Johnson & Johnson Sterrad 100NX User Manual

STERRAD

®

STERRAD®100NX

STERRAD® 100NX® Sterilization System

User’s Guide

Ref 99994

99994_05

January 2017

STERRAD® 100NX® Sterilization System

User’s Guide

AT

BE

1-888-STERRAD ASP U.S.A. Professional Services

ASP International 949-581-5799

Please visit www.aspjj.com

For warranty information, please visit our website or contact ASP Professional Services.

ASP International Customer Support; call your local ASP Representative

©. 2008-2016 Division of Ethicon. All rights reserved. STERRAD®, CYCLESURE®, SEALSURE®, APTIMAX® and 100NX®

are registered trademarks of Advanced Sterilization Products (ASP). Tefl on

E.I. du Pont de Nemours and Company. Radel

Kraton Polymers LLC. Santoprene™ is a trademark of ExxonMobil Corporation. Ultem

da Vinci

their respective owners. Please note: the screen displays shown in this guide are for reference only. The actual displays on your

system may be slightly different depending on your system’s confi guration and software revision. Reproduction, adaptation, or

®

is a registered trademark of Intuitive Surgical, Inc. Other products mentioned in this publication are trademarked by

translation of this publication without prior written permission is prohibited. Printed in the U.S.A.

®

is a registered trademark of Solvay SA. Kraton® is a registered trademark of

®

, Delrin®, and Tyvek® are registered trademarks of

®

is a registered trademark of SABIC.

Contents

Chapter 1. Introduction .....................................................................................5

How to Use This Guide ............................................................................................5

Intended Use ............................................................................................................5

The STERRAD

If You Have Questions .............................................................................................6

Chapter 2. Safety Information ............................................................................ 7

Personal Safety and First Aid ...................................................................................7

Personal Protective Equipment ................................................................................9

Device Safety ...........................................................................................................9

Warnings, Cautions, and Notes ..............................................................................13

Symbols..................................................................................................................14

Chapter 3. Load Preparation ............................................................................ 15

®

Sterilization Process .....................................................................6

Load Weight Requirements ....................................................................................15

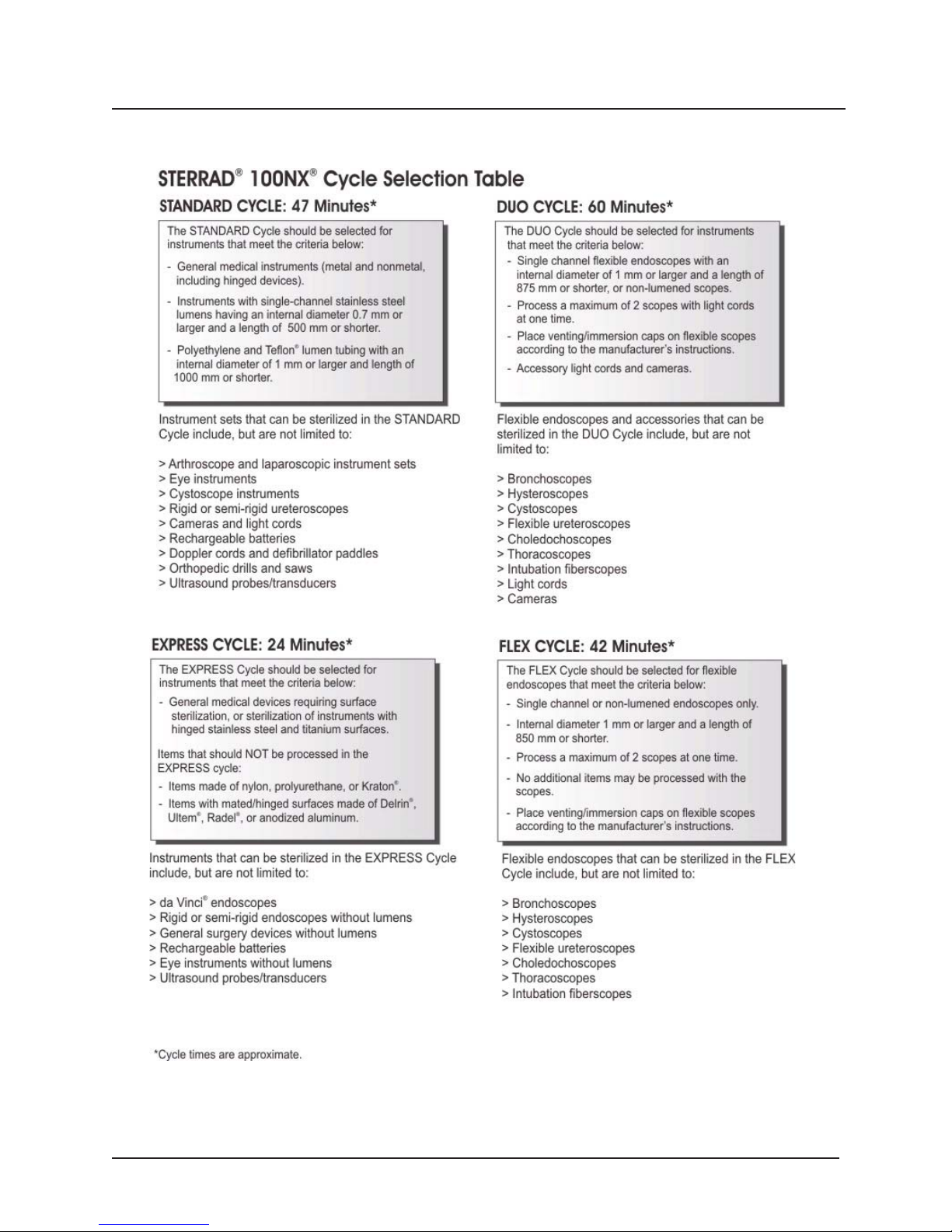

Cycles and Materials Processing ...........................................................................18

