Page 1

ZFR1810 Wireless Field Bus Coordinator

Installation Instructions

MS-ZFR1810-x

Application

IMPORTANT: Use the ZFR1810 Wireless Field

Bus Coordinator only to provide an input to

equipment under normal operating conditions.

Where failure or malfunction of the ZFR1810

Coordinator could lead to personal injury or pr operty

damage to the controlled equipment or other

property, additional precautions must be designed

into the control system. Incorporate and maintain

other devices, such as supervisory or alarm systems

or safety or limit controls, intended to warn of or

protect against failure or malfunction of the

ZFR1810 Coordinator.

IMPORTANT: The ZFR1800 Series Wireless Field

Bus System is not designed or intended for use in

mission-critical or life/safety applications.

Part No. 24-10325-2, Rev. L

Issued April 2016

A ZFR1810 Coordinator can operate from eithe r of two

power sources:

• a 24 VAC, Class 2 power source when used with

an NAE55 supervisory controller

• 15 VDC power provided from the FC Bus

st Field Equipment or Supervisory Controllers

mo

that are connected directly to the FC Bus

The ZFR1810 Coordinator features a remote-mount

antenna and cable to allow transmission when the

ZFR1810 Coordinator is mounted inside a metal panel.

Refer to the ZFR1800 Series Wireless Field Bus

System Technical Bulletin (LIT-12011295) or the

ZFR1800 Series Wireless Field Bus System Quick

Reference Guide (LIT-12011630) for information on

commissioning and configuring a ZFR1800 Series

Wireless Field Bus System for operation.

Jack on

A ZFR1810 Wireless Field Bus Coordinator provides a

wireless interface between field controllers equipped

with a ZFR1811 Router and a Network Automation

Engine (NAE) 35/45/55 or Network Control Engine

(NCE) 25 supervisory controller. Each wireless mesh

network requires one ZFR1810 Coordinator, which

initiates the formation of the network.

ZFR1810 Wireless Field Bus Coordinator Installation Instructions 1

Page 2

North American Emissions Compliance

Installation

United States

Compliance Statement (Part 15.19)

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

1. This device may not cause harmful interference,

and

2. This device must accept any interference

received, including interference that may cause

undesired operation.

Warning (Part 15.21)

Changes or modifications not expressly approved by

the party responsible for compliance could void the

user’s authority to operate the equipment.

Canada

Industry Canada Statement(s)

The term IC before the certification/registration

number only signifies that the Industry Canada

technical specifications were met.

This device has been designed to operate with an

antenna having a maximum gain of 2 dB. Antenna

having a higher gain is strictly prohibited per

regulations of Industry Canada. The required

antenna impedance is 50 ohms.

To reduce potential radio interference to other users,

the antenna type and its gain should be so chosen

that the Equivalent Isotropically Radiated Power

(EIRP) is not more than that required for successful

communication.

Le terme « IC » précédant le numéro d'accré ditation /

inscription signifie simplement que le produit est

conforme aux spécifications techniques d'Industry

Canada.

Cet appareil a été conçu pour fonctionner avec une

antenne d'un gain maximum de 2 dBi. En a pplication

des réglementations d'Industry Canada, l'utilisation

d'une antenne de gain supérieur est strictement

interdite. L'impédance d'antenne requise est de 50

ohms.

IMPORTANT: Before installing the ZFR1810

Coordinator in plenum applications, verify

acceptance of exposed plastic materials in plenum

areas with the local building authority. Building

codes for plenum requirements vary by location.

Some local building authorities accept compliance to

UL 1995, Heating and Cooling Equipment, while

others use different acceptance criteria.

Follow these guidelines when installing a ZFR1810

Coordinator.

• Transport the ZFR1810 Coordinator in the original

container to minimize vibration and shock damage.

• Verify that all the parts shown in Parts Included

shipped with the ZFR1810 Coordinator.

• Do not drop the ZFR1810 Coordinator or subject it

to physical shock.

Parts Included

Verify that the following parts shipped with the

ZFR1810 Coordinator:

• one ZFR1810 Coordinator and:

- one three-position screw terminal pluggable

block for 24 V~ power

- one four-position screw terminal pluggable

block for FC/SA Bus In

- four No. 6 pan-head, sheet-metal screws

• adjustable antenna with 1.2 m (4 ft) cable and:

- galvanized steel mounting bracket

- two No. 6 Trade Size pan-head, sheet-metal

screws

- round bushing

- hexagonal bushing

• one installation instructions sheet

Pour réduire les interférences radio potentielles

avec les dispositifs d'autres utilisateurs, le type

d'antenne et son gain doivent être choisis de façon à

ce que la Puissance Isotrope Rayonnée Équivalente

(PIRE) ne soit pas supérieure à la puissance

nécessaire pour une bonne communication.

