Johnson Controls Y20EBD Series, Y20EBD-2, Y20EBD-1, Y20EBD-3, Y20EBD-5 Technical Bulletin

...Page 1

FANs 121, 125

•

•

•

•

•

•

•

•

Technical Bulletin

Issue Date 0493

Y20EBD Valve Linkage

for M100 Motor Actuators

lntroduction 3

Application Details 3

Glossary 4

Installation Procedures 5

Tools Needed 5

Kit Includes 5

Installation Overview 6

Configuration and Mounting 7

Actuator and Linkage 13

Travel Limits 16

Checkout Procedure 22

Replacement Parts 23

© 1993 Johnson Controls, Inc.

Part No. 34-420-6, Rev. A

Code No. LIT-121775

1

Page 2

2 M Motor Actuators

Y20EBD Valve Linkage for M100 Motor Actuators

—

Page 3

lntroduction

Application

Details

The Y20EBD Valve Linkage converts the rotary motion of an M100

Series Motor Actuator to a linear movement in order to operate several

types of valves.

A rack and pinion drive mechanism provides the linear movement. The

rack assembly contains a spring that, when compressed by over travel, will

maintain valve close off to rated values. The pinion gear may be reversed

for manual operation with a 3/8 inch socket drive extension for service of

controlled equipment.

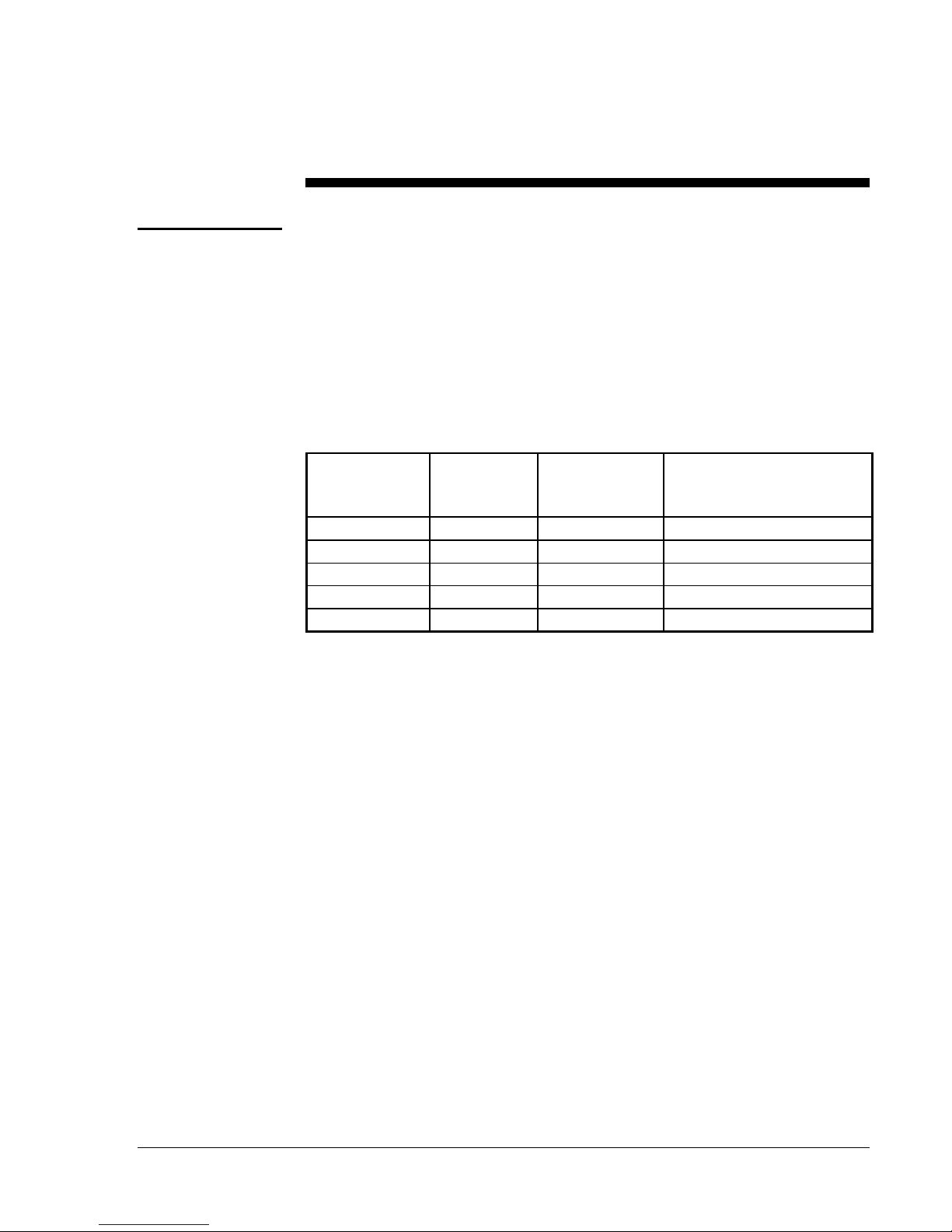

Table 1: Selection Table--Actuators and Linkages

Linkage

Number

Y20EBD-1

Y20EBD-2

Y20EBD-3

Y20EBD-5

Y20EBD-6

Spring

Return

Actuator

M130 M120 75 (334) Green

--- M140 150 (607) Yellow

--- M150 270 (1201) Red

M110 --- 40 (178) Orange

M130 M120 100 (449)

Non-spring

Return

Actuator

Valve Seating Load, lb (n)

Note: The Y20EBD linkage kit can be used on Barber-Colman

1-1/2 to 2 inch valves. Use the grooved adapter bushing provided

with the linkage kit for V-90 Series and the mid-bracket position.

