Min

VM D754TE3

VM D754TE3

7015088 (12V)

7008519 (24V)

850

850

1800

1800

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01

Chapter - Scheduled Maintenance

7:7

VT551 - Maintenance

Please refer to the Operator’s Guide Section 6 for the Routine Maintenance Schedules.

The following covers items not included in the above guide.

HYDRAULIC OIL RETURN FILTER

The filter should be changed every B Service, however there is an integral filter indicator on the side of

the filter head and, should this indicate red whilst the suction fan is operating, i.e. body raised, then the

filter is contaminated and requires changing at an earlier interval.

HYDRAULIC OIL RESERVOIR

Note: The filters can only be changed when the tank has been drained.

RENEWING THE RETURN FILTER

Unscrew cover (A) with a suitable spanner and lift out the cartridge element (B). Refit cartridge and screw

on the cover, some force will be required to compress the carriage retaining spring.

SYSTEM DRAINING

The oil can be drained by opening the tap

(G) and draining into a suitable receptacle.

RENEWING THE SUCTION FILTER

Change the filter whilst the system is empty.

The filter is changed as follows:

Remove the hydraulic hoses (D) to gain

access to the filter element (E). Replace

element and reassemble.

SYSTEM REFILLING

The system capacity dry is 80 litres. Refer to

Chapter 6 of the Operator’s Guide detailing

the correct oil level in the reservoir.

This should only be changed when the oil is cold, as the system could be

pressurised. Leave for 60 seconds after stopping for any pressure to be

dissipated before removing the return filter.

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01Chapter - Scheduled Maintenance7:8

VT551 - Maintenance

FILTER REGULATOR UNIT

Comprises of a combined air filter/pressure regulator (A). It is mounted near the fan case on the right

hand side of the machine.

Safety Precautions

The shut off valve must be used when servicing any item on the air system

IN

A

B

C

D

CURRENT TYPE ‘A’ UNIT

(WITH SHUT OFF BALL VALVE ‘C’)

93MA. 017-2

The air filter unit incorporates a semi automatic drain which automatically dumps accumulated water when

the air supply is isolated by the shut off valve (C). It can also be drained by pushing up the drain tube (B)

that protrudes from the underside.

The pressure regulator (A) ensures the equipment is not over pressurised. It is factory set and sealed at

7

.

5 bar (108 psi).

A pressure switch (D) is fitted to illuminate the low air pressure warning lamp on the cab switch panel.

PNEUMATIC CYLINDER MAINTENANCE

Periodically inspect the cylinder rods for damage, blemishes or build up of material such as tar, cement,

paint etc. The rods can be cleaned with fine wire wool and/or spirit and should be kept clean to ensure

long seal life.

HYDRAULIC CYLINDER MAINTENANCE

Observe the notes on damage etc. described under pneumatic cylinders, especially with regard to the

wide sweep brush slewing cylinder on dual sweep machines and the channel brush lift cylinder.

Avoid playing the water washdown hose over the body tip cylinder when in the fully raised condition.

CLEANING THE VEHICLE

With the advent of high pressure steam and washdown equipment, damage can be caused by playing

this equipment onto the electrical control system, paintwork etc. and great care should be exercised when

it is carried out.

All Copyright and rights are the property of Johnston Sweepers Ltd

CHAPTER

8

Hydraulic System

Table of Contents

Section Page

Introduction

General Description 8 : 2

Circuit Pressures

Brushes 8 : 2

Water System 8 : 3

Suction Fan 8 : 3

Hopper Raise/Lower 8 : 3

Fan Pump Set Up 8 : 4

Hydraulic System

Initial Operation 8 : 5

Valve Identification 8 : 5

Circuit Diagrams

Hydraulic Tank Connections 8 : 6

Single Sweep 8 : 7

Dual Sweep 8 : 8

Suction Fan / Load Discharge 8 : 9

Pump Services 8 : 10

Emergency Hand Pump 8 : 11

Chapter - Hydraulic System

8:1

Page Issue 01

VT551 - Maintenance

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01Chapter - Hydraulic System8:2

VT551 - Maintenance

GENERAL DESCRIPTION

The hydraulic system may be divided into four hydraulic circuits fed from a common hydraulic reservoir.

1 Sweep system.

2 Water system.

3 Fan drive system and load discharge.

Hydraulic filtration is provided by suction filters within the hydraulic tank, together with replaceable type ‘in

line’ return filter mounted externally on the upper face of the hydraulic tank.

CIRCUIT PRESSURES

Test points are provided on the hydraulic system to carry out pressure checks.

POINT NO. FUNCTION

T7 Sweep system test point

T8 Fan drive system/body discharge

T9 Water system (i.e. Supawash)

To set the hydraulic pressures select menu 4. Set

pressures from the main CANview screen and choose

sub menu 11.

NB : There is a default setting on this menu 4.11.6

to input default figures, in order for you to be able to

initially set the machine up and run the engine.

BRUSH PRESSURE - MENU 4.11.1

Connect a suitable 250 bar gauge to test point T7 (see

Valve Identification).

It is necessary to remove hose 201 in port C1 of the

‘sweep block 4’ and plug with a suitable plug and

also cap off the hose. Follow the on screen CANview

instructions.

This pressure should be 225 bar.

If necessary manually adjust RV1.

NB : DO NOT run the pressure test for longer than 30 seconds or damage maybe caused to the system.

93OG. 027-35

50%

14:00

25%4.0

93OG. 027-41

50%

14:00

25%

4.11

4.11

&

1 3 5

2 4 6

93OG. 027-36

50%

14:00

25%4.11.1

T7

C1

BLOCK 4

RV1

1800

n/min

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 02

Chapter - Hydraulic System

8:3

VT551 - Maintenance

WATER SYSTEM - MENU 4.11.2

Connect a suitable 250 bar gauge to test point T9.

Follow the on screen CANview instructions.

This pressure should be 220 bar. Remember to cap off

hose 206 when port W1 is plugged.

If necessary manually adjust RV2.

SUCTION FAN - MENU 4.11.3

Fit a 250 bar minimum pressure gauge to test point T8.

Follow the on screen CANview instructions.

This pressure should be 150 bar.

If necessary press + or - to adjust the pressure to 150 bar

± 5. Press to save setting.

HOPPER RAISE - MENU 4.11.4

Connect a suitable 250 bar gauge to Test Point T8.

Follow the on screen CANview instructions.

This pressure should be 175 bar.

If necessary press + or - to adjust the pressure to 175 bar

± 5. Press to save setting.

HOPPER LOWER - MENU 4.11.5

Connect test point as detailed above and follow the on

screen CANview instructions.

This pressure should be 80 bar.

If necessary adjust pressure by pressing + or -.

Press to save setting.

93OG. 027-37

50%

14:00

25%4.11.2

T9

W1

BLOCK 4

RV2

1800

n/min

93OG. 027-38

50%

14:00

25%4.11.3

T8

1800

n/min

+

-

+

-

RP

409MA

93OG. 027-39

50%

14:00

25%4.11.4

T8

1400

n/min

+

-

+

-

RP

348MA

93OG. 027-40

50%

14:00

25%4.11.5

T8

1400

n/min

+

-

+

-

RP

204MA

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01Chapter - Hydraulic System8:4

VT551 - Maintenance

FAN PUMP

If the fan pump is changed it is necessary to check the pump pressure setting.

1. Standby - 20 bar.

*Run the auxiliary engine and measure the pressure on test point T8. The standby pressure should

be set at 20 bar.

2. Main Operating Pressure - 150 bar

To check this setting enter the suction fan pressure menu 4.11.3, follow on screen instructions and

increase RP output until the pressure reading on T8 remains the same. Ensure is pressed to save

the settings.

Please note that if the CANview node (node 3) is changed, the fan pump set up will need to be

re-checked.

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01

Chapter - Hydraulic System

8:5

VT551 - Maintenance

HYDRAULIC SYSTEM INITIAL OPERATION

Start the auxiliary engine and open and close the rear door three times to ensure all air is purged from

the system.

Failure to carry out this procedure may cause the rear door lock to function incorrectly.

VALVE IDENTIFICATION

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01Chapter - Hydraulic System8:6

VT551 - Maintenance

Hydraulic Tank Connections - Diagram SH301a02

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01

Chapter - Hydraulic System

8:7

VT551 - Maintenance

Single Sweep - Diagram SH302z02

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01Chapter - Hydraulic System8:8

VT551 - Maintenance

Dual Sweep - Diagram SH303z02

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01

Chapter - Hydraulic System

8:9

VT551 - Maintenance

Suction Fan / Load Discharge - Diagram SH304a01

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01Chapter - Hydraulic System8:10

VT551 - Maintenance

Pump Services - Diagram SH306a02

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01

Chapter - Hydraulic System

8:11

VT551 - Maintenance

Emergency Hand Pump - Diagram SH307z01

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01Chapter - Hydraulic System8:12

VT551 - Maintenance

All Copyright and rights are the property of Johnston Sweepers Ltd

Chapter - Electrical System

CHAPTER

9

Electrical System

9:1

Table of Contents

Section Page

Introduction

General Description 9 : 2

System Description 9 : 2

Component Identification

Relay Box 9 : 3

Relays/Fuses and Connector Refs. 9 : 4

Electrical Components Diagrams 9 : 9

Page Issue 01

VT551 - Maintenance

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01Chapter - Electrical System9:2

VT551 - Maintenance

GENERAL DESCRIPTION

The system is integrated with that of the chassis in that it shares its battery and power source. The

auxiliary engine is equipped with a second alternator to supplement power generation. The system

activates all operational functions of the machine.

