Page 1

®

2594H 7/29/09 10:12 AM Page 1

22X Builder’s Level

Model No. 40-6900

Instruction Manual

Congratulations on your choice of this 22X Builder’s Level. We

suggest you read this instruction manual thoroughly before using

the instrument. Save this instruction manual for future use.

©2009 Johnson Level & Tool Rev. 1 1

Page 2

2594H 7/29/09 10:12 AM Page 2

Table of Contents

1. Kit Contents

2. Features and Functions

3. Location of Parts/Components

4. Operating Instructions

5. Calibration

6. Technical Specifications

7. Care and Handling

8. Product Warranty

9. Product Registration

10. Accessories

1. Kit Contents

Description Qty.

22X Builder’s Level 1

Instruction Manual with Warranty Card 1

Hard Shell Carrying Case 1

2. Features and Functions

• Horizontal Circle - Graduated to single degrees and reads by

vernier direct to 15 minutes

• Horizontal Tangent Screw - For precise movement control.

• Built-in Sunshade - For clear sighting

• Top Mounted Leveling Vial - For effortless viewing

• Large Leveling Screws - Easy to turn

• Versatile - Ideal for leveling foundations, driveways, patios,

floors, for grading street, curbs ditches for aligning fences; or

any other light construction job.

2 ©2009 Johnson Level & Tool

Page 3

2594H 7/29/09 10:12 AM Page 3

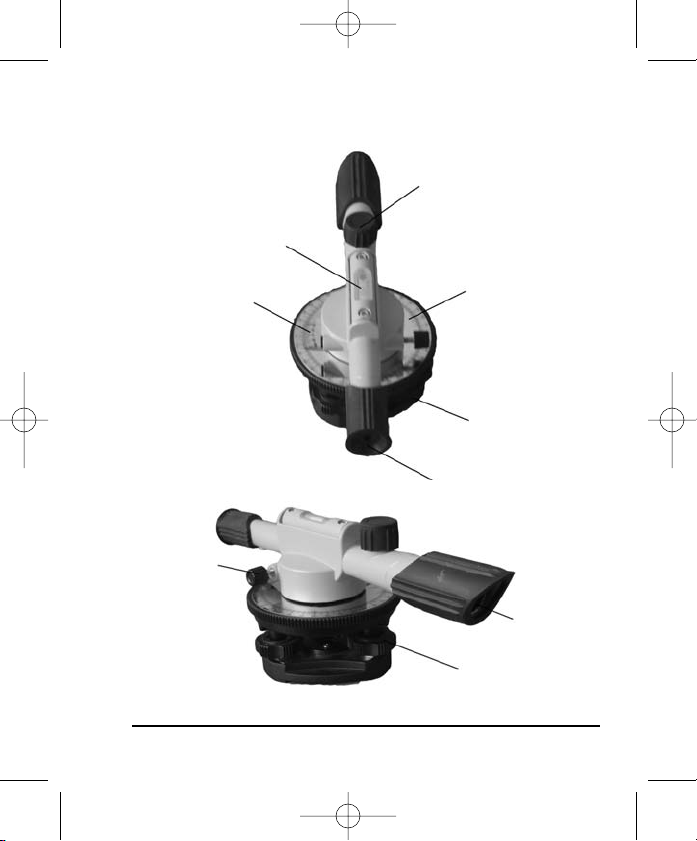

3. Location of Part/Components

Leveling

Vial

Focusing Knob

Horizontal

Vernier

Horizontal

Tangent Knob

©2009 Johnson Level & Tool 3

Horizontal

Graduated Circle

Base

Eyepiece

Telescope

Objective

Lens

Leveling

Screw

Page 4

2594H 7/29/09 10:12 AM Page 4

4. Operating Instructions

IMPORTANT: It is the responsibility of the user to verify the

calibration of the instrument before each use.

