Johnson Controls Y Seroes, DHY24NWB21S, DHY09CSB21S, DHY12CSB21S, DHY18CSB21S Installation And Maintenance Manual

...Page 1

Installation

and

Maintenance

Manual

"Y" SERIES

INVERTER-DRIVEN AIR

CONDITIONING UNITS

Type

INDOOR UNITS

Type

OUTDOOR UNITS

Model

DHY09NWB21S

DHY12NWB21S

DHY18NWB21S

DHY24NWB21S

Model

DHY09CSB21S

DHY12CSB21S

DHY18CSB21S

DHY24CSB21S

,03257$17

PLEASE READ AND

UNDERSTAND THIS

MANUAL BEFORE USING

THIS INVERTER

AIR CONDITIONING UNIT.

KEEP THIS MANUAL FOR

FUTURE REFERENCE.

-DRIVEN

Page 2

Important Notice

● Johnson Controls, Inc. pursues a policy of continuing improvement in design and performance in its

products. As such, Johnson Controls, Inc. reserves the right to make changes at any time without

prior notice.

● Johnson Controls, Inc. cannot anticipate every possible circumstance that might involve a potential hazard.

● This inverter air conditioning unit is designed for standard air conditioning applications only. Do not use

this unit for anything other than the purposes for which it was intended for.

● The installer and system specialist shall safeguard against leakage in accordance with local pipetter

and electrical codes. The following standards may be applicable, if local regulations are not available.

International Organization for Standardization: (ISO 5149 or European Standard, EN 378). No part of

this manual may be reproduced in any way without the expressed written consent of Johnson Controls,

Inc.

● This inverter-driven (cooling or heat pump) air conditioning unit will be operated and serviced in the

United States of America and comes with all required Safety, Danger, and Caution, warnings.

● If you have questions, please contact your distributor or dealer.

● This manual provides common descriptions, basic and advanced information to maintain and service

this inverter-driven (cooling or heat pump) air conditioning unit which you operate, as well for other

models.

● This inverter-driven (cooling or heat pump) air conditioning unit has been designed for a specic

temperature range. For optimum performance and long life, operate this unit within range limits.

● This manual should be considered as a permanent part of the air conditioning equipment and should

remain with the air conditioning equipment.

Product Inspection upon Arrival

1. Upon receiving this product, inspect it for any damages incurred in transit. Claims for damage, either

apparent or concealed, should be led immediately with the shipping company.

2. Check the model number, electrical characteristics (power supply, voltage, and frequency rating), and

any accessories to determine if they agree with the purchase order.

3. The standard utilization for this unit is explained in these instructions. Use of this equipment for

purposes other than what it designed for is not recommended.

4. Please contact your local agent or contractor as any issues involving installation, performance, or

maintenance arise. Liability does not cover defects originating from unauthorized modications

performed by a customer without the written consent of Johnson Controls, Inc. Performing any

mechanical alterations on this product without the consent of the manufacturer will render your

warranty null and void.

2

P5415467

Page 3

Table of contents

Table of Contents

Introduction and Safety Summary

1.

2. Installation

2.1 Installation Dimension Diagram ......................................................................................1

2.2 Main Tools for Installation and Maintenance .................................................................2

2.3 Installation Procedures.....................................................................................................3

Installation Checking Parts

2.4

2.5 Selection of Installation Location ....................................................................................4

2.6 Electric Connection Requirement ....................................................................................4

2.7 Installation of Indoor Unit...................................................................................................4

2.8 Installation of Outdoor Unit ...............................................................................................7

2.9 Vacuum Pump/Leak Detection ........................................................................................8

2.10 Post Installation Testing ................................................................................................8

3. Troubleshooting

3.1 Precautions before Performing Inspection or Repair .....................................................9

................................................................................................................1

.............................................................................................4

..................................................................................................9

.......................................................i

3.2 Confirmation .................................................................................................................10

3.3 Flashing LED of Indoor/Outdoor Unit and Primary Judgment .....................................10

3.4 How to Check Simply the Main Part .............................................................................19

3.4 Troubleshooting for Normal Malfunction .......................................................................32

Appendix:

Appendix 1: Reference Sheet of Celsius and Fahrenheit ...................................................34

Appendix 2: Configuration of Connection Pipe ....................................................................34

Appendix 3: Pipe Expanding Method ..................................................................................35

Appendix 4: List of Resistance for Temperature Sensor .....................................................36

Customer Service, Technical Support

.......................................................................................................................34

..................................................39

Page 4

1. Introduction

This manual concentrates on inverter-driven cooling or heat pump air conditioning units. Read this manual

carefully before installation.

This manual should be considered as a permanent part of the air conditioning equipment and should

remain with the air conditioning equipment.

2. Important Safety Instructions

Safety Messages

Indicates a hazardous situation that, if not avoided, could result in death or

serious injury.

Indicates a hazardous situation that, if not avoided, could result in minor or

moderate injury.

Indicates information considered important, but not hazard-related (for

example, messages relating to property damage).

General Precautions

To reduce the risk of serious injury or death, read these instructions

thoroughly and follow all warnings or cautions included in all manuals that

accompanied the product and are attached to the unit. Refer back to these

safety instructions as needed.

● This system should be installed by personnel certied by Johnson Controls, Inc. Personnel must be

qualied according to local, state and national building and safety codes and regulations. Incorrect

installation could cause leaks, electric shock, re or explosion. In areas where Seismic ‘’Performance

requirements are specied, the appropriate measures should be taken during installation to guard against

possible damage or injury that might occur in an earthquake if the unit is not installed correctly, injuries may

occur due to a falling unit.

● Use appropriate Personal Protective Equipment (PPE), such as gloves and protective goggles and,

where appropriate, have a gas mask nearby. Also use electrical protection equipment and tools suited

for electrical operation purposes. Keep a quenching cloth and a re extinguisher nearby during brazing.

Use care in handling, rigging, and setting of bulky equipment.

● When transporting, be careful when picking up, moving and mounting these units. Although the unit may

be packed using plastic straps, do not use them for transporting the unit from one location to another. Do

not stand on or put any material on the unit. Get a partner to help, and bend with your knees when lifting

to reduce strain on your back. Sharp edges or thin aluminum ns on the air conditioner can cut ngers,

so wear protective gloves.

● Do not touch or adjust any safety devices inside the indoor or outdoor units. All safety features,

disengagement, and interlocks must be in place and functioning correctly before the equipment is put

into operation. If these devices are improperly adjusted or tampered with in any way, a serious accident

can occur. Never bypass or jump-out any safety device or switch.

● Johnson Controls, Inc. will not assume any liability for injuries or damage caused by not following steps

outlined or described in this manual. Unauthorized modications to Johnson Controls products are

prohibited as they…

◦ May create hazards which could result in death, serious injury or equipment damage.

◦ Will void product warranties.

◦ May invalidate product regulatory certications.

◦ May violate OSHA standards.

31

i

P5415467

Page 5

Take the following precautions to reduce the risk of property damage.

● Be careful that moisture, dust, or variant refrigerant compounds not enter the refrigerant cycle during

installation work. Foreign matter could damage internal components or cause blockages.

● If air lters are required on this unit, do not operate the unit without the air lter set in place. If the air

lter is not installed, dust may accumulate and breakdown may result.

● Do not install this unit in any place where silicon gases can coalesce. If the silicon gas molecules

attach themselves to the surface of the heat exchanger, the nned surfaces will repel water. As a

result, any amount of condensate can overow from the condensate pan and could run inside of the

electrical box, possibly causing electrical failures.

● When installing the unit in a hospital or other facility where electromagnetic waves are generated

from nearby medical and/or electronic devices, be prepared for noise and electronic interference

Electromagnetic Interference (EMI). Do not install where the waves can directly radiate into the

electrical box, controller cable, or controller. Inverters, appliances, high-frequency medical equipment,

and radio communications equipment may cause the unit to malfunction. The operation of the unit

may also adversely affect these same devices. Install the unit at least 10 ft. (approximately 3m) away

from such devices.

● When a wireless zone controller is used, locate at a distance of at least 3.3 ft. (approximately 1 meter)

between the indoor unit and electric lighting. If not, the receiver part of the unit may have difculty

receiving operation commands.

● Do not install the unit in any location where animals and plants can come into direct contact with the

outlet air stream. Exposure could adversely affect the animals and plants.

● Do not install the unit with any downward slope to the side of the drain boss. If you do, you may have

water owing back which may cause leaks.

● Be sure the condensate hose discharges water properly. If connected incorrectly, it may cause leaks.

● Do not install the unit in any place where oil can seep onto the units, such as table or seating areas in

restaurants, and so forth. For these locations or social venues, use specialized units with oil-resistant

features built into them. In addition, use a specialized ceiling fan designed for restaurant use. These

specialized oil-resistant units can be ordered for such applications. However, in places where large

quantities of oil can splash onto the unit, such as a factory, even the specialized units cannot be used.

These products should not be installed in such locations.

Installation Precautions

To reduce the risk of serious injury or death, the following installation

precautions must be followed.

● When installing the unit into…

▫ A wall: Make sure the wall is strong enough to hold the unit’s weight. It may be necessary to

construct a strong wood or metal frame to provide added support.

▫ A room: Properly insulate any refrigerant tubing run inside a room to prevent “sweating” that can

cause dripping and water damage to wall and oors.

▫ Damp or uneven areas: Use a raised concrete pad or concrete blocks to provide a solid, level

foundation for the unit to prevent water damage and abnormal vibration.

▫ An area with high winds: Securely anchor the outdoor unit down with bolts and a metal frame.

Provide a suitable air bafe.

▫ A snowy area (only for heat pump model): Install the outdoor unit on a raised platform that is

higher than drifting snow. Provide snow vents.

● Do not install the unit in the following places. Doing so can result in an explosion, re, deformation,

corrosion, or product failure.

▫ Explosive or ammable atmosphere

▫ Where re, oil, steam, or powder can directly enter the unit, such as in close proximity or directly

above a kitchen stove.

▫ Where oil (including machinery oil) may be present.

▫ Where corrosive gases such as chlorine, bromine, or sulde can accumulate, such as near a hot

tub or hot spring.

▫ Where dense, salt-laden airow is heavy, such as in coastal regions.

▫ Where the air quality is of high acidity.

▫ Where harmful gases can be generated from decomposition.

ii

4

P5415467

Page 6

● Do not position the condensate pipe for the indoor unit near any sanitary sewers where corrosive

gases may be present. If you do, toxic gases can seep into breathable air spaces and can cause

respiratory injuries. If the condensate pipe is installed incorrectly, water leakage and damage to the

ceiling, oor, furniture, or other possessions may result. If condensate piping becomes clogged,

moisture can back up and can drip from the indoor unit. Do not install the indoor unit where such

dripping can cause moisture damage or uneven locations: Use a raised concrete pad or concrete

blocks to provide a solid, level foundation for the unit to prevent water damage and abnormal

vibration.

● Before performing any brazing work, be sure that there are no ammable materials or open

ames nearby.

