Page 1

™

40-6520_6530 4/20/05 4:12 PM Page 1

Self-Leveling Rotary Laser Level

Model Nos. 40-6520 and 40-6530

Instruction Manual

Congratulations on your choice of this Self-Leveling Rotary Laser

Level. We suggest you read this instruction manual thoroughly before

using the instrument. Save this instruction manual for future use.

This tool emits one rotating laser beam level line that is ideal for layout

of indoor or outdoor construction projects. Since the product is

equipped with a beam detector (in model no. 40-6530 only), visibility of

the beam in various lighting conditions is not an issue.

This is a Class IIIa laser tool and is manufactured to comply

with CFR 21, parts 1040.10 and 1040.11 as well as international

safety rule IEC 285.

©2005 Johnson Level & Tool 1

Page 2

40-6520_6530 4/20/05 4:12 PM Page 2

Table of Contents

1. Kit Contents

2. Features and Functions

3. Safety Instructions

4. Location/Content

of Warning Labels

5. Location of Parts/Components

6. Operating Instructions

7. Using the Product

8. Self-Check and Calibration

9. Technical Specifications

10. Application Demonstrations

11. Care and Handling

12. Product Warranty

13. Product Registration

14. Accessories

1. Kit Contents

For Model No. 40-6520

Description Qty.

Self- Leveling Rotary Laser Level 1

Ni-MH Rechargeable Battery Pack 1

“C” Alkaline Battery Holder (batteries not included) 1

6V Battery Adapter 1

Vertical Mounting Adapter 1

Tinted Glasses 1

Instruction Manual with Warranty Card 1

Hard Shell Carrying Case 1

For Model No. 40-6530

Description Qty

Self- Leveling Rotary Laser Level 1

Ni-MH Rechargeable Battery Pack 1

“C” Alkaline Battery Holder (batteries not included) 1

6V Battery Adapter 1

Vertical Mounting Adapter 1

Tinted Glasses 1

Detector with 9V Battery and Quick Clamp 1

Instruction Manual with Warranty Card 1

Hard Shell Carrying Case 1

2 ©2005 Johnson Level & Tool

.

Page 3

40-6520_6530 4/20/05 4:12 PM Page 3

2. Features and Functions

• Magnetic dampening compensation system.

• Laser flashes and sounds alarm when product is not within

leveling tolerance.

• Projects a horizontal rotating plane with one up plumb beam.

• Projects a vertical rotating plane with one horizontal beam.

• Optional scan range from small to large providing user visible

chalk line.

• Adjustable scan orientation.

• Adjustable scan speed.

• Long battery life. Applicable for both alkaline batteries and

rechargeable battery-pack.

• Dust and rain resistant.

3. Safety Instructions

Please read and understand all of the following instructions, prior

to using this tool. Failure to do so, may result in bodily injury.

CAUTION: If using this product with any type of tinted goggles,

please note safety warning below.

DANGER!

Class IIIa Laser Product

Max. Power Output: ≤ 5mW

Wavelength: 625-645nm

THIS TOOL EMITS LASER RADIATION.

DO NOT STARE INTO BEAM.

AVOID DIRECT EYE EXPOSURE.

©2005 Johnson Level & Tool 3

Page 4

40-6520_6530 4/20/05 4:12 PM Page 4

ATTENTION IMPORTANT

• Read all instructions prior to operating this laser tool. Do not remove any labels from

tool.

• Use of controls or performance of procedures other than those specified herein may

result in hazardous radiation exposure.

• Do not stare directly at the laser beam.

• Do not project the laser beam directly into the eyes of others.

• Do not set up laser tool at eye level or operate the tool near a reflective surface as

the laser beam could be projected into your eyes or into the eyes of others.

• Do not place the laser tool in a manner that may cause someone to unintentionally

look into the laser beam. Serious eye injury may result.

• Do not operate the tool in explosive environments, i.e. in the presence of gases or

flammable liquids.

• Keep the laser tool out of the reach of children and other untrained persons.

