VSD Series II

Quick Start Guide

Effective October 2012

New Information

Important Notice–Please Read

The product discussed in this literature is subject to terms and conditions outlined

in Johnson Controls Inc. selling policies. The sole source governing the rights and

remedies of any purchaser of this equipment is the relevant Johnson Controls Inc.

selling policy.

NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WARRANTIES OF

FITNESS FOR A PARTICULAR PURPOSE OR MERCHANTABILITY, OR

WARRANTIES ARISING FROM COURSE OF DEALING OR USAGE OF TRADE,

ARE MADE REGARDING THE INFORMATION, RECOMMENDATIONS AND

DESCRIPTIONS CONTAINED HEREIN. In no event will Johnson Controls Inc. or

Eaton Electrical Inc. be responsible to the purchaser or user in contract, in tort

(including negligence), strict liability or otherwise for any special, indirect, incidental

or consequential damage or loss whatsoever, including but not limited to damage or

loss of use of equipment, plant or power system, cost of capital, loss of power,

additional expenses in the use of existing power facilities, or claims against the

purchaser or user by its customers resulting from the use of the information,

recommendations and descriptions contained herein.

The information contained in this manual is subject to change without notice.

Cover Photo: Johnson Controls® VSD Series II Drive

VSD Series II

Warranty and Liability Information

In accordance with details on next page, Johnson Controls Inc. warrants the product

delivered in the Johnson Controls shipping package to be free from defects in

material and workmanship, under normal use and service. Products that fail during

this period will be repaired or replaced at Johnson Controls discretion, with the

same or a functionally equivalent product, provided the original purchaser (A) returns

the failed product, and (B) provides proof of original date of purchase. The original

purchaser of the product must obtain a Johnson Controls Return Material

Authorization (RMA) number prior to returning any defective product. (When

purchased through an Authorized Distributor, the Distributor should supply an

RMA number to their customer.)

The maximum liability of this warranty is limited to the purchase price of the

product. In no event, regardless of cause, shall Johnson Controls Inc. or Eaton

Electrical Inc. be liable (a) for penalties or penalty clauses of any description, or (b)

for certification not otherwise specifically provided herein and/or indemnification of

purchaser or others for costs, damages or expenses, each arising out of or related to

the product or services of any order or (c) for any damages resulting from loss of

profits, use of products or for any incidental indirect or consequential damages,

even if advised of the possibility of such damages.

VSD Series II LIT-12011773—October 2012 www.johnsoncontrols.com i

VSD Series II

Standard Warranty

Subject to the limitations and conditions stated herein, that all new Series II VSD

products shall be free from defects in material and workmanship and shall deliver

their rated output as indicated on the nameplates for a period of thirty (30) months

from date of shipment.

This warranty shall provide coverage for replacement parts only and does not cover

failure or damage due to storage, installation, operation or maintenance not in

conformance with Johnson Controls recommendations and industry standard

practice or due to accident, misuse, abuse or negligence. In addition, this warranty

does not cover reimbursement for labor, including any removal/installation expenses

which may be incurred in connection with repair or replacement, unless otherwise

agreed upon by Johnson Controls.

Warranty with Certified Start-Up

Provided the equipment is commissioned by an authorized EATON® service

provider (including individuals certified through Johnson Controls VSD Start-up/

Commissioning Certification Training

new Series II VSD products shall be free from defects in material and workmanship

and shall deliver their rated output as indicated on the nameplates for a period of

thirty-nine (39) months

from date of shipment.

This warranty shall provide coverage for replacement parts and on-site labor,

including any removal/installation expenses associated with the warranty claim.

), JOHNSON CONTROLS warrants that all

Return Authorization/General Returns

Product Description Credit

Open, Type 1, Type 12 Drives 100%

®

Intellipass

Custom Engineered Drives and Obsolete Products 0%

1. JOHNSON CONTROLS agrees to accept VSD Open products for return and

2. JOHNSON CONTROLS agrees to accept VSD Intellipass and Intellidisconnect

3. JOHNSON CONTROLS shall promptly refund or credit said customer for any

and Intellidisconnect Type 1, Type 12 and Type 3R Enclosed Branded Drives 85%

without penalty or restocking charge. JOHNSON CONTROLS will issue a 100%

credit—provided the product is in its original unopened package and is returned

within 120 days of receipt of product by JOHNSON CONTROLS.

Drives with a 15% restocking fee provided the product is in its original

unopened package and is returned within 120 days of receipt of product by

JOHNSON CONTROLS.

and all payments made by the buyer for such product(s). The buyer will be

responsible for all freight charges associated with products authorized for return

to JOHNSON CONTROLS.

ii VSD Series II LIT-12011773—October 2012 www.johnsoncontrols.com

Support Services

The goal of Johnson Controls is to ensure your greatest possible satisfaction with the

operation of our products. We are dedicated to providing fast, friendly, and accurate

assistance. Whether it’s by phone, fax, or e-mail, you can access support information

listed below.

You should contact your local Johnson Controls Sales Representative for product pricing,

availability, ordering, expediting, and repairs.

Web Site

Use the Johnson Controls Web site to find product information.

Web Site Address

www.johnsoncontrols.com –> HVAC Controls –> Variable Speed Drives

Johnson Controls Product Sales Operation

Call the Johnson Controls PSO Team if you need assistance with placing an order, stock

availability or proof of shipment, expediting an existing order, emergency shipments, product

price information and returns (including warranty returns).

Voice: 1-800-ASK-JNSN [275-5676] (US); 1-800-321-4023 (CA)

FAX: 1-800-356-1191 (US); 1-800-321-4024 (CA)

Support Hours of Operation: Monday–Friday, 6:30 a.m.–5:30 p.m. CST

(No evening or weekend Customer Service hours).

If you are in the U.S. or Canada, you can take advantage of our toll-free line for technical

assistance. Technical support engineers are available for calls during regular business hours.

Johnson Controls Field Support Center

1-888-281-3792 Monday–Friday, 7:30 a.m.–5:30 p.m. CST

email: CGFieldSupportCenter@jci.com

VSD Series II

For emergency assistance, contact: Eaton Technical Resource Center

Voice: 877-ETN-CARE (386-2273) (8:00 a.m.–5:00 p.m. EST)

FAX: 828-651-0549

e-mail: TRC@Eaton.com

VSD Series II LIT-12011773—October 2012 www.johnsoncontrols.com iii

VSD Series II

iv VSD Series II LIT-12011773—October 2012 www.johnsoncontrols.com

HVAC Application

The Johnson Controls VSD Series II drive contains a

preloaded application for instant use.

The parameters of this application are listed in the complete

Application Manual. The Application Manual can be found at

http://www.johnsoncontrols.com —> HVAC Controls —>

Variable Speed Drives.

Specific Functions of Johnson Controls

VSD Series II Application

The Johnson Controls VSD Series II application is an

easy-to-use application for not only basic pump and fan

applications where only one motor and one drive is needed,

but also offers extensive possibilities for PID control.