● Perform a run test to ensure normal operation. Safety guards, shields, barriers, covers, and protective

devices must be in place while the compressor/unit is operating. During the test run, keep ngers and

clothing away from any moving parts.

● Clean up the site when nished, remembering to check that no metal scraps or bits of wiring have

been left inside the unit being installed.

● During transportation, do not allow the backrest of the forklift to make contact with the unit,

otherwise, it may cause damage to the heat exchanger and also may cause injury when

stopped or started suddenly.

● Remove gas inside the closing pipe when the brazing work is performed. If the brazing ller metal is

melted with remaining gas inside, the pipes will be blown off and it may cause injury.

● Be sure to use nitrogen gas for an airtight test. If other gases such as oxygen gas, acetylene gas or

uorocarbon gas are accidentally used, it may cause explosion or gas intoxication.

After installation work for the system has been completed, explain the “Safety Precautions,” the proper use

and maintenance of the unit to the customer according to the information in all manuals that came with the

system. All manuals and warranty information must be given to the user or left near the Indoor Unit.

Refrigerant Precautions

To reduce the risk of serious injury or death, the following refrigerant

precautions must be followed.

● As originally manufactured, this unit contains refrigerant installed by Johnson Controls. Johnson

Controls uses only refrigerants that have been approved for use in the unit’s intended home country

or market. Johnson Controls distributors similarly are only authorized to provide refrigerants that

have been approved for use in the countries or markets they serve. The refrigerant used in this unit

is identied on the unit’s faceplate and/or in the associated manuals. Any additions of refrigerant into

this unit must comply with the country’s requirements with regard to refrigerant use and should be

obtained from Johnson Controls distributors. Use of any non-approved refrigerant substitutes will void

the warranty and will increase the potential risk of injury or death.

● If installed in a small room, take measures to prevent the refrigerant from exceeding the maximum

allowable concentration in the event that refrigerant gases should escape. Refrigerant gases can

cause asphyxiation (0.42 kg/m3 based on ISO 5149 for R410A). Consult with your distributor for

countermeasures (ventilation system and so on). If refrigerant gas has leaked during the installation

work, ventilate the room immediately.

● The design pressure for this product is 601 psi (4.15MPa). The pressure of R410A refrigerant is 1.4

times higher than that of the refrigerant R22. Therefore, the refrigerant piping for R410A shall be

thicker than that for R22. Make sure to use the specified refrigerant piping. If not, the refrigerant

piping may rupture due to an excessive refrigerant pressure. Besides, pay attention to the piping

thickness when using copper refrigerant piping. The thickness of copper refrigerant piping differs

depending on its material.

● The refrigerant R410A is adopted. The refrigerant oil tends to be affected by foreign matters such

as moisture, oxide lm, (or fat). Perform the installation work with care to prevent moisture, dust, or

different refrigerant from entering the refrigerant cycle. Foreign matter can be introduced into the

cycle from such parts as expansion valve and the operation may be unavailable.

● To avoid the possibility of different refrigerant or refrigerant oil being introduced into the cycle, the

sizes of the charging connections have been changed from R407C type and R22 type. It is necessary

to prepare the appropriate tools before performing the installation work.

● Use refrigerant pipes and joints which are approved for use with R410A.

● A compressor/unit comprises a pressurized system. Never loosen threaded joints while the system is

5

P5415467

iii

Page 7

under pressure and never open pressurized system parts.

● Before installation is complete, make sure that the refrigerant leak test has been performed. If

refrigerant gases escape into the air, turn OFF the main switch, extinguish any open ames and

contact your service contractor. Refrigerant (Fluorocarbon) for this unit is odorless. If the refrigerant

should leak and come into contact with open ames, toxic gas could be generated. Also, because the

uorocarbons are heavier than air, they settle to the oor, which could cause asphyxiation.

● When installing the unit, and connecting refrigerant piping, keep all piping runs as short as

possible, and make sure to securely connect the refrigerant piping before the compressor starts

operating. If the refrigerant piping is not connected and the compressor activates with the stop

valve opened, the refrigerant cycle will become subjected to extremely high pressure, which can

cause an explosion or re.

● Tighten the are nut with a torque wrench in the specied manner. Do not apply excessive force to the

are nut when tightening. If you do, the are nut can crack and refrigerant leakage may occur.

● When maintaining, relocating, and disposing of the unit, dismantle the refrigerant piping after the

compressor stops.

● When pipes are removed out from under the piping cover, after the insulation work is completed,

cover the gap between the piping cover and pipes by a packing (eld-supplied). If the gap is not

covered, the unit may be damaged if snow, rain water or small animals enter the unit.

● Do not apply an excessive force to the spindle valve at the end of opening. Otherwise, the spindle

valve ies out due to refrigerant pressure. At the run test, fully open the gas and liquid valves,

otherwise, these devices will be damaged. (It is closed before shipment.)

● If the arrangement for outdoor units is incorrect, it may cause owback of the refrigerant and result in

failure of the outdoor unit.

● The refrigerant system may be damaged if the slope of the piping connection kit exceeds +15o.

Electrical Precautions

Take the following precautions to reduce the risk of electric shock, re or

explosion resulting in serious injury or death.

● Highly dangerous electrical voltages are used in this system. Carefully refer to the wiring diagram

and these instructions when wiring. Improper connections and inadequate grounding can cause

serious injury or death.

● Perform all electrical work in strict accordance with this installation and maintenance manual and all

the relevant regulatory standards.

● Before servicing, open and tag all disconnect switches. Never assume electrical power is

disconnected. Check with meter and equipment.

● Only use electrical protection equipment and tools suited for this installation.

● Use specied cables between units.

● The new air conditioner may not function normally in the following instances:

▫ If electrical power for the new air conditioner is supplied from the same transformer as the device*

referred to below.

▫ If the power source cables for this device* and the new air conditioner unit are located in close

proximity to each other.

Device*: (Example): A lift, container crane, rectier for electric railway, inverter power

device, arc furnace, electric furnace, large-sized induction motor and large-sized switch.

Regarding the cases mentioned above, surge voltage may be inducted into the power supply

cables for the packaged air conditioner due to a rapid change in power consumption of the

device and an activation of a switch.

Check eld regulations and standards before performing electrical work in order to protect the

power supply for the new air conditioner unit.

iv

6

P5415467

Page 8

● Communication cabling shall be a minimum of 18-Gauge, 2-Conductor, Stranded Copper. Shielded

cable must be considered for applications and routing in areas of high EMI and other sources of

potentially excessive electrical noise to reduce the potential for communication errors. When shielded

cabling is applied, proper bonding and termination of the cable shield is required as per Johnson

Controls guidelines. Plenum and riser ratings for communication cables must be considered per

application and local code requirments.

● Use an exclusive power supply for the air conditioner at the unit’s rated voltage.

● Be sure to install circuit breakers (ground fault interrupter, isolating switch, molded case circuit

breaker and so on), with the specied capacity. Ensure that the wiring terminals are tightened securely

to recommended torque specications.

● Clamp electrical wires securely with a cable clamp after all wiring is connected to the terminal block.

In addition, run wires securely through the wiring access channel.

● When installing the power lines, do not apply tension to the cables. Secure the suspended cables at

regular intervals, but not too tightly.

● Make sure that the terminals do not come into contact with the surface of the electrical box. If the

terminals are too close to the surface, it may lead to failures at the terminal connection.

● Turn OFF and disconnect the unit from the power source when handling the service connector. Do not

open the service cover or access panel to the indoor or outdoor units without turning OFF the main

power supply.

● After ceasing operation, be sure to wait at least ve minutes before turning off the main power

switch. Otherwise, water leakage or electrical breakdown may result. Disconnect the power source

completely before attempting any maintenance for electrical parts. Check to ensure that no residual

voltage is present after disconnecting the power source.

● Do not clean with, or pour water into, the controller as it could cause electric shock and/or damage the

unit. Do not use strong detergent such as a solvent. Clean with a soft cloth.

● Check that the ground wire is securely connected. Do not connect ground wiring to gas piping, water

piping, lighting conductor, or telephone ground wiring.

● If a circuit breaker or fuse is frequently activated, shut down the system and contact your

service contractor.

● Perform all electrical work in accordance with this manual and in compliance with all regulations and

safety standards.

● Do not open a service access cover or panel of an indoor or outdoor unit without rst turning OFF the

power at the main power supply.

● Residual voltage can cause electric shock. At all times, check for residual voltage after disconnecting

from the power source before starting work on the unit.

● This equipment can be installed with a Ground Fault Circuit Breaker (GFCI), which is a recognized

measure for added protection to a properly grounded unit. Install appropriate sized breakers/fuses/

overcurrent protection switches, and wiring in accordance with local, state and NEC codes and

requirements. The equipment installer is responsible for understanding and abiding by applicable

codes and requirements.

v

7

P5415467

Page 9

Installation and Maintenance

2.