• Do not attempt to view the laser beam through optical tools such as telescopes as

serious eye injury may result.

• Always turn the laser tool off when not in use or left unattended for a period of time.

• Remove the batteries when storing the tool for an extended time (more than 3 months)

to avoid damage to the tool should the batteries deteriorate.

• Do not attempt to repair or disassemble the laser tool. If unqualified persons attempt

to repair this tool, serious injury may result.

• Use only original AccuLine Pro

Pro authorized dealer. Use of non-AccuLine Pro parts and accessories will void warranty.

™

parts and accessories purchased from your AccuLine

WARNING!

The tinted goggles are designed to enhance

the visibility of the laser beam. They DO NOT

offer protection to the eyes from direct exposure

of the laser beam.

4 ©2005 Johnson Level & Tool

Page 5

40-6520_6530 4/20/05 4:12 PM Page 5

4. Location/Content of Warning Labels

©2005 Johnson Level & Tool 5

Page 6

40-6520_6530 4/20/05 4:12 PM Page 6

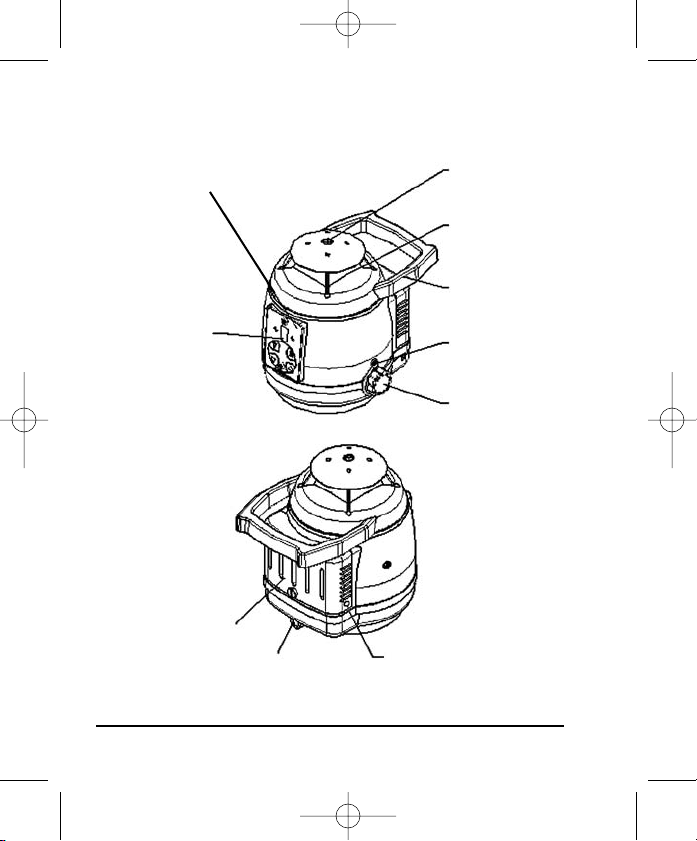

5. Location of Part/Components

Operation Panel

Vertical Plumb

Laser Beam

Output Widnow

Rotating Laser

Output Widow

Handle

Bubble

Battery Box

Jack for

Adjusting Knob

6 ©2005 Johnson Level & Tool

Lock/Unlock

Locking Knob

DC 6V Power Jack

Page 7

40-6520_6530 4/20/05 4:12 PM Page 7

6. Operating Instructions

IMPORTANT: It is the responsibility of the user to verify the calibration

of the instrument before each use.