ZFR1810 Wireless Field Bus Coordinator Installation Instructions2

Page 3

Dimensions

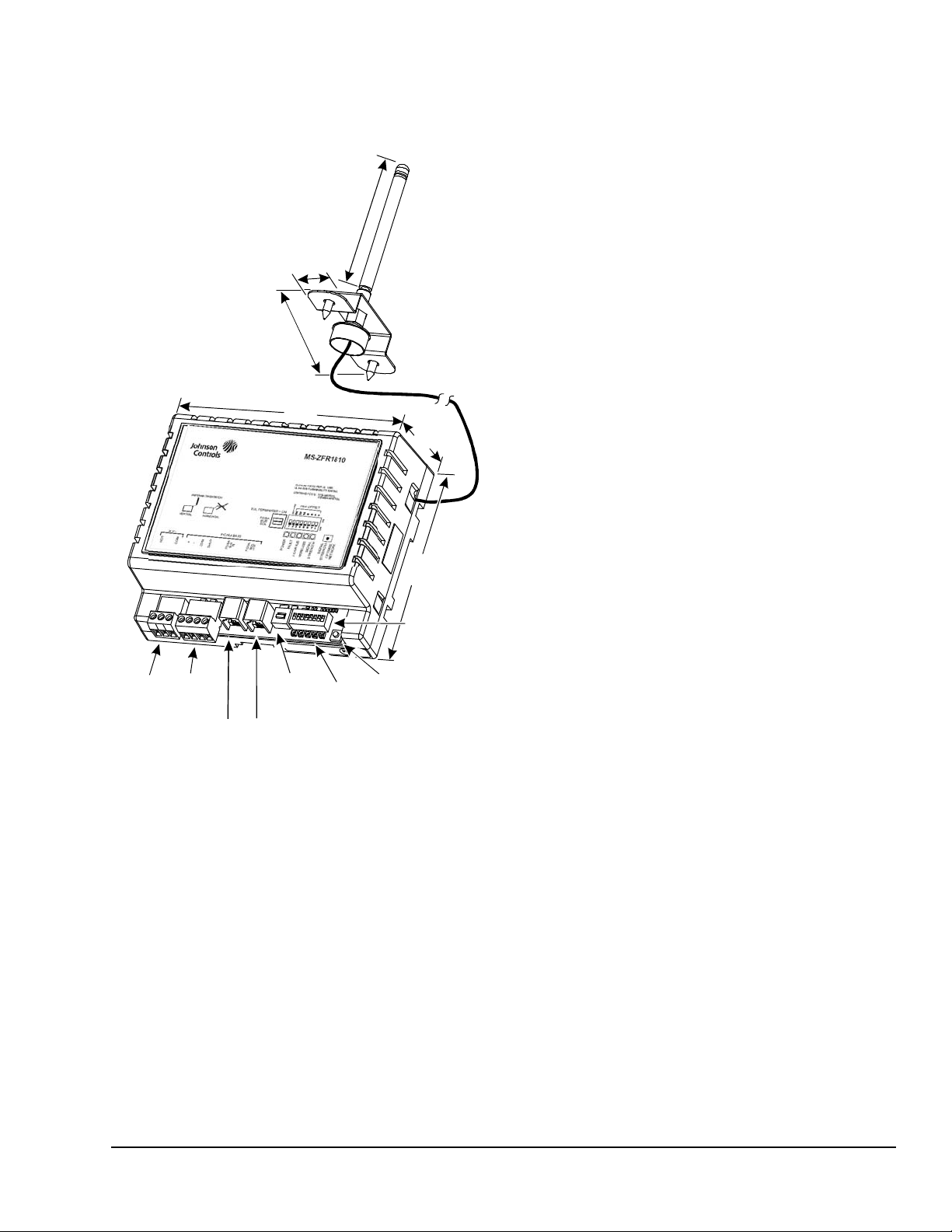

Figure 1: ZFR1810 Coordinator Physical

Features and Dimensions, mm (in.)

(4.8)

52

24 VAC

Input

Power

FC

BUS

Terminals

FC BUS

PWR OUT

Jack

FC BUS

PWR IN

Network

Button

LEDs

FIG:ZFR1810_ dimfeat

25

Switch

90

(50)

See Figure 1 for physical features and dimensions of

the ZFR1810 Coordinator.

(3.5)

• Due to the nature of the radio frequency waves, a

wireless device may have significantly different

signal strengths if its position changes relative to

another wireless device or if its environment

changes. If a ZFR1810 Coordinator shows poor

signal strength, you can improve the signal

strength by moving the device’s antenna a couple

of inches in either horizontal direction.

Termin al s

Jack

(1)

102

(4)

146

(5.8)

End-of-Line

Status

122

PAN OFFSET

DIP Switches

Optimize/Reform

(2.1)

1,270

• Locate the ZFR1810 Coordinator’s antenna in

line-of-sight with as many ZFR1811 Routers as

possible.