Larger Barber-Colman valves can mount onto the Y20EBD yoke

directly; however, adding locally purchased large washers under

the linkage bracket to prevent paint damage is recommended.

A selection of models are available to adapt M100 Motor Actuators to

several types of valves.

A Y20EBD-4 linkage is available to enable an M150 Motor Actuator to

operate S91 auxiliary switches for automatic heating/cooling changeover

applications. The Y20EBD-4 allows additional over travel after valve

close off for switch operation. See Y20 Series Linkage Kits Product

Bulletin for a complete description.

Y20EBA valve linkage kits are available to adapt the M100 Series

Actuators to valves made by other manufacturers. See Y20 Series Linkage

Kits Product Bulletin for more information.

Refer to the technical bulletin provided with the motor actuator for

information on wiring the motor actuator and related adjustments.

M Motor Actuators

Y20EBD Valve Linkage for M100 Motor Actuators 3

—

Page 4

Glossary

The following terminology is used in these instructions:

CW--Clockwise refers to the direction of rotation of the actuator shaft as

seen from the load end.

Zero Position--The fully counterclockwise position of the actuator

shaft--the de-energized position of a spring return actuator.

Stem Up--The initial position of the stem is up before operating the valve.

Stem Down--The initial position of the stem is down before operating the

valve.

Push/Drive Down to Open--Pushing or driving the stem down opens

the valve.

Push/Drive Down to Close--Pushing or driving the stem down closes

the valve.

Pull/Drive Up to Open--Pulling or driving the stem up opens the valve.

Pull/Drive Up to Close--Pulling or driving the stem up closes the valve.

Stem Up/Drive Down--The stem is initially in the up position and the

motor actuator through the linkage will drive the stem down.

Stem Down/Drive Up--The stem is initially in the down position and the

motor actuator through the linkage will drive the stem up.

Three Way Mixing Valve--A valve with two inlets and one outlet. Valve

seats on both stem up and stem down travel.

Three Way Diverting Valve--A valve with one inlet and two outlets.

Valve seats on both stem up and stem down travel.

