Page 1

ZFR1812 Wall Mount Wireless Field Bus Router

Installation Instructions

MS-ZFR1812-x

Part No. 24-10325-45, Rev. A

Issued April 2016

Application

Use the ZFR1812 Wireless Field Bus Router only to

provide an input to equipment under normal

operating conditions. Where failure or malfunction of

the ZFR1812 Router could lead to personal injury or

property damage to the controlled equipment or

other property, additional precautions must be

designed into the control system. Incorporate and

maintain other devices, such as supervisory or

alarm systems or safety or limit controls, intended to

warn of or protect against failure or malfunction of

the ZFR1812 Router.

IMPORTANT: The ZFR1800 Series Wireless Field

Bus System is not designed or intended for use in

mission-critical or life/safety applications.

A ZFR1812 Wireless Field Bus Router is used with

Advanced Application Field Equipment Controllers

(FACs), Field Equipment Controllers (FECs), Input/

Output Modules (IOMs), and Variable Air Volume

Modular Assembly (VMA) Series field controllers.

The ZFR1812 Router provides a wireless interface

between:

• a field controller and the supervisory controller (b

ans of a ZFR1810 Coordinator)

me

• a field controller and associated WRZ Seri

Wireless Room

Additionally, the ZFR1812 Wireless Field Bus Router

can be used as a repeater in WRZ-7860-0 One-to-One

Wireless Room Temperature Sensing System. For

more information, refer to the WRZ Series One-to-One

Wireless Room Sensing System Technical Bulletin

(LIT-12011641).

Up to nine WRZ Series Sensors can be associated

with a single field controller. In multi-sensor

applications, the ZFR1812 Router passes all the

sensor data to an FAC, FEC, IOM, or VMA controller,

which can be configured to either average the sensors’

input or select the highest or lowest sensed condition

for control of the target zone.

Sensors

y

es

A ZFR1812 Router is powered directly from the

connected field controller’s 15 VDC output.

The ZFR812 Router is also included in the Repeater

Accessory Kits, MS-ZFRRPTK-H1 or MS-ZFRRPTKH2. These kits include a 24 VAC to 15 VDC converter

power supply for stand-alone operation. As a repeater,

the ZFR1812 extends the range and strengthens the

wireless mesh network.

Refer to the ZFR1800 Series Wireless Field Bus

System Technical Bulletin (LIT-12011295) or the

ZFR1800 Series Wireless Field Bus System Quick

Reference Guide (LIT-12011630) for information on

commissioning and configuring a ZFR1800 Series

Wireless Field Bus System for operation.

North American Emissions Compliance

United States

Compliance Statement (Part 15.19)

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

1. This device may not cause harmful interference

an

d

2. This device must accept any interference

received, including interference that may cause

undesired operation.

Warning (Part 15 .21)

Changes or modifications not expressly approved by

the party responsible for compliance could void the

user’s authority to operate the equipment.

Canada

Industry Canada Statement

The term IC before the certification/registration

number only signifies that the Industry Canada

technical specifications were met.

Le terme « IC » précédant le numéro d'accréditation/

inscription signifie simplement que le produit est

conforme aux spécifications techniques d'Industry

Canada.