Installation

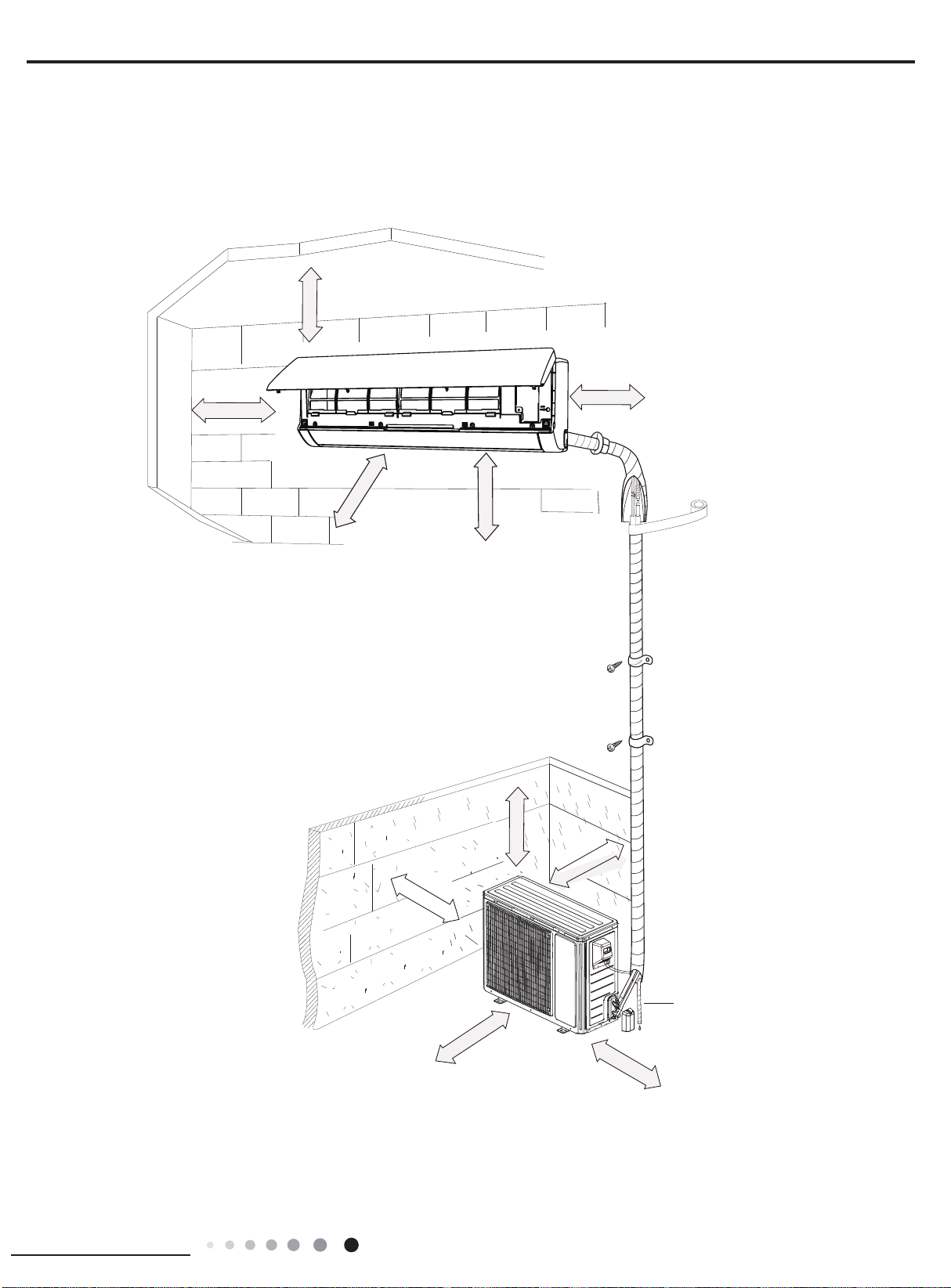

2.1 Installation Dimension Diagram

At least 5 8/9 inch

Space to the ceiling

Space to the wall

At least 5 8/9 inch

Space to the wall

At least 5 8/9 inch

roolf eht ot ecapS

At least 118 inch

Space to the obstruction

Space to the wall

At least 11 4/5 inch

At least 98 3/7 inch

Space to the obstruction

At least 19 2/3 inch

Space to the obstruction

At least 11 4/5 inch

Space to the obstructio

At least 78 3/5 inch

Condensate pipe

Space to the obstruction

At least 19 2/3 inch

1

Page 10

Installation and Maintenance

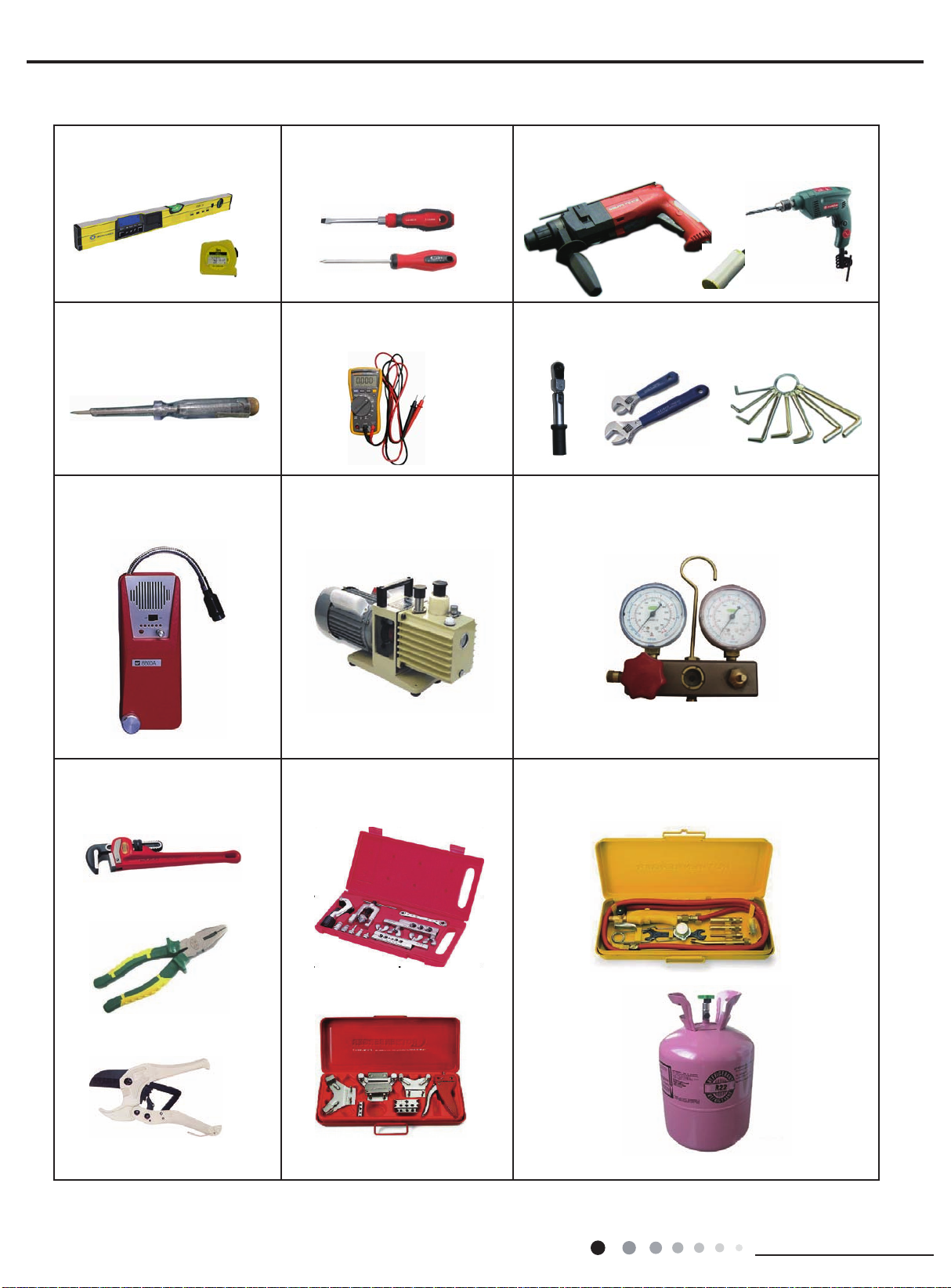

2.2 Main Tools for Installation and Maintenance

1. Level meter, measuring tape

4. Electroprobe

7. Electronic leakage detector

2. Screw driver

5. Universal meter

8. Vacuum pump

3. Impact drill, drill head, electric drill

6. Torque wrench, open-end wrench, inner

hex wrench

9. Manifold gauge

10. Pipe pliers, pipe cutter

11. Pipe expander, pipe bender

12. Soldering appliance, refrigerant container

2

Page 11

Installation and Maintenance

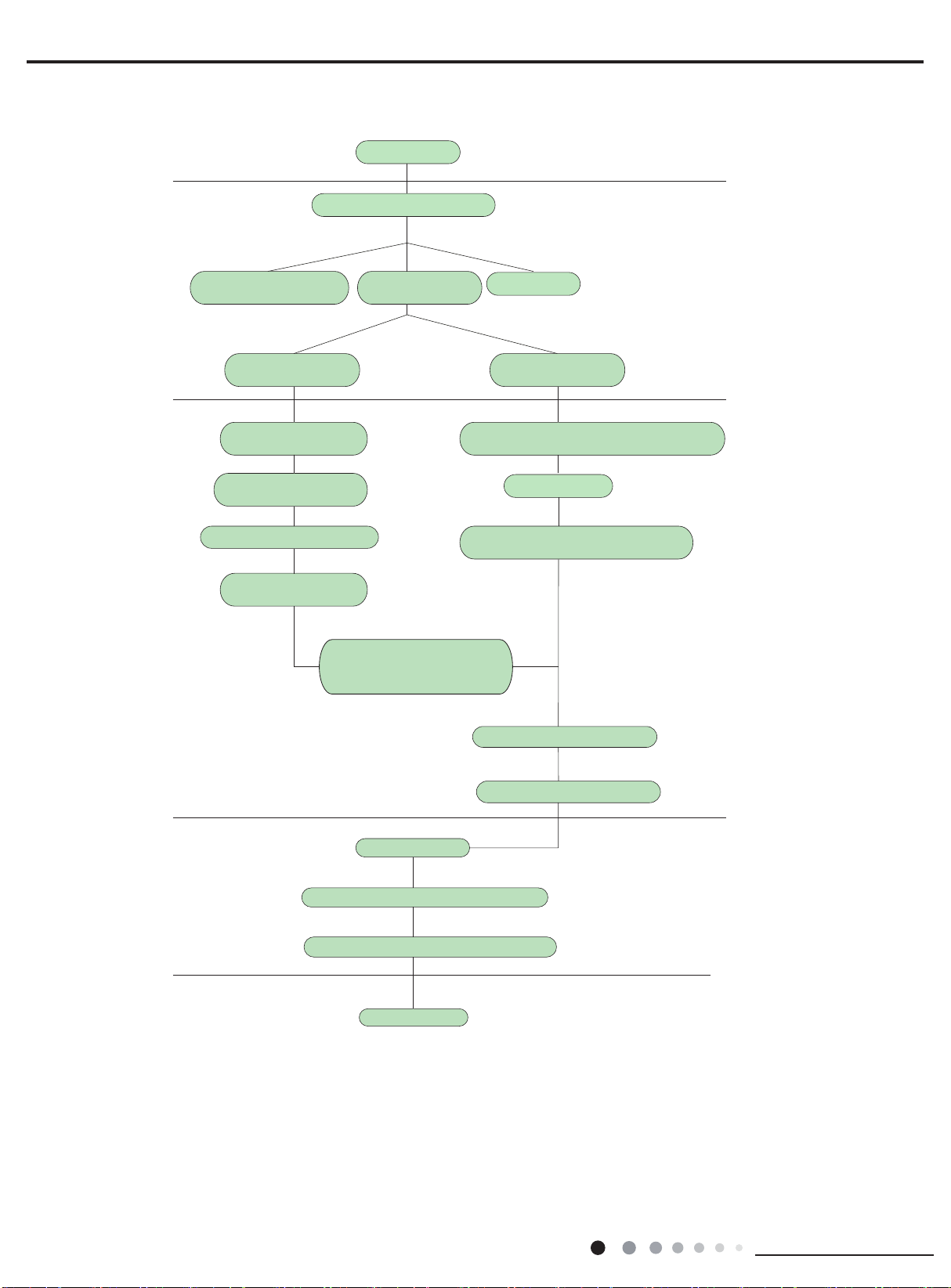

2.3 Installation Procedures

Start installation

Preparation before installation

Read the requirements

for electric connection

Select indoor unit

installation location

Install wall-mounting

frame, drill wall holes

Connect pipes of indoor

unit and drainage pipe

Connect wires of indoor unit

Bind up pipes and

hang the indoor unit

Make the bound pipes pass

through the wall hole and then

connect outdoor unit

Select installation

location

Prepare tools

Select outdoor unit

installation location

Install outdoor unit mount

(select it according to the actual situation)

Mount outdoor unit

Install drainage joint of outdoor unit

(only for cooling and heating unit)

Connect pipes of outdoor unit

Connect wires of outdoor unit

Arrange the pipes

Vacuum pumping and leakage detection

Check after installation and test operation

Finish installation

Note: This flow is only for reference; please find more detailed installation steps in this section.