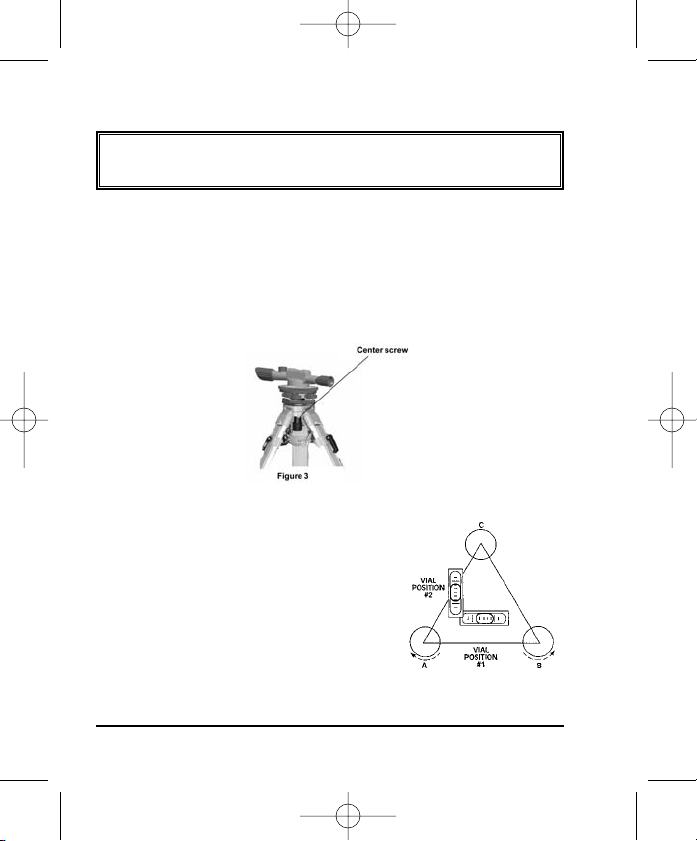

Set-Up the instrument on the tripod

When setting up the tripod, make sure the three tripod points are firmly

into the ground and the top of the tripod head is as level as possible.

Adjust the height of the tripod to a comfortable viewing height,

secure the retractable legs. Attach the instrument to the tripod head

with the center screw and tighten securely as shown in figure 3.

Leveling

Mount the instrument on the tripod and line

up the telescope vial in position #1 as sho

Then grasp screws A & B so that both thumbs

are moving in opposite directions, either

toward each other or away from each other.

Note that the bubble moves in the same

direction as your left thumb.

wn.

and

4 ©2009 Johnson Level & Tool

Page 5

2594H 7/29/09 10:12 AM Page 5

Keep about half the length engaged. When the bubble is centered in position #1, turn the instrument and observe the vial in position #2. Now center the bubble in position #2 using only screw C. The instrument should

now be leveled, but to be certain, double-check. Rotate the instrument

180º so the vial is reversed. If the bubble will not center when reversed,

follow adjustment procedure outlined under “Bubble Adjustments.”

Aiming and Focusing

Rotate the instrument by hand to aim the telescope to the far object.

te the focusing knob until the object can be observed clearly.

Rota

Rotate the horizontal tangent knob, to place the vertical cross hairs

on the object.