,

ZFR1812 Wall Mount Wireless Field Bus Router Installation Instructions

1

Page 2

Installation

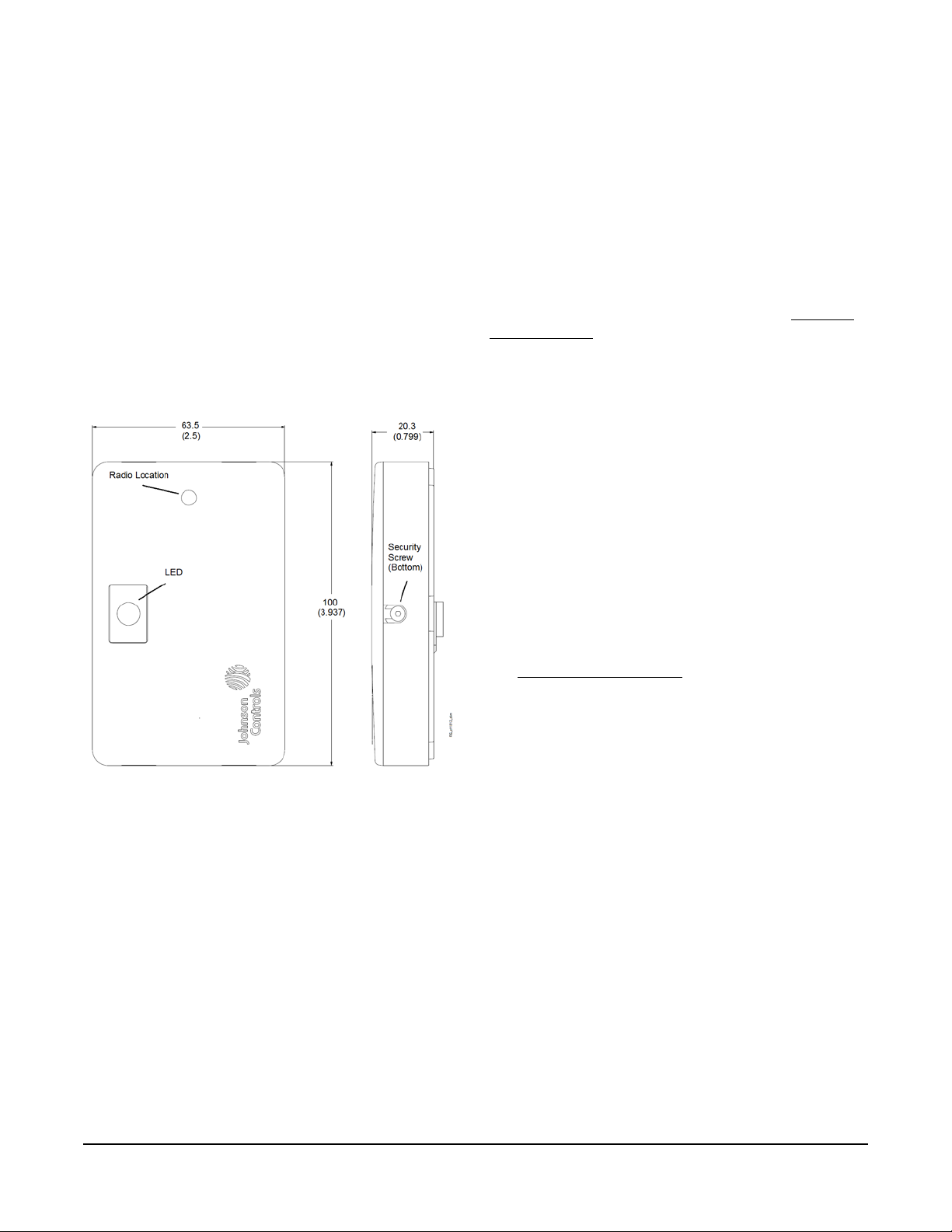

Figure 1: ZFR1812 Wireless Field Bus Router,

Physical Features and Dimensions, mm (in.)

Follow these guidelines when installing a

ZFR1812 Router:

• Transport the ZFR1812 Router in the original

container to minimize vibration and shock damage.

• Do not drop the ZFR1812 Router or subject it to

physical shock.

Materials and Special Tools Needed

• A 1.5 mm (1/16 in.) Allen wrench or a Johnson

Controls® T- 4000-119 Allen-He ad Adjustment Tool

is required for tightening or loosening the security

screw

Dimensions

See Figure 1 for physical features and dimensions of

the ZFR1812 Router.

The ZFR1812 can be mounted directly to drywall with

drywall anchors. Both the standalone and repeater kit

versions of the ZFR1812 include a 10 foot long RJ12

cable hardwired to the device. The Repeater Kit

versions (the ZFRRPTK-H1 and ZFRRPTK-H2)

provide additional flexibility for mounting such as a

separate power supply. ZFR1812s can be flush

mounted to a wall or ceiling, or mounted on a 4x4 box

using a standard mudplate. When mounting the

ZFR1812 Router to an enclosure, mount it to the top,

bottom, or side of the enclosure. For floor mount

unitary equipment, mounting on top where books or

other items may be placed is not ideal. See Location

Considerations.