4 M Motor Actuators

Y20EBD Valve Linkage for M100 Motor Actuators

—

Page 5

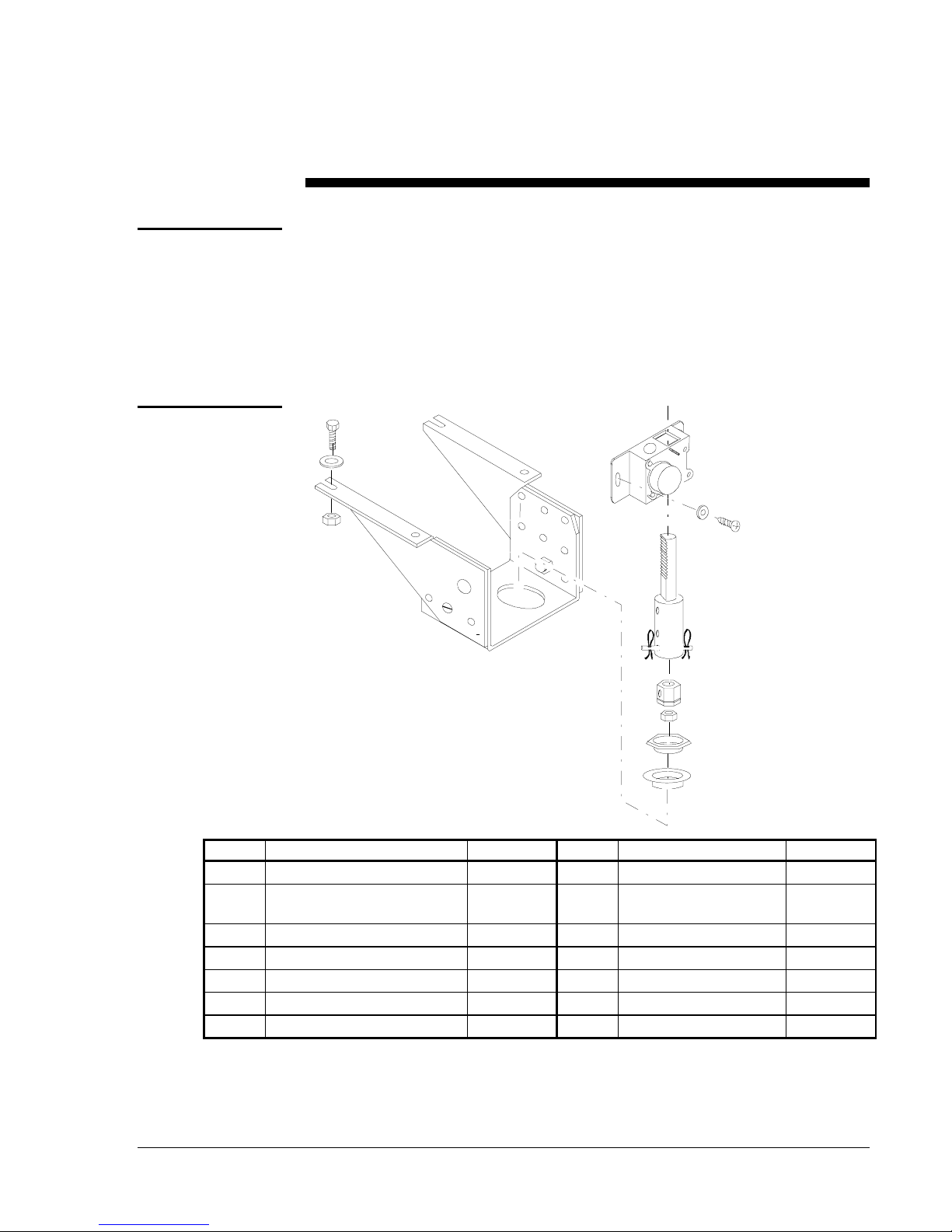

Installation Procedures

Tools Needed

Kit Includes

• screwdriver, small blade

• screwdriver, medium blade

• pliers

• wrench, adjustable, medium

• socket wrench, 3/8 inch drive

7

8

9

1

Y20D1-01

12

13

14

11

10

5/6

4

2/3

Item Description Quantity Item Description Quantity

Mounting Bracket Assembly 1

1

Valve Bushing, 3/4 in. Not

2

Grooved

Valve Bushing, 1 in. Grooved 1

3

Yoke Nut 1

4

Hex (Jam) Nut, 1/4-28 1

5

Hex (Jam) Nut, 3/8-20 1

6

Hex Cap Screw 4

7

1

Washer (High Temp) 4

8

Hex Nut, 1/4-20 4

9

Valve Stem Connector 1

10

Rack Subassembly 1

11

Gear Subassembly 1

12

Washer, Black 2

13

Screw 2

14

Figure 1: Kit Components

M Motor Actuators

Y20EBD Valve Linkage for M100 Motor Actuators 5

—

Page 6

Installation

Overview

Upright mounting of the motor actuator is recommended.

When valve mounting, do not mount below the horizontal plane of the

valve piping to prevent damage to the motor actuator if the valve leaks or

develops condensation.

Do not install the motor actuator in atmospheres with explosive vapors or

escaping gases, or where vapors having deteriorating properties might

attack the actuator’s metal parts.

Do not install where the ambient temperature of the surrounding area falls

below -40°F (-40°C) for non-spring return motor actuators, or

-35°F (-37°C) for spring return motor actuators. The maximum ambient

temperature of the surrounding area of the motor actuator should not

exceed 125°F (52°C).

Valve medium temperatures above 250°F (121°C) are permissible only if

the maximum ambient temperature at the motor actuator is less than 105°F

(41°C).

Use insulating washers furnished with the linkage kit for valve medium

temperature applications over 250°F (121°C).

Locate the motor actuator where the shaft and wiring terminals are

accessible.

The non-spring return M100 Actuator will hold its position if power is

removed. The spring return actuator will return to its zero position if

power is removed. Both types will hold their current position if the

control signal is satisfied.

Note: The spring return is intended only as a safety feature to drive the

actuator to its zero position in the event power is interrupted or

turned off.

There are three sections to the installation of the Y20EBD valve linkage

kit:

1. Configure and mount the yoke on the valve.

2. Mount the actuator and linkage assembly to the yoke and connect to

the valve.

3. Adjust the travel limits to actuate the over travel spring and seat the

valve.