3

Page 12

Installation and Maintenance

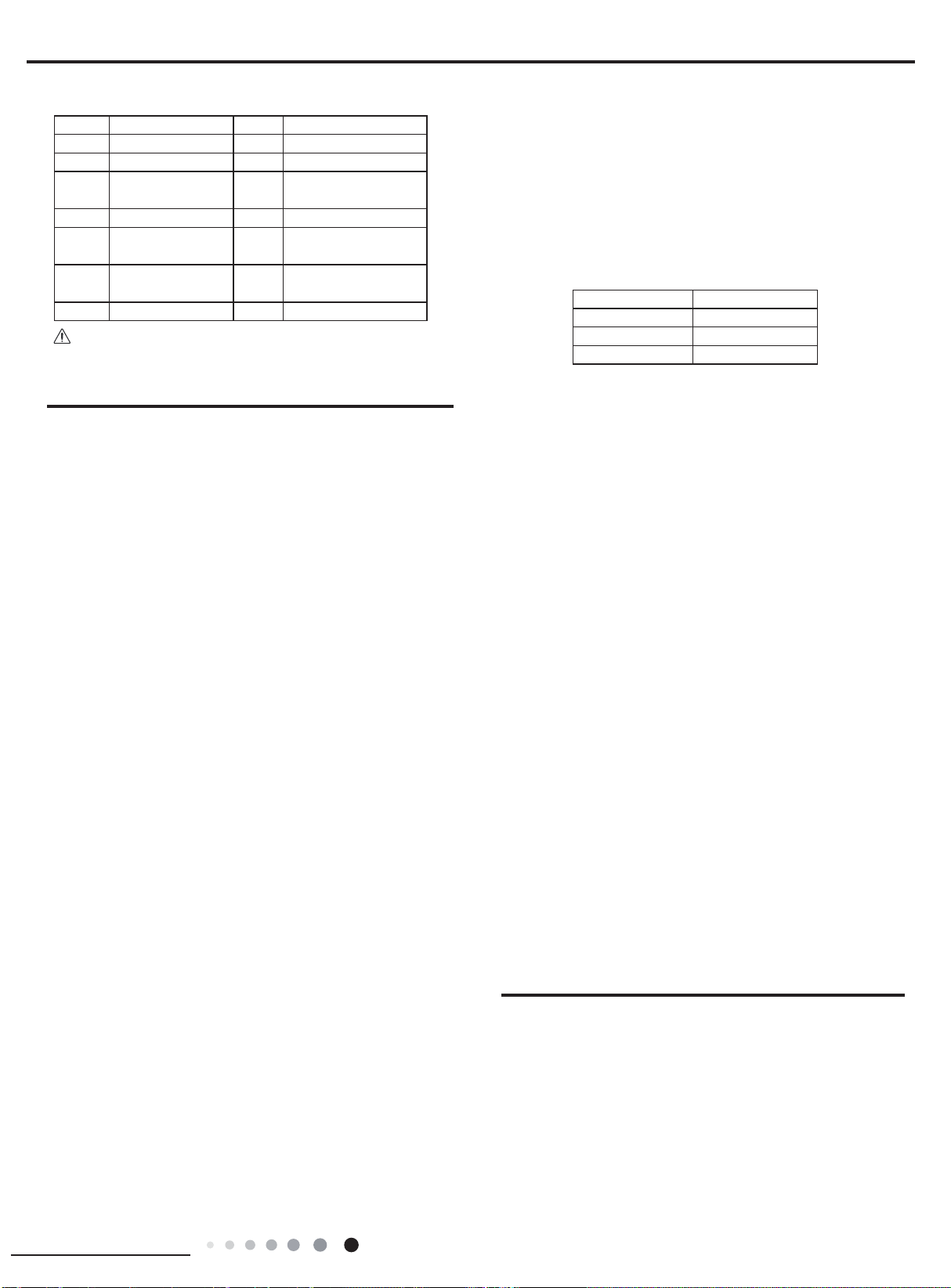

2.4 Installation - Checking Parts

No. Name No. Name

1 Indoor unit 8 Sealant

2 Outdoor unit 9 Wrapping tape

3 Connection pipe 10

4 Drainage pipe 11 Fixing screw

Wall-mounting

5

frame

Connecting

6

cable(power cord)

7 Wall pipe

Note:

1. Please contact the local agent for installation.

2. Don't use unqualied power cord.

.5 Selection of Installation Location

2

Basic Requirement:

1.

Installing the unit in the following places may cause

malfunction. If it is unavoidable, please consult the local dealer:

(1) Areas with strong heat sources, vapors, flammable or

explosive gas, or volatile objects spread in the air.

(2) Areas with high-frequency devices

machine, medical equipment).

(3) Areas near coast.

(4) Areas with oil or fumes in the air.

(5) Areas with sulfureted gas.

(6) Other places with special circumstances.

2. Indoor Unit:

(1) There should be no obstruction near air inlet and air outlet.

(2) Select a location where the condensation water can be

dispersed easily and won't affect other people.

(3) Select a location which is convenient to connect the

outdoor unit and near the power socket.

(4)

Select a location which is out of reach for children.

(5) The location should be able to withstand the weight of

indoor unit and won't increase noise and vibration.

(6) The appliance must be installed 98 3/7 inch above oor.

(7) Don't install the indoor unit right above the electric

appliance.

(8) The appliance should not be installed in a laundry area.

3. Outdoor Unit:

1.Select a location where the noise and outow air emitted by

the outdoor unit will not affect neighborhood.

2.The location should be well ventilated and dry, in which the

outdoor unit won't be exposed directly to sunlight or strong

wind.

3.The location should be able to withstand the weight of

outdoor unit.

Make sure that the installation complies with requirements

4.

iof the installation dimensions diagram.

5.Select a location which is out of reach for children and far

away from animals or plants.If it is unavoidable, please add

fence for safety purposes.

Support of outdoor

unit

Drainage plug(cooling

12

and heating unit)

Owner’s manual,

13

remote controller

(such as welding

2.6 Electric Connection Requirement

1. Safety Precaution

(1) All electric safety regulations must be followed when

installing the unit.

(2) Use proper power supply circuit and air switch in

accordance with local safety regulations.

(3) The power supply must be sized to meet the requirements

of air conditioning unit. Incorrect sizing/wiring may result in

electric shock,fire hazard or malfunction.

Air-conditioner Air switch capacity

09/12K 16A

18K 20A

24K 30A

(4) Properly connect the live wire, neutral wire and grounding

wire of power socket.

(5) Be sure to cut off the main power supply before

performing any electrical work.

(6) Do not turn power back on until installation is complete.

(7) For appliances with type Y attachment,the instructions

shall contain the substance of thefollowing.If the supply cord is

damaged, it must be replaced by the manufacturer, its

service agent or a qualified technician to avoid any shock

hazards.

(8) The temperature of refrigerant circuit will be high, please

keep the interconnection cable away from the copper tube.

Grounding Requirements:

2.

(1) The air conditioning unit must be properly grounded with

a specialized grounding device by a certified technician.

Please make sure it is always grounded effectively, otherwise

it may cause electric shock.

(2) The yellow-green wire in air conditioner is grounding wire,

which can't be used for other purposes.

(3) The grounding resistance should comply with national

electric safety regulations.

(4) The unit must be positioned so that the plug is

accessible.

(5) An all-pole disconnect switch having a contact separation of at

least 1/8 inch in all poles should be connected in fixed wiring.

(6) Including an air switch with suitable capacity, please note the

following table. Air switch should be included magnet buckle and

heating buckle function, it can protect the circuitshort and

overload. (Caution: Please do not use only the fuse to

protect the circuit.)