• Do not mount the ZFR1810 Coordinator’s antenna

in recessed areas, metal enclosures, or shelving

units.

Follow these additional guidelines when installing a

ZFR1810 Coordinator:

• Locate the ZFR1810 Coordinator near the center

of the associated array of ZFR1811 Routers.

• At a minimum, position a ZFR1810 Coordin at or

within 15.2 m (50 ft) of at least two

ZFR1811 Routers.

• At a minimum, position all ZFR1811 Routers within

15.2 m (50 ft) of at least two other ZFR1811

Routers or one ZFR1811 Router and the ZFR1810

Coordinator.

• Locate the ZFR1810 Coordinator on the same floor

as the associated ZFR1811 Router and

WRZ Series Sensors.

• Test the transmission signal strength between the

ZFR1810 Coordinator and the associated

ZFR1811 Router and WRZ Series Sensors to

ensure a reliable mesh network is in place. For

more information, see the ZFR1800 Series

Wireless Field Bus System Technical Bulletin

(LIT-12011295).

Mounting

Location Considerations

Follow these guidelines when locating a ZFR1810

Coordinator within a ZFR1800 Series system.

• Locate the ZFR1810 Coordinator so that it is easily

accessible.

• For best signal transmission, vertically orient the

ZFR1810 Coordinator’s antenna with at least

50 mm (2 in.) exposed below (and clear of) any

pipes, duct work, or other metal obstructions. Do

not mount the antenna in a horizontal orientation.

ZFR1810 Wireless Field Bus Coordinator Installation Instructions 3

• Avoid metal obstructions and concrete or brick

walls between the ZFR1810 Coordinator and the

associated ZFR1811 Router and WRZ Series

Sensors.

• Avoid configurations where a microwave oven is

located between two wireless devices. At a

minimum, ensure no microwave ovens are within

6 m (20 ft) of a ZFR1810 Coordinator.

Note: For detailed information on location guidelines

for a ZFR1800 Series system, and for estimating the

number of ZFR1811 Routers needed as repeaters for

extending wireless transmission range, refer to the

ZFR1800 Series Wireless Field Bus System Technical

Bulletin (LIT-12011295).