Features

●

Startup Wizard for extremely fast setup for basic pump or

fan applications

●

Mini-Wizards to ease the setup of applications

●

Hand/Off/Auto button for easy change between Hand

(keypad), OFF, and Auto (Remote control) place. The auto

control place is selectable by parameter (I/O or Fieldbus)

●

Control page for easy operation and monitoring of the

most essential values

●

Run interlock input (damper interlock). Drive will not start

before this input is activated

●

Maximum output frequency 320 Hz

●

Real-time clock and timer functions available. Possible to

program three time channels to achieve different functions

on the drive (for example, Start/Stop and Preset

frequencies)

HVAC Application

●

External PID-controller available. Can be used to control a

valve using the drive’s I/O, for example

●

Sleep mode function which automatically enables and

disables drive running with user defined levels to save

energy

●

Two-zone PID-controller (two different feedback signals;

minimum and maximum control)

●

Two setpoint sources for the PID-control. Selectable with

digital input

●

PID setpoint boost function

●

Feed forward function to improve the response to the

process changes

●

Process value supervision

●

Multi-pump control

●

Pressure loss compensation for compensating pressure

losses in the pipework, for example, when sensor is

incorrectly placed near the pump or fan

VSD Series II LIT-12011773—October 2012 www.johnsoncontrols.com 1

HVAC Application

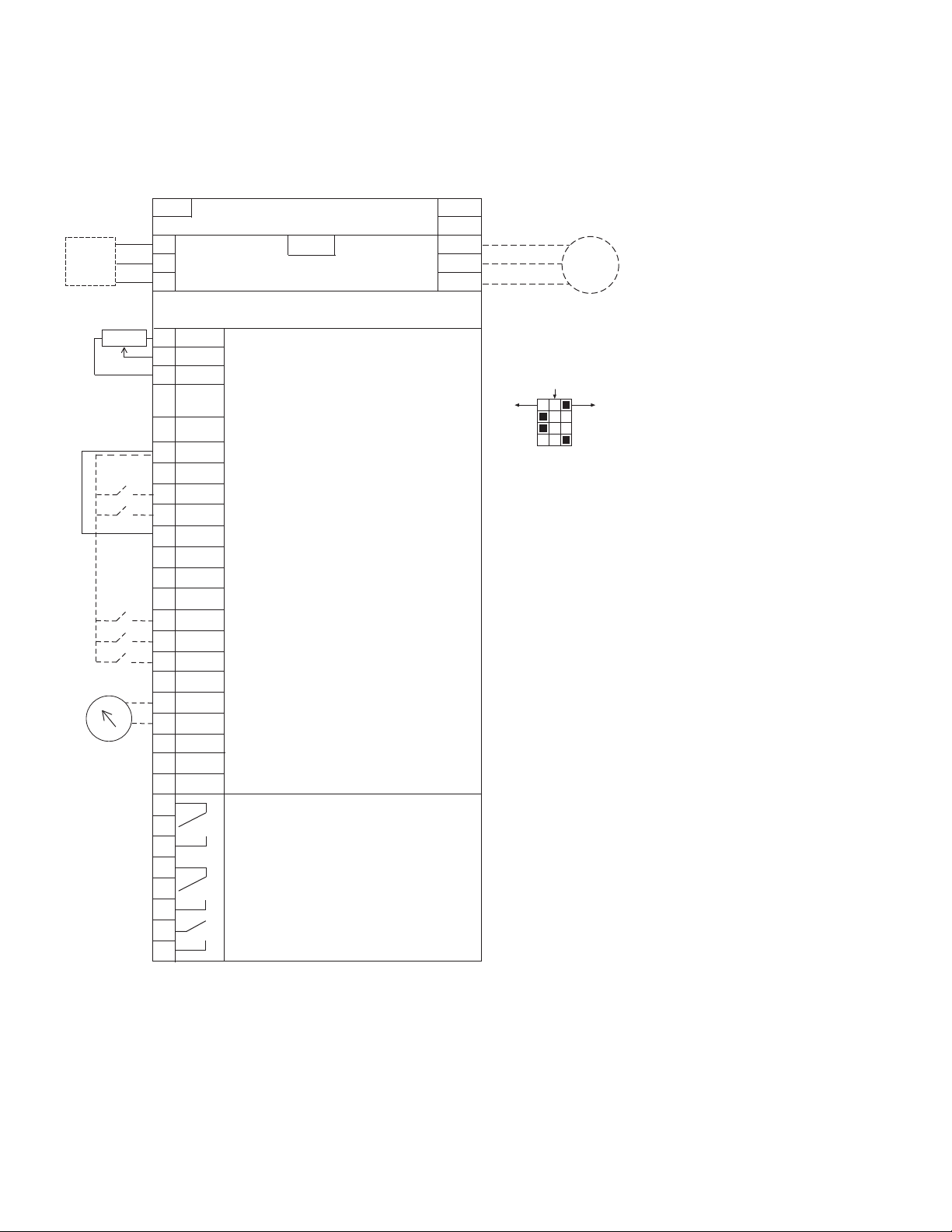

Example of Control Connections

Control Connections

BACnet/IP Ethernet Industrial Protocol

RJ-45

Modbus/TCP Transmission Control Protocol (Ethernet Based)

Optional

L1

Circuit

Breaker

Resistor

Factory

Jumper

Analog

Three-Phase Input

Input

L2

(Single-Phase not available)

L3

Slot A

Terminal

1

+10V

AI–1+

2

3

Vin

4

AI–2+

5

AI–2–

6

24V

GND

7

8

DIN1

9

DIN2

10

DIN3

COM

11

12

24Vout

GND

13

14

DIN4

DIN5

15

16

DIN6

CMB

17

18

AO–1+

19

AO–1–

30

24 VdcinAuxiliary Input Voltage

DATA –

A

B

DATA +

21

22

Factory Default Signal

Reference Output

Analog Input Voltage (Range 0–10 Vdc)

(can be programmed to current 4–20 mA)

Analog Output Common (Ground)

Analog Input Current (Range 4–20 mA)

(can be programmed to voltage 0–10 Vdc)

PI Setpoint or Feedback

Analog Input Common

PI Setpoint or Feedback

out

Control Voltage Output (0.1A max.)

I/O Ground

START/STOP (Contact closed = start)

External Fault (Closed = fault)

Run Interlock Permissive IP Interlock

(Closed = OK)

DIN1–DIN6 Common

Control Voltage Output (0.1A max.)

I/O Ground

Speed Select 0–100% (Preset speed)

Fire Mode (Contact closed = fire mode)

Force Bypass (Contact closed = bypass)

DIN1–DIN6 Common

Output Frequency (0–20 mA)

Analog Output Common (Ground)

RS-485 DATA–

RS-485 DATA+

Relay Board 1

Default Signal

RO1 Bypass Run

23

24

25

RO2 Drive Run

26

32

33

RO3 Fault

5% DC Link

Reactor

Three-Phase

Programmable BACnet,

Modbus, N2

Slot B

24 Vdc/8A

250 Vac/8A

125 Vdc/0.4A

DB

Chopper

Output

R+

R–

U (T1)

V (T2)

W (T3)