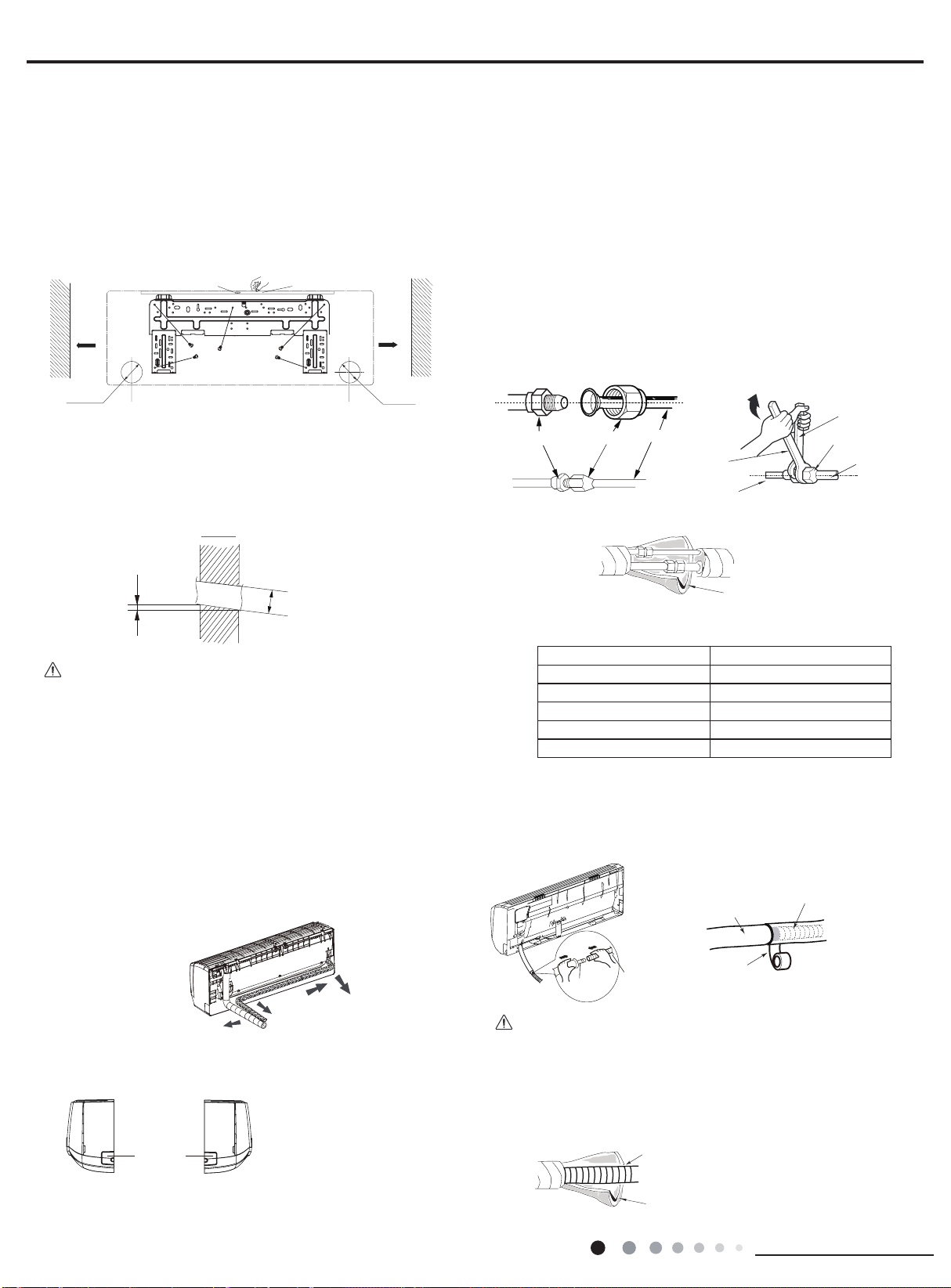

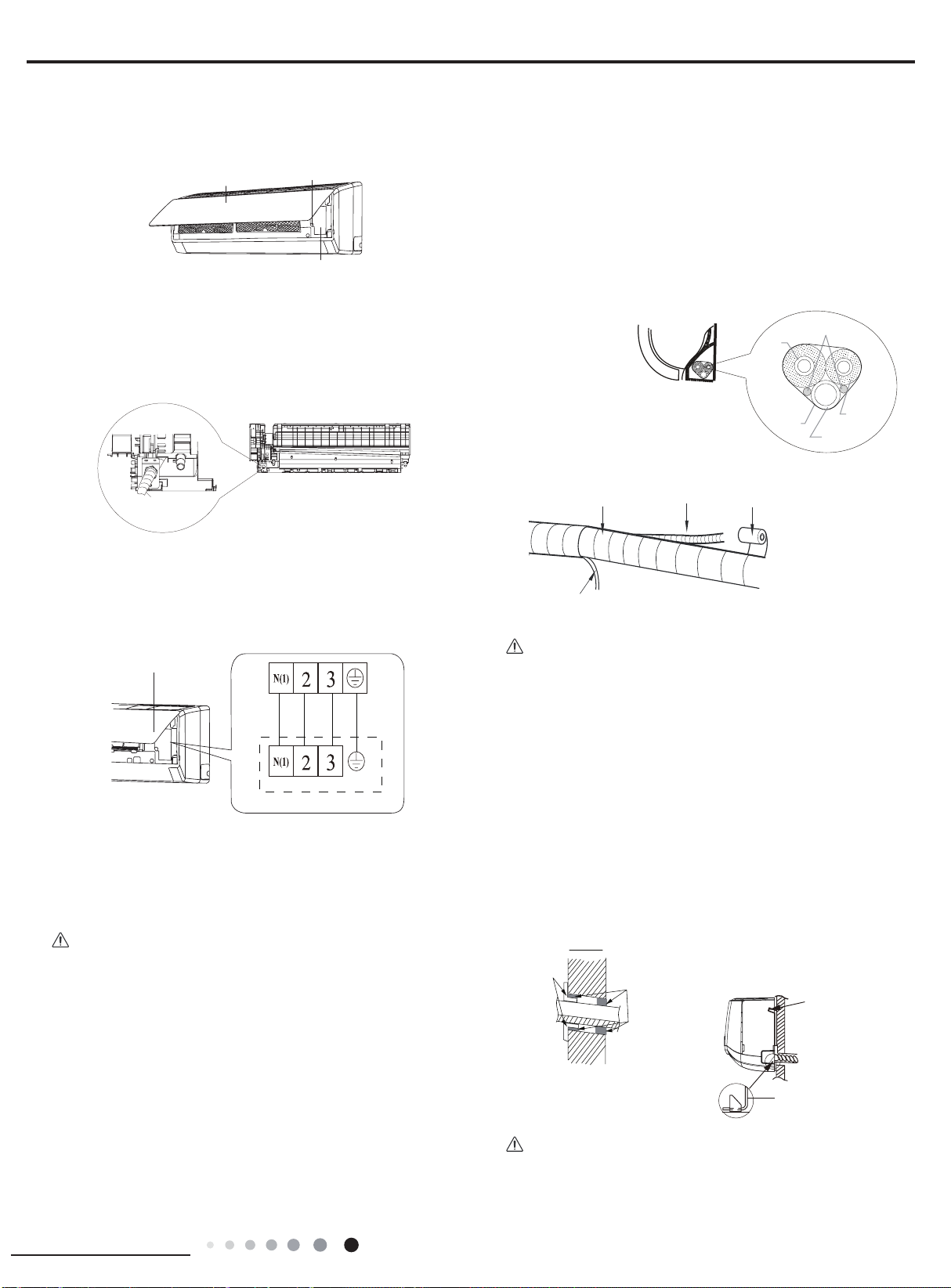

2.7 Installation of Indoor Unit

1. Choosing Installation Iocation

Recommend installation location to the client based on field

conditions; then proceed after client approval.

2. Install Wall-mounting Frame

(1) Hang the wall-mounting frame on the wall; adjust it in

horizontal position with the level meter and then point out the

screw xing holes on the wall.

(2) Drill the screw xing holes on the wall with impact drill (the

specification of drill head should be the same as the plastic

expansion particle) and then ll the plastic expansion particles

4

Page 13

Installation and Maintenance

Rear left

h

Indoor

Outdoor

in the holes.

Wall

Wall

(Rear piping hole)

(Rear piping hole)

Tape

Outlet pipe

Torque wrenc

Open-end

Drain hose

e

(3) Fix the wall-mounting frame on the wall with tapping screws

(ST4.2X25TA) and then check if the frame is rmly installed by

pulling the frame. If the plastic expansion particle is loose,

please drill another xing hole nearby.

3. Install Wall-mounting Frame

(1) Choose the position of piping hole accor

ding to the direction

of outlet pipe. The position of piping hole should be a little

lower than the wall-mounted frame.(As shown in Fig.1)

Space

to the

wall

5 8/9inch

above

Mark on the middle of it

Gradienter

Space

to the

wall

5 8/9inch

above

5. Connect the Pipe of Indoor Unit

(1) Aim the pipe joint at the corresponding bellmouth.(As

shown in Fig.5)

(2) Pretightening the union nut with hand.

(3) Adjust the torque force by referring to the following sheet.

Place the open-end wrench on the pipe joint and place the

torque wrench on the union nut. Tighten the union nut

with torque wrench.(As shown in Fig.6)

(4) Wrap the indoor pipe and joint of connection pipe with

insulating pipe, and then wrap it with tape.(As shown in Fig.7)

(5) If a 18k indoor unit is to be connected with a DHM or

DHW outdoor unit, a transitional pipe joint (provided)

should be added at the pipe joint of indoor unit evaporator

assy as the pipe joint of evaporator assy adopts pipe

diameter of Φ5/8. Please refer to step 1-4 during installation.

Left

Ф2 3/4inch Ф2 3/4inch

Fig.1

(2) Open a piping hole with the diameter of Φ2

Right

3/4inch on the

selected outlet pipe position.In order to drain smoothly, slant

the piping hole on the

wall slightly downward to the

outdoor side with the gradient of 5-10°.(As shown in Fig.2)

5-10

°

Φ2 3/4inc

Fig.2

Note:

(1) Pay attention to dust prevention and take relevant safety

measures when opening the hole.

(2) The plastic expansion particles are not provided and should

be bought locally.

4. Outlet Pipe

(1) The pipe can be led out in the direction of right, rear right,

left or rear left.(As shown in Fig.3)

(2) When selecting leading out the pipe from left or right, please

cut off the corresponding hole on the bottom case.(As show in

Fig.4)

wrench

Fig.7

Pipe

Union nut

h

Indoor pipe

Insulating pipe

Union nutPipe joint

Fig.5 Fig.6

Refer to the following table for torque tightening:

Hex nut diameter(inch) Tightening torque(ft·Ibf)

Φ1/4 11.10~14.75

Φ3/8 20.12~29.50

Φ1/2 33.19~40.56

Φ5/8 44.24~47.94

Φ3/4 51.32~55.31

6. Install Drain Hose

(1) Connect the condensate hose to the outlet pipe of indoor

unit.(As shown

in Fig.8)

(2) Bind the joint with tape.(As show in Fig.9)

Condensate hose

Pipe

5

Fig.3

Right

Left Right

Cut off

the hole

Left

Rear right

Fig.4

pipe

Condensate hose

Fig.9

Outlet

Fig.8

Note:

(1) Add insulating pipe in the indoor condensate hose in

order to prevent condensation.

(2) The plastic expansion particles are not provided.

(As shown in Fig.10)

Insulating pip

Fig.10

Page 14

Installation and Maintenance

Indoor power cord

7. Connect Wire of Indoor Unit

Indoor

Outdoor

Wall pipe

Upper hook

wall-mounting frame

Wiring cover

Screw

(1) Open the panel, remove the screw on the wiring cover

and then take down the cover.(As shown in Fig.11)

Panel

Fig.11

8. Bind up Pipe

(1) Bind up the connection pipe, power cord and

condensate hose with the band.(As shown in Fig.14)

(2) Reserve a certain length of drain hose and power cord

for installation when binding them. When binding to a certain

degree, separate the indoor power and then separate the

condensate hose.(As shown in Fig.15)

(3) Bind them evenly.

(4) The liquid pipe and gas pipe should be bound separately at

the end.

(2) Fix the wire crossing board on connection wire sleeve at

the bottom case; let the connection wire sleeve go through the

wire crossing hole at the back of indoor unit, and then pull it out

from the front.(As shown in Fig.12)

connection wire sleeve

Fig.12

(3) Remove the wire clip; connect the power connection wire

to the wiring terminal; tighten the screw and then fix the power

connection wire with wire clip.(As shown in Fig.13)

Wiring Cover

Outdoor unit

Fig.13

(4) Put wiring cover back and then tighten the screw.

(5) Close the panel.

Indoor and

outdoor power cord

Gas

pipe

Band

Band

Liquid

pipe

Condensate hose

Fig.14

Connection pipe

Indoor unit

Condensate hose

Fig.15

Note:

(1) The power cord and control wire can't be crossed or

winding.

(2) The condensate hose should be bound at the bottom.

9. Hang the Indoor Unit

(1) Put the bound pipes in the wall pipe and then make them

pass through the wall hole.

(2) Hang the indoor unit on the wall-mounting frame.

(3) Stuff the gap between pipes and wall hole with sealing gum.

(4) Fix the wall pipe.

(As show in Fig.16)

(5) Check if the indoor unit is installed firmly and closed to the

wall.(As shown in Fig.17)

Note:

(1) All wires of indoor unit and outdoor unit should be

connected by a professional.

(2) If the length of power connection wire is insufcient, please

contact the supplier for a new one. Avoid extending the wire by

yourself.

(3) For the air conditioning unit a with plug, the plug

should be reachable after finishing installation.

(4) For the air conditioning unit without a plug, an air switch

must be installed in the line. The air switch should be allpole parting and the contact parting distance should be more

than 3/32 inch.

Fig.17

Sealant

Fig.16

Lower hook of

Note:

Do not bend the condensate hose too excessively in order to

prevent blocking.