6 M Motor Actuators

Y20EBD Valve Linkage for M100 Motor Actuators

—

Page 7

Configuration

and Mounting

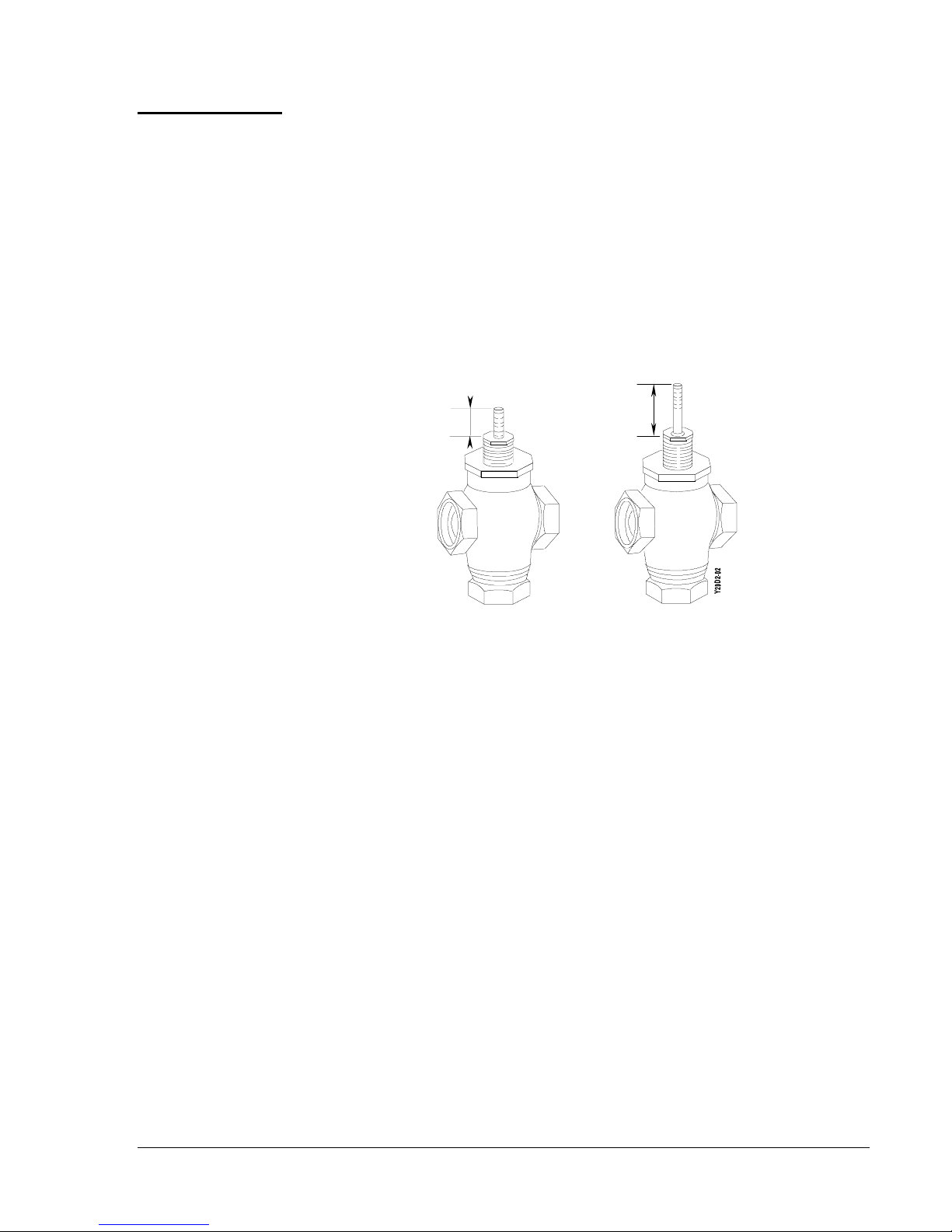

Valve Lift

The information obtained in the following steps will be used for the travel

adjustments later. The reason that these measurements are here is that it is

easier to take the measurements prior to installing the linkage and actuator

than after.

For valves with various lift requirements, the actuator will require a

change in travel by 15° for each additional 0.1 inch (2.54 mm) of lift

required.

To determine the lift required:

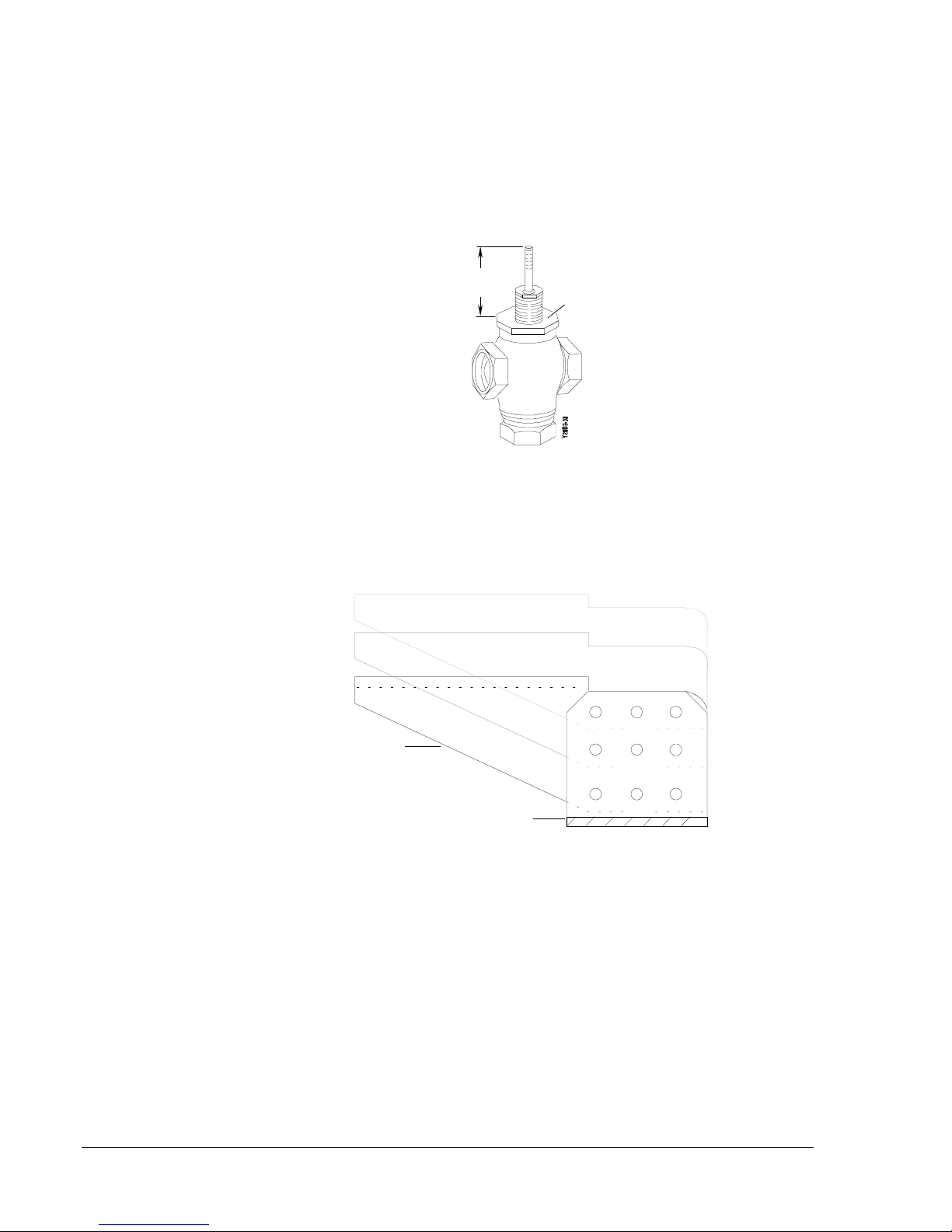

Valve Stem

Full Down

Valve Stem

Full Up

Figure 2: Stem Travel Measurement

1. Measure the valve stem length in the full down position as shown in

Figure 2.