ON

CURRENT

CURRENT

CURRENT

Test

Motor

OFF

VOLTAGE

VOLTAGE

VOLTAGE

RS485

AO1

AI2

AI1

2 VSD Series II LIT-12011773—October 2012 www.johnsoncontrols.com

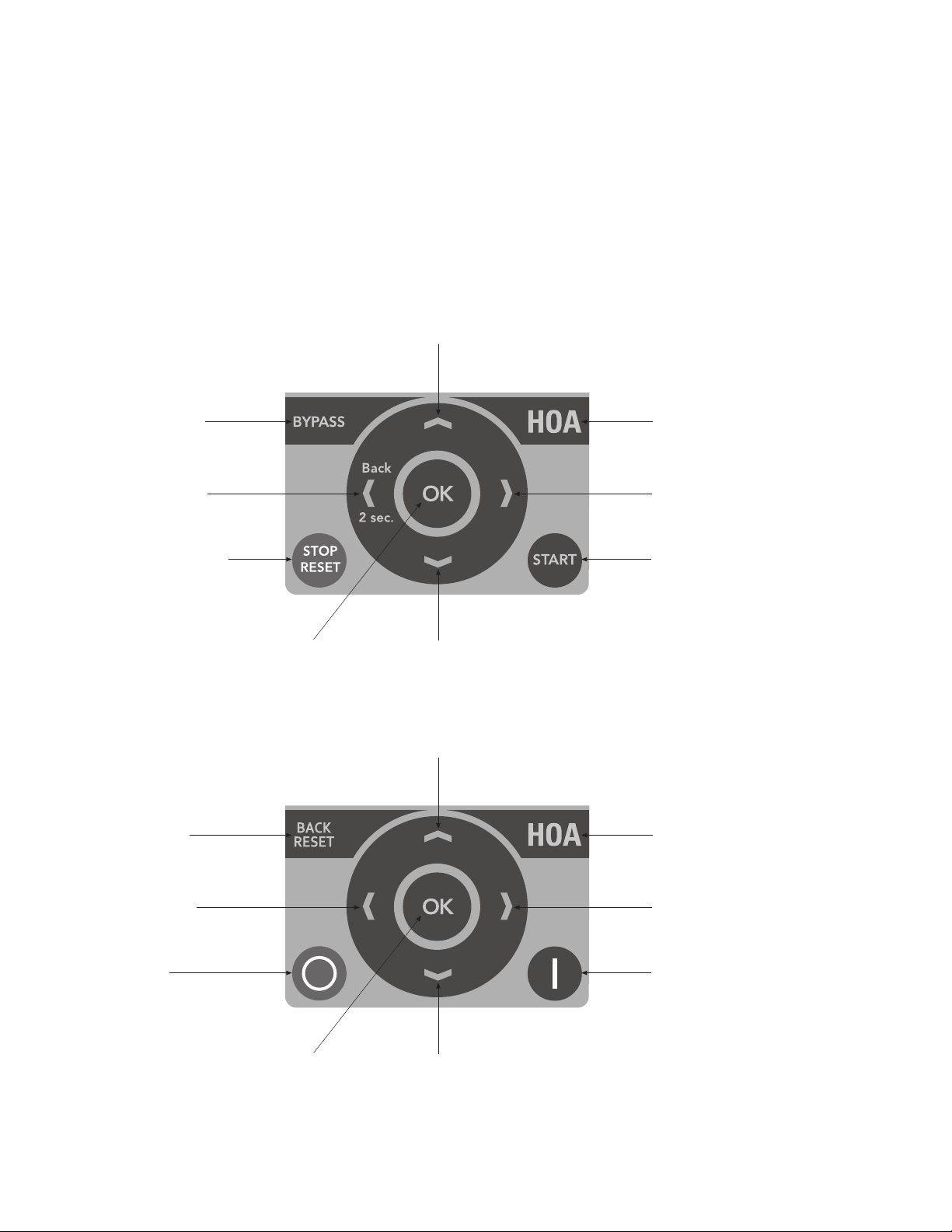

Keypad of the Drive

Keypad of the Drive

The control keypad is the interface between the Johnson

Controls VSD Series II frequency converter and the user.

With the control keypad it is possible to control the speed of

a motor, to supervise the state of the equipment and to set

the frequency converter’s parameters.

There are two different keypads used with the Series II drive.

The North American Keypad is slightly different than the

EMEA Keypad. Functionality is quite similar. The EMEA

keypad does not support the bypass functionality commonly

used in the United States.

US Keypad Buttons

Increase Value

Scroll Menu Up

Switching Between

Drive and Bypass

Move Cursor Left

Back when Pressed

for two Seconds

Stop Button/Fault Reset Start Button

Change Control Place

Between Hand-Off-Auto

Move Cursor Right

Enter Menu

Confirm Selection

Decrease Value

Scroll Menu Down

EMEA Keypad Buttons

Increase Value

Scroll Menu Up

Back Fault Reset

Move Cursor Left

Stop Button Start Button

Enter Menu

Confirm Selection

Decrease Value

Scroll Menu Down

Change Control Place

Between Hand-Off-Auto

Move Cursor Right

VSD Series II LIT-12011773—October 2012 www.johnsoncontrols.com 3

Keypad of the Drive

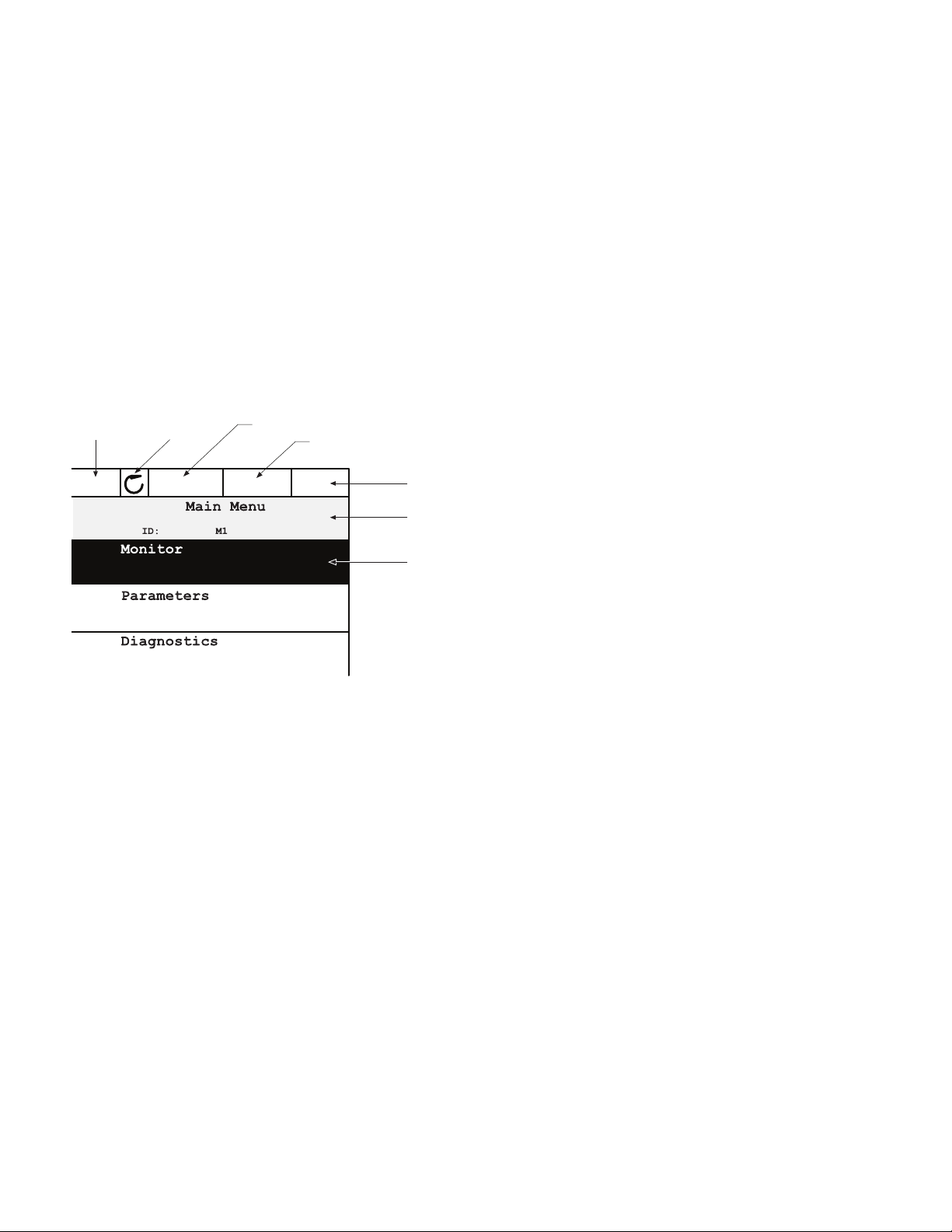

Keypad Display

The keypad display indicates the status of the motor and the drive and any irregularities in

motor or drive functions. On the display, the user sees information about his present location

in the menu structure and the item displayed.

Main Menu

The data on the control keypad are arranged in menus and submenus. Use the up and down

arrows to move between the menus. Enter the group/item by pressing the OK button and

return to the former level by pressing the Back/Reset button.