SYSTEM DESCRIPTION

The electrical system circuit diagrams are sub divided into modularised sub circuits and are identified

by an eight digit code, i.e. SE511Z01. The first five digits identify the machine and a particular control

feature, the last three digits identify variation and design status of the particular control feature. When the

sixth digit is a ‘Z’, then there is only one design variation, thought there could be other variations identified

by the seventh and eighth digits.

To assist fault finding and troubleshooting, the solenoids have an LED in the electrical connection plug

which illuminate when power is achieved.

RELAY/FUSE BOX

EP

FUSE RATINGS

F11

F12

F13

F14

F15

F1

F2

F6

F8

F10

10A RED

15A BLUE

15A RED

20A YELLOW

5A ORANGE

-

-

-

-

-

-

-

-

-

-

10A RED

20A YELLOW

15A BLUE

15A RED

15A BLUE

93MA. 012-3

MCB

MCB

30A

F1 F2

F13

F14

F15

F6 F8

(A)

F11

F12

F10

10A RED

15A BLUE

10A RED

20A YELLOW

5A ORANGE

10A RED

20A YELLOW

15A BLUE

10A RED

15A BLUE

12V 24V

ALWAYS turn OFF the truck ignition before changing / replacing fuses on the machine.

NEVER carry out welding on the machine without first disconnecting the two plugs on

Node 1 and Node 2 - failure to observe these procedures could damage the nodes.

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01

Chapter - Electrical System

9:3

VT551 - Maintenance

The electrical system is protected by various fuses mounted in the relay box - See Operators Guide

Chapter 2.

The main feed from the battery to the electrical system is protected by a circuit breaker (MCB) which is

also mounted in the relay box.

The button (A) will pop out when activated and is ‘pushed in’ to reset when the fault has been cleared.

COMPONENT IDENTIFICATION

All Copyright and rights are the property of Johnston Sweepers Ltd

Relays

Ident. Description / Function Circuit(s) Ref. Location Notes

R1

Main Power Relay

Fuses 01-03

SE302 Relay Box

R2

Main Power Relay

Fuses 05-08

SE302 Relay Box

R3

Main Power Relay

Fuses 09-12

SE302 Relay Box

R4

Main Power Relay

Fuses 13-14

SE302 Relay Box

R5

Auxiliary Engine Cranking Power

Active with signal from CANView

SE302 Relay Box

R6

Beacon Power

Active with Beacon / Additional Beacon switch

SE302 Relay Box

R7 Not fitted

R8 Not fitted

R9

LH Worklamp Power

Active with Worklamp / Additional Worklamp switch

and Sweep Select Switch in LH or Dual mode

SE302 Relay Box

R10

RH Worklamp Power

Active with Worklamp / Additional Worklamp switch

and Sweep Select Switch in RH or Dual mode

SE302 Relay Box

R11

Battery Charge Changeover

Relay Box

R12

Additional Beacon Power

Active with Additional Beacon switch

SE302 Relay Box

R13

Additional Worklamp Power

Active with Additional Worklamp Switch

SE302 Relay Box

R14

Heat Start

Active with Heatstart Signal

SE302 Relay Box

Page Issue 01Chapter - Electrical System9:4

VT551 - Maintenance

Ref WD 227 issue 01

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01

Chapter - Electrical System

9:5

VT551 - Maintenance

Ref WD 227 issue 01

Fuses

Ident. Description / Function

Rating (A)

12V/24V

Circuit(s) Ref. Location Notes

MCB Master Circuit Breaker 30/30 SE304 Relay Box

F01 Work Mode 10/10 SE304 Relay Box

F02 Auxiliary Engine Crank Solenoid 15/15 SE304 Relay Box

F03 Spare

F04 Spare

F05 Spare

F06 Additional Beacon 15/10 SE304 Relay Box Option

F07 Spare

F08 Node 2 20/20 SE304 Relay Box

F09 Spare

F10 Node 5 5/5 SE304 Relay Box

F11 Autolube, Cowl Work Lamp 10/10 SE304 Relay Box Option

F12 Node 1 20/20 SE304 Relay Box

F13 Worklamps 15/10 SE304 Relay Box

F14 Node 3 & Node 4 15/15 SE304 Relay Box

F15 Beacon 15/15 SE304 Relay Box

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01Chapter - Electrical System9:6

VT551 - Maintenance

WD 227 Issue 01

Connectors - Numeric

Ident. No.Ways Location

Harness Ref.

(Female)

Harness Ref.

(Male)

P1 29 Relay Box 293716-1 293714-1

P2 31 Relay Box 293714-1 293717-1

P03

P04

P05

P06

P07

P08 12 Engine Bay 293719-1 293717-1

P09 4 Engine Bay 293719-1 293717-1

P10 8 Subframe – Rear 293718-2 293717-1

P11 8 Subframe – Rear 293718-3 293718-2

P12

P13

P14

P15

P16

P17

P18

P19

P20

P21

P22

P23

P24

P25

P26 2 Cowl 293775-1

P27

P28

P29

P30

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01

Chapter - Electrical System

9:7

VT551 - Maintenance

WD 227 Issue 01

Connectors Alphanumeric

Ident. No.Ways Location

Harness Ref.

(Female)

Harness Ref.

(Male)

AL 2 Subframe – Autolube 293717-1

ALT-D 1 Auxiliary Engine – Alternator 293719-1

AR-1 4 Armrest Connector 293716-1 741928-1

AWB 2 Subframe – Additional Beacon 293717-1

AWL 2 Subframe – Additional Worklamp 293717-1

BEAC 5 Cab Beacon 293716-1

BEAC 2 Rear Beacon 293718-2

BEAC 2 Rear Beacon 293718-2

CAM 5 Camera Input 293716-1

CF 2 Chassis Fuel Tank 293717-1

CT 3 Subframe – CAN Terminator 293717-1

CVA 12 Switch Panel – CANView A 293716-1

CVB 12 Switch Panel – CANView B 293716-1

CVC 12 Switch Panel – CANView C 293716-1

CVD 17 Switch Panel 293716-1 293713-1

DAW 2 Front Valance – Discharge Buzzer 293726-1

DS1 2 Cowl Door – Limit Switch 293718-3

DS2 2 Cowl Door – Limit Switch 293718-3

ESC 2 Auxiliary Engine – Throttle Actuator 293719-1

ESOS 1 Auxiliary Engine – ESOS Valve 293719-1

ESS 3 Auxiliary Engine – Speed Sensor 293719-1

EWL 2 Engine Bay Worklamp 293717-1

F1 2 Fuel Tank #1 – Level Sensor 293717-1

F2 2 Fuel Tank #2 – Level Sensor 293717-1

FSS 3 Fancase – Fan Speed Sensor 293726-1

HOL 2 Hydraulic Tank – Oil Level 293725-1

HRW 2 Body – Hopper Raise Switch 293718-3

LA 2 FRL Unit – Air Pressure Switch 293717-1

LH-AWL 2 Body – Additional Worklight 293774-1

LMML 2 RH Cowl Door – Marker Light 293718-3

LRML 2 Rear of Body – LH Marker Light 293718-2

continues

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01Chapter - Electrical System9:8

VT551 - Maintenance

WD 227 Issue 01

LWL 2 LH Work Lamp 293717-1

ML 2 Marker Lamp 293717-1

N1A 6 Node 1 – Power 293717-1 293725-1

N1 40 Node 1 – I/O 293725-1

N1B 12 Powapak 293717-1 293725-1

N2A 6 Node 2 – Power 293717-1 293726-1

N2 40 Node 2 – I/O 293726-1

N2B 8 Powapak 293717-1 293726-1

NP 2 Number Plate 293717-1

OPS 1

Auxiliary Engine –

Oil Pressure Sensor

293719-1

PCIA 17 Cab 293716-1

PEN 7 Cab 293716-1 283440-1

RH-AWL 2 Body – Additional Worklight 293774-1

RMML 2 RH Cowl Door – Marker Light 293718-3

RRML 2 Rear of Body – RH Marker Light 293718-2

RT 5 Auxiliary Engine – Heat Start Relay 293719-1

RWL 2 RH Work Lamp 293717-1

SM-S 1

Auxiliary Engine –

Starter Motor Solenoid

293719-1

SS 2 Connect for single sweep machines 293716-1 293716-1

VM4 4 Node 5 – Pneumatics 293717-1

VM5 5 Node 5 – Pneumatics 293717-1

WLI 2 Weight Load Indicator 293717-1

WTM 2 Water Tank – Mid Switch 293718-3

WTE 2 Water Tank – Empty Switch 293717-1

WTS 2

Auxiliary Engine –

Water Temperature Sender

293719-1

All Copyright and rights are the property of Johnston Sweepers Ltd

Electrical Components Diagram - SE300z02

Page Issue 02

Chapter - Electrical System

9:9

VT551 - Maintenance

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 02Chapter - Electrical System9:10

