Page 1

6274H-2_Manuals 9/26/12 11:32 AM Page 1

Electronic Self-Leveling Dual Grade

Horizontal Rotary Laser

Model No. 40-6584

Instruction Manual

Congratulations on your choice of this Electronic Self-Leveling Dual

Grade Horizontal Rotary Laser. We suggest you read this instruction

manual thoroughly before using the instrument. Save this instruction

manual for future use.

This is a Class IIIa laser tool and is manufactured to comply with CFR 21,

parts 1040.10 and 1040.11 as well as international safety rule IEC 285.

©2012 Johnson Level & Tool 1

Page 2

6274H-2_Manuals 9/26/12 11:32 AM Page 2

Table of Contents

1. Kit Contents

2. Features and Functions

3. Safety Instructions

4. Location/Content

of Warning Labels

5. Location of Parts/Components

6. Operating Instructions

7. Using the Product

8. Self-Check & Fine Calibration

9. Technical Specifications

10. Application Demonstrations

11. Care and Handling

12. Product Warranty

13. Warranty Registration

14. Accessories

1. Kit Contents

Description Model No. 40-6584 Qty.

Electronic Self-Leveling Dual Grade Horizontal Rotary Laser

Li-ion Rechargeable Battery Pack 1

Battery Adapter 1

Remote Control with 2 AA Batteries 1

Detector with 9V Battery and Clamp 1

Alkaline Battery Compartment (batteries not included) 1

Sighting Scope 1

Slope Plate 1

Fine Adjusting Plate 1

Instruction Manual with Warranty Card 1

Hard-Shell Carrying Case 1

2. Features and Functions

• Large ±8° electronic auto-level range. When beyond the leveling

range, the laser beam will flash, rotation of the beam will stop, and

an audible alarm will activate.

• Electronic beam shield to turn the laser beam off in one to three

quadrants, when multiple lasers are being used.

• Programmable dual slope operation function allows user to

perform slope at different inclinations in both x and y axis.

• Height of Instrument/Tilt alarm function ensures product accuracy.

• Dust and rain resistant.

• Operates with remote control.

• LCD display with backlight illumination.

• Adjustable rotation speeds of 600 and 1100 rpms.

1

2 ©2012 Johnson Level & Tool

Page 3

6274H-2_Manuals 9/26/12 11:32 AM Page 3

3. Safety Instructions

Please read and understand all of the following instructions, prior

to using this tool. Failure to do so, may void the warranty.

DANGER!

Class IIIa Laser Product

Max. Power Output: ≤ 5mW

Wavelength: 625-645nm

THIS TOOL EMITS LASER RADIATION.

DO NOT STARE INTO BEAM.

AVOID DIRECT EYE EXPOSURE.

ATTENTION IMPORTANT

• Read all instructions prior to operating this laser tool. Do not remove any labels from tool.

• Do not stare directly at the laser beam.

• Do not project the laser beam directly into the eyes of others.

• Do not set up laser tool at eye level or operate the tool near a reflective surface as

the laser beam could be projected into your eyes or into the eyes of others.

• Do not place the laser tool in a manner that may cause someone to unintentionally

look into the laser beam. Serious eye injury may result.

• Do not operate the tool in explosive environments, i.e. in the presence of gases or

flammable liquids.

• Keep the laser tool out of the reach of children and other untrained persons.

• Do not attempt to view the laser beam through optical tools such as telescopes as

serious eye injury may result.

• Always turn the laser tool off when not in use or left unattended for a period of time.

• Remove the batteries when storing the tool for an extended time (more than 3 months)

to avoid damage to the tool should the batteries deteriorate.

• Do not attempt to repair or disassemble the laser tool. If unqualified persons attempt

to repair this tool, warranty will be void.

• Use only original Johnson

authorized dealer. Use of non-Johnson®parts and accessories will void warranty.