The Location field indicates your current location. The Status field gives information about the

present status of the drive. See “Control Connections” on Page 2.

Main Menu

Status Field

STOP/RUN

Direction

Run Mode

Hand/Off/Auto

STOP

E-Energy Hand I/O

Control Place

PC/IO/KEYPAD/FIELDBUS

Location Field

(Parameter ID number and

current menu location)

Activated Group/Item

Press OK to Enter

Using the Graphical Keypad

Editing Values

Change value of a parameter following the procedure below:

1. Locate the parameter.

2. Enter the Edit mode.

3. Set new value with the up/down arrow buttons. You can also move from digit to digit

with the arrow buttons left/right if the value is numerical and then change the value with

the up/down arrow buttons.

4. Confirm change with OK button or ignore change by returning to previous level with

Back/Reset button.

4 VSD Series II LIT-12011773—October 2012 www.johnsoncontrols.com

Editing Values on Graphical Keypad

Keypad of the Drive

STOP READY I/O

STOP READY I/O

OK OK

STOP READY I/O

OR:

HOA Control Button

The HOA (Hand-Off-Auto) button is used for two functions:

to quickly access the Control page and to easily change

between the Hand (Keypad), Off, and Auto (Remote) control

places.

Control Place

The control place is the source of control where the drive can

be started and stopped. Every control place has its own

parameter for selecting the frequency reference source. In

the HVAC drive, the Hand control place is always the keypad.

The Auto control place is determined by parameter P2.1.1

(Keypad, I/O Terminal, I/O three-wire, or Fieldbus CTRL). The

selected control place can be seen on the status bar of the

keypad.

STOP READY I/O

OK

BACK

RESET

STOP READY I/O

Changing Control Place

Change of control place from Hand to Auto (keypad).

1. Anywhere in the menu structure, push the HOA button.

2. Push the arrow up or the arrow down button to select

Hand/Off/Auto and confirm with the OK button.

3. On the next display, select Hand, Off, or Auto and again

confirm with the OK button.

4. The display will return to the same location as it was

when the HOA button was pushed. However, if the

Remote control place was changed to Hand (Keypad)

you will be prompted for keypad reference.

Local Control

The keypad is always used as control place while in hand

control. Hand control has higher priority than auto control.

Therefore, if, for example, bypassed by parameter P2.1.17

through digital input while in Remote, the control place will

still switch to Keypad if Hand is selected. Switching between

Hand, Off, and Auto Control can be done by pressing the

HOA button on the keypad.

VSD Series II LIT-12011773—October 2012 www.johnsoncontrols.com 5

Keypad of the Drive

Accessing the Control Page

The Control page is meant for easy operation and monitoring of the most essential values.

1. Anywhere in the menu structure, push the HOA button.

2. Push the arrow up or the arrow down button to select Control page and confirm with the

OK button.

3. The control page appears. If keypad control place and keypad reference are selected to

be used, you can set the Keypad reference after having pressed the OK button. If other

control places or reference values are used, the display will show Frequency reference

which is not editable. The other values on the page are Multimonitoring values. You can

choose which values appear here for monitoring (for this procedure, see Application

Manual).

Accessing Control Page

STOP READY I/O

HOA

STOP READY Keypad

Edit

STOP READY Keypad

OK

STOP READY Keypad

0.00 Hz

OK

Help Texts

The graphical keypad features instant help and information displays for various items.

All parameters offer an instant help display. Select Help and press the OK button.

Text information is also available for faults, alarms and the Startup Wizard.

Help Text Example

STOP READY I/O STOP READY I/O

STOP READY I/O

0.00 Hz

OK

OK OK

6 VSD Series II LIT-12011773—October 2012 www.johnsoncontrols.com

Johnson Controls Series II—Startup

Startup Wizard

In the Startup Wizard, you will be prompted for essential

information needed by the drive so that it can start

controlling your process. In the Wizard, you will need the

following keypad buttons:

Left/Right arrows. Use these to easily move

between digits and decimals.

Up/Down arrows. Use these to move between

options in menu and to change value.

OK

BACK

RESET

Once you have connected power to your Johnson Controls

Series II frequency converter, follow these instructions to

easily set up your drive.

1

2

3

4

5

6

Note

OK button. Confirm selection with this button.

Back/Reset button. Pressing this button, you can

return to the previous question in the Wizard. If

pressed at the first question, the Startup Wizard will

be cancelled.

Run Startup Wizard Yes

Language Select Depends on language package

Daylight Saving

Time

Day

Year

These questions appear if battery is installed.

No

Russia

US

EU

OFF

hh:mm:ss

dd.mm.

yyyy

Johnson Controls Series II—Startup

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Now the Startup Wizard is done.

The Startup Wizard can be re-initiated by pressing and

holding the back/reset button for two seconds. The Startup

Wizard will appear upon next power up.

Application Standard

PID

Multi-Pump

Bypass Enabled

Disabled

Motor Nominal Current Min: 0.26A

Max: Drive Dependent

Motor Nominal Voltage Min: 180.0V

Max: 690.0V

Motor Nominal Frequency Min: 8 Hz

Max: 320 Hz

Motor Nominal Speed Min: 24 RPM

Max: 19200 RPM

Min Frequency Min: 0 Hz

Max: 60 Hz

Max Frequency Min: 12 Hz

Max: 320 Hz

Accel Time 1 Min: 0.1s

Max: 3000s

Decel Time 1 Min: 0.1s

Max: 3000s

StartSourceHand Keypad

FieldbusCTRL

I/O Three-Wire

I/O Terminal

StartSourceAuto I/O Terminal

Keypad

FieldbusCTRL

I/O Three-Wire

SpeedSetptHand Keypad Ref

P1D1 Activated

AI1 + AI2

AI2

AI1

Fieldbus

SpeedSetptAuto PID1 Activated

AI1 + AI2

AI2

AI1

Fieldbus

Keypad Ref

VSD Series II LIT-12011773—October 2012 www.johnsoncontrols.com 7

Johnson Controls Series II—Startup

PID Mini-Wizard

The PID Mini-Wizard is activated in the Quick Setup menu.

This Wizard presupposes that you are going to use the PID

controller in the “one feedback/one setpoint” mode. The

control place will be I/O A and the default process unit “%”.

The PID Mini-Wizard asks for the following values to be set:

1

2

3

FeedBack1 Srce AI2

AI1

Not Used

ProceDataIn8

ProceDataIn7

ProceDataIn6

ProceDataIn5

ProceDataIn4

ProceDataIn3

ProceDataIn2

ProceDataIn1

AI6

AI5

AI4

AI3

Process Unit Selection (Several Selections)

Process Unit Min —

Multi-Pump

If Multi-Pump is the selected application, parameter group

2.16 will be visible in the menu structure. Default values may

need to be adjusted to meet your application needs.

Parameter

Group Name

Parameter Group 2.16:

Multi-Pump

Parameter

Number

P2.16.1 Number of motors

P2.16.2 Interlock function

P2.16.3 Include FC

P2.16.4 Autochange

P2.16.5 Autochange interval

P2.16.6 Autochange frequency limit

P2.16.7 Autochange motor limit

P2.16.8 Bandwidth

P2.16.9 Bandwidth delay

Parameter

Name

4

5

6

7

Process Unit Max —

P-Gain Min: 0%

Max: 200%

Integration Time Min: 0.00s

Max: 600.00s

SetPT1 Source Keypad SP1

Not Used

ProceDataIn8

ProceDataIn7

ProceDataIn6

ProceDataIn5

ProceDataIn4

ProceDataIn3

ProceDataIn2

ProceDataIn1

AI6

AI5

AI4

AI3

AI2

AI1

8 VSD Series II LIT-12011773—October 2012 www.johnsoncontrols.com

Menu Structure

For more information, the complete Application Manual can be referenced at:

http://www.johnsoncontrols.com —> HVAC Controls —> Variable Speed Drives.