VT551 - Maintenance

Electrical Components Diagram - SE300z03

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 02

Chapter - Electrical System

9:11

VT551 - Maintenance

System Map Diagram - SE301z01

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 02Chapter - Electrical System9:12

VT551 - Maintenance

Relay and Fuse Box Diagram 24 Volt - SE302z01

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 02

Chapter - Electrical System

9:13

VT551 - Maintenance

Relay and Fuse Box Diagram 12 Volt - SE302z02

All Copyright and rights are the property of Johnston Sweepers Ltd

Chapter - Electrical System Page Issue 029:14

VT551 - Maintenance

Node 1 Diagram - SE303z01

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 02

Chapter - Electrical System

9:15

VT551 - Maintenance

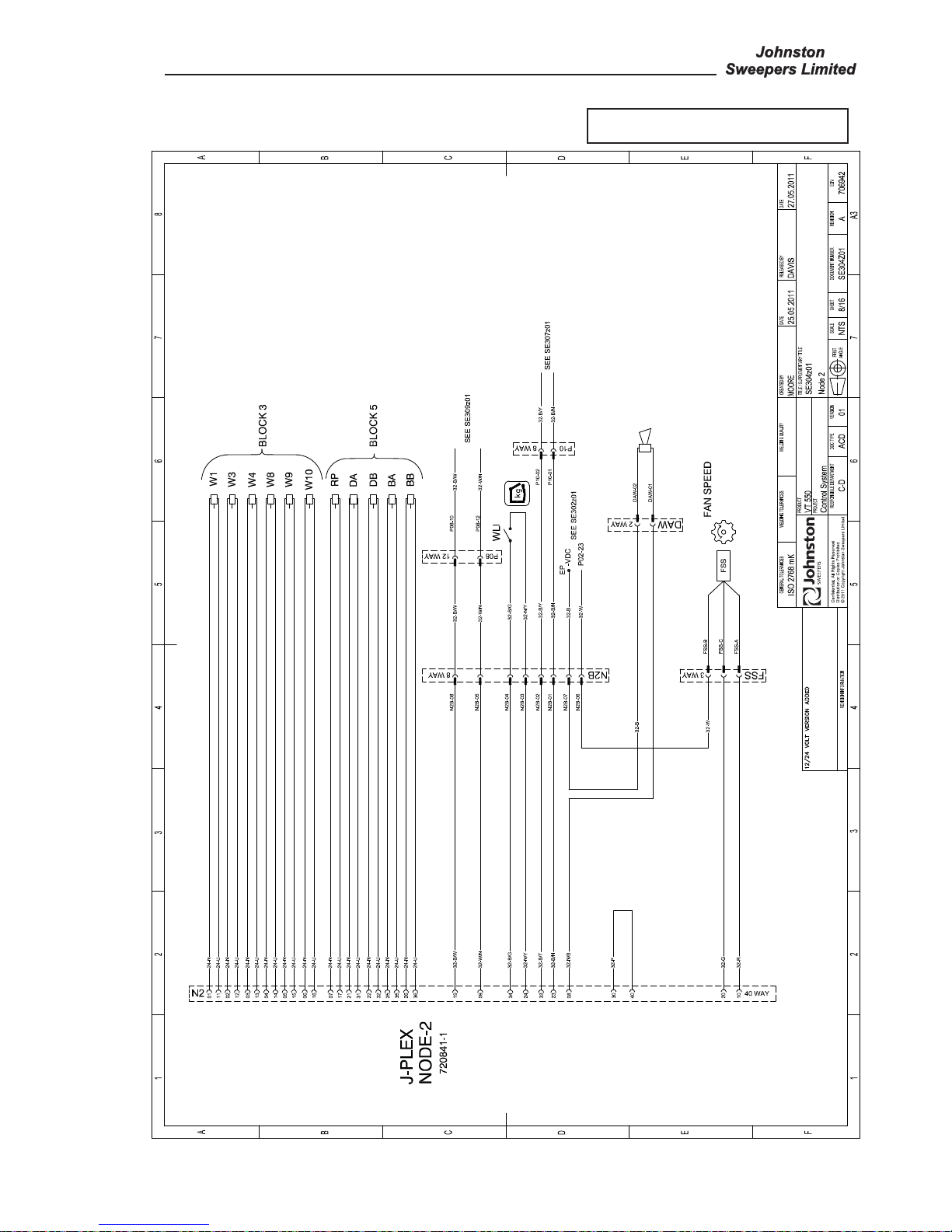

Node 2 Diagram - SE304z01

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 02Chapter - Electrical System9:16

VT551 - Maintenance

P1 CANview Diagram - SE305z03

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 02

Chapter - Electrical System

9:17

VT551 - Maintenance

P2 Subframe Diagram - SE306z02

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 02Chapter - Electrical System9:18

VT551 - Maintenance

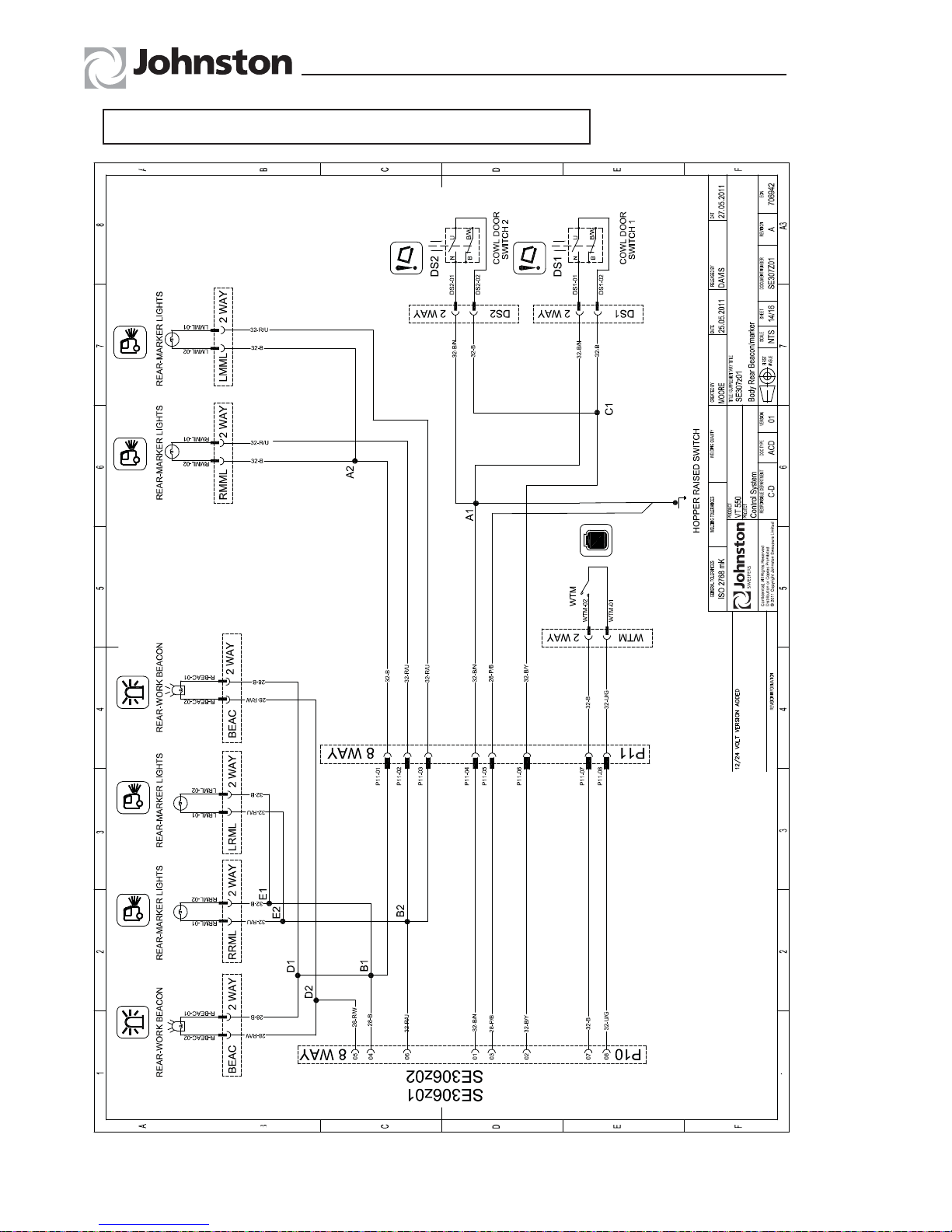

Body Rear Beacon / Marker Lamp Diagram - SE307z01

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 02

Chapter - Electrical System

9:19

VT551 - Maintenance

Switch Panel Diagram - SE308z01

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 02Chapter - Electrical System9:20