Page 4

Wireless Signal Transmission Considerations

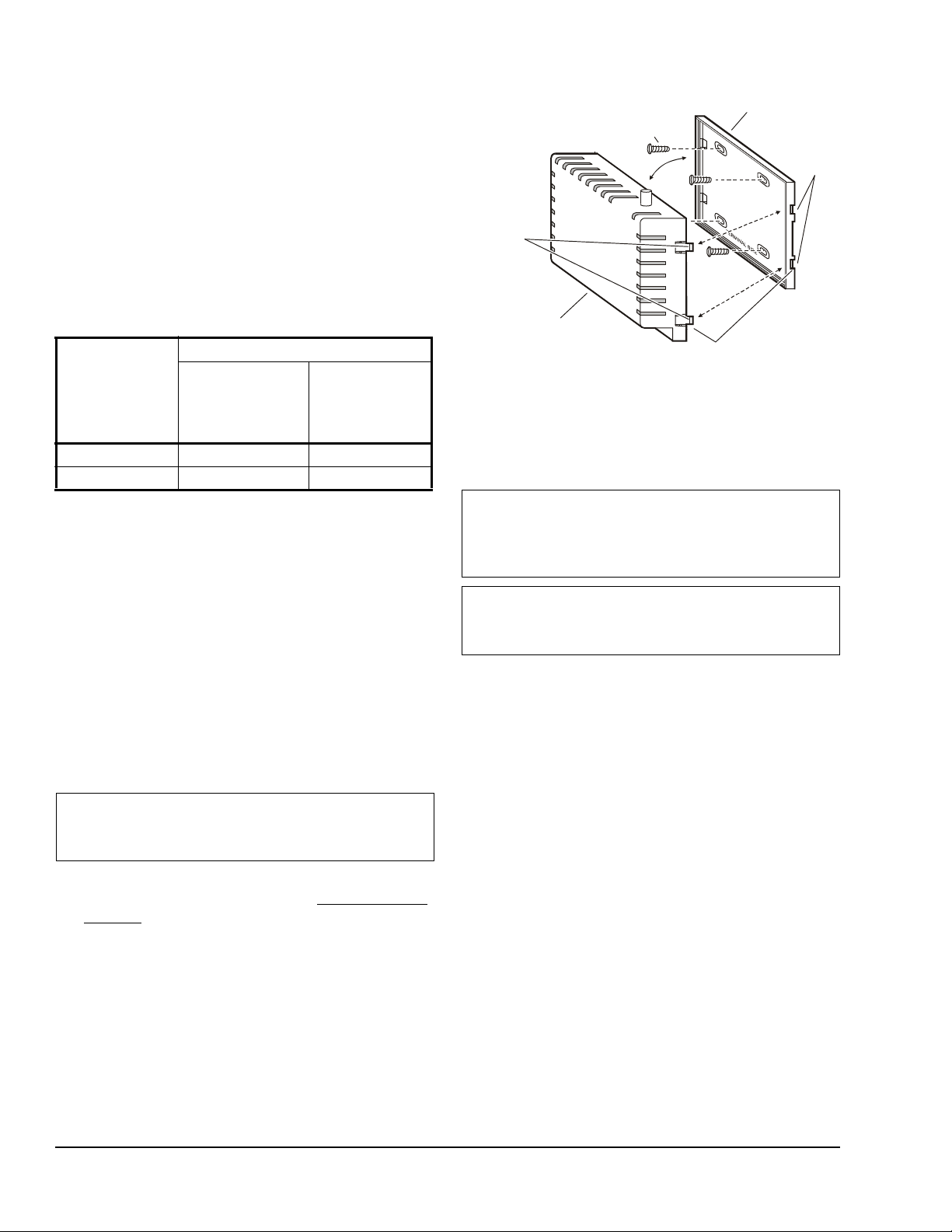

Figure 2: Mounting the ZFR1810 Coordinator

mount holes on mounting base and

tighten them evenly to the surface.

4. Reins t al l r eceiver

housing by alignin g l ocking

tabs with slots on mounting

base and pressing housing

until it locks on to base.

F

I

G

:

Z

F

R

1

8

1

0

_

m

n

t

_

b

s

e

Slots

Locking

Tabs (4)

Line-of-sight transmission ranges between a

ZFR1810 Coordinator, ZFR1811 Router, and/or a

WRZ Series Sensor can be less than the maximum

distances shown in Table 1. The effective transmission

range for indoor applications varies because of

wireless signal absorption and reflection due to metal

obstructions, walls (or floors), and furniture found in

typical building interiors. The effective transmission

range for outdoor applications varies based on

environmental conditions.

Table 1: Indoor Line-of-Sight Transmission

Ranges

Range Type Transmission Distance

ZFR1810

Coordinator,

ZFR1811

Router

Recommended 15.2 m (50 ft) 15.2 m (50 ft)

Maximum 76.2 m (250 ft) 30 m (100 ft)

Mounting the Base

The ZFR1810 Coordinator can be surface mounted

using the four No. 6 Trade Size self-tapping, pan-head

screws supplied.

To mount the ZFR1810 Coordinator base with screws:

1. Remove the ZFR1810 Coordinator from the

mounting base (Figure 2).

2. Use the mounting base as a template, and place

the mounting base against the mount i ng sur fa c e.

3. Drill pilot holes at the marked locations a nd se cu re

the mounting base to the surface with the four No.

6 Trade Size screws supplied.

IMPORTANT: Do not overtighten the mounting

screws. Overtightening the mounting screws may

damage the mounting base or mounting surface.

4. Mount the antenna and connect the antenna cable

to the ZFR1810 Coordinator. See Assembling the

Antenna.

5. Reinstall the ZFR1810 Coordinator housing to the

mounted base.

ZFR1810 Wireless Field Bus Coordinator Installation Instructions4

WRZ Series

Sensor

3. Insert the four No. 6 screws into

2. Use the mounting base

for screw hole template.

1. Remove receiver housing by

pressing th e l ocking tabs in at

the slots in the mounting base t o

release the receiver from base.

Assembling the Antenna

IMPORTANT: Use the antenna provided. Do not

alter the antenna in any way or use another

antenna. Do not modify the antenna cable in any

way.

IMPORTANT: Minimum bend radius for the

antenna cable is 25 mm (1 in.). Any bend with a

smaller radius may damage the cable.

If mounting the ZFR810 Coordinator in a control panel,

choose a location on the top side of the control panel

for placement of the antenna. Ensure that the selected

location has line-of-sight to two or more ZFR1811

Routers.

Use Figure 3 and the following steps to assemble the

remote-mount antenna:

1. Remove the knock-out tab on the enclosure/panel

box or drill a 7/8 in. diameter hole in the desired

location on the top of the enclosure.

2. Insert the round bushing into the hole in the

enclosure.

3. Insert the hexagonal bushing into the antenna

mounting bracket.

4. Thread the antenna cable through the hexagonal

bushing.

5. Insert the base of the antenna into the hexagonal

bushing and press until it snaps securely in place.

6. Thread the antenna cable through the round

bushing at the top of the panel.

Page 5

2. Remove the adhesive backing on two pieces of

Figure 3: Mounting the Antenna

Antenna

Antenna

Bracket

Hexagonal

Bushing

Round

Bushing

Screws

Antenna

Cable

Recloseable

Fastener Tape

t

n

m

_

t

n

a

_

0

1

8

1

R

F

Z

:

G

I

F

RFT and place one piece on the bottom of each

antenna bracket mounting foot.