6

Page 15

Installation and Maintenance

The drain hos

Union nut

Foot holes

Foot holes

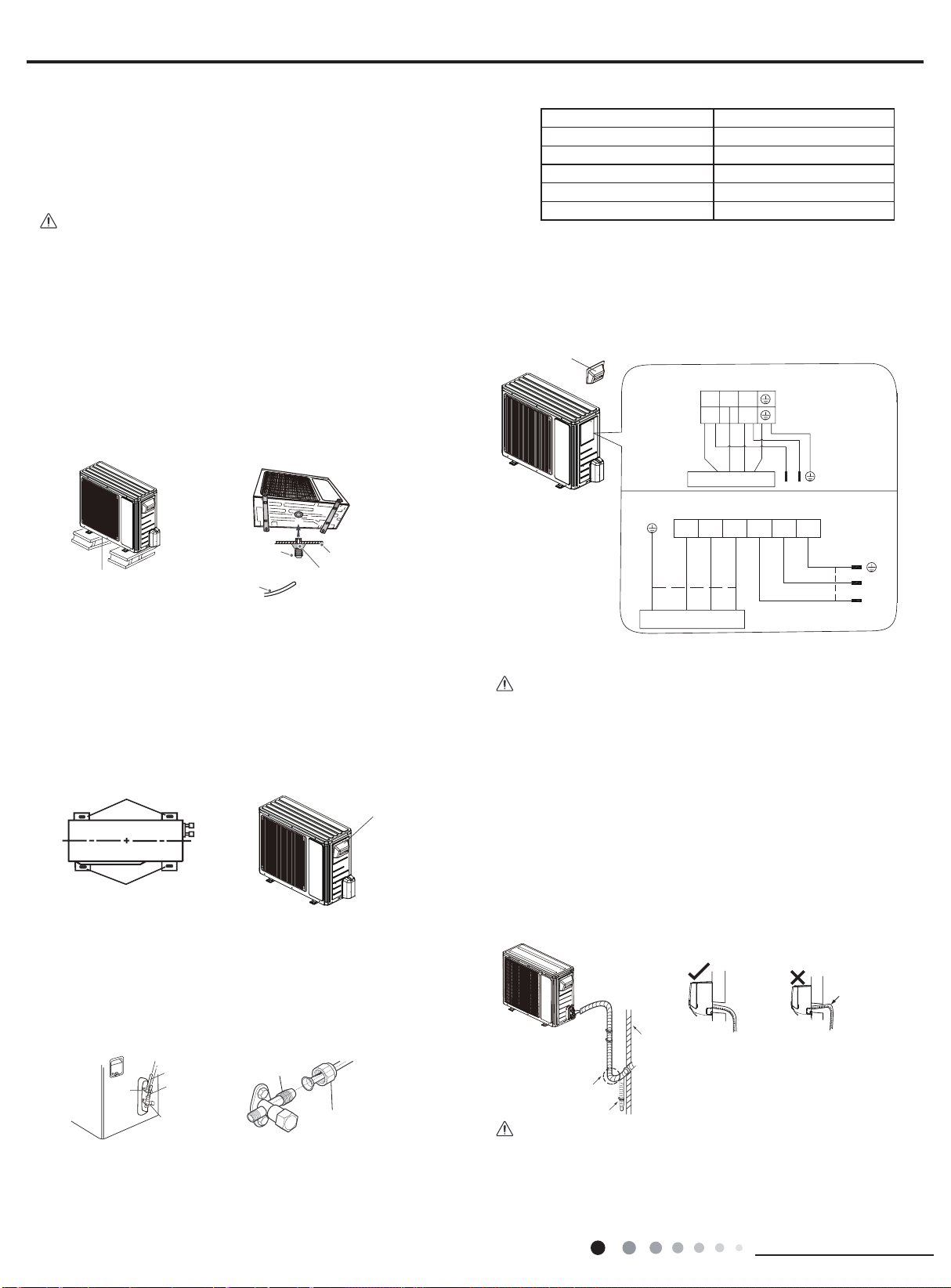

2.8 Installation of Outdoor Unit

Wall

Drain hose

A

r

Outdoor drain joint

Drain ven

Installupport of Outdoor Unit(select it according to the

1.

actual installation situation)

(1) Select installation location according to the house structure.

(2) Secure

with expansion screws.

(1) Take sufficient protective measures when installing the

outdoor unit.

(2) Make sure the support can withstand at least four times the

unit weight.

(3) The outdoor unit should be installed at least 1 1/6 inch

above the oor in order to install drain joint.(As show in Fig.18)

(4) For the unit with cooling capacity of 2300W~5000W, 6

expansion screws are needed; for the unit with cooling capacity

of 6000W~8000W, 8 expansion screws are needed; for the

unit with cooling capacity of 10000W~16000W, 10 expansion

screws are needed.

the support of outdoor unit on the selected location

Note:

Refer to the following table for torque tightening:

Hex nut diameter(inch) Tightening torque(ft·Ibf)

Φ1/4 11.10~14.75

Φ3/8 20.12~29.50

Φ1/2 33.19~40.56

Φ5/8 44.24~47.94

Φ3/4 51.32~55.31

5. Connect Outdoor Electric Wire

(1) Remove the c

onnection wire sleeve go through the two

holes of bafe; tighten the connection joint of sleeve and bafe;

remove the wire clip; connect the power connection wire and

power cord to the wiring terminal; fix them with screws.(As

shown in Fig.23)

Handle

09/12K

N(1)

223

L1L1L2

t least 1 1/6 inch above the floo

t

Condensate hose

Chassis

Fig.18 Fig.19

2. Install Drain Joint(only for cooling and heating unit)

(1) Connect the outdoor drain joint into the hole on the

chassis.(2) Connect the condensate hose into the drain

vent.(As shown in Fig.19)

3. Fix Outdoor Unit

(1) Place the outdoor unit on the support.

(2)

Fix the foot holes of outdoor unit with

bolts.(As shown in Fig.20)

Handle

Fig.20

Fig.21

4. Connect Indoor and Outdoor Pipes

(1) Remove the screw on the right handle of outdoor unit and

then remove the handle.(As show in Fig.21)

(2) Remove the screw cap of

valve and aim the pipe joint at the

bellmouth of pipe.(As shown in Fig.22)

Fig.23

G

N(1)

Indoor unit connection

Indoor unit connection

18/24K

3

Power

L1

L2

L2

G

L2

L1

(2) Fix the power connection wire and power cord with wire clip.

Note:

(1) After tightening the screw, pull the power cord slightly to

check if it is rm.

(2) Never cut the power connection wire to prolong or shorten

the distance.

Arrange the Pipes

6.

(1) The pipes should be placed along the wall, bent reasonably

and hidden. The semidiameter of bending the pipe is 4 in.

(2) If the outdoor unit is higher than the wall hole, a U-shaped

curve in the pipe is a must before pipe goes into the room, in

order to prevent rain from getting into the room.(As shown in

Fig.24)

can't raise

upwards

Power

Liquid pipe

Liquid

valve

gas pipe

gas valve

Fig.22

(3) Pretightening the union nut with hand.

(4) Tighten the union nut with torque wrench .

7

Pipe joint

Fig.24

U-shaped curve

Note:

(1) The through-wall height of drain hose shouldn't be higher

than the outlet pipe hole of indoor unit.(As shown in Fig.25)

(2) Slant the condensate hose slightly downwards. The

condensate hose can't be curved, raised or fluctuant.(As

shown in Fig.26)

Fig.25

Page 16

Installation and Maintenance

(3) The water outlet can't be placed in water in order to drain

Refrigerant charging

vent

Nut of refrigerant

Charging vent

outlet can't be

The water outlet

can't be placed

in water

smoothly.(As show in Fig.27)

The drain hose can't be fluctuant

The drain hose

can't be fluctuant

The water

fluctuant

Fig.27

Fig.26

2.9 Vacuum Pump/Leak Detection

1. Use Vacuum Pump

(1) Remove the valve caps on the liquid valve and gas valve

and the nut of refrigerant charging vent.

(2) Connect the charging hose of manifold gauge to the

refrigerant charging vent of gas valve and then connect the

other charging hose to the vacuum pump.

(3) Open the manifold gauge completely and operate for

10-15min to check if the pressure of manifold gauge remains in

-0.1MPa.

(4) Close the vacuum pump and maintain this status for 1-2min

to check if the pressure of manifold gauge remains in

-0.1MPa. If the pressure decreases, there may be leakage.

(5) Remove the manifold gauge, open the valve core of liquid

valve and gas valve completely with inner hex wrench.

(6) Tighten the screw caps of valves and refrigerant charging

vent.(As shown in Fig.28)

Liquid valve

Gas valve

Inner hex

wrench

Fig.28

Manifold gauge

Valve cap

Vacuum pump

Close

Open

Lo Hi

2.10 Post Installation Testing

1. Check after Installation

Check according to the following requirements after

finishing installation.

No. Items to be checked Possible malfunction

Has the unit been

1

installed rmly?

Have you done the

2

refrigerant leakage test?

Is heat insulation of

3

pipeline sufcient?

4 Is water drained well?

Is the voltage of power

supply according to the

5

voltage marked on the

nameplate?

Is electric wiring and

6

pipeline installed

correctly?

Is the unit grounded

7

securely?

Does the power cord

8

follow the specication?

Is there any obstruction

9

in air inlet and air outlet?

The dust and

sundries caused

10

during installation are

removed?

The gas valve and liquid

11

valve of connection pipe

are open completely?

2. Test Operation

(1) Preparation of test operation

● The client approves the air conditioner installation.

● Specify the important notes for air conditioner to the client.

(2) Method of test operation

● Put through the power, press ON/OFF button on the remote

controller to start operation.

● Press MODE button to select AUTO, COOL, DRY, FAN and

HEAT to check operations.

● If the ambient temperature is lower than 16

conditioner can’t start cooling.

The unit may drop, shake or

emit noise.

It may cause insufcient cooling

(heating) capacity.

It may cause condensation and

water dripping.

It may cause condensation and

water dripping.

It may cause malfunction or

damage the parts.

It may cause malfunction or

damage the parts.

It may cause electric shock.

It may cause malfunction or

damage the parts.

It may cause insufcient cooling

(heating).

It may cause malfunction or

damaging the parts.

It may cause insufficient

cooling (heating).

, the air

℃

2. Leakage detection

(1) Check for leaks using the leak detector:

(2) With soap water:

if a leak detection tool is unavailable, use soap water to detect

any leak. Apply soap water to the suspected leak position and

observe for 3 minutes, if bubbles appear then there is a leak.

8

Page 17

Installation and Maintenance

Troubleshooting

3.

3.1 Precautions before Performing Inspection or Repair

Be cautious during installation and maintenance. Follow safety

due to drop from high attitude.

Static maintenance is is performed while the unit is d-energized.

*

For static maintenance, make sure that the unit is de-energized and the plug is disconnected.

*dynamic maintenance is the maintenance during energization of the unit.