VT551 - Maintenance

VM Engine Diagram - SE309z01

All Copyright and rights are the property of Johnston Sweepers Ltd

Chapter - Water System

CHAPTER

10

Water System

10:1

Table of Contents

Section Page

Introduction

General Description 10 : 2

Supawash 10 : 2

Circuit Pressures 10 : 2

Component Maintenance and Settings

Relief Valve 10 : 3

Solenoid Valves 10 : 3

Hydrant Filter 10 : 3

Circuit Diagrams

Piping Diagram 10 : 4

Single Sweep Low Pressure Water 10 : 6

Dual Sweep Low Pressure Water 10 : 7

Supawash Pump

Pump Repair 10 : 9

Seal and Valve Maintenance 10 : 10

Exploded View of Pump 10 : 13

High Pressure Water Circuit Diagram 10 : 14

Page Issue 01

VT551 - Maintenance

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01Chapter - Water System10:2

VT551 - Maintenance

GENERAL DESCRIPTION

Pressure for the water supply is provided by a piston pump hydraulically driven from the auxiliary engine.

Pressure regulation is by a relief valve situated at the rear of the machine. Filtration is by a in-line type

located at the right hand rear of the machine. An isolator valve is built into the in-line filter for ease of

element servicing. All sweeping spray jets are controlled by simple solenoid valves, manifold mounted on

the front of the engine tub.

Control of the washdown hose is by manual valves near the hose reel. The washdown hose is omitted

when high pressure water option is fitted.

SUPAWASH

This optional equipment comprises a hydraulically driven high pressure water pump, and a hand lance

mounted on the chassis with a 15 metre hose wound onto a recoiling reel.

Front and nozzle spraybars are optional equipment.

Supawash Unloader Valve - Pressure Setting

1. Ensure that the hydraulic relief valve has been set as outlined in section 8.

2. Fit a hydraulic test gauge to the Supawash manifold (T13).

3. Disconnect the 3/8” bypass pipe at the unloader valve and plug the hose end.

4. Turn on the front spraybar tap.

5. Activate the Supawash and increase the engine speed to 1800 rpm. Check to see if any water is

leaking from the bypass port on the unloader, if not loosen the retaining nut on the top of the unloader

and unscrew anticlockwise until water dribbles from the bypass port. Gently turn the adjuster clockwise

until water stops dribbling, then turn the adjuster 1/2 turn clockwise and lock off the retaining nut. The

operational pressure at the manifold should be 80-90 bar nominal. If the pressure is higher check again

for blocked jets. If the pump operates at a pressure in excess of 100 bar there is a problem that will effect

the life of the pump and invalidate any warranty.

NB - Do not turn off the front Supawash spraybar or water will be ejected from the bypass valve where

the hose has been removed.

6. Stop the engine and reconnect the bypass hose.

CIRCUIT PRESSURES

Two test points are provided for checking the water pressures.

Test Point No. Function

WTP Dust Suppression Sweep System

T13 Supawash System

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01

Chapter - Water System

10:3

VT551 - Maintenance

RELIEF VALVE

This valve is factory set and should not normally be

touched, but should it be necessary to make adjustments,

the pressure is set as follows.

PRESSURE SETTING

Remove the cover (A) and loosen adjuster locknut (B).

Connect a pressure gauge to the test point located in the

systems locker. With the auxiliary engine running at low

idle speed (750/800), and all water sprays switched off,

turn adjuster screw (C) until gauge reads 3.5 bar (50 psi).

Tighten locknut and replace cover.

SOLENOID VALVES

Solenoid valves control the water spray jets and are

located on the front valance. Each valve incorporates a

filter (A) in its suction port and a manual lift override lever

(B). Turning the lever anticlockwise opens the valve;

clockwise closes it. This manual lift facility can be used

when draining the water system in winter (see Operator’s

Guide, Chapter 3) and for actuating the valve should it for

any reason fail to operate electrically.

The valve is readily dismantled for inspection or cleaning

by unscrewing the retaining cap (C) through the coil (D).

To access the armature, unscrew the four retaining screws

(E) and remove the armature cover (F). The armature (G)

can be removed. When refitting parts ensure the ‘O’ ring

(H) is in good condition and located correctly.

HYDRANT FILTER

Periodically the hydrant filler filter (A) should be cleaned,

or replaced if damaged. To gain access to the filter,

unscrew the hydrant coupling (B) and withdraw the filter

from its housing (C).

95MA. 021

95MA. 021

(A)

(A)

(C)

(C)

(B)

(B)

95MA. 020

95MA. 020

(C)

(C)

(A)

(A)

(B)

(B)

95MA. 019

95MA. 019

(C)

(C)

(D)

(D)

(B)

(B)

(H)

(H)

(E)

(E)

(F)

(F)

(G)

(G)

(A)

(A)

ON

ON

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01Chapter - Water System10:4

VT551 - Maintenance

93MA. 011-4

DUAL SWEEP (D/S)

SHOWN

7

1

3

4

14

5

6

6

13

12

8

11

BLOCK 3

W1 W4 W3

WTP

W8 W9 W10

WTP

W1 W4 W3 W10

LH SINGLE

DUAL

WTP

W10 W3 W4 W1

RH SINGLE

WTP

16a16b

2

2

10

9

Piping Diagram - Low Pressure System

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01

Chapter - Water System

10:5

VT551 - Maintenance

Illustration Component Key

1 Water tank

2 Tank overflow vent

3 Water pump - output 30 l/m

4 Unloader

5 Suction filter

6 Tank flushing ports

7 Tank filler port - hosepipe

8 Water level sight glass

9 Tank drain/flushing valve

10 Hydrant filler port for water tank

11 Type ‘A’ anti syphon water break

12 Relief valve

13 Washdown hose

*14 Additional wide sweep brush spraybar

Water valve manifold - see table below:

16a LH Water valve manifold

16b RH Water valve manifold

WTP Water test point

* Options

WATER VALVE STATION UTILISATION

*Options

S/S D/S VALVES WATER

VALVES LH RH SPRAYS

W1 W1 - Wide Sweep Brush Spraybar

W4 W4 W9 Nozzle (internal) Sprays

W3 W3 W8 Channel Brush and Gutter Sprays

W10 - W10 *Additional Spraybar

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01

Chapter - Water System10:6

VT551 - Maintenance

Single Sweep Low Pressure Water - Diagram SW301a02

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01

Chapter - Water System

10:7

VT551 - Maintenance

Water System Low Pressure Dual Sweep - Diagram SW302a01

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01

VT551 - Maintenance

Chapter - Water System10:8

LP / HP Valve Location

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01

Chapter - Water System

10:9

VT551 - Maintenance

Water Pump Repair

Water pumps by their very nature are subject to erosion and wear from the process of pumping water.

The life of the pump will depend on the quality of the water being used. The more particles that are in

suspension in the water the sooner the seals and valves in the pump will wear and require replacing and

are therefore considered as consumable items.

The main components in the pump that will require servicing are the suction and discharge valves and the

seals on the plunger pipes.

A pump working correctly will normally not have any water leaks. If the plunger seals wear water will leak

from the underside of the pump as shown below.

A drip ever 5 -10 seconds is an indication that the seals need replacing in the very near future.

A continuous drip from underneath the pump shows the seals are severely worn and require urgent and

prompt replacement. Shown by the arrows in the above picture.

If a steady stream of water leaking from the pump is observed the pump should NOT be used. Should the

pump be used in this condition water will be drawn back into the crankcase by the motion of the plungers.

This water ingress into the crankcase will cause a catastrophic failure of the pump.

When the suction and discharge valves wear the out put of the pump will be reduced and this will be

noticed as reduced output from the spray jets.

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01Chapter - Water System10:10

VT550 - Maintenance

P22/34-100 Johnston Water pump 283701-1

Seal and Valve Maintenance Instructions

The following shows the overhaul procedure for the valves and plunger seals

1. With a 22mm socket,

remove the three discharge

valve plugs (43) from the

top of the manifold.

2. With a pair of needle nose pliers remove the spring

tension cap (34), spring (35) and plate (36)

3. Use a valve extractor

tool (99.061) to remove the

valve seats (37)

4. Inspect the valve seat

(37) and valve seat (36) for

signs of wear or cavitation

and replace as necessary.

5. Using an 8mm Allen key

remove the inner hexagon

screws (45)

6. With a rubber mallet tap

the back of the valve casing

(29) and pull the valve

casing (29) off the plungers

(24a).