3. Affix a mating piece of RFT onto each piece of RFT

on the mounting bracket so that the fasteners

mesh together. Remove the adhesive backing on

the mating pieces.

Mounting

Mounting

Mounting the Antenna Using Screws To mount the antenna using screws:

1. Center the antenna mounting bracket over the

7/8 in. (22 mm) round bushing.

2. Using the bracket as a template, drill two 3/32 in.

(2 mm) pilot holes into the enclosure.

3. Screw the bracket into place using the supplied

self-tapping mounting screws.

Mounting the Antenna Using Recloseable Fastener Tape (RFT)

When the unit is part of a panel assembly, the package

includes six pieces of RFT. Use this tape between the

antenna bracket and the enclosure. To mount the

antenna using RFT:

4. Center the bracket over the 7/8 in. (22 mm) round

bushing and apply the bracket to the top of the

panel. Push down on the feet of the bracket until

you feel the fasteners lock into position and the

adhesive bonding to the panel is completely

attached.

Note: Extra pieces of RFT are provided so that you

can change the mounting location on the top of the

panel at a later date if necessary.

Attaching the Antenna to the ZFR1810 Wireless Field Bus Coordinator

To attach the antenna to the ZFR1810 Coordinator:

1. Remove the top cover of the ZFR1810 Coordinator

by simultaneously pushing in both flexible tabs on

one side of the unit, followed by pushing in the tabs

on the other side of the unit.

2. Remove the top portion of the unit.

3. Apply the antenna wire firmly to the connection

point (see Figure 1) until it locks into place.

IMPORTANT: The connection from the antenna

cable to the ZFR1810 Coordinator is intended to be

made only once. Do not remove it once you have

inserted it into the jack. If you must remove the

antenna, disassemble the case of the Z FR 18 10

Coordinator and remove the antenna from the jack

by pulling on the knurled end of the antenna's

connector only. Pulling on the antenna cable from

anywhere else can result in damage to the antenna.

Avoid any repeat removals and re-insertions as this

may impact wireless connection integrity and unit

performance.

1. Ensure all mounting surfaces are clean and free of

dust, oils, and debris before applying the RFT.

ZFR1810 Wireless Field Bus Coordinator Installation Instructions 5

4. Replace the top portion and cover of the ZFR1810

Coordinator.

Page 6

Wiring

Figure 4: ZFR1810 Coordinator 24 VAC Power

Supply Connection

ZFR1810

Supply Power

Terminal Block

Plug

Wires from

Johnson C ontrols

24 VAC, Class 2

Power Transformer

(COM)

(24 VAC)

F

I

G

:

Z

F

R

1

8

1

0

_

P

w

r

_

P

r

t

24V~

C

O

M

H

O

T

Figure 5: ZFR1810 Coordinator Communication

Connection

FC/SA BUS

Terminal

Block

FC/SA BUS

Terminal Block

Plug

F

I

G

:

Z

F

R

1

8

1

0

_

F

C

_

S

A

_

B

s

S

H

L

D

A

C

O

M

-

Wiring Considerations and Guidelines

IMPORTANT: Do not connect supply power to the

ZFR1810 Coordinator before finishing wiring and

checking all wiring connections. Short circuits or

improperly connected wires may result in permanent

damage to the ZFR1810 Coordinator.

IMPORTANT: Use copper conductors only. Make

all wiring in accordance with local, national, and

regional regulations. The ZFR1810 Coordinator is a

low-voltage (less than 30 VAC) device. Do not

exceed the ZFR1810 Coordinator’s electrical

ratings.

IMPORTANT: Prevent any static electric discharge

to the ZFR1810 Coordinator. Static electric

discharge can damage the ZFR1810 Coordinator

and void any warranties.

IMPORTANT: Do not connect the ZFR1810

Coordinator to the power supply before setting the

PAN OFFSET switches.

M

O

C

ZFR1810

Supply Power

Terminal Block

Orange Wire

Brown W ir e

Terminal Blocks - Communication

Connect the communication wires from the NAE or

NCE to the four-position screw terminal pluggable

block, as shown in Figure 5 and Figure 1.

Follow these guidelines when wiring a

ZFR1810 Coordinator:

• Route the wires at least 50 mm (2 in.) away from

the vent slots on the sides of the

ZFR1810 Coordinator housing.

• Provide slack in the wires. Keep wires routed

neatly around the ZFR1810 Coordinator to

promote good ventilation, Light-Emitting Diode

(LED) visibility, and ease of service.

Power Input and Communication

Wiring for power input and communication uses one of

two methods: terminal blocks or the FC Bus jack.