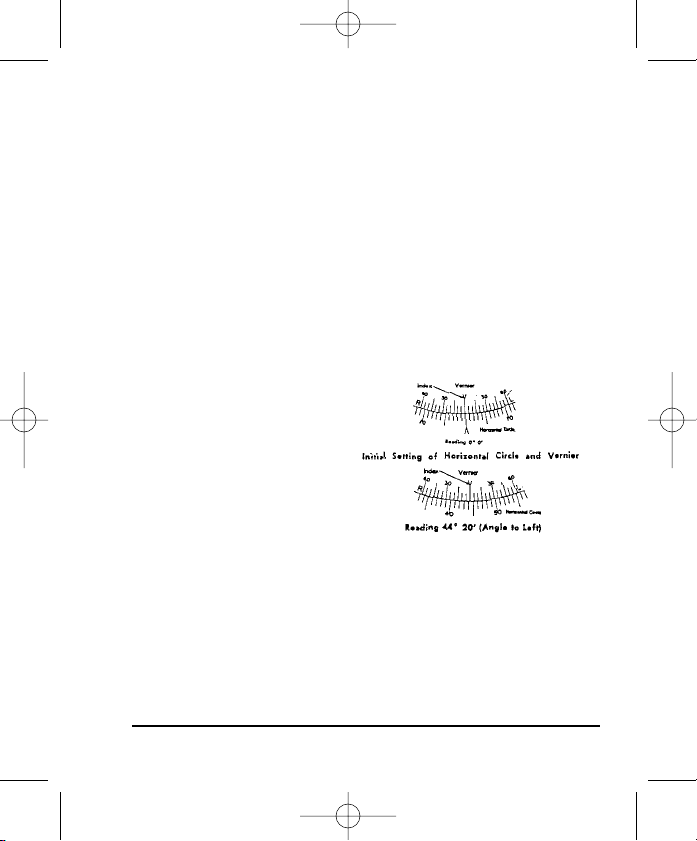

Reading the Vernier

The vernier is actually a double

, that is, two verniers in

vernier

one. This makes it possible to

read any angle turned by the

telescope, whether to the right

or to the left. For example,

consider that you have turned

an angle to the left (counterclockwise) after first having set the circle to read 0º. Refer to the

bottom figure, this is what your vernier looks like after having turned

the angle.

©2009 Johnson Level & Tool 5

Page 6

2594H 7/29/09 10:12 AM Page 6

In the illustration above, the index has

passed the 44 degree line but has not

gone as far as the 45 degree line. In

this case, the third vernier line from the

index is lined up with one of the lines

on the circle. Since each vernier line

represents 15 minutes add 45 minutes to the 44 degree reading

(3 times 15 minutes equals 45 minutes). Therefore our exact reading

is 44 degrees, 45 minutes (44º45’).

5. Calibration

5.1 Bubble adjustment

If the telescope bubble does not

remain centered after ha

leveled the instrument, and

reversed the telescope end for

end (180º) (as described under the Leveling section) the need for

adjustment is indicated. Use a 3mm hex key.

With an adjusting screw “A” facing to the right of the bubble and with

telescope directly in line with two of the three leveling screws, note

to which side the bubble is off. If to the left, loosen screw “B” and

tighten screw “A” very slightly to remove ONE-HALF the error.

Remove the other half of the error with the two level screws in line

with the telescope.

the procedure. If bubble is off to the right, loosen screw “A” and

tighten screw “B”. Otherwise the procedure is identical.

ving

If the bubble is still not exactly centered, repeat

6 ©2009 Johnson Level & Tool

Page 7

2594H 7/29/09 10:12 AM Page 7

5.2 Instrument accuracy check

Set up the instrument in an area that is as level as possible and

which is about 220 ft.

long. Place two matching level rods about

200 ft. apart with the faces toward each other. Position and level

the instrument so that the distance from the instrument to each rod

is the same. (Fig. 1)

Take a reading on each rod with the instrument. Note the difference

and record them. Next, move the instrument to another point in line

with the two level rods as shown in Fig. 2. Level the instrument and

take readings on the two level rods. The difference should be the

same (A-A should equal B-B). The difference between A-A and B-B is

the instrument error at 200 feet.

Fig. 1

Fig. 2

©2009 Johnson Level & Tool 7

Page 8

2594H 7/29/09 10:12 AM Page 8

5.3 Instrument accuracy adjustment

If the error is more than 3/16” at 100’, it is

necessary to adjust the instrument.

When adjusting the instrument:

1. Remove rubber cover to expose the two

calibration set screws.

Using a 1.5mm Allen wrench, loosen the two calibration set screws.

2.

Eyepiece seat

Set Screws

Eyepiece tube

3. Rotate the eyepiece seat to make the crosshair center in the reticle of

instrument on the same level with a known reference point. Then

rotate the eyepiece tube to make the horizontal hair on the reticle of

instrument level by using a known level reference point.