7. Using a 6mm Allen

key remove the two inner

hexagon screws (46).

8. Separate the intermediate

casing (48) from the valve

casing (29)

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01

Chapter - Water System

10:11

VT550 - Maintenance

9. Remove and inspect the

low pressure seal (50) and

replace if necessary.

10. Turn over intermediate

casting (48) Remove

and inspect the high

pressure seal (31) and the

support ring (32) replace if

necessary.

11. Remove the seal case

(39) from the valve casing

(29) and inspect both O

Rings (40) for wear.

12. Using needle nose

pliers, remove the spring

tensioning caps (34), valve

spring (35), valve plate (36)

from the valve casing (29)

Using a valve extractor

(99.061) to remove the

valve seat (37) from the

valve casing (29).

13. Inspect the valve seat

(37) and valve seat (36) for

signs of wear or cavitation

and replace as necessary.

14. Install the inlet valve

assembly (34 – 38) back

into the valve casing.

Ensure the “f ngers” of the

spring tensioning cap (34)

DO NOT obstruct the cross

bore in the valve casing

(29).

15. Install the seal case (39)

with O Rings (40) into the

valve casing (29)

16. Install the support ring

(32) and the high pressure

seal (31) into the intermediate plate (48)

17. Lubricate the low

pressure seal (50) and

install into the intermediate

casing (48).

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01Chapter - Water System10:12

VT550 - Maintenance

18. Replace the three

spacer sleeves (26a) over

the plunger (24a) with the

f anged side toward the

valve casing (29)

19. Install the pressure

rings (30) over the plungers

(24a). Make sure that the

small o ring (49) is in place

in the intermediate casing

(49)

20. Secure the intermediate

casing (48) to the valve

casing (29) with the inner

hexagon screws (46).

Torque to 12 NM.

21. Place the valve casing

(29) over the plungers

(24a). Secure with inner

hexagon screws (45) Torque

evenly to 45 NM

22. Install the high pressure

valve assemblies with o

rings (34 – 38) Ensuring

the f ngers of the spring

tensioning cap (34) DO

NOT obstruct the cross bore

in the head (29).

23. Replace the high

pressure plugs (43) and

torque to 70 NM.

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01

Chapter - Water System

10:13

VT550 - Maintenance

Exploded view of Pump

Item Number Quantity Part Number Description

19 1 283701-13 Woodruff Key

20 3 283701-14 Connecting Rod

24A 3 283701-12 Ceramic Liner

31,32,40,49,50 1 Kit 283701-10 Plunger Seal kit - for 3 plungers

34,35,36,37,38 1 Kit 283701-11 Valve Kit - for the 6 valves

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01Chapter - Water System10:14

VT551 - Maintenance

High Pressure Water - Diagram SW303z02

All Copyright and rights are the property of Johnston Sweepers Ltd

Chapter - Pneumatic System

CHAPTER

11

Pneumatic System

11:1

Table of Contents

Section Page

Introduction

General Description 11 : 2

Circuit Pressures 11 : 2

Pneumatic Pipe Colours 11 : 2

Component Valve Identification 11 : 3

Component Removal

Air Filtration and Regulator (FR) 11 : 4

Pneumatic Valve Island 11 : 4

Wide Sweep Brush Regulator Maintenance 11 : 6

Circuit Diagrams

Maxigap Single Sweep 11 : 7

Maxigap Dual Sweep 11 : 8

Mesh Shakers and Littasnatch Option 11 : 9

Page Issue 01

VT551 - Maintenance

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01Chapter - Pneumatic System11:2

VT551 - Maintenance

GENERAL DESCRIPTION

The air supply for the pneumatic system is taken from the vehicle braking system via a safety regulating

valve that ensures the braking system receives priority in the event of a failure to the sweeper air system.

Alternatively, where an air system is not available on the chassis air may be supplied by an electrically

driven air compressor system. A filter regulator unit with integral shut off/drain facility and low air pressure

warning buzzers are located near the fan case as are the electrical solenoid control valves for operation

of channel brush/nozzle and wide sweep brush. Wide sweep brush balance adjustment is provided by

pressure regulators.

CIRCUIT PRESSURES

A test point PTP (on piping diagram) is provided on the filter regulator unit (FR) to carry out pressure

checks, i.e. 8.0 bar (115 PSI).

The pressure in the Powathrust system is preset at 3.5 bar.

The pressure in the Powascrub system (option) is preset at 2 bar.

1 First ensure truck air system is up to pressure and sweepgear is lifted.

2 Fit a 25 bar minimum pressure gauge to test point PTP.

If pressure is incorrect, adjustment is carried out by turning the regulator control on the filter regulator unit.

NB : Provided on the (FR) unit is an air charge point (AC) via an airline push in connector supplied with

the sweeper.

PNEUMATIC PIPE COLOURS

A system of colour coding has been introduced to assist pipe identification and fault finding. The following

colours have been adopted.

R = Red - used for live feed/supply

U = Blue - used for switched supply via valve or tap

B = Black - used for permanent vent/exhaust line

Before servicing any components on this system, the air supply should be shut off by means of

the shut off valve mounted on top of the filter regulator unit. This not only severs the pneumatic

supply, it also exhausts the air from the system causing the nozzle and wide sweep brush to

lower. Wait approximately 15 seconds to allow air to completely exhaust before carrying out any

work. The shut off valve does not drain air from the vehicle braking system.

Safety Precautions

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01

Chapter - Pneumatic System

11:3

VT551 - Maintenance

COMPONENT IDENTIFICATION

NODE 5

FR

R2

R3

R4

R5

93MA. 003

VM

V6V8V12V

14

V

2

V5V

7

V9V11V13V15V17V

19

V1V

3

V21V

23

V

20

V22V

24

B2

A1

A2 B1

R1

Regulators

A1 - B2 Wide Sweep Brush Balance - adjustable

R1 Channel brush Powasave - adjustable

R2 Wide sweep brush Powascrub - fixed

R3 Channel brush Powathrust (yellow) - fixed

R4 Left hand channel brush Kickback - adjustable

R5 Right hand channel brush Kickback - adjustable

FR Air filter regulator unit - see over page

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01Chapter - Pneumatic System11:4

VT551 - Maintenance

AIR FILTRATION AND REGULATOR (FR)

A filter regulator unit, located near the fan case in the right hand side of the body, filters the air for the

sweeper section of the pneumatic system to prolong the life of the components served by it.

Before carrying out any major work on the unit, other than that described in the Routine Maintenance

Section of the Operator’s Guide, it will be necessary to remove it by first draining the vehicle air system,

then disconnecting the supply pipes and releasing the fixing bolts.

PNEUMATIC VALVE ISLAND

The pneumatic valve island is a modular unit comprising various valve segments. Each valve segment

has an indicator light that illuminates when energised (A) and a manual override button (B) for ports 2 or

4 on each segment

The segments are identified by a code and are not all the same - see following tables.

B

3

0

0

N

B

6

U

N

G

6

U

N

B

6

U

N

A

6

U

N

G

6

U

N

B

6

U

N

A

6

U

N

A

6

U

N

G

6

U

N

G

6

U

N

G

6

U

V21 23

V22 24

(H)

(G)

(F)

93MA. 004

VALV E

NUMBERS

OVERRIDE BUTTONS FOR

VALVES V2 - V24

OVERRIDE BUTTONS FOR

VALVES V1 - V23

DUAL SWEEP VALVE

WITH OPTIONS SHOWN

VALV E

NUMBERS

SEGMENT

CODES

(C)

(E)

(A)

(D)

(B)

(B)

12 - LAMPS FOR VALVES V2 - V24

14 - LAMPS FOR VALVES V1 - V23

V2 4 6 8 10 12 14 16 18 20

V1 3 5 7 9 11 13 15 17 19

To replace a valve segment -

1) Remove the 4 fixing screws (C).

2) Remove the 4 socket head screws (D).

3) Remove the valve cover containing the valve operating coils (E).

4) Unscrew (F) each side of the segment to be replaced.

5) Fold open the segment (G) and replace ensuring the rubber gasket (H) is in position.

6) Tighten screws (F).

7) Replace top cover (E).

8) Replace screws (D).