Keypad Menus

Monitor Basic Diagnostics Active Faults

Timer Functions Reset Faults

Multimonitor Fault History

Parameters Basic Parameters Total Counters

Analog Inputs Trip Counters

Digital Inputs Software Info

Analog Outputs I/O & Hardware Basic I/O

Digital Outputs Slot D

Drive Control Slot E

Motor Control Real Time Clock

Protections Power Unit Settings

Fixed Frequencies Keypad

Fire Mode RS485

Multi-Pump —

Braking Ethernet

Fieldbus User Settings —

Second Parameter Set Favorites —

Timer Functions

Menu Structure

VSD Series II LIT-12011773—October 2012 www.johnsoncontrols.com 9

Parameter List

Parameter List

Parameter Group Name Parameter Number Parameter Name ID

Parameter Group 2.1—Basic Parameters

Basic P2.1.1 Application 213

P2.1.2 ByPass 214

P2.1.3 HOA Control Stc 1359

P2.1.4 Start Srce Hand 1300

P2.1.5 Speed Setpt Hand 1301

P2.1.6 Start Srce Auto 1302

P2.1.7 Speed Setpt Auto 1303

P2.1.8 Min Frequency 101

P2.1.9 Max Frequency 102

P2.1.10 Accel Time 1 103

P2.1.11 Decel Time 1 104

P2.1.12 Motor Nom Currnt 113

P2.1.13 Motor Nom Voltg 110

P2.1.14 Motor Nom Freq 111

P2.1.15 Motor Nom Speed 112

P2.1.16 MotorPowerFactor 120

P2.1.17 Current Limit 107

P2.1.18 Service Factor 1357

Parameter Group 2.2—Analog Inputs

Analog Input 1 P2.2.1.1 AI1 Signal selection 377

P2.2.1.2 AI1 Signal Inv 387

P2.2.1.3 AI1 Signal Range 379

P2.2.1.4 AI1 Custom Min 380

P2.2.1.5 AI1 Custom Max 381

P2.2.1.6 AI1 Filter Time 378

Analog Input 2 P2.2.2.1 AI2 Signal selection 388

P2.2.2.2 AI2 Signal Inv 398

P2.2.2.3 AI2 Signal Range 390

P2.2.2.4 AI2 Custom Min 391

P2.2.2.5 AI2 Custom Max 392

P2.2.2.6 AI2 Filter Time 389

Analog Input 3 P2.2.3.1 AI3 Signal selection 141

P2.2.3.2 AI3 Signal Inv 151

P2.2.3.3 AI3 Signal Range 143

P2.2.3.4 AI3 Custom Min 144

P2.2.3.5 AI3 Custom Max 145

P2.2.3.6 AI3 Filter Time 142

10 VSD Series II LIT-12011773—October 2012 www.johnsoncontrols.com

Parameter List

Parameter Group Name Parameter Number Parameter Name ID

Parameter Group 2.2—Analog Inputs, continued

Analog Input 4 P2.2.4.1 AI4 Signal selection 152

P2.2.4.2 AI4 Signal Inv 162

P2.2.4.3 AI4 Signal Range 154

P2.2.4.4 AI4 Custom Min 155

P2.2.4.5 AI4 Custom Max 156

P2.2.4.6 AI4 Filter Time 153

Analog Input 5 P2.2.5.1 AI5 Signal selection 188

P2.2.5.2 AI5 Signal Inv 198

P2.2.5.3 AI5 Signal Range 190

P2.2.5.4 AI5 Custom Min 191

P2.2.5.5 AI5 Custom Max 192

P2.2.5.6 AI5 Filter Time 189

Analog Input 6 P2.2.6.1 AI6 Signal selection 199

P2.2.6.2 AI6 Signal Inv 209

P2.2.6.3 AI6 Signal Range 201

P2.2.6.4 AI6 Custom Min 202

P2.2.6.5 AI6 Custom Max 203

P2.2.6.6 AI6 Filter Time 200

Parameter Group 2.2—Basic Parameters

Basic P2.2.7.1 Ref Scale Min. 1307

P2.2.7.2 Ref Scale Max. 1308

Parameter Group 2.3—Digital Inputs

Digital Input 1 P2.3.1.1 DI1 Open Invert Not accessible

P2.3.1.2 DI1 Function Not accessible

Digital Input 2 P2.3.2.1 DIN 2 Invert 1419

P2.3.2.2 DIN2 Function 1320

Digital Input 3 P2.3.3.1 DIN 3 Invert 1420

P2.3.3.2 DIN3 Function 1321

Digital Input 4 P2.3.4.1 DIN 4 Invert 1421

P2.3.4.2 DIN4 Function 1322

Digital Input 5 P2.3.5.1 DIN 5 Invert 1422

P2.3.5.2 DIN5 Function 1323

Digital Input 6 P2.3.6.1 DIN 6 Invert 1423

P2.3.6.2 DIN6 Function 1324

Digital Input Ext 1 P2.3.7.1 Ext-D1 Terminal 1325

P2.3.7.2 Ext-D1 Function 1326

Digital Input Ext 2 P2.3.8.1 Ext-D2 Terminal 1327

P2.3.8.2 Ext-D2 Function 1328

VSD Series II LIT-12011773—October 2012 www.johnsoncontrols.com 11

Parameter List

Parameter Group Name Parameter Number Parameter Name ID

Parameter Group 2.3—Basic Parameters

Basic P2.3.9.1 Start logic 1304

P2.3.9.2 INTLK Timeout 1305

P2.3.9.3 Delay Time 1306

P2.3.9.4 Intrlk Stop Mode 1356

P2.3.9.5 Interlock 1 Text 1315

P2.3.9.6 Interlock 2 Text 1316

P2.3.9.7 Interlock 3 Text 1317

Parameter Group 2.4—Analog Outputs

Analog Output 1 P2.4.1.1 AO1 Function 10050

P2.4.1.2 AO1 Filter Time 10051

P2.4.1.3 AO1 Min Signal 10052

P2.4.1.4 AO1 MinScale 10053

P2.4.1.5 AO1 MaxScale 10054

P2.4.1.6 AO1 Invert 10060

Parameter Group 2.5—Digital Outputs

Digital Output 1 P2.5.1.1 RO1 function 11001

P2.5.1.2 RO1 Invert 11020

P2.5.1.3 RO1 ON delay 11002

P2.5.1.4 RO1 OFF delay 11003

Digital Output 2 P2.5.2.1 RO2 function 11004

P2.5.2.2 RO2 Invert 11021

P2.5.2.3 RO2 ON delay 11005

P2.5.2.4 RO2 OFF delay 11006

Digital Output 3 P2.5.3.1 RO3 function 11007

Supervision P2.5.9.1 Superv1 Item 1622

P2.5.9.2 Supervision #1 mode 1623

P2.5.9.3 Supervision #1 limit 1624

P2.5.9.4 Supervision #1 limit hysteresis 1625

P2.5.9.5 Superv2 Item 1626

P2.5.9.6 Supervision #2 mode 1627

P2.5.9.7 Supervision #2 limit 1628

P2.5.9.8 Supervision #2 limit hysteresis 1629

12 VSD Series II LIT-12011773—October 2012 www.johnsoncontrols.com

Parameter List

Parameter Group Name Parameter Number Parameter Name ID

Parameter Group 2.6—Drive Control

Basic P2.6.1.1 Start Function 505

P2.6.1.2 Stop Function 506

P2.6.1.3 InhibitDirection 1336

P2.6.1.4 Reference Unit 1362