Before dynamic maintenance, check that the unit is properly grounded using a voltage tester. Check the copper piping and housing of

the unit to ensure there are no voltage leaks. After ensure insulation place and the safety, the maintenance can be performed.

Take sufficient care to avoid directly touching any of the circuit parts without first turning off the power.

At times such as when the circuit board is to be replaced, place the circuit board assembly in a vertical position.

Please follow troubleshooting procedures as described below.(Refer to the check points written on the wiring diagrams attached to the

indoor/outdoor units.)

regulations at all times to avoid electric shock and casualty or even death

No. Troubleshooting procedures

1 Conrmation

Judgment by Flashing LED of Indoor/Outdoor Unit

2

3 How to Check the Main Parts

NOTE:

A large-capacity electrolytic capacitor is used in the outdoor unit controller(inverter).Therefore,if the power supply is

turned off, charge(charging voltage DC280V to 380V)remains and discharging takes a lot of time. After turning off the power source,if

touching the charging section before discharging, an electrical shock may be caused.

Discharging method

(1)remove the inverter cover(Outoor Unit)

(2)As shown below,connect the discharge rescharge resistance(approx.100Ω,20W) or plug of the soldering iron to voltage between + -

terminals of the electrolytic capacitor (test 3*D* and *E* point) on PC Board for 30s ,and then perform discharging

9

Page 18

Installation and Maintenance

3.2 Confirmation

(1)Conrmation of Power Supply

Conrm that the power breaker operates(ON) normally;

(2)Conrmation of Power Voltage

Conrm that power voltage is AC 208-230 ±10%. If power voltage is not in this range, the unit may not operate normally.

3.3 Flashing LED of Indoor/Outdoor Unit and Primary Judgment

10

Page 19

Installation and Maintenance

(1)Models:09/12K:

Malfunction and Status Display Table

15 times

No. Malfunction Name

1 Malfunction of Circuit for zero cross detection U8

2 Malfunction protection for jumper cap C5

3 No feedback from indoor motor H6

Indoor ambient temp sensor has open or short

4

Indoor evaporator temp sensor has open or

5

Liquid valve temp sensor has open or short

6

7

8 Module temp sensor has open or short circuit P7

9

10

11

12

13

14

15

16 Demagnetization protection of compressor HE

17 Malfunction of voltage drop of DC bus bar U3

18 Module temperature protection P8

19

20 Malfunction of charging for capacitor PU

21 High pressure protection for the system E1

22

23

24

25 Overspeed (for commercial air conditioner)

26 Malfunction of

27

28

29

30

31 Thermal overload protection for compressor H3

32 Non-match between indoor and outdoor units LP

33 Malfunction of memory chip

Gas valve temp sensor has open or short

Outdoor ambient temp sensor has open or

Outdoor inlet pipe temp sensor of condenser

has open or circuit (for commercial use)

Outdoor middle pipe temp sensor of condenser

Outdoor outlet pipe of condenser has open or

Outdoor discharge temp sensor has open or

Communication malfunction of indoor and

Malfunction of circuit for detecting phase

Lack of refrigerant or block protection for the

Reset of drive module (for commercial air

AC contactor protection (for commercial air

Temperature drift protection(for commercial air

Sensor connection protection (for commercial

Communication malfunction for drive board(for

has open or short circuit

short circuit (for commercial use)

current of compressor

system (not applicable to residential air

Low pressure protection for the system

Lock of compressor (for commercial air

commercial air conditioner)

circuit

short circuit

circuit

circuit

short circuit

short circuit

outdoor units

conditioner)

reserved

conditioner)

conditioner)

conditioner)

conditioner)

air conditioner)

Malfunction

Type

Malfunction

of

hardware

Display

Nixie

Tube

F1

F2

b5

b7

F3

A5

F4

A7

F5

E6

U1

F0

E3

LE / / /

P0 / / /

LF

PF

P9 / / /

PE / /

Pd / / /

P6

EE

Display of Malfunction of Indoor Unit

Status of LED Lamp

LED

Lamp

for

Operation

Blinks

for 17

times

Blinks

for 15

times

Blinks

for 11

times

Blinks

for 6

times

Blinks

once

Blinks

for 3

times

/ / /

/ / /

Blinks

for 16

times

LED Lamp

for

Cooling

Blinks

once

Blinks

twice

Blinks for

19 times

Blinks for

22 times

Blinks for

3 times

Blinks for

4 times

Blinks for

5 times

Blinks for

10 times

LED Lamp

for

Heating

Blinks for

18times

Blinks for

12 times

Blinks for

14 times

Blinks for

20 times

Blinks for

19 times

Blinks for

17 times

Blinks for

3 times

Blinks for

Malfunction of

Outdoor Unit

Status of LED

Lamp

Yellow

LED

Lamp

Blinks for

10 times

Blinks for

8 times

Blinks for

16 times

Red

LED

Lamp

Blinks

for 6

times

Blinks

for 5

times

Blinks

for 7

times

Blinks

for 9

times

11

Page 20

Installation and Maintenance

34

Wrong connection of communication wire or

times

35

36

37 Mode conflict E7

38 Refrigerant reclaiming mode Fo

39 Oil return under defrosting or heating H1

40 Nominal cooling or heating (capacity test code) P1 / / /

41 Max. cooling or heating (capacity test code) P2 / / /

42 Middle cooling or heating(capacity test code) P3 / / /

43 Min. cooling or heating(capacity test code) P0 / /

44 Failure of startup of compressor Lc

45

46 Overload protection E8

47 Overcurrent protection for the complete unit E5

48 Overcurrent protection for the complete unit P5

49 Desynchronizing of compressor H7

50 Lack/reverse phase protection of Ld / / /

51 Module current protection (IPM protection) H5

52 Overlow voltage protection for DC bus bar PL

53 Overhigh voltage protection for DC bus bar PH

54 PFC protection HC

55 Overhigh power protection (not for outdoor L9

56 Abnormal reversing of 4-way valve U7

57

58

59

60 Frequency limit/decrease for freeze protection FH

61 Frequency limit/decrease for overload F6

62

63 Oil return in cooling F7

64 Cold air prevention E9

65 Freeze protection E2

66 Reading malfunction of EEPROM

67 Reaching temperature for turning on the unit

68 Frequency limit (power)

69 Malfunction of outdoor fan

malfunction of expansion valve (free match)

Malfunction of current detection for the

Wrong connection of communication wire or

status of detecting malfunction of expansion

High discharge temperature protection of

Frequency limit/decrease for current protection

Frequency limit/decrease for current protection

of the module (phase current)

Frequency limit/decrease for high discharge

Frequency limit/decrease for module

complete unit

valve (free match)

compressor

of the complete unit

temperature

temperature protection

Display is

controlled

by remote

control

dn / / /

U5

dd / / /

Blinks

for 7

times

Blinks

once

E4

F8

En / / /

F9

EU

Blinks

for 4

times

Blinks

for 8

times

Blinks

for 5

times

Blinks

for 20

times

Blinks

for 9

times

Blinks

twice

Blinks for

13 imes

Blinks

once

Blinks for

11 times

Blinks for

20 times

Blinks for

8 times

Blinks for

9 times

Blinks

twice

Blinks for

6 times

Blinks for

6 times

Blinks for

7 times

Blinks

once

Blinks for

11 times

Blinks for

15 times

Blinks for

7 times

Blinks for

5 times

Blinks for

21 times

Blinks for

6 times

Blinks

twice

Blinks for

6 times

Blinks

twice

Blinks for

7 times

Blinks for

6 times

Blinks for

5 times

Blinks for

4 times

Blinks for

12 times

Blinks for

13 times

Blinks for

14 times

Blinks for

9 times

Blinks for

3 times

Blinks for

11 times

Blinks

once

Blinks

twice

Blinks

for 4

times

Blinks

for 3

times

Blinks

for 11

times

Blinks

for 8

times

Blinks

for

13time

s

Blinks

for 14

12

Page 21

Installation and Maintenance

If malfunction occurs,corresponding code will display and the unit will resume normal until protection or

malfunction disappears.

Compressor stars (normal)Yellow indicator blinks for once

Yellow indicator

blinks for twice

Yellow indicator blinks for 3 times

Yellow indicator blinks for 4 times

Yellow indicator blinks for 5 times

Yellow indicator blinks for 6 times

Yellow indicator blinks for 7 times

Yellow indicator blinks for 8 times

Defrosting

Anti-freezing protection (normal

IPM protection

Overcurrent protection

Overload protection

Exhaust protection

Overlod protection of compresoor

(normal display of indoor unit)

display of indoor unit)

Indicator display

of outdoor unit

Red indicator blinks for once

Red indicator blinks for twice

Red indicator blinksfor 3 times

Cooling (dehumidify) or heating current

dropped frequency current.

Exhaust temp. dropped frequency temp.

Tube

temp. dropped frequency temp.

Red indicator blinks for 4 times

Red indicator blinks for 5 times

Red indicator for 6 times

Red indicator blinks for 7 times

Red indicator blinks for 8 times

Green indicator does not blink

T

tube-in

dropped frequency temp.

Outdoor condenser temp. sensor mal.

Outdoor ambient temp. sensor mal.

Outdoor exhaust temp. sensor mal.

Starting at temp. does not reach

Communication is abnormal

13

Page 22

Installation and Maintenance

A

nalysis or processing of some of the malfunction display:

1. Compressor discharge protection

operation;

malfunction of compressor; malfunction of protection relay; malfunction of discharge sensor; outdoor temperature too

high.

Processing method: refer to the malfunction analysis in the above section

2. Low voltage overcurrent protection

Possible reason: Sudden drop of supply voltage.

3.

4. Sensor open or short circuit

Processing

f

lead wire is found.

5.

Possible

compresso

Processing

the

6.

Overload

e

temperature of indoor heat exchanger when heating) is too high, protection will beactivated.

Please refer to the malfunction analysis in the previous section for handling method

7. IPM module protection

Processing

power

the malfunction still exists,replace the module.

(2)Models:18/24K:

Communication malfunction

Processing method: Check if communication signal cable is connected reliably.

method: Check whethers ensor is normal, connected with the corre sponding position on the controller and if damage o

.

Compressor overload protection

reasons: insufficient or too much refrigrant; blockage of capillary an dincrease of suction temp.; improper running of

r, burning in or stuck of bearing, damage of discharge valve; malfunction of protector.

method: adjust refrige rant amount; replace the capillary; replace the compressor; use univers al meter to check if

System malfunction

protection.When tube temperature(Check the temperature of outdoor heat exchanger when cooling and check th

method:Once the module malfunction happens,if it persists for a long time and can not be self-canceled, cut off the

and turn off the unit,and then re-energize the unit again after about 10 min.After repeating the procedure for sever times, if

.

.

14

Page 23

Installation and Maintenance

NO.