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01

Chapter - Pneumatic System

11:5

VT551 - Maintenance

VALVE ISLAND PORT CONFIGURATION (VALVES NOT TICKED ARE REPLACED WITH B000)

VALVE

SEGMENT

CODE

* = T (12V)

* = N (24V)

PORT 4 / LED 14 PORT 2 / LED 12

293455-12

12V SINGLE

293455-24

24V SINGLE

293455-212

12V DUAL

293455-224

24V DUAL

V1 & V2 *G6U AUTOPROP EXTEND (NC) AUTOPROP RETRACT (NO)

3333

V3 *G6U CHANNEL BRUSH OUT LH (NC) CHANNEL BRUSH IN LH (NO)

3333

V5 & V6 *B6U V5 = CHANNEL BRUSH RAISE/LOWER LH (NO) V6 = NOZZLE RAISE/LOWER LH (NO)

3333

V7 & V8 *A6U V7 = MAXIGAP RH (NC) V8 = MAXIGAP LH (NO)

3333

V9 *G6U CHANNEL BRUSH OUT RH (NC) CHANNEL BRUSH IN RH (NO)

33

V11 & V12 *B6U V11 = CHANNEL BRUSH RAISE/LOWER RH (NO) V12 = NOZZLE RAISE/LOWER RH (NO)

33

V13 & V14 *A6U V13 = POWASCRUB (NC) V14 = POWATHRUST (NC)

3333

V15 *G6U FLAP LH FULL BORE (NC) FLAP LH ANNULUS (NO)

3333

V17 *G6U FLAP RH FULL BORE (NC) FLAP RH ANNULUS (NO)

33

V19 & V20 *A6U V19 = WSB BALANCE RH (NC) V20 = WSB BALANCE LH (NC)

33

V21 & V22 B300 BLANKED EXHAUST (5) BLANKED EXHAUST (3)

33

V23 & V24 *B6U V23 = WSB LOWER LH (NO) V24 = WSB LOWER RH (NO)

3333

REV REVISION INFORMATION

05

SLICE FOR V1 & V2 WAS BLANK

ED23490 - RD - 14/06/200704VALVE SLICE PREFIXES ADDED FOR 12V AND 24V

ED23384 - RD - 10/05/200703V19 & V20 REMOVED FROM -12 & -24, V23 & 24 ADDED TO -12 & -24

ED22500 - RD - 05/06/2006

REMOVE ALL BURRS AND SHARP EDGES.

DEV293

CANOpen

TITLE:SIMILAR TO:

MATERIAL:

930911

USED ON ASSEMBLIES:

283305

MASS (kg):

FINISH:

SEE DETAILS

1.13KG

AS SUPPLIED

VM10 PNEUMATIC VALVE ISLAND

SCALE:

DRG No:

1:2

02/12/2005

RD

MODEL:

DRAWN:

DATE:

REV.

A3

DRAWING STANDARDS TO BS 8888 WELD SYMBOLS TO EN 22553:1994 (ISO 2553:1991)

ALL DIMENSIONS SHOWN IN MILLIMETRES

COPYRIGHT IN THIS DRAWING AND DESIGN

IT IS AN INFRINGEMENT OF THE COMPANY'S

0.5° ANGULAR DIMENSIONS =

0.25 #.## AND HOLE DIAMETERS =

0.50 #.# AND ALL HOLE POSITIONS =

1.00

OF THE METRIC DIMENSION THUS:

ARE INDICATED BY THE DECIMAL PLACING

UNLESS OTHERWISE STATED, TOLERANCES

PROJECTION

293455

05

PROCESSING RESIDUE.

REMOVE ALL BURRS SHARP EDGES AND

CONSENT OF JOHNSTON SWEEPERS LTD.

TO ANY THIRD PARTY WITHOUT THE WRITTEN

TO COPY OR COMMUNICATE IT'S CONTENTS

#. EXCEPT MATERIAL THICKNESS =

DO NOT SCALE. IF IN DOUBT ASK.

Johnston

CURTIS ROAD, DORKING, SURREY RH4 1XF

SWEEPERS

A

100

53

202

VM1

VM2

78.5

V1 (4)

VIEW ON ARROW 'A' - SCALE 1:1

V5 (4)

V3 (4)

V7 (4)

V9 (4)

V11 (4)

V13 (4)

V21 (4)

V17 (4)

(2) V22

(2) V4

V19 (4)

(2) V6

(2) V8

(2) 10

(2) V12

(2) V14

(2) V16

(2) V18

(2) V20

(2) V24

(2) V2

(293455-212 & 293455-224 SHOWN ABOVE)

V15 (4)

PORT CONFIGURATION FOR VALVE ISLANDS - REFER TO TABLE BELOW

V23 (4)

Pneumatic Valve Island Configuration

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01Chapter - Pneumatic System11:6

VT551 - Maintenance

WIDE SWEEP BRUSH REGULATOR MAINTENANCE

Before any work can be carried out on these units, they must be removed from their locations under the

ends of the subframe crossmember+ as follows.

Exhaust the system using filter regulator shut off valve, disconnect pipes from regulator and shuttle

valve, unscrew regulator securing nut. The regulator, shuttle and non-return valves can be removed as

a complete assembly.

REGULATOR

Remove the regulator by undoing the securing nut

(A). Use retaining ring pliers to remove the top plate

(6) and retaining ring (7). Pull cap (8) and ‘O’ ring (9)

from body.

Unscrew socket head screw (1), then remove button

(2), spring (3), knob (4), tumblers (5), couple (10) and

‘O’ ring (11).

Remove, as an assembled unit, the adjusting screw

(12) with upper and lower piston assemblies (Items 13

through 20). Remove spring (21).

Unscew the adjusting screw (12), then separate upper

and lower piston assemblies (Item 13 through 20).

The adjusting screw has left hand threads. Make sure

‘O’ ring (19) remains attached to the lower piston. If

not, retrieve it from inside the upper piston (13).

Unscrew bottom plug (22) to gain access to the parts

(23 through 36) located in the lower portion of the

body.

Clean and inspect each item for damage.

A repair kit, Part No. 253-10, is available comprising

Items 9, 11, 12, 14, 19, 20, 23-27, 29, 30 and 36.

When reassembling, lightly smear the ‘O’ rings and

rubbers with a silicon grease. Reassemble in the

reverse procedure.

PC. 0014

1

19

18

20

21

37

25

26

27

28

29

36

23

24

22

30

2

3

4

5

A

6

7

8

9

11

10

12

14

13

15

Make sure retaining ring (7) is fully seated in the groove in the body before

testing or refitting onto the machine.

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01

Chapter - Pneumatic System

11:7

VT551 - Maintenance

Maxigap Single Sweep - Diagram SP301z02

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01Chapter - Pneumatic System11:8

VT551 - Maintenance

Maxigap Dual Sweep - Diagram SP302z03

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01

Chapter - Pneumatic System

11:9

VT551 - Maintenance

Mesh Shakers and Littasnatch Option - Diagram SP305z01

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01Chapter - Pneumatic System11:10

VT551 - Maintenance

All Copyright and rights are the property of Johnston Sweepers Ltd

Chapter - Wearing Items

CHAPTER

12

Wearing Items

12:1Page Issue 01

VT551 - Maintenance

Table of Contents

Section Page

Replacement Instructions

Fan Impeller 12 : 2

Intake Duct Flap 12 : 3

Wear Plate 12 : 3

Intake Duct 12 : 4

Intake Trunking 12 : 4

Intake Seat 12 : 5

Suction Nozzle Wheel 12 : 5

Nozzle Wheel Bearings 12 : 6

Suction Nozzle Rubbers 12 : 6

Channel Brush 12 : 6

Wide Sweep Brush Fills 12 : 7

All Copyright and rights are the property of Johnston Sweepers Ltd

THESE ITEMS HAVE BEEN SPECIFICALLY DESIGNED FOR LO-NOISE EMISSIONS AND FITTING

OF ALTERNATIVE ITEMS COULD CAUSE AN INCREASE IN THE OPERATIONAL NOISE OF THE

MACHINE.

FAN IMPELLER

INSPECTION -This should be on a regular basis as outlined in the routine maintenance. The impeller

should be replaced as soon as the blade thickness is less than 2mm or the blades have visible signs of

wear/damage.

REMOVAL

1. Raise the body and ensure the body prop is

engaged in the rack.

2. Isolate the battery.

3. Remove the 12 bolts (A) holding on the fan

cover and remove cover (B).

4. Remove the capscrew (C) in the centre of the

fan.

5. The fan impeller should slide off the shaft, a

bearing puller 437-2 can be used if required.

Page Issue 01Chapter - Wearing Items12:2

VT551 - Maintenance

WEARING PARTS REPLACEMENT INSTRUCTIONS

It is important that the following safety precautions are observed when working on the machines.

Ensure the machine is standing on firm, level ground and there are no obstructions above or

to the rear before raising the body.

Ensure the safety prop is engaged at all times when working under the body.

Ensure operators are fully conversant with the controls and operation.

Isolate the air in the systems locker before working on any pneumatically operated or

controlled equipment.

Disconnect or isolate the vehicle battery when working on the electrical system.

Do not approach the fan inlet while the fan is running.

Do not grasp any part of the engine or exhaust system without first ascertaining whether it

has cooled sufficiently to avoid scalding.

Be aware of the safety instructions relative to the suction fan given in the equipment

maintenance notes.

Keep hands, loose clothing, hair etc. well clear of moving parts.

Do not climb on the engine walkways unnecessarily or approach the fan inlet whilst the engine

is running.

Do not use ill-fitting tools such as spanners that may slip and cause injury.