P2.6.1.5 Keypad Reference 184

P2.6.1.6 Keypad Direction 123

P2.6.1.7 Keypad Reference copy 181

P2.6.1.8 Keypad Stop Button 114

P2.6.1.9 Accel Time 2 502

P2.6.1.10 Decel Time 2 503

P2.6.1.11 RampselectMode 1333

P2.6.1.12 Accel2Threshold 526

P2.6.1.13 Decel2Threshold 1334

P2.6.1.14 S-Ramp 1 Shape 500

P2.6.1.15 S-Ramp 2 Shape 501

Skip Frequencies P2.6.2.1 Range 1 Low Lim 509

P2.6.2.2 Range 1 High Lim 510

P2.6.2.3 Range 2 Low Lim 511

P2.6.2.4 Range 2 High Lim 512

P2.6.2.5 Range 3 Low Lim 513

P2.6.2.6 Range 3 High Lim 514

P2.6.2.7 Range 4 Low Lim 1337

P2.6.2.8 Range 4 High Lim 1338

P2.6.2.9 Range 5 Low Lim 1339

P2.6.2.10 Range 5 High Lim 1340

P2.6.2.11 Range 6 Low Lim 1341

P2.6.2.12 Range 6 High Lim 1342

P2.6.2.13 RampTimeFactor 518

Parameter Group 2.7—Motor Control

Motor Control P2.7.1 V/Hz RatioSelect 108

P2.7.2 Field WeakngPnt 602

P2.7.3 Voltage at FWP 603

P2.7.4 V/Hz Mid Freq 604

P2.7.5 V/Hz Mid Voltage 605

P2.7.6 Zero Freq Voltg 606

P2.7.7 Switching Freq 601

VSD Series II LIT-12011773—October 2012 www.johnsoncontrols.com 13

Parameter List

Parameter Group Name Parameter Number Parameter Name ID

Parameter Group 2.8—Faults

Faults P2.8.1.1 AI Low Fault 700

P2.8.1.2 Undervoltage Flt 727

P2.8.1.3 OutputPhase Flt 702

P2.8.1.4 Motor Duty Cycle 708

P2.8.1.5 Underload Flt 713

P2.8.1.6 Motor Therm Prot 704

P2.8.1.7 MotAmbient Temp 705

P2.8.1.8 ZeroSpeedCooling 706

P2.8.1.9 ThermTimeConst 707

P2.8.1.10 Thermistor Fault 732

P2.8.1.11 External Fault 701

P2.8.1.12 FieldbusComm Flt 733

P2.8.1.13 InputPhaseFault 730

P2.8.1.14 MotorStall Flt 709

P2.8.1.15 PID1 Supervision 749

P2.8.1.16 PID2 Supervision 757

P2.8.1.17 SlotCommFlt 734

P2.8.1.18 Preset Alarm Freq 183

Automatic Reset P2.8.2.1 Automatic Reset 731

P2.8.2.2 Restart function 719

P2.8.2.3 Wait Time 717

P2.8.2.4 Trial Time 718

P2.8.2.5 Number of trials 759

P2.8.2.6 Undervoltage Flt 720

P2.8.2.7 Overvoltage Flt 721

P2.8.2.8 Overcurrent Flt 722

P2.8.2.9 AI Low Fault 723

P2.8.2.10 UnitOverTemp Flt 724

P2.8.2.11 MotorOverTempFlt 725

P2.8.2.12 External Fault 726

P2.8.2.13 IGBT temp 1358

14 VSD Series II LIT-12011773—October 2012 www.johnsoncontrols.com

Parameter List

Parameter Group Name Parameter Number Parameter Name ID

Parameter Group 2.9—PID Controller

PID Controller 1, Basic Settings P2.9.1.1.1 Gain, PID Controller 1 118

P2.9.1.1.2 Integration Time, PID Controller 1 119

P2.9.1.1.3 Derivation Time, PID Controller 1 132

P2.9.1.1.4 ProcessUnitSel, PID Controller 1 1036

P2.9.1.1.5 ProcessUnitMin, PID Controller 1 1033

P2.9.1.1.6 ProcessUnitMax, PID Controller 1 1034

P2.9.1.1.7 ProcessUnitDecimals, PID Controller 1 1035

P2.9.1.1.8 Error Inversion, PID Controller 1 340

P2.9.1.1.9 Dead Band, PID Controller 1 1056

P2.9.1.1.10 Dead band delay, PID Controller 1 1057

PID Controller 1, Setpoints P2.9.1.2.1 Keypad SP 1, PID Controller 1 167

P2.9.1.2.2 Keypad SP 2, PID Controller 1 168

P2.9.1.2.3 Ramp Time, PID Controller 1 1068

P2.9.1.2.4 SetPt 1 Source, PID Controller 1 332

P2.9.1.2.5 SetPt 1 min, PID Controller 1 1069

P2.9.1.2.6 SP 1 maximum, PID Controller 1 1070

P2.9.1.2.7 SP 1 Sleep Freq, PID Controller 1 1016

P2.9.1.2.8 SP 1 Sleep delay, PID Controller 1 1017

P2.9.1.2.9 SP 1 WakeUpLevel, PID Controller 1 1018

P2.9.1.2.10 SP 1 boost, PID Controller 1 1071

P2.9.1.2.11 SP 2 Source, PID Controller 1 431

P2.9.1.2.12 SP 2 minimum, PID Controller 1 1073

P2.9.1.2.13 SP 2 maximum, PID Controller 1 1074

P2.9.1.2.14 SP 2 Sleep Freq, PID Controller 1 1075

P2.9.1.2.15 SP 2 Sleep delay, PID Controller 1 1076

P2.9.1.2.16 SP 2 WakeUpLevel, PID Controller 1 1077

P2.9.1.2.17 SP 2 boost, PID Controller 1 1078

PID Controller 1, Feedbacks P2.9.1.3.1 Function, PID Controller 1 333

P2.9.1.3.2 Gain, PID Controller 1 1058

P2.9.1.3.3 FeedBack 1 Srce, PID Controller 1 334

P2.9.1.3.4 FB 1 Minimum, PID Controller 1 336

P2.9.1.3.5 FB 1 Maximum, PID Controller 1 337

P2.9.1.3.6 FB 2 Source, PID Controller 1 335

P2.9.1.3.7 FB 2 Minimum, PID Controller 1 338

P2.9.1.3.8 FB 2 Maximum, PID Controller 1 339

PID Controller 1, Feedforward P2.9.1.4.1 Function, PID Controller 1 1059

P2.9.1.4.2 Gain, PID Controller 1 1060

P2.9.1.4.3 FF 1 Source, PID Controller 1 1061

P2.9.1.4.4 FF1 Minimum, PID Controller 1 1062

P2.9.1.4.5 FF1 Maximum, PID Controller 1 1063

P2.9.1.4.6 FF 2 Source, PID Controller 1 1064

P2.9.1.4.7 FF2 Minimum, PID Controller 1 1065

P2.9.1.4.8 FF2 Maximum, PID Controller 1 1066

VSD Series II LIT-12011773—October 2012 www.johnsoncontrols.com 15

Parameter List

Parameter Group Name Parameter Number Parameter Name ID

Parameter Group 2.9—PID Controller, continued

PID Controller 1, Process Supervision P2.9.1.5.1 Enable Superv, PID Controller 1 735

P2.9.1.5.2 Upper limit, PID Controller 1 736

P2.9.1.5.3 Lower limit, PID Controller 1 758

P2.9.1.5.4 Delay, PID Controller 1 737

PID Controller 1, Pressure Loss Compensation P2.9.1.6.1 Enable SP 1, PID Controller 1 1529