2. Measure the valve stem length in the full up position as shown in

Figure 2.

3. Subtract the full down position from the full up position, this will

provide the valve lift.

4. Divide the valve lift by 0.1 inch.

5. Multiply the result by 15°.

6. Provide additional 15° rotation on 2-way valves and 30° additional

rotation on 3-way valves for over travel seating.

Note: Maximum actuator rotation is 270°, which allows up to 1.7 inches

lift on 2-way valves and 1.6 inches lift on 3-way valves.

Note: VT valves have only 5/16 inch lift which requires a reduction of

actuator travel by 25° from factory setting.

Record the value for use with the travel adjustments.

M Motor Actuators

Y20EBD Valve Linkage for M100 Motor Actuators 7

—

Page 8

Configuring Yoke

When configuring the yoke, two areas have to be considered:

• the distance the actuator will be from the valve (height)

• the direction of drive the actuator is going to provide to the valve

Height

To determine the height:

Valve Stem

Full Up

Valve Stem

Full Up

Yoke

Mounting

Surface

Figure 3: Height Measurement

1. Raise the valve stem to its full up position.

2. Measure from the yoke mounting surface to the top of the stem.

8 M Motor Actuators

High

Brackets

Medium

Y20A1-04

Yoke

Low

Figure 4: Linkage Bracket Positions

The linkage brackets can be mounted to the yoke in one of three positions:

low, medium, or high.

• Low position for stem lengths from 2 inches up to 3 inches

(50.8 to 76.2 mm) in full up position. Johnson brass valves up to

2 inch (50.8 mm) pipe size.

• Medium position for stem lengths from 3 inches to 4 inches

(76.2 to 101.6 mm) in full up position. Johnson iron valves from

2-1/2 inches (63.5 mm) pipe size and larger. V90BA valves up to

2 inch (50.8 mm) and V90CA valves up to 3 inch (76.2 mm) pipe

sizes.

Y20EBD Valve Linkage for M100 Motor Actuators

—

Page 9

• High position for stem lengths from 4 inches to 5-7/8 inches

(101.6 to 147.2 mm) in full up position. V90CA valves from 4 inch

through 6 inch (101.6 through 152.4 mm) pipe sizes.

LOAD ENDLOAD END

Y20A1-05

Figure 5: Long and Short Stem Valve Bodies

The left side of Figure 5 shows a Y20EBD Valve Linkage in the high

position connecting a 3-way valve body with a long stem to a M100 Motor

Actuator for stem up operation.

Direction

The right side of Figure 5 shows a Y20EBD Valve Linkage in the low

position connecting a 2-way valve body with a short stem to a M100

Motor Actuator for stem up operation.

Except for M100C (reverse acting) and M100H models, with an increasing

signal, the actuator always operates Clockwise (CW) from its zero

mechanical position. This clockwise rotation can be used to drive the

valve stem up or down, depending on the way the gear housing is attached

to the actuator.

To determine the direction of actuator drive:

Direction of

Drive Rotation

LOAD END

Y20D1- 06

Figure 6: Motor Actuator and Valve

M Motor Actuators

Y20EBD Valve Linkage for M100 Motor Actuators 9

—

Page 10

1. With the motor actuator next to the valve, view the motor actuator

from the load end.

2. Determine the type of valve being used and the direction that will be

required to drive the stem from its initial position.

• Stem Up Two Way Valve--Drive Down to Close

• Stem Up Two Way Valve--Drive Down to Open

• Stem Down Two Way Valve--Drive Up to Open

• Stem Down Two Way Valve--Drive Up to Close

• Stem Up Three Way Valve

• Stem Down Three Way Valve

Changing Yoke

Load End

Y20A1-07

Load End

Figure 7: Stem Up/Drive Down and Stem Down/Drive Up

3. For valves with the stem in the initial up position, the hole in the yoke

will be to the right of center when facing the load end as shown in the

left illustration of Figure 7.

For valves with the stem in the initial down position, the hole in the

yoke will be to the left of center when facing the load end as shown in

the right illustration of Figure 7.

The brackets are assembled at the factory in the low position and for stem

up/drive down valve application with the hole in the yoke to the right of

center as shown in the left illustration of Figure 7.

For any other application, the yoke and brackets must be disassembled and

reassembled for the specific application as described below.

10 M Motor Actuators

Y20EBD Valve Linkage for M100 Motor Actuators

—

Left Side

Bracket

Yoke

Screw

Washer/

Nut

Figure 8: Bracket Components

Right Side

Bracket

Y20D1-O8

Page 11

1. Remove the screw, washer, and nut securing the left and right side

brackets to the base bracket.

2. Position the yoke, left side, and right side brackets as determined

previously. The pins on the side brackets will fit into the holes in the

yoke until the screw is inserted.

3. Install the screw, washer, and nut to secure the side brackets to the

yoke and tighten.

Mounting Yoke

Note: The Y20EBD Linkage Kit can be used on Barber-Colman 1-1/2 to

2 inch valves. Use the grooved adapter bushing provided with the

linkage kit for V-90 Series and the mid-bracket position. Larger

Barber-Colman valves can mount onto the Y20EBD yoke directly;

however, adding locally purchased large washers under the linkage

bracket to prevent paint damage is recommended.