4. Tighten the two set screws and restore rubber cover to its original

position.

5.4 Determining difference in elevation

Measuring a difference in elevation from one set-up

To find the difference of elevation between two points which can be observed

from one position, set up and level your instrument about midway between these

points. Be sure that a leveling rod held on both opposite points can be read when

your telescope is level. Each point should not be greater than 150 to 200 feet

away from the instrument or you may have difficulty reading the rods. The height

of the line of sight (horizontal crosshair) above or below each of the points is

found by reading the rod.

A line of sight 69 inches above A and 40 inches above B is shown above.

Therefore, B is higher than A by 29 inches.

8 ©2009 Johnson Level & Tool

Page 9

2594H 7/29/09 10:12 AM Page 9

Suppose one of your points is below the line of sight and the other

above (Fig B.), C is 4 feet 6-1/2 inches below the line of sight, and

point D, the underside of a floor beam is 7 feet 9-3/8 inches above

the line of sight (the latter reading having been obtained by holding

the rod upside down with the foot of the rod against the beam). D is

then higher than C by an amount equal to 4 feet 6-1/2 inches plus 7

feet 9-3/8 inches, or a total of 12 feet 3-7/8 inches.

5.5 Measure the difference in elevation requiring more than

one set-up

If two points are either too far apart or at too great a difference of

tion to be observed from one set-up, the procedure shown below

eleva

is recommended. This example assumes that you want to find the

difference in elevation between points A and D. To make the finding of

this difference simple, use the convenient terms plus (+) sight and

minus (-) sight and carry the readings at each set-up as shown.

The difference of elevation between D and A is found by taking the

difference between the sum of the plus sights and the sum of the

minus sights. If the sum of the plus sights is larger, the final point is

higher than the starting point. If the sum of the minus sights is larger,

the final point is lo

©2009 Johnson Level & Tool 9

wer than than the starting point.

Page 10

2594H 7/29/09 10:12 AM Page 10

5.6 Stadia Distance Measuring

Distance measuring can be done using the stadia hairs of the reticle.

The distance between the upper stadia hair and the lower stadia hair is

set at a 1:100 ration. So if the difference is 1 foot, the person holding

the grade rod is 100 feet away from the instrument.

5.7 Measuring Horizontal Angles

To measure or lay out an angle, set the instrument over a point and

level it up.

Use a plumb bob with about six feet of string. Attach the

plumb bob string to the hook under the instrument by means of a large

loop fastened by a slipknot and adjust the plumb bob until it is clear of

the ground point. By shifting the entire instrument, set the tripod

(keeping tripod head as level as possible by estimation) so that the

plumb bob appears to be over the ground point. Next, press the legs of

the tripod into the ground and lower the plumb bob until its point is

about one-quarter inch above the point on the ground. The final

centering of the instrument can be made by loosening (about one-half

turn) any two adjacent (not opposite) leveling screws and slowly

shifting the instrument until the plumb bob is directly over the point on

the ground. Then retighten the same two leveling screws you loosened

and re-level the instrument.

To measure horizontal angles, such as FIG (Fig. 8), center and level your

10 ©2009 Johnson Level & Tool

Page 11

2594H 7/29/09 10:12 AM Page 11

instrument over point F in accordance with previous instructions.

Rotate the instrument until point E is nearly in line with the vertical

crosshair. Turn tangent screw until vertical crosshair is on point E. By

hand set the horizontal circle to read zero. Now, swing the telescope

toward point G until the vertical crosshair is exactly on point G. Your

instrument is furnished with a vernier and you will be able to read the

angle closer than a single degree. The use of a vernier is explained

earlier in this manual.

Fig. 8

Fig. 9

In layout work, it is frequently necessary to set off an angle, usually

90º. Assume that the 90º angle HIJ is to be laid off and points H and I

are shown (Fig. 9). Therefore, J is the point you are to set.

