Page 1

!

WARNING:

4430H-English_Manuals 2/22/11 11:08 AM Page 1

Electronic Digital Theodolite

Model No. 40-6932 and 40-6935

Instruction Manual

Congratulations on your choice of this Electronic Digital Theodolite.

We suggest you read this instruction manual thoroughly before using

the instrument. Save this instruction manual for future use.

©2011 Johnson Level & Tool 1

Page 2

4430H-English_Manuals 2/22/11 11:08 AM Page 2

Table of Contents

1. Kit Contents

2. Features and Functions

3. Location of Parts/Components

4. Operating Instructions

5. Using the Product

6. Self-Check & Fine Calibration

7. Technical Specifications

8. Care and Handling

9. Product Warranty

10. Warranty Registration

11. Accessories

1. Kit Contents

Description for Model 40-6932 & 40-6935 Qty.

Electronic Digital Theodolite

Alkaline Battery Pack (batteries not included) 1

NiMH Rechargeable Battery Pack 1

NiMH Battery Charger 1

Rain Hood 1

Adjustment Tools 1

Instruction Manual with Warranty Card 1

Hard-Shell Carrying Case 1

1

2 ©2011 Johnson Level & Tool

Page 3

4430H-English_Manuals 2/22/11 11:08 AM Page 3

2. Features and Functions

• 2” or 5” angular accuracy - accurate enough for any construction job

• Vertical axis compensation - tilt sensor provides the highest level

of accuracy and can be turned on or off depending on job

requirements

• Dual LCD with large characters - easy to see angle readings

eliminate errors and reduces eye fatigue

• Backlit LCD screen and telescope reticle - allows work in low light

conditions including indoors and extended hours near dawn

and dusk

• Simple six button keypad - quick setups and simple operation with

low operator learning curve

• Large suite of programmable settings - provide multiple options for

various users and job requirements including zero position of

vertical angle

• Measurement units in degrees, gon, or mils

• 90 degree angle audible notification - for quick turning and set out

of right angles

• Instant conversion of vertical angles to percent of grade convenient for slope work