Recommended Materials .......................................................................................22

Thermoplastics ..................................................................................................22

Thermoplastic Elastomers .................................................................................22

Thermosetting Elastomers .................................................................................23

Glass ..................................................................................................................23

Metal .................................................................................................................23

Items Not To Be Processed ....................................................................................23

Do Not Process in the EXPRESS Cycle ...........................................................24

Do Not Process in the DUO Cycle ....................................................................24

Guidelines for Preparing Items to Be Sterilized ....................................................25

Cleaning, Rinsing, and Drying ...............................................................................25

Packaging and Loading ..........................................................................................27

Instrument Trays................................................................................................27

Tray Mats ..........................................................................................................27

Packaging ..........................................................................................................27

Loading .............................................................................................................28

Chemical Indicators ..........................................................................................29

Special Considerations for Flexible Endoscopes ..............................................29

STERRAD® 100NX® User’s Guide 1

Chapter 4. Operation ....................................................................................... 31

Before You Start .....................................................................................................31

Start and Warm-up .................................................................................................31

Biological Indicators ..............................................................................................31

Login ......................................................................................................................32

Entering Load Information ....................................................................................33

Enter Load Item Data ........................................................................................33

Loading the Chamber .............................................................................................36

Selecting and Starting a Cycle ...............................................................................40

System Ready Screen ........................................................................................41

Inserting a Cassette ...........................................................................................41

Cycle in Progress ...................................................................................................43

Canceling a Cycle .............................................................................................44

Cycle Completed ....................................................................................................45

Processing a Sterilized Load ..................................................................................46

Inspecting Chemical Indicators .........................................................................46

Processing Biological Indicators .......................................................................46

Chapter 5. Troubleshooting ............................................................................. 49

Running Diagnostics ..............................................................................................49

System Message Table ...........................................................................................50

Temperature Messages ......................................................................................50

Messages Not In This Table ..............................................................................50

Call Your ASP Representative ...............................................................................54

Chapter 6. Sterilizer Overview ......................................................................... 55

Sterilizer Cycles .....................................................................................................55

Sterilizer Features ..................................................................................................56

Cassette .............................................................................................................57

Cassette Disposal Box .......................................................................................58

Touch Screen and Speaker ................................................................................58

Chamber ............................................................................................................59

Printer ................................................................................................................60

Touch Screen Data Entry ..................................................................................61

Chapter 7. Maintenance ................................................................................... 63

Automatic Maintenance ........................................................................................63

Automatic Lamp Adjustment ............................................................................63

Manual Maintenance ..............................................................................................64

2 STERRAD® 100NX® User’s Guide

Disposing of Cassettes ...........................................................................................64

Removing a Cassette Disposal Box ..................................................................65

Replacing the Printer Paper ...................................................................................66

Cleaning the Sterilizer Exterior .............................................................................69

Cleaning the Hydrogen Peroxide Monitor Detector Lens .....................................70

PCMCIA Card Handling and Replacement ...........................................................71

Data Transfer Using a Memory Stick................................................................72

Sterilizer Disposal ..................................................................................................73

Chapter 8. Reports and Files ........................................................................... 75

Displayed Reports .................................................................................................75

Cycle History ....................................................................................................75

Printed Reports .......................................................................................................77

Short Report ......................................................................................................77

Parametric Report..............................................................................................77

Long Report ......................................................................................................77

Chapter 9. Access Levels and Supervisor Tasks ..............................................79

Overview ................................................................................................................79

Access Levels .........................................................................................................79

Additional Utilities Menu ......................................................................................80

Date and Time Settings ..........................................................................................81

Set Date .............................................................................................................82

Set Time ............................................................................................................82

Time Zone .........................................................................................................82

Date Format .......................................................................................................82

Time Format ......................................................................................................82

Cancel/Done ......................................................................................................82

System Confi guration.............................................................................................83

Access Control Option ......................................................................................83

IMS ....................................................................................................................83

Vacuum Units ....................................................................................................83

Load Data Entry Option ....................................................................................84

Load Removal Option .......................................................................................84

Notepad Option .................................................................................................84

Auto Send Network Files ..................................................................................84

Alarm Volume ...................................................................................................84

Backlight Conservation (Minutes) ....................................................................84

Language Selection ...........................................................................................84

Sterilizer Settings ..............................................................................................85

Printer Settings ..................................................................................................86

Transfer Settings ...............................................................................................87

Cancel/Done ......................................................................................................87

STERRAD® 100NX® User’s Guide 3

User Administration ...............................................................................................88

Add User ...........................................................................................................89

Modify User ......................................................................................................90

Upload User Data ..............................................................................................91

Cassette Functions .................................................................................................93

Dispose Cassette................................................................................................94

Peroxide Clearance............................................................................................95

Network ..................................................................................................................96

Diagnostics .............................................................................................................96

Diagnostic T ests ................................................................................................97

Service Functions ...................................................................................................97

File Management ...................................................................................................98

Calibration Files ................................................................................................98

Diagnostic Files .................................................................................................98

Upload File .............................................................................................................99

Input/Output Doors ..............................................................................................100

Product Options ...................................................................................................100

Appendix A. Sterilizer Specifi cations ............................................................... 103

Appendix B. Consumables, Accessories, and Additional Parts ........................ 107

Appendix C. User’s Network Connection Information Guide ............................ 109

4 STERRAD® 100NX® User’s Guide

Chapter 1. Introduction

Introduction

How to Use This Guide

If you are a STERRAD® 100NX® Sterilizer operator, you must read

the “Safety Information, “ the “Introduction,” “Load Preparation,” and

“Operation” chapters prior to operating the sterilizer. This “Introduction”

explains the features and parts of the sterilizer. “Load Preparation” explains

how to prepare and package instruments for processing. “Operation” explains

how to operate the sterilizer and obtain optimal results.

