Page 1

3515H-All_Manuals 6/2/10 10:16 AM Page 1

Self-Leveling Rotary Laser Level

Model Nos. 40-6515, 40-6516 and 40-6517

Instruction Manual

Congratulations on your choice of this Self-Leveling Rotary Laser

Level. We suggest you read this instruction manual thoroughly before

using the instrument. Save this instruction manual for future use.

This is a Class IIIa laser tool and is manufactured to comply

with CFR 21, parts 1040.10 and 1040.11 as well as international

safety rule IEC 285.

©2010 Johnson Level & Tool - Rev. 1 1

Page 2

3515H-All_Manuals 6/2/10 10:16 AM Page 2

Table of Contents

1. Kit Contents

2. Features and Functions

3. Safety Instructions

4. Location/Content

of Warning Labels

5. Location of Parts/Components

6. Operating Instructions

7. Using the Product

8. Self-Check & Fine Calibration

9. Technical Specifications

10. Application Demonstrations

11. Care and Handling

12. Product Warranty

13. Warranty Registration

14. Accessories

1. Kit Contents

For Model No. 40-6515

Description Qty.

Self- Leveling Rotary Laser Level 1

“AA” Alkaline Batteries 4

Tinted Glasses 1

Instruction Manual with Warranty Card 1

Soft Sided Carrying Case 1

For Model No. 40-6516

Description Qty.

Self- Leveling Rotary Laser Level 1

“AA” Alkaline Batteries 4

Tinted Glasses 1

Detector with 9V Battery and Clamp 1

Instruction Manual with Warranty Card 1

Hard Shell Carrying Case 1

For Model No. 40-6517

Description Qty.

Self- Leveling Rotary Laser Level 1

“AA” Alkaline Batteries 4

Tinted Glasses 1

Detector with “AAA” Batteries and Clamp 1

Magnetic Target 1

Elevating Tripod 1

Wall/Ceiling Mount 1

8’ Grade Rod 1

Instruction Manual with Warranty Card 1

Hard Shell Carrying Case 1

2 ©2010 Johnson Level & Tool - Rev. 1

Page 3

3515H-All_Manuals 6/2/10 10:16 AM Page 3

2. Features and Functions

• Self-leveling with magnetically dampened compensation system.

• If laser is out of its self-leveling range, rotation stops and alarm

sounds.

• Projects a horizontal laser plane.

• Projects a vertical laser plane with a simultaneous 90° split

beam.

• Laser rotation speed is 200 (L), 400 (M), 600 (H) RPM.

• Illuminated vertical vial.

• Water and dust resistant.

3. Safety Instructions

Please read and understand all of the following instructions, prior

to using this tool.

DANGER!

Class IIIa Laser Product

Max. Power Output: ≤ 5mW

Wavelength: 625-645nm

THIS TOOL EMITS LASER RADIATION.

DO NOT STARE INTO BEAM.

AVOID DIRECT EYE EXPOSURE.

©2010 Johnson Level & Tool - Rev. 1 3

Page 4

3515H-All_Manuals 6/2/10 10:16 AM Page 4

ATTENTION IMPORTANT

• Read all instructions prior to operating this laser tool. Do not remove any labels from tool.

• Do not stare directly at the laser beam.

• Do not project the laser beam directly into the eyes of others.

• Do not set up laser tool at eye level or operate the tool near a reflective surface as

the laser beam could be projected into your eyes or into the eyes of others.

• Do not place the laser tool in a manner that may cause someone to unintentionally

look into the laser beam. Serious eye injury may result.

• Do not operate the tool in explosive environments, i.e. in the presence of gases or

flammable liquids.

• Keep the laser tool out of the reach of children and other untrained persons.

• Do not attempt to view the laser beam through optical tools such as telescopes as

serious eye injury may result.

• Always turn the laser tool off when not in use or left unattended for a period of time.

• Remove the batteries when storing the tool for an extended time (more than 3 months)

to avoid damage to the tool should the batteries deteriorate.

• Do not attempt to repair or disassemble the laser tool. If unqualified persons attempt

to repair this tool, warranty will be void.

®

• Use only original Johnson

authorized dealer. Use of non-Johnson®parts and accessories will void warranty.

parts and accessories purchased from your Johnson

®

4 ©2010 Johnson Level & Tool - Rev. 1

Page 5

3515H-All_Manuals 6/2/10 10:16 AM Page 5

4. Location/Content of Warning Labels

©2010 Johnson Level & Tool - Rev. 1 5

Page 6

3515H-All_Manuals 6/2/10 10:16 AM Page 6

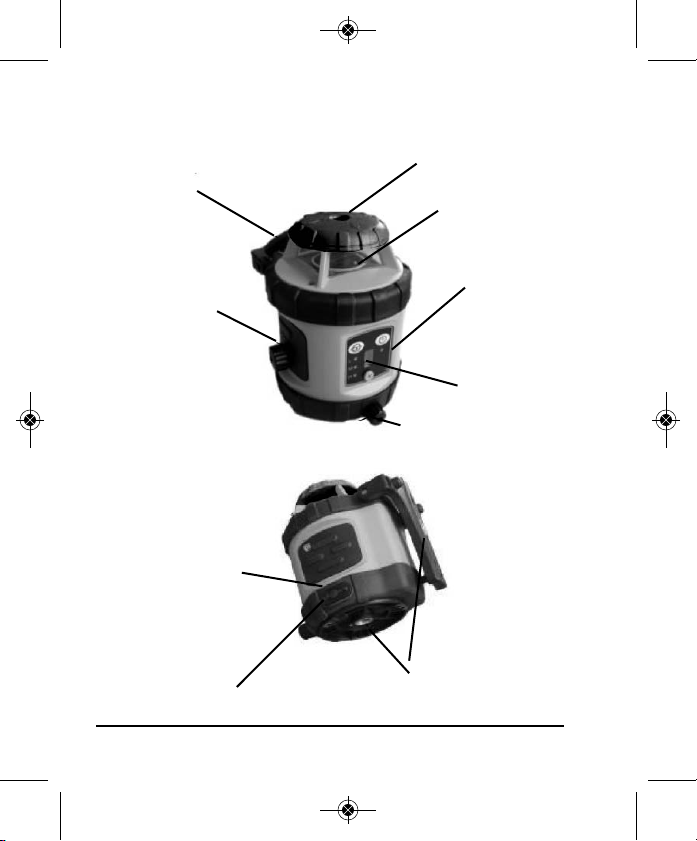

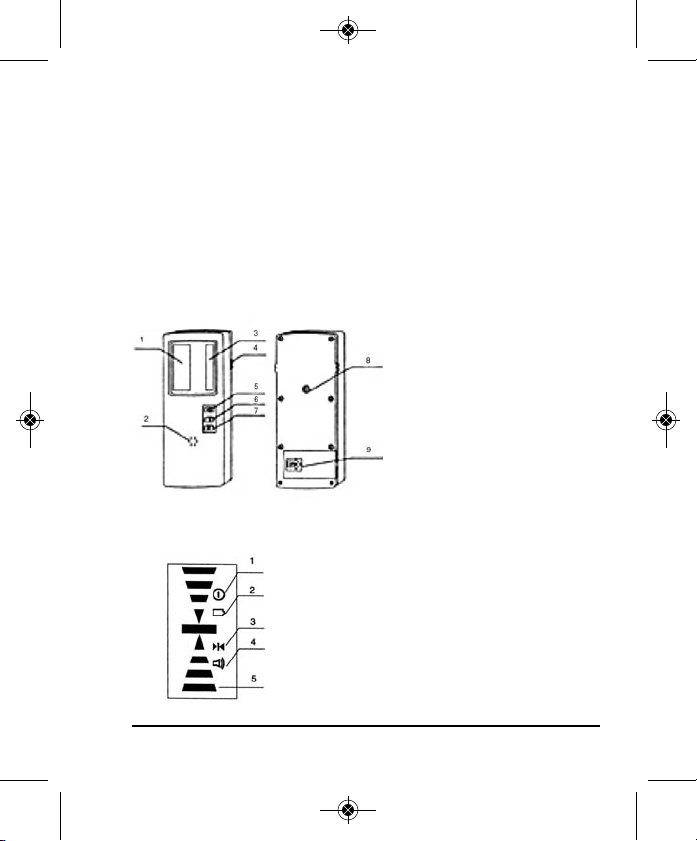

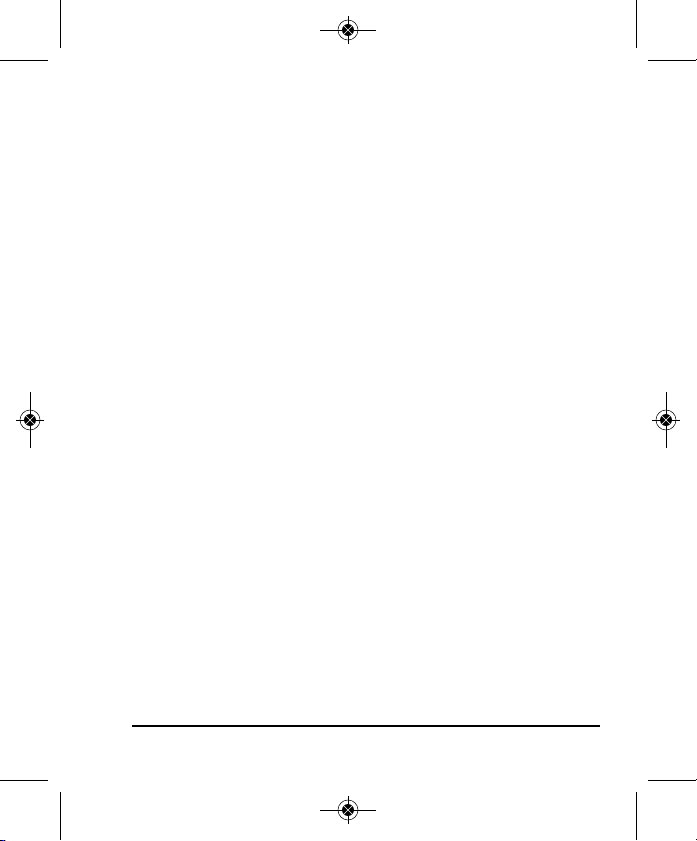

5. Location of Part/Components

Battery Door

Lock Knob –

Compensator/

Transportation

DC 6V Outlet

(6V Adapter not

included)

90° Split Beam Laser

Output Window

Rotating Laser

Output Widow

Keypad

Vertical Vial

Vertical Vial Adjustment

Knob

Charging LED

6 ©2010 Johnson Level & Tool - Rev. 1

5/8” – 11 Screw

Thread

Page 7

3515H-All_Manuals 6/2/10 10:16 AM Page 7

6. Operating Instructions

IMPORTANT: It is the responsibility of the user to verify the

calibration of the laser before each use.

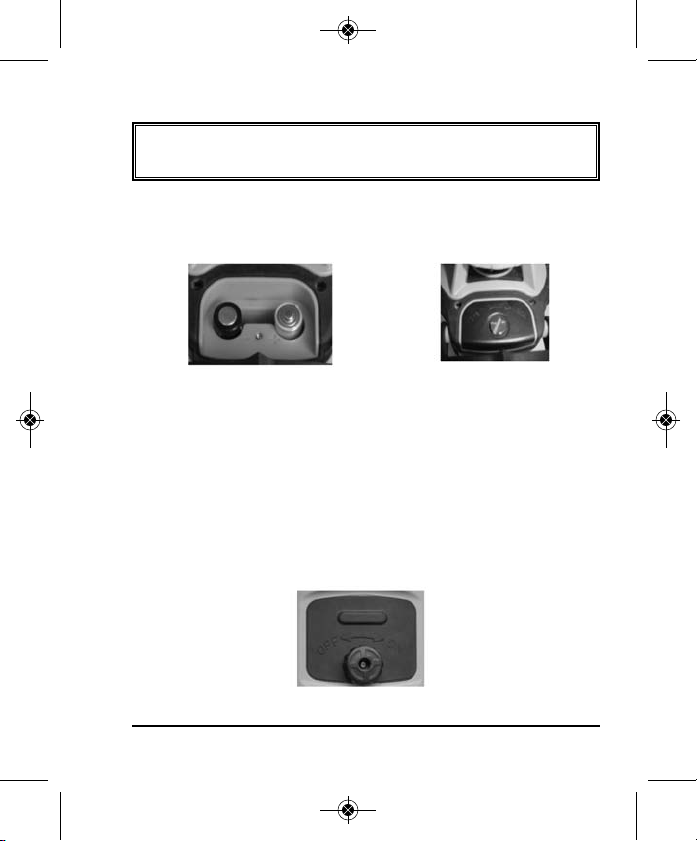

Alkaline Battery Installation

Note: Always check to be sure that the on/off switch is in the off

position before removing and replacing batteries.

1. Install alkaline batteries into the battery case according to the

polarity illustrated in the battery compartment.