®

parts and accessories purchased from your Johnson

®

©2012 Johnson Level & Tool 3

Page 4

6274H-2_Manuals 9/26/12 11:32 AM Page 4

4. Location/Content of Warning Labels

4 ©2012 Johnson Level & Tool

Page 5

6274H-2_Manuals 9/26/12 11:32 AM Page 5

5. Location of Part/Components

Sighting Scope

Laser

Output

Window

Handle

LCD

Display

Keypad

Charging Port

Battery

Cover

Battery

Cover Screw

Connection to

the Laser

Screw

Slope Plate

©2012 Johnson Level & Tool 5

5/8” - 11

Screw

Thread

Fine Adjustment Knobs

Lock Knob

5/8” - 11 Screw Thread

Fine Adjusting Plate

5/8” - 11

Screw

Thread

Page 6

6274H-2_Manuals 9/26/12 11:32 AM Page 6

6. Operating Instructions

IMPORTANT: It is the responsibility of the user to verify the

calibration of the instrument before each use.

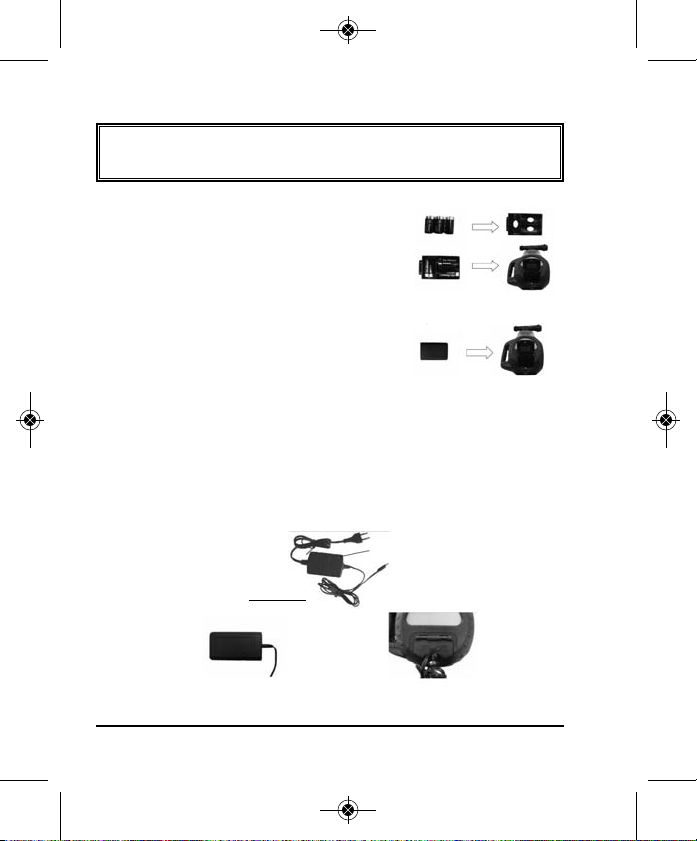

Alkaline Battery Installation:

Put 3 “D” alkaline batteries (not included)

into the battery pack according to the polarity

direction, then insert the battery pack into the

laser. (Note: Batteries facing up.)

Rechargeable Battery Pack Installation:

Install the rechargeable battery pack into

the laser.

Charging the Rechargeable Battery Pack:

Charge the rechargeable battery pack by inserting the charger into

the charging port. The LED on the charger is red during the charging

process; the LED on the charger will turn green when the battery is

fully charged.

Charging LED

Charger

Charge the rechargeable battery pack

outside the laser

6 ©2012 Johnson Level & Tool

Charge the rechargeable battery pack with

battery pack inside the laser

Page 7

6274H-2_Manuals 9/26/12 11:32 AM Page 7

Note:

(1) Charge the rechargeable battery when the battery power is low

(battery symbol on the LCD is flashing). This will extend the

battery life.

(2) If the laser is not going to be used for a long period of time,

charge the rechargeable battery every 2-3 months.

(3) The instrument can operate while the batteries are recharging.