• Ni-MH rechargeable battery pack and charger - lower operating cost

with reusable batteries

• Alkaline battery pack standard - provides backup and eliminates

downtime if the charge is lost in the middle of a job

• Battery status indicator - no power surprises and allows for better

planning

• Automatic shutoff - conserves battery life when not in use - can be

disabled if desired

©2011 Johnson Level & Tool 3

Page 4

4430H-English_Manuals 2/22/11 11:08 AM Page 4

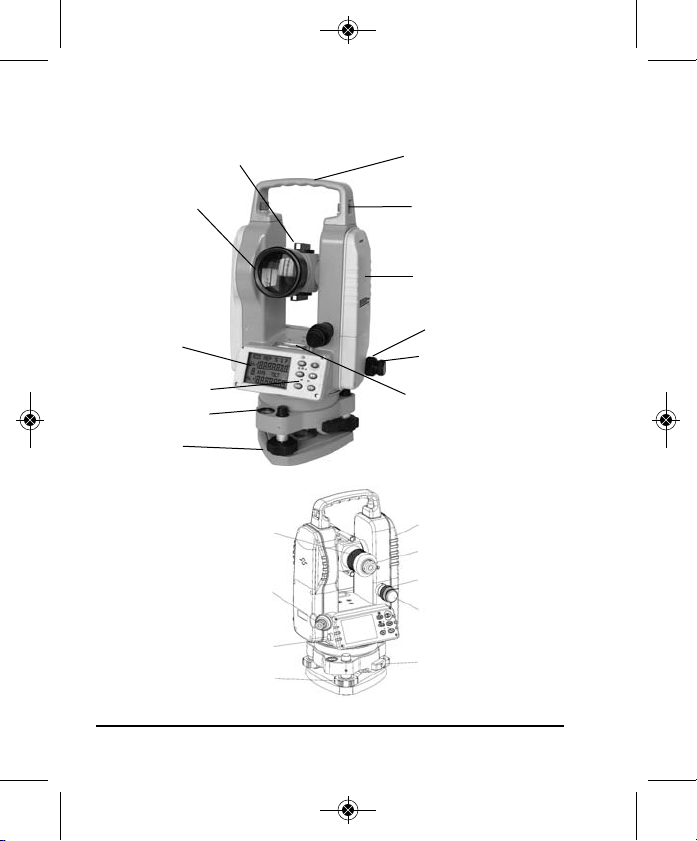

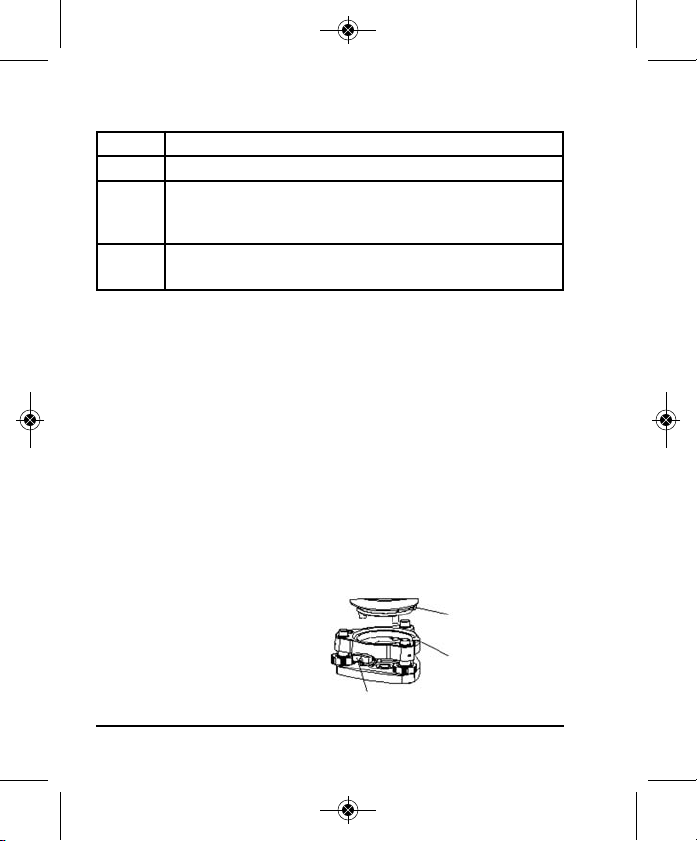

3. Location of Part/Components

Targeting Sight

Objective Lens

LCD Display

Operating Keys

Circular Vial

Tripod

Base Plate

Focusing Ring

Optical Plummet

Communication Port

Leveling Screw

Handle

Handle Screw

Center Mark &

Vertical Plate

Horizontal Fine

Motion

Horizontal Clamp

Tubular Vial

Battery Case

Eyepiece

Telescope Fine

Motion

Telescope Clamp

Tribrach

Locking Lever

4 ©2011 Johnson Level & Tool

Page 5

4430H-English_Manuals 2/22/11 11:08 AM Page 5

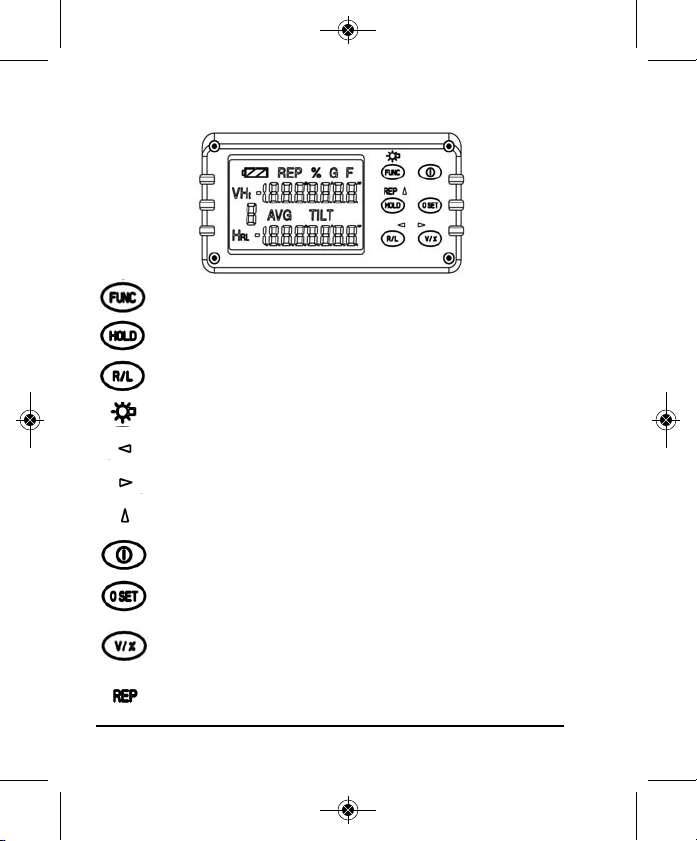

4. Operating Instructions

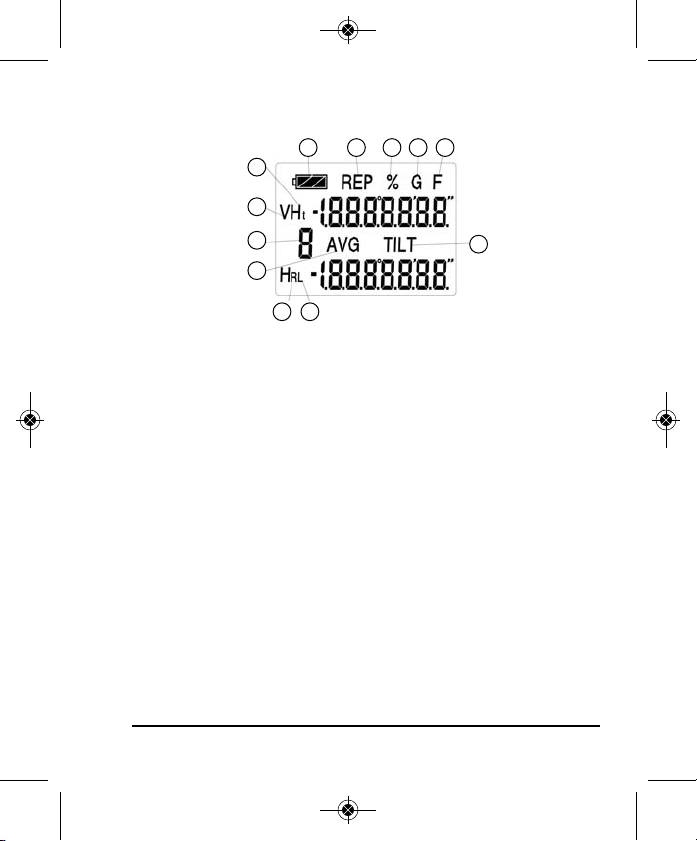

101112

1

2

3

4

5 6

Display and Display Explanation

1. Ht - Total value of repeated angles measured

2. V - Vertical angle

3. Number of repeated measurements

4. AVG - Value of repeated angle measurements

5. HR - Angle increases with clockwise turning

6. HL - Angle increases with counterclockwise turning

7. TILT - Tilt sensor

8. F - Function mode

9. G - Angle unit GON

10. % - Vertical slope in percent

11. REP - Repeated angle measurement mode

12. Battery power indication

89

7

Note: If the display shows “b” after activating the tilt sensor, the

instrument exceeds its compensation range and the instrument

should be leveled.

©2011 Johnson Level & Tool 5

Page 6

4430H-English_Manuals 2/22/11 11:08 AM Page 6

Operating Panel and Operating Keys

Function key selection

Hold horizontal angle reading

Set horizontal-angle rotation direction

lluminating the display

Moving the cursor to the left

Moving the cursor to the right

Change the number indicated by the cursor

Power key

Zero the horizontal angle reading

Change vertical angle to percent of grade

Repeated angle measurement

6 ©2011 Johnson Level & Tool

Page 7

4430H-English_Manuals 2/22/11 11:08 AM Page 7

Preparation Before Measurement

Centering and Leveling with Optical Plummet

• Level and center the instrument precisely to ensure its best

performance.

• Extend the tripod legs to a suitable working height with equal length

legs. Spread the tripod legs and make the tripod head as level as

possible while at the same time placing the center of the tripod head

directly over the ground point. Press the leg feet firmly into the

ground and make sure the tripod legs are locked.

• Set the instrument carefully on the center of the tripod head

orientating the leveling screws centered with each tripod leg. Attach

the instrument to the tripod. Make sure the center mark is visible on

all three leveling screws (this ensures a complete leveling range).

• Adjust the Optical Plummet Eyepiece to focus the bullseye. Adjust the

Optical Plummet telescope focus to see the ground clearly. If you can

not see the ground point while looking through the optical plummet,

carefully lift two of the tripod legs, then pivot on the third leg,

carefully moving the tripod until the ground point is within one inch of

the reticule. Press the two tripod feet back into the ground and

recheck the optical plummet alignment. Repeat if necessary until the

ground point can be seen in the optical plummet field. Complete the

alignment by turning the leveling screws (you will not be level but

you are pointed correctly).

• Now center the instruments Circular Vial by carefully extending or

shortening the tripod legs closest to the bubble. Note: Use only two

legs. Repeat until alignment is within 6mm (1/4 inch) or better.

©2011 Johnson Level & Tool 7

Page 8

4430H-English_Manuals 2/22/11 11:08 AM Page 8

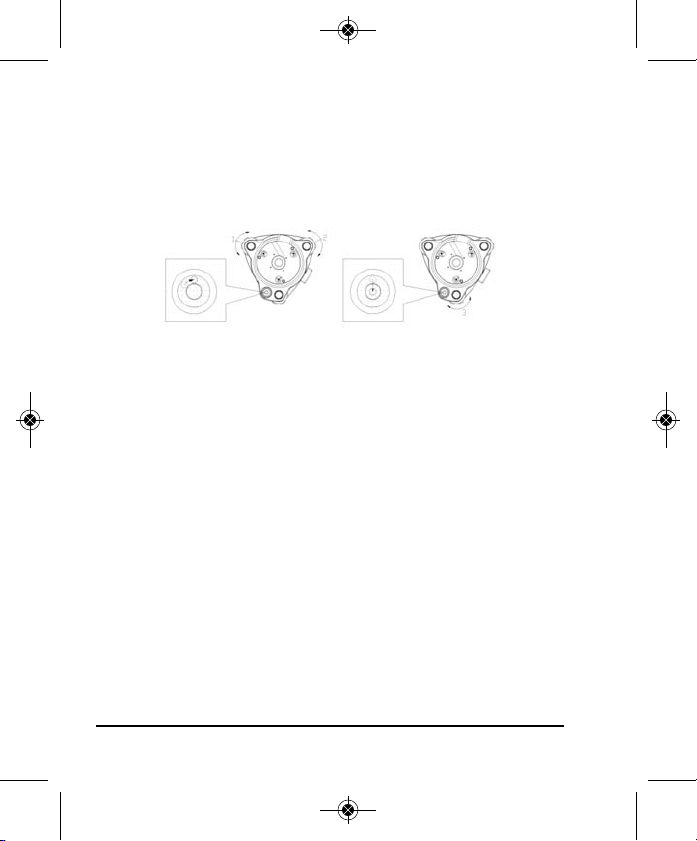

• Rotate the leveling screw 1, 2 to move the bubble to the center line

of circular level which is perpendicular to the connection line 1,2.