P2.9.1.6.2 SP 1 Max Comp., PID Controller 1 1530

P2.9.1.6.3 Enable SP 2, PID Controller 1 1531

P2.9.1.6.4 SP 2 Max Comp., PID Controller 1 1532

PID Controller 2, Basic Settings P2.9.2.1.1 Gain, PID Controller 2 1631

P2.9.2.1.2 Integration Time, PID Controller 2 1632

P2.9.2.1.3 Derivation Time, PID Controller 2 1633

P2.9.2.1.4 ProcessUnitSel, PID Controller 2 1635

P2.9.2.1.5 ProcessUnitMin, PID Controller 2 1664

P2.9.2.1.6 ProcessUnitMax, PID Controller 2 1665

P2.9.2.1.7 ProcessUnitDecimals, PID Controller 2 1666

P2.9.2.1.8 Error Inversion, PID Controller 2 1636

P2.9.2.1.9 Dead Band, PID Controller 2 1637

P2.9.2.1.10 Dead band delay, PID Controller 2 1638

PID Controller 2, Setpoints P2.9.2.2.1 Keypad SP 1, PID Controller 2 1640

P2.9.2.2.2 Keypad SP 2, PID Controller 2 1641

P2.9.2.2.3 Ramp Time, PID Controller 2 1642

P2.9.2.2.4 SetPt 1 Source, PID Controller 2 1643

P2.9.2.2.5 SetPt 1 min, PID Controller 2 1644

P2.9.2.2.6 SP 1 maximum, PID Controller 2 1645

P2.9.2.2.7 SP 2 Source, PID Controller 2 1646

P2.9.2.2.8 SP 2 minimum, PID Controller 2 1647

P2.9.2.2.9 SP 2 maximum, PID Controller 2 1648

PID Controller 2, Feedbacks P2.9.2.3.1 Function, PID Controller 2 1650

P2.9.2.3.2 Gain, PID Controller 2 1651

P2.9.2.3.3 FeedBack 1 Srce, PID Controller 2 1652

P2.9.2.3.4 FB 1 Minimum, PID Controller 2 1653

P2.9.2.3.5 FB 1 Maximum, PID Controller 2 1654

P2.9.2.3.6 FB 2 Source, PID Controller 2 1655

P2.9.2.3.7 FB 2 Minimum, PID Controller 2 1656

P2.9.2.3.8 FB 2 Maximum, PID Controller 2 1657

PID Controller 2, Process Supervision P2.9.2.4.1 Enable Superv, PID Controller 2 1659

P2.9.2.4.2 Upper limit, PID Controller 2 1660

P2.9.2.4.3 Lower limit, PID Controller 2 1661

P2.9.2.4.4 Delay, PID Controller 2 1662

16 VSD Series II LIT-12011773—October 2012 www.johnsoncontrols.com

Parameter List

Parameter Group Name Parameter Number Parameter Name ID

Parameter Group 2.10—Fixed Frequencies

Fixed Frequencies P2.10.1 Preset Freq 1 105

P2.10.2 Preset Freq 2 106

P2.10.3 Preset Freq 3 126

P2.10.4 Preset Freq 4 127

P2.10.5 Preset Freq 5 128

P2.10.6 Preset Freq 6 129

P2.10.7 Preset Freq 7 130

Parameter Group 2.11—Fire Mode

Fire Mode P2.11.1 Firemode Freq 1598

Parameter Group 2.12—Multi-Pump

Multi-Pump P2.12.1 Number of motors 1001

P2.12.2 Interlock function 1032

P2.12.3 Include FC 1028

P2.12.4 Autochange 1027

P2.12.5 Autochange interval 1029

P2.12.6 Autochange: frequency limit 1031

P2.12.7 Autochange: motor limit 1030

P2.12.8 Bandwidth 1097

P2.12.9 Bandwidth delay 1098

Parameter Group 2.13—Braking

Braking P2.13.1 DC Brake Current 507

P2.13.2 DC Time Stop 508

P2.13.3 DC BrakeFreqStop 515

P2.13.4 StartMagnTime 516

P2.13.5 StartMagnCurrent 517

P2.13.6 Preheat Current 1335

Parameter Group 2.14—Fieldbus

Fieldbus P2.14.1 FB Data Out1 Sel 852

P2.14.2 FB Data Out2 Sel 853

P2.14.3 FB Data Out3 Sel 854

P2.14.4 FB Data Out4 Sel 855

P2.14.5 FB Data Out5 Sel 856

P2.14.6 FB Data Out6 Sel 857

P2.14.7 FB Data Out7 Sel 858

P2.14.8 FB Data Out8 Sel 859

Parameter Group 2.15—Second Param Set

Motor 2 P2.15.1.1 Motor Nom Currnt, Set2 1347

P2.15.1.2 Motor Nom Voltg, Set2 1348

P2.15.1.3 Motor Nom Freq, Set2 1349

P2.15.1.4 Motor Nom Speed, Set2 1350

P2.15.1.5 MotorPowerFactor, Set2 1351

P2.15.1.6 Current Limit, Set2 1352

P2.15.1.7 Motor Therm Prot, Set2 1353

VSD Series II LIT-12011773—October 2012 www.johnsoncontrols.com 17

Parameter List

Parameter Group Name Parameter Number Parameter Name ID

Parameter Group 2.15—Second Param Set, continued

Drive Control 2 P2.15.2.1 Min Frequency, Set2 1343

P2.15.2.2 Max Frequency, Set2 1344

P2.15.2.3 Accel Time 1, Set2 1345

P2.15.2.4 Decel Time 1, Set2 1346

P2.15.2.5 V/Hz RatioSelect, Set2 1355

Parameter Group 2.16—Timer Functions

Interval 1 P2.16.1.1 ON Time, Interval 1 1670

P2.16.1.2 Off Time, Interval 1 1671

P2.16.1.3 From Day, Interval 1 1672

P2.16.1.4 To Day, Interval 1 1673

P2.16.1.5 Assign to channel, Interval 1 1674

Interval 2 P2.16.2.1 ON Time, Interval 2 1675

P2.16.2.2 Off Time, Interval 2 1676

P2.16.2.3 From Day, Interval 2 1677

P2.16.2.4 To Day, Interval 2 1678

P2.16.2.5 Assign to channel, Interval 2 1679

Interval 3 P2.16.3.1 ON Time, Interval 3 1680

P2.16.3.2 Off Time, Interval 3 1681

P2.16.3.3 From Day, Interval 3 1682

P2.16.3.4 To Day, Interval 3 1683

P2.16.3.5 Assign to channel, Interval 3 1684

Interval 4 P2.16.4.1 ON Time, Interval 4 1685

P2.16.4.2 Off Time, Interval 4 1686

P2.16.4.3 From Day, Interval 4 1687

P2.16.4.4 To Day, Interval 4 1688

P2.16.4.5 Assign to channel, Interval 4 1689

Interval 5 P2.16.5.1 ON Time, Interval 5 1690

P2.16.5.2 Off Time, Interval 5 1691

P2.16.5.3 From Day, Interval 5 1692

P2.16.5.4 To Day, Interval 5 1693

P2.16.5.5 Assign to channel, Interval 5 1694

Timer 1 P2.16.6.1 Duration 1695

P2.16.6.2 Assign to channel 1696

Timer 2 P2.16.7.1 Duration 1697

P2.16.7.2 Assign to channel 1698

Timer 3 P2.16.8.1 Duration 1699

P2.16.8.2 Assign to channel 1700

18 VSD Series II LIT-12011773—October 2012 www.johnsoncontrols.com

Diagnostics

Diagnostics

Under this menu, you can find Active faults, Reset faults, Fault history, Counters and Software info.

Active Faults

Menu Function Note

Active faults When a fault/faults appear(s), the display with the name of

the fault starts to blink. Press OK to return to the

Diagnostics menu. The Active faults submenu shows the

number of faults. Select the fault and push OK to see the

fault-time data.