©2009 Johnson Level & Tool 11

Page 12

2594H 7/29/09 10:12 AM Page 12

6. Technical Specifications

Telescope Erect

Magnification 22X

Leveling accuracy ± 3/16"/100 ft. (±5mm/30m)

Working range Up to 200’ (60m)

Minimum focus 4’ (1.2m)

Clear objective aperture 22mm

Field of view ± 2’/100 ft. (±0.6m/30m)

Number of lenses 5

Level vial 4’ per 2mm

Horizontal circle:

Graduation diameter 110mm

Graduations 1º

Number Each 10º, 0-90-0º

Vernier Double direct to 15 min.

Weight 2.204 lbs (1Kg)

Center screw thread 5/8” - 11

12 ©2009 Johnson Level & Tool

Page 13

2594H 7/29/09 10:12 AM Page 13

7. Care and Handling

Care must be taken to maintain the accuracy of the instrument.

• After each use, the instrument should be wiped clean and kept in

its carrying case.

• Remove dust from the lenses with a soft brush or a nonabrasive

wipe. Never tough the lenses with your fingers.

• Store the instrument in a dust-free area with low humidity.

8. Product Warranty

Johnson Level & Tool offers a one year limited warranty on each its

products. You can obtain a copy of the limited warranty for a

Johnson Level & Tool product by contacting Johnson Level & Tool's

Customer Service Department as provided below or by visiting us

online at www.johnsonlevel.com. The limited warranty for each

product contains various limitations and exclusions.

Do not return this product to the store/retailer or place of purchase.

Required repair/calibration must be done by an authorized

AccuLine Pro® service center or Johnson Level & Tool's limited

warranty, if applicable, will be void and there will be NO WARRANTY.

Contact our Customer Service Department to obtain a Return Material

Authorization (RMA) number for return to an authorized service center.

Proof of purchase is required.

©2009 Johnson Level & Tool 13

Page 14

2594H 7/29/09 10:12 AM Page 14

NOTE: The user is responsible for the proper use and care of the

product.

It is the responsibility of the user to verify the calibration of the

instrument before each use.

For further assistance, or if you experience problems with this product

that are not addressed in this instruction manual, please contact our

Customer Service Department.

In the U.S., contact Johnson Level & Tool’s Customer Service

Department at 800-563-8553.

In Canada, contact Johnson Level & Tool’s Customer Service

Department at 800-346-6682.

9. Product Registration

Enclosed with this instruction manual you will find a warranty card to be

completed for product warranty registration. Product warranty registration

can also be completed online at our web site www.johnsonlevel.com.

You will need to locate the serial number for your product that is located

on the bottom of the level. PLEASE NOTE THAT IN ADDITION TO

THER LIMITATIONS OR CONDITIONS OF JOHNSON LEVEL &

ANY O

TOOL'S LIMITED WARRANTY, JOHNSON LEVEL & TOOL MUST

HAVE RECEIVED YOUR PROPERLY COMPLETED WARRANTY CARD

WITHIN 30 DAYS OF YOUR PURCHASE OF THE PRODUCT OR ANY

LIMITED WARRANTY THAT MAY APPLY SHALL NOT APPLY AND

THERE SHALL BE NO WARRANTY.

14 ©2009 Johnson Level & Tool

Page 15

2594H 7/29/09 10:12 AM Page 15

10. Accessories

AccuLine Pro® accessories are available for purchase through

authorized AccuLine Pro dealers. Use of non-AccuLine Pro accessories

will void any applicable limited warranty and there will be NO WARRANTY.

If you need any assistance in locating any accessories, please contact

our Customer Service Department.

In the U.S., contact Johnson Level & Tool’s Customer Service

Department at 800-563-8553.

In Canada, contact Johnson Level & Tool’s Customer Service

Department at 800-346-6682.

©2009 Johnson Level & Tool 15

Page 16

2594H 7/29/09 10:12 AM Page 16

16 ©2009 Johnson Level & Tool

Loading...

Loading...