• Rotate the leveling screw 3 to move the bubble to the center of the

circular level.

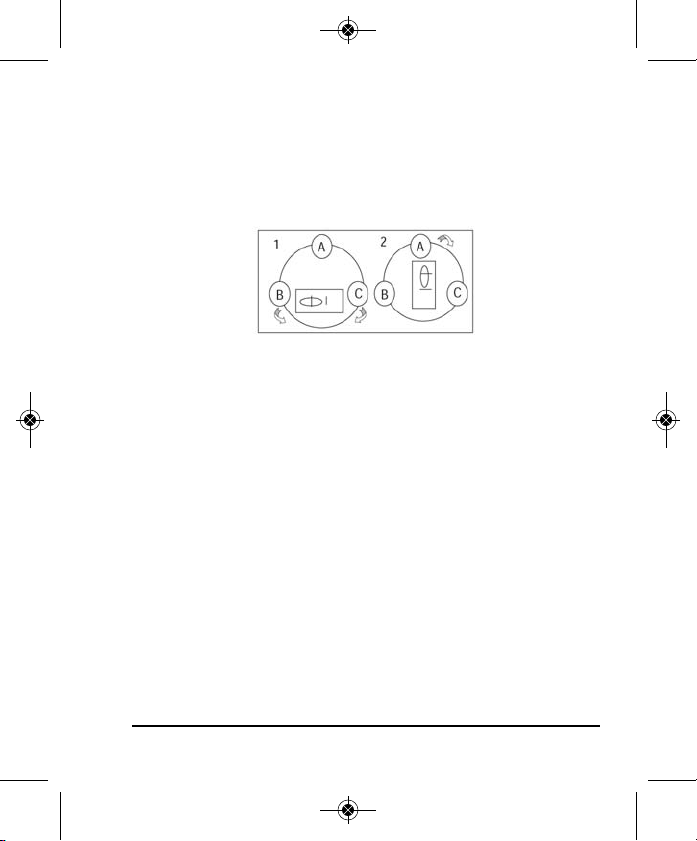

• Next use the Tubular Vial to accurately level the instrument. Unlock

and turn the instrument so that the tubular vial is parallel to BC, any

two leveling screws. Note the direction to turn the leveling screws in

the graphic. When turning the two screws, adjust them equally. The

bubble will move in the direction that your left thumb turns. To move

the bubble to the right, turn the B leveling screw in and

simultaneously turn the C leveling screw in. To move the bubble left,

move both screws out simultaneously. Once centered turn the

instrument 90º over A leveling screw and turn screw A in or out until

bubble is centered. Go back to the first position BC, and repeat until

the bubble is centered in both positions. Then from position BC turn

180º to check the adjustment. If the bubble stays centered or within

1/4 division, you are level.

8 ©2011 Johnson Level & Tool

Page 9

4430H-English_Manuals 2/22/11 11:08 AM Page 9

• Now check the ground point centering. If you are not directly on the

point, carefully loosen the tripod fastener and move the instrument on

the tripod head in an x - y direction. Do not rotate the instrument.

Recheck leveling and repeat until instrument is level and over the

ground point at the same time. With practice, this becomes easier.

©2011 Johnson Level & Tool 9

Page 10

4430H-English_Manuals 2/22/11 11:08 AM Page 10

5. Using the Product

Turning on the Instrument

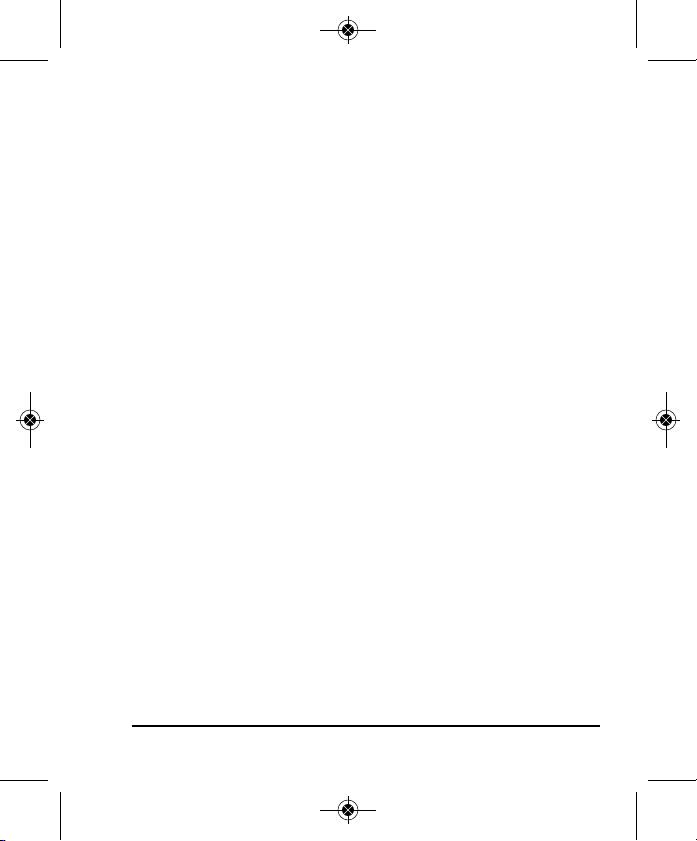

Press the power key on the instrument for 2 seconds

and all the symbols will be displayed on the LCD. The

buzzer will sound twice and the horizontal angle value

and “0-set” will be displayed. When “0-set” is

displayed none of the key pads operate except for the

power key. Rotate the telescope 360º to activate the vertical

measuring mode and to activate the keypad.

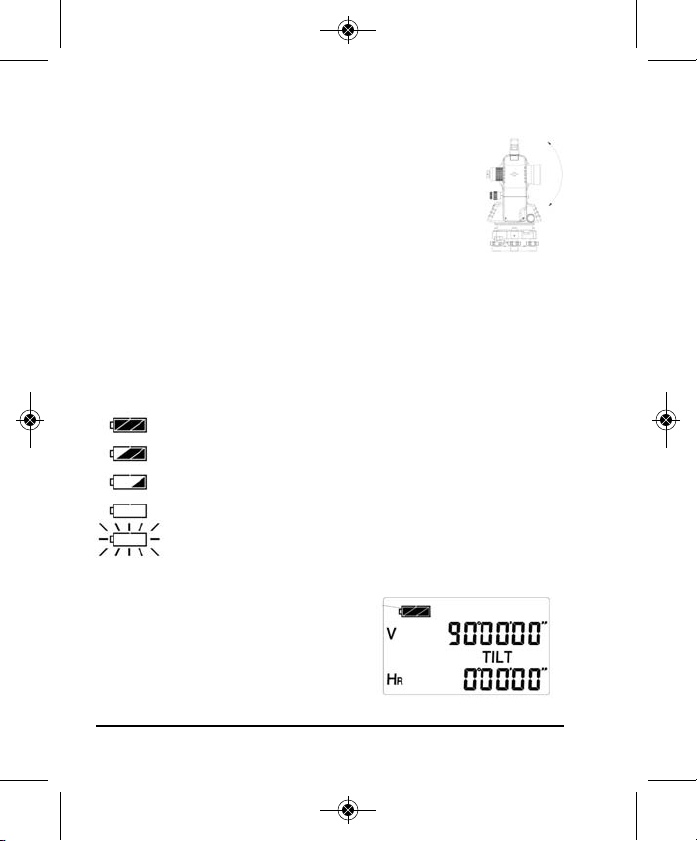

Battery Strength Indicator

The battery symbol on the LCD window displays the current

battery strength.

Full power

Effective battery

Effective battery

Weak voltage but still effective, suggest changing battery packs

Powers off automatically after symbol blinks. Replace the

battery pack or recharge it.