Always get a second person to check periodically that all is well when only one person is

working on the machine or inside the body.

Safety Precautions

93MA. 015-2

(A)

(B)

(C)

(D)

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01

Chapter - Wearing Items

12:3

VT551 - Maintenance

REFITTING

1. Replacement is the reverse of removal.

2. Lightly grease the fan motor spline using grease part number 94-24 before fitting the impeller.

3. Fit a new Tuflok capscrew and torque up to 101 Nm (75lbf. ft.).

4. Refit fan case cover with a suitable silicone sealant between the mating surfaces.

From July 2009 all impellers have a ‘’V’’ mark (D) at Top Dead Centre (TDC) applied when they are

manufactured. When fitting a replacement impeller it should be rotated so this mark is at the 12 o’clock

(TDC) position before the retaining bolt is tightened to the prescribed torque.

INTAKE DUCT FLAP

When the flap plate is in the open position, it is abraded by the material

discharging from the intake duct into the body. The flap should be

inspected periodically and replaced when worn. To inspect one must

first open the rear door and suitably prop open, then depressurise the air

system in the systems locker, this will allow the flap to be opened and

closed manually from the interior of the body. Enter body and inspect

the flap valve plate which is secured to actuating fingers by a pair of

spring clips.

REMOVAL

To remove a flap plate the springs must be withdrawn using a suitable tool or bar. Notice how the springs

were fitted from each side of the finger guide and around the groove in the finger assembly. Once the

springs are removed the flap plate can be detached from the finger.

REFITTING

Before refitting or fitting a new flap plate, ensure the springs are in good condition and the finger adjustment

areas have been cleaned, then locate flap on the finger and replace springs. Ensure the flap plate seats

correctly on top of the inlet tube, if not, check for excessive wear on the inlet tube/flap, or adjustment of

the flap operating mechanism.

WEAR PLATE

REMOVAL

Enter the body after carrying out precautions as for intake

duct flap. The wear plate (A) is secured by two screws and

a clamp bar (B). It is a wise precaution to prop the wear

plate before attempting to remove these screws. Once the

screws are removed, support the wear plate and remove

the prop. Allow the wear plate to fall slightly and unhook

from the hooks (C) attached to the body outer skin, and

remove. Help may be required in removal as this unit weighs

approximately 36kg.

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01Chapter - Wearing Items12:4

VT551 - Maintenance

INTAKE DUCT

These parts are also abraded by the material being conveyed from the suction nozzle and must be

periodically inspected and replaced when worn or holed. The duct is 250mm diameter.

REMOVAL

Enter body after carrying out the same precautions as for

intake flap replacement. Remove the four bolts securing

the collar (A) around the intake duct (B). Lift up the flap

manually (if fitted) and remove collar. A rubber cord (C)

will now be visible which should also be removed with care

to prevent damage. Dismount from body. Tip body and

support on prop. Remove the four bolts in the square flange

carrying the flexible trunking seat seal (D). The intake duct

can now be pulled downwards clear of the body.

REFITTING

Reverse of removal procedure, but if fitting a new duct a

new trunking seat seal should be used and secured using a

contact adhesive, Part No. 9903. Fit two bolts in diagonal

holes, the duct (B) has two holes with keyhole slots. Align

slots over the bolt heads and twist. Fit the other two

bolts and tighten. The rest is the reverse of the removal

instructions. Replace the rubber cord (C) and collar plate

(A) inside the body and secure. Finally, fully tighten the four

duct top retaining bolts.

NB : Torque for brass M12 bolts 22 Nm (25ft. lbf.).

FLEXIBLE INTAKE TRUNKING

REMOVAL

Lower suction nozzle to the ground, release worm drive clips at either end and remove trunking. The

nozzle trunking has an inside diameter of 250mm.

REFITTING

Loosely fit worm drive clips to either end of trunking. Engage trunking onto the nozzle with a 55mm (2”)

overlap and tighten clip. Fit other end to the intake seat and secure. Check trunking is not twisted or

rucked and does not foul anything when the nozzle is raised or lowered again.

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01

Chapter - Wearing Items

12:5

VT551 - Maintenance

INTAKE SEAT

REMOVAL

Firstly tip body and support on prop. Release trunking from tube

as described on previous page. Release and remove the three

countersunk screws and nuts (A). Lift seat (B) clear of bracket.

REFITTING

Reverse of removal procedure. As no adjustment for seal

compression is provided, it is wise to check seal compression

when the body is lowered.

Note : When replacing the intake seat, it is important that the

correct length is used. The correct length of intake seat is

determined by measuring dimension A, as shown below,

from ground to underside of the subframe (i.e. top of

chassis).

SUCTION NOZZLE WHEEL

REMOVAL

Release nozzle wheel adjustment nut (A) on inner end of wheel spindle. Remove wheel complete.

REFITTING

Reverse of removal procedure.

TYRE - SUCTION NOZZLE WHEEL

REMOVAL

Remove nozzle wheel as above. Remove

five screws securing tyre plate (B) and prise

off. Remove tyre from hub.

REFITTING

Reverse of removal procedure.

Note : Ensure correct re-setting of nozzle rubbers in relation to the ground.

Dimension A

Inlet Seat

Part No. ‘B’

900 - 999

1000 - 1099

1100 - 1199

94990-1

94990-3

94990-4

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01Chapter - Wearing Items12:6

VT551 - Maintenance

NOZZLE WHEEL BEARINGS

REMOVAL

To withdraw bearing remove wheel assembly from carriage and remove the three setscrews from the

retaining plate. Refit washer and nut, insert M6c x 50mm setscrews, Part No. 124-113, in the three unused

retainer plate holes. Tighten each bolt half a turn at a time to extract the bearing. Remove drift bearing

from shaft.

REFITTING

Reverse of removal procedures.

SUCTION NOZZLE RUBBERS

REMOVAL

This can be effected without removing the nozzle assembly from the machine but if personnel are

inexperienced it will probably be easier to remove nozzle assembly and turn upside down. Release two

screws retaining bump bar at kerb end of nozzle. Release securing nuts retaining the rubbers. Pull away

the two short end rubbers, then remove the front and rear side rubbers.

REFITTING

Reverse of removal procedure remembering to fit the radius rubber to the nozzle rear. Do not over tighten

the nuts as this will cause distortion of the rubber. Refit bump bar.

CHANNEL BRUSH

REMOVAL

It is preferable to have brush in working position with auxiliary engine stopped. Release four nuts from

coach bolts securing brush stock assembly drive plate. Remove brush.

REFITTING

Reverse of removal procedure. Any loops of steel tines which project above the head of the stock should

be hammered flush before offering up brush stock assembly to driving plate.

WIDE SWEEP BRUSH CORE ASSEMBLY

See Chapter 6 in the Operator’s Guide.

Sharp objects

Sharp objects

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01

Chapter - Wearing Items

12:7

VT551 - Maintenance

Replaceable Segment Option

REMOVAL

Release and remove the retaining screws (F) securing the end plate / adaptor (A). Slide off the segments

(B) and spacers (C) from the central core. Note : On earlier machines the driving pin (E) on the inner

diameter of the segments must be aligned with a slot (D) on the core (G) where the two parts join.

REFITTING

First slide on a segment then alternately a spacer and a segment. Sufficient spacers and segments must

be fitted to allow the end plate to nearly abut with the core and also clamp them tightly. The peg (E) on

the segment (B) to be alternatively located round the core clock face at 12, 2, 4 o’clock and so on until

the core is filled, failure to observe this could cause the brush to bounce. The last segment must have the

pin (E) on the segment (B) located in the cut out (D) to ensure the peg does not interfere when the parts

are bolted together.

Note : Lightly smear the retaining screws (F) with grease.

This assembly is designed to accommodate 340mm diameter segments.

Plastic Throw Away Stock

The stock (H) is removed and can be recycled as plastic waste.

WIDE SWEEP BRUSH FILLS

There are two types of brush fills:

a) Plastic ‘throw away’ stock tines.

b) Replacement segments.

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01Chapter - Wearing Items12:8

VT551 - Maintenance

All Copyright and rights are the property of Johnston Sweepers Ltd

Chapter - Remove and Refit Procedures

CHAPTER

13

Remove and Refit Procedures

13:1

Table of Contents

Section Pages

Removal and Refitting Instructions

Water Pump 13 : 2

Wide Sweep Brush Motor 13 : 2

Channel Brush Motor 13 : 3

Channel Brush Cylinder 13 : 3

Body and Body Tip Ram 13 : 4

Radiator 13 : 5

Hydraulic Pump 13 : 5

Fan Impeller 13 : 5

Fan Case and Fan Motor 13 : 6

Fuel Tanks 13 : 7

Engine Actuator 13 : 7

Page Issue 01

VT551 - Maintenance

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01Chapter - Remove and Refit Procedures13:2

VT551 - Maintenance

This section describes the removal and refitting of some of the major components on the machine. These

are not routine jobs and should normally only need to be undertaken when overhauling or exchanging

these units.