To mount the yoke on the valve:

Yoke Nut

Packing Nut

Spring P late

Valve

Y20D1-09

Figure 9: Preparing Valve

1. Remove the yoke nut (if present), packing nut (if necessary), and

spring plate (if present) from the valve as shown in Figure 9.

Note: Valves with 1/4 inch stems use the furnished yoke nut having a

3/4 inch thread to install the bushing and secure the bracket.

Larger valves have a one inch packing box thread on the yoke

which fits the smaller hole bushing and requires a separate yoke

nut that is usually furnished with the valve.

M Motor Actuators

Y20EBD Valve Linkage for M100 Motor Actuators 11

—

Page 12

Jam Nu t

Packing Nu t

Yoke Nut

Bushing

Valve

Y20D1- 10

Figure 10: Mounting Yoke

2. Place the yoke on the valve over the stem and bonnet.

3. Select the proper bushing and slide it over the bonnet and into the

yoke hole.

1.078

27.38

Y20D1- 11

1.015

25.78

Figure 11: Bushings

Note: Two bushings are provided:

• large hole--1.078 in. (27.38 mm) inside diameter which is

identified by a smooth outer edge

• small hole--1.015 inch (25.78 mm) inside diameter which is

identified by a groove on its outer edge

In general, valves up to two inch pipe size have 1/4 inch stems and use

the large hole (no groove) bushing; valves larger than two inch pipe

size have 3/8 inch stems and use the small hole bushing (with groove).

4. Install the yoke nut. For valve bodies 2-1/2 inch and larger, use the

yoke nut furnished with the valve. Fasten the yoke in place securely

by tightening the yoke nut with a wrench 1/8 turn past finger tight.

5. If the packing nut was removed, reinstall and tighten it. For valves

with U-Cup packing, tighten the nut 1/8 turn past “finger tight.” For

all other valves, tighten finger tight.

Note: JCI valves have U-Cup packing.

12 M Motor Actuators

Y20EBD Valve Linkage for M100 Motor Actuators

—

Page 13

6. Install the proper size jam nut onto the valve stem as far as it will go.

Do not tighten.

M Motor Actuators

Y20EBD Valve Linkage for M100 Motor Actuators 13

—

Page 14

Actuator and

Linkage

Mounting

Actuator

M100

Motor

Actuator

Hex Capscrew

High

Temp erature

Washer

Nut

Y20D1- 12

Figure 12: Mounting Motor Actuator

1. Locate the load end over the yoke.

2. Mount the actuator onto the brackets using the four bolts and nuts, but

do not tighten.

Note: If the temperature of the valve or its media is high enough to raise

the actuator temperature above its limit of 125°F (52°C), insert the

four white insulating washers (provided with the linkage kit)

between the actuator and the brackets. For lower temperature

applications, omit the insulating washers.

14 M Motor Actuators

Y20EBD Valve Linkage for M100 Motor Actuators

—

Page 15

Valve Stem

Connector

As received, the valve stem connector (mounted in the spring housing of

the rack subassembly) accommodates a 1/4 inch stem valve. If the valve

has a 3/8 inch stem, replace the connector with the 3/8 inch connector

furnished separately. To change the valve stem connector:

Spring

Housing

Mounting

Linkage

Pin

Y20A1-11

Spring Clip

Valve Stem

Connector

Figure 13: Valve Stem Connector

1. Remove the spring clip and pin from the spring housing as shown in

Figure 13.

2. Insert the connector nut so that the holes line up with the holes in the

spring housing.

3. Replace the pin and spring clip.

Note: It is a good idea to verify which valve stem connector is inserted

prior to installation.

To mount the gear housing and rack assembly to the motor actuator and

valve, proceed as follows:

Hole for

Rack Subassembly

1. Loosen the two gear cover screws and remove the gear cover and gear

Gear

Housing

Y20A1-12

Gear

Gear

Cover

Gear Cover

Screws

Figure 14: Gear Housing Assembly

from the gear housing as shown in Figure 14.

M Motor Actuators

Y20EBD Valve Linkage for M100 Motor Actuators 15

—

Page 16

2. Determine the required position of the gear housing on the load end of

the actuator so that the opening for the rack assembly is located as

follows:

• stem up position, drive down operation--rack to the right

• stem down position, drive up operation--rack to the left

Housing

Lockin g Sc re w

Rack

Subassembly

Y20A1-13

Figure 15: Inserting Rack Subassembly

3. Insert the rack subassembly into the gear housing by sliding it from

the bottom through the hole in the gear housing as shown in Figure

15.

Note: If the rack subassembly has difficulty being inserted, check the

locking screw to make sure that it is not interfering with movement

of the rack. If it is, back it out until there is no interference.

4. When the rack subassembly is completely in the housing, tighten the

locking screw to secure the rack subassembly in position.

Washers

Screws

Rack Subassembly

Spring Housing

Jam Nu t

16 M Motor Actuators

Y20EBD Valve Linkage for M100 Motor Actuators

—

Y20D1-15

Figure 16: Mounting Gear Housing

Page 17

Travel Limits

5. Position the gear housing and rack subassembly over the valve stem

and align the gear housing with the M100 drive shaft.

6. Attach the gear housing to the motor actuator with the washers and

gear housing screws. Do not tighten the screws at this time.

7. Loosen the locking screw and lower the rack subassembly to the

valve stem. Thread the rack subassembly spring housing completely

onto the valve stem.

8. Tighten the jam nut (shown in Figure 16) against the stem connector.

9. Align the actuator with the valve body to avoid binding of the linkage

and tighten the four mounting bolts.