Mounting Directly to Drywall with Drywall Anchors

- ZFR1812

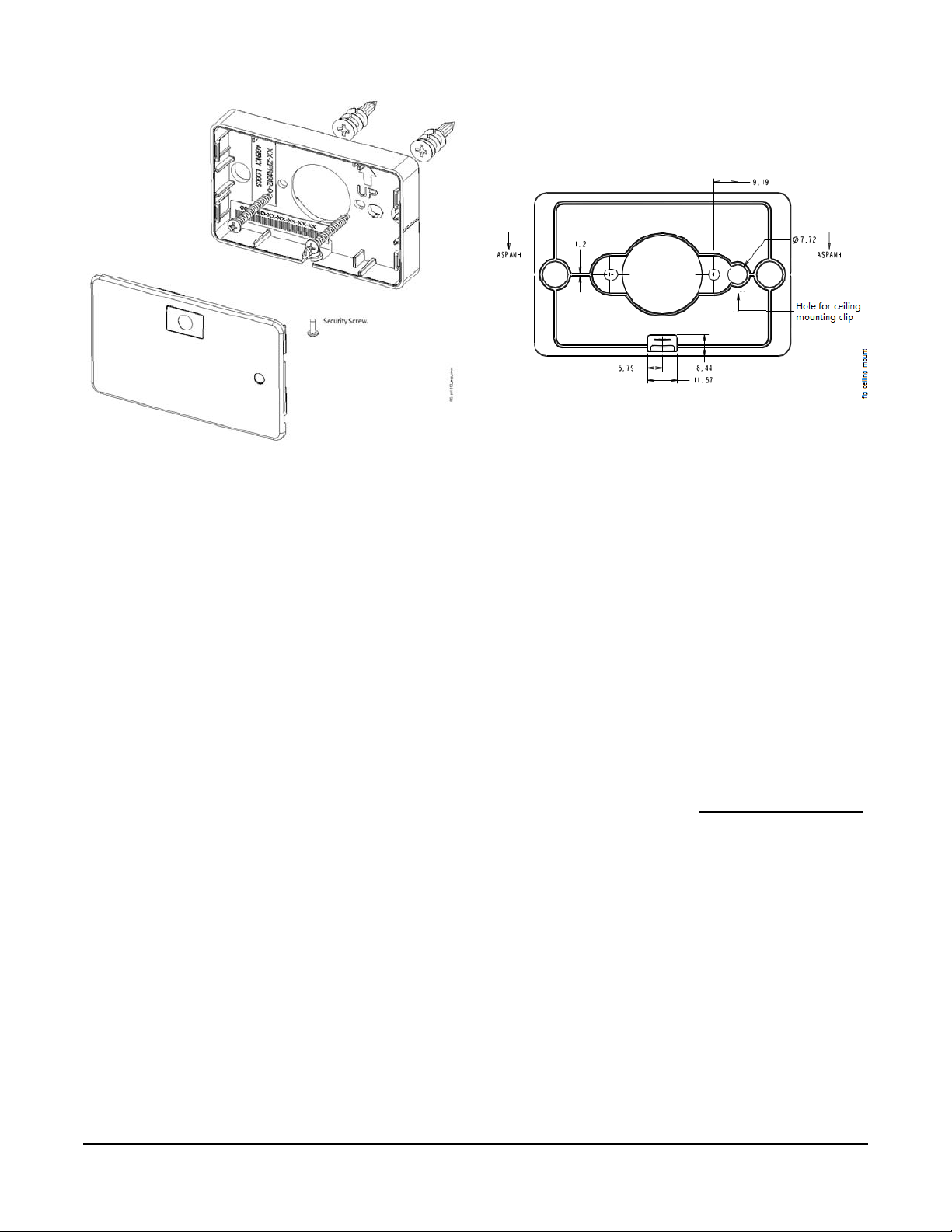

1. Separate the plastic base and circuit board

assembly (cover). Do not remove the security

screw from the cover. See Figure 2.

IMPORTANT: The label showing the unit MAC

address is on the plastic base of the unit. Be sure to

keep the plastic base and circuit board assemblies

together so the correct MAC address is shown.

Mounting

Note: These instructions are for mounting new

ZFR1812s rather than retrofitting factory-mounted

routers.

2. Determine where to secure the plastic base to the

surface using the mounting holes and supp lie d

screws. A template (Figure 11) is provided at the

end of this document to help you place the

mounting holes.

3. Set the DIP switches. (See

Setup and Adjustments

4. Reattach the circuit board assembly in the plastic

base being careful not to pinch the a t tached RJ-12

cable.

5. Tighten the security screw to prevent tampering

using a 1.5 mm (1/16 in.) Allen wrench or a

Johnson Controls® T-4000-119 Allen-Head

Adjustment Tool. Use caution when tightening the

screw to avoid stripping the plastic threads in the

ZFR1812.

Mounting the ZFRRPTK-H1

The ZFRRPTK-H1 is intended for flush wall mount or

ceiling mount applications. In addition to the ZFR1812,

it includes a power supply, a 10 ft RJ-12 cable for

connecting the power supply, and an adapter to

connect the power supply to the RJ-12 cable.

).

ZFR1812 Wall Mount Wireless Field Bus Router Installation Instructions

To mount the ZFRRPTK-H1:

1. Separate the plastic base and circuit board

assembly (cover). Do not remove the security

screw from the cover. See Figure 2.

2

Page 3

IMPORTANT: The label showing the unit MAC

Figure 2: ZFR1812 Wireless Field Bus Router,

with Plastic Base and Circuit Board Assy

Separated

Figure 3: ZFR1812 Wireless Field Bus Router,

with Plastic Base Hole for Ceiling Mount

address is on the plastic base of the unit. Be sure to

keep the plastic base and circuit board assemblies

together so the correct MAC address is shown.

2. Decide whether you are mounting on a wall or

ceiling.

a. For flush wall mount applications, determine

where to secure the plastic base to the surface

using the mounting holes and supplied screws.

A template (Figure 1 1) is provided at the end of

this document to help you place the mounting

holes.

b. For ceiling mount applications, mount the

ZFR1812 to the grid between the tiles. Ther e

are a number of ceiling mounting clips

available from third parties which can be used.

Make sure to match the clip you purchase to

the grid in the location where you are doing the

installation. Ceiling grid dimensions and offsets

vary, so using an incorrectly sized clip may

prevent mounting the ZFR1812 flush for a

professional appearance. A hole is provided in

the base of the assembly for this purpose

(Figure 3).

IMPORTANT: If you are using a ceiling mounting clip

you must make sure that no part of the clip makes

contact with the circuit board assembly when installed.

