Page 1

System 9100 Technical Manual 636.4

Configuration Guides Section

Configuration Guide

Issue Date 0896

XT-9100 Configuration Guide

XT-9100 Extension Module/XP-910x Expansion Modules Page 3

•

Introduction 3

•

Hardware Configuration 4

•

Model Codes 4

Software Configuration 7

•

XT-9100 Type Settings 7

•

XT-9100 Configuration 9

•

Analog Input 10

•

Digital Input Configuration 15

•

Analog Output Configuration 16

•

Digital Output Configuration 19

•

Download/Upload 21

Appendix 1: SX Tool Item Description and Tables 23

•

General 23

•

Item Address 23

•

Item Type 23

•

Item Tag 24

•

Read/Write Data (R/W) 24

•

Floating Point Numbers 25

•

Item List 25

© 1996 Johnson Controls, Inc.

Code No. LIT-6364050

1

Page 2

2 Configuration Guides—XT-9100 Configuration Guide

Page 3

XT-9100 Extension Module/

XP-910x Expansion Modules

Introduction

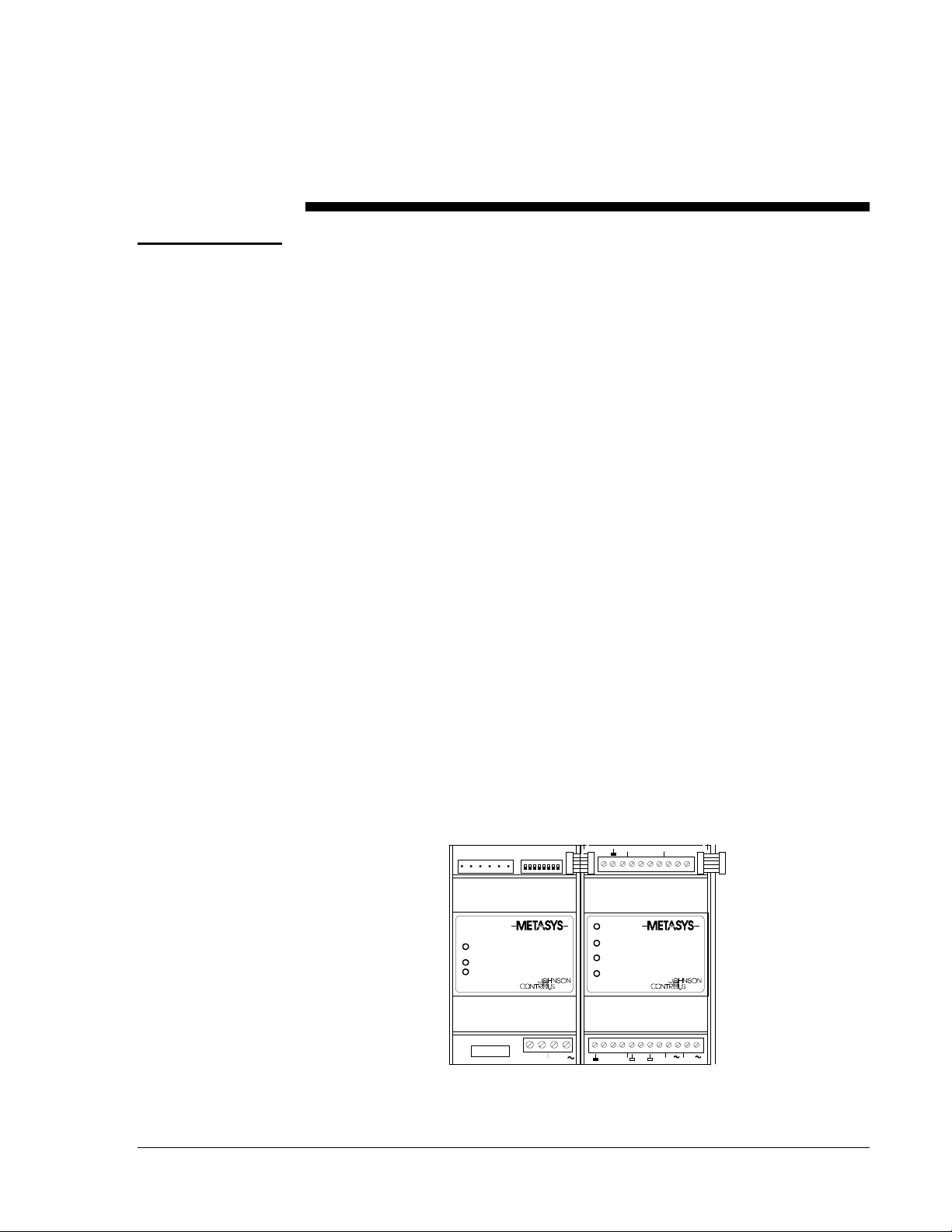

The XT-9100 Extension Module and its expansion modules have been

designed to provide additional input and output capacity within Metasys

Networks and specifically for the DX-9100 Extended Digital Controller.

The XT-9100 module provides the communication interface and the

XP modules provide the analog and digital inputs and outputs.

A Supervisory System communicates with an XT-9100 via the N2 Bus or

Bus 91*. Each XT-9100, depending on its expansion module combination,

can have up to 16 inputs/outputs, eight of which may be analog.

The DX-9100 communicates with the XT-9100 via the XT-Bus, and when

the DX-9100 is connected to an N2 Bus (or Bus 91), data from the

XT-9100 is available to a Supervisory System. Up to eight XT-9100

modules can be connected to the XT-Bus. Each XT-9100 provides,

depending on the type of the connected XP expansion modules, either

eight analog points or eight digital points, extending the input/output of a

DX-9100 by up to 64 remote input/outputs. Modules with 16

input/outputs may also be connected, provided that the total number of

remote input/output points on the DX-9100 does not exceed 64.

Configuration of the XT-9100 is achieved by using a personal computer

with GX-9100 Graphic Configuration Software (GX Tool) supplied by

Johnson Controls. When the serial interface of the XT-9100 is connected

directly to the N2 Bus (Bus 91), the GX-9100 will download and upload

configurations over the N2 Bus (Bus 91). When the serial interface of the

XT-9100 is connected to the XT Bus, the GX-9100 will download and

upload configurations via the N2 Bus (Bus 91) connected to the DX-9100

to which the XT-Bus is connected. The DX-9100 retransmits

configuration data to the XT-9100 on its XT-Bus.

RS485

EXP

EXP

ADDRESS

A B C A B C

AI1 AI2 AI3 AI4

+15V

EXP

max

AO7

Power

RD

TD

XT9100

FUSE

COM

24V

min

max

AO8

min

XP9102

AI5 AI6 V A O7 AO8

C

24V

xt910x

Figure 1: XT-9100 Extension Module and XP-910x Expansion Modules

* The term “Bus 91” is not used in North America.

Configuration Guides—XT-9100 Configuration Guide 3

Page 4

Hardware

Configuration

For full details of the hardware configuration, refer to the XT-9100

Technical Bulletin (LIT-6364040).

An XT-9100 combined with expansion modules provides the following

configurations, either:

• eight analog inputs/outputs, or

• eight digital inputs/outputs, with digital counters associated with the

digital inputs, or

• eight analog inputs/outputs and eight digital inputs/outputs, or

• sixteen digital inputs/outputs, with digital counters associated with the

digital inputs within the first eight inputs/output points

The extension module address is set with the address switches on the

XT-9100. When connected to a DX-9100 controller, this address must

also be set in the DX-9100 software configuration. The address must be

unique not only on the XT-Bus, but also on the N2 Bus (Bus 91) to which

the DX-9100 is connected.

The XT-9100 must be supplied with a 24 VAC power source. All models

are suitable for 50 Hz or 60 Hz through software configuration.

For the analog inputs and outputs, the input and output type are set by

jumpers on the analog expansion module board. These settings must

comply with the software configuration settings.

Model Codes

Note: When an extension module is configured with 16 inputs/outputs,

the DX-9100 considers the single physical module as two logical

modules, each with eight inputs/outputs. A DX-9100 can

communicate with up to eight logical modules, with a maximum of

64 inputs/outputs.

Table 1: XT/XP/TR Model Codes

XT-9100-8004

XP-9102-8004

XP-9103-8004

XP-9104-8004

XP-9105-8004

XP-9106-8004

TR-9100-8001*

TR-9100-8002*

* TR-9100 is not available in North America.