If you are a supervisor overseeing the STERRAD

you should read the entire user’s guide and pay particular attention to the

chapter featuring “Access Levels and Supervisor Level Tasks.” This chapter

describes tasks and options that are only available through “Supervisor

Level” access.

Introduction 1

®

100NX® Sterilizer,

Intended Use

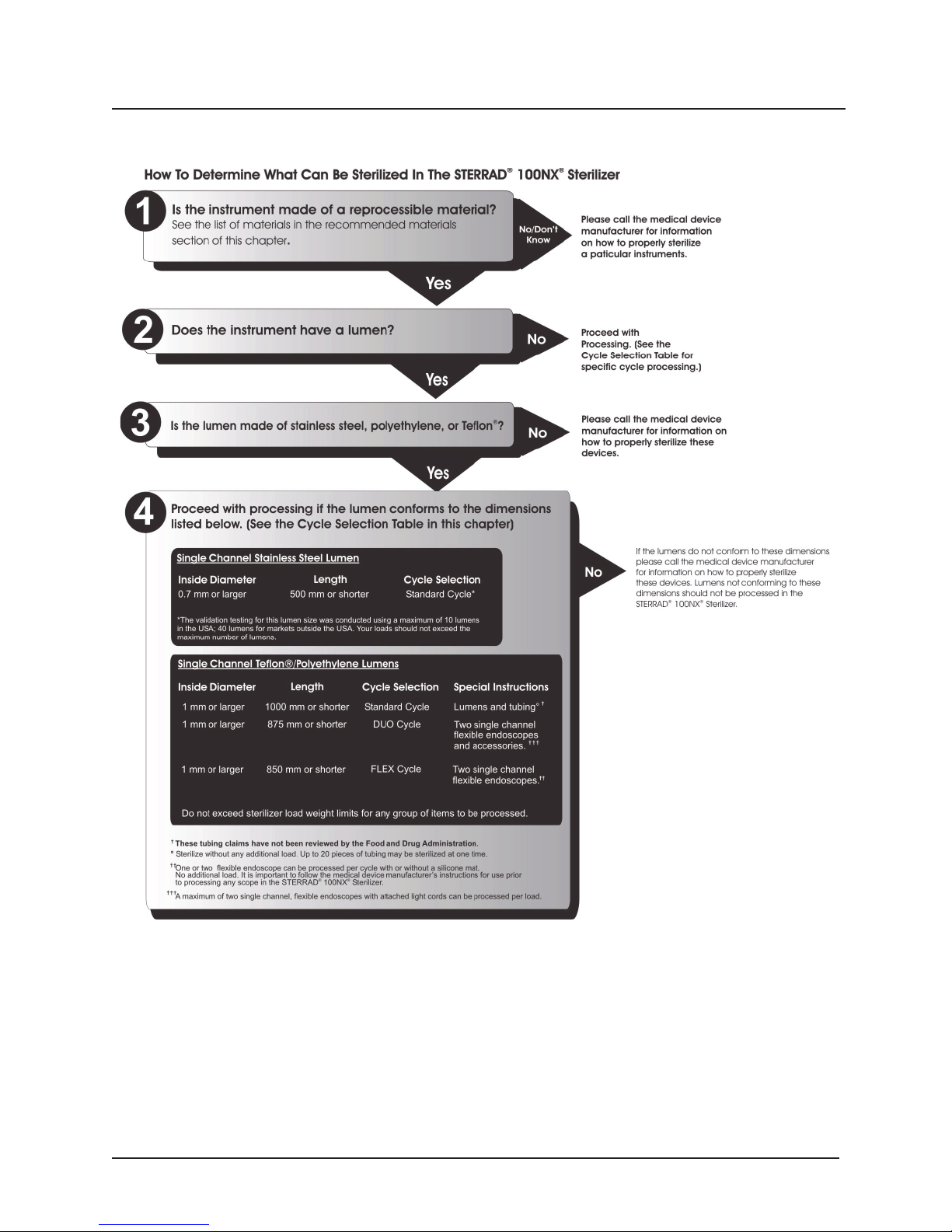

The STERRAD® 100NX® Sterilization System is a general purpose, low

temperature sterilizer which uses the STERRAD

inactivate microorganisms on a broad range of medical devices and surgical

instruments.

When used as directed by the instructions in this user’s guide, the

STERRAD

nonmetal medical devices at low temperatures. Please review “How to

Determine What Can Be Sterilized in the STERRAD

in the “Load Preparation” chapter along with the cycle information to make

sure you follow the directions for processing items in each type of cycle.

STERRAD® 100NX® User’s Guide 5

®

100NX® Sterilization System will sterilize both metal and

®

100NX® Process to

®

100NX® Sterilizer”

1 Introduction

The STERRAD® Sterilization Process

The STERRAD® 100NX® Sterilizer sterilizes medical devices by diffusing

hydrogen peroxide vapor into the chamber and then electromagnetiy exciting

the hydrogen peroxide molecules into a low-temperature plasma state. The

combined use of hydrogen peroxide vapor and plasma safely and rapidly

sterilizes medical instruments and materials without leaving toxic residue.

All stages of the sterilization cycle operate within a dry environment at a low

temperature, and thus the cycle is not damaging to compatible instruments

that are sensitive to heat and moisture.