2. Place the battery door back and tighten the screw.

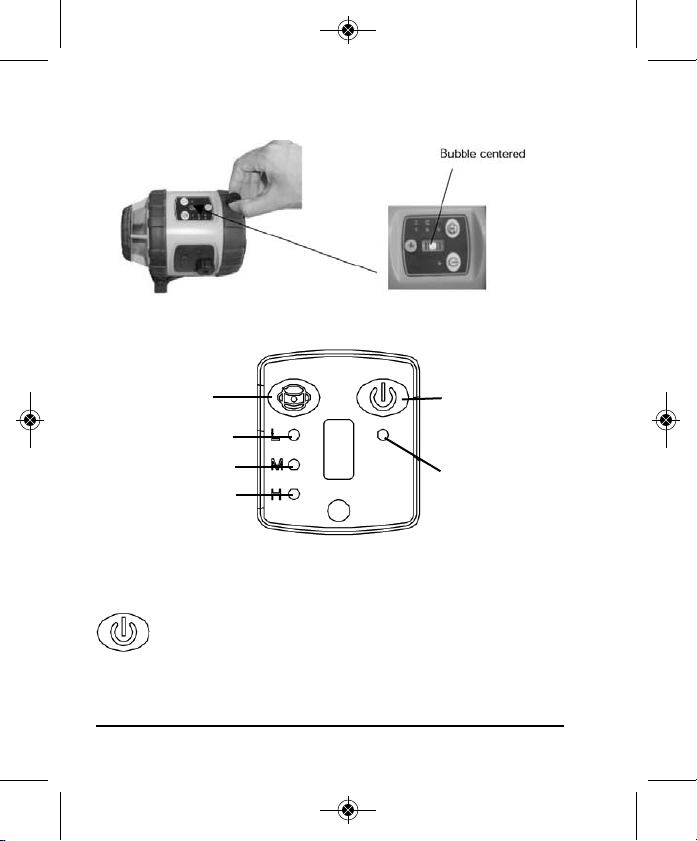

Bubble Adjustment While in Use Vertically

1. Turn the lock knob counter-clockwise to off position to “LOCK” the

compensator. The laser is now operating in a “manual mode”

and is not self-leveling.

©2010 Johnson Level & Tool - Rev. 1 7

Page 8

3515H-All_Manuals 6/2/10 10:16 AM Page 8

2. Turn the vertical adjustment knob to center the bubble in the

vertical vial.

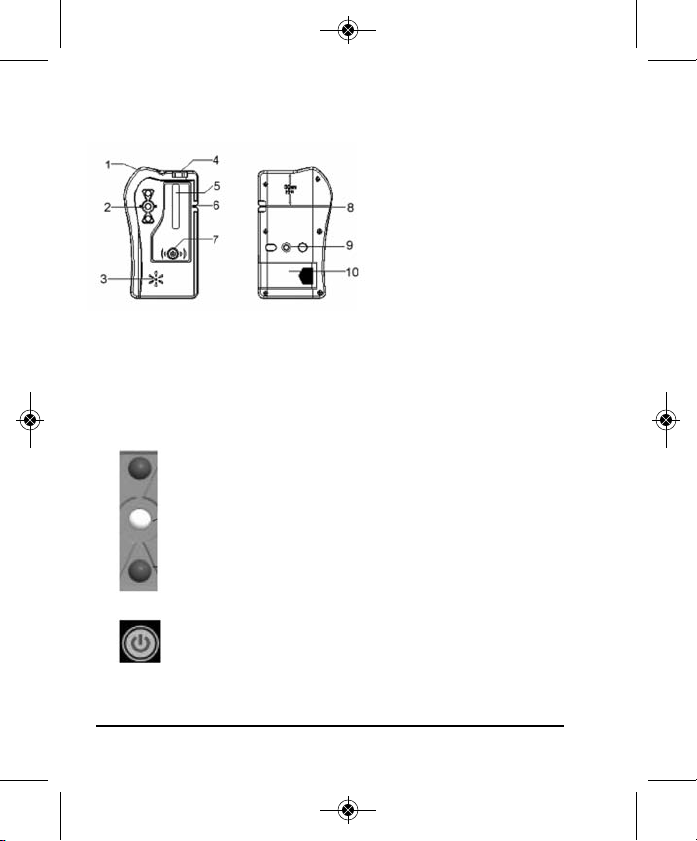

7. Using the Product

Keypad

Rotating speed

switch key

Low speed LED

Middle speed LED

High speed LED

When the laser is in the horizontal position, the laser will not

power on until the compensator/transportation lock knob is

turned to the “On” position.

Power Key

Power LED

Power Key: Press this key to power on/off the laser.

Power LED: Lighted LED mean power-on

Extinguished LED means power-off

Flashing LED means weak battery voltage

8 ©2010 Johnson Level & Tool - Rev. 1

Page 9

3515H-All_Manuals 6/2/10 10:16 AM Page 9

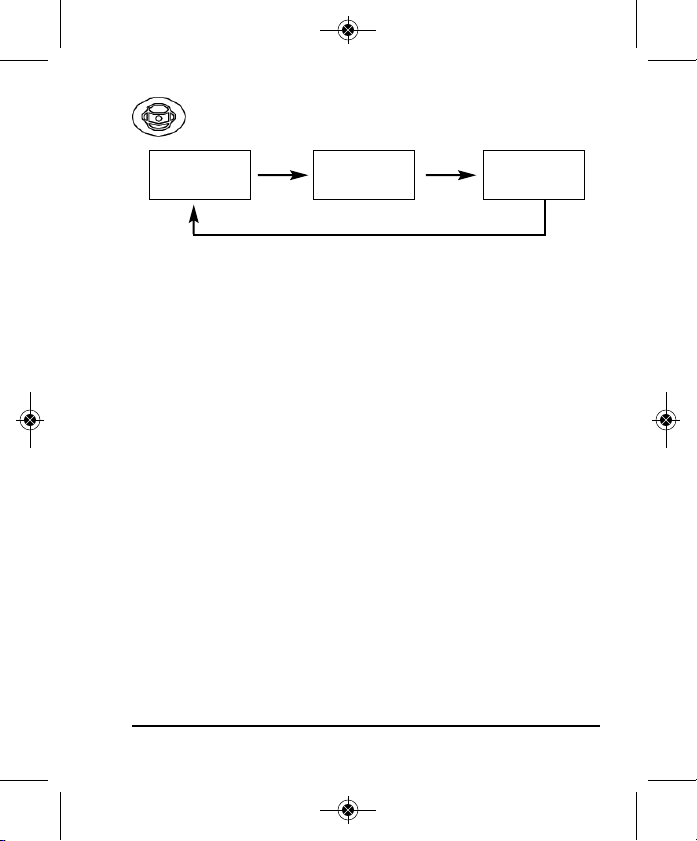

Rotating speed switch key

600 (H)

High speed

Note: When starting the unit, the laser will be in the high-speed rotating status.

When switching the rotating speed, the corresponding LED will light up.

400 (M)

Middle speed

200 (L)

Low speed

Out of Level

Set the lock knob to the on position. Power on. During the process of

self-leveling, if the laser is tilted to exceed its self-leveling range, it

will stop rotating and will give a sound alarm.

©2010 Johnson Level & Tool - Rev. 1 9

Page 10

3515H-All_Manuals 6/2/10 10:16 AM Page 10

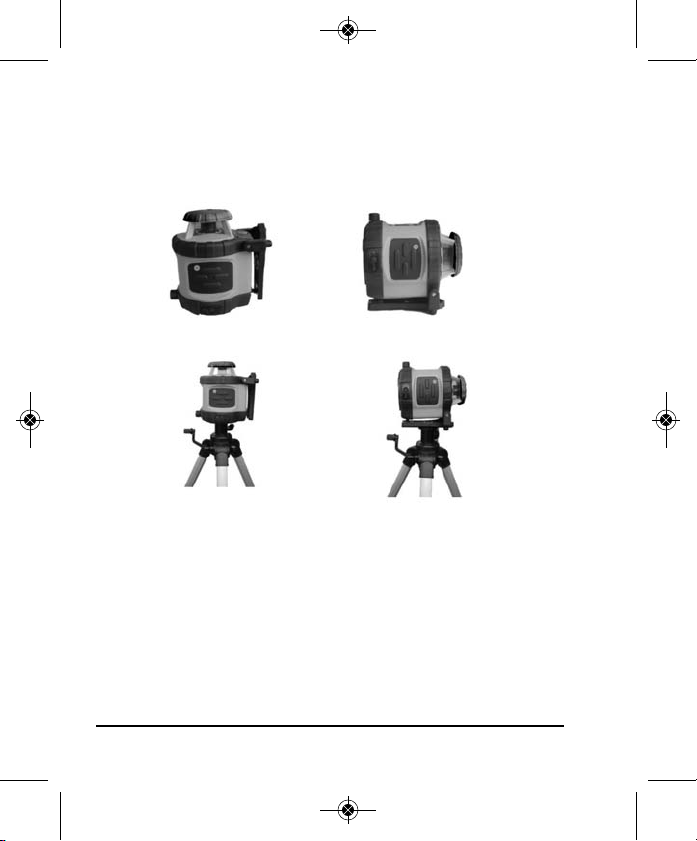

Application Methods

Install the alkaline batteries into the instrument. Put the laser on a

platform or connect the laser to a tripod using the 5/8” - 11 screw

thread.

Use on a platform

Connect the laser with the tripod using the 5/8” - 11 screw thread

Note:

1. To use the laser in the self-leveling status, please set the lock knob

to the on position.

2. While the laser is in the vertical status (manual mode), please set

the lock knob to off position.

3. Power on the laser and select your desired speed by pressing the

keys on the keypad.

4. After operations or before moving the unit, please power off and

lock the laser first.

10 ©2010 Johnson Level & Tool - Rev. 1

Page 11

3515H-All_Manuals 6/2/10 10:16 AM Page 11

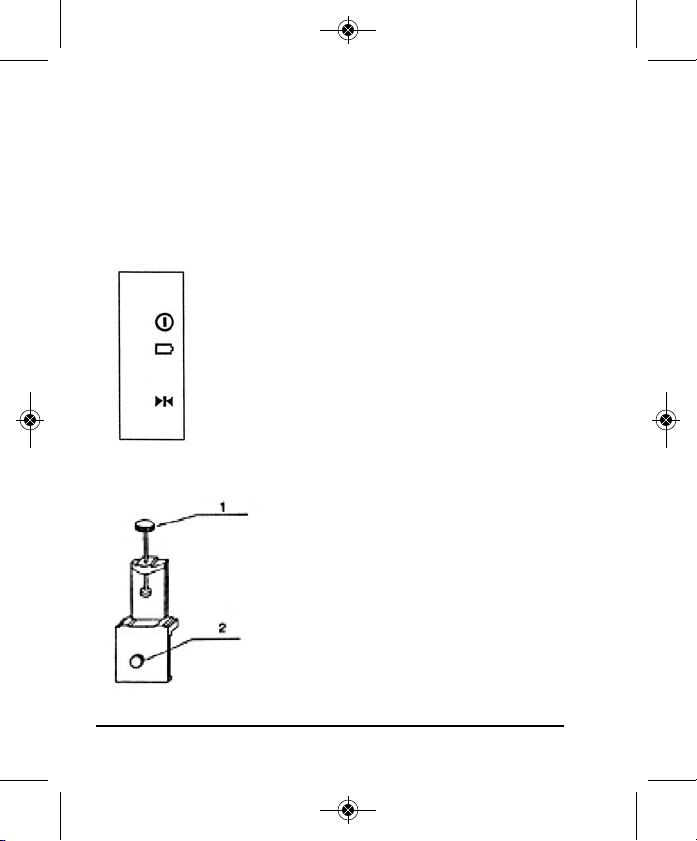

Detector Usage (included in Model No. 40-6516)

1. Technical Specifications

Detecting precision Fine: ±0.039" (±1mm)

Coarse: ±0.098" (±2.5mm)

Turn-off timer 10 minutes

Three types of sound

Size 6.614" x 2.677" x 0.905" (168 X 68 X 23mm)

2. Components

(a) Structure

(b) Display

1. Power symbol

2. Low battery symbol

3. Coarse/Fine detection symbol

4. Sound symbol

5. Detecting position symbol

1. Display window

2. Buzzer

3. Receiving window

4. Reference rabbet

5. Sound button

6. Coarse/Fine detection button

7. Power button

8. Threaded hole

9. Battery-box cap

©2010 Johnson Level & Tool - Rev. 1 11

Page 12

3515H-All_Manuals 6/2/10 10:16 AM Page 12

3. Operation Guide

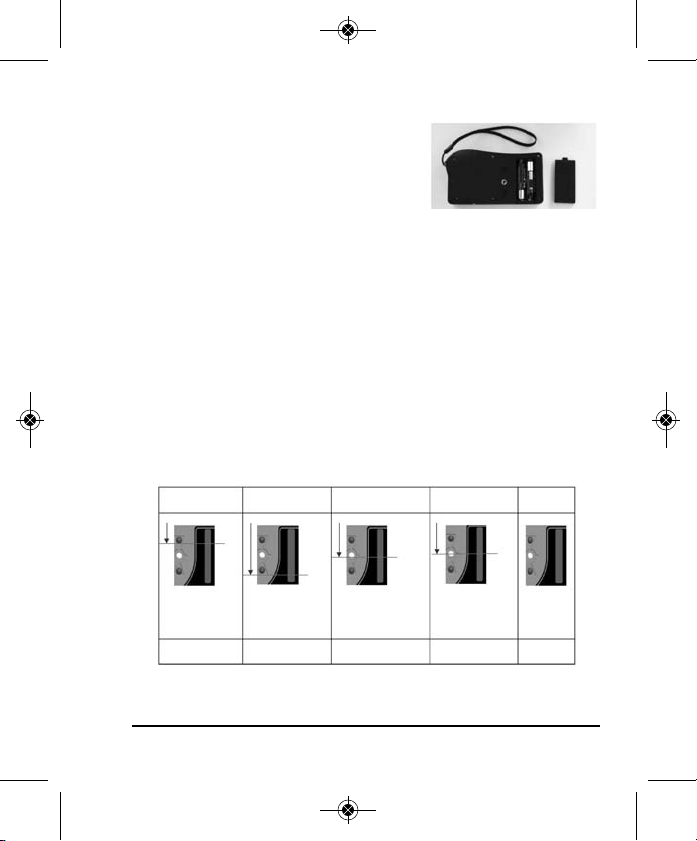

(a) Installation of battery

• Open the battery-box cap and connect the cable inside with the

two polarities of the 9V battery.