Extension Module 24 VAC supply

Expansion Module 6 analog inputs

2 analog outputs

Expansion Module 8 digital outputs (triacs)

Expansion Module 4 digital inputs

4 digital outputs (triacs)

Expansion Module 8 digital inputs

Expansion Module 4 digital outputs (relay)

Transformer, 24V/12 VA Primary: 240 VAC

Transformer, 24V/12 VA Primary: 220 VAC

4 Configuration Guides—XT-9100 Configuration Guide

Page 5

HOT GND NEUT

RS485

Bus Connector (provided)

EXP

EXP

ADDRESS

A B C A B C

AI1 AI2 AI3 AI4

+15V

EXP

EXP

DO1 DO2 DO3 DO4

EXP

Power

RD

TD

XT9100TR9100

FUSE

COM

24V

FUSE

COM

XT XP1 XP2TR

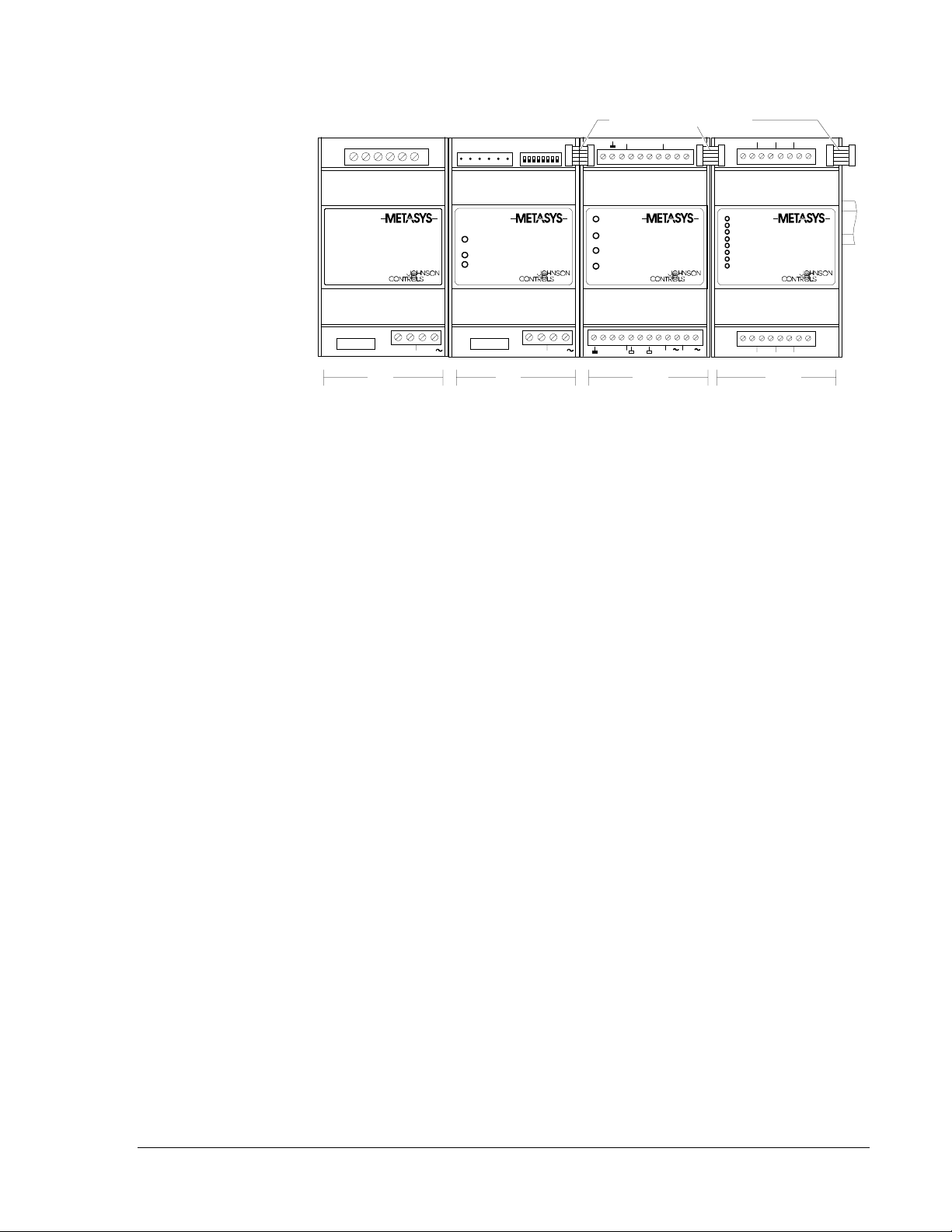

Figure 2: Typical XT-9100 Configuration

Table 2: XT Configurations

TR

XT

XP1

Transformer TR-9100 (optional)

Processor XT-9100

Analog

XP-9102

or

Digital

XP-9103

XP-9104

XP-9105

1 or 2 x XP-9106

24V

max

AO7

min

max

AO8

min

XP9102

AI5 AI6 V

DO1

DO2

DO3

DO4

DO5

DO6

DO7

DO8

XP9103

AO7

24VC

AO8

(See Note 1.)

(See Notes 2 and 4.)

DO5 DO6 DO 7 DO8

emtxt-4

XP2

Digital XP-9103

XP-9104

XP-9105

1 or 2 x XP-9106

(optional)

(optional)

(optional)

(optional) (See Notes 2, 3, and 4.)

Notes:

1. The analog XP-9102 must be placed in position XP1.

2. Two XP-9106 modules are considered as one XP module when installed next to each

other in Position XP1 or XP2. When a single XP-9106 is installed in Position XP1 and

another type of XP module is installed in Position XP2, the total number of I/Os is

restricted to 12.

3. The XP-9106 can only be placed in Position XP2 when Position XP1 is filled by an

analog XP or two XP-9106 modules.

4. The first XP-9106 in position XP1 or XP2 controls points DO1-DO4 and the second

XP-9106 in either position controls points DO5-DO8.

5. Digital modules with counters must be in position XP1.

Configuration Guides—XT-9100 Configuration Guide 5

Page 6

6 Configuration Guides—XT-9100 Configuration Guide

Page 7

XT-9100 Type

Settings

Software Configuration

Software configuration involves the setting of all the Items of the

extension module to values which correspond to the intended application.

Typically, use the GX Tool to configure a system, and the SX Tool to

troubleshoot. To use these tools, refer to the GX-9100 Software

Configuration Tool for Windows User’s Guide (LIT-6364060) and the

SX-9100 Service Module User’s Guide (LIT-6364070). Proceed in the

following order:

1. Define XT-9100 type settings.

2. Define XT-9100 configuration.

3. Define analog input characteristics.

4. Define digital input characteristics.

5. Define analog output characteristics.

6. Define digital output characteristics.

Power Line

Frequency

(50 or 60 Hz)

Output

Hold/Reset on

Comm. Failure

Flag

Via the GX Tool

Select DX-9100 and then Global. Enter the frequency as 50 or 60. The

XT frequency and the DX frequency are both defined here.

Via the SX Tool

Set Bit X1 of Item XTS (RI.69).

X1 = 0 50 Hz power line

X1 = 1 60 Hz power line

Via the GX Tool

First configure an XT Module. Select XTn, then Analog or Digital. Then

select the just configured XTn, XTn, and Data.

To set this flag, at the “Status on comm. fail” (communication failure)

field, enter 0 or 1.

When this bit is set to “0,” the digital outputs are switched off upon a

serial interface failure, and the corresponding Item values are reset to zero.

When set to “1,” the digital outputs hold their current state upon a serial

interface failure.

Configuration Guides—XT-9100 Configuration Guide 7

Page 8

Via the SX Tool

The “Output Hold/Reset on Communication Failure” flag is set at Bit X2

of Item XTS (RI.69).

X2 = 0 Output reset upon communication failure

X2 = 1 Output hold upon communication failure

Maximum Time

Between

Communications

Operational Mode

(SX Only)

When communication fails for the period set in this Item, the XT-9100

goes into “communication failure” state, indicated by a blinking power

LED on the front of the module. The default value is 60 seconds.

Via the GX Tool

First configure an XT Module. Select XTn, then Analog or Digital. Then

select the just configured XTn, XTn, and Data. At the “Comm. timeout

(sec)” field, enter the value in seconds.

Via the SX Tool

The “Maximum Time Between Communications” (in seconds) is entered

at Item MTBC (RI.86).

The operational mode of the XT-9100 can be seen at Item OPMO (RI.01)

with following status bits:

X8 = 1 PWR Power Failure. This bit is set when a XT is

powered up or when there is a serial interface

communication failure.

The setting in Item XTS (RI.69) Bit X2 (“Output Hold/Reset on

Communication Failure” flag) is repeated in Item OPMO (RI.01) Bit X7

so that it can be read by the DX-9100 or any other monitoring system.

XT Address

Via the GX Tool

In order to download the XT-9100 devices it is necessary to enter the

XT addresses. These addresses will also be loaded into the DX-9100.

When performing a download through a DX-9100 Controller, the

controller only downloads the addresses of its own XT set. The

XT address is not stored in the XT-9100 but must be set on the address

switches on the module.

First configure an XT Module. Select XTn, then Analog or Digital. Then

select the just configured XTn, XTn, and Data. At the “Hardware

Address” field, enter the address (1-255) of the XT-9100 module.

Via SX Tool

Refer to the Extension Module Configuration section in the DX-9100

Configuration Guide (LIT-6364030).

8 Configuration Guides—XT-9100 Configuration Guide

Page 9

XT-9100

Configuration

Settings

Via the GX Tool

The I/O type and map details are automatically generated by the GX-9100

Graphic Configuration Software when all I/O data for extension modules

has been entered. It is then downloaded into the XT-9100 directly or via

the DX-9100 and XT-Bus. (Refer to the Download/Upload section,

further in this document.)