10. Tighten the screws securing the gear housing to 25 in·lb (2.83 N·m)

maximum.

!

CAUTION: Do not perform the following operations if the valve is

under pressure. Shut off pump power, including

standby power, before attempting manual operation.

The procedure for adjusting the travel limits is different for the different

configurations of valves:

• Stem Up Two Way Valve--Drive Down to Close Drive down to close,

spring return open is the most common configuration for heating.

• Stem Up Two Way Valve--Drive Down to Open

• Stem Down Two Way Valve--Drive Up to Open

• Stem Down Two Way Valve--Drive Up to Close

• Stem Up Three Way Valve

• Stem Down Three Way Valve

!

CAUTION: Travel adjustments are made with power connected to

the actuator. On M100A Actuators, always

disconnect power from the actuator before adjusting

the slide stop to increase travel.

M Motor Actuators

Y20EBD Valve Linkage for M100 Motor Actuators 17

—

Page 18

Direction of Drive

Rotation COM

to CW Shorted

Keywa y

Direction of

Drive Rotation

COM to CCW Shorted

LOAD END

10° (AX)

Zero Reference

Positi o n

Drive Shaft

Y20A1-15

Figure 17: Actuator Zero Position

The actuators are factory set at zero position which is 10° clockwise from

square and for 90° clockwise travel as shown in Figure 17. Each 15° of

actuator rotation results in 0.1 inch (2.54 mm) of linear movement of the

rack assembly. The 90° actuator rotation provides 1/2 inch (12.7 mm) of

valve stem lift plus 0.1 inch (2.54 mm) of over travel.

Disconnect all control wires to the actuator. Refer to the technical bulletin

provided with the motor actuator for information on wiring the motor

actuator and related adjustments.

Connect only 24 VAC to terminals T1-T2. Be sure that power is off while

connections are made or changed. For quick reference, Table 2 provides

the connections for individual actuators.

Stem Up Two

Way Valve

Note: The M100C requires a Y199 tester to drive the motor actuator.

For stem up valves, make certain that the rack is assembled to the right of

the gear housing center.

Drive Down to Close Valves

1. Manually move the rack and spring housing assembly, connected to

the valve stem, to the full up position.

Y20A1-16

Figure 18: Pinion Gear Ends

2. Insert the pinion gear into the gear housing with the square hole end

(Figure 18) over the actuator shaft.

3. Replace the gear cover and tighten the gear cover screws. See

Figure 14.

18 M Motor Actuators

Y20EBD Valve Linkage for M100 Motor Actuators

—

Page 19

4. Refer to the technical bulletin provided with the motor actuator and

adjust the actuator travel to drive the stem down and compress the

spring in the housing (turn power off when adjusting M100A slide

stops).

Actuator

Drive

Upper

Visual

Guide

Lower

Visual

Guide

Flat

Washers

Figure 19: Upper Visual Guide Indicating Full Down Travel

5. As shown in Figure 19, when the edge of the upper flat washer is

opposite the notch in the upper visual guide, the travel is properly

adjusted. This represents 0.1 inch (2.54 mm) compression of the

spring with the valve seated.

Drive Down to Op en V alv es

1. Power the actuator to position the actuator 15° from zero. This is

equivalent to 0.1 inch (2.54 mm) of stem travel.

2. Manually move the rack and spring housing assembly, connected to

the valve stem, to the full up position.

3. Insert the pinion gear into the gear housing with the square hole over

the actuator shaft.

4. Replace the gear cover and tighten the gear cover screws.

5. Allow the actuator to return to zero position.

Actuator

Drive

Upper

Visual

Guide

Lower

Visual

Guide

Flat

Washers

M Motor Actuators

Y20EBD Valve Linkage for M100 Motor Actuators 19

—

Page 20

Figure 20: Lower Visual Guide Indicating Full Up Travel

6. As shown in Figure 20, the edge of the lower flat washer should

appear opposite the notch in the lower visual indicator to indicate

compression of the spring with the valve seated.

7. Refer to the technical bulletin provided with the motor actuator and

adjust the actuator travel for the full lift as described in the Valve Lift

section.

Stem Down Two

Way Valves

For stem down valves, make certain that the rack is assembled to the left

of the gear housing.

Drive Up to Close Valves

1. Manually move the rack and spring housing assembly, connected to

the valve stem, to the full down position.

2. Insert the pinion gear into the gear housing with the square hole over

the actuator shaft.

3. Replace the gear cover and tighten the gear cover screws.

4. Refer to the technical bulletin provided with the motor actuator and

adjust the actuator travel to drive the stem up and compress the spring

in the housing (turn power off when adjusting the M100A slide stop).

5. When the edge of the lower flat washer is opposite the notch in the

lower visual guide, the travel is properly adjusted. This represents

0.1 inch (2.54 mm) compression of the spring with the valve seated.

Drive Up to Open Valves

1. Power the actuator to position the actuator 15° from zero. This is

equivalent to 0.1 inch (2.54 mm) of stem travel.

2. Hold the rack in its full down position.

3. Insert the pinion gear into the gear housing with the square hole over

the actuator shaft.

4. Replace the gear cover and tighten the gear cover screws.

5. Allow the actuator to return to zero position. The edge of the upper

flat washer should appear opposite the notch in the upper visual

indicator to indicate compression of the spring with the valve seated.

6. Refer to the technical bulletin provided with the motor actuator and

adjust the actuator travel for full lift as described in the Valve Lift

section.