Note: Take the battery out if the detector if not used for a long time.

• Put the 9V battery into the battery box and close the battery-box cap.

(b) Turn on/off

• Press the on/off button. When Power symbol is

displayed, the detector is ready for coarse

detection.

• When low battery symbol is displayed, change

the battery.

• Press the on/off button again to turn off the

detector.

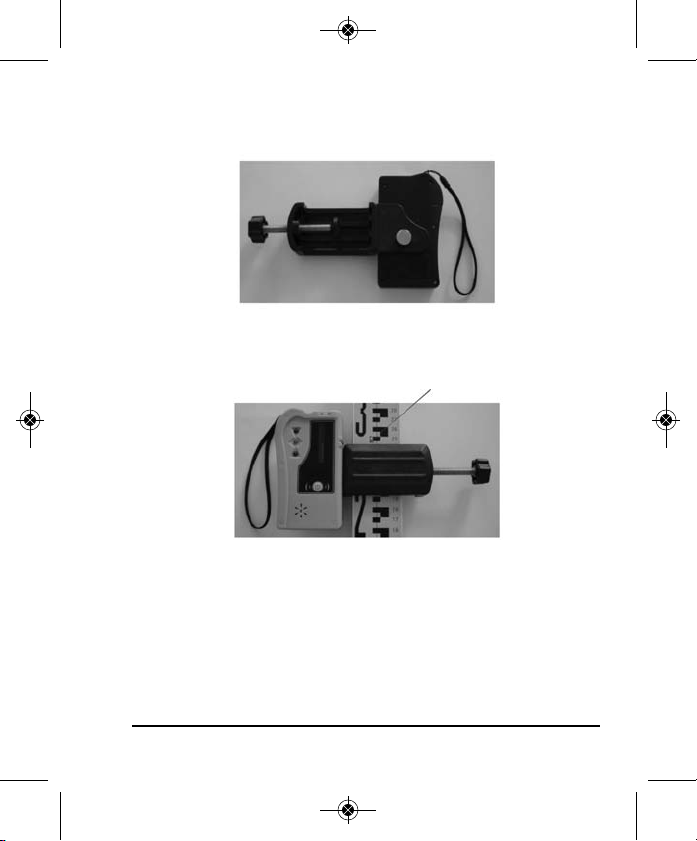

c) Using the clamp holder

1. clamp bolt

2. screw

• Position the detector on the clamp

holder using the screw of the clamp

holder.

• Position the clamp holder on rod

using the clamp bolt of the clamp

holder.

12 ©2010 Johnson Level & Tool - Rev. 1

Page 13

3515H-All_Manuals 6/2/10 10:16 AM Page 13

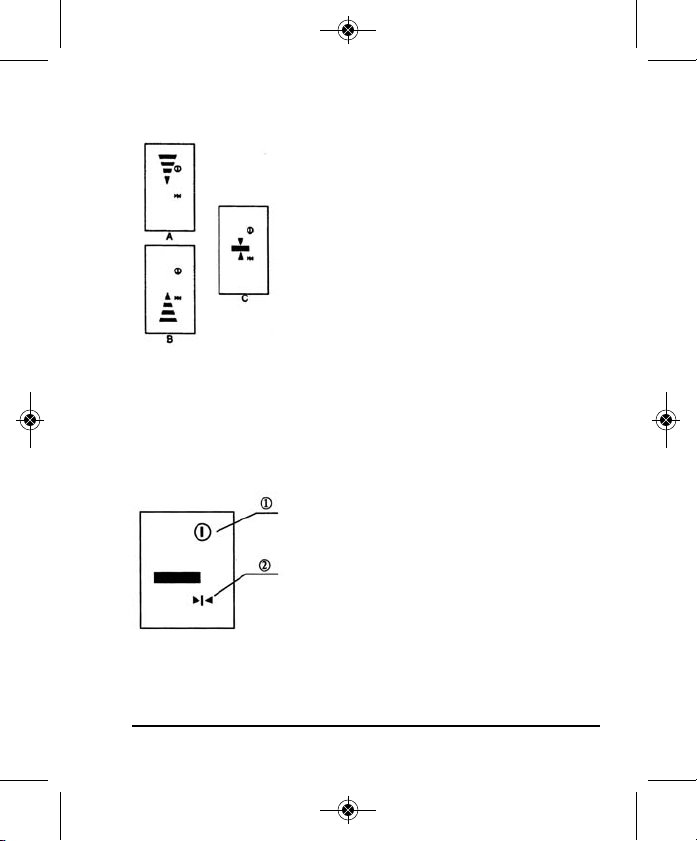

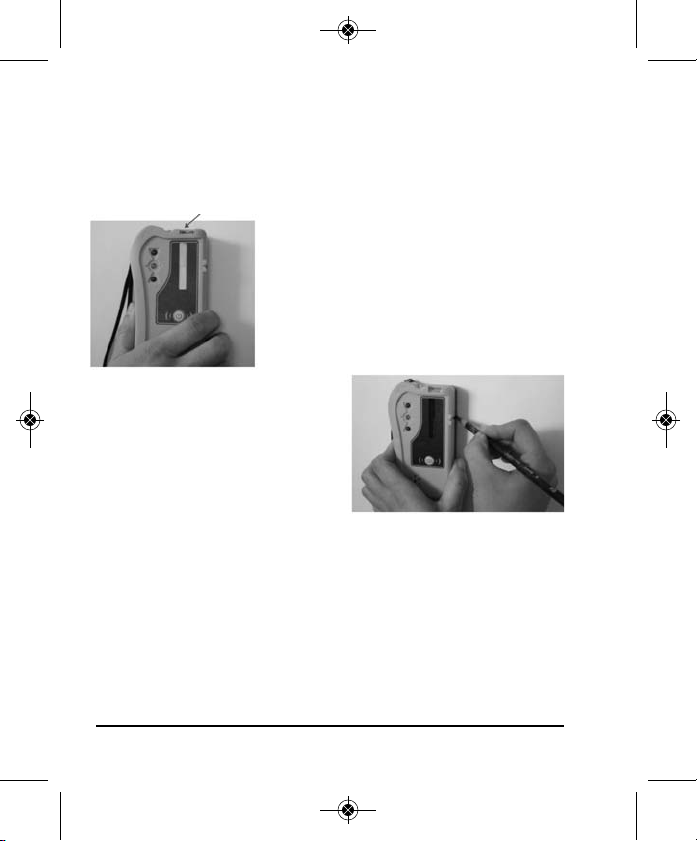

(d) Detection

1. Coarse detection

• Aim the receiving window at the

rotating laser. Loosen the clamp bolt

and move the detector up and down

to receive the laser scanning signals

transmitted by the rotating laser.

• When the detector displays like Fig. (A),

move the detector slightly down as

indicated by the arrow. When it displays

like Fig. (B), move it slightly up as

indicated by the arrow.

• When Fig. (C) is displayed, the detector is level with the rotating

laser beam.

• Tighten the clamp bolt and note the position on the grade rod by the

rabbet. This mark will be the horizontal reference in the coarse mode.

2. Fine detection

1. power symbol

2. fine detection symbol

• Press coarse/fine detection button. The

detector is ready for fine detection.

• Move the detector slightly up and down

like the coarse detection procedure.

Figure 6

• When the detector displays like Fig 6, it is

level with the rotating laser beam.

• Tighten the clamp bolt and note the position on the grade rod by the

rabbet. This mark will be the horizontal reference in the fine detection.

©2009Johnson Level & Tool 13

Page 14

3515H-All_Manuals 6/2/10 10:16 AM Page 14

e) Sound function

• If the detector is working in a circumstance that makes it difficult to

use the display function, the sound function can be used instead.

• Press the sound function button. The sound symbol is displayed

which means it is in sound mode.

• When the sound signal has a rapid sound, move the detector

slightly up.

• When the detector has a short sound, move it slightly down.

• When the detector makes a continuous sound, it is level with the

rotating laser beam.

• If there is no sound heard, the detector is not receiving a laser

signal.

(f) Turn-off timer

• The detector will automatically turn off if it has not received laser

signal for 10 minutes

(g) Detector Maintenance

• When you are done using the detector, return it to its carrying case.

• Keep the detector, particularly the detecting window, clean. If

detector becomes dusty, use a clean cloth to gently wipe it clean.

• Avoid knocking the detector over or allowing it to fall on the

ground.

• Although the detector is rain resistant, you should avoid

submerging the unit in water or other liquids. If the detector

comes into contact with water or other liquids, wipe it dry

immediately.

• Do not use detector around fire or expose it to fire in any way.

14 ©2010 Johnson Level & Tool - Rev. 1

Page 15

3515H-All_Manuals 6/2/10 10:16 AM Page 15

Detector Usage (included in Model No. 40-6517)

1. Technical Specifications

Detecting accuracy: ±1.5mm (<50m) ±2.5mm (>50m)

Turn-off timer 6 min ±1min

Power 2 “AAA” Batteries

Battery life 45 hours of continuous use

Sound function Short sound and solid sound

LED indication Upper red, middle orange, middle green,

down red

Size 4.645” x 2.637” x 0.984”

(118mm x 67mm x 25mm)

Weight 0.253 lbs. (115g)

©2010 Johnson Level & Tool - Rev. 1 15

Page 16

3515H-All_Manuals 6/2/10 10:16 AM Page 16

2. Components

(a) Exterior Instruction

1) Holding Cord

2) Signal Indicator

3) Horn

4) Horizontal Vial

5) Detecting Window

6) Reference Front Marker

7) Power Key

8) Reference Back Marker

9) Connection Port

10) Battery Door

(b) Display

When first turning the detector on, the middle signal

indicator turns red first and then turns green. If the

horn gives two short sounds and the detector powers

off automatically, it means that the battery voltage is

seriously low and it is necessary to replace the battery

immediately. When turning the power on and the down

signal indicator flashes, it means that the battery is low

and it is necessary to replace the battery.

Power Key: Turn on/off the detector

16 ©2010 Johnson Level & Tool - Rev. 1

Page 17

3515H-All_Manuals 6/2/10 10:16 AM Page 17

3. Operation Guide

Battery Installation

1. Open the battery cover and put

the batteries into the battery case

according to the polarity shown in

the battery slot.

2. Slide the battery cover back.

Note: Take the batteries out when the unit is not in use for a

long time.

4. Detecting Methods

1. This detector can detect a red rotating laser beam.

2. Press the Power Key once , the middle signal indicator will

quickly turn red first and then turns green. It will beep once

to indicate that the detector is ON.

While detecting, the signal indicators show as follows:

The lower red

LED is on

Laser Line

The laser beam isupThe laser beam is

Sound: Single short

sound

The upper red

LED is on

Laser Line

down

Sound: Single short

sound

The middle LED

is orange

Laser Line

The laser beam is close

to center

Sound: Single short

sound

The middle LED

is green

Laser Line

The laser beam is

exactly to center

Sound: Solid sound Sound:

All LEDs

are off

No laser

beam is

detected

No Sound

©2010 Johnson Level & Tool - Rev. 1 17

Page 18

3515H-All_Manuals 6/2/10 10:16 AM Page 18

Note:

1. While detecting a horizontal laser beam, it is necessary to

have the horizontal bubble vial centered, as the tilt of the

detector will influence its receiving accuracy.

Horizontal Vial

2. Keep the detecting window facing

the rotating laser.

3. Keep the detector still while

detecting the laser beam

4. When the laser beam is centered,

mark at the front reference marker.

5. When the detector does not

receive a laser signal for 6

minutes, and there are no

buttons pushed during these

6 minutes, the middle signal

indicator will turn green first

and then turn red. The horn

will give two short sounds and

the detector will power off automatically.

18 ©2010 Johnson Level & Tool - Rev. 1

Page 19

3515H-All_Manuals 6/2/10 10:16 AM Page 19

5. Accessories Usage

• Connecting to the grade rod bracket

• Connecting to the grade rod

©2010 Johnson Level & Tool - Rev. 1 19

Page 20

3515H-All_Manuals 6/2/10 10:16 AM Page 20

6. Maintenance

• Keep the detector, particularly the detecting window, clean. If unit

becomes dusty, use a clean cloth to gently wipe it clean.

• Avoid knocking the detector over or allowing it to fall on the

ground.

• Although the detector is rain resistant, you should avoid

submerging the unit in water or other liquids. If detector comes

into contact with water or other liquids, wipe it dry immediately.

• Do not use detector around fire or expose it to fire in any way.

20 ©2010 Johnson Level & Tool - Rev. 1

Page 21

3515H-All_Manuals 6/2/10 10:16 AM Page 21

8. Self-Check and Calibration

IMPORTANT: It is the responsibility of the user to verify the

calibration of the instrument before each use.