Battery Strength

10 ©2011 Johnson Level & Tool

Page 11

4430H-English_Manuals 2/22/11 11:08 AM Page 11

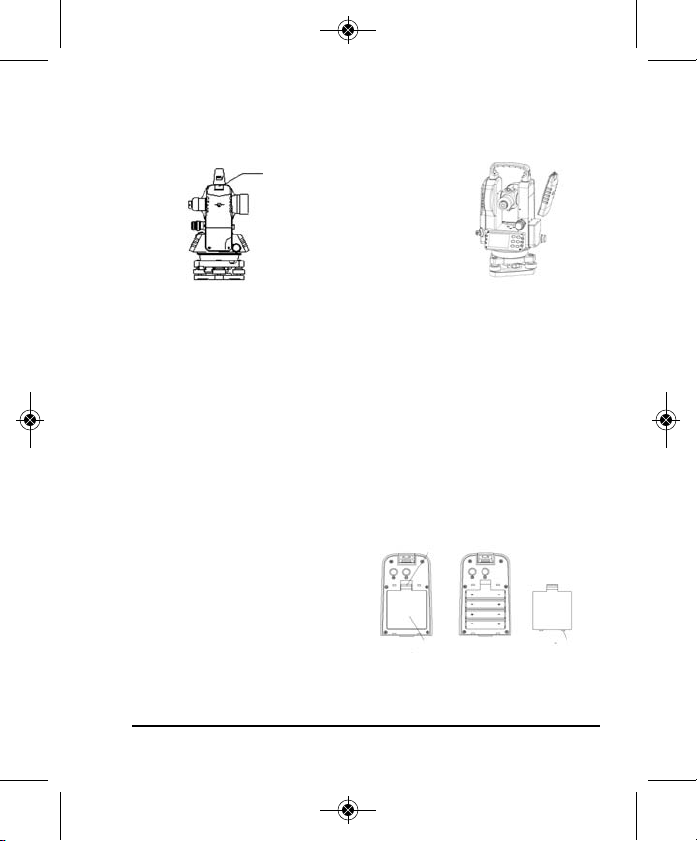

Battery Replacement

Remove Battery Box

Battery Box Button

Push down to remove

the battery box

Replace Alkaline Batteries

• Push down the battery cover tab and pull the battery cover away

from the battery box.

• Take the old batteries out and put the new batteries in paying

attention to the “+” and “-” pole.

• Snap the battery cover back into place.

Placing the Battery Box on the Instrument

Place the projection on the bottom

Hook

of the battery box into the slot on

the instrument. Push the top of

the battery box until it clicks into

place.

Battery Cover Battery Cover

©2011 Johnson Level & Tool 11

Page 12

4430H-English_Manuals 2/22/11 11:08 AM Page 12

Rechargeable Batteries

• Connect the charger to the AC outlet. Remove the battery box from

the instrument and insert plug of charger into the recharge socket

of battery box. A red indicator light on the charger means the

instrument is recharging. A green light means the instrument is

fully recharged.

• The plug should be pulled out from the rechargeable battery box

after the unit is recharged, the charger is equipped with an overcharge protective circuit.

• Rechargeable batteries can be used repeatedly for 300-500 times.

Complete discharge of the battery will shorten the battery’s life.

• Recharge batteries at least once per month to keep its longest life.

Measurement of Angle

Observing in the “Normal” and “Reverse” positions of the telescope.

The normal, or direct, position of the telescope refers to observation

with the vertical circle opposite the battery door being on the left.

The reverse position refers to observation with the vertical circle

being on the right. The mechanical errors can be offset by averaging

the values measured in the normal and reverse positions.

12 ©2011 Johnson Level & Tool

Page 13

4430H-English_Manuals 2/22/11 11:08 AM Page 13

Using the Telescope

• Point the telescope at the target and focus the eyepiece until the

crosshair can be seen clearly.

• Aim the telescope coarsely using the targeting sight. Keep a slight

distance between the targeting sight and your eye when aiming

coarsely.

• Focus the telescope by turning the focusing knob on the telescope.

Horizontal Angle “0-set”

1. Aim at target “A” using crosshair in the telescope.

2. Press 0-Set key once to set reading of horizontal

angle 0º00’00”.

• 0-set key is only available for the horizontal angle.

• Horizontal angle can be set to “0” at any time

except when the horizontal angle is in the hold status.

Measuring Horizontal and Vertical Angle (HR, V or HL, V)

Horizontal angle right rotation increment and Vertical

angle measurement (HR, V)

1. Aim at the first “A” using the center crosshair.

2. Press 0-set key once to set the reading of

horizontal angle of target “A” at 0º00’00”.

3. Rotate the instrument clockwise and aim at the

second target “B” to get the horizontal and vertical

angle of target “B”.

©2011 Johnson Level & Tool 13

Page 14

4430H-English_Manuals 2/22/11 11:08 AM Page 14

Conversion between horizontal angle right (HR)

and left (HL) rotation

1. Aim at a target “A” using the center of crosshair

in the telescope.

2. Press the R/L key to change horizontal angle mode

from HR to mode HL.

3. Measure in mode HL.

• The R/L button has no effect to the vertical angle.

• Press the R/L button again, and the horizontal angle is transformed

back from HL to HR again.

Holding the Horizontal Angle

Press the HOLD button to hold the horizontal angle. The reading will

blink while being held. The reading of the horizontal angle will

remain unchanged even if the direction of telescope is changed.

Press HOLD button again, the hold of horizontal angle is released.

1. Rotate the instrument to the target.

2. Press the HOLD key once to lock the value of the

horizontal angle, the reading will flash.

3. Press the HOLD key again to unlock the reading.

• The HOLD key has no effect to the vertical angle.

14 ©2011 Johnson Level & Tool

Page 15

4430H-English_Manuals 2/22/11 11:08 AM Page 15

Measurement of Vertical Angle

The angle position can be set as required in the initial setting.

0º

90º

270º

180º

90º

0º

180º

270º

Display of Slope

1. Press the V/% key to switch the vertical

measurement shown from degrees to percent

of grade.

2. Press the V/% key again to switch from grade

percent back to the vertical measurement

shown in degrees.

Note: When vertical angle is converted to slope, the precision of the

slope reading is two digits after the decimal. The value of slope is

displayed only within a 45º (100%). When measure angle exceeds

100%, the percent will be shown as “----”.

©2011 Johnson Level & Tool 15

Page 16

4430H-English_Manuals 2/22/11 11:08 AM Page 16

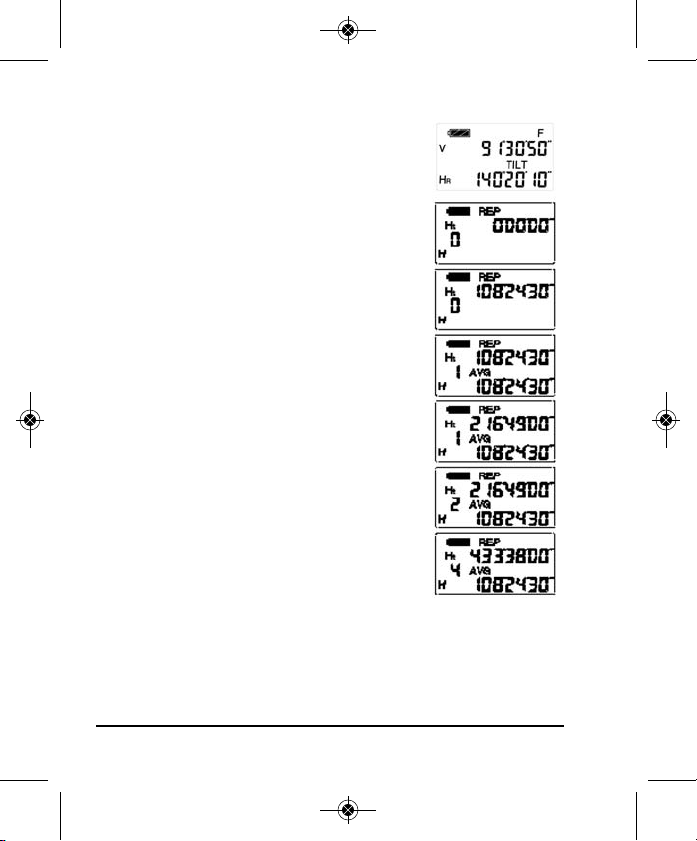

Repeat Angle Measurement

1. Press the FUNC key.

2. Press the REP key to put the instrument in

repeat mode.