Terminal Blocks - Power

Use a 24 VAC nominal, 50/60 Hz, Class 2 power

supply to power the ZFR1810 Coordinator . See Table 4

for recommended Johnson Controls® transformers.

Connect the 24 VAC supply power wires from the

transformer to the HOT and COM terminals of the

24 V~ three-position screw terminal pluggable block as

shown in Figure 4 and Figure 1. The middle terminal is

not used.

Note: Transformers not manufactured by

Johnson Controls may have different color wires.

Follow the manufacturer’s instructions when mounting

and wiring transformers.

ZFR1810 Wireless Field Bus Coordinator Installation Instructions6

D

M

L

O

H

S

A

C

(MS/TP)

FC/SA Bus

-

+

+

= + - COM

FC Bus Jack - Power and Communication

Use a six conductor SA Bus RS-485 cable with

RJ12 connectors to connect the ZFR1810 Coordinator

to the FC Bus connector (FC/SA BUS IN) on the NAE

or NCE supervisory engine. This connection provides

both power and communication to the ZFR1810

Coordinator.

Page 7

Power Supply Output

Figure 6: Setting the DIP Switches

IMPORTANT: Do not exceed the power supply

output of the ZFR1810 Coordinator. The ZFR1810

Coordinator’s power supply input must be able to

source the ZFR1810 Coordinator and the connected

external devices. Exceeding the power supply input

limits may cause the ZFR1810 Coordinator to shut

down.

Use a six-conductor SA Bus RS-485 cable with

RJ45 connectors to connect an external Metasys®

device to the FC BUS OUT jack as shown in Figure 1.

Setup and Adjustments

PAN Offset

IMPORTANT: Ensure that the PAN Offset switches

are set to the same value for the

ZFR1810 Coordinator and each associated

ZFR181 1 Router , and WRZ Series Sensor in a mesh

network.

IMPORTANT: To avoid MS/TP address conflicts,

do not connect the ZFR1810 Coordinator to the

power supply before setting the PAN Offset

switches.

PAN Offset and MS/TP Address Interaction

At Release 4.1 and later, the MS/TP address of the

ZFR1810 Coordinator is no longer fixed at 2. The new

address is 120 plus the sum of the first three va lues

of the P AN Offse t that are set to the ON position, giving

an MS/TP address range of 120 to 127.

Set the PAN Offset value of the ZFR1810 Coordinator

using the Dual Inline Package (DIP) switches to

configure the ZFR1810 Coordinator to communicate

with the ZFR1811 Routers assigned to it. See Figure 1

and Figure 6.

The PAN Offset value equals the sum of the numbe r s

set to ON. For example, if the DIP switches labelled

1, 4, and 8 are set to ON, the PAN Offset value is 13

(1 + 4 + 8 = 13).

When selecting a PAN Offset value for a wireless

system:

• Use a unique PAN Offset value for each wireless

mesh network at a job site.

• Use the same PAN Offset value for each wireless

device in a wireless mesh network - the

ZFR1810 Coordinator and each associated

ZFR1811 Router and WRZ Series Sensor.

ZFR1810 Wireless Field Bus Coordinator Installation Instructions 7

Page 8

Note: Only the values associated with the first three

Figure 7: EOL Switch

1

O

N

ON Position

OFF Position

F

I

G

:

E

O

L

_

s

w

t

c

h

switches (right to left) set to the ON position count

towards the MS/TP address of the ZFR1810

Coordinator. See the top of Figure 6.

Refer to the ZFR1800 Series Wireless Field Bus

System Technical Bulletin (LIT-12011295) for more

information on determining the signal strength between

ZFR1800 Series devices in your application.

Note: On some date code labels, the switch position

numbers on the bottom of the dip switch are reversed.

In either case, the switch positions are always read

right to left.

In Figure 6, the PAN Offset of the ZFR1810

Coordinator is configured by adding the values

associated with the first seven switch positions (right to

left). The eighth switch position is no t used. In Figu re 6

the PAN Offset is configured to 13 (values 1, 4, and 8)

to the ON position. In Figure 6, the MS/TP address of

the ZFR1810 Coordinator is configured by adding the

values associated with the first three switch positions

(right to left).The sum of the values is 5, so the MS/TP

address of the ZFR1810 Coordinator is 120 + 5, which

equals 125.

Setting the FC Bus End-of-Line (EOL) Switch

The FC Bus End-of-Line termination switch allows you

to designate the ZFR1810 Coordinator as the end of

the FC Bus. The default position is OFF. If the

ZFR1810 Coordinator is at the end of a daisy chain of

devices on the FC Bus, set the EOL switch to the ON

position. See Figure 1 and Figure 7.