25’

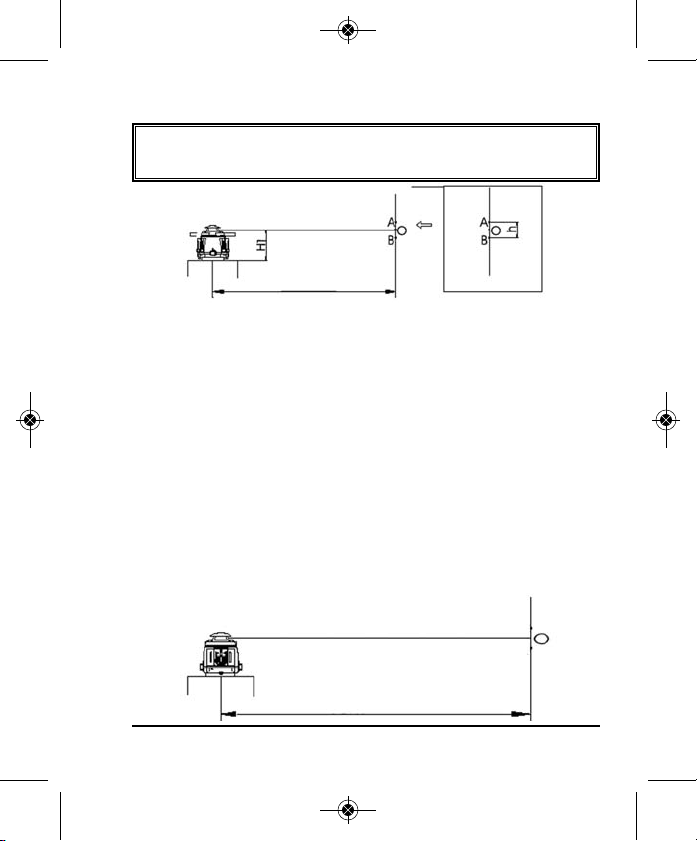

X&Y-Direction Accuracy Self-Check

1. Note X & Y-direction as indicated on top of laser.

2. Place the laser on a platform that is 25’ away from a wall

indoors. Position the laser so the X-direction is facing the

wall. Unlock the laser and set to low speed.

3. Mark on the wall where the beam hits the wall and mark that as A.

(Note: This test should be done indoors with dim lighting. It’s

critical that the laser mark is easily seen.)

4. Turn the laser by 180 degrees, mark the beam as point B.

5. Measure the vertical distance between point A and point B. If A &

B are more than 1/16” apart at 25’, the laser is out of calibration.

A

B

25’

©2010 Johnson Level & Tool - Rev. 1 21

Page 22

3515H-All_Manuals 6/2/10 10:16 AM Page 22

6. Turn the laser 90° and place it on the platform. Position the

laser so the Y-direction is facing the wall. Perform Y-direction

self-check with the same method as X-direction self-check,

and mark point C and point D by turns.

7. If point C and point D are within 1/16” at 25’, the accuracy is

within tolerance.

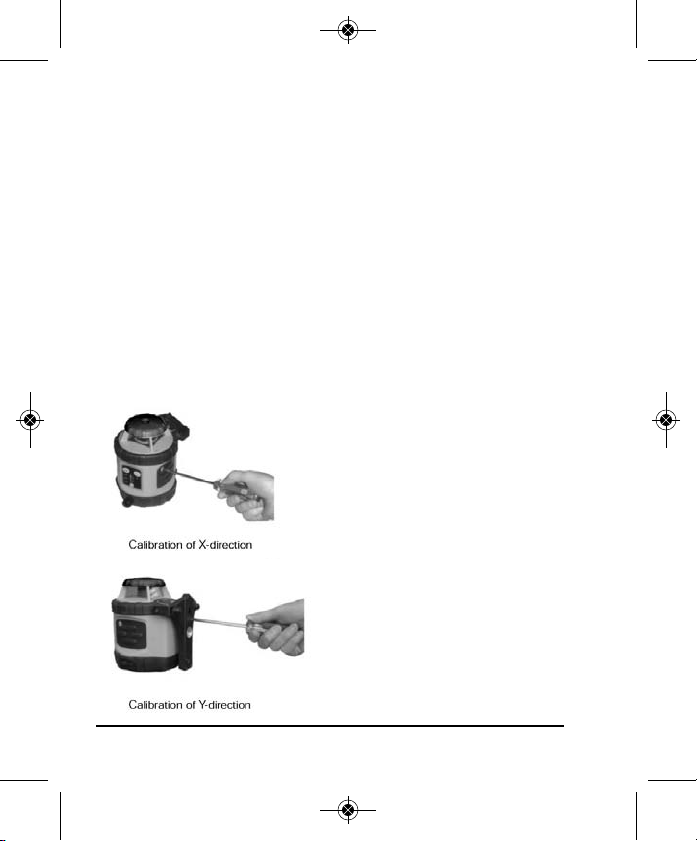

Accuracy Calibration

1. As shown in the following figures, screw off the adjustment-hole

bolt with the cross screwdriver, and adjust the fine-adjustment

bolt in the instrument core with a flat head screwdriver until the

laser line in within 1/8” at 50’.

2. Adjust the X-direction and the Y-direction with the same method.

Note: The laser should be turned off and the compensator

must be locked prior to making any

adjustments. If the accuracy is

beyond tolerance, calibrate the

X-direction through the adjustment

hole as shown.

3. After X is calibrated, rotate the

instrument 90º to calibrate the Ydirection.

Note: The alkaline batteries

must be removed to access the

instrument core with a flat head

screwdriver.

4. Reinstall the adjustment-hole bolt.

22 ©2010 Johnson Level & Tool - Rev. 1

Page 23

3515H-All_Manuals 6/2/10 10:16 AM Page 23

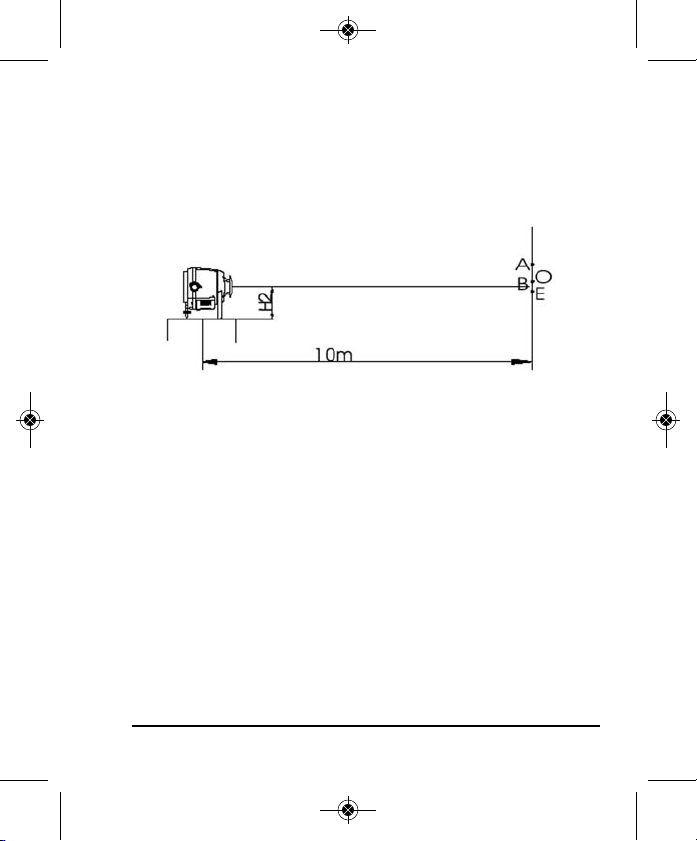

Accuracy Self-Check for Vertical Output Status

1. Follow the prior operations, and measure the distance H1

between the laser rotating plane and the platform surface.

2. Set the locking knob to locking position, and place the instrument

horizontally.

3. Adjust the adjusting screw to center the bubble.

4. Measure the distance H2 between the top laser beam and the

platform surface.

5. Mark out E in the position that is (H1 –H2 ) lower than point 0.

6. If e – point 0 < 0.394" (10mm), the accuracy is within tolerance.

Vertical Bubble Calibration

1. Use a screwdriver to screw out the bubble-adjustment-hole bolt.

2. Insert the Allen wrench into the adjustment hole to adjust the

Allen screw.

3. Rotate the Allen wrench to center the bubble.

4. After adjustment operation, please install the bubble-adjustmenthole bolt back to its original position.

Wall

©2010 Johnson Level & Tool - Rev. 1 23

Page 24

3515H-All_Manuals 6/2/10 10:16 AM Page 24

Screw off the self-calibration-hole bolt

Calibrate the bubble

Note: If you fail to calibrate the accuracy according to the above

steps, please contact Johnson Level & Tool for service.

9. Technical Specifications

Laser Wavelength 635nm±10nm

Laser Classification Class IIIa

Maximum Power Output ≤5mW

Accuracy ±1/8"/50 ft. (±2mm/10m)

Interior Range Up to 200 ft (60m) diameter depending

upon light conditions

Exterior Range Up to 800 ft (240 m) diameter with detector

Self-Leveling Range ±3°

Power Supply 4 “AA” alkaline batteries (included)

Battery Life Approx. battery life 20 hours continuous use

Dimensions 5” x 6 1/2” x 6 1/2” (126x170x168mm)

Weight 3.3 lbs (1.5 Kg)

Working Temperature 14°F to 113°F (-10°C to +45°C)

Center screw thread 5/8" – 11

Rotation Speed 200 rpm, 400 rpm, 600 rpm

IP protection class 54

24 ©2010 Johnson Level & Tool - Rev. 1

Page 25

3515H-All_Manuals 6/2/10 10:16 AM Page 25

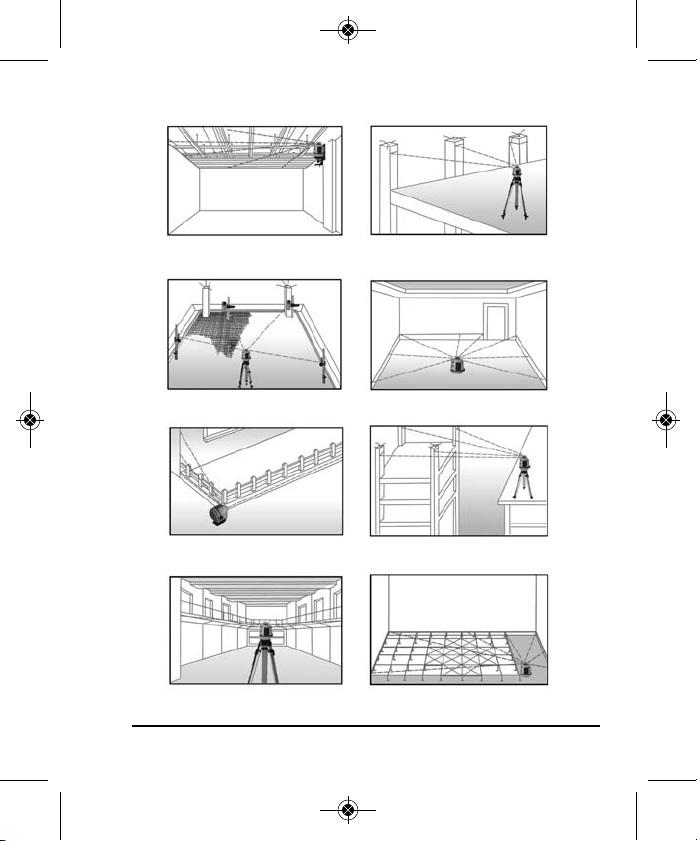

10. Application Demonstrations

Ceiling installation

Squaring and leveling

Fence installation

Window installation

©2010 Johnson Level & Tool - Rev. 1 25

Wall or footing

construction

Baseboard installation

Cement floor installation

Anti-static flooring

installation

Page 26

3515H-All_Manuals 6/2/10 10:16 AM Page 26

11. Care and Handling

•This laser unit is a precision tool that must be handled with care.

•Avoid exposing unit to shock vibrations and extreme temperatures.

•Before moving or transporting the unit, make sure that the unit is

turned off.

•Remove the batteries when storing the unit for an extended time

(more than three months) to avoid damage to the unit should the

batteries deteriorate.

•Always store the unit in its case when not in use.

•Avoid getting the unit wet.

•Keep the laser unit dry and clean, especially the laser output

window. Remove any moisture or dirt with a soft, dry cloth.

•Do not use harsh chemicals, strong detergents or cleaning solvents

to clean the laser unit.

12. Product Warranty

Johnson Level & Tool offers a three year limited warranty on each of its

products. You can obtain a copy of the limited warranty for a Johnson

Level & Tool product by contacting Johnson Level & Tool's Customer

Service Department, as provided below, or by visiting our web site at

www.johnsonlevel.com. The limited warranty for each product

contains various limitations and exclusions.

Do not return this product to the store/retailer or place of purchase.

Non-warranty repairs and course calibration must be done by an

authorized Johnson

®

service center or Johnson Level & Tool's limited

warranty, if applicable, will be void and there will be NO WARRANTY.

Contact one of our service centers for all non-warranty repairs. A list

26 ©2010 Johnson Level & Tool - Rev. 1

Page 27

3515H-All_Manuals 6/2/10 10:16 AM Page 27

of service centers can be found on our web site at www.johnsonlevel.com

or by calling our Customer Service Department. Contact our

Customer Service Department for Return Material Authorization (RMA)

for warranty repairs (manufacturing defects only). Proof of purchase

is required.

NOTE: The user is responsible for the proper use and care of the

product. It is the responsibility of the user to verify the calibration of the

instrument before each use.