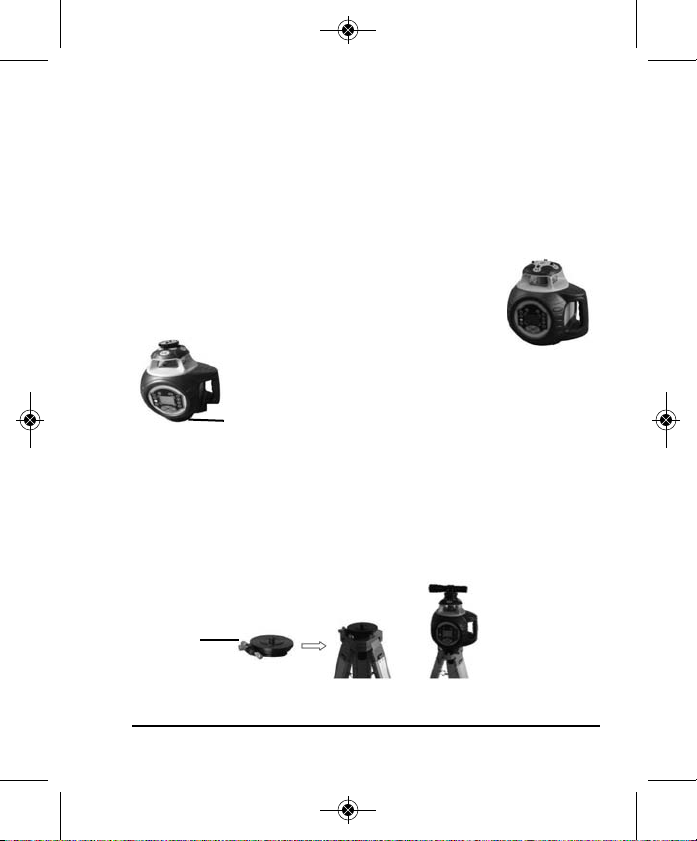

Use of the Slope Plate and Fine Adjusting Plate:

If the laser is operating with less than +12% grade in

the Y-axis, the slope plate is not required.

If the laser is operating between +12% and +25% in

the Y-axis, the slope plate is required.

Slope Plate

For exact positioning of the X or Y-axis, screw the Fine Adjusting Plate

on the tripod and then screw the laser to the Fine Adjusting Plate.

Use the sighting scope to rotate the laser to the exact position

required. Use the Fine Adjustment Knobs for fine movement. Use the

Lock Knob when positioned in the correct position.