20 M Motor Actuators

Y20EBD Valve Linkage for M100 Motor Actuators

—

Page 21

Three Way Valves

Three way valves, mixing or diverting, can be assembled so that the upper

seat is initially closed (stem up) or so that the lower seat is initially closed

(stem down). Stem up or stem down operation is determined by the yoke

configuration and position of the rack and gear housing. Travel

adjustments are similar for either case and require both upper and lower

limits to be set. Both mixing and diverting 3-way valves are adjusted the

same way.

1. Power the actuator to position the drive shaft 15° from zero. This is

equivalent to 0.1 inch of stem travel.

2. Manually position the rack to the full stem up or stem down position

as required.

3. Insert the pinion gear into the gear housing with the square hole over

the actuator shaft.

4. Replace the gear cover and screws.

. . . .

. . . .

. . . .

. . . .

Modulating Lower Seat Closed Upper Seat Closed

Upper

Visual Guide

For Lower

Seat Close Off

Upper Valve Seat

(3-way Valves)

Valve Plug

Lower Valve

Seat (2- wa y an d

3-way Valves)

. . . .

. . . .

. . . .

. . . .

Lower

Visual Guide

For Upper

Seat Close Off

. . . .

. . . .

. . . .

. . . .

Figure 21: Linkage Adjustment Stem Up 3-Way Valve

5. Allow the actuator to return to the zero position. The flat washer

should align with the notch at the bottom of the spring case for stem

up valves or with the upper notch for stem down valves. This

indicates valve seating at the zero position.

6. Refer to the technical bulletin provided with the motor actuator and

adjust the travel to fully stroke the valve and compress the over travel

spring at full lift. The washer should be aligned with the notch

opposite the starting point.

7. Figure 21 illustrates the over travel indication for seating stem up

3-way valves.

M Motor Actuators

Y20EBD Valve Linkage for M100 Motor Actuators 21

—

Page 22

Manual Operation

!

CAUTION: Do not perform this operation if the valve is under

pressure. Shut off pump power, including standby

power, before attempting manual operation.

The valve can be manually operated without electrical power when

necessary for maintenance or emergency operation. To operate the valve

manually:

1. Remove the gear cover.

2. Remove the pinion gear from the gear housing and insert the gear

with the square hole facing out.

3. A 3/8 inch socket wrench drive will fit in the square hole and enable

manual positioning of the valve.

4. The spring can be compressed and then held in position by turning the

locking screw (located on the gear housing) in to hold the rack in

position.

IMPORTANT: To return to automatic operation, return the actuator to

the zero position and reinstall the gear with the square

hole engaging the actuator shaft. Repeat the travel limit

adjustments as necessary.

22 M Motor Actuators

Y20EBD Valve Linkage for M100 Motor Actuators

—

Page 23

Checkout Procedure

After Installation and adjustment, run the system through several complete

open/close cycles to be sure that all components are functioning correctly.

Check to be sure that the actuator responds to the controller and operates

the valve properly. Check for proper voltage. Check for operation of the

linkage without binding.

!

CAUTION: The actuator should not be stalled by the valve. The

actuator may be damaged if it is not free to complete

its full stroke.

Table 2: Actuator Connections for Travel Limit Adjustment

Jumper Terminals

Model Clockwise (CW) Counterclockwise (CCW)

M100A

M100C

M100E

M100F

M100G or M100H

M100J

M100Q

M100M

Apply 24 VAC to relay terminals A and C for clockwise rotation.

*

1 and 2 1 and 3

COM to CW COM to CCW

S1 to S2* Disconnect S1, S2, A, C

8 and 9 8 and 10

8 to T1 8 to 10

8 and 9 8 and 10

8 to T1 8 to 10

R to B Disconnect R from B

Note: On all models, remove controller wires and apply 24 VAC to

terminals T1 and T2 while making adjustments. Spring return

models will go full CCW when power to T1 and T2 is removed.

M Motor Actuators

Y20EBD Valve Linkage for M100 Motor Actuators 23

—

Page 24

Replacement Parts

Table 3 shows replacement parts that may be ordered from your nearest

Johnson Controls branch or distributor.

Table 3: Y20 Linkage Repair Parts

Description Code Number Remarks

Gear Assembly

Gear Only

Gear Cover

Spring Housing

and Rack

Assembly *

* Rack and Spring Housing are an assembly with spring and standard connector (1/4-28)

installed.

Specify Spring Load for application when ordering.

GER18A-600 Includes CVR115-1 and GER28-1

GER28-1

CVR115-1 Includes Mounting Screws

RCK12A--620

RCK12A--621

RCK12A--622

RCK12A--623

RCK12A--624

RCK12A--626

270 lb (1201 N) -- used with Y20EBD-3

179 lb (796 N) -- used with Y20EBD-4

150 lb (667 N) -- used with Y20EBD-2

75 lb (334 N) -- used with Y20EBD-1

40 lb (178 N) -- used with Y20EBD-5

100 lb (445 N) -- used with Y20EBD-6

Table 4: Accessories

Description Part Number

5/16 inch Stem Connector

VT Adapter Kit

Y20EBE-1

Y20EBE-2

24 M Motor Actuators

Y20EBD Valve Linkage for M100 Motor Actuators

—

Page 25

Notes

Controls Group

507 E. Michigan Street

P.O. Box 423 Printed in U.S.A.

Milwaukee, WI 53201

M Motor Actuators

Y20EBD Valve Linkage for M100 Motor Actuators 25

—

Loading...

Loading...