3. Aim at the first target “A” and press the 0-set

key once to set the first target reading 0º00’00”.

4. Rotate the instrument and aim at the second

target “B”.

5. Press the HOLD key to hold the horizontal

angle and store it in the instrument.

6. Rotate the instrument to aim at the target “A”

again. Press R/L key to release the angle

hold status.

7. Rotate the instrument to aim at the target

“B” again.

8. Press the HOLD key to hold the horizontal

angle and store it in the instrument. Double

and average angle-value will be shown on

the display.

9. Repeat the last three steps according to

measuring requirements.

10. If needed return back to normal angle measurement, press FUNC

key, and then press the HOLD key.

16 ©2011 Johnson Level & Tool

Page 17

4430H-English_Manuals 2/22/11 11:08 AM Page 17

• The reading of horizontal angle can accumulate to reach

+1999º59’59” when in repeat angle measurement mode.

• Repeat measurement does not function if the angle between two

targets is less than 30”.

• The repeat measurement should be limited to 15 times when the

instrument is in the repeat measuring mode, otherwise the error

Err-04 will be shown. Start again from step 1.

• Err-04 will show on the display when measuring >+30” during the

repeat measurement, then go back to step 1.

• Press the FUNC key, and then press the HOLD key to withdraw

from repeat measurement and back to the original status.

Switching Between Measuring Units

This instrument has three types of angle measurement units to

choose from: DEG, GON and MIL and can be chosen in the

preliminary setting, or by following this procedure. Simultaneously

press R/L and V/%, the angle measurement units will switch between

DEG, GON and MIL.

©2011 Johnson Level & Tool 17

Page 18

4430H-English_Manuals 2/22/11 11:08 AM Page 18

Other Functions

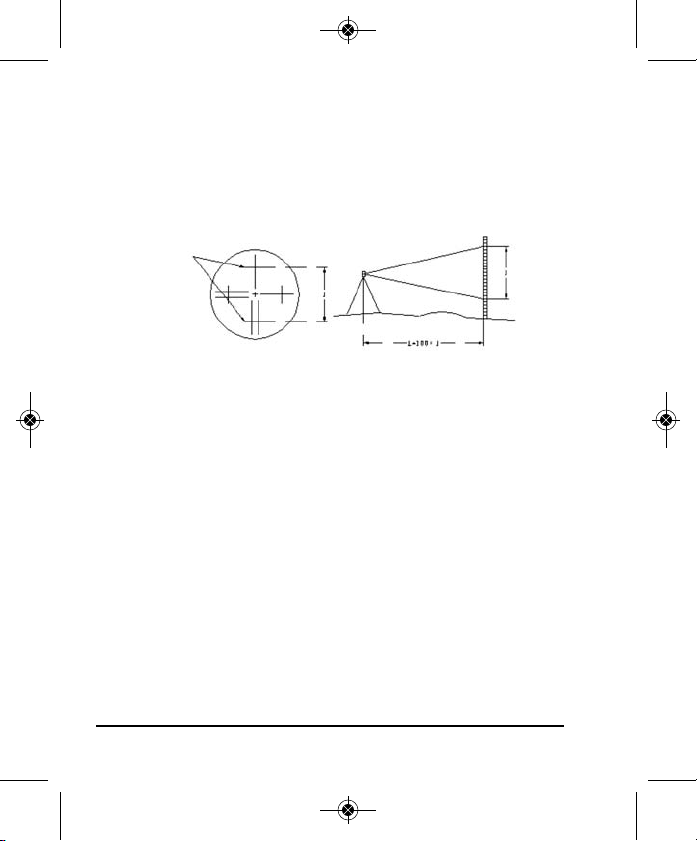

Measuring Distance Using the Stadia Method

Read the leveling rod using the stadia hair on the reticule of the

telescope. Multiply the reading by 100 to obtain the actual distance

L from the target to the measured point. (100 is the multiplication

constant error of the instrument, i.e. 1 = 1 x 100)

Stadia Hair

Tilt Sensor

This theodolite is equipped with a tilt sensor. The inclined angle of the

instrument will be compensated automatically by the tilt sensor. If the

instrument is inclined too much, a symbol “b” will be shown on the

display , this means the instrument exceeds the compensated range.

Level the instrument by hand.

To turn on the tilt sensor and hold the R/L button in for 3 seconds

after moving the telescope to get into vertical measuring mode. The

word “Tilt” will appear on the display. If the instrument is inclined

within +3º the tilt sensor can compensate the vertical angle. If the

inclination is greater than + 3º the instrument will display “b”.

18 ©2011 Johnson Level & Tool

Page 19

4430H-English_Manuals 2/22/11 11:08 AM Page 19

Sound Function

When the sound function is activated and the instrument is rotated,

the instrument will sound when the horizontal angle passes 0°, 90°,

180°, & 270°. Please refer to “initial setting” chapter to set horizontal

angle sound function.

Backlight LCD Telescope Reticle and Timing Power-Off

The display and telescope’s reticle on this theodolite are equipped

with a lighting device. Press the FUNC key twice to turn on the light.

Press the key twice again to turn it off. The instrument will

automatically turn off to save power if it has not received an

operation within 10 minutes, 20 minutes or 30 minutes. Please refer

to the “initial setting” section.

©2011 Johnson Level & Tool 19

Page 20

4430H-English_Manuals 2/22/11 11:08 AM Page 20

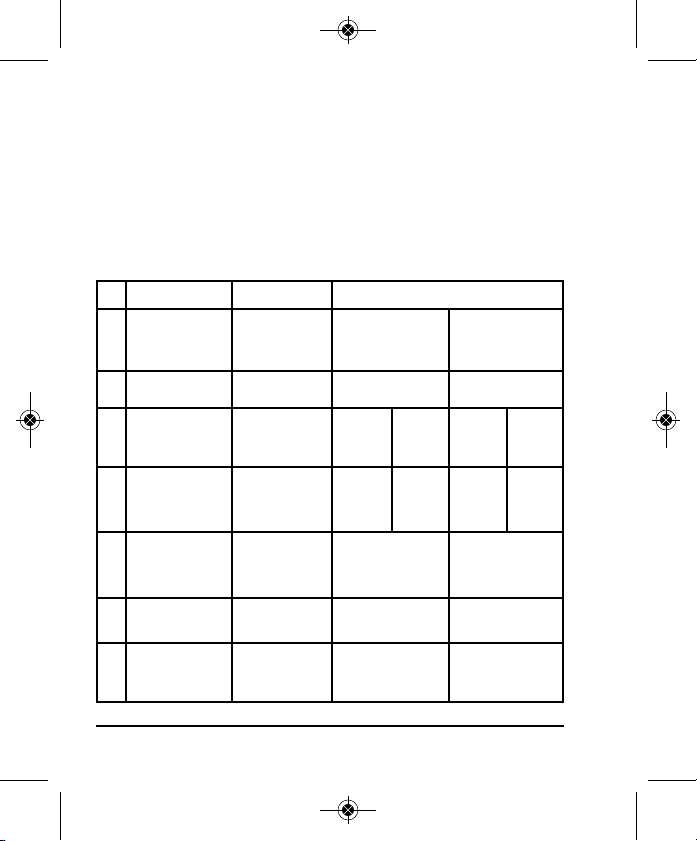

INITIAL SETTING

Initial Setting Instruction

The instrument has several settings for your option to meet different

requirements of measuring. After your purchase and before your

operation, do the initial setting for the instrument.