For further assistance, or if you experience problems with this product

that are not addressed in this instruction manual, please contact our

Customer Service Dept.

In the U.S., contact Johnson Level & Tool’s Customer Service

Department at 888-9-LEVELS.

In Canada, contact Johnson Level & Tool’s Customer Service

Department at 800-346-6682.

13. Warranty Registration

Enclosed with this instruction manual you will find a warranty

registration card to be completed for your product. You will need to

locate the serial number for your product that is located on the bottom

of the unit. PLEASE NOTE THAT IN ADDITION TO ANY OTHER

LIMITATIONS OR CONDITIONS OF JOHNSON LEVEL & TOOL'S

LIMITED WARRANTY, JOHNSON LEVEL & TOOL MUST HAVE

RECEIVED YOUR PROPERLY COMPLETED WARRANTY CARD AND

PROOF OF PURCHASE WITHIN 30 DAYS OF YOUR PURCHASE OF

THE PRODUCT OR ANY LIMITED WARRANTY THAT MAY APPLY

SHALL NOT APPLY AND THERE SHALL BE NO WARRANTY.

©2010 Johnson Level & Tool - Rev. 1 27

Page 28

3515H-All_Manuals 6/2/10 10:16 AM Page 28

14. Accessories

Johnson®accessories are available for purchase through authorized

®

Johnson

applicable limited warranty and there will be NO WARRANTY. If you need

any assistance in locating any accessories, please contact our

Customer Service Department.

In the U.S., contact Johnson Level & Tool’s Customer Service

Department at 888-9-LEVELS.

In Canada, contact Johnson Level & Tool’s Customer Service

Department at 800-346-6682.

dealers. Use of non-Johnson®accessories will void any

28 ©2010 Johnson Level & Tool - Rev. 1

Page 29

3515H-All_Manuals 6/2/10 10:16 AM Page 29

Nivel láser giratorio autonivelante

Modelo N° 40-6515, 40-6516 y 40-6517

Manual de instrucciones

Felicitaciones por haber elegido este nivel láser giratorio con autonivelación.

Sugerimos leer detalladamente este manual de instrucciones antes de

utilizar el instrumento. Guarde este manual de instrucciones para uso futuro.

Ésta es una herramienta láser de Clase IIIa y se fabrica en

acatamiento con las partes 1040.10 y 1040.11 de CFR 21, así como

con la regla internacional de seguridad IEC 285.

©2010 Johnson Level & Tool - Rev. 1 29

Page 30

3515H-All_Manuals 6/2/10 10:16 AM Page 30

Índice

1. Contenido del Kit

2. Características y Funciones

3. Instrucciones de Seguridad

4. Ubicación y Contenido de las

Etiquetas de Advertencia

5. Ubicación de las Piezas y

Componentes

6. Instrucciones de Operación

7. Cómo Utilizar el producto

8. Autocomprobación y

calibración fina

9. Especificaciones Técnicas

10. Demostraciones de Aplicación

11. Cuidado y Manipulación

12. Garantía del Producto

13. Registro de la garantía

14. Accesorios

1. Contenido del Kit

Modelo No. 40-6515

Descripción

Nivel láser giratorio con autonivelación 1

"AA" Baterías Alcalinas 4

Gafas con tinte 1

Manual de instrucciones con tarjeta de garantía 1

El Esqueleto suave que Lleva el Caso 1

Modelo No. 40-6516

Descripción Cant.

Nivel láser giratorio con autonivelación 1

"AA" Baterías Alcalinas 4

Gafas con tinte 1

Detector con batería de 9 voltios y pinza de conexión rápida 1

Manual de instrucciones con tarjeta de garantía 1

Estuche de transporte de costados rígidos 1

Modelo No. 40-6517

Descripción

Nivel láser giratorio con autonivelación 1

"AA" Baterías Alcalinas 4

Gafas con tinte 1

Detector con baterías “AAA” y abrazadera 1

Diana magnética 1

Trípode para elevación 1

Montaje en techo y en pared 1

Estadal de 8’ (2,4 metros) 1

Manual de instrucciones con tarjeta de garantía 1

Estuche de transporte de costados rígidos 1

30 ©2010 Johnson Level & Tool - Rev. 1

Cant.

Cant.

Page 31

3515H-All_Manuals 6/2/10 10:16 AM Page 31

2. Características y funciones

• De nivelación automática con sistema de compensación de

amortiguación magnética.

• Si el láser está fuera del rango de nivelación automática, la

rotación se detiene y suena la alarma.

• Proyecta un plano láser horizontal.

• Proyecta un plano láser vertical con un rayo dividido a 90°

simultáneo.

• La velocidad de rotación del láser es de 200 (L), 400 (M),

600 (H) RPM.

• Ampolla vertical iluminada.

• Resistente al agua y al polvo.

3. Instrucciones de seguridad

Sírvase leer y comprender todas las instrucciones siguientes antes

de utilizar esta herramienta. Si no lo hace, podrían producirse

lesiones corporales.

¡PELIGRO!

Producto láser de Clase IIIa

Máxima salida de potencia: ≤ 5mW

Longitud de onda: 625-645nm

ESTA HERRAMIENTA EMITE RADIACIÓN LÁSER

NO MIRE DIRECTAMENTE AL HAZ

EVITE LA EXPOSICIÓN OCULAR DIRECTA

©2010 Johnson Level & Tool - Rev. 1 31

Page 32

3515H-All_Manuals 6/2/10 10:16 AM Page 32

ATTENTION IMPORTANT

• Lea todas las instrucciones antes de operar esta herramienta láser. No quite ninguna etiqueta de la herramienta.

• No mire directamente al rayo láser.

• No proyecte el rayo láser directamente a los ojos de otras personas.

• No ajuste la herramienta láser al nivel de los ojos ni opere la herramienta cerca de

una superficie reflectiva ya que el rayo láser puede ser proyectado a sus ojos o a

los ojos de otras personas.

• No ubique la herramienta láser de manera que pueda causar que alguien mire sin

intención hacia el rayo láser. Se puede provocar una lesión grave en la vista.

• No opere la herramienta en ambientes explosivos, es decir en la presencia de gases

o líquidos inflamables.

• Mantenga la herramienta láser fuera del alcance de los niños o de personas no capacitadas.

• No intente ver el rayo láser a través de herramientas ópticas como telescopios

porque se puede provocar una lesión grave en la vista.

• Siempre apague la herramienta láser cuando no la utiliza o no la supervisa por un

período de tiempo.

• Retire las baterías cuando guarda la herramienta por un período largo (más de 3 meses)

para evitar que se dañe la herramienta si se deterioran las baterías.

• No intente reparar ni desarmar la herramienta láser. Si una persona no calificada

intenta reparar esta herramienta, se anulará la garantía.

• No procure reparar ni desmontar el instrumento del láser. Si personas sin título

procuran reparar este instrumento, la garantía será vacío.

32 ©2010 Johnson Level & Tool - Rev. 1

Page 33

3515H-All_Manuals 6/2/10 10:16 AM Page 33

4. Ubicación y contenido de las etiquetas

de advertencia

ESTA HERRAMIENTA EMITE

RADIACIÓN LÁSER.

NO MIRE FIJAMENTE AL RAYO.

EVITE LA EXPOSICIÓN DIRECTA

A LOS OJOS.

Producto Láser de Clase IIIa

Salida Máxima de Corriente: 5mW

Longitud de Onda: 625-645nm

Este Producto cumple con los

requerimientos aplicables de 21

CFR parts 1040.10 y 1040.11.

©2010 Johnson Level & Tool - Rev. 1 33

Page 34

3515H-All_Manuals 6/2/10 10:16 AM Page 34

5. Ubicación de piezas y componentes

Puerta de

Compartimiento

de las Baterías

Perilla de Seguro –

Compensador/

Transporte

Salida de 6V CC

(el Adaptador de

6V no se incluye)

Ventana de Salida del

Láser de Rayo Divido

a 90°

Ventana de

Salida del Láser

de Rotación

Teclado

Ampolla

Vertical

Perilla de Ajuste de la

Ampolla Vertical

LED de carga

34 ©2010 Johnson Level & Tool - Rev. 1

Tornillo de 5/8” – 11

Page 35

3515H-All_Manuals 6/2/10 10:16 AM Page 35

6. Instrucciones de operación

IMPORTANTE: Es responsabilidad del usuario verificar la cali-

bración del instrumento antes de cada uso.

Instalación de Baterías Alcalinas

Nota: Siempre compruebe que el interruptor de encendido/apagado

esté en la posición de apagado antes de retirar y reemplazar las baterías.

1. Instale baterías alcalinas en el estuche de baterías de acuerdo

con la polaridad que se muestra en el compartimiento de baterías.

2. Vuelva a colocar la puerta de compartimiento de las baterías y ajuste

el tornillo.

Ajuste de Burbuja Mientras el Instrumento está en Uso

Verticalmente

1. Gire la perilla de seguro en el sentido contrario al de las agujas

del reloj a la posición de apagado (off) para bloquear (lock) el

compensador. El láser está operando ahora en “modo

manual” y no está en modo autonivelante.

©2010 Johnson Level & Tool - Rev. 1 35

Page 36

3515H-All_Manuals 6/2/10 10:16 AM Page 36

2. Gire la perilla de ajuste vertical para central la burbuja en la

ampolla vertical.

Burbuja centrada

7. Uso del producto

Teclado

Tecla de interruptor de velocidad

de rotación

LED de baja velocidad

LED de velocidad

intermedia

LED de alta velocidad

Cuando el láser no esté en la posición horizontal, éste no encenderá

hasta que el compensador/perilla de seguro para transporte se gire

a la posición “On” (encendido).

Botón de encendido: Oprima esta tecla para encender y

apagar el láser.

LED de El LED Encendido significa que el instrumento está

encendido: encendido

El LED Apagado significa que el instrumento está apagado

El LED que emite destellos significa que la tensión de

las baterías es baja

36 ©2010 Johnson Level & Tool - Rev. 1

Tecla de

encendido

LED de

encendido

Page 37

3515H-All_Manuals 6/2/10 10:16 AM Page 37

Tecla de interruptor de velocidad de rotación

600 (H)

velocidad alta

Aviso: Al arrancar la unidad, el láser estará en el estado de rotación de alta

velocidad. Cuando cambie la velocidad de rotación, el LED correspondiente

se encenderá.

400 (M)

velocidad

intermedia

200 (L)

velocidad baja

Fuera de Nivel

Fije la perilla de seguro en la posición de encendido (on). Encendido.

Durante el proceso de nivelación automática, si el láser se inclina y

supera su rango de nivelación automática, dejará de rotar y activará una

alarma sonora.

©2010 Johnson Level & Tool - Rev. 1 37

Page 38

3515H-All_Manuals 6/2/10 10:16 AM Page 38

Métodos de Aplicación

Instale las baterías alcalinas en el instrumento. Ponga el láser

en una plataforma o conéctelo a un trípode utilizando el tornillo

de 5/8” - 11.

Utilícelo en una plataforma

Una el instrumento al trípode utilizando el tornillo de 5/8” - 11

Aviso:

1. Para utilizar el láser en el estado de nivelación automática, ponga

la perilla de seguro en la posición de encendido (on).

2. Mientras el láser está en el estado vertical (modo manual), ponga

la perilla de seguro en la posición de apagado (off).

3. Encienda el láser y seleccione la velocidad deseada al oprimir las

teclas del teclado.

4. Después de las operaciones o antes de mover la unidad, apague y

asegure el láser primero.

38 ©2010 Johnson Level & Tool - Rev. 1

Page 39

3515H-All_Manuals 6/2/10 10:16 AM Page 39

Uso del detector (incluido en el modelo no. 40-6516)

1. Especificaciones técnicas

Detección de la precisión Fina: ± 0.012"/pie (± 1mm)

Gruesa: ±0.030"/pie (±2.5mm)

Cronómetro de apagado 10 minutos

Tres tipos de sonidos

Tamaño 6.614" x 2.677" x 0.905" (168 X 68 X 23mm)

2. Componentes

(a) Estructura

1. Ventana de visualización

2. Zumbador

3. Ventana de recepción

4. Rebajo de referencia

5. Botón de sonido

6. Botón de detección gruesa/fina

7. Botón de encendido

8. Orificio roscado

9. Tapa de la caja de baterías

(b) Pantalla

1. Símbolo de potencia

2. Símbolo de batería con poca carga

3. Símbolo de detección gruesa/fina

4. Símbolo de sonido

5. Símbolo de posición de detección

©2010 Johnson Level & Tool - Rev. 1 39

Page 40

3515H-All_Manuals 6/2/10 10:16 AM Page 40

3. Guía de operación

(a) Instalación de la batería

• Abra la tapa de la caja de batería y conecte el cable en su

interior con las dos polaridades de una batería de 9 V.

Aviso: Retire la batería si el detector no se va a usar durante un

tiempo prolongado.

• Ponga la batería de 9 V en la caja de la batería y cierre la tapa de la

caja de la batería.

(b) Encendido / apagado

• Presione el botón de encendido/apagado. Cuando

se muestra el símbolo de encendido/apagado, el

detector está listo para la detección basta.

• Cuando aparece el símbolo de batería con poca

carga, cambie la batería.

• Presione el botón de encendido/apagado para

apagar el detector.

c) Uso del soporte de sujeción

1. perno de sujeción

2. tornillo

• Coloque el detector en el soporte de

sujeción con el tornillo del perno de

sujeción.

• Coloque el soporte de sujeción en la

varilla con el perno de sujeción del

soporte de sujeción.