Fine Adjusting

Plate

©2012 Johnson Level & Tool 7

Page 8

6274H-2_Manuals 9/26/12 11:32 AM Page 8

7. Using the Product

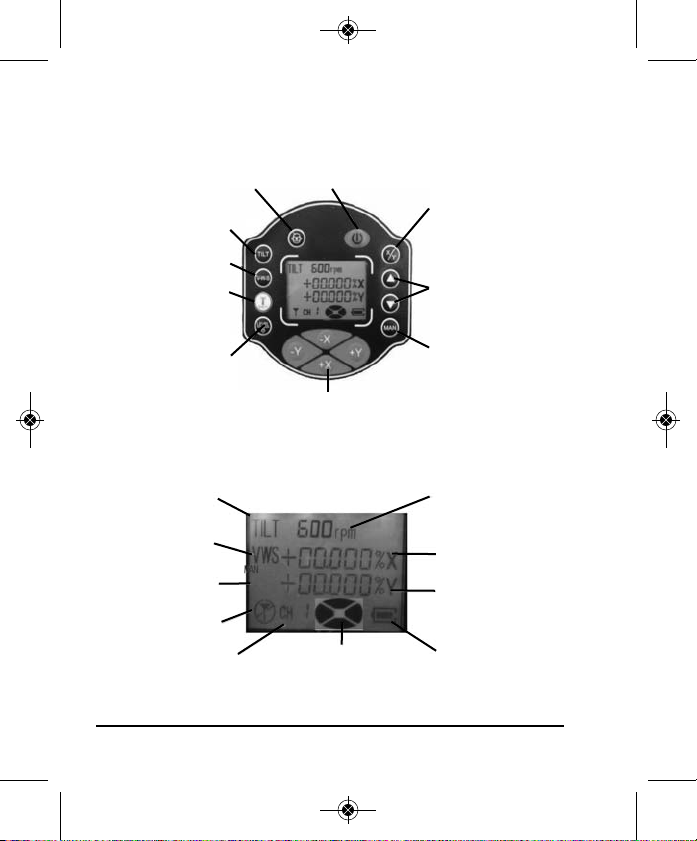

Keypad Controls

Rotating Speed Button On/Off Button

Tilt Button

Vibrate/VWS Button

Remote Channel Button

Level Button /

LCD Backlight Button

Beam Shield Buttons

Grade Axis and

Position Button

Grade Value Buttons

Manual Mode Button

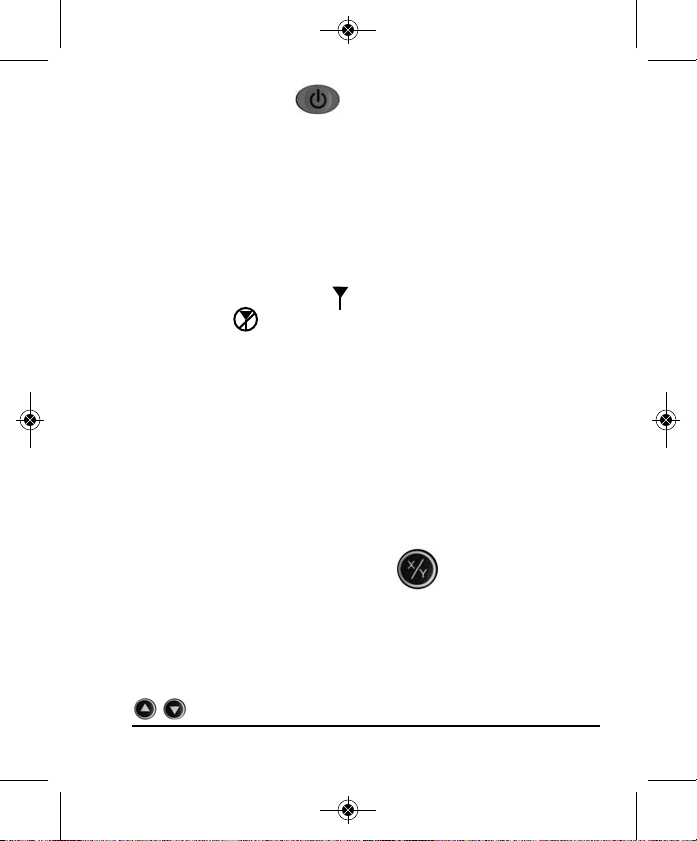

LCD Display

Tilt Mode

Vibrate/VWS Mode

Manual Mode

Remote On/Off

Remote Channel

8 ©2012 Johnson Level & Tool

Beam Shield

Rotating Speed

X-Axis Grade Value

Y-Axis Grade Value

Battery Capacity

Page 9

6274H-2_Manuals 9/26/12 11:32 AM Page 9

Power On/Off Button:

Press this button to power on/off the laser.

The laser is in self-leveling status when powered on.

Default rotate speed is 600 RPM

Default beam shield is off in all four quadrants;

Default grade for X-axis and Y-axis is 0.

The remote channel will display CH1.

If there is a matched remote control with the power on, the

remote status will display if there is not a matched remote, it

will display .

When powered on, the laser will automatically check the battery

capacity.

When powering on the laser it will enter into the self-leveling mode.

The TILT display will blink for thirty seconds after the lasers starts

to rotate. During these thirty seconds, if the laser is moved it will

stop rotating and re-level itself. After thirty seconds, the laser

will enter into the TILT mode and the LCD will show a solid

TILT display. (See TILT button)

Grade axis and Grade Value Button:

With the laser on, press the Grade Axis and Position button and hold

in for two seconds. The laser will beep once and the laser will enter

the X-axis grade setting mode. The X-axis symbol “X” and axis

direction symbol (+) will flash. A short press of the button will move

the position to the next symbol. Pressing the grade value buttons

will change the values. When the X-axis setting is

©2012 Johnson Level & Tool 9

Page 10

6274H-2_Manuals 9/26/12 11:32 AM Page 10

completed, press the grade axis button for two seconds to enter into the

Y-axis grade setting mode. The Y-axis symbol “Y” and axis direction

symbol (+) will flash. The setting method is the same as the X-axis.

After the Y-axis grade setting is completed, press this key for two

seconds to confirm the grade setting. The laser will beep once

and will quit the grade setting mode and start to work under the

confirmed grade.

Note: If there is no buttons pressed for eight seconds in the

grade setting mode, the laser will confirm the current grade

setting data automatically. The laser will beep once and leave

the grade setting mode.

Rotating Speed Button:

Press this button to select the rotating speed from 600 RPM

to 1100 RPM.