When in the GX Tool, select the XT module, then define it as Analog or

Digital (if Digital, define it as 8 DI, 4DI/4DO, or 8DO). This defines

Module XP1. If an XT has 16 points (XP2 is connected), select the

XT box immediately to the right of the configured module, select

EXP.DIG and define it as 8DI, 4DI/4DO, or 8DO. “EXP” will appear in

the XT box. Then select XT (or EXP) again and define each point in the

selected configuration in the same way as when defining the points in the

DX-9100. The following pages describe how to define each of the points

individually.

Via the SX Tool

Each extension module configuration is defined by the I/O types and

map which are configured in Extension Module Items IOMAP (RI.77),

IOTYP (RI.78), and IOMOD (RI.79).

1. The I/O map (IOMAP) defines which inputs/outputs (in pairs) on the

extension module are used. Each extension module can be defined

with eight used points, which normally reside in the XP1 (first)

Expansion Module (points I/O1-I/O8), defined in bits X1-X4.

When an extension module has an XP2 (second) Expansion Module

with a further eight points, these points must be defined in bits X5-X8.

2. The I/O type (IOTYP) defines which inputs/outputs (in pairs) are

analog and which are digital. As the points on XP2 (if used) must be

digital, only bits X1-X4 can be configured.

3. The I/O mode (IOMOD) defines points as “input” or “output”

(in pairs). Only those points declared as “used” in Item IOMAP will

be monitored or controlled.

The combination of data in the Items IOMAP, IOTYP, and IOMOD

completely defines the configuration of an extension module. When

connected to a DX-9100 Controller, an identical set of data must be

entered into the Item data base in the DX-9100 Controller, so that,

when the DX-9100 and XT-9100 are connected and started up, the

DX-9100 will compare data bases and only send commands to the

extension module if the data is identical, thus avoiding incorrect

control actions.

Configuration Guides—XT-9100 Configuration Guide 9

Page 10

Analog Input

Note: The data base in the XT-9100 has been designed to accept most

configuration of inputs and outputs. All inputs and outputs

which are physically connected through expansion modules

must be configured, and only those points. If there is a

difference between the physical configuration and the software

configuration, the XT-9100 will signal an error condition to the

DX-9100 (XTnERR).

Configuration

Each analog input is defined and configured by the following parameters:

• Tag name (optional, GX-only)

• Measurement units (for RTD inputs)

• Enable square root

• Alarm on unfiltered value

• Input signal range

• Alarm limits

• Filter time constant

The GX Tool determines the input signal range with a 2-stage process:

you must first decide if the input is active or passive; the remaining

options depend on this choice. With the SX Tool, this information is

entered into a number of Items.

Via the GX Tool

Select XTn, AIn, then either Active or Passive.

Note: All AI points must be configured even if not connected to a sensor

to enable the generation of a complete IO Map and to ensure

correct operation with the DX-9100 Controller.

AI Input Type:

Measurement

Units

Via the GX Tool

The selection of Celsius or Fahrenheit, is set in the Global data of the

DX-9100 (select DX-9100, then Global. At the “Temperature Units”

field, enter “C” for Celsius or “F” for Fahrenheit).

To determine the measurement units of active inputs, select XTn, AIn,

Data, and then enter in the “Measurement Units” field:

0 = None

1 = Temperature (“C” or “F” as entered in Global)

2 = Percent (%)

Note: The units of an active input are not read by the DX-9100

Controller, but are available to any other Supervisory System

which may be connected.

10 Configuration Guides—XT-9100 Configuration Guide

Page 11

Via the SX Tool

The input type for the eight possible inputs (n = 1 to 8) can be configured

in Item AITn (RI.88, RI.96, RI.104, RI.112, RI.120, RI.128, RI.136, and

RI.144).

The unit of each analog input can be selected with following bits: (For

RTD inputs, Celsius or Fahrenheit must be selected.)

X4 X3 X2 X1 = 0000 No Units

X4 X3 X2 X1 = 0001 Celsius

X4 X3 X2 X1 = 0010 Fahrenheit

X4 X3 X2 X1 = 0011 Percent

Changing individual temperature units for each AI can only be done in the

SX Tool.

AI Input Type:

Enable Square

Root

This function allows the linearization of the differential pressure signal

from a 0-10 VDC or 0/4 - 20 mA active sensor; the function is effective

over the selected range:

AI = sqrt(PR%/100) * (HR - LR) + LR

Where %PR = the Analog Value in % of the physical input range;

HR = High Range Value; and LR = Low Range Value.

Via the GX Tool (Option Only Available with Active Sensor)

Select XTn, AIn, and Data. At the “Square Root” field, enter “0” for No,

or “1” for Yes (to enable the square root calculation).

Via the SX Tool (Option Only Available with Active Sensor)

Select Item AITn.

X5 = 1 Enable Square Root of Input

X5 = 0 Disable Square Root of Input

Configuration Guides—XT-9100 Configuration Guide 11

Page 12

AI Input Type:

Alarm on

Unfiltered Value

An alarm from the High Limit (HIAn) and Low Limit Alarm (LOAn) will

be generated from the unfiltered or filtered input. (See Filter Time

Constant.)

Via the GX Tool

Select XTn, AIn, and Data. At the “Alarm Unfiltered” field, enter “0” for

No (Alarm on Filtered Value), or “1” for Yes (Alarm on Unfiltered

Value).

Via the SX Tool

Select Item AITn.

X6 = 0 Alarm on Filtered Value

X6 = 1 Alarm on Unfiltered Value

AI Input Type:

Input Signal

Range

Via the GX Tool

(You must first have selected whether the input is active or passive. See

the beginning of Analog Input--Configuration.)

For active inputs, select XTn, AIn, then Data. At the “Type of Active

Input” field, enter:

0 = 0-10 VDC

1 = 4-20 mA

2 = 0-20 mA

Each analog input module channel performs the conversion of the input

signal to a numeric value using the high range and low range.

Select XTn, AIn, then Data.

High Range = enter the equivalent number for reading at high input

(10V, 20 mA)

Low Range = Enter the reading at low input (0V, 0 mA, 4 mA)

For passive inputs, select XTn, AIn, then Data. At the “Type of Passive

Input” field, enter:

1 = Ni1000 (JCI Type)

2 = Ni1000 Extended Range

3 = A99 (JCI Type)

4 = Pt 1000 (DIN)

Note: Selections 5 and 6 on the screen are not available in the

XT-9100.

For RTD inputs, the range of the displayed value is fixed according to the

type of sensor.

12 Configuration Guides—XT-9100 Configuration Guide

Page 13

Via the SX Tool

Input Type:

X7 = 0 0-10 volts

X7 = 1 0-20 mA

X8 = 1 20% suppression 2-10V or 4-20 mA)

Linearization and Sensor Type:

X11 X10 X9 = 000 Linear (Active Sensor)

X11 X10 X9 = 001 Ni 1000 RTD Passive Sensor (JCI Type)

(-45 to +121°C/-50 to +250°F)

X11 X10 X9 = 010 Ni 1000 RTD High Temperature Sensor

(+21 to +288°C/70 to +550°F)

X11 X10 X9 = 011 RTD Sensor A99

(-50 to +100°C/-58 to +212°F)

X11 X10 X9 = 100 RTD Sensor Platinum 1000

(+50 to +200°C/-58 to +320°F)

AI Input Type:

Alarm Limits

For active inputs, each analog input module channel performs the

conversion of the input signal to a numeric value using the high range at

Item HRn (RI.89, RI.97, RI.105, RI.113, RI.121, RI.129, RI.137, and

RI.145) and low range at Item LRn (RI.90, RI.98, RI.106, RI.114,

RI.122, RI.130, RI.138, and RI.146).

For RTD inputs, the range of the displayed value is fixed according to the

type of sensor.

The high limit and the low limit define at which levels the analog input

reading will generate an alarm, either for remote monitoring or for internal

use within the control sequences in the DX-9100.

Note: The limits cannot be deleted. If you do not want alarms, enter

limits beyond the range.

Via the GX Tool

Select XTn, AIn, then Data. At the respective field, enter the limit:

High Limit =

Low Limit =

Limit Differential =

Configuration Guides—XT-9100 Configuration Guide 13

Page 14

Via the SX Tool

The high limit is at Item HIAn (RI.91, RI.99, RI.107, RI.115, RI.123,

RI.131, RI.139, and RI.147), the low limit is at Item LOAn (RI.92,

RI.100, RI.108, RI.116, RI.124, RI.132, RI.140, and RI.148). These Items

may also be set by a Supervisory System and will always be set by

a DX-9100 Controller.

The differential on alarm limits is adjustable with Item ADFn (RI.93,

RI.101, RI.109, RI.117, RI.125, RI.133, RI.141, and RI.149).

Filter Time

Constant

AI Notes

The Filter Time Constant Ts (seconds) is used to filter out any cyclic

instability in the analog input signals. The calculations are:

FVt = FV

Where: FV

+ [1/(1 + Ts)] * [AIt - FV

t-1

= Filtered Analog Value at current time

t

FV

AI

= Filtered Analog Value at previous poll

t-1

= Actual Analog Value at current time

t

t-1

]

A value of “0” disables the filter.