Item Setting

No.

1

2

3

4

5

6

7

Item Description Parameter Setting

Setting

0

DEG

Setting

0

OFF

vertical angle

Setting 0

1”

2”

Setting 0

OFF

Setting 0

Setting 0

OFF

Setting 0

OFF

Setting

Setting

10 min

Reading resolution

(minimal reading

display unit)

Sound function

Angle unit

Automatic

Shut-off

Measuring mode for

Vertical Angle

Tilt sensor Set tilt function

Data transmission

Confirming sound

Selecting angle display

unit DEG, GON, MIL

Setting interval for

automatic shut-off

without an operation

Setting measuring

mode for vertical angle

Set data transmission

40-6932

40-6935

every 90º

function

GON

Setting 1

2”

5”

Setting 1

ON

Setting

2

MIL

Setting

2

20 min

Setting 1

zenith angle

Setting 1

ON

Setting 1

ON

Setting

3

DEG

Setting

3

30 min

1

1

20 ©2011 Johnson Level & Tool

Page 21

4430H-English_Manuals 2/22/11 11:08 AM Page 21

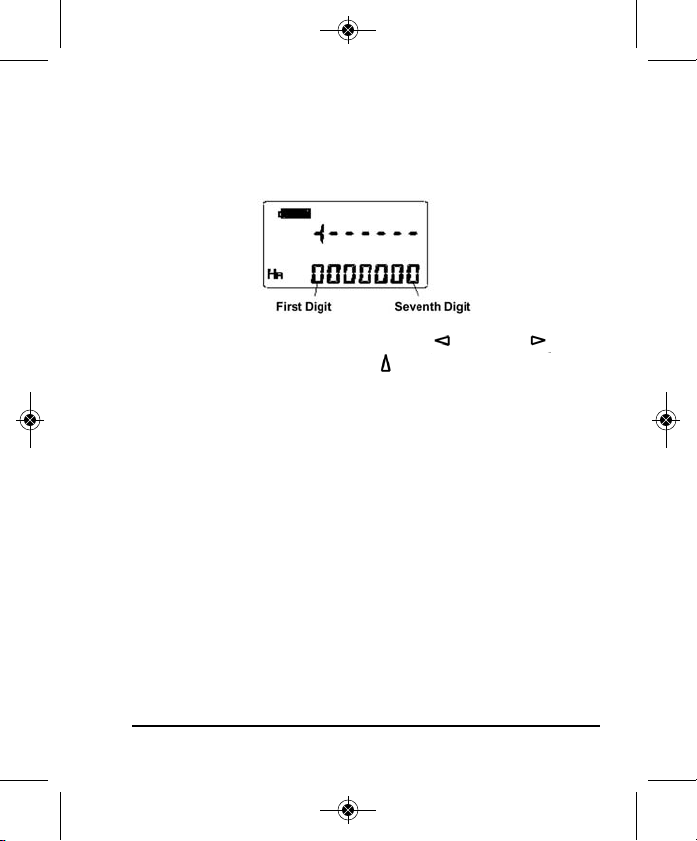

Settings

Power on the instrument, press the FUNC key once, then press the

power key once. The instrument will enter the initial setting mode

and will display as follows:

Move to the digit required by using the Left or Right keys.

Change the digit value using the up key. After changing the

various settings, press the FUNC key once, and then press Power

key once to exit the setting status and return back to the anglemeasuring function. The new settings will be saved.

Factory Settings

• Minimal Resolution Reading: 2” (40-6932), 5” (40-6935)

• Sound Function: OFF

• Angle Display Unit: 360º

• Automatic Shut Off: OFF

• Measuring-Mode for Vertical Angle: Vertical Angle

• Tilt Sensor: OFF

• Data Transmission Function: OFF

©2011 Johnson Level & Tool 21

Page 22

4430H-English_Manuals 2/22/11 11:08 AM Page 22

Error Display

Display

b Instrument exceeds its self-leveling range, level the instrument again.

Difference between every measuring value exceeds 30” during the repeated angle measurement.

Err-04

Measuring times of repeated angle measurement is more than 15. Press “0-SET” to measure again.

Err-06

Errors during the process of the vertical angle 0-set or adjusting 0-set when the inclination

Error Display & Explanation & Action

Press “0-SET” key and measure again.

to the horizontal angle exceeds 45º the instrument needs adjusting.

Note: If above errors appear, act according to corresponding actions

mentioned above. If errors still exist, then the instrument needs repair.

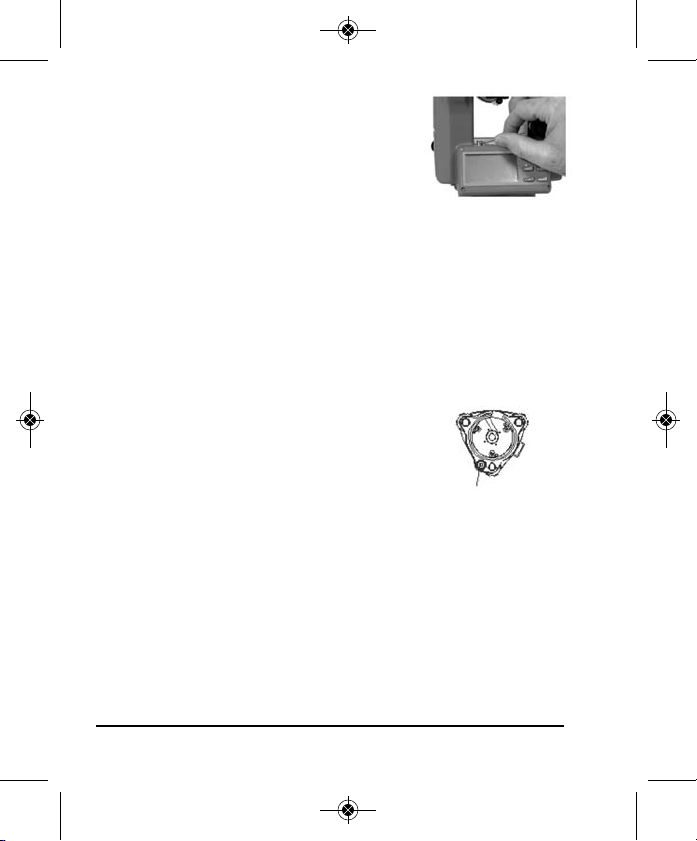

Installation and Removal of the Base

Base Removal

• Rotate the Tribrach locking lever 180° counterclockwise.

• Hold the base plate with one hand, and with the other hand lift up

the instrument by the handle.

Base Installation

• Lift the instrument by hand, and aim the positioning block to the

notch on the base plate. Mount the instrument on the base plate

carefully.

• Tighten the clamp knob on

Positioning block

the base plate.

Notch

Tribrach Locking Level

22 ©2011 Johnson Level & Tool

Page 23

4430H-English_Manuals 2/22/11 11:08 AM Page 23

6. Self-Check & Fine Calibration

• Calibration should be carried out according to the following steps

because each step’s calibration is based on its former one’s result.

Disorder of the steps will default the calibration.

• Tighten the screw after calibration. Be careful not to over tighten

because excessive tightening will damage the thread.

• After calibration, repeat the inspection to make sure that the

calibration has been successful.

Check and Calibrate The Tubular Vial

Checking

• Attach the instrument to a tripod and rough level. Position the

tubular vial parallel to a line connecting any two of the three

leveling screws on the base. Adjust the two leveling screws so that

the tubular bubble is centered.