Beam Shield Buttons:

When turning on the laser, the beam shield will be off in all four

quadrants. All four quadrants on the LCD will be displayed. Pushing

one of the buttons will turn the beam off in that quadrant and that

quadrant will not be displayed on the LCD.

Note: One, two or three quadrants can be turned off simultaneously.

10 ©2012 Johnson Level & Tool

Page 11

6274H-2_Manuals 9/26/12 11:32 AM Page 11

TILT Button:

When turning on the laser, the laser will self-level and begin to rotate.

The TILT symbol on the LCD will blink for thirty seconds after the laser

begins to rotate. During these thirty seconds, if the laser is moved the

laser will stop rotating, re-level and begin to rotate again. After thirty

seconds the TILT symbol will stop blinking and become solid. If the

laser is moved when the TILT symbol is solid, the laser will stop rotating.

The laser beam will blink on and off and the TILT symbol will blink

quickly alerting the user that the height of instrument may have been

changed. Pressing the level button will allow the laser to re-level and

start rotating again and the TILT mode will repeat.

Vibrate VWS Button:

When pushing this button once, the VWS symbol will be displayed on

the LCD. Note: If the TILT mode display is turned off, pushing the

VWS button will turn the TILT mode display on. In this mode, the

laser will not react to slight vibration near the laser. To turn the VWS

mode display off, push the button one more time.

MAN Button:

When holding this button in for three seconds, the laser will enter into

manual mode. The self-leveling motors are turned off and the laser

will rotate in any position. Note: Grade value cannot be entered

when in manual mode. To exit manual mode, hold the button in

again for three seconds or push the TILT button to enter TILT mode.

©2012 Johnson Level & Tool 11

Page 12

6274H-2_Manuals 9/26/12 11:32 AM Page 12

Level Button/LCD Backlight Button:

Push this button once to start self-leveling after the laser has been

moved in TILT mode. Hold this button in for three seconds to turn on

the LCD backlight.

Remote Channel Button:

Push this button to switch the remote channel from CH1 to CHF.

Battery Status Indicator :

When powered on, the laser will automatically check the battery

capacity and show the following status.

Full battery

Half battery

Low battery

Very low battery and laser should be charged

Empty battery and laser needs to be charged

12 ©2012 Johnson Level & Tool

Page 13

6274H-2_Manuals 9/26/12 11:32 AM Page 13

Using the Remote Control:

1. Install two “AA” batteries in the battery compartment following the

diagram inside the compartment.

2. With the laser turned on, turn on the remote by pressing the

power button.

3. The LCD on the remote will display the following

4. The laser and remote default into channel (CH1) 1. The remote

control will only work when the laser and remote are on the same

channel. If other lasers are in the area, the remote and laser can

be changed from CH1 to CH9 and CHA to CHF making it so the

remote will only work for a specific laser. To change the remote

channel, press the remote button.

5. If the LCD on the laser displays the remote is not turned on, is

too far away from the laser or is on a different channel.

6. If the LCD displays on the laser and remote, the remote and

laser are on the same channel.

©2012 Johnson Level & Tool 13

Page 14

6274H-2_Manuals 9/26/12 11:32 AM Page 14

Note: The battery symbol display on the remote shows the battery

strength of the remote batteries and not the laser battery strength.

The differences between the remote button and laser buttons are

as follows:

1. Holding the on the remote Level/Backlight for three seconds

will turn on the remote backlight. To turn off the backlight, hold

the same button in again for another three seconds.

2. One press of the manual button will put the laser in “sleep”

mode. All the laser settings will be saved on the laser. The only

button that will work on the laser is the power button. The

only buttons that will work on the remote is the manual

button and power button. Another press of the manual

button will turn the laser back on to its original setting. This

“sleep” mode can be used to save on the battery life if the laser is

not going to be used for a period of time.

If the laser is not used after sixty minutes in “sleep” mode, the laser

will power off automatically and all stored information will be lost.

14 ©2012 Johnson Level & Tool

Page 15

6274H-2_Manuals 9/26/12 11:32 AM Page 15

Detector Usage

Two-Sided Laser Detector with Clamp

Model No. 40-6715

The 40-6715 laser detector is an indispensable accessory when

using rotary laser levels. The main function of the detector is to

detect the position of the laser signals that are transmitted by rotary

lasers. This detection quickly and precisely provides the user with the

horizontal reference.