The STERRAD

devices, and can also sterilize instruments that have diffi cult-to-reach

(diffusion-restricted) spaces, such as hinges on forceps. Refer to the “Safety

Information” chapter for more information on device safety.

The sterilizer consistently provides a Sterility Assurance Level (SAL) of 10

as defi ned by U.S. Food and Drug Administration (FDA) and international

standards, for clinical use on all allowed substrates within the limits of

the claims for materials and geometries when used in accordance with the

directions in this user’s guide.

®

100NX® Sterilizer can be used for both metal and nonmetal

-6

,

If You Have Questions

If you have questions about the STERRAD® 100NX® Sterilizer or questions

about which items may be safely sterilized by the STERRAD

please call your local Advanced Sterilization Products (ASP) Representative

or visit our website at www.aspjj.com.

®

Process,

6 STERRAD® 100NX® User’s Guide

Chapter 2. Safety Information

Safety Information

Safety Information 2

Your safety is of primary concern to Advanced Sterilization Products (ASP).

This chapter provides information on safely using the STERRAD

Sterilizer. You must read and understand the safety information in

this chapter before operating the sterilizer. Always pay attention to the

warnings, cautions and notes throughout this user’s guide. This information

is for your safety and to ensure that you receive the most benefi t from the

safe operation of your STERRAD

®

100NX® Sterilization System.

Personal Safety and First Aid

WARNING! HYDROGEN PEROXIDE IS CORROSIVE.

Concentrated hydrogen peroxide is corrosive to skin, eyes, nose, throat, lungs, and

the gastrointestinal tract. Always wear chemical resistant latex, PVC (vinyl), or nitrile

gloves while removing items from the sterilizer following a cancelled cycle or if any

moisture is noted on items in the load following a completed cycle.

WARNING! HYDROGEN PEROXIDE IS AN OXIDIZER.

Hydrogen peroxide is strong oxidizing agent and poses a hazard for fi re, explosion,

or container rupture. Avoid allowing hydrogen peroxide to contact organic materials,

including paper, cotton, wood, or lubricants. Do not use or store near heat or open

fl ame. Shoes, clothing, or other combustible material that have come into contact

with hydrogen peroxide must be immediately and thoroughly rinsed with water to

avoid a potential fi re hazard. In case of fi re, use only water to extinguish.

®

100NX®

WARNING! RISK OF EYE INJURY.

Direct hydrogen peroxide contact with eyes can cause irreversible tissue damage. If

contact with eyes occurs, hold the eyes open and fl ush with large amounts of water

for at least 15-20 minutes. Remove contact lenses, if present, and then continue

rinsing the eyes. Consult a physician immediately after fl ushing the eyes.

STERRAD® 100NX® User’s Guide 7

2 Safety Information

WARNING! RISK OF SKIN INJURY.

Direct hydrogen peroxide contact with the skin can cause severe irritation. Wear

chemical resistant latex, PVC (vinyl), or nitrile gloves when handling new, used, or

ejected cassettes, items from a cancelled cycle, or items that have moisture present

after a completed cycle. Immediately take off contaminated clothing and rinse

thoroughly with water to avoid potential fi re hazard and wash before re-use.

WARNING! RISK OF RESPIRATORY IRRITATION.

Inhalation of hydrogen peroxide mist can cause severe irritation of lungs, throat,

and nose. If inhalation occurs, move to the person to fresh air. If the person is not

breathing, call for emergency medical attention, or an ambulance, then give artifi cial

respiration, preferably mouth-to-mouth, if possible. Consult a physician immediately.

WARNING! CONCENTRATED HYDROGEN PEROXIDE IS TOXIC.

Ingestion of hydrogen peroxide may be life-threatening. If swallowed, call a “poison

control” center or physician immediately for treatment advice. Have the person drink

plenty of water if the person is able to swallow. Do not give anything by mouth to an

unconscious person. Do not induce vomiting unless instructed to do so by the poison

control center or physician.

WARNING! HEATED STERILIZATION SURFACES.

At the end of a cycle, the interior of the sterilizer may be hot. Do not touch the inside

of the chamber or door with your bare or gloved hands. Allow the sterilizer to cool

before touching interior surfaces.

WARNING! AVOID EXPOSURE TO ULTRAVIOLET LIGHT.

The hydrogen peroxide monitor uses an ultraviolet light source located inside the

chamber behind the door. To avoid eye injury, do not stare directly at the ultraviolet

light source for an extended period of time.

WARNING! HYDROGEN PEROXIDE MAY BE PRESENT.

If white residue is visible on the load, this is residue from the hydrogen peroxide

stabilizer. Wear chemical resistant latex, PVC (vinyl), or nitrile gloves when

removing a load with visible white residue. White residue can be minimized by

making sure regular Planned Maintenance procedures are performed on your system.

The system will inform you when Planned Maintenance is due. Please schedule your

PM service in a timely manner.

8 STERRAD® 100NX® User’s Guide

Safety Information 2

WARNING! RISK OF BREATHING DIFFICULTIES.

On rare occasions, the outlet fi lter on the vacuum pump can prematurely fail. If this

occurs, you may see mist or what some users have described as “haze” or “smoke”

in the room where the sterilizer is operating. The chemical composition of the mist

is primarily airborne mineral oil with trace amounts of other compounds. Oil mist

exposure may, theoretically, pose an increased risk to people with certain respiratory

conditions, such as asthma, and they should take special precautions not to be

exposed to the mist. If you observe these conditions, personnel should leave the room

as a precaution and discontinue use of the STERRAD

repaired. Personnel should avoid working in the room until the mist has cleared.