O

1

N

WRZ-SST-120 Wireless Sensing System Tool

Use the WRZ-SST-120 Wireless Sensing System Tool

with a WRZ Series Sensor as a site survey tool to

determine the wireless signal strength between a

ZFR1810 Coordinator and a ZFR1811 Router or

between two ZFR1811 Routers. Refer to the

WRZ-SST-120 Wireless Sensing System Tool

Installation Instructions (Part No. 24-10563-12) for

more information on testing signal strength in your

application.

Network Optimize/Reform Button

The Network Optimize/Reform Button allows the

ZFR1810 Coordinator to use any of three functions:

• Signal Strength

• Network Optimize

• Network Reform

Use the Signal Str ength mode to aid in signal strength

testing. Signal Strength mode causes the LEDs on the

ZFR1811 routers to turn on and display signal strength

for two hours.

Use the Network Optimize mode to clear the mesh

device routing tables of the ZFR1811 Routers and

attempt to find shorter and/or stronger signal paths to

the ZFR1810 Coordinator.

Troubleshooting

Wireless Signal Strength

A wireless signal strength indication LED displays the

reception strength of the transmissions between the

ZFR1810 Coordinators, ZFR1811 Routers, and the

WRZ Series Sensors. This LED helps determine the

network connectivity status when selecting locations for

the devices during system installation.

Approximately once every 10 seconds, the Signal

Strength LED flashes to indicate the reception strength

of the signal from neighboring devices. See Table 3

and Figure 1.

Note: The Network Optimize process can take up to

15 minutes to complete.

Refer to the ZFR1800 Series Wireless Field Bus

System Technical Bulletin (LIT-12011295) for more

information about the Network Reform function.

Table 2: Network Optimize/Reform Button

Holding the Network

Optimize/Reform Button

for ___

0–5 Seconds Signal Strength

1

5–10

More than 10

1. Once the Signal Strength LED begins blinking rapidly,

release the button (between 5 to 10 seconds).

2. Once the Signal Strength LED stops blinking rapidly and

stays ON, release the button (approximately

10 seconds).

2

Puts the ZFR1810

Coordinator into the

_____ Mode

Network Optimize

Network Reform

ZFR1810 Wireless Field Bus Coordinator Installation Instructions8

Page 9

Troubleshooting LEDs

The ZFR1810 Coordinator has five LEDs that indicate

power, fault status, FC Bus activity, wireless activity,

and signal strength. See Figure 1. These status LEDs

are described in Table 3.

Table 3: ZFR1810 Coordinator Status LEDs

Name Color Normal Descriptions

Power Green On Off Steady = No power.

On Steady = Normal operation (power available

from 24 VAC connector or Field Controller

Sensor Actuator [FC/SA] Bus IN jack).

Fault Red Off Off Steady = Normal.

On Steady = Internal Errors detected.

FC Bus Green Blink Blink - 2 Hz = Normal operation (ZFR1810

Wireless Green Blink Blink - 2 Hz = Normal operation (ZFR1810

Signal Strength Green

Signal Strength

3 Flashes - Excellent

2 Flashes - Good

1 Flash - Weak

OFF for 3 seconds - None

1

Indication:

Coordinator is receiving BACnet® frames over the

wire).

Off Steady = Attempting to Auto Baud, or not

connected to active MS/TP network.

On Steady = Auto Baud complete and not

receiving BACnet frames.

Coordinator is receiving BACnet frames over the

wire).

Off Steady = Not receiving BACnet frames.

On Steady = Stopped receiving BACnet frames.

OFF Steady = Not able to start a network.

ON Steady with Signal Strength displayed once

every 10 seconds = Normal operation (ZFR1810

Coordinator is a member of a wireless network).

1. Signal Strength appears once every 10 seconds or when the Network Optimize/Reform button on the

ZFR1810 Coordinator is depressed momentarily (less than 5 seconds).

Repair Information

If the ZFR1810 Wireless Field Bus Coordinator fails to

operate within its specifications, replace the unit. For a

Note: The firmware in the ZFR1810 Coordinator can

be upgraded using the Controller Configuration Tool

(CCT).

replacement ZFR1810 Coordinator , contact the nearest

Johnson Controls representative.

ZFR1810 Wireless Field Bus Coordinator Installation Instructions 9

Page 10

Accessories

Table 4: Accessories (Order Separately)

Product Code

Product Description

Number

TP-2420 Transformer, Wall Plug Mount, 120 VAC to 24 VAC, 20 VA, Class 2

WRZ-SST-120 Wireless Sensing System Tool. Requires WRZ Series Sensor to function as a site survey tool for

ZFR1800 Wireless Field Bus System, or for WRZ-7860-0 One-to-One Room Sensing System.