This product features high sensitivity, a double-faced display, low

power consumption, good reliability and easy manipulation. It can be

used with most types of rotating laser levels.

1. Technical Specifications

Detecting accuracy: Fine: ±0.039" (±1mm)

Automatic Shut-off: 6 minutes ±1 minute

Power Supply: 9V battery, 30 hrs continuous use

Sound indicator: slow short beep, rapid short beep and

LED display: down arrow, up arrow, horizontal on

Dimensions: 6.30" x 3.35" x 1.10" (160 x 85 x 28mm)

Weight: 1 lb. (0.45kg)

Others: Rain and dust resistant

©2012 Johnson Level & Tool 15

Coarse 1: ±0.098" (±2.5mm)

when range ≥ 492 ft. (150m)

Coarse 2: ±0.394" (±10mm)

when range ≥ 492 ft. (150m)

(with LCD illumination off)

continuous sound

grade bar

Page 16

6274H-2_Manuals 9/26/12 11:32 AM Page 16

2. Components

(a) Exterior Instruction

1) Horizontal vial

2) Front display window

3) Front on grade mark

4) Vertical vial

5) LED key

6) Power key

7) Beeper

8) Reception window

9) Fine/Coarse accuracy key

10) Beeper key

11) Back display window

12) Back on grade mark

13) Bracket screw thread

14) Battery cover screw

15) Battery cover

(b) Display

1. Power on symbol

2. Low battery indicator

3. Fine/Coarse symbol

4. Beeper symbol

5. Position indication arrows

Power Key: Turn on/off the power

Fine/Coarse Accuracy Key: Switch detecting accuracy

LED Key: Turn on/off the LCD’s light

Volume Key: Cycles between high, low and off

16 ©2012 Johnson Level & Tool

Page 17

6274H-2_Manuals 9/26/12 11:32 AM Page 17

3. Operation Guide

(a) Battery Installation

• Open the battery cover door by turning the battery cover screw

counter-clockwise. Put the battery into the

battery case noting the polarity shown in

the battery compartment.

• Put the battery cover door back, and tighten

the screw.

Note: 1) Remove the battery when the unit is being stored for a

long time.

2) When the low battery indicator is displayed, change the

battery soon.

4. Operating Instructions

Power On

Press the power key to turn the unit on. The

LCD display will illuminate all the indicator

segments for 0.5 second (Fig.2). When the

indicator segments are no longer

illuminated, the detector is ready for use.

Note: The LCD display will still have the

power, detection and sound indicators illuminated (Fig. 3).

Figure 2

Figure 3

©2012 Johnson Level & Tool 17

Page 18

6274H-2_Manuals 9/26/12 11:32 AM Page 18

Fine/Coarse accuracy key

Power on and press the

fine/coarse accuracy key, the

unit will cycle between three

accuracy options: fine, coarse

1, coarse 2. The accuracy

symbol displayed on the LCD will change.

Volume Key

Power on and press the volume

key, the unit will cycle between a

high sound, low sound and mute.

The sound symbol displayed on the LCD will change accordingly.

Note: There will be two beeps when turning the unit on and off.

There will be one beep when changing functions.

Detecting Laser Level Signals

While detecting laser signals, the LCD will display as follows: (take

the set-up state of high sound and fine detection as an example)

Laser signal

Laser signal

Laser signal

The laser signal is down

Sound: rapid short beeps

18 ©2012 Johnson Level & Tool

The laser signal is up

Sound: slow short beeps

Horizontal bar indicated on-grade

Sound: continuous sound

No laser signal is detected

Sound: no sound

Page 19

6274H-2_Manuals 9/26/12 11:32 AM Page 19

When the laser signal is near the on-grade mark, the displayed up

and down arrows will decrease as the distance to the on-grade mark

decreases.

Laser signal Laser signal Laser signal Laser signal

1. When detecting a horizontal laser signal, it is

important to have the bubble vial centered, as the

deflection of the receiver will influence its receiving

accuracy.

2. When detecting a vertical laser signal, it is important

to have the bubble vial centered, as the deflection of

the receiver will influence its receiving accuracy.