®

System until the system is

Please note that all STERRAD

ventilated environment (a minimum of 10 air exchanges per hour).

®

Sterilizers should be used and installed in a well

Personal Protective Equipment

WARNING! HYDROGEN PEROXIDE MAY BE PRESENT.

Wear chemical resistant latex, PVC (vinyl), or nitrile gloves whenever handling a

load after a cycle cancellation. Hydrogen peroxide liquid may be present on the load

or in the chamber.

Device Safety

WARNING! RISK OF INJURY OR DAMAGE TO STERILIZER.

The STERRAD® 100NX® Sterilizer should not be used stacked with other equipment.

CAUTION: RISK OF DAMAGE TO LOAD.

Metal objects must not come into contact with the chamber walls, the door, or the

electrode. Contact with the walls, door, or electrode could damage the sterilizer or the

metal objects.

STERRAD® 100NX® User’s Guide 9

2 Safety Information

CAUTION: KNOW WHAT YOU CAN PROCESS.

Before processing any item in the STERRAD® 100NX® Sterilizer, make sure

you know how the STERRAD Sterilization Process will affect the item. Read,

understand, and follow the medical device manufacturers’ instructions for their

products. This guide lists certain types of items and materials that can be safely

processed in certain cycle choices. Make sure you understand the parameters of each

cycle type before processing your items. This guide is not intended to replace any

medical device manufacturers’ instructions. If you have questions, or if you are in

doubt about the materials in your devices, contact the medical device manufacturer or

your ASP Customer Representative for more information.

CAUTION: RISK OF VIOLATION OF WARRANTY.

Improper processing may limit our liability for damage to processed instruments.

Improper processing may also violate your instrument warranty.

CAUTION: RISK OF DAMAGE TO LOAD – METAL OBJECTS.

Metal objects must not come into contact with the chamber walls, the doors, or the

electrode. Contact with the walls, doors, or electrode could damage the sterilizer or

the metal objects.

CAUTION: RISK OF DAMAGE TO LOAD – VENTING CAPS.

Take special care to confi rm that venting caps are placed according to the

manufacturers’ instructions. Venting caps are intended to prevent damage to fl exible

scopes that are being exposed to a vacuum, regardless of the sterilant used.

CAUTION: RISK OF DAMAGE TO LOAD – IMMERSION CAPS.

You must remove the water-resistant immersion cap (if present) prior to processing

in the sterilizer. If the immersion cap is not removed prior to processing in the

STERRAD

to properly vent.

CAUTION: KNOW WHAT YOU CAN PROCESS – FLEXIBLE

ENDOSCOPES.

Prior to processing fl exible endoscopes in the STERRAD® 100NX® Sterilizer, you

must read, understand, and follow the medical device manufacturer’s instructions

for use for the particular scope to be processed. Please contact the medical device

manufacturer for more information on what can be processed in the STERRAD

100NX

CAUTION: RF COMMUNICATIONS EQUIPMENT.

Portable and mobile RF communications equipment can affect medical electrical

equipment.

®

100NX® Sterilizer, it will damage the fl exible scope due to the inability

®

Sterilizer.

®

10 STERRAD® 100NX® User’s Guide

Safety Information 2

Guidance And Declaration-Electromagnetic Emissions

The STERRAD® 100NX® Sterilizer is intended for use in the electromagnetic environment specifi ed below.

Assure that it is used in such an environment.

Emissions Test Compliance Electromagnetic Environment - Guidance

RF emissions CISPR 11 Group 1

RF emissions CISPR 11 Class A

Harmonic emissions

IEC 61000-3-2

Voltage fl uctuations/fl icker

emissions IEC 61000-3-3

Class A

Complies

System is confi gured with FCC ID: AXJ100NXRFID

or FCC ID: AXJ02532480 or contains FCC ID: AXJ02532481

System is confi gured with IC Certifi cation Number:

10207A-100NXRFID

or IC Certifi cation Number: 10207A-02532480 or

contains IC Certifi cation Number 10207A-02532481

The STERRAD® 100NX® Sterilizer uses RF energy

only for its internal function. Therefore, its RF

emissions are very low and are not likely to cause any

interference in nearby electronic equipment.

The STERRAD® 100NX® Sterilizer is suitable for

use in all establishments other than domestic and

those directly connected to the public low-voltage

power supply network that supplies buildings used for

domestic purposes.

WARNING! (PART 15.21) RISK OF NON-COMPLIANCE.

Changes or modifi cations not expressly approved by Advanced Sterilization Products

could void the user’s authority to operate the equipment. Manufacturer is not

responsible for any radio or TV interference caused by unauthorized modifi cations to

this equipment.

STERRAD® 100NX® User’s Guide 11

2 Safety Information

FCC Rules and Industry Canada (IC) Regulatory Information

Compliance Statement (Part 15.19)

The equipment device complies with Part 15 of the FCC Rules. Operation

is subject to the following two conditions: (1) This device may not cause

harmful interference, and (2) This device must accept any interference

received including interference that may cause undesired operation.

Compliance Statement (Part 15.105(b))

Note: This equipment has been tested and found to comply with the limits for

a Class A digital device, pursuant to part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own expense.

This device complies with Industry Canada license-exempt RSS standard(s).

Operation is subject to the following two conditions: (1) this device may

not cause interference, and (2) this device must accept any interference,

including interference that may cause undesired operation of the device.

Class A digital device notice “CAN ICES-3 (A)/NMB-3(A)”

RF Radiation Exposure Statement

This equipment complies with the FCC/IC radiation exposure limits set forth

for portable transmitting devices operation in a controlled environment. End

users must follow the specifi c operating instructions to satisfy RF exposure

compliance.