40 ©2010 Johnson Level & Tool - Rev. 1

Page 41

3515H-All_Manuals 6/2/10 10:16 AM Page 41

(d) Detección

1. Detección basta

• Apunte la ventana receptora hacia el láser

giratorio. Afloje el perno de sujeción y mueva

el detector hacia arriba y hacia abajo para

recibir las señales de escaneo del láser

transmitidas por el láser de rotación.

• Cuando el detector se muestra como la fig. (A),

mueva levemente el detector hacia abajo como

indica la flecha. Cuando se muestra como la

fig. (B), muévalo levemente hacia arriba como

indica la flecha.

• Cuando se muestra la fig. (C), el detector se nivela con el rayo láser

giratorio.

• Ajuste el perno de sujeción y marque la posición en el estadal con la ranura. Esta marca será la referencia horizontal del modo de detección basta.

2. Detección fina

1. símbolo de encendido/apagado

2. símbolo de detección fina

• Presione el botón de detección basta/fina. El

detector está listo para realizar la detección fina.

• Mueva el instrumento levemente hacia

abajo y hacia arriba, al igual que en el

procedimiento de detección basta.

Figura 6

• Cuando el detector muestre como la fig. (6),

éste se nivela con el rayo láser giratorio.

• Ajuste el perno de sujeción y marque la posición en el estadal con la

ranura. Esta marca será la referencia horizontal de la detección fina.

©2010 Johnson Level & Tool - Rev. 1 41

Page 42

3515H-All_Manuals 6/2/10 10:16 AM Page 42

e) Función de sonido

• Si el detector funciona de forma tal de que es difícil usar la función

de visualización, se puede usar la función de sonido en su lugar.

• Presione el botón de la función de sonido. Se muestra el símbolo

de sonido, lo que significa que está en modo de sonido.

• Cuando la señal de sonido emita un sonido rápido, mueva el

detector levemente hacia arriba.

• Cuando el detector emita un sonido corto, muévalo levemente

hacia abajo.

• Cuando el detector emita un sonido continuo, está nivelado con el

rayo láser giratorio.

• Si no se escucha ningún sonido, el detector no recibe la señal del

láser.

(f) Cronómetro de apagado

• El detector se apagará automáticamente si no recibe una señal de

láser durante 10 minutos.

(g) Mantenimiento del detector

• Cuando termine de usar el detector, colóquelo nuevamente en su

estuche.

• Mantenga limpio el detector, en especial la ventana de detección. Si el

detector se ensucia, use un paño limpio para limpiarlo suavemente.

• Evite voltear el detector o dejarlo caer al suelo.

• Aunque el detector es resistente al agua, debe evitar sumergirlo en

agua u otros líquidos. Si el detector se moja con agua u otros

líquidos, séquelo inmediatamente.

• No use el detector cerca del fuego ni lo exponga al fuego de

manera alguna.

42 ©2010 Johnson Level & Tool - Rev. 1

Page 43

3515H-All_Manuals 6/2/10 10:16 AM Page 43

Utilización del Detector (se incluye sólo en el

Modelo N.º 40-6517)

1. Especificaciones Técnicas

Exactitud de detección ± 1.5 mm (< 50 m) ± 2.5 mm (> 50 m)

Apagado del temporizador 6 min ±1min

Alimentación 2 baterías “AAA”

La vida útil de las baterías es de 45 horas de uso continuo

Función de sonido Sonido corto y sonido continuo

Indicación LED rojo superior, naranja medio, verde medio,

rojo inferior

Tamaño 4.645” x 2.637” x 0.984”

(118mm x 67mm x 25mm)

Peso 0.253 lbs. (115g)

©2010 Johnson Level & Tool - Rev. 1 43

Page 44

3515H-All_Manuals 6/2/10 10:16 AM Page 44

2. Componentes

(a) Estructura

1) Cable de Sujeción

2) Indicador de Señal

3) Alarma

4) Ampolla Horizontal

5) Ventana del Detector

6)

Marcador Frontal de Referencia

7) Botón de Encendido

8)

Marcador Posterior de Referencia

9) Puerto de Conexión

10) Puerta del Compartimiento

de las Baterías

(b) Pantalla

Al encender el detector por primera vez, el indicador de

señal del medio se pondrá rojo primero y luego verde.

Si la alarma emite dos sonidos cortos y el detector se

apaga automáticamente, el voltaje de la batería es muy

bajo y es necesario reemplazarla inmediatamente. Si se

enciende el instrumento y el símbolo indicador de

batería aparece de forma intermitente, la batería está

baja, y debe cambiarla.

Botón de encendido: Sirve para encender y apagar el

detector

44 ©2010 Johnson Level & Tool - Rev. 1

Page 45

3515H-All_Manuals 6/2/10 10:16 AM Page 45

3. Guía de Operación

Instalación de las Baterías

1. Abra la tapa del compartimiento de

las baterías y coloque baterías de

acuerdo con la polaridad que se

muestra en la ranura.

2. Vuelva a colocar la tapa del compartimiento para baterías.

Aviso: Retire las baterías si la unidad no se va a utilizar durante un

tiempo prolongado.

4. Métodos de detección

1. Este detector puede detectar un rayo láser giratorio rojo.

2. Presione el botón de encendido una vez; rápidamente el

indicador de señal del medio se pondrá rojo primero y verde

después. Emitirá un pitido para indicar que el detector está

ENCENDIDO.

Al detectar, los indicadores de señal se ven como se muestra

a continuación:

El LED rojo inferior

está encendido

Línea Láser

El LED superior rojo

está encendido

Línea Láser

El LED del medio es

de color naranja

Línea Láser

El LED del medio es

verde

Línea Láser

Todos los LED

están apagados

El rayo láser está

Sonido: Un solo

sonido corto

arriba

El rayo láser es hacia

abajo

Sonido: Un solo

sonido corto

El rayo láser es cercano

centrar

Sonido: Un solo sonido

corto

El rayo láser es de

centrar exactamente

Sonido: Sonido

continuo

Ningún rayo

láser es

discernido

Sonido:

Sin sonido

©2010 Johnson Level & Tool - Rev. 1 45

Page 46

3515H-All_Manuals 6/2/10 10:16 AM Page 46

Adviso:

1. Al detectar un rayo láser horizontal, es necesario que la

ampolla de la burbuja horizontal esté centrada, ya que la

inclinación del detector influenciará la exactitud recibida.

Ampolla Horizontal

2. Mantenga la ventana de recepción

mirando hacia el láser giratorio.

3. Mantenga el detector quieto mientras

busca el rayo láser

4. Cuando el rayo láser esté en el

centro, haga una marca en el

marcador frontal de referencia.

5. Cuando el detector no recibe

una señal láser ni se presionan

botones durante 6 minutos, el

indicador de señal del medio se

pondrá verde primero y rojo

después.La alarma emitirá dos

sonidos cortos, y el detector se apagará automáticamente.

46 ©2010 Johnson Level & Tool - Rev. 1

Page 47

3515H-All_Manuals 6/2/10 10:16 AM Page 47

5. Utilización de los Accesorios

• Conexión al soporte del estadal

• Conexión al estadal

©2010 Johnson Level & Tool - Rev. 1 47

Page 48

3515H-All_Manuals 6/2/10 10:16 AM Page 48

6. Mantenimiento

• Mantenga limpio el detector, en especial la ventana de detección.

Si la unidad se ensucia, use un paño limpio para limpiarlo

suavemente.

• Evite voltear el detector o dejarlo caer al suelo.

• Aunque el detector es resistente al agua, debe evitar sumergirlo en

agua u otros líquidos. Si el detector se moja con agua u otros

líquidos, séquelo inmediatamente.

• No use el detector cerca del fuego ni lo exponga al fuego de

manera alguna.

48 ©2010 Johnson Level & Tool - Rev. 1

Page 49

3515H-All_Manuals 6/2/10 10:16 AM Page 49

8. Autocomprobación y calibración fina

IMPORTANTE: El usuario es responsable de verificar la calibración

del instrumento antes de cada uso.

25’

Autocomprobación de la precisión de la dirección X e Y

1. Observe la dirección X e Y como se indica en la parte superior

del láser.

2. Coloque el láser en una plataforma que esté a 25 pies (7 metros) de distancia de una pared de interior. Posicione el láser de

modo tal que la dirección X se dirija a la pared. Retire el

seguro del láser y ajústelo a baja velocidad.

3. Marque con la letra A en la pared el punto en que el rayo alcanza la

pared. (Nota: Esta prueba se deberá hacer en interiores con iluminación

tenue. Es crucial que se pueda ver fácilmente la marca del láser).

4. Gire el láser 180 grados y marque el rayo como punto B.

5. Mida la distancia vertical entre el punto A y el punto B. Si A y B

están a más de 1/16” (1,6 mm) de distancia a 25’ (7 metros), el

láser está fuera de calibración.

A

B

25’

©2010 Johnson Level & Tool - Rev. 1 49

Page 50

3515H-All_Manuals 6/2/10 10:16 AM Page 50

6. Gire el láser 90 grados y colóquelo en la plataforma. Posicione

el láser de modo tal que la dirección Y se dirija a la pared.

Ejecute la autocomprobación en dirección Y con el mismo

método que la autocomprobación en dirección X, y marque a

su vez el punto C y D.

7. Si el punto C y el punto D están a menos de 1/16” (1,6 mm) a

25’ (7 metros), la precisión está dentro de la tolerancia.

Calibración de precisión

1. Como se muestra en las siguientes figuras, desatornille el perno

del orificio de ajuste con el destornillador en cruz y ajuste el

perno de ajuste fino en el núcleo del instrumento con un

destornillador plano hasta que la línea de láser esté a menos de

1/8” (3,2 mm) a 50’ (15 metros).

2. Ajuste la dirección X y la Y usando el mismo método.

Adviso: Se debe apagar el láser y se debe bloquear el compen-

sador antes de realizar los ajustes.

Si la exactitud está fuera de tolerancia,

calibre la dirección X mediante el

orificio de ajuste, como se muestra.

3. Después de calibrar X, gire el

Calibración de la dirección X

instrumento 90° para calibrar la

dirección Y.

Adviso: Se debe retirar las baterías

alcalinas con un destornillador plano

para acceder al núcleo del instrumento.

4. Vuelva a instalar el perno del orificio

Calibración de la dirección Y

de ajuste.

50 ©2010 Johnson Level & Tool - Rev. 1

Page 51

3515H-All_Manuals 6/2/10 10:16 AM Page 51

Autocomprobación de exactitud para el estado de salida vertical

1. Siga los pasos anteriores y mida la distancia H1 entre el plano

giratorio del láser y la superficie de la plataforma.

2. Fije la perilla de seguro a la posición de bloqueo y coloque el

instrumento de forma horizontal.

3. Ajuste el tornillo de ajuste para centrar la burbuja.

4. Mida la distancia “H2” entre el rayo láser superior y la superficie

de la plataforma.

5. Marque E en la posición que es igual a (H1 - H2) por debajo del

punto 0.

6. Si E -punto 0 es menor de 0,394" (10 mm), la exactitud está dentro de la tolerancia.

Calibración de la burbuja vertical

1. Utilice un destornillador para desatornillar el perno del orificio de

ajuste de la burbuja.

2. Introduzca la llave Allen en el orificio de ajuste para ajustar el

tornillo Allen.

3. Gire la llave Allen para centrar la burbuja.

4. Después de la operación de ajuste, vuelva a instalar el perno del

orificio de ajuste de la burbuja en su posición original.

©2010 Johnson Level & Tool - Rev. 1 51

Wall

Page 52

3515H-All_Manuals 6/2/10 10:16 AM Page 52

Desatornille el perno del orificio de autocalibración

Calibre la burbuja

Nota: Si sigue los pasos anteriores y no puede calibrar la precisión,

comuníquese con el servicio técnico de Johnson Level & Tool.

9. Especificaciones técnicas

Longitud de onda del láser 635nm±10nm

Clasificación del láser Clase IIIa

Máxima salida de potencia ≤ 5mW

Alcance en Interiores Hasta de 200 pies (60 m) dependiendo de las

condiciones de luz

Alcance en Exteriores Hasta un diámetro de 800 pies (240 m) con detector

Rango de autonivelación ±3°,

Fuente de alimentación 4 baterías alcalinas “AA” (se incluyen)

Vida Útil de la Batería La vida útil de la batería es de aproximadamente

de 24 horas de uso continuo

Dimensiones 5" x 6 1/2" x 6 1/2" (126 x 170 x 168mm)

Peso 3.3lbs (1.5Kg)

Temperatura de trabajo 14°F a 113°F (-10°C a +45°C)

Rosca del tornillo central 5/8" – 11

Velocidad de rotación 200 rpm, 400 rpm, 600 rpm

Clase de protección IP 54

52 ©2010 Johnson Level & Tool - Rev. 1

Page 53

3515H-All_Manuals 6/2/10 10:16 AM Page 53

10. Demostraciones de Aplicación

Instalación de techos

Escuadrado y nivelación

Instalación de vallas

Instalación de ventanas

©2010 Johnson Level & Tool - Rev. 1 53

Construcción de muros o

cimentación

Instalación de zócalos

Instalación de piso de

cemento

Instalación de pisos

antiestáticos

Page 54

3515H-All_Manuals 6/2/10 10:16 AM Page 54

11. Cuidado y Manipulación

• Esta unidad láser es una herramienta de precisión que se debe manipular

con cuidado.