3. Keep the reception window facing the laser while detecting.

4. Hold the unit stable while detecting.

LED Function

Power on and press the LED key, the LCD will now be backlit.

Automatic Shut-off Function

When the unit does not receive a laser signal for 6 minutes, the

unit will power off automatically.

Low Battery Display Function

When the battery sign blinks on the LCD, the battery is

low and needs to be replaced. If the battery is very low,

the unit will power off automatically. Replace the battery.

©2012 Johnson Level & Tool 19

Page 20

6274H-2_Manuals 9/26/12 11:32 AM Page 20

Rod Clamp

Connecting to the rod clamp.

Connecting to the grade rod.

5. Detector Maintenance

• Keep the unit, particularly the reception window, clean. If it does get dirty,

use a cloth to wipe it clean.

20 ©2012 Johnson Level & Tool

Page 21

6274H-2_Manuals 9/26/12 11:32 AM Page 21

8. Self-Check & Fine Calibration

IMPORTANT: It is the responsibility of the user to verify the

calibration of the instrument before each use.

The instrument must be self-checked for accuracy periodically,

specifically before a large project, where accuracy is critical. If the

accuracy is found to be beyond tolerance, some adjustment may be

made as follows.

X-Axis and Y-Axis Accuracy Check:

1. Place a table indoors, approximately 20m from a wall. Place the

instrument on the table with the X-axis facing the wall.

2. Power the instrument on and allow it to self-level. Adjust the

rotating speed to make the output laser line clear and visible.

Mark a vertical line on the wall that intersects the laser line from

the instrument. Mark a line where the laser line hits the vertical

line, and label as ‘A’.

h

©2012 Johnson Level & Tool 21

Page 22

6274H-2_Manuals 9/26/12 11:32 AM Page 22

(Turning in a clockwise direction):

A = X+

B = Y+

C = XD = Y-

3. Rotate the instrument 90°, and after self-level completes, mark a

line and label as ‘B’. Repeat two more times, labeling lines as ‘C’,

and ‘D’.

4. Measure the vertical distance ‘h’ between the highest and the

lowest points among A, B, C, and D.

5. If h=2mm or less, accuracy is qualified. If h>2mm but <10mm,

adjust the calibration. If h>10mm, please contact an authorized

service center or dealer for repair.

Accuracy Calibration of the X and Y-Axis:

1. Power off the instrument and face the X-axis to the wall.

2. Press and simultaneously, and then release while still

pressing for approximately ten seconds. The instrument will

then enter Calibration mode, and ‘CAL’ will be displayed.

3. Using the Remote Control, press the button to select the axis

to be calibrated.

4. On the remote, press the buttons to move the laser line

up and/or down, until the laser line hits directly on reference

point ‘0’.

22 ©2012 Johnson Level & Tool

Page 23

6274H-2_Manuals 9/26/12 11:32 AM Page 23

Calibration Confirm:

Press the button to confirm the calibration value after calibration

is completed. Instrument will return to normal operation mode.

Note: In the self-check and calibration mode, self-calibration

coefficient is from 1600-2495. If user calibrates in this range,

and accuracy is still not achievable, please contact an Authorized

Service Center or Dealer for repair.

• After Calibration is complete, user must turn the instrument

off and then back on. Calibration is then complete.

• When calibrating, the user must check accuracy of both the

X and Y Axis, until both are within accuracy specification.

©2012 Johnson Level & Tool 23

Page 24

6274H-2_Manuals 9/26/12 11:32 AM Page 24

9. Technical Specifications

Laser Wavelength 635nm±10nm

Laser Classification Class IIIa

Maximum Power Output ≤5mW

Accuracy ±1/16"/100 ft. (±1.5mm/30m)

Interior Range Up to 200 ft. (60m) diameter depeding on

light conditions

Exterior Range Up to 2000 ft. (600m) diameter

Remote Range Up to 200 ft. (60m) diameter

Auto-Leveling Range ±8°

Grade Setting X Axis -10% – +10%

Scan Speed 600 and 1100 rpm

Power Supply Li-ion Rechargeable Battery Pack or

Battery Life

Dimensions 9.252" x 7.086" x 9.763"

Weight 7.275 lbs. (3.3Kg)