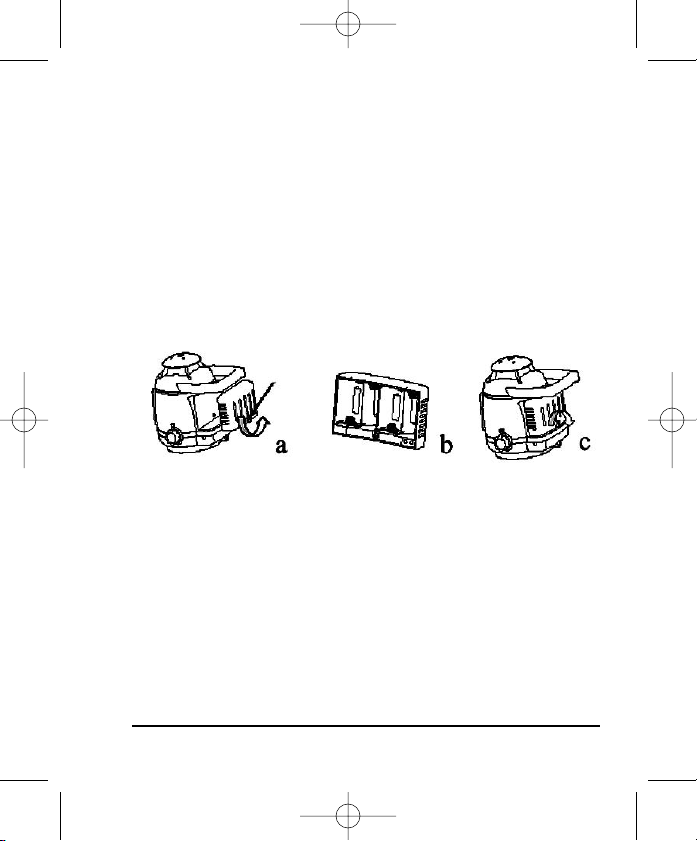

Battery Installation

Note: Always check to be sure that the on/off switch is in the off

position before removing and replacing batteries.

Battery kit: • “C” alkaline battery box

• Rechargeable battery-pack

Bolt

Alkaline Battery

1. Loosen the set-bolt and take the battery box apart from the unit,

as shown in fig. a.

2. Put in four “C” batteries (not included) according to the polarity

illustrated in the battery box, and snap the battery box back into

place, as shown in fig. b and c.

3. If using the rechargeable battery-pack, fix the battery-box onto the

unit directly, and tighten the bolt (fig. c).

©2005 Johnson Level & Tool 7

Box

Page 8

40-6520_6530 4/20/05 4:12 PM Page 8

Note:

• For the first two charges of new battery pack, it is necessary to

charge for 12-plus hours.

• After having been fully charged, we suggest that users should

charge for 2 more hours to ensure battery-pack's capacity.

• The instrument can still work even if it is being charged with

adapter.

• Do not charge alkaline batteries to avoid explosion.

• Used (discharged) batteries are hazardous waste and should be

disposed of properly.

Instrument Usage

1. Put in Ni-MH battery pack or alkaline batteries, or connect with 6V

DC power through power jack.

2. Place the instrument on platform or tripod, and connect with tripod

through 5/8" thread at the bottom of instrument.

Note: If instrument is inclined beyond the self-leveling range, it will

deliver an audible alarm. Re- position the instrument until leveled.

3. Rotate locking knob counter-clockwise to unlock, then turn power

on, and press the keys on control panel to adjust to your desired

working status.

4. After finishing operation or before moving the instrument, proceed

to turn power off and return locking knob to the locked position.

8 ©2005 Johnson Level & Tool

Page 9

40-6520_6530 4/20/05 4:12 PM Page 9

7. Using the Product

Operating Panel

Range Scan

Indicator Lamp

Power Indicator

Lamp

Range Scan

Mode Button

Down Button

1. On/Off Button

• Pressing the button will turn the unit on / off.

2. Power Indicator Lamp

• Lit indicator lamp means power-on.

• Unlit indicator lamp means power-off.

• Flashing indicator lamp means low voltage.

3. Range scan Indicator Lamp

• Stable indicator lamp means continuous scan.

• Flashing indicator lamp means range scan.

4. Range scan mode button

• With the first press of this button, the instrument emits a short

bright horizontal laser line.

• With a second press of this button, the instrument emits a long

bright horizontal laser line.