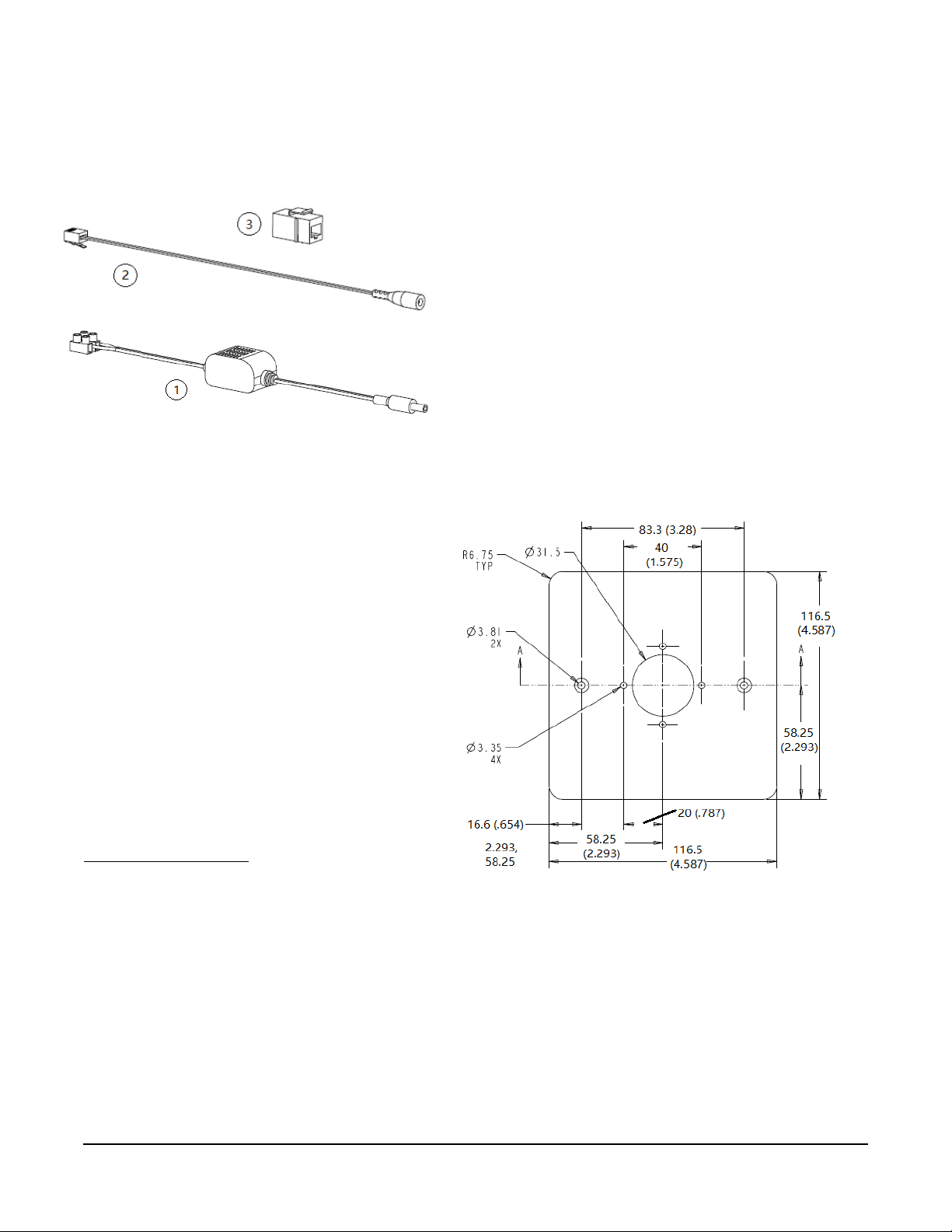

3. Assemble the external power and adapters as

necessary (Figure 4).

a. The 24 VAC to 15 VDC power supply (1) uses

screw terminals to attach to a 24 volt source.

b. The adapter connects the 15 VDC output of the

power supply to an RJ12 adapter (2). Plug this

adapter directly to the cable coming from the

ZFR1812 through a connector (3 ).

c. This connector (3) is then used to connect to

the 10 ft RJ-12 cable which is attached to the

ZFR.

Note: Any inline adapter used to extend the

connection of the ZFR1812 to a controller or po wer

must be a straight through adapter instead of

crossover.

4. Set the DIP switches. See Setup and Adjustments

5. Reattach the circuit board assembly in the plastic

base.

.

ZFR1812 Wall Mount Wireless Field Bus Router Installation Instructions

3

Page 4

6. Tighten the security screw to prevent tampering

Figure 4: Power supply and adapters

Figure 5: ZFR1812 Wireless Field Bus Router,

Wall Plate Dimensions mm (in.)

using a 1.5 mm (1/16 in.) Allen wrench or a

Johnson Controls® T-4000-119 Allen-Head

Adjustment Tool. Use caution when tightening the

screw to avoid stripping the plastic threads in the

ZFR1812.

Mounting in a Wall Plate - ZFRRPTK-H2

Note: The wall plate is intended to attach to a

mudplate rather than directly to the wall.

7. Assemble the external power and adapters as

necessary (Figure 4). Note that the power supply

can be secured in an electrical box with the

provided two-sided tape. An electrical box is not

included with the kit.

a. The 24 VAC to 15 VDC power supply (1) uses

screw terminals to attach to a 24 volt source.

b. The adapter connects the 15 VDC output of the

power supply to an RJ12 adapter (2). This

adapter can be plugged directly into the RJ12

jack on the ZFR1812 or connected to a

connector (3).

c. This conn e cto r (3 ) is then used to connect to

the 10ft RJ12 cable which is attached to the

ZFR1812.

8. Mount the wall plate with ZFR1812 in the selected

location using standard box screws. Be sure to

leave enough slack in the cable so you can still pull

the ZFR1812 if you need to change the DIP

switches.

1. Separate the plastic base and circuit board

assembly (cover). Do not remove the security

screw from the cover. See Figure 2.