Working Temperature 14°F to 113°F (-10°C to 45°C)

Center Screw Thread 5/8" – 11

IP Protection Class 66

Y Axis -1% – +25%

|X| + |Y| = 20%

adapter (included); 3 “D” Alkaline

batteries (not included)

Approx. 40 hours with Li-ion Rechargeable

Battery Pack (included)

(235 x 180 x 248mm)

24 ©2012 Johnson Level & Tool

Page 25

6274H-2_Manuals 9/26/12 11:33 AM Page 25

10. Application Demonstrations

Squaring Leveling

Elevation

©2012 Johnson Level & Tool 25

Grading

Set Forms

Page 26

6274H-2_Manuals 9/26/12 11:33 AM Page 26

11. Care and Handling

• This laser unit is a precision tool that must be handled with care.

• Avoid exposing unit to shock vibrations and extreme temperatures.

• Before moving or transporting the unit, make sure that the unit is turned off.

• Remove the batteries when storing the unit for an extended time (more than

three months) to avoid damage to the unit should the batteries deteriorate.

• Always store the unit in its case when not in use.

• Avoid getting the unit wet.

• Keep the laser unit dry and clean, especially the laser output window.

Remove any moisture or dirt with a soft, dry cloth.

• Do not use harsh chemicals, strong detergents or cleaning solvents to clean

the laser unit.

12. Product Warranty

Johnson Level & Tool offers a three year limited warranty on each of its products.

You can obtain a copy of the limited warranty for a Johnson Level & Tool

product by contacting Johnson Level & Tool's Customer Service Department,

as provided below, or by visiting our web site at www.johnsonlevel.com. The

limited warranty for each product contains various limitations and exclusions.

Do not return this product to the store/retailer or place of purchase.

Non-warranty repairs and course calibration must be done by an authorized

Johnson®service center or Johnson Level & Tool's limited warranty, if

applicable, will be void and there will be NO WARRANTY. Contact one of our

service centers for all non-warranty repairs. A list of service centers can be

found on our web site at www.johnsonlevel.com or by calling our Customer

Service Department. Contact our Customer Service Department for Return

Material Authorization (RMA) for warranty repairs (manufacturing defects

only). Proof of purchase is required.

26 ©2012 Johnson Level & Tool

Page 27

6274H-2_Manuals 9/26/12 11:33 AM Page 27

NOTE: The user is responsible for the proper use and care of the product. It is the

responsibility of the user to verify the calibration of the instrument before each use.

For further assistance, or if you experience problems with this product that are not

addressed in this instruction manual, please contact our Customer Service Dept.

In the U.S., contact Johnson Level & Tool’s Customer Service Department at

888-9-LEVELS.

In Canada, contact Johnson Level & Tool’s Customer Service Department at

800-346-6682.

13. Warranty Registration

Enclosed with this instruction manual you will find a warranty

registration card to be completed for your product. You will need to

locate the serial number for your product that is located on the bottom

of the unit. PLEASE NOTE THAT IN ADDITION TO ANY OTHER

LIMITATIONS OR CONDITIONS OF JOHNSON LEVEL & TOOL'S

LIMITED WARRANTY, JOHNSON LEVEL & TOOL MUST HAVE

RECEIVED YOUR PROPERLY COMPLETED WARRANTY CARD AND

PROOF OF PURCHASE WITHIN 30 DAYS OF YOUR PURCHASE OF

THE PRODUCT OR ANY LIMITED WARRANTY THAT MAY APPLY

SHALL NOT APPLY AND THERE SHALL BE NO WARRANTY.

©2012 Johnson Level & Tool 27

Page 28

6274H-2_Manuals 9/26/12 11:33 AM Page 28

14. Accessories

Johnson®accessories are available for purchase through authorized

®

Johnson

applicable limited warranty and there will be NO WARRANTY. If you need

any assistance in locating any accessories, please contact our

Customer Service Department.

In the U.S., contact Johnson Level & Tool’s Customer Service

Department at 888-9-LEVELS.

In Canada, contact Johnson Level & Tool’s Customer Service

Department at 800-346-6682.

dealers. Use of non-Johnson®accessories will void any

28 ©2012 Johnson Level & Tool

Loading...

Loading...