• With a third press of this button, the instrument emits a bright

laser point.

• With a fourth press of this button, the laser will once again

rotate at high speed.

©2005 Johnson Level & Tool 9

On/Off Button

Up Button

Page 10

40-6520_6530 4/20/05 4:12 PM Page 10

5 and 6. Up/Down button

In continuous scan mode

• Press to increase scan speed

• Press to decease scan speed

In range scan mode

• Press to make the scanned range rotate clockwise

• Press to make the scanned range rotate counterclockwise

Usage for horizontal output status

• Reference “Instrument Usage” previously discussed

Usage for vertical output status

IMPORTANT: Keep “Locking Knob” in the “Locked” position.

1. Install batteries/battery pack as previously discussed.

2. Insert the “Adjusting knob” and place the instrument horizontally

on a stable platform (see fig. 5) or mount it on the tripod with

vertical mount.

3. Turn the “Adjusting Knob” until the bubble is centered.

4. Power on and select

the work state that you

Leveling Vial

need by pressing the

mode button on the

operating panel.

5. Power the instrument off

when you finish work or

make any movement.

Adjusting

Knob

Handle

Vertical

Mount

10 ©2005 Johnson Level & Tool

Page 11

40-6520_6530 4/20/05 4:12 PM Page 11

Detector Usage (included in Model No. 40-6530 only)

1. Technical Specifications

Detecting range ≥820 ft. (250m)

Detecting accuracy Fine ±0.039" (±1mm)

Coarse ±0.098" (±2.5mm)

Turn-off time 5 minutes

Operating voltage DC9V

Size 6-3/4" x 3" x 1" (0.266 x 0.118 x 0.029mm)

Weight 0.55 Ibs (0.249 Kg)

Dust and rain resistant

Illuminated Screen

Multi-functional double sides display

Buzzer for recognizing location

2. Components

(a) Structure

1. Display window

2. Level vial

3. Coarse/Fine detection button

4. Buzzer

5. Power button

6. Sound button

7. Illuminator button

8. Receiving window

9. Reverse display window

10. Reference rabbet

11. Location hole

12. Threaded hole

13. Battery-box cap

©2005 Johnson Level & Tool 11

Page 12

40-6520_6530 4/20/05 4:12 PM Page 12

(b) Display

1. Power symbol

2. Low battery symbol

3. Coarse/Fine detection symbol

4. Sound symbol

5. Detecting position symbol

3. Operation Guide

(a) Installation of battery

• Open the battery-box cap

• Put the 9V battery into the battery-box. Please note the polarity.

Then close the battery-box cap.

Note: Take the battery out if the instrument is not use for a long time.

(b) Turn on/off

• Press the power button. When Power symbol is

displayed, the instrument is ready for coarse

detection.

• When low battery symbol is displayed, change

the battery.

• Press the power button again to turn off the

instrument.

12 ©2005 Johnson Level & Tool

Page 13

40-6520_6530 4/20/05 4:12 PM Page 13

(c) Using the clamp holder

1. clamp bolt

2. button

3. M5 screw

(d) Detection

1. Coarse detection

• Aim the receiving window at the

rotating laser instrument. Loosen the

clamp bolt and move the instrument

up and downwards to receive the

laser scanning signals transmitted by

the rotating laser instrument.

• When the instrument displays like

Fig. (A), move the instrument slightly

downwards as indicated by the arrow.

When it displays like Fig. (B), move it

slightly upwards as indicated by the

arrow.

• When Fig. (C) is displayed, the instrument is at the right position.

• Tighten the clamp bolt and mark the position of the object on the

rabbet. This mark will be the horizontal reference of the coarse

detection.

©2005 Johnson Level & Tool 13

Page 14

40-6520_6530 4/20/05 4:12 PM Page 14

2. Fine detection

1. power symbol

2. fine detection symbol

• Press coarse/fine detection button. The

instrument is ready for fine detection.

• Move the instrument slightly up and

downwards like the coarse detection

procedure.