1

2

3

4

5

6

7

Malfunction

Name

High

pressure

protection of

system

Antifreezing

protection

High

discharge

temperature

protection of

compressor

Overcurrent

protection

Communication

Malfunction

High

temperature

resistant

protection

Internal

motor (fan

motor) do not

operate

Display Method of Indoor Unit

Dual-8

Display

Indicator Display (during

blinking, ON 0.5s and OFF 0.5s)

Code

E1

E2

E4

E5

E6

E8

H6

Operation

Indicator

OFF 3s

and blink

once

OFF 3S

and blink

twice

OFF 3S

and blink 4

times

OFF 3S

and blink 5

times

OFF 3S

and blink 6

times

OFF 3S

and blink 8

times

OFF 3S

and blink

11 times

Cool

Indicator

Heating

Indicator

Display Method of

Outdoor Unit

(Indicator has 3 kinds

of display status and

they will be displayed

circularly every 5s.)

□OFF

■Illuminated

D5

(D40)D6(D41)

ƿ

D16

(D42)

Blink

D30

(D43)

ƶƿƿƿ

ƵƶƵƶ

ƵƶƵƿ

ƶƵƿƶ

ƶƶƶƿ

ƵƶƵƵ

A/C status Possible Causes

During cooling and drying

operation, except indoor

fan operates, all loads stop

operation.

During heating operation, the

complete unit stops.

During cooling and drying

operation, compressor and

outdoor fan stop while indoor

fan operates.

During cooling and drying

operation, compressor and

outdoor fan stop while indoor

fan operates. During heating

operation, all loads stop.

During cooling and drying

operation, compressor and

outdoor fan stop while indoor

fan operates. During heating

operation, all loads stop.

During cooling operation,

compressor stops while indoor

fan motor operates. During

heating operation, the complete

unit stops.

During cooling operation:

compressor will stop while

indoor fan will operate. During

heating operation, the complete

unit stops.

Internal fan motor, external fan

motor, compressor and electric

heater stop operation,guide

louver stops at present location.

Possible reasons:

1. Refrigerant was superabundant;

2. Poor heat exchange (including

and bad radiating environment );

Ambient temperature is too high.

1. Poor air-return in indoor unit;

2. Fan speed is abnormal;

3. Evaporator is dirty.

Please refer to the malfunction

analysis (discharge protection,

overload).

1. Supply voltage is unstable;

2. Supply voltage is too low and

load is too high;

3. Evaporator is dirty.

Refer to the corresponding

malfunction analysis.

Refer to the malfunction analysis

(overload, high temperature

resistant).

1. Bad contact of DC motor

feedback terminal.

2. Bad contact of DC motor

control end.

3. Fan motor is stalling.

4. Motor malfunction.

5. Malfunction of mainboard rev

detecting circuit.

15

8

9

10

Malfunction

protection of

jumper cap

Indoor

ambient

temperature

sensor is

open/short

circuited

Overcurrent

protection of

phase

current for

compressor

C5

F1

P5

OFF 3S

and blink

15 times

OFF 3S

and blink

once

OFF 3S

and blink

15 times

ƶƿƶƶ

Wireless remote receiver and

button are effective, but can

not dispose the related

command

During cooling and drying

operation, indoor unit operates

while other loads will stop;

during heating operation,

the complete unit will stop

operation.

During cooling and drying

operation, compressor will stop

while indoor fan will operate;

During heating operation, the

complete unit will stop

operation.

1. No jumper cap insert on

mainboard.

2. Incorrect insert of jumper cap.

3. Jumper cap damaged.

4. Abnormal detecting circuit of

mainboard.

1. Loosening or bad contact of

indoor ambient temp. sensor and

mainboard terminal.

2. Components in mainboard fell

down leads short circuit.

3. Indoor ambient temp. sensor

damaged.(check with sensor

resistance value chart)

4. Mainboard damaged.

Refer to the malfunction

analysis (IPM protection, loss

of synchronism protection and

overcurrent protection of phase

current for compressor.

Page 24

Installation and Maintenance

Malfunction

n

position

y

normal

electrolytic

e

operation.

n

,

s

NO.

Name

Dual-8

Display

Indoor

evaporator

temperature

11

sensor is

open/short

circuited

Outdoor

ambient

temperature

12

sensor is

open/short

circuited

Outdoor

condenser

temperature

13

sensor is

open/short

circuited

Outdoor

discharge

temperature

14

sensor is

open/short

circuited

Limit/

decrease

frequency

15

due to

overload

Decrease

frequency

16

due to

overcurrent

Decrease

frequency

due to

17

high air

discharge

Voltage for

DC bus-bar

18

is too high

Malfunction

of complete

19

units current

detection

Display Method of Indoor Unit

Indicator Display (during

blinking, ON 0.5s and OFF 0.5s)

Code

Operation

Indicator

F2

F3

F4

F5

F6

F8

F9

PH

U5

Cool

Indicator

OFF 3S

and

blink

twice

OFF 3S

and

blink

3 times

OFF 3S

and

blink

4 times

OFF 3S

and

blink

5 times

OFF 3S

and

blink

for 6

times

OFF 3S

and

blink

8 times

OFF 3S

and

blink

9 times

OFF 3S

and

blink

11 times

OFF 3S

and

blink

13 times

Heating

Indicator

Display Method of

Outdoor Unit

(Indicator has 3 kinds

of display status and

they will be displayed

circularly every 5s.)

□OFF

■Illuminated

D5

(D40)D6(D41)

ƶƶƿƵ

ƶƶƿƶ

ƿ

D16

(D42)

Blink

D30

(D43)

ƶƶƿƿ

Ƶƶƿƿ

ƵƵƶƵ

ƵƵƶƶ

ƶƵƶƿ

ƶƵƿƵ

A/C status Possible Causes

AC stops operation once

reaches the setting

temperature. Cooling, drying:

internal fan motor stops

operation while other loads

stop operation; heating: AC

stop operation

During cooling and drying

operating, compressor stops

while indoor fan operates;

During heating operation, the

complete unit will stop operation

During cooling and drying

operation, compressor stops

while indoor fan will operate;

During heating operation,

the complete unit will stop

operation.

During cooling and drying

operation, compressor will sop

after operating for about 3 mins,

while indoor fan will operate;

During heating operation, the

complete unit will stop after

operating for about 3 mins.

All loads operate normally, while

operation frequency for

compressor is decreased

All loads operate normally, while

operation frequency for

compressor is decreased

All loads operate normally, while

operation frequency for

compressor is decreased

During cooling and drying

operation, compressor will stop

while indoor fan will operate;

During heating operation, the

complete unit will stop

operation.

During cooling and drying

operation, the compressor will

stop while indoor fan will operate;

During heating operating,

the complete unit will stop

1. Loosening or bad contact of

Indoor

evaporator temp. sensor and

mainboard terminal.

2. Components on the mainboard

fall

down leads short circuit.

3. Indoor evaporator temp. sensor

damaged.(check temp. sensor

value

chart for testing)

4. Mainboard damaged.

Outdoor temperature sensor

hasnt been connected well or

is damaged. Please check it by

referring to the resistance table for

temperature sensor)

Outdoor temperature sensor

hasnt been connected well or

is damaged. Please check it by

referring to the resistance table for

temperature sensor)

1.Outdoor temperature sensor

hasnt been connected well or is

damaged. Please check it by

referring to the resistance table for

temperature sensor)

2.The head of temperature sensor

hasnt been inserted into the

copper tube

Refer to the malfunction analysis

(overload, high temperature

resistant)

The input supply voltage is too

low;

System pressure is too high and

overload

Overload or temperature is too

high;

Malfunction of electric expansio

valve (EKV)

1. Measure the voltage of

L and N on wiring board (XT), if

the voltage is higher than 265VAC,

turn on the unit after the suppl

voltage is increased to the

range.

2.If the AC input is normal,

measure the voltage of

capacitor C on control panel (AP1),

if its normal,

for the circuit, please replace th

control panel (AP1)

Theres circuit malfunction o

outdoor units control panel AP1

please replace the outdoor unit

control panel AP1.

theres malfunction

16

Page 25

Installation and Maintenance

Malfunction

nalysis

NO.

20 Defrosting H1

Name

Dual-8

Code

Display

Display Method of Indoor Unit

Indicator Display (during

blinking, ON 0.5s and OFF 0.5s)

Operation

Indicator

Cool

Indicator

Heating

Indicator

OFF 3S

and blink

once

Display Method of

Outdoor Unit

(Indicator has 3 kinds

of display status and

they will be displayed

circularly every 5s.)

□OFF

■Illuminated

D5

(D40)D6(D41)

ƿ

D16

(D42)

Blink

A/C statusPossible Causes

D30

(D43)

Defrosting will occur in heating

mode. Compressor will operate

while indoor fan will stop

operation.

Its the normal state

21

22

23

24

25

26

27

28

29

Static

dedusting

protection

Overload

protection for

compressor

System is

abnormal

IPM

protection

PFC

protection

Desynchronizing of

compressor

Decrease

frequency

due to high

temperature

resistant

during

heating

operation

Failure startup

Malfunction

of phase

current

detection

circuit for

compressor

H2

H3

H4

H5

HC

H7

H0

LC

U1

OFF 3S

and blink

twice

OFF 3S

and blink

3 times

OFF 3S

and blink

4 times

OFF 3S

and blink

5 times

OFF 3S

and blink

6 times

OFF 3S

and blink

7 times

OFF 3S

and blink

10 times

OFF 3S

and blink

11 times

OFF 3S

and blink

13 times

ƶƿƿƶ

ƵƶƵƵ

ƶƿƶƵ

ƶƵƿƿ

ƶƿƵƿ

Ƶƶƿƿ

ƶƿƶƿ

ƶƿƵƶ

During cooling and drying

operation, compressor will stop

while indoor fan will operate;

During heating operation, the

complete unit will stop

operation.

During cooling and drying

operation, compressor will stop

while indoor fan will operate;

During heating operation, the

complete unit will stop

operation.

During cooling and drying

operation, compressor will stop

while indoor fan will operate;

During heating operation, the

complete unit will stop

operation.

During cooling and drying

operation, compressor will stop

while indoor fan will operate;

During heating operation, the

complete unit will stop

operation.

During cooling and drying

operation, compressor will stop

while indoor fan will operate;

During heating operation, the

complete unit will stop

operation.

All loads operate normally, while

operation frequency for

compressor is decreased

During cooling and drying

operation, compressor will stop

while indoor fan will operate;

During heating operation, the

complete unit will stop

operation.

During cooling and drying

operation, compressor will stop

while indoor fan will operate;

During heating operation, the

complete unit will stop

/

1. Wiring te rminal OVC-COMP

is loosened. In normal state, the

resistance for this terminal should

be less than 1ohm.

2.Refer to the malfunction a

( discharge protection, overload)

Refer to the malfunction analysis

(overload, high temperature

resistant)

Refer to the malfunction

analysis (IPM protection, loss

of synchronism protection and

overcurrent protection of phase

current for compressor.

Refer to the malfunction analysis

Refer to the malfunction

analysis (IPM protection, loss

of synchronism protection and

overcurrent protection of phase

current for compressor.

Refer to the malfunction analysis

(overload, high temperature

resistant)

Refer to the malfunction analysis

Replace outdoor control panel AP1

17