The equipment should only be used where there is normally at least 20cm

separation between the antenna and all person/user.

This transmitter must not be co-located or operation in conjunction with any

other antenna or transmitter.

Any changes or modifi cations not expressly approved by the party

responsible for compliance could void the user’s authority to operate this

equipment.

12 STERRAD® 100NX® User’s Guide

Warnings, Cautions, and Notes

Warnings and cautions are accompanied by symbols surrounded by a triangle or a

square and are printed in the text in bold. Warnings indicate events or conditions that

can result in serious injury or death. Cautions indicate events or conditions that can

result in severe damage to the equipment.

Notes are printed in italics and have a checkmark in front of the word “Note.” Notes

highlight specifi c information about the proper use and maintenance of the sterilizer.

Safety Information 2

STERRAD® 100NX® User’s Guide 13

2 Safety Information

Symbols

Hot surfaces present.

Do not touch without protection.

Hazardous chemical present.

Use personal protective equipment.

Corrosive chemical present.

Use personal protective equipment.

Oxidizing chemical present.

Avoid exposure, contact, or ingestion.

Use personal protective equipment.

WEEE Symbol

Toxic chemical present.

Avoid exposure, contact, or ingestion.

Ultraviolet (UV) light hazard.

Do not look at the light without UV eye protection.

High voltage hazard.

I/O On/Off.

Alternating current.

14 STERRAD® 100NX® User’s Guide

Chapter 3. Load Preparation

Load Preparation

Load Preparation 3

The STERRAD® 100NX® Sterilizer is designed for sterilization of both

metal and nonmetal medical devices at low temperatures. The STERRAD

sterilization process is a multiphase sterilization process that utilizes

a combination of exposure to hydrogen peroxide vapor and plasma to

safely sterilize medical instruments and materials without leaving toxic

residue. Because the cycle operates within a dry environment and at low

temperatures, it is especially suitable for instruments sensitive to heat and

moisture.

CAUTION: KNOW WHAT YOU CAN PROCESS.

Before processing items in the sterilizer, make sure you know how the STERRAD

Sterilization Process will affect the item. When constructing your load, the total

weight of the load to be sterilized should not exceed the load requirements for the

specifi c cycle. If you have questions, or if you are in doubt about the materials

in your devices, contact the medical device manufacturer or your ASP Customer

Representative for more information.

CAUTION: RISK OF VIOLATION OF WARRANTY.

Improper processing may limit our liability for damage to processed instruments.

Improper processing may also void your instrument warranty.

®

®

Load Weight Requirements

The weight of the items to be sterilized must conform to the weights used for

validating the sterilizer processes. These weights are listed in the following

table. The weight of the load depends on the cycle selected and whether one

or both shelves are used.

STANDARD Cycle 9.7 kg (21.4 lbs) total weight 1 or 2 shelves

DUO Cycle 6.0 kg (13.2 lbs) total weight 1 or 2 shelves

EXPRESS Cycle 4.9 kg (10.7 lbs) total weight Bottom shelf only

FLEX Cycle 9.7 kg (21.4 lbs) total weight 1 or 2 shelves

STERRAD® 100NX® User’s Guide 15

Cycle T ype Weight Shelves

3 Load Preparation

STANDARD Cycle Processing

The STERRAD® 100NX® Sterilizer can sterilize instruments which have

diffusion-restricted spaces, such as the hinged portion of forceps and scissors.

Medical devices with the following materials and dimensions can be

processed in the STERRAD

Single channel stainless steel lumens with an inside diameter of 0.7 mm

®

100NX® Sterilizer STANDARD cycle:

or larger and a length of 500 mm or shorter.†

Processing Tubing

ASP has validated the processing of non-reusable polyethylene and

®

Tefl on

(polytetrafl uoroethylene) medical grade tubing with the

dimension and cycles listed below. (These tubing claims have not been

reviewed by the Food and Drug Administration (FDA) as the FDA does

not classify tubing as medical devices.):

An inside diameter of 1 mm or larger and a length of 1000 mm

or shorter can be processed in the STERRAD

STANDARD cycle.

*

®

100NX® Sterilizer

DUO Cycle Processing

Medical devices, including many fl exible endoscopes with accessory devices

such as light cords and cameras with the following material and dimensions

can be processed in the STERRAD

Single channel polyethylene and Tefl on

fl exible endoscopes with an inside diameter of 1 mm or larger and a

length of 875 mm or shorter.

®

100NX® DUO Cycle.

®

(polytetrafl uoroethylene)

Cameras.

Accessory light cords.

Flexible endoscopes without lumens.

Note: Do not include more than 2 fl exible endoscopes per

load.

†The validation testing for this lumen size was conducted using a maximum of 10 lumens in

the USA; 40 lumens for markets outside the USA. Your loads should not exceed the validated

maximum number of lumens.

*Sterilize without any additional load. Up to 20 pieces of tubing may be sterilized at one time.

16 STERRAD® 100NX® User’s Guide

Load Preparation 3

EXPRESS Cycle Processing

The following types of medical devices can be sterilized in the EXPRESS

Cycle:

General medical devices requiring surface sterilization, or sterilization of

mated titanium and stainless steel surfaces.

Rigid or semi-rigid endoscopes without lumens; for example da Vinci

endoscopes.

FLEX Cycle Processing

®

Medical devices, including most fl exible endoscopes, with the following

materials and dimensions can be processed in the STERRAD

®

100NX®

Sterilizer FLEX cycle:

Single channel polyethylene and Tefl on

®

(polytetrafl uoroethylene)

fl exible endoscope with an inside diameter of 1 mm or larger and length

of 850 mm or shorter.