• Turn the instrument 180º and check if the bubble remains at center.

Calibrating

• If the bubble remains at the center, no adjustment is required.

Otherwise, perform adjustment as follows:

• Using the bubble adjustment screws and adjustment pin, move the

bubble towards the tube center for half of the error.

• Turn the leveling screw to correct the other half of the error so that

the bubble is centered.

©2011 Johnson Level & Tool 23

Page 24

4430H-English_Manuals 2/22/11 11:08 AM Page 24

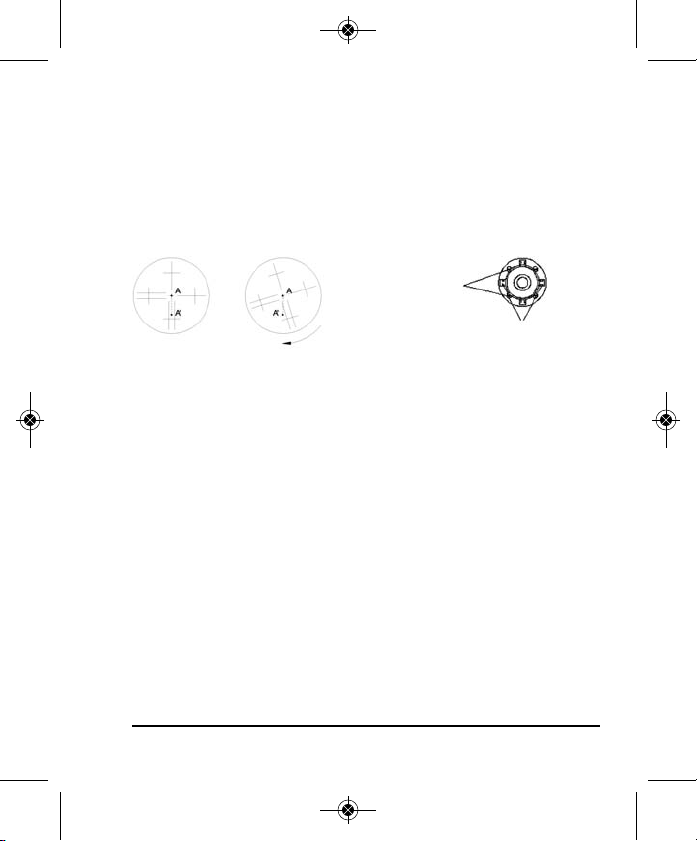

• Rotate the instrument 180 degrees and check

if the bubble remains centered. If the bubble

is centered, the adjustment is complete. If

not, repeat the steps until the bubble is

centered when the instrument is at any

position.

Check and Calibrate The Circular Vial

Checking

If the circular vial is centered correctly after leveling the instrument

by the tubular vial, then no further calibration is necessary. If not,

proceed with the following calibration.

Calibrating

There are three adjusting screws on the bottom

of the circular vial. When calibrating, loosen the

screw opposite to the bubble’s moving

direction (one or two), and then tighten the

screws along the bubble’s moving direction to

Circular Vial

center the bubble. The tightening of these three screws should

be consistent.

Perpendicularity of Vertical Crosshair Reticle of Telescope

Checking

• Mount the instrument on the tripod and level it carefully.

• Set a target point, A, 50 meters away from the instrument, aim the

telescope at point A .

24 ©2011 Johnson Level & Tool

Page 25

4430H-English_Manuals 2/22/11 11:08 AM Page 25

• Move the telescope using the vertical fine movement and observe

whether point A moves along the vertical hair.

• If point A moves along the vertical hair of the reticle, no adjustment

is necessary.

• Adjustment is necessary if the point A strays from the vertical

crosshair.

Clamp Screws

of Reticle Base

Calibrating

• Turn counterclockwise and remove the reticle cover between the

eyepiece and focusing handwheel. This will expose four reticle set

screws.

• Loosen these four set screws equally with a screwdriver. Turn the

Assembly so that point A coincides with the vertical crosshair.

• Tighten these four set screws equally and observe whether any

transversal deviation appears when point A moves along the

vertical hair. If not, the adjustment is over.

• Assemble back the protective cover to its original position.

Reticle Adjusting Screw

©2011 Johnson Level & Tool 25

Page 26

4430H-English_Manuals 2/22/11 11:08 AM Page 26

Perpendicular Degree of The Visual Axis and The Horizontal Axis

Checking

• Set two targets as high as the instrument, one in front of and the

other behind the instrument, each about 50 meters away from the

instrument. Level the instrument precisely and power it on.

• Aim at target A with crosshair of the telescope in plate-leftward

position.

• Rotate the telescope around the horizontal axis 180º to aim it in

the opposite direction.

• Aim at target B which is the same distance to target A.

• Rotate the instrument 180°. Aim at the target A, then lock the

horizontal clamp.

• Rotate the telescope 180º around the horizontal axis again. Aim at

the target C. Target C should be the same with target B.

• If not coincident, adjustment is necessary.

26 ©2011 Johnson Level & Tool

Page 27

4430H-English_Manuals 2/22/11 11:08 AM Page 27

Calibrating

• Remove the reticle cover between the eyepiece

of the telescope and the focusing handwheel.

• Set up point D between point B and C. The

distance of DC should be a quarter of BC.

Adjust the two adjusting screws to move the

reticle to have its cross aim at point D.

• Repeat above inspection steps until B and C are coincident.

• Assemble the reticle cover back to its original position.

• Loosen one screw if the vertical hair of the crosshair should be

moved, then tighten the adjusting screw on the other side about

the same number of turns. Loosen the screw counterclockwise

and tighten in the clockwise direction. The turn should be as little

as possible for both loosening and tightening.

• After above calibration, the zero reset of the upright angle should

be carried out, to reset the zero point of the upright angle.

Automatic Compensation of the Vertical Axis Incline

The instrument is equipped with the electronic incline sensor device (tilt

sensor), which can automatically compensate the vertical axis incline.

Checking

• After mounting and leveling the instrument, position the direction

of the telescope with a line between the center of the instrument

and any of its foot screws. Then tighten the horizontal braking

handwheel.

©2011 Johnson Level & Tool 27

Page 28

4430H-English_Manuals 2/22/11 11:08 AM Page 28

• Position the telescope to zero after power-on. Tighten the vertical

clamp and the instrument will display the current value in the

upright position.

• Slowly turn the foot screw in one direction about 1/2” or so (circle

distance), the value of upright angle changes correspondingly until

it disappears and the symbol “b” is shown, this means the incline

of the instrument’s axis has exceeded the compensation range.

When turning the foot screw in reverse, the instrument goes back

to display the upright angle (repeat testing and observe the

changes on the critical point), this means the compensation device

is working.

Calibrating

When the compensation doesn’t work well or works abnormally, send

the instrument to an authorized repair facility for repairs.

Vertical Plate Angle Specification ( “i” angle) and its Zero Setting

• After mounting and leveling, power on the instrument. Aim the tele

scope at any clear target A to get the reading L, which is the

upright angle plate left reading.

• Turn the telescope to the reverse position and aim at target A again

to get the reading R, which is the upright angle plate right reading.

• If upright angle is in the zenith angle mode, then i=(L+R-360°) /2.

If upright angle is in the vertical angle mode, then i=(L+R-180°)/2

or i=(L+R-540°)/2

• If the specification errors |i|° ≤ 10”, 0 reset of the upright plate

specification is necessary.

28 ©2011 Johnson Level & Tool

Page 29

4430H-English_Manuals 2/22/11 11:08 AM Page 29

Calibrating

Operating Procedures Operation Display

1. Level the instrument accurately with the long vial.

2. Power on the instrument, the vertical angle and horizontal angle

are displayed after the telescope passes zero position.