IMPORTANT: The label showing the unit MAC

address is on the plastic base of the unit. Be sure to

keep the plastic base and circuit board assemblies

together so the correct MAC address is shown.

2. Attach the plastic base to the supplied wall plate.

Figure 5 shows the wall plate dimensions.

3. Connect the external cable assembly to the 6-pin

modular receptacle.

4. Set the DIP switches. (See

Setup and Adjustments

5. Reattach the circuit board assembly in the plastic

base.

6. Tighten the security screw to prevent tampering

using a 1.5 mm (1/16 in.) Allen wrench or a

Johnson Controls® T-4000-119 Allen-Head

Adjustment Tool. Use caution when tightening the

screw to avoid stripping the plastic threads in the

ZFR1812.

)

ZFR1812 Wall Mount Wireless Field Bus Router Installation Instructions

4

Page 5

The preferred orientation for the ZFR1812 Router is in

Figure 6: ZFR1812 Mounted in Wall Plate

a horizontal orientation with the green LED at the top. If

you feel that you are not able to get proper signal

strength, you can rotate the device 90 degrees on its

plastic wall plate. See Figure 6.

Location Considerations

Follow these guidelines when locating a ZFR1812

Router within a ZFR1800 Series System.

• Locate the ZFR1812 Router so that it is easily

accessible.

• For best signal transmission, mount the ZFR1812

Router in an unobstructed location below (and

clear of) any pipes, duct work, or other metal

obstructions by at least 50 mm (2 in.).

• Due to the nature of the radio frequency waves, a

wireless device may have significantly different

signal strengths if its position changes relative to

another wireless device or if its environment

changes.

• Locate the ZFR1812 Router in line-of-sight with as

many ZFR1812 Routers and WRZ Sensors as

possible.

• Do not mount the ZFR1812 Router in recessed

areas, metal enclosures, or shelving units.

Note: For detaile d information on location guidelines

for a ZFR1800 Series system, and for estimating the

number of ZFR1812 Routers needed as repeaters for

extending wireless transmission range, refer to the

ZFR1800 Series Wireless Field Bus System Technical

Bulletin (LIT-12011295).

Wireless Signal Transmission Considerations

Line-of-sight transmission ranges between a

ZFR1810 Coordinator, ZFR1812 Router, and a

WRZ Sensor can be less than the maximum distances

shown in Table 1. The effective transmission range for

indoor applications varies because of wireless signal

absorption and reflection due to metal obstructions,

walls (or floors), and furniture found in typical building

interiors.

Table 1: Indoor Line-of-Sight Transmission

Ranges

Range Type Transmission Distance

ZFR1810

Coordinator,

ZFR1812 Router

Recommended 15.2 m (50 ft) 15.2 m (50 ft)

Maximum 76.2 m (250 ft) 30 m (98 ft)

WRZ Series

Sensor

Wiring

Wiring Considerations and Guidelines

IMPORTANT: Do not connect supply power to the

ZFR1812 Router before finishing wiring and

checking all wiring connections. Short circuits or

improperly connected wires may result in permanent

damage to the Router.

IMPORTANT: Use copper conductors only. Make

all wiring in accordance with local, national, and

regional regulations. The ZFR1812 Router is a

low-voltage (less than 30 VAC) device. Do not

exceed the ZFR1812 Router’s electrical ratings.

IMPORTANT: Prevent any static electric discharge

to the ZFR1812 Router . Static electric discharge can

damage the ZFR1812 Router and void any

warranties.

IMPORT ANT: Do not connect the ZFR1812 Router

to the power supply before setting the PAN OFFSET

switches.

Wiring with an FEC or VMA16 Series Field Controller

Connect the ZFR1812 Router to the field controller as

shown in Table 2. This connection provides both power

and communication to the ZFR1812 Router.

Note: When using a field controller in a wireless field

bus network, ensure that the DIP switch for Address

128 is set to the ON position.

ZFR1812 Wall Mount Wireless Field Bus Router Installation Instructions

5

Page 6

Figure 7: Pin Number Assignments for

RJ-12 Jack

(15 VDC)

SA or FC Bus

-

Bus and Power Common

Power

(15 VDC)

(RJ-12 Mod ul ar Jack)

Bus and Power Common

p

Table 2: Connecting the ZFR1812 Router to a Field Controller

Field

Controller

Model

Plug the ZFR1812 Router

Connector Cable into the

Following Jack on the Field

Controller:

Connection Points for the

Bluetooth® CVT

Commissioning Interface

and Other SA Bus Products

Use This

Communications Port

between WEFC and

1

Wired IOMs, WRZ

Sensors, or VFDs:

FAC26 FC Bus RJ-12 Jack SA Bus RJ-12 Jack SA Bus Terminals

FAC36 FC Bus RJ-12 Jack SA Bus RJ-12 Jack SA Bus Terminals

FEC16 FC Bus RJ-12 Jack SA Bus RJ-12 Jack SA Bus Terminals

FEC26 FC Bus RJ-12 Jack SA Bus RJ-12 Jack SA Bus Terminals

2,3

IOM17

2,3

IOM27

2,3

IOM37

IOM472,

VMA1615/30 FC Bus RJ-12 Jack SA Bus RJ-12 Jack SA Bus Terminals

1. SA Bus Products include the DIS1710 Local Controller Display, the MS-BTCVT-1 Wireless

Commissioning Converter, and the NS Series (hard-wired) Network Sensors, Balancing Sensors, and

Discharge Air Temperature Sensors.