Flexible endoscopes without lumens.

**

Note: Do Not process more than 2 fl exible endoscope per

load.

Check the medical device manufacturer’s instructions before loading any

item into the STERRAD

®

100NX® Sterilizer.

**One or two fl exible endoscopes can be processed per sterilization cycle. No additional load.

STERRAD® 100NX® User’s Guide 17

3 Load Preparation

Cycles and Materials Processing

CAUTION: RISK OF DAMAGE TO LOAD OR STERILIZER.

Do not attempt to sterilize items or materials that do not comply with the guidelines

specifi ed in this user’s guide. Consult the medical device manufacturer’s instructions

or call your ASP Representative to determine if an item can be sterilized by the

STERRAD

®

100NX® Sterilization System.

This chapter includes cycle information regarding recommended items,

materials, and some typical devices that can be sterilized in each of the cycles

on the STERRAD

you need materials information.

®

100NX® Sterilizer. Please refer to these pages whenever

Check the medical device manufacturer’s instructions before loading any

item into the STERRAD

There is a wide variety of materials and devices that can be sterilized in the

STERRAD

Representative or visit our website at www.aspjj.com. Information may also

be obtained from the device manufacturer.

®

100NX® Sterilizer. For more information contact your local ASP

®

100NX® Sterilizer.

18 STERRAD® 100NX® User’s Guide

Load Preparation 3

STERRAD® 100NX® User’s Guide 19

3 Load Preparation

20 STERRAD® 100NX® User’s Guide

Load Preparation 3

STERRAD® 100NX® User’s Guide 21

3 Load Preparation

Recommended Materials

There is a wide variety of materials and devices that may be sterilized in the

sterilizer. The materials listed below are commonly found in medical devices

and represent typical classes of materials used to construct medical devices.

The items marked with an asterisk (*) may have limited life after repeated

sterilization.

Please contact your ASP Representative for more information. Information

may also be obtained from the device manufacturer.

Thermoplastics

Ethylvinyl Acetate (EV A)

Kraton

Liquid Crystal Polymer (LCP)

Polyacetal (Delrin

®

Polymers

®

acetal resin)*

Polyamide (Nylon)*

Polycarbonate

Polyetheretherketone (PEEK)

Polyetherimide (ULTEM

Polyethylene

Polymethyl methacrylate (PMMA)*

Polyphenylene sulfone (Radel

Polypropylene

Polystyrene

Polytetrafl uoroethylene (Tefl on

Thermoplastic Elastomers

Santoprene™

®

Polymers)

®

)*

®

)

22 STERRAD® 100NX® User’s Guide

Thermosetting Elastomers

Silicone

Polyurethane

PVC

Glass

Glass

Metal

Aluminum

Brass

Gold

Stainless steel

Load Preparation 3

Titanium

Items Not To Be Processed

Single use items for which the manufacturer does not recommend

resterilization.

Liquids and powders.

Items or materials that absorb liquids.

Items made of materials that contain cellulose, such as cotton, paper or

cardboard, linens, huck towels, gauze sponges, or any item containing

wood pulp

Paper instrument count sheets or lot stickers.

Items with hinged/mated nylon surfaces.

Instruments and devices that cannot withstand a vacuum and are labeled

for gravity steam sterilization methods only.

Items whose design permits the surfaces to collapse onto each other

unless some method is used to keep the surfaces separated.

Devices with dead-end lumens.

STERRAD® 100NX® User’s Guide 23

3 Load Preparation

Devices with internal parts, such as sealed bearings, that cannot be

immersed, may present diffi culties in cleaning and should not be

processed in the STERRAD

®

100NX® Sterilizer.

Implants for which the manufacturer has not specifi cally recommended

sterilization in the STERRAD

Do Not Process in the EXPRESS Cycle

Items made of nylon cannot be processed in the EXPRESS Cycle.

Items made of Kraton

Items made of Polyurethane cannot be processed in the EXPRESS Cycle.

Items with mated Delrin

®

cannot be processed in the EXPRESS Cycle.

®

surfaces cannot be processed in the EXPRESS

Cycle.

Items with mated anodized aluminum surfaces cannot be processed in the

EXPRESS Cycle.

Items with mated Radel

®

surfaces cannot be processed in the EXPRESS

Cycle.

Items with mated Ultem

®

surfaces cannot be processed in the EXPRESS

Cycle.

Items with lumens cannot be processed in the EXPRESS Cycle.

Do Not Process in the DUO Cycle

®

100NX® Sterilizer.

Items with mated anodized aluminum surfaces cannot be processed in the

DUO Cycle.

24 STERRAD® 100NX® User’s Guide

Load Preparation 3

Guidelines for Preparing Items to Be

Sterilized

Note: All items must be cleaned, rinsed, and thoroughly

dried before being placed in the STERRAD

Sterilizer. Loads containing moisture may cause cycle

cancellations.

Cleaning, Rinsing, and Drying

Cleaning and sterilization are two separate processes. Proper cleaning of

instruments and devices is a critical and necessary step prior to sterilization.

All items including accessories must be thoroughly cleaned, rinsed, and

dried before loading into the sterilizer.

Carefully inspect all instruments, devices, and accessories for cleanliness

and dryness prior to packaging. If visible soil is present, the item must be

re-cleaned and dried prior to sterilization. If moisture is present, dry the

item thoroughly prior to sterilization.

Carefully inspect all instruments, devices, and accessories for fl aws

or damage prior to packaging. Items with fl aws or damage should be

replaced or repaired before using.

®

100NX®

Note: Periodic careful inspection of items after repeated

exposure to disinfectant/cleaner/sterilant is necessary,

due to the potential damaging effects of the chemical

agents.