Y65T31-0

ZFR-USBHA-0 USB Dongle with ZFR Driver provides a wireless connection through the CCT to allow wireless

ZFR-1810ANT-700 Replacement antenna kit for ZFR1810 Wireless Field Bus Coordinator. Includes antenna, coaxial

1. Additional Y60 Series Transformers are available from Johnson Controls.

1

Transformer, 120/2 08/240 VAC to 24 VAC, 40 VA, Class 2, Foot Mount, 20 cm (8 in.) Primary Leads

and Secondary Screw Terminals

commissioning of the wireless enabled FAC, FEC, IOM, and VMA16 controllers. The USB ZFR Dongle

is also used with the ZFR Checkout Tool used to troubleshoot and validate ZFR wireless meshes using

a laptop computer.

cable, and mounting hardware.

Technical Specifications

ZFR1810 Wireless Field Bus Coordinator (Part 1 of 2)

Product Code Number MS-ZFR1810-x

Power Supply Input One of the following:

• 24 VAC +10%/-15%, 50/60 Hz, Class 2. Transformer allowance should be 2.5 VA

maximum, 2 VA typical. Provided through the three-position 24 V~ screw terminal

pluggable block.

• 15 VDC, 180 mA (7 to 18 VDC, 185 mA maximum current draw) on the FC Bus

provided through the FC/SA BUS IN RJ-12 jack from the FC Bus Jack on a Field

Controller or NxE supervisory engine.

Power Supply Output 15 VDC; Provided through the FC/SA BUS, FC/SA BUS OUT RJ-12 jack for external

devices.

Addressing DIP Switches, Field Adjustable

Wireless Band Direct-Sequence Spread-Spectrum, 2.4 GHz ISM Bands

Transmission Power 10 mW Maximum

Transmission Range 76.2 m (250 ft) Maximum Line-of-Sight

15 m (50 ft) Recommended

Ambient Conditions Operating: 0 to 50°C (32 to 122°F), 5 to 95% RH, Noncondensing

Storage: -20 to 70°C (-4 to 158°F), 5 to 90% RH, Noncondensing

Materials White Plastic Housing with Plenum rating per UL1995 UL94-5VB Fl ammability Rating

Terminations Two spade terminals with three-position screw terminal pluggable block for 24 VAC power

Dimensions 146 x 122 x 52 mm (5.8 x 4.8 x 2.1 in.)

supply input.

Four spade terminals with four-position screw terminal pluggable block for RS-485

communications.

RJ-12 IN jack for 15 VDC power supply and communications connection from an NxE or

FEC FC Bus jack.

RJ-12 OUT jack supplies 15 VDC and communications to BTCVT Wireless

Commissioning Converter.

ZFR1810 Wireless Field Bus Coordinator Installation Instructions10

Page 11

Metasys® and Johnson Controls® are registered trademarks of Johnson Controls, Inc.

All other marks herein are the marks of their respective owners. © 2016 Johnson Controls, Inc.

Building Efficiency

507 E. Michigan Street, Milwaukee, WI 53202

ZFR1810 Wireless Field Bus Coordinator (Part 2 of 2)

Mounting Hardware Four No. 6 Trade Size Sheet Metal Screws

Shipping Weights 0.45 kg (1.0 lb)

Compliance United States:

Intended for Connection to an NEC Class 2 Power Source;

UL 916 Energy Management

Plenum rated per UL1995 UL94-5VB Flammability Rating

FCC Compliant to CFR47, Part 15, Subpart B, Class A

Transmission Complies with FCC Part 15.247 Regulations for Low Power Unlicensed

Transmitters

Transmitter Identification ZFR1810-0: FCC: TFB-MATRIXL

Transmitter Identification ZFR1810-1: FCC: OEJ-WRZRADIO

Canada:

CAN/CSA C22.2 No. 205, Signal Equipment

Industry Canada (IC) Compliant to Canadian ICES-003, Class B Limits

Industry Canada (IC) RSS-210

Transmitter Identification ZF R1810-0: 5969A-MATRIXLP

Transmitter Identification ZFR1810-1: 279A-WRZRADIO

Australia and New Zealand: RCM Mark, Australia/NZ Emissions Compliant

Europe:

CE Mark – Johnson Controls, Inc., declares that this product is in compliance with the

essential requirements and other relevant provisions of the EMC Directive.

The performance specifications are nominal and conform to acceptable industry standard. For application at conditions beyond these

specifications, consult the local Johnson Controls office. Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or

misuse of its products.

European Single Point of Contact: NA/SA Single Point of Contact: APAC Single Point of Contact:

JOHNSON CONTROLS

WESTENDHOF 3

45143 ESSEN

GERMANY

JOHNSON CONTROLS

507 E MICHIGAN ST

MILWAUKEE WI 53202

USA

JOHNSON CONTROLS

C/O CONTROLS PRODUCT MANAGEMENT

NO. 22 BLOCK D NEW DISTRICT

WUXI JIANGSU PROVINCE 214142

CHINA

ZFR1810 Wireless Field Bus Coordinator Installation Instructions 11

Published in U.S.A. www.johnsoncontrols.com

Loading...

Loading...