Reset Faults

Menu Function Note

Reset faults In this menu you can reset faults. For closer instructions. CAUTION! Remove external Control signal before

The fault remains active until it is cleared with the Reset

button (push for 2s) or with a reset signal from the I/O

terminal or Fieldbus or by choosing Reset faults (see

below). The memory of active faults can store the

maximum of 10 faults in the order of appearance.

resetting the fault to prevent unintentional restart

of the drive.

Fault History

Menu Function Note

Fault history 40 latest faults are stored in the Fault history. Entering the Fault history and clicking OK on the selected

fault shows the fault time data (details).

Fault Codes

Fault Codes and Descriptions

Fault

Code

1 1 Overcurrent

2 10 Overvoltage

3 20 Earth fault

5 40 Charging switch The charging switch is open, when the

Fault

ID Fault Name Possible Cause Remedy

(hardware fault)

2 Overcurrent

(software fault)

(hardware fault)

11 Overvoltage

(software fault)

(hardware fault)

21 Earth fault

(software fault)

AC drive has detected too high a current

) in the motor cable:

(>4*I

H

• Sudden heavy load increase

• Short circuit in motor cables

• Unsuitable motor

The DC-link voltage has exceeded the

limits defined:

• Too short a deceleration time

• Brake chopper is disabled

• High overvoltage spikes in supply

• Start/Stop sequence too fast

Current measurement has detected that

the sum of motor phase current is not zero:

• Insulation failure in cables or motor

START command has been given:

• Faulty operation

• Component failure

• Check loading

• Check motor

• Check cables and connections

• Make identification run

• Check ramp times

• Make deceleration time longer

• Use brake chopper or brake resistor

(available as options)

• Activate overvoltage controller

• Check input voltage

Check motor cables and motor

• Reset the fault and restart

• Should the fault re-occur, contact the

distributor near to you

VSD Series II LIT-12011773—October 2012 www.johnsoncontrols.com 19

Diagnostics

Fault Codes and Descriptions, continued

Fault

Code

7 60 Saturation Various causes:

8 600 System fault Communication between control board

9 80 Undervoltage

10 91 Input phase Input line phase is missing Check supply voltage, fuses and cable

11 100 Output phase

Fault

ID Fault Name Possible Cause Remedy

• Cannot be reset from keypad

• Defective component

• Brake resistor short-circuit or overload

and power unit has failed

602 Watchdog has reset the CPU

603 Voltage of auxiliary power in power unit

604 Phase fault: Voltage of an output phase

605 CPLD has faulted but there is no detailed

606 Control and power unit software are

607 Software version cannot be read. There is

608 CPU overload. Some part of the software

609 Memory access has failed. For example,

610 Necessary device properties cannot be read

647 Software error Update software. Should the fault re-occur,

648 Invalid function block used in application.

649 Resource overload:

(fault)

81 Undervoltage

(alarm)

supervision

is too low

does not follow the reference

information about the fault

incompatible

no software in power unit

(for example application) has caused an

overload situation. The source of fault

has been suspended

retain variables could not be restored

System software and application are not

compatible

• Error when loading parameter initial

values

• Error when restoring parameters

• Error when saving parameters

DC link voltage is under the voltage limits

defined:

• Most probable cause: Too low a supply

voltage

• AC drive internal fault

• Defect input fuse

• External charge switch not closed

Note: This fault is activated only if the drive

is in Run state.

Current measurement has detected that there

is no current in one motor phase

• Switch off power

• DO NOT RECONNECT POWER! Contact

factory

• If this fault appears simultaneously with

F1, check motor cables and motor

Reset the fault and restart. Should the fault

re-occur, contact the distributor near you

Update software. Should the fault re-occur,

contact the distributor near you

Update power unit software. Should the fault

re-occur, contact the distributor near you

Reset the fault and restart. Should the fault

re-occur, contact the distributor near you

contact the distributor near you

In case of temporary supply voltage break reset

the fault and restart the AC drive. Check the

supply voltage. If it is adequate, an internal

failure has occurred. Contact the distributor

near you

Check motor cable and motor

20 VSD Series II LIT-12011773—October 2012 www.johnsoncontrols.com

Diagnostics

Fault Codes and Descriptions, continued

Fault

Code

12 110 Brake chopper supervision

13 120 AC drive undertemperature

14 130 AC drive overtemperature

15 140 Motor stalled Motor is stalled Check motor and load

16 150 Motor overtemperature Motor is overloaded Decrease motor load. If no motor overload

17 160 Motor underload Motor is underloaded Check load

19 180 Power overload

25 — Motor control fault Start angle identification has failed.

32 312 Fan cooling Fan lifetime is up Change fan and reset fan lifetime counter

33 — Fire mode enabled Fire mode of the drive is enabled. The

37 360 Device changed

38 370 Device changed

39 380 Device removed Optional board removed from slot Device no longer available

40 390 Device unknown Unknown device connected (power

41 400 IGBT temperature IGBT temperature (unit temperature + I

43 420 Encoder fault Encoder 1 channel A is missing • Check encoder connections

Fault

ID Fault Name Possible Cause Remedy

(hardware fault)

111 Brake chopper

saturation alarm

(fault)

121 AC drive overtemperature

(alarm)

(fault, heatsink)

131 AC drive overtemperature

(alarm, heatsink)

132 AC drive overtemperature

(fault, board)

133 AC drive overtemperature

(alarm, board)

(short-time supervision)

181 Power overload

(long-time supervision)

(same type)

(same type)

421 Encoder 1 channel B is missing

422 Both encoder 1 channels are missing

423 Encoder reversed

424 Encoder board missing

• No brake resistor installed

• Brake resistor is broken

• Brake chopper failure

Too low temperature measured in power

unit’s heatsink or board. Heat- sink

temperature is under –10°C

Too high temperature measured in power

unit’s heatsink or board. Heat- sink

temperature is over 100°C

Drive power is too high Decrease load

Generic motor control fault

drive’s protections are not in use

Option board changed for one previously

inserted in the same slot. The board’s

parameter settings are saved

Option board added. The option board was

previously inserted in the same slot. The

board’s parameter settings are saved

unit/option board)

is too high

2

Check brake resistor and cabling. If these are

OK, the chopper is faulty. Contact the

distributor near you

—

• Check the correct amount and flow of

cooling air

• Check the heatsink for dust

• Check the ambient temperature

• Make sure that the switching

frequency is not too high in relation to

ambient temperature and motor load

exists, check the temperature model

parameters

—

—

Device is ready for use. Old parameter settings

will be used

Device is ready for use. Old parameter settings

will be used

Device no longer available

T)

• Check loading

• Check motor size

• Make identification run

• Check encoder and encoder cable

• Check encoder board

• Check encoder frequency in open loop

VSD Series II LIT-12011773—October 2012 www.johnsoncontrols.com 21

Diagnostics

Fault Codes and Descriptions, continued

Fault

Code

44 430 Device changed

45 440 Device changed

51 1051 External fault Digital input —

52 1052 Keypad communication

53 1053 Fieldbus communication

54 1354 Slot A fault Defective option board or slot Check board and slot

65 1065 PC communication fault The data connection between the PC and

66 1066 Thermistor fault The thermistor input has detected an

69 1310 Fieldbus mapping error Non-existing ID number is used for

101 1101 Process supervision fault

105 1105 Process supervision fault

Fault

ID Fault Name Possible Cause Remedy

(different type)

(different type)

1352

1454 Slot B fault

1654 Slot D fault

1754 Slot E fault

1311 Not possible to convert one or more

1312 Overflow when mapping and converting

fault

fault

(PID1)

(PID2)

Option board changed for one not present

in the same slot before. No parameter

settings are saved

Option board added. The option board was

not previously present in the same slot. No

parameter settings are saved

The connection between the control

keypad and frequency converter is broken

The data connection between the Fieldbus

master and Fieldbus board