Cleaning is necessary to remove organic and inorganic soil and debris from

equipment. This process also removes many microorganisms from the

surface of the items. Sterilization then inactivates all remaining spores and

live microorganisms.

Clean your devices according to the medical device manufacturers’

instructions. You must remove all blood, tissue, and soil from items using

appropriate detergents, cleansers and/or methods.

Rinse items thoroughly to remove detergent or cleanser residue. Use

treated water that is of a quality that ensures hard water stains do not

occur. Failure to remove all organic materials or detergents may result in

the formation of light-colored residue on the devices. If residue is visible,

you should clean, rinse, dry, and resterilize the device prior to use.

STERRAD® 100NX® User’s Guide 25

3 Load Preparation

WARNING! POSSIBLE RESIDUAL HYDROGEN PEROXIDE CONTACT!

Failure to ensure that instruments are completely dry before they are processed in

the STERRAD

on the surface of the load after the cycle is complete. This may cause contact burns

when the surface of the load is handled.

Dry all items thoroughly. An acceptable method for drying is to blow

compressed gas through the lumen until no moisture exits the distal end

of the device. Please ensure that any method used to dry the devices is

in accordance with the manufacturers’ instructions for use or contact

the device manufacturer to obtain appropriate and safe procedures. It

is necessary to remove moisture from all parts of the items. Only dry

items should be loaded into the sterilization chamber to prevent cycle

cancellation.

®

sterilizer may result in residual hydrogen peroxide being present

Some complex reusable medical devices may require disassembly for

proper cleaning and sterilization. It is very important that you follow

the device manufacturers’ recommendations concerning cleaning and

sterilization. In the absence of STERRAD

please contact the relevant medical device manufacturer.

®

System-specifi c instructions,

WARNING! POSSIBLE NON-STERILE DEVICE!

Loads containing moisture may result in either a non-sterile device or cycle

cancellation. Wear chemical resistant gloves when handling items from any load

containing moisture.

26 STERRAD® 100NX® User’s Guide

Packaging and Loading

If you choose to package the instruments (highly recommended), proper use

and preparation of trays, pouches, and instruments can minimize or prevent

cycle cancellations and positive biological indicator (BI) results due to load

related problems. All instruments must be cleaned, rinsed, and thoroughly

dried before loading into the sterilizer.

Special considerations for loading and processing fl exible endoscopes are

presented at the end of this chapter.

Instrument Trays

Only STERRAD

Trays, are recommended for use in the STERRAD

These instrument trays are specially designed to allow diffusion of

hydrogen peroxide and plasma around every item in the load.

®

Instrument Accessories and APTIMAX® Instrument

Load Preparation 3

®

100NX® Sterilizer.

Tray Mats

Packaging

Instrument trays should only be padded with STERRAD

®

Mats or polypropylene sterilization wrap. Never use linen, cellulose, or

any materials listed in the “Items Not To Be Processed” section.

Follow the Instructions for Use included with the STERRAD

Instrument Mats to determine the number of mats that can be used at one

time in the chamber. Do not use more than the recommended amount of

mat material in the chamber at any time.

Cycle Name Square Centimeters Square Inches

STANDARD 2250 349

DUO 2774 430

FLEX 2250 349

EXPRESS 1387 215

Do not use foam pads in instrument trays as they may absorb the

hydrogen peroxide.

Use only STERRAD

wrap and Tyvek

®

Sterilizer-compatible polypropylene sterilization

®

pouches.Tyvek® Pouches and Rolls with STERRAD®

Chemical Indicators are the only pouches and rolls available on the

market that are validated by ASP. They are the only pouches and rolls

validated by ASP for effi cacy and stability.

Instrument

®

STERRAD® 100NX® User’s Guide 27

3 Load Preparation

Do not use paper pouches or sterilization wraps containing cellulose or

cotton.

Do not use any wraps or packaging that are not approved by ASP or

materials listed in the “Items Not To Be Processed” section. In the USA,

use only FDA-cleared polypropylene wraps.

Properly arrange the items or the scope in a tray to ensure adequate

diffusion of hydrogen peroxide throughout the load.

Place peel pouches on edge, if possible. Arrange them so that the

transparent side of a pouch faces the opaque side of the next pouch. Do

not stack pouches on top of each other.

Do not stack instruments inside the trays. Do not stack trays. Do not

stack trays within trays. Do not wrap instruments within a wrapped tray.

Loading

If you are using rigid containers cleared by the FDA for use in the

STERRAD

®

100NX® Sterilizer, follow the Instructions for Use provided

by the rigid container manufacturer. Verify that the rigid containers are

cleared for use in each sterilization cycle. Remember the following:

Do not stack instruments inside the containers.

Do not stack containers.

Do not stack containers within containers.

Do not wrap instruments within the containers.

Place STERRAD

®

Chemical Indicator Strips inside trays and pouches as

needed.

Do not allow any item to touch the walls of the sterilization chamber,

door, or electrode.

STANDARD and FLEX Cycles Loading Preparation

The STERRAD

were validated using a load weight of 4.9 kg (10.7 lbs) per shelf. When

constructing your load, the total weight of the load to be sterilized should

not exceed 9.7 kg (21.4 lbs).

®

100NX® Sterilizer STANDARD and FLEX Cycles

DUO Cycle Loading Preparation

The STERRAD

28 STERRAD® 100NX® User’s Guide

®

100NX® Sterilizer DUO Cycle was validated using

a total load weight of 6.0 kg (13.2 lbs). When constructing your load,

the total weight of the load to be sterilized should not exceed 6.0 kg

(13.2 lbs).

Loading...

Loading...