Via the GX Tool

Select XTn, AIn, and Data. At the “Filter Constant (sec)” field, enter a

number within the recommended range 0 to 10.

Via the SX Tool

The Filter Time Constant is entered at Item FTCn (RI.94, RI.102, RI.110,

RI.118, RI.126, RI.134, RI.142, and RI.150).

1. When the XT-9100 is connected to a DX-9100 Controller, you can

view the AI value and alarm limits from the DX front panel. See

Display Panel and Keypads in the DX-9100 Extended Digital

Controller Technical Bulletin (LIT-6364020).

2. Analog input values can be read via the SX Tool at Item AIn

(RI.12 to RI.19).

3. Analog input alarm status can be seen via the SX Tool at Item AIS

(RI.11), Bit X1, X3....X15 for high alarm condition and X2, X4....X16

for low alarm condition.

4. Configure all AIs as Active or Passive, whether they are used or

not. A configured AI is shown by a thick bar to the left and right

of its selection box.

14 Configuration Guides—XT-9100 Configuration Guide

Page 15

Digital Input

Configuration

An XT-9100 can accept up to 16 digital inputs, which will be considered

active when driven to a common digital ground. The first eight digital

inputs are connected to XP1 and the next eight digital inputs to XP2.

Each digital input is defined and configured by the following parameters:

• Tag name (optional, GX-9100 only)

• Input type

• Counter prescaler

Inputs may be defined as maintained or pulse type. With maintained type

contacts the extension module status follows the status of the contact.

With pulse type contacts the extension module sets and resets the status at

each pulse of the input contact.

DI: Input Type

Via the GX Tool

Select XTn (or EXP), DIn, then Data. At the “Digital Input Type” field

enter 0 for maintained contact or 1 for pulse contact.

Via the SX Tool

The input type for the 2 x 8 possible inputs can be configured in Item

DIT1 for XP1 (RI.64) and in Item DIT2 (RI.65) for XP2, bits X1-X8 for

D11-DI8, as follows:

0 = Maintained Contact

1 = Pulse Contact

Configuration Guides—XT-9100 Configuration Guide 15

Page 16

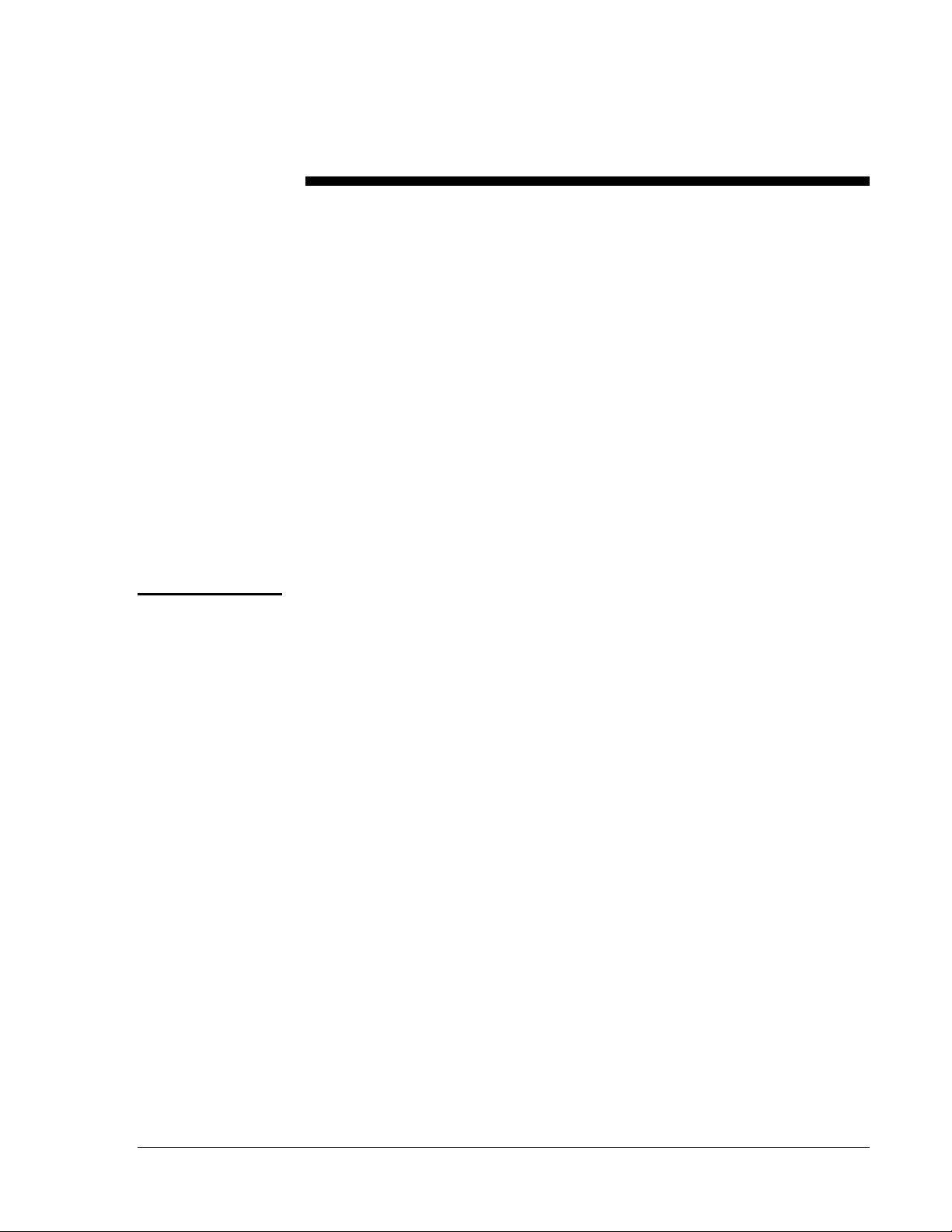

DI: Counter

Prescaler

The digital input transitions of XP1 are counted as follows:

Digital

Input

DIn

Prescale

PCn

Count

Transition

Pulse

Counter

CNTRn

(RI.09) (RI.48-55) (RI.32-39)

emcmxt-3

Figure 3: Counter Prescaler

A count transition occurs when the number of positive transitions of the

digital input (DIn) equals the value of the prescaler (PCn). The Pulse

Counter (CNTn) counts the count transitions (n = 1-8).

Note: Counters are only available in the XP1 location.

Via the GX Tool

Select XTn, DIn, then Data. At the “Prescaler (counts)” field, enter from 1

to 255. When the XT-9100 is connected to a DX-9100 Controller the total

counts can be read on the DX-9100 front panel.

DI Notes

Analog Output

Configuration

Via the SX Tool

Enter the prescaler at Item PCn (RI. 48-55) within the range 1-255.

1. When the XT-9100 is connected to a DX-9100 Controller, you can

view the DI status and counter values from the DX-9100 front panel.

See the Display Panel and Keypads section in the DX-9100 Extended

Digital Controller Technical Bulletin (LIT-6364020).

2. The status of the digital inputs can be seen at Item DIS1 (RI.09), bits

X1-X8, and Item DIS2 (RI.10), bits X1-X8.

Each analog output is defined and configured by the following parameters:

• Tag name (GX-9100 only)

• Output type

When the XT is connected to a DX-9100 Controller, the following

parameters are defined in the DX-9100 for the analog output:

• Source

• Range

16 Configuration Guides—XT-9100 Configuration Guide

Page 17

AO: Output Type

Via the GX Tool

Select XTn, ANALOG, XTn, AOn, and Data, then enter the output code:

0 = disabled

1 = 0 to 10 VDC

2 = 0 to 20 mA

3 = 4 to 20 mA

Via the SX Tool

The output type can be configured in Item AOT (RI.87) in bit pairs

X2 X1, X4 X3, ...X16 X15 for Outputs 1-8). To define the output signal

set the bits (for Output 7, for example) as follows:

X14 X13 = 00 Output Disabled

X14 X13 = 01 Output 0-10V

X14 X13 = 10 Output 0-20 mA

X14 X13 = 11 Output 4-20 mA

AO: Range

(with DX-9100

only)

The AO range of the analog output is defined in the DX-9100 Controller.

The High Range defines the level of control source signal that corresponds

to an output of 100%.

The Low Range defines the level of control source signal that corresponds

to an output of 0%.

When the source point is equal to the high range, then the output will be at

the maximum signal (10V/20 mA). When the source point is equal to low

range, then the output will be at the minimum signal (0V, 0/4 mA).

Via the GX Tool

Select XTn, AOn, and Data, then enter the desired values in the “High

Range” and “Low Range” fields.

Via the SX Tool

Refer to the Extension Module Configuration section of the DX-9100

Configuration Guide (LIT-6364030).

Configuration Guides—XT-9100 Configuration Guide 17

Page 18

AO: Source

(with DX-9100

Only)

The source of the analog output signal is defined in the DX-9100

Controller.

Via the GX Tool

Select XTn, AOn, Data, and the “Source Point” field. Enter * and select

the required source variable.