• When the instrument displays as shown

in the figure, it is at the right position.

• Tighten the clamp bolt and mark the position of the object on the

rabbet. This mark will be the horizontal reference of the fine detection.

(e) Sound function

• If the instrument is working in a circumstance that makes it difficult

to use the display function, the sound function can be used instead.

• Press the sound function button. The sound symbol is displayed

which means it is ready for sound function. The instrument then

conducts coarse/fine detection through sound (buzz) signals.

• When the sound signal is ultra-short buzz, move the instrument

slightly upwards.

• When the instrument makes short buzz, move it slightly downwards.

• When the instrument makes intermittent, continuous sound, it is at

the right position.

• If there is no buzz heard, the instrument has not received the laser

scanning signal.

14 ©2005 Johnson Level & Tool

Page 15

40-6520_6530 4/20/05 4:12 PM Page 15

(f) Turn-off timer

• The instrument will automatically turn off if it has not received

laser scanning signal for 5 minutes

(g) Illuminator system

• There is an illuminator system at the right-faced display window.

Press the illuminator button which will illuminate the display window.

8. Self-Check and Calibration

X-Direction Accuracy Self-Check

1. For clarity, we define the direction of handle as X-direction,

and another direction as Y-direction

Wall

2. Place the unit on a platform that is 30 feet (10m) away from a

wall indoors, with the handle facing the wall head-on. Unlock

the unit and adjust it to the quick-scan status.

3. Draw one vertical line on exactly front wall, which intersection

with the laser line can be marked as point A.

Note: This test should be done indoors with dim lighting It’s

(

critical that the laser mark is easily seen)

4. Turn the instrument by 180 degrees, mark the intersection of

vertical line and laser line as point B, and also mark the center

of point A and point B as point 0.

©2005 Johnson Level & Tool 15

Page 16

40-6520_6530 4/20/05 4:12 PM Page 16

5. Measure the vertical distance h between point A and point B.

6. As shown, turn the instrument by 90° and place it on the

platform, with the operating panel facing you. Perform

Y-direction self-check with the same method as X-direction

self-check, and mark point C and point D by turns.

7. If h<0.236" (6mm), the accuracy is within tolerance.

Otherwise reference section 12 of this document.

Accuracy Self-Check for Vertical Output Status

1. Follow the operations as above, and measure the distance H1

between the laser rotating plane and the platform surface.

2. Set the locking knob to locking position, and place the instrument

horizontally.

Wall

Wall

16 ©2005 Johnson Level & Tool

Page 17

40-6520_6530 4/20/05 4:12 PM Page 17

3. Adjust the adjusting screw to center the bubble.

4. Measure the distance H2 between the top laser beam and the

platform surface.

5. Mark out E in the position that is (H1 –H2 ) lower than point 0.

6. If e – point 0 < 0.394" (10mm), the accuracy is within tolerance.

Otherwise reference section 12 of this document.

9. Technical Specifications

Laser Wavelength 635nm±10nm

Laser Classification Class IIIa

Maximum Power Output

Accuracy Horizontal Rotation = ±3/8"/100 ft.

Working Range Maximum 100 ft. (30m) depending upon

Measuring Range 820 ft. (250m) radius with detector

Self-Leveling Range ±3.5°, Delivers an alarm if beyond range,

Power Supply 4 “C” alkaline batteries (not included)

Dimens ions 5-3/4" x 7-3/4" x 7-5/8" (146 x 197 x 194mm)

Weight 4.4lbs (2Kg)

Working Temperature 14°F to 113°F (-10°C to +45°C)

Center screw thread 5/8" – 11

Rotation Speed 300 rpm, 600 rpm, 900 rpm

Range Scan Area Continuous, small range, large range, point

Enclosure Dust and rain resistant

©2005 Johnson Level & Tool 17

≤5mW

(±3mm/10m)

Vertical Rotation = ±5/8"/100 ft.