3. Press the FUNC key once, and then press the V/% key.

4. Rotate the instrument and precisely aim at the clear and stable

target A as high as the instrument in the distance.

5. Press the 0-Set key once.

6. Turn the instrument and aim the right of the vertical plate at the

same target A.

7. Press the 0-Set key and the measured values are set. The

instrument goes back to the angle measurement mode, and the

calibration is finished.

• Send the instrument to an authorized repair facility for repairs after operations are repeated many times

without any effect.

Rotate the

telescope

Aim at the

plate left

position of A

Aim at the

plate right

position of A

Check and Calibrate the Optical Plummet

To align the optical axis of the optical plummet and the vertical axis,

calibration for the optical plummet is necessary, otherwise the

vertical axis will not be on the true anchor point.

Checking

• Attach the theodolite to a tripod (no leveling required).

• Place a target under the instrument.

• Focus the image of the target then adjust the leveling screws so

that the target is centered in the reticle.

©2011 Johnson Level & Tool 29

Page 30

4430H-English_Manuals 2/22/11 11:08 AM Page 30

• Turn the instrument 180º.

• If the target remains at the center of the reticle, no adjustment is

required. Otherwise, adjust as follows.

Calibrating

• Turn counterclockwise and remove the black

ring/adjusting screw cover located between

the optical eyepiece and the focusing knob.

• Place a sheet of paper under the instrument

and mark the optical plummet center mark

each time the instrument turns 90º, as shown in the figure:

point A, B, C, D.

• Line up points AC and BD to get the point of their intersection O.

• Adjust the four adjusting screws on the optical eyepiece with the

adjusting pin to align the center mark with point O.

30 ©2011 Johnson Level & Tool

Page 31

4430H-English_Manuals 2/22/11 11:08 AM Page 31

Communication Format

All data is sent in ASCII. When communication is on, vertical angle

and horizontal angle are sent in turns with 4Hz frequency.

All angle data sent begins with the letter “A” (angle), and finish with

the enter key (OXOD). Their form is as follows:

A + Angle Type Character + Display Mode Character + Angle

Value + 0X0D

Angle Type Character

“P” – Vertical Angle

“H” – Horizontal Angle

Display Mode Character

“D” – Angle In Degree (360°„)

“G” – Angle In Gon (400 Gon)

“M” – Angle In Mil (6400 Mil)

“%”– Slope Angle (-100% ~ +100%)

The transmission angle value keeps consistent with the display value

on the LCD.

©2011 Johnson Level & Tool 31

Page 32

4430H-English_Manuals 2/22/11 11:08 AM Page 32

7. Technical Specifications

Telescope

Image Erect

Magnification 30x

Aperture 1.7in (45mm)

Resolution 3’’

Angle of view 1°30’

Shortest Distance 5ft (1.4m)

Stadia Constant 100

Overall Length 6.18in (157mm)

Angle Measuring System

Angle Measurement Incremental

Minimal Reading 1”, 2”, 5”, optional

Angle Measurement Unit 360°, 400gon, 6400mil, optional

Accuracy 40-6932 - 2”, 40-6935 - 5”

Vial

Tubular Vial 30”/2mm

Circular Vial 8”/2mm

Compensator

Tilt Sensor Upright Angle Automatic

Compensation

Compensation Range +3’

32 ©2011 Johnson Level & Tool

Page 33

4430H-English_Manuals 2/22/11 11:08 AM Page 33

Optical Plummet

Imaging Erect

Magnification 3x

Focusing range 0.5m

Field Angle 5°

Display

Type LCD with Double Side

Data Input and Output

Joint (one) RS232

Power

Battery 5 “AA” Alkaline Batteries or

Rechargeable NiMH Battery Pack

Operating Voltage 6V DC

Operating Time 16 hours

Working Environment

Temperature Range -4F to +104F (-20C° to +40C°)

Size and Weight

Outside Dimension 6.29” x 5.90” x 12.99”

(160x150x330mm)

Weight 10.14 lbs (4.6kg)

©2011 Johnson Level & Tool 33

Page 34

4430H-English_Manuals 2/22/11 11:08 AM Page 34

8. Care and Handling

• Care must be taken to maintain the accuracy of the instrument.

• Do not aim the instrument’s telescope directly at the sun.

• When mounting or removing the instrument from the tripod, hold

the instrument with one hand, turn the central screw on the tripod

with the other hand to prevent the instrument from falling. If the

instrument must be carried on the tripod, hold the instrument as

vertically as possible. Never carry the instrument on the tripod in

a horizontal position over your shoulder. Any long distance

transportation should be done with the instrument in its carrying case.

• Put the instrument in its carrying case to avoid possible damage

during transportation.

• After each use, the instrument should be wiped clean and kept in

its carrying case.

• Remove dust from the lenses with a soft brush or a nonabrasive

wipe. Never touch the lenses with your fingers.

• Store the instrument in a dust-free area with low humidity.

• A bag of silica gel dryer is included with each instrument.

• Always remove the batteries when the instrument is not being used

for a long time.

34 ©2011 Johnson Level & Tool

Page 35

4430H-English_Manuals 2/22/11 11:08 AM Page 35

9. Product Warranty

Johnson Level & Tool offers a three year limited warranty on each of its products.

You can obtain a copy of the limited warranty for a Johnson Level & Tool

product by contacting Johnson Level & Tool's Customer Service Department,

as provided below, or by visiting our web site at www.johnsonlevel.com. The

limited warranty for each product contains various limitations and exclusions.

Do not return this product to the store/retailer or place of purchase.

Non-warranty repairs and course calibration must be done by an authorized

Johnson®service center or Johnson Level & Tool's limited warranty, if

applicable, will be void and there will be NO WARRANTY. Contact one of our

service centers for all non-warranty repairs. A list of service centers can be

found on our web site at www.johnsonlevel.com or by calling our Customer

Service Department. Contact our Customer Service Department for Return

Material Authorization (RMA) for warranty repairs (manufacturing defects

only). Proof of purchase is required.

NOTE: The user is responsible for the proper use and care of the product. It is the

responsibility of the user to verify the calibration of the instrument before each use.

For further assistance, or if you experience problems with this product that are not

addressed in this instruction manual, please contact our Customer Service Dept.

In the U.S., contact Johnson Level & Tool’s Customer Service Department at

888-9-LEVELS.

In Canada, contact Johnson Level & Tool’s Customer Service Department at

800-346-6682.

©2011 Johnson Level & Tool 35

Page 36

4430H-English_Manuals 2/22/11 11:08 AM Page 36

10. Warranty Registration

Enclosed with this instruction manual you will find a warranty

registration card to be completed for your product. You will need to

locate the serial number for your product that is located on the

bottom of the unit. PLEASE NOTE THAT IN ADDITION TO ANY

OTHER LIMITATIONS OR CONDITIONS OF JOHNSON LEVEL &

TOOL'S LIMITED WARRANTY, JOHNSON LEVEL & TOOL MUST

HAVE RECEIVED YOUR PROPERLY COMPLETED WARRANTY CARD

AND PROOF OF PURCHASE WITHIN 30 DAYS OF YOUR PURCHASE

OF THE PRODUCT OR ANY LIMITED WARRANTY THAT MAY APPLY

SHALL NOT APPLY AND THERE SHALL BE NO WARRANTY.

11. Accessories

Johnson®accessories are available for purchase through authorized

Johnson®dealers. Use of non-Johnson®accessories will void any

applicable limited warranty and there will be NO WARRANTY. If you

need any assistance in locating any accessories, please contact our

Customer Service Department.

In the U.S., contact Johnson Level & Tool’s Customer Service Department

at 888-9-LEVELS.

In Canada, contact Johnson Level & Tool’s Customer Service Department

at 800-346-6682.

36 ©2011 Johnson Level & Tool

Loading...

Loading...