Via the SX Tool

Refer to the Extension Module Configuration section of the DX-9100

Configuration Guide (LIT-6364030).

AO Notes

1. When the XT-9100 is connected to a DX-9100 Controller, you can

view and override the AO value from the DX-9100 front panel. See

Display Panel and Keypads in the DX-9100 Extended Digital

Controller Technical Bulletin (LIT-6364020).

2. The analog output values can be read in percent at Item AOn

(RI.20-27) with the SX Tool.

18 Configuration Guides—XT-9100 Configuration Guide

Page 19

Digital Output

Configuration

Each digital output is defined and configured by the following parameters:

• Tag name (GX-9100 only)

• Output type

• Pulse time

When the XT is connected to a DX-9100 Controller, the following

parameter is defined in the DX-9100 for the digital output:

• Source

DO: Type of

Output

DO: Pulse Time

Via the GX Tool

Select XTn (or EXP) and DOn, then select either of the On/Off or

Pulse fields. For the Pulse type, the output switches for a configurable

pulse time for each state transition of the command output.

Via the SX Tool

The output type for outputs DO1-DO8 can be selected in Item DOT1

(RI.66) for XP1 and Item DOT2 (RI.67) for XP2 as follows:

X1 = 0 On/Off Type (Maintained)

X1 = 1 Pulse Type; the output switches for a configurable pulse time

for each state transition of the command output

This parameter is set once for all pulse type outputs in the XT-9100.

Via the GX Tool

Select XTn, XTn, and Data, then enter a value in the “Digital Output Pulse

Time” field. The valid range is 1 to 250 (5 msec to 1.25 seconds pulse

time).

Via the SX Tool

The digital output pulse time can be defined in Item DOPT (RI.68) in units

of 5 msec. The default value is 200, which represents a pulse time of

1 second.

Note: All connected DO points must be configured to ensure correct

operation with the DX-9100 Controller. When a single XP-9106

(4DO) relay module is connected, select 8 DO on the GX Tool and

define outputs DO1-DO4 only.

Configuration Guides—XT-9100 Configuration Guide 19

Page 20

DO Source

(with DX-9100

Only)

The source of the digital output signal is defined in the DX-9100

Controller.

Via the GX Tool

Select XTn or (EXP), DOn, Data, and then the “Source Point” field. Enter

* and select the required source variable.

Via the SX Tool

Refer to the Extension Module Configuration section in the DX-9100

Configuration Guide (LIT-6364030).

DO Notes

1. When the XT-9100 is connected to a DX-9100 Controller, you can

view and override the DO value from the DX-9100 front panel. See

Display Panel and Keypads in the DX-9100 Extended Digital

Controller Technical Bulletin (LIT-6364020).

2. The digital output status can be seen at Item DOS1 (DI.07) for XP1

and Item DOS2 (DI.08) for XP2, bits X1-X8 for outputs DO 1-8 with

the SX Tool.

3. A configured DO is shown by a thick bar to the left and right of

its selection box.

Configure all DOs as ON/OFF or PULSE, whether they are used

or not. The only exception is for the 4-output relay module

(XP-9106). When only one XP-9106 module is installed, select

8DO, but only configure DO1-DO4. When two XP-9106 modules

are installed, configure both as one 8DO module, and configure

DO1-DO8.

20 Configuration Guides—XT-9100 Configuration Guide

Page 21

Download/

Upload

Via the GX Tool

Download via DX-9100 Controller and N2 Bus

Connect an RS-232-C/RS-485 converter (type MM-CVT101-x in North

America and type IU-9100-810x in Europe) to one of the serial

communication ports (COM1 or COM2) of the personal computer on

which the GX Tool is running. Connect the N2 Bus of the DX-9100 to the

converter unit connected to the PC.

Set the address switches and jumpers on the DX-9100 and XT/XP devices

as required, and connect the XT/XP devices to the XT Bus of the

DX-9100. (See the DX-9100 Extended Digital Controller Technical

Bulletin (LIT-6364020) and XT-9100 Technical Bulletin (LIT-6364040)

for details.)

If the DX-9100 and XT/XP devices are installed and wired, verify all field

wiring and sensor voltage/current signals. It is recommended that

controlled devices be isolated during download and initial startup.

Note: Do not download an untested configuration into an installed

device. Test the configuration on a simulator panel before

downloading.

Apply 24 VAC power to the DX-9100 and XT/XP devices.

On the GX Tool, select DX-9100, DOWNLD, and DX. Enter the

DX-9100 address (0-255) in the “Controller Address” field and the PC

serial communication port (1 or 2) in the “PC Port” field. Press <Enter>.

Checks are made before the data is downloaded to the controller, and a

message is displayed on the screen if a value is outside the normal range

for that parameter. The user may abort the download process and change

the value in the configuration or press <Enter> to ignore the message and

download the entered value.

When the download is complete, select DX-9100, DOWNLD, and XT.

Verify that the correct “PC Port” is selected and press <Enter>.

For subsequent downloads, where the XT addresses have not been

changed, the loading can be done in one process by selecting DX-9100,

DOWNLD, and DX&XT.

Download via DX-9100 Controller (RS-232-C Port)

Connect the serial communication port of the PC directly to the

RS-232-C port of the DX-9100 Controller. See DX-9100 Extended Digital

Controller Technical Bulletin (LIT-6364020) for details. Proceed as for

Download via DX-9100 Controller and N2 Bus previously in the

Download/Upload section.

Configuration Guides—XT-9100 Configuration Guide 21

Page 22

Upload via a DX-9100 Controller

Only complete DX-9100/XT-9100 configurations should be uploaded

from the DX-9100. Select DX-9100 and NEW to clear the PC screen.

Select DX-9100, UPLOAD, and DX&XT. Enter the DX-9100 Controller

address (0-255) and PC port (1 or 2). Press <Enter>.

Download via the N2 Bus

Set the address switches and jumpers on the XT/XP devices as required.

Connect the XT/XP devices to the N2 Bus and the N2 Bus to the converter

on the PC. (See the XT-9100 Technical Bulletin (LIT-6364040) for

connection details.)

If the XT/XP devices are installed and wired, verify all field wiring and

sensor voltage/current signals. It is recommended that controlled devices

be isolated during download and initial startup. Apply 24 VAC power to

the XT/XP devices.

Up to eight XT-9100s may be downloaded at one time from the GX Tool

over the N2 Bus.

If the XT/XP devices are not used with a DX-9100, it is recommended that

one configuration file is created for each XT-9100 in Position XT1.

Set the address switches and jumpers on the XT/XP devices as required.

Connect the XT/XP devices to the N2 Bus and the N2 Bus to the converter

on the PC. (See the XT-9100 Technical Bulletin (LIT-6364040) for deta ils.)

If the XT/XP devices are installed and wired, verify all field wiring and

sensor voltage/current signals. It is recommended that controlled devices

be isolated during download and initial startup. Apply 24 VAC power to

the XT/XP devices.

Up to eight XT-9100s may be downloaded at one time from the GX Tool

over the N2 Bus.

If the XT/XP devices are not used with a DX-9100, it is recommended that

one configuration file is created for each XT-9100 in Position XT1.

Select DX-9100, DOWNLD, and XT. Enter the PC serial communication

port (1 or 2) in the “PC Port” field and press <Enter>.

Upload via the N2 Bus

Only one XT-9100 may be uploaded at one time and the configuration will

be stored under XT1. Select DX-9100, UPLOAD, and XT. Enter the

XT-9100 address (1-255) in the “Controller Address” field and the PC

serial communication point (1, 2) in the “PC Port” field. Press <Enter>.

Via the SX Tool

XT-9100 configuration data can only be changed item by item with the

SX Tool. It is not possible to download or upload a complete

configuration.

22 Configuration Guides—XT-9100 Configuration Guide

Page 23

Appendix 1: SX Tool Item

Description and Tables

The following information is important when commissioning with the

SX Service Module.

General

Item Address

Item Type

Each constant, variable, or value in an XT-9100 Extension Module can be

addressed via an Item code. All Items are contained in the Item List.

Note: It is important to note that EEPROM Items can only be written

approximately 10,000 times, so that write commands from cyclical

processes in Supervisory Systems must be avoided.

A configuration comprises a set of parameters which are stored in a series

of memory locations in the XT-9100. These parameters are called Items.

Each Item is assigned an Item Address.

Active parameters such as analog values are stored in RAM.

Configuration parameters are stored in EEPROM. Data stored in

EEPROM is retained when the power is switched off.

The Item List at the end of this manual gives a brief description of each

Item available within the module.

The format of any XT-9100 Item is described by the following types:

Number: Floating point number (2 bytes)

1 Byte: Unsigned 8-bit hexadecimal number used to transfer logic

states or integer numbers 0-255

2 Bytes: Unsigned 16-bit hexadecimal number used to transfer logic

states or unsigned integer numbers

4 Bytes: Unsigned 32-bit hexadecimal number used to transfer logic

states or unsigned integer numbers

The information stored in the Items can have one of several formats:

1. Floating Point Numerical Items are real numbers, with a +/- sign.

They refer to input or output values, limit values, etc. They are

displayed and entered as numbers, with a sign and a decimal point.