• Evite sacudir la unidad para que no la afecten las vibraciones y exponerla a

temperaturas extremas.

• Antes de mover o transportar la unidad, asegúrese de que la misma esté

apagada.

• Retire las baterías cuando guarda la herramienta por un período largo (más

de 3 meses) para evitar que se dañe la unidad si se deterioran las baterías.

• Siempre guarde la unidad en el estuche cuando no la utiliza.

• Evite que se moje la unidad.

• Mantenga la unidad seca y limpia, especialmente la ventana de salida del

láser. Quite cualquier humedad o suciedad con un paño seco y suave.

• No utilice químicos abrasivos, detergentes fuertes ni disolventes de limpieza

para limpiar la unidad del láser.

12. Garantía del Producto

Johnson Level & Tool ofrece una garantía limitada de tres años para cada uno de sus

productos. Puede obtener una copia de la garantía limitada de un producto Johnson Level

& Tool comunicándose con el Departamento de Servicio al Cliente de Johnson Level & Tool

según se indica debajo o visitando nuestra página Web en www.johnsonlevel.com. La

garantía limitada para cada producto contiene varias limitaciones y exclusiones.

No devuelva este producto a la tienda/minorista o lugar de compra. Las reparaciones sin

garantía y la calibración basta deben ser realizadas por un centro de servicio autorizado

de Johnson® o de lo contrario la garantía limitada de Johnson Level & Tool, si

corresponde, se anulará y NO HABRÁ GARANTÍA. Comuníquese con uno de nuestros

cuatro centros de servicio para todas las reparaciones sin garantía. Para obtener la lista

de los centros de servicio, consulte nuestra página Web en www.johnsonlevel.com o llame

a nuestro Departamento de Servicio al Cliente. Comuníquese con nuestro Departamento

54 ©2010 Johnson Level & Tool - Rev. 1

Page 55

3515H-All_Manuals 6/2/10 10:16 AM Page 55

de Servicio al Cliente para obtener una Autorización de Material Devuelto (RMA por sus

siglas en inglés) para reparaciones con garantía (únicamente defectos de fabricación).

Se requiere una prueba de la compra.

NOTA: El usuario es el responsable del uso correcto y del cuidado del producto.

El usuario es responsable de verificar la calibración del instrumento antes de

cada uso.

Para obtener más ayuda, o si tiene problemas con un producto que no se mencione en este manual de instrucciones, comuníquese con el Departamento de

Servicio al Cliente.

En Estados Unidos, comuníquese con el Departamento de Servicio al Cliente de

Johnson Level & Tool llamando al 888-9-LEVELS.

En Canadá, comuníquese con el Departamento de Servicio al Cliente de Johnson

Level & Tool llamando al 800-346-6682.

13. Registro de la garantía

Con este manual de instrucciones encontrará incluida una tarjeta de

registro de garantía que debe completarse para su producto. Tendrá

que ubicar el número de serie de su producto que está ubicado en la

parte inferior de la unidad. TENGA EN CUENTA QUE ADEMÁS DE

TODAS LAS LIMITACIONES Y CONDICIONES DE LA GARANTÍA

LIMITADA DE JOHNSON LEVEL & TOOL, JOHNSON LEVEL & TOOL

DEBE HABER RECIBIDO SU TARJETA DE GARANTÍA COMPLETADA

CORRECTAMENTE Y LA PRUEBA DE COMPRA EN UN PERÍODO DE

30 DÍAS A PARTIR DE LA FECHA DE COMPRA DEL PRODUCTO, DE

LO CONTRARIO TODA GARANTÍA QUE SE PUEDA APLICAR, NO SE

APLICARÁ Y NO HABRÁ GARANTÍA.

©2010 Johnson Level & Tool - Rev. 1 55

Page 56

3515H-All_Manuals 6/2/10 10:16 AM Page 56

14. Accesorios

Los accesorios Johnson®están disponibles para la compra en los comercios

autorizados de Johnson

lará toda garantía aplicable y NO HABRÁ GARANTÍA.

Si necesita ayuda para ubicar algún accesorio, comuníquese con nuestro

Departamento de Servicio al Cliente.

En Estados Unidos, comuníquese con el Departamento de Servicio al Cliente

de Johnson Level & Tool llamando al 888-9-LEVELS.

En Canadá, comuníquese con el Departamento de Servicio al Cliente de

Johnson Level & Tool llamando al 800-346-6682.

®

. El uso de accesorios que no sean Johnson®anu-

56 ©2010 Johnson Level & Tool - Rev. 1

Page 57

3515H-All_Manuals 6/2/10 10:16 AM Page 57

Niveau laser rotatif horizontal à

nivellement automatique

Modèles n° 40-6515, 40-6516 et 40-6517

Mode d'emploi

Félicitations pour avoir choisi ce niveau laser rotatif automatique. Nous

vous suggérons de lire ce mode d'emploi en entier avant d'utiliser

cet appareil. Conservez ce mode d'emploi pour utilisation ultérieure.

Cet appareil est un outil laser de Classe IIIa et est fabriqué conformément

au titre 21 du CFR, parties 1040.10 et 1040.11, et à la norme de sécurité

internationale IEC 285.

©2010 Johnson Level & Tool - Rev. 1 57

Page 58

3515H-All_Manuals 6/2/10 10:16 AM Page 58

Table des matières

1. Contenu de la trousse

2. Caractéristiques et fonctions

3. Consignes de sécurité

4. Emplacement et contenu

des étiquettes de mise en garde

5. Emplacement des pièces et

des composants

6. Mode d’emploi

7. Utilisation du produit

8. Contrôle automatique et

calibrage fin

9. Caractéristiques techniques

10. Illustrations d’applications

pratiques

11. Entretien et manipulation

12. Garantie du produit

13.

Enregistrement de la garantie

14. Accessoires

1. Contenu de l'ensemble

Modèle n° 40-6515

Description Qté.

Niveau laser rotatif automatique 1

“AA” les Piles Alcalines 4

Paire de lunettes teintées 1

Mode d'emploi et carte de garantie 1

Porter le cas pris parti doux 1

Modèle n° 40-6516

Description Qté.

Niveau laser rotatif automatique 1

“AA” les Piles Alcalines 4

Paire de lunettes teintées 1

Détecteur avec pile 9 V et pince rapide 1

Mode d'emploi et carte de garantie 1

Étui de transport rigide 1

Modèle n° 40-6517

Description Qté.

Niveau laser rotatif automatique 1

“AA” les Piles Alcalines 4

Paire de lunettes teintées 1

Détecteur avec piles AAA et pince de blocage 1

Cible magnétique 1

Trépied réglable en hauteur 1

Support pour plafond et mur 1

Tige graduée de 2,4 m (8 pi) 1

Mode d'emploi et carte de garantie 1

Étui de transport rigide 1

58 ©2010 Johnson Level & Tool - Rev. 1

Page 59

3515H-All_Manuals 6/2/10 10:16 AM Page 59

2. Caractéristiques et fonctions

• Nivellement automatique avec système de compensation à

amortissement magnétique.

• Lorsque le laser se trouve en dehors de sa plage de nivellement automatique, la rotation s’arrête et l’alarme retentit.

• Permet de projeter un plan laser horizontal.

• Permet de projeter un plan laser vertical avec un faisceau

simultané et divisé de 90 º.

• Les vitesses de rotation du laser sont de 200 (B), 400 (I) et

600 (H) tr/min.

• Fiole verticale éclairée.

• Étanche à la poussière et à l’eau.

3. Consignes de sécurité

Veuillez lire et saisir toutes les instructions suivantes avant d'utiliser

cet outil. Toute négligence à vous y conformer pourrait provoquer des

blessures corporelles.

DANGER!

Outil laser de Classe IIIa

Puiss. utile max. : ≤ 5 mW

Long. d'onde : 625-645 nm

CET OUTIL ÉMET UN RAYONNEMENT LASER

NE FIXEZ PAS LE FAISCEAU DIRECTEMENT

ÉVITEZ TOUTE EXPOSITION DIRECTE DE L'ŒIL

©2010 Johnson Level & Tool - Rev. 1 59

Page 60

3515H-All_Manuals 6/2/10 10:16 AM Page 60

ATTENTION IMPORTANT

• Veuillez lire toutes les consignes avant d’utiliser cet outil. Ne retirez aucune étiquette de l’outil.

• Ne placez pas le faisceau devant les yeux.

• Ne projetez pas le faisceau laser directement dans les yeux d'autres personnes.

• Ne placez pas le niveau laser à la hauteur des yeux et ne le faites pas fonctionner près d'une

surface réfléchissante – le faisceau laser pourrait être projeté dans vos yeux ou dans ceux de

quelqu'un d'autre.

• Ne placez pas le niveau laser dans une position où une personne pourrait involontairement fixer des

yeux le faisceau laser. Il pourrait en résulter de graves blessures aux yeux.

• Ne faites pas fonctionner l’outil dans un milieu potentiellement explosif, par exemple dans

une atmosphère qui contient du gaz ou des liquides inflammables.

• Gardez l’outil à laser hors de portée des enfants et des personnes qui ne savant pas s’en servir.

• Ne tentez pas de regarder le faisceau laser par le truchement d'un dispositif optique comm

un télescope. Il pourrait en résulter de graves blessures aux yeux.

• Assurez-vous de toujours placer l’interrupteur de l’outil à la position « arrêt » lorsque celui-ci

n’est pas utilisé ou s’il est laissé sans surveillance pendant une certaine période de temps.

• Retirez les piles lorsque vous entreposez l'outil pendant une période prolongée (plus de trois mois)

afin d'éviter que l'outil ne soit endommagé si jamais les piles se détérioraient.

• N’essayez pas de réparer ou de démonter l’outil laser. Si une personne non qualifiée tente de

réparer cet outil, la garantie sera annulée.

• Ne pas tenter de réparer ou démonter l'outil laser. Si les personnes incompétentes

tentent de réparer cet outil, la garantie sera vide.

60 ©2010 Johnson Level & Tool - Rev. 1

Page 61

3515H-All_Manuals 6/2/10 10:16 AM Page 61

4. Emplacement et contenu des étiquettes

de mise en garde

©2010 Johnson Level & Tool - Rev. 1 61

Page 62

3515H-All_Manuals 6/2/10 10:16 AM Page 62

5. Emplacement des pièces et composantes

Fenêtre de sortie du

faisceau laser divisé

Trappe du

compartiment

des piles

Molette de

réglage –

Compensateur/

Transport

Sortie 6 V CC

(adaptateur 6 V

non fourni)

à 90°

Fenêtre de

sortie du laser

en rotation

Molette de réglage de

la fiole verticale

Bloc

numérique

Fiole verticale

DEL de charge

62 ©2010 Johnson Level & Tool - Rev. 1

Filetage 5/8 po – 11

Page 63

3515H-All_Manuals 6/2/10 10:16 AM Page 63

6. Instructions d'utilisation

IMPORTANT : Il relève de la responsabilité de l'utilisateur de

vérifier l'étalonnage de l'appareil avant chaque utilisation.

Installation des piles alcalines

Remarque : Assurez-vous toujours que l'interrupteur est en position

«arrêt» avant de retirer les piles et de les remplacer.

1. Installez les piles dans leur logement en respectant la polarité

indiquée dans le compartiment des piles.

2. Remettez en place le couvercle du compartiment des piles et serrez la vis.

Réglage de la bulle en cas d’utilisation verticale

1. Tournez le bouton de verrouillage dans le sens inverse des aiguilles

d’une montre sur la position d’arrêt afin de verrouiller le compensateur.

Le laser est prêt à fonctionner en mode normal et non en

mode de nivellement automatique.

©2010 Johnson Level & Tool - Rev. 1 63

Page 64

3515H-All_Manuals 6/2/10 10:16 AM Page 64

2. Tournez la molette de réglage vertical afin de centrer la bulle dans

la fiole verticale.

Bulle centrée

7. Utilisation de l'appareil

Bloc numérique

Bouton de commutation de la

vitesse de rotation

DEL basse vitesse

DEL vitesse

intermédiaire

DEL haute vitesse

Lorsque le laser est en position horizontale, le laser s’allume

uniquement lorsque la molette de réglage du compensateur/

transport est à la position de marche (« On »).

Touche d’arrêt/de mise en marche: Appuyez sur cette

touche pour allumer/éteindre le laser.

DEL de misesous tension:

Une DEL allumée signifie que l’appareil est sous tension.

Une DEL éteinte signifie que l’appareil est hors tension.

Une DEL qui clignote signifie que la tension de la batterie est faible.

64 ©2010 Johnson Level & Tool - Rev. 1

Bouton

d’arrêt/mise en

marche

DEL de mise

sous tension

Page 65

3515H-All_Manuals 6/2/10 10:16 AM Page 65

Bouton de commutation de la vitesse de rotation

600 tr/min

(H)–Haute vitesse

400 tr/min

(I) – Vitesse

intermédiaire

200 tr/min

(B)–Basse vitesse

Remarque : Au démarrage, la vitesse de rotation du laser est réglée sur haute

vitesse. Lorsque vous commutez la vitesse de rotation, la DEL correspondante

s’allume.

Erreur de nivellement

Tournez le bouton de verrouillage sur la position de marche (« On »).

L’appareil est sous tension. Pendant le nivellement automatique, si le

laser est incliné de manière à dépasser la plage de nivellement

automatique, il s’arrête de tourner et une alarme retentit.