2. IOMs cannot be used in wireless mode to extend the IO of a field controller. You must always hardwire

IOMs to their host field controller.

3. Do not connect any device to the SA Bus/FC Bus terminal block when using the IOM with a ZFR1812.

SA/FC Bus RJ-12 Jack Not available in wireless mode.

Use CCT with ZFR Dongle.

SA/FC Bus RJ-12 Jack Not available in wireless mode.

Use CCT with ZFR Dongle.

SA/FC Bus RJ-12 Jack Not available in wireless mode.

3

SA/FC Bus RJ-12 Jack Not available in wireless mode.

Use CCT with ZFR Dongle.

Use CCT with ZFR Dongle.

N/A

N/A

N/A

N/A

For further information on how to set up a field

controller to work with the ZFR1812 Router, refer to the

following documents:

• FAC3611 Advanced Application Field Equipment

Controller Installation Instructions (Part No. 2410143-470)

• FEC16 Field Equipment Controller Installation

Instructions (Part No. 24-10143-136)

• FEC26 Field Equipment Controller Installation

Instructions (Part No. 24-10143-144)

• IOM17 and IOM27 Input/Output Modules

Installation Instructions (Part No. 24-1044-76)

• IOM37 Input/Output Module Installation

Instructions (Part No. 24-1044-84)

• IOM47 Input/Output Module Installation

Instructions (Part No. 24-1044-92)

• VMA16 Series Variable Air Volume Controllers

Installation Instructions (Part No. 24-10143-20)

Sensor, SA Bus, or FC Bus Port

Power

6

5

4

3

2

1

SA or FC Bus +

FIG:RJ_

inout

ZFR1812 Wall Mount Wireless Field Bus Router Installation Instructions

6

Page 7

The value equals the sum of the numbers set to ON.

Figure 8: Connecting an IOM to a

Wireless-Enabled VMA1615/1630 Field Controller

Figure 9: Wiring a Discharge Air Net sensor , Zone

Netsensor with Terminal Block, or IOM to a

Wireless-Enabled VMA1615/1630 Field

Controller

For example, if the DIP switches labeled 1, 4, and 8

are set to ON, the PAN Offset value is 13

(1 + 4 + 8 = 13).

When selecting a PAN Offset value for a wireless

system:

• Use a unique PAN Offset value for each wireless

mesh network at a job site.

• Use the same PAN Offset value for each wireless

device in a wireless mesh network—the

ZFR1810 Coordinator and each associated

ZFR1812 Router and WRZ Sensor.

• If, after setting the PAN Offset value you find that

you are unable to communicate with the desired

network, it may help to toggle the DIP switches to

ensure a good connection. Power down the

ZFR1812 and toggle the switches (all off, then all

on) and then set the switches to the desired PAN.

Restore power to the ZFR1812 and see that it joins

the correct network.

• If the ZFR1812 misread the dip switches, it might

become the child of another network and use up an

available child slot in a device you did not expect. If

this situation occurred, a reform on the incorrect

network should clear up the now unusable child

address.

Setup and Adjustments

IMPORTANT: Ensure that the PAN OFFSET

switches are set to the same value for each

ZFR1810 Coordinator, ZFR1812 Router, and

WRZ Sensor in a mesh network.

IMPORT ANT: Do not connect the ZFR1812 Router

to the power supply before setting the PAN OFFSET

switches.

IMPORTANT: On the MS/TP Address switch block

of the associated FEC/IOM/VMA16 Field Controller,

set switch 128 to ON for use with a ZFR1812

Router.

Set the P AN Offset value of the ZFR1812 Router using

the DIP switches (located on the back of the cover) to

configure the ZFR1812 Router to communicate on the

wireless mesh network. See Figure 1 and Figure 10.

Note: On some date code labels, the switch position

numbers on the bottom of the DIP switch are reversed.

In either case, the switch positions are always read

right to left.

ZFR1812 Wall Mount Wireless Field Bus Router Installation Instructions

7

Page 8

Figure 10: Sample DIP Switch Settings

Wireless transmissions between ZFR1810

Coordinators and ZFR1812 Routers occur as needed.

Wireless transmissions between ZFR1812 Routers

and WRZ Sensors occur approximately every 60

seconds or when the occupancy button on the WRZ

Sensor is pressed. Refer to the WRZ Series Wireless

Room Temperature Sensors Installation Instructions

(Part No. 24-10332-2) for more information.

Approximately once every 10 seconds, the Signal

Strength LED flashes to indicate the strength of the

signal received from neighboring devices. See Table 3.

Note: The Signal Strength LEDs on all the ZFR1812

routers in a network extinguish after approximately

2 hours of normal operation, making the ZFR1812 less

distracting when installed in an open area. To re-enable

the ZFR1812 LEDs for troubleshooting purposes,

perform a scan using the ZFR Checkout Tool (ZCT).

Alternatively, push the Network Optimize/Reform Push

Button on the ZFR1810 coordinator for 0 to 5 seconds.