(± 5mm/10m)

light conditions

and stops rotation simultaneously

Rechargeable battery pack, or 6V adapter

Page 18

40-6520_6530 4/20/05 4:12 PM Page 18

10. Application Demonstrations

Plumb reference

for ceiling installation

Reference for squaring

and leveling

Reference for fence

installation

Reference for window

installation

18 ©2005 Johnson Level & Tool

Reference for wall or

footing construction

Reference for baseboard

installation

Reference for cement

floor installation

Reference for anti-static

flooring installation

Page 19

40-6520_6530 4/20/05 4:12 PM Page 19

11. Care and Handling

• This laser unit is a precision tool that must be handled with care.

• Avoid exposing unit to shock vibrations and extreme temperatures.

• Before moving or transporting the unit, make sure that the unit

is turned off and in the locked position. Failure to lock before

transport or storage may cause damage to the units inner

mechanism and void warranty.

• Remove the batteries when storing the unit for an extended time

(more than three months) to avoid damage to the unit should

the batteries deteriorate.

• Always store the unit in its case when not in use.

• Avoid getting the unit wet.

• Keep the laser unit dry and clean, especially the laser output

window. Remove any moisture or dirt with a soft, dry cloth.

• Do not use harsh chemicals, strong detergents or cleaning solvents

to clean the laser unit.

12. Product Warranty

Johnson Level & Tool offers a one year limited warranty on each its

products. You can obtain a copy of the limited warranty for a

Johnson Level & Tool product by contacting Johnson Level & Tool's

Customer Service Department as provided below or by visiting us

online at www.johnsonlevel.com. The limited warranty for each

product contains various limitations and exclusions.

Do not return this product to the store/retailer or place of purchase.

Required repair/calibration must be done by an authorized AccuLine

Pro™ service center or Johnson Level & Tool's limited warranty, if

applicable, will be void and there will be NO WARRANTY. Contact our

©2005 Johnson Level & Tool 19

Page 20

40-6520_6530 4/20/05 4:12 PM Page 20

Customer Service Department to obtain a Return Material

Authorization (RMA) number for return to an authorized service center.

Proof of purchase is required.

NOTE: The user is responsible for the proper use and care of the

product.

It is the responsibility of the user to verify the calibration of the

instrument before each use.

For further assistance, or if you experience problems with this product

that are not addressed in this instruction manual, please contact our

Customer Service Department.

In the U.S., contact Johnson Level & Tool’s Customer Service

Department at 800-563-8553.

In Canada, contact Johnson Level & Tool’s Customer Service

Department at 800-346-6682.

13. Product Registration

Enclosed with this instruction manual you will find a warranty card to be

completed for product warranty registration. Product warranty registration

can also be completed online at our web site www.johnsonlevel.com.

You will need to locate the serial number for your product that is located

on the bottom of the unit.

OTHER LIMITATIONS OR CONDITIONS OF JOHNSON LEVEL &

TOOL'S LIMITED WARRANTY, JOHNSON LEVEL & TOOL MUST

HAVE RECEIVED YOUR PROPERLY COMPLETED WARRANTY CARD

WITHIN 30 DAYS OF YOUR PURCHASE OF THE PRODUCT OR ANY

LIMITED WARRANTY THAT MAY APPLY SHALL NOT APPLY AND

THERE SHALL BE NO WARRANTY

20 ©2005 Johnson Level & Tool

PLEASE NOTE THAT IN ADDITION TO ANY

.

Page 21

40-6520_6530 4/20/05 4:12 PM Page 21

14. Accessories

AccuLine Pro™ accessories are available for purchase through

authorized AccuLine Pro dealers. Use of non-AccuLine Pro accessories

will void any applicable limited warranty and there will be NO WARRANTY.

If you need any assistance in locating any accessories, please contact

our Customer Service Department.

In the U.S., contact Johnson Level & Tool’s Customer Service

Department at 800-563-8553.

In Canada, contact Johnson Level & Tool’s Customer Service

Department at 800-346-6682.

©2005 Johnson Level & Tool 21

Loading...

Loading...