©2010 Johnson Level & Tool - Rev. 1 65

Page 66

3515H-All_Manuals 6/2/10 10:16 AM Page 66

Applications

Installez les piles alcalines dans l’appareil. Placez le laser sur une

surface plane ou positionnez-le sur un trépied en utilisant le raccord

fileté de 1,59 cm (5/8 po) – 11.

Utilisation sur surface plane

Raccordez l’appareil au trépied au moyen du raccord fileté de 5/8 po –

Remarques :

1. Pour utiliser le laser en mode de nivellement automatique, placez

le bouton de verrouillage sur la position de marche (« On »).

2. Lorsque le laser est en position verticale (mode manuel), veuillez

placer le bouton de verrouillage sur la position d’arrêt (« Off »).

3. Mettez le laser sous tension, puis sélectionnez la vitesse de rota-

tion voulue à l’aide du bloc numérique.

4. Après l’utilisation, ou avant de déplacer le laser, mettez-le hors

tension et verrouillez-le.

66 ©2010 Johnson Level & Tool - Rev. 1

Page 67

3515H-All_Manuals 6/2/10 10:16 AM Page 67

Utilisation du détecteur (inclus avec le modèle n° 40-6516 seulement)

1. Fiche technique

Précision de détection Fine : ± 1mm/m (± 0,098 po/pi)

Grossière : ± 2,5 mm/m (± 0,099 po/pi)

Minuterie d'arrêt 10 minutes

Trois types de signal sonore

Dimensions 168 x 68 x 23 mm (6,614 po x 2,677 po x 0,905 po)

2. Composantes

(a) Structure

(b) Affichage

1. Symbole de fonctionnement

2. Symbole de pile faible

3. Symbole de détection fine/grossière

4. Symbole de signal sonore

5. Symbole de détection de position

1. Fenêtre d'affichage

2. Vibreur

3. Fenêtre de réception

4. Rainure de référence

5. Bouton de signal sonore

6. Bouton de détection

fine/grossière

7. Interrupteur

8. Trou fileté

9. Couvercle du compartiment de pile

©2010 Johnson Level & Tool - Rev. 1 67

Page 68

3515H-All_Manuals 6/2/10 10:16 AM Page 68

3. Guide d’utilisation

(a) Installation de la pile

• Ouvrez le couvercle du compartiment des piles et reliez le câble

situé à l’intérieur aux deux bornes de la pile de 9 V.

Remarques : Retirez la pile si vous n’utilisez pas le détecteur pendant

une période prolongée.

• Mettez la pile de 9 V dans le compartiment et refermez le couvercle.

(b) Marche/Arrêt

• Appuyez sur le bouton marche/arrêt. Lorsque le

symbole de mise en marche s’affiche, le détecteur

est prêt à effectuer une détection macrométrique.

• Lorsque le symbole de faible puissance des piles

s’affiche, vous devez remplacer les piles.

• Appuyez de nouveau sur le bouton de mise en

marche pour éteindre le détecteur.

c) Utilisation du support à pince

1. boulon de blocage

2. vis

• Fixez le détecteur sur le support à

pince à l’aide de la vis du support à

pince.

• Placez le support à pince sur la tige

à l’aide du boulon de blocage du

support à pince.

68 ©2010 Johnson Level & Tool - Rev. 1

Page 69

3515H-All_Manuals 6/2/10 10:16 AM Page 69

(d) Détection

1. Détection macrométrique

• Orientez la fenêtre de réception vers le laser rotatif.

Desserrez le boulon de blocage et déplacez le

détecteur vers le haut et vers le bas pour recevoir les

signaux de balayage laser transmis par le laser rotatif.

• Lorsque le détecteur affiche le symbole de la flèche

illustrée à la figure A, déplacez lentement le détecteur

vers le bas, comme l’indique la flèche. Lorsque le

détecteur affiche le symbole de la flèche illustrée à la

figure B, déplacez lentement le détecteur vers le haut,

comme l’indique la flèche.

• Lorsque le symbole de la figure C s’affiche, le détecteur est à

niveau par rapport au faisceau laser rotatif.

• Serrez le boulon de blocage et marquez l’emplacement sur la tige d’inclinaison près de la rainure. Cette marque servira de référence horizontale en mode de détection macrométrique.

2. Détection micrométrique

1. symbole de mise en marche

2. symbole de détection micrométrique

• Appuyez sur le bouton de détection

micrométrique/macrométrique. Le détecteur est

prêt à effectuer une détection micrométrique.

• Déplacez légèrement le détecteur vers le haut

Figure 6

et vers le bas en suivant la procédure

appliquée pour la détection grossière.

• Lorsque le détecteur affiche le symbole illustré à la figure 6, le

détecteur est à niveau par rapport au faisceau laser rotatif.

• Serrez le boulon de blocage et marquez l’emplacement sur la tige d’inclinaison près de la rainure. Cette marque servira de référence horizontale au moment de la détection fine.

©2010 Johnson Level & Tool - Rev. 1 69

Page 70

3515H-All_Manuals 6/2/10 10:16 AM Page 70

e) Fonction d’avertissement sonore

• Si le contexte d’utilisation du détecteur rend la lecture de l'affichage difficile, la fonction sonore peut être utilisée à la place.

• Appuyez sur le bouton d’avertissement sonore. Le symbole de

l’avertisseur s’affiche à l’écran, ce qui signifie que le mode d’avertissement sonore est activé.

• Lorsque le détecteur émet un bip rapide, déplacez-le légèrement

vers le haut.

• Lorsqu’il émet un bip court, déplacez-le légèrement vers le bas.

• Lorsque le détecteur émet un bip continu, il est à niveau par rapport au faisceau laser rotatif.

• Lorsqu’aucun bip ne retentit, le détecteur ne capte pas le signal du

faisceau laser.

(f) Minuteur de mise hors tension

• Le détecteur se met automatiquement hors tension lorsqu’il ne

reçoit aucun signal laser pendant 10 minutes.

(g) Entretien du détecteur

• Lorsque vous avez fini d’utiliser le détecteur, remettez-le dans sa

mallette de transport.

• Veillez à ce que le détecteur (la fenêtre de détection en particulier)

soit toujours propre. Si de la poussière s’accumule sur l’appareil,

utilisez un chiffon doux pour l’enlever.

• Évitez de renverser le détecteur ou de le faire tomber au sol.

• Bien que le détecteur soit étanche, évitez de le tremper dans l’eau

ou dans d’autres liquides. Si le détecteur entre en contact avec de

l’eau ou d’autres liquides, essuyez-le immédiatement.

• N’utilisez jamais le détecteur à proximité du feu et ne l’exposez

jamais au feu.

70 ©2010 Johnson Level & Tool - Rev. 1

Page 71

3515H-All_Manuals 6/2/10 10:16 AM Page 71

Utilisation du détecteur (fourni avec le modèle 40-6517)

1. Fiche technique

Précision de détection ±1,5 mm (<50 m) ±2,5 mm (>50 m)

Minuteur de mise hors tension 6 min ±1min

Alimentation 2 piles «AAA»

Durée de vie des piles environ 45 heures en utilisation continue

Fonction d’avertissement sonore

Voyant d’indication à DEL haut – rouge, centre – orange,

Dimensions 118 mm x 67 mm x 25 mm

Poids 115 g (0,253 lb)

son court et son continu

centre – vert, bas – rouge

(4,645 po x 2,637 po x 0,984 po)

©2010 Johnson Level & Tool - Rev. 1 71

Page 72

3515H-All_Manuals 6/2/10 10:16 AM Page 72

2. Composants

(a) Structure

1) Cordon de retenue

2) Voyant

3) Avertisseur sonore

4) Fiole horizontale

5) Fenêtre de détection

6) Repère avant

7) Touche d’arrêt/de mise en

marche

8) Repère arrière

9) Port de raccordement

10) Couvercle du

(b) Affichage

Au moment de la mise en marche initiale de l'appareil,

le voyant du centre devient d’abord rouge, puis vert. Si

l’avertisseur sonore émet deux sons courts et que le

détecteur s’éteint automatiquement, la tension électrique est extrêmement faible et les piles doivent être

remplacées sur-le-champ. Lorsque, au moment de la

mise en marche, le voyant du bas clignote, les piles

sont faibles et doivent être remplacées.

compartiment des piles

Touche d’arrêt/de mise en marche : Utilisez cette touche

pour mettre le détecteur en marche et l’éteindre.

72 ©2010 Johnson Level & Tool - Rev. 1

Page 73

3515H-All_Manuals 6/2/10 10:16 AM Page 73

3. Guide d’utilisation

Installation de la pile

1. Ouvrez le compartiment des piles et

insérez-y les piles en respectant la

polarité indiquée à l’emplacement

des piles.

2. Remettez le couvercle du compartiment des piles en place.

Remarque: Retirez les piles si vous n’utilisez pas l’appareil pendant

une période prolongée.

4. Modes de détection

1. Cet appareil peut détecter un faisceau laser rotatif rouge.

2. Appuyez une fois sur la touche de mise en marche; rapidement, le voyant du centre devient d’abord rouge, puis vert. Il

émettra un son pour signaler qu’il est en marche.

Lors de la détection, les voyants seront en allumés comme suit:

Le voyant à DEL rouge

du bas est allumé

Ligne laser

Le voyant à DEL rouge

du haut est allumé

Ligne laser

Le voyant à DEL du

centre est orange

Ligne laser

Le voyant à DEL du

centre est vert

Ligne laser

Tous les voyants à

DEL sont éteints

Le rayon laser est

Son: Un seul son

en haut

court

Le rayon laser est en

bas

Son: Un seul son

court

Le rayon laser est

proche pour centrer

Son: Un seul son court Son: Son continu Son:

Le rayon laser est

exactement de

centrer

Aucun rayon

laser est

détecté

Aucun son

©2010 Johnson Level & Tool - Rev. 1 73

Page 74

3515H-All_Manuals 6/2/10 10:16 AM Page 74

Remarques:

1. Il faut centrer la fiole lorsque vous voulez détecter un fais

ceau laser horizontal, car l’inclinaison du détecteur modifiera

la précision de sa réception.

Fiole horizontale

2. Maintenez la fenêtre de détection

face au faisceau laser en rotation.

3. Maintenez le récepteur immobile

pendant la détection du faisceau laser.

4. Une fois le faisceau laser centré,

faites une marque pour le point de

repère avant.

5. Lorsque le détecteur ne

capte pas le signal laser durant

six minutes et qu'aucun bouton

n'est enfoncé durant cette

même période, le voyant du

centre deviendra vert, puis

rouge. L’avertisseur sonore

émettra deux sons courts et le détecteur s’éteindra

automatiquement.

74 ©2010 Johnson Level & Tool - Rev. 1

Page 75

3515H-All_Manuals 6/2/10 10:16 AM Page 75

5. Utilisation des accessoires

• Raccordement au support de la tige d’inclinaison

• Raccordement à la tige d’inclinaison

©2010 Johnson Level & Tool - Rev. 1 75

Page 76

3515H-All_Manuals 6/2/10 10:16 AM Page 76

6. Entretien

• Veillez à ce que le détecteur (la fenêtre de détection en particulier)

soit toujours propre. Si de la poussière s’accumule sur l’appareil,

utilisez un chiffon doux pour l’enlever.

• Évitez de renverser le détecteur ou de le faire tomber au sol.

• Bien que le détecteur soit étanche, évitez de le tremper dans l’eau

ou dans d’autres liquides. Si le détecteur entre en contact avec de

l’eau ou d’autres liquides, essuyez-le immédiatement.

• N’utilisez jamais le détecteur à proximité du feu et ne l’exposez

jamais au feu.

76 ©2010 Johnson Level & Tool - Rev. 1

Page 77

3515H-All_Manuals 6/2/10 10:16 AM Page 77

8. Contrôle automatique et calibrage fin

IMPORTANT: Il incombe à l’utilisateur de vérifier le calibrage de

l’appareil avant chaque utilisation.

25’

Contrôle automatique de la précision des axes des X et des Y

1. Prenez note des axes des X et des Y sur le dessus du laser.

2. Placez le laser sur une surface plane à 7,6 m (25 pi) d'un mur

intérieur. Placez le laser de manière à ce que l'axe des X soit

face au mur. Déverrouillez le laser et réglez-le sur basse vitesse.

3. Faites un repère (A) à l’endroit où le faisceau atteint le mur.

(Remarque: Effectuez cet essai à l’intérieur avec un éclairage

de faible intensité. Il est essentiel de bien distinguer le repère

où vient frapper le laser.)

4. Faites pivoter le laser sur 180 º, puis faites un repère (B) correspondant au faisceau.

5. Mesurez la distance verticale entre le point A et le point B. Si A et

B sont distants de plus de 1,6 mm (1/16 po) l’un par rapport à

l’autre à 7,6 m (25 pi), le laser n’est pas calibré.

A

B

25’

©2010 Johnson Level & Tool - Rev. 1 77

Page 78

3515H-All_Manuals 6/2/10 10:16 AM Page 78

6. Faites pivoter le laser de 90 º et placez-le sur la surface plane.

Placez le laser de manière à ce que l'axe des Y soit face au mur.

Effectuez le contrôle automatique de l'axe des Y en suivant la

même procédure que celle pour effectuer le contrôle automatique

de l'axe des X, puis identifiez ces points C et D, respectivement.

7. Si les points C et D sont distants de moins de 1,6 mm (1/16 po)

à 7,6 m (25 pi), la précision est conforme aux tolérances.

Calibrage de la précision

1. En vous référant aux figures ci-dessous, dévissez la vis du trou de