Note that if you press this button more than 5 seconds,

a Network Optimize or Reform is initiated.

Refer to the ZFR1800 Series Wireless Field Bus

System Technical Bulletin (LIT-12011295) for more

information on determining the signal strength between

ZFR1800 Series devices in your application.

Troubleshooting

Use the Status LED (see Figure 1) along with the

information in Table 3 to troubleshoot the ZFR1812

Router.

Wireless Signal Strength

A wireless signal strength indication LED displays the

reception strength of the transmissions between the

ZFR1810 Coordinators, ZFR1812 Routers, and the

WRZ Series Sensors. This LED helps determine the

network connectivity status when selecting locations for

the devices during system installation.

ZFR1812 Wall Mount Wireless Field Bus Router Installation Instructions

8

Page 9

WRZ-SST-120 Wireless Sensing System Tool

Use the WRZ-SST-12 0 Wireless Sensing System Tool

with a WRZ Series Sensor as a site survey tool to

determine the wireless signal strength between a

ZFR1810 Coordinator and a ZFR1812 Router or

between two ZFR1812 Routers. Refer to the

WRZ-SST-120 Wireless Sensing System Tool

Installation Instructions (Part No. 24-10563-12) for

more information on testing signal strength in your

application.

Table 3: ZFR1812 Router Status LED

Name Visual

Descriptions

Indication of:

General

Operation

Signal

Strength

Indication

Network

Reform

Network

Ping

Normal

operation

Wireless signal

strength

1

Operation

during network

reform

Wireless node

function in the

network

OFF Steady = No power (or normal operation for more than 2 hours).

OFF Steady with 1 Flash every 10 seconds = ZFR1812 Router is not a member of a

wireless network, invalid PAN OFFSET setting, no ZFR1810 Coordinators or ZFR1812

Routers in area.

ON Steady with Signal Strength displayed once every 10 seconds = ZFR1812 Router

is a member of a wireless network.

OFF Steady with Signal Strength displayed once every 10 seconds = Wireless network

is actively communicating, but ZFR1810 Coordinator cannot be reached (for example,

coordinator lost power).

3 Flashes - Excellent

2 Flashes - Good

1 Flash - Weak

OFF for 3 seconds - None

Rapid Flashes for 5 minutes = rapid flashes occur for up to 5 minutes:

• when the Reform Network option is initiated to the network, the ZFR1812 Router

disconnects itself from the network

• when the PAN OFFSET is changed on the ZFR1812 Router

• when the PAN OFFSET is changed on the ZFR1812 Router after it has already joined

another PAN

• when the Channel Mask in the ZFR1810 is changed from CCT

Network pings provide a means of physically locating connected devices. There are two

methods with different use cases:

1) Use ZFR Checkout T ool (ZCT) to ping an address. The LED on the connected ZFR1812

blinks, indicating the device mapped to that specific MS/TP address.

2) Press the Occupancy push button on a WRZ Network Sensor. The ZFR1812 connected

to the paired device blinks. This blinking response can be used to validate switch settings

on the sensor during installation.

1. The Signal Strength LEDs on all the ZFR1812 Routers in a network extinguish after approximately 2 hours of normal

operation, making the ZFR1812 less distracting when installed in an open area. To re-enable the ZFR1812 LEDs for

troubleshooting purposes, perform a scan using the ZCT or push the Network Optimize/Reform Push Button on the

ZFR1810 Coordinator.

ZFR1812 Wall Mount Wireless Field Bus Router Installation Instructions

9

Page 10

Repair Information

If the ZFR1812 Wireless Field Bus Router fails to

operate within its specifications, replace the unit. For a

replacement ZFR1812 Route r, contact the nearest

Johnson Controls® representative.

Accessories

See Table 4 for information on accessories for the

ZFR1812 Router . Use the ZFRRPT -H1/H2 repeater kits

for below ceiling repeater applications where the router

is in visible space. Mounting the repeater in an open or

visible space increases the transmission distances for

improved wireless coverage.

Table 4: Accessories

Product Code

Product Description

Number

MS-ZFRRPT-0 Optional Repeater Accessory for use with ZFR1811 Routers as a repeater. Includes power supply

MS-ZFRRPTK-H1 ZFR1812-0 wireless router repeater kit. Includes ZFR1812 router, 24 VAC to 15 VDC power supply,

MS-ZFRRPTK-H2 ZFR1812-0 wireless router repeater kit. Includes ZFR1812 router, 24 VAC to 15 VDC power supply,

WRZ-SST-120 Wireless Sensing System Tool. Requires WRZ Series Sensor to function as a site survey tool for

ZFR-USBHA-0 USB Dongle with ZFR Driver provides a wireless connection through the CCT to allow wireless

(20 to 28 VAC or 16 to 30 VDC input power and 12 VDC output power).

The ZFRRPT-0 with ZFR1811-1 combination is used for above ceiling repeater applications or

wherever mounting of the ZFR router is better facilitated using a ½ Inch conduit EMT connector.

RJ-12 cable for power extension, and mounting hardware.

Use the ZFRRPT-H1 for flush wall mount or ceiling mount applications.

RJ-12 cable for power extension, mounting hardware, and mounting plate for electrical box.

Use the ZFRRPT-H2 for mounting directly to a single or double gang electrical box. The electrical box is

not included with the kit.