1. WATER PUMP - REMOVAL AND REFITTING

1. Isolate the water supply at the filter unit.

2. Mark up the position of the water and hydraulic feed

and return pipes before disconnecting. It will be

necessary to cap the hydraulic pipes to prevent oil loss.

3. Remove the 4 bolts (A) holding the pump brackets to

the centre subframe crossmember.

4. Refit in the reverse order.

5. Turn on the water at the filter and run pump to check for

water and hydraulic leaks.

NB - It is possible to replace the pump suction and discharge

valves in situ.

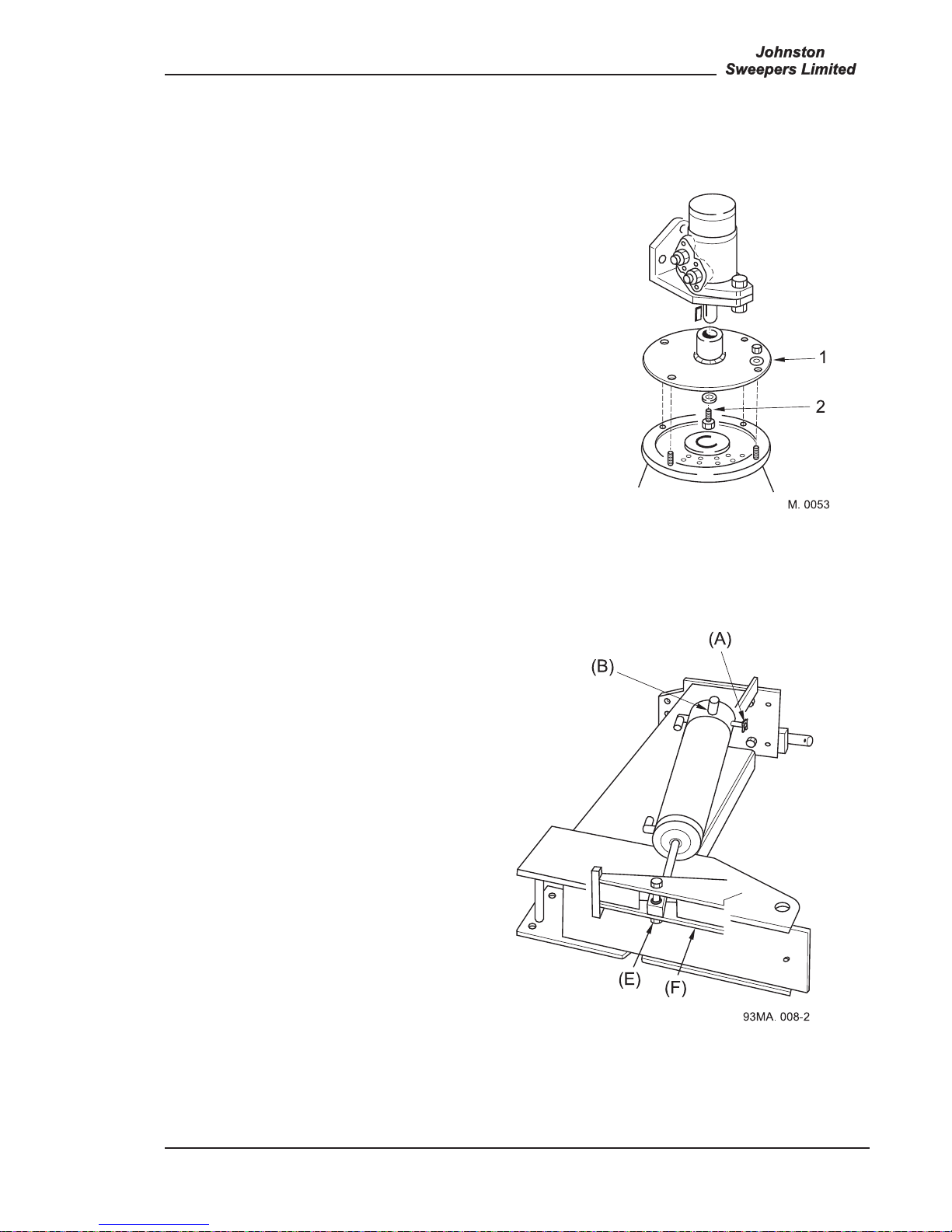

2. WIDE SWEEP BRUSH MOTOR - REMOVAL AND REFITTING

1. Remove the brush stock as described in Chapter 6.

2. Unscrew the four end plate securing setscrews and remove plate complete with motor assembly and

drive shaft or drive dog.

FIGURE 4 - WIDE SWEEP BRUSH

MOTOR

1. End plate securing screws.

2. Drive shaft retaining screws.

3. Drive shaft/drive dog.

4. Retaining plate.

5. Drive adaptor retaining screw.

6. Drive adaptor

7. Motor securing screws

The hinged prop stowed beneath the body SHOULD BE USED AT ALL TIMES to prop the body

when carrying out any inspection, servicing or maintenance work beneath the body.

Disconnect or isolate the battery before undertaking any of the following operations

on the sweeper and remove the chassis ignition key to isolate the power units.

Safety Precautions

93MA.018

A

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01

Chapter - Remove and Refit Procedures

13:3

VT551 - Maintenance

3. CHANNEL BRUSH MOTOR - REMOVAL AND REFITTING

1. Unscrew the four nuts (A) from the coach b olts

securing the channel brush to the drive adaptor plate

and remove brush.

2. Unscrew the retention screw (B) from the centre of the

drive adaptor plate and remove plate. A special tool,

Part No. 48094-1, is available for this purpose.

3. Disconnect the two hydraulic hoses from the motor.

4. Unscrew the two bolts securing the motor to mounting

bracket and lift off motor.

5. Refitting is the reverse of removal.

4. CHANNEL BRUSH CYLINDER - REMOVAL AND REFITTING

1. Isolate air supply at FR unit.

2. Disconnect the 2 air hoses from the rear.

3. Remove clip on pin (A) and push through.

4. Remove pin (B) by pushing through.

5. Remove cylinder eye pivot bolt (E) from the

lever pivot head (F).

6. Refit is reverse.

7. Grease items (E) and (B) prior to refitting.

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01Chapter - Remove and Refit Procedures13:4

VT551 - Maintenance

5. LIFTING OR REMOVAL OF THE BODY

If it is necessary to raise the body, 2 holes are

provided in the front of the body.

Remove blanking bolts (A).

Insert eye bolt item (B) part no. 422-1 into the

M16 socket.

If the body has to be removed use the two lifting

eyes and point (C) with a suitable chain or web

strap.

6. BODY TIP RAM - REMOVAL AND REFITTING

1. Raise the body and rest on the body

prop, which should be set on the lowest

notch.

2. Fit brackets 293909-1 to the subframe

crossmember and the front of the body.

Secure each with two M12 x 30 bolts

plus washers and nuts.

3. Raise the body a little and get an

assistant to place the special workshop

prop 293856-1 between the two brackets.

Insert pins (A) through the holes in the

brackets and prop and retain with the ‘R’

clips.

4. Stop the auxiliary engine. Remove truck

ignition keys to isolate the unit.

93MA. 009-2

Before the body tip ram can be removed it is necessary to fit the special workshop

retaining prop KT 01893 to ensure the body does not tip over when the ram is removed.

93MA. 013-2

293909-1

293909-1

293856-1

(A)

(A)

All Copyright and rights are the property of Johnston Sweepers Ltd

Page Issue 01

Chapter - Remove and Refit Procedures

13:5

VT551 - Maintenance

5. The hydraulic hoses to the tip ram can now be removed.

6. Fit a nylon strap round the tip ram and remove the 4 bolts holding the trunnion brackets to body

front after ensuring the strap will hold the ram correctly.

7. Remove the lower pin through the ram eye on the crossmember and move the ram away from the

body.

8. The refit procedure is the reverse of the above. Remember to remove the prop mounting brackets.

9. When first operating the ram it will be necessary to raise and lower the body several times to expel

any air in the system.

7. RADIATOR - REMOVAL AND REFITTING

1. Drain the engine coolant (collar plug in radiator).

2. Drain the hydraulic reservoir.

3. Loosen the hydraulic pipe at the bottom of the radiator to drain the remaining oil and disconnect the

hoses.

4. Remove the kick plate at the bottom of the radiator.

5. Remove the 6 securing bolts.

6. Remove radiator.

7. Refit procedure is the reverse of the above. Remember to replace the coolant and hydraulic fluids.

8. Check for fluid leaks on testing and rechecking oil and water levels after the engine has been run.

8. HYDRAULIC PUMP - REMOVAL AND REFITTING

1. Drain the hydraulic tank.

2. Remove the hoses from the tandem pump and the setscrews holding the pump to the fan pump.

3. To remove the fan pump remove the hoses to the fan pump and the 4 setscrews holding the pump

to the engine flywheel cover.