These Items are shown in the Item List with “Number” in the Type

column.

2. Integer Items are positive whole numbers used as scale factors.

These Items are shown in the Item List with “1 Byte Int” in the Type

column.

Configuration Guides—XT-9100 Configuration Guide 23

Page 24

3. Totalized Numerical Items are actual positive numbers. They refer

to totalized values of pulse counters. They are displayed and entered

as whole numbers, without a sign or decimal point. These Items are

shown in the Item List with “4 Bytes” in the Type column.

4. Status Items are either 1-byte or 2-byte Items giving information on

the actual status or configuration of the inputs, outputs and modules,

where each bit has a specific meaning as described in the Item List.

These Items are shown in the Item List with the number of bytes in

the Type column. Data is displayed and entered as bytes. In the list

the bytes will be represented using X1-X8 or X1-X16.

1 Byte = X8 X7 X6 X5 X4 X3 X2 X1

2 Bytes = X16 X15 X14 X13 X12 X11 X10 X9 X8 X7 X6 X5 X4 X3 X2 X1

Item Tag

Read/Write Data

(R/W)

Each Item in the Item List has a unique name or “tag,” which summarizes

the description and the meaning of the data which is stored in the XT-9100

memory.

The Items are shown in the Item List with their respective names in the

Tag column.

The Items shown in the Item List can be divided into three basic

categories:

1. Input values and status of the XT-9100 can be read but not changed

by a Supervisory System. These Items are shown in the Item List

with an “R” in the R/W column.

2. Variables in the XT-9100 can be read and modified by the GX-9100

Graphic Configuration Software or Supervisory System. These Items

are shown in the Item List with an “R/W” in the R/W (read/write)

column. (E) indicates that the Item is stored in EEPROM.

3. All other Items in the XT-9100 refer to configuration parameters of

the controller and contain information such as analog ranges, output

type, etc., and they can only be changed with the GX-9100 Graphic

Configuration Software. These Items are shown in the Item List with

a “CNF” (configuration) in the R/W column.

All Items can be accessed by the SX Tool via a DX-9100 Controller.

24 Configuration Guides—XT-9100 Configuration Guide

Page 25

Floating Point

Numbers

A DX-9100 floating point number consists of two bytes with following

format:

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

E3 E2 E1 E0 S M10 M9 M8 M7 M6 M5 M4 M3 M2 M1 M0

where: EEEE = 4 bits exponent

S = sign (1=negative)

MMMMMMMMMMM = 11 bits mantissa

Note: 216 = 32,768; subtracting 4 bits for the exponent, 1 bit for the sign,

and 11 bits for the mantissa leaves a maximum value of 2047 for

most numeric entries with single digit resolution.

• A number is normalized when the most significant bit is true

(M10 = 1).

• The value of the n.th mantissa bit (n from 0-10) is:

2 exp -(<EXPONENT>-n)

• A number is zero when all bits of the mantissa are 0.

• The value of a number is:

<NUMBER> = <SIGN> * .<MANTISSA> * 2 exp <EXPONENT>

Item List

Examples:

1 = 1400H or B001H

-1 = 1C00H or B801H

100 = 7640H or B064H

Symbols used in the Item List:

DI. Decimal Item Address

HI. Hexadecimal Item Address

Type Item Type

R/W Read Write conditions:

R Read only Item

R/W Read/Write Item

R/W (E) Read/Write Item (EEPROM)

CNF Configuration Item (EEPROM)

Tag Label for Item or bit written within an Item

Configuration Guides—XT-9100 Configuration Guide 25

Page 26

Table 3: Item List

RI. HI. Type R/W Tag Description

00 00 1 Byte R MODL Device Model : 08H

01 01 1 Bytes R/W OPMO Operation Mode (status)

X8 X7 X6 X5 X4 X3 X2 X1

X1 = 1 Watchdog text

X2 = DO Error

X3 = DI Error

X4 = AI Error

X5 = AO Error

X6 = Not Used

X7 = FAIL XT Fail Mode (= XTS, bit X2)

X8 = 1 PWR Power Fail or Comm. Failure

02 02 1 Byte R I2CE Bus Error

X8 X7 X6 X5 X4 X3 X2 X1

X1 = 1 XP1: DO Error

X2 = 1 XP2: DO Error

X3 = 1 XP1: DI Error

X4 = 1 XP2: DI Error

X5 = 1 Analog or Counter Error (1-4)

X6 = 1 Analog or Counter Error (5-8)

X7 = 1 FAIL EEPROM Error

X8 = 1 PWR XP Hardware Fault

03 03 1 Byte Spare

04 04 1 Byte Spare

05 05 1 Byte Spare

06 06 1 Byte Spare

26 Configuration Guides—XT-9100 Configuration Guide

Page 27

RI. HI. Type R/W Tag Description

07 07 1 Byte R/W DOS1 Digital Output Status XP1

X8 X7 X6 X5 X4 X3 X2 X1

X1 = 1 XP1 : Output 1 is On

X2 = 1 XP1 : Output 2 is On

X3 = 1 XP1 : Output 3 is On

X4 = 1 XP1 : Output 4 is On

X5 = 1 XP1 : Output 5 is On

X6 = 1 XP1 : Output 6 is On

X7 = 1 XP1 : Output 7 is On

X8 = 1 XP1 : Output 8 is On

08 08 1 Byte R/W DOS2 Digital Output Status XP2

X8 X7 X6 X5 X4 X3 X2 X1

X1 = 1 XP2 : Output 1 is On

X2 = 1 XP2 : Output 2 is On

X3 = 1 XP2 : Output 3 is On

X4 = 1 XP2 : Output 4 is On

X5 = 1 XP2 : Output 5 is On

X6 = 1 XP2 : Output 6 is On

X7 = 1 XP2 : Output 7 is On

X8 = 1 XP2 : Output 8 is On

09 09 1 Byte R DIS1 Digital Input Status XP1

X8 X7 X6 X5 X4 X3 X2 X1

X1 = 1 XP1 : Digital Input 1 is On

X2 = 1 XP1 : Digital Input 2 is On

X3 = 1 XP1 : Digital Input 3 is On

X4 = 1 XP1 : Digital Input 4 is On

X5 = 1 XP1 : Digital Input 5 is On

X6 = 1 XP1 : Digital Input 6 is On

X7 = 1 XP1 : Digital Input 7 is On

X8 = 1 XP1 : Digital Input 8 is On

Configuration Guides—XT-9100 Configuration Guide 27

Page 28

RI. HI. Type R/W Tag Description

10 0A 1 Byte R DIS2 Digital Input Status XP2

X8 X7 X6 X5 X4 X3 X2 X1

X1 = 1 XP2 : Digital Input 1 is On

X2 = 1 XP2 : Digital Input 2 is On

X3 = 1 XP2 : Digital Input 3 is On

X4 = 1 XP2 : Digital Input 4 is On

X5 = 1 XP2 : Digital Input 5 is On

X6 = 1 XP2 : Digital Input 6 is On

X7 = 1 XP2 : Digital Input 7 is On

X8 = 1 XP2 : Digital Input 8 is On

11 0B 2 Byte R AIS Analog Input Status

X16 X15 X14 X13 X12 X11 X10 X9 X8

X7 X6 X5 X4 X3 X2 X1

X1 = 1 AIH1 High Alarm Condition

X2 = 1 AIL1 Low Alarm Condition

X3 = 1 AIH2 High Alarm Condition

X4 = 1 AIL2 Low Alarm Condition

X5 = 1 AIH3 High Alarm Condition

X6 = 1 AIL3 Low Alarm Condition

X7 = 1 AIH4 High Alarm Condition

X8 = 1 AIL4 Low Alarm Condition

X9 = 1 AIH5 High Alarm Condition

X10= 1 AIL5 Low Alarm Condition

X11= 1 AIH6 High Alarm Condition

X12= 1 AIL6 Low Alarm Condition

X13= 1 AIH7 High Alarm Condition

X14= 1 AIL7 Low Alarm Condition

X15= 1 AIH8 High Alarm Condition

X16= 1 AIL8 Low Alarm Condition

28 Configuration Guides—XT-9100 Configuration Guide

Page 29

RI. HI. Type R/W Tag Description

12 0C Number R AI1 Analog Input Value 1

13 0D Number R AI2 Analog Input Value 2

14 0E Number R AI3 Analog Input Value 3

15 0F Number R AI4 Analog Input Value 4

16 10 Number R AI5 Analog Input Value 5

17 11 Number R AI6 Analog Input Value 6

18 12 Number R AI7 Analog Input Value 7

19 13 Number R AI8 Analog Input Value 8

20 14 Number R/W AO 1 Analog Output Value 1

21 15 Number R/W AO 2 Analog Output Value 2

22 16 Number R/W AO 3 Analog Output Value 3

23 17 Number R/W AO 4 Analog Output Value 4

24 18 Number R/W AO 5 Analog Output Value 5

25 19 Number R/W AO 6 Analog Output Value 6

26 1A Number R/W AO7 Analog Output Value 7

27 1B Number R/W AO8 Analog Output Value 8

28 1C Spare

29 1D Spare

30 1E Spare

31 1F Spare

32 20 4 Bytes R/W CNT1 DI1 Pulse Count*

33 21 4 Bytes R/W CNT2 DI2 Pulse Count*

34 22 4 Bytes R/W CNT3 DI3 Pulse Count*

35 23 4 Bytes R/W CNT4 DI4 Pulse Count*

36 24 4 Bytes R/W CNT5 DI5 Pulse Count*

37 25 4 Bytes R/W CNT6 DI6 Pulse Count*

38 26 4 Bytes R/W CNT7 DI7 Pulse Count*

39 27 4 Bytes R/W CNT8 DI8 Pulse Count*

40 28 Spare

41 29 Spare

42 2A Spare

43 2B Spare

44 2C Spare

45 2D Spare

46 2E Spare

47 2F Spare

* Pulse Count Items are stored in EEPROM upon power failure and restored to RAM upon

power restoration.

Configuration Guides—XT-9100 Configuration Guide 29

Page 30

RI. HI. Type R/W Tag Description

48 30 1 Byte Int CNF PC1 Prescaler DI1 Counter

49 31 1 Byte Int CNF PC2 Prescaler DI2 Counter

50 32 1 Byte Int CNF PC3 Prescaler DI3 Counter

51 33 1 Byte Int CNF PC4 Prescaler DI4 Counter

52 34 1 Byte Int CNF PC5 Prescaler DI5 Counter

53 35 1 Byte Int CNF PC6 Prescaler DI6 Counter

54 36 1 Byte Int CNF PC7 Prescaler DI7 Counter

55 37 1 Byte Int CNF PC8 Prescaler DI8 Counter

56 38 1 Byte CNF DIL1 Internal use only

57 39 1 Byte CNF DIL5 Internal use only

58 3A 1 Byte CNF DIL9 Internal use only

59 3B 1 Byte CNF DILD Internal use only

60 3C 1 Byte CNF DOL1 Internal use only

61 3D 1 Byte CNF DOL5 Internal use only

62 3E 1 Byte CNF DOL9 Internal use only

63 3F 1 Byte CNF DOLD Internal use only

64 40 1 Byte CNF DIT1 Digital Input Type XP1

X8 X7 X6 X5 X4 X3 X2 X1

X1 = 0 XP1 : DI1 = Maintained Contact

X1 = 1 XP1 : DI1 = Pulse Contact

X2 = 0 XP1 : DI2 = Maintained Contact

X2 = 1 XP1 : DI2 = Pulse Contact

X3 = 0 XP1 : DI3 = Maintained Contact

X3 = 1 XP1 : DI3 = Pulse Contact

X4 = 0 XP1 : DI4 = Maintained Contact

X4 = 1 XP1 : DI4 = Pulse Contact

X5 = 0 XP1 : DI5 = Maintained Contact

X5 = 1 XP1 : DI5 = Pulse Contact

X6 = 0 XP1 : DI6 = Maintained Contact

X6 = 1 XP1 : DI6 = Pulse Contact

X7 = 0 XP1 : DI7 = Maintained Contact

X7 = 1 XP1 : DI7 = Pulse Contact

X8 = 0 XP1 : DI8 = Maintained Contact

X8 = 1 XP1 : DI8 = Pulse Contact

30 Configuration Guides—XT-9100 Configuration Guide

Page 31

RI. HI. Type R/W Tag Description

65 41 1 Byte CNF DIT2 Digital Input Type XP2

X8 X7 X6 X5 X4 X3 X2 X1

X1 = 0 XP2 : DI1 = Maintained Contact

X1 = 1 XP2 : DI1 = Pulse Contact

X2 = 0 XP2 : DI2 = Maintained Contact

X2 = 1 XP2 : DI2 = Pulse Contact

X3 = 0 XP2 : DI3 = Maintained Contact

X3 = 1 XP2 : DI3 = Pulse Contact

X4 = 0 XP2 : DI4 = Maintained Contact

X4 = 1 XP2 : DI4 = Pulse Contact

X5 = 0 XP2 : DI5 = Maintained Contact

X5 = 1 XP2 : DI5 = Pulse Contact

X6 = 0 XP2 : DI6 = Maintained Contact

X6 = 1 XP2 : DI6 = Pulse Contact

X7 = 0 XP2 : DI7 = Maintained Contact

X7 = 1 XP2 : DI7 = Pulse Contact

X8 = 0 XP2 : DI8 = Maintained Contact

X8 = 1 XP2 : DI8 = Pulse Contact

66 42 1 Byte CNF DOT1 Digital Output Type XP1

X8 X7 X6 X5 X4 X3 X2 X1

X1 = 0 XP1 : DO1 = ON/OFF Type

X1 = 1 XP1 : DO1 = Pulse Type

X2 = 0 XP1 : DO2 = ON/OFF Type

X2 = 1 XP1 : DO2 = Pulse Type

X3 = 0 XP1 : DO3 = ON/OFF Type

X3 = 1 XP1 : DO3 = Pulse Type

X4 = 0 XP1 : DO4 = ON/OFF Type

X4 = 1 XP1 : DO4 = Pulse Type

X5 = 0 XP1 : DO5 = ON/OFF Type

X5 = 1 XP1 : DO5 = Pulse Type

X6 = 0 XP1 : DO6 = ON/OFF Type

X6 = 1 XP1 : DO6 = Pulse Type

X7 = 0 XP1 : DO7 = ON/OFF Type

X7 = 1 XP1 : DO7 = Pulse Type

X8 = 0 XP1 : DO8 = ON/OFF Type

X8 = 1 XP1 : DO8 = Pulse Type

Configuration Guides—XT-9100 Configuration Guide 31

Page 32

RI. HI. Type R/W Tag Description

67 43 1 Byte CNF DOT2 Digital Output Type XP2

X8 X7 X6 X5 X4 X3 X2 X1

X1 = 0 XP2 : DO1 = ON/OFF Type

X1 = 1 XP2 : DO1 = Pulse Type

X2 = 0 XP2 : DO2 = ON/OFF Type

X2 = 1 XP2 : DO2 = Pulse Type

X3 = 0 XP2 : DO3 = ON/OFF Type

X3 = 1 XP2 : DO3 = Pulse Type

X4 = 0 XP2 : DO4 = ON/OFF Type

X4 = 1 XP2 : DO4 = Pulse Type

X5 = 0 XP2 : DO5 = ON/OFF Type

X5 = 1 XP2 : DO5 = Pulse Type

X6 = 0 XP2 : DO6 = ON/OFF Type

X6 = 1 XP2 : DO6 = Pulse Type

X7 = 0 XP2 : DO7 = ON/OFF Type

X7 = 1 XP2 : DO7 = Pulse Type

X8 = 0 XP2 : DO8 = ON/OFF Type

X8 = 1 XP2 : DO8 = Pulse Type

68 44 1 Byte CNF DOPT Digital Output Pulse Time (*5 ms.)

(default = 200)

69 45 1 Byte CNF XTS XT-9100 Type Settings

0 0 0 0 0 X3 X2 X1

X1 = 0 50 Hz Power Line

X1 = 1 60 Hz Power Line

X2 = 0 Output Reset on communication

failure

X2 = 1 Output Hold on communication

failure

X3 Internal use only

70 46 1 Byte CNF Spare

71 47 1 Byte CNF Spare

72 48 1 Byte CNF Spare

73 49 1 Byte CNF Spare

74 4A 1 Byte CNF Spare

75 4B 1 Byte CNF AI2C Internal use only

76 4C 1 Byte CNF AMOD Internal use only

32 Configuration Guides—XT-9100 Configuration Guide

Page 33

RI. HI. Type R/W Tag Description

77 4D 1 Byte CNF IOMAP Extension Module I/O Map

X8 X7 X6 X5 X4 X3 X2 X1

X1 = 0 XP1 : I/O1 and I/O2 Not Used

X1 = 1 XP1 : I/O1 and I/O2 Used

X2 = 0 XP1 : I/O3 and I/O4 Not Used

X2 = 1 XP1 : I/O3 and I/O4 Used

X3 = 0 XP1 : I/O5 and I/O6 Not Used

X3 = 1 XP1 : I/O5 and I/O6 Used

X4 = 0 XP1 : I/O7 and I/O8 Not Used

X4 = 1 XP1 : I/O7 and I/O8 Used

X5 = 0 XP2 : I/O1 and I/O2 Not Used

X5 = 1 XP2 : I/O1 and I/O2 Used

X6 = 0 XP2 : I/O3 and I/O4 Not Used

X6 = 1 XP2 : I/O3 and I/O4 Used

X7 = 0 XP2 : I/O5 and I/O6 Not Used

X7 = 1 XP2 : I/O5 and I/O6 Used

X8 = 0 XP2 : I/O7 and I/O8 Not Used

X8 = 1 XP2 : I/O7 and I/O8 Used

78 4E 1 Byte CNF IOTYP Extension Module I/O Type

0 0 0 0 X4 X3 X2 X1

X1 = 0 XP1 : I/O1 and I/O2 Digital

X1 = 1 XP1 : I/O1 and I/O2 Analog

X2 = 0 XP1 : I/O3 and I/O4 Digital

X2 = 1 XP1 : I/O3 and I/O4 Analog

X3 = 0 XP1 : I/O5 and I/O6 Digital

X3 = 1 XP1 : I/O5 and I/O6 Analog

X4 = 0 XP1 : I/O7 and I/O8 Digital

X4 = 1 XP1 : I/O7 and I/O8 Analog

Configuration Guides—XT-9100 Configuration Guide 33

Page 34

RI. HI. Type R/W Tag Description

79 4F 1 Byte CNF IOMOD Extension Module I/O Mode

X8 X7 X6 X5 X4 X3 X2 X1

X1 = 0 XP1 : I/O1 and I/O2 Input

X1 = 1 XP1 : I/O1 and I/O2 Output

X2 = 0 XP1 : I/03 and I/O4 Input

X2 = 1 XP1 : I/O3 and I/O4 Output

X3 = 0 XP1 : I/O5 and I/O6 Input

X3 = 1 XP1 : I/O5 and I/O6 Output

X4 = 0 XP1 : I/O7 and I/O8 Input

X4 = 1 XP1 : I/O7 and I/O8 Output

X5 = 0 XP2 : I/O1 and I/O2 Input

X5 = 1 XP2 : I/O1 and I/O2 Output

X6 = 0 XP2 : I/O3 and I/O4 Input

X6 = 1 XP2 : I/O3 and I/04 Output

X7 = 0 XP2 : I/O5 and I/O6 Input

X7 = 1 XP2 : I/O5 and I/O6 Output

X8 = 0 XP2 : I/O7 and I/O8 Input

X8 = 1 XP2 : I/O7 and I/O8 Output

80 50 1 Byte CNF Spare

81 51 1 Byte CNF Spare

82 52 1 Byte CNF Spare

83 53 1 Byte CNF Spare

84 54 1 Byte CNF Spare

85 55 1 Byte CNF Spare

86 56 2 Byte CNF MTBC Maximum Time Between

87 57 2 Byte CNF AOT Analog Output Type

X16 X15 X14 X13 X12 X11 X10 X9

X8 X7 X6 X5 X4 X3 X2 X1

X2 X1

= 00 Output Disabled

= 01 Output 0 to 10V

= 10 Output 0 to 20 mA

= 11 Output 4 to 20 mA

X4 X3 Signal Analog Output 2 (as X2 X1)

X6 X5 Signal Analog Output 3 (as X2 X1)

X8 X7 Signal Analog Output 4 (as X2 X1)

X10 X9 Signal Analog Output 5 (as X2 X1)

X12 X11 Signal Analog Output 6 (as X2 X1)

X14 X13 Signal Analog Output 7 (as X2 X1)

X16 X15 Signal Analog Output 8 (as X2 X1)

34 Configuration Guides—XT-9100 Configuration Guide

Communications (default = 60 sec.)

Signal Analog Output 1

Page 35

RI. HI. Type R/W Tag Description

88 58 2 Bytes CNF AIT1 Input Type of Analog Input 1

0 0 0 0 0 X11 X10 X9

X8 X7 X6 X5 X4 X3 X2 X1

X4 X3 X2 X1

= 0000 No Units

= 0001 Degrees Celsius or Kelvin

= 0010 Degrees Fahrenheit

= 0011 Percent

X5 = 1 Enable Square Root of Input

X6 = 1 Alarm on Unfiltered Value

X7 = 0 0-10 Volts

X7 = 1 0-2 Volts, 0-20 mA or RTD

X8 = 1 20 % Suppression

X11 X10 X9 Linearization and Sensor Type

= 000 Linear (active sensor)

= 001 Nickel 1000 (JCI)

= 010 Nickel 1000 Ext. Rng

= 011 A99 Sensor

= 100 PT1000 Sensor

89 59 Number CNF HR1 High Range Analog Input 1

90 5A Number CNF LR1 Low Range Analog Input 1

91 5B Number R/W (E) HIA1 High Alarm Limit Analog Input 1

92 5C Number R/W (E) LOA1 Low Alarm Limit Analog Input

93 5D Number R/W (E) ADF1 Differential on Alarm Limit [units]

94 5E Number CNF FTC1 Filter Constant Analog Input 1

Unit of Measure

95 5F 2 Bytes Spare

96 60 2 Bytes CNF AIT2 Input Type of Analog Input 2 (bits

as AIT1)

97 61 Number CNF HR2 High Range Analog Input 2

98 62 Number CNF LR2 Low Range Analog Input 2

99 63 Number R/W (E) HIA2 High Alarm Limit Analog Input 2

100 64 Number R/W (E) LOA2 Low Alarm Limit Analog Input 2

101 65 Number R/W (E) ADF2 Differential on Alarm Limit [units]

102 66 Number CNF FTC2 Filter Constant Analog Input 2

103 67 2 Bytes Spare

Configuration Guides—XT-9100 Configuration Guide 35

Page 36

RI. HI. Type R/W Tag Description

104 68 2 Bytes CNF AIT3 Input Type of Analog Input 3

(bits as AIT1)

105 69 Number CNF HR3 High Range Analog Input 3

106 6A Number CNF LR3 Low Range Analog Input 3

107 6B Number R/W (E) HIA3 High Alarm Limit Analog Input 3

108 6C Number R/W (E) LOA3 Low Alarm Limit Analog Input 3

109 6D Number R/W (E) ADF3 Differential on Alarm Limit [units]

110 6E Number CNF FTC3 Filter Constant Analog Input 3

111 6F 2 Bytes Spare

112 70 2 Bytes CNF AIT4 Input Type of Analog Input 4

(bits as AIT1)

113 71 Number CNF HR4 High Range Analog Input 4

114 72 Number CNF LR4 Low Range Analog Input 4

115 73 Number R/W (E) HIA4 High Alarm Limit Analog Input 4

116 74 Number R/W (E) LOA4 Low Alarm Lim it Analog Input 4

117 75 Number R/W (E) ADF4 Differential on Alarm Limit [units]

118 76 Number CNF FTC4 Filter Constant Analog Input 4

119 78 2 Bytes Spare

120 74 2 Bytes CNF AIT5 Input Type of Analog Input 5

(bits as AIT1)

121 79 Number CNF HR5 High Range Analog Input 5

122 7A Number CNF LR5 Low Range Analog Input 5

123 7B Number R/W (E) HIA5 High Alarm Limit Analog Input 5

124 7C Number R/W (E) LOA5 Low Alarm Limit Analog Input 5

125 7D Number R/W (E) ADF5 Differential on Alarm Limit [units]

126 7E Number CNF FTC5 Filter Constant Analog Input 5

127 7F 2 Bytes Spare

36 Configuration Guides—XT-9100 Configuration Guide

Page 37

RI. HI. Type R/W Tag Description

128 80 2 Bytes CNF AIT6 Input Type of Analog Input 6

(bits as AIT1)

129 81 Number CNF HR6 High Range Analog Input 6

130 82 Number CNF LR6 Low Range Analog Input 6

131 83 Number R/W (E) HIA6 High Alarm Limit Analog Input 6

132 84 Number R/W (E) LOA6 Low Alarm Lim it Analog Input 6

133 85 Number R/W (E) ADF6 Differential on Alarm Limit [units]

134 86 Number CNF FTC6 Filter Constant Analog Input 6

135 87 2 Bytes Spare

136 88 2 Bytes CNF AIT7 Input Type of Analog Input 7

(bits as AIT1)

137 89 Number CNF HR7 High Range Analog Input 7

138 8A Number CNF LR7 Low Range Analog Input 7

139 8B Number R/W (E) HIA7 High Alarm Limit Analog Input 7

140 8C Number R/W (E) LOA7 Low Alarm Limit Analog Input 7

141 8D Number R/W (E) ADF7 Differential on Alarm Limit [units]

142 8E Number CNF FTC7 Filter Constant Analog Input 7

143 8F 2 Bytes Spare

144 90 2 Bytes CNF AIT8 Input Type of Analog Input 8

(bits as AIT1)

145 91 Number CNF HR8 High Range Analog Input 8

146 92 Number CNF LR8 Low Range Analog Input 8

147 93 Number R/W (E) HIA8 High Alarm Limit Analog Input 8

148 94 Number R/W (E) LOA8 Low Alarm Lim it Analog Input 8

149 95 Number R/W (E) ADF8 Differential on Alarm Limit [units]

150 96 Number CNF FTC8 Filter Constant Analog Input 8

151 97 2 Bytes Spare

Configuration Guides—XT-9100 Configuration Guide 37

Page 38

Notes

38 Configuration Guides—XT-9100 Configuration Guide

Page 39

Notes

Configuration Guides—XT-9100 Configuration Guide 39

Page 40

Notes

Controls Group FAN 636.4

507 E. Michigan Street System 9100 Technical Manual

P.O. Box 423 Printed in U.S.A.

Milwaukee, WI 53201

40 Configuration Guides—XT-9100 Configuration Guide

Loading...

Loading...