ZFR1800 Wireless Field Bus System, or for WRZ-7860-0 One-to-One Room Temperature Sensing

System.

commissioning of the wireless-enabled FAC, FEC, IOM, and VMA16 controllers. The USB ZFR Dongle

is also used with the ZFR Checkout To ol used to troubleshoot and validate ZFR wireless meshes using

a laptop computer.

ZFR1812 Wall Mount Wireless Field Bus Router Installation Instructions

10

Page 11

Technical Specifications

ZFR1812 Wireless Field Bus Router (Part 1 of 2)

Product Code Number MS-ZFR1812-0: Field Equipment, Wireless Interface, Surface Mount, includes

hardwired 10 foot RJ-12 cable.

MS-ZFRRPTK-H1: ZFR1812-0 wireless router repeater kit. Includes ZFR1812 router, 24

VA C to 15 VDC power supply, RJ-12 cable for power extension, and mounting hardware.

MS-ZFRRPTK-H2: ZFR1812-0 wireless router repeater kit. Includes ZFR1812 router, 24

VA C to 15 VDC power supply , RJ-12 cable for power extension, mounting hardware, and

mounting plate.

Power Supply Input 8 to 18 VDC, 15 VDC Nominal. Provided from the FC/SA BUS RJ-12 jack on the FEC or

VMA16 controller or from 24 VAC to 15 VDC power supply.

The power converter for the repeater power supply has a flexible input power range and

provides regulated 12 VDC output.

Input power:

• 20–28 VAC at 78–62 mA (maximum)

• 16–30 VDC at 45–28 mA (maximum)

• Output power: 12 VDC regulated at 500 mA maximum.

Current Consumption 90 mA maximum

Addressing DIP Switches, Field Adjustable.

Wireless Band Direct-Sequence Spread-Spectrum, 2.4 GHz ISM Bands

Transmission Power 10 mW Maximum

Transmission Range 76.2 m (250 ft) Maximum Indoor Line-of-Sight

15 m (50 ft) Recommended Indoor

Ambient Conditions Operating: 0 to 50°C (32 to 122°F), less than 90% RH, Noncondensing

Non-Operating (Storage): -40 to 80°C (-40 to 176°F), less than 95% RH,

Noncondensing

Maximum Dew Point Temperature: 30°C (86°F)

Condensation: Recovers after 30 minute dry time

Materials White PC/ABS Cycoloy

Terminations RJ-12 plug for connection to FEC or VMA16 FC/SA Bus jack

Dimensions 61 x 100 x 20.5 mm (5-3/8 x 3-15/16 x 3/4 in.)

Mounting Hardware Screw mounted

Shipping Weights ZFR1812: 0.113 kg (.25 lb)

Repeaters: 227 kg (.50 lb)

ZFR1812 Wall Mount Wireless Field Bus Router Installation Instructions

11

Page 12

ZFR1812 Wireless Field Bus Router (Part 2 of 2)

Compliance United States:

Intended for Connection to an NEC Class 2 Power Source;

UL 916 Energy Management

Plenum rated per UL1995 UL94-5VB Flammability Rating

FCC Compliant to CFR47, Part 15, Subpart B, Class A

Transmission Complies with FCC Part 15.247 Regulations for Low Power Unlicensed

Transmitters

Transmitter Identification ZFR1812-0: FCC: TFB-MATRIXL;

Transmitter Identification ZFR1812-1: FCC: OEJ-WRZRADIO;

Canada:

CAN/CSA C22.2 No. 205, Signal Equipment

Industry Canada (IC) Compliant to Canadian ICES-003, Class B Limits

Industry Canada (IC) RSS-210

Transmitter Identification ZFR1810-0: 5969A-MATRIXLP

Transmitter Identification ZFR1810-1: 279A-WRZRADIO

Australia and New Zealand:

RCM Mark, Australia/NZ Emissions Compliant

Europe:

CE Mark – Johnson Controls, Inc., declares that this product is in compliance with the

essential requirements and other relevant provisions of the RED Directive.

The performance specifications are nominal and conform to acceptable industry standard. For application at conditions beyond these

specifications, consult the local Johnson Controls office. Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or

misuse of its products.

European Single Point of Contact: NA/SA Single Point of Contact: APAC Single Point of Contact:

JOHNSON CONTROLS

WESTENDHOF 3

45143 ESSEN

GERMANY

JOHNSON CONTROLS

507 E MICHIGAN ST

MIL WAUKEE WI 53202

USA

JOHNSON CONTROLS

C/O CONTROLS PRODUCT MANAGEMENT

NO. 22 BLOCK D NEW DISTRICT

WUXI JIANGSU PROVINCE 214142

CHINA

ZFR1812 Wall Mount Wireless Field Bus Router Installation Instructions

12

Page 13

ZFR1812 Wall Mount Wireless Field Bus Router Installation Instructions

Metasys® and Johnson Controls® are registered trademarks of Johnson Controls, Inc.

All other marks herein are the marks of their respective owners. © 2016 Johnson Controls, Inc.

Building Efficiency

507 E. Michigan Street, Milwaukee, WI 53202

Figure 11: ZFR18 12 Mounting Template - Scale 1.000

Published in U.S.A. www.johnsoncontrols.com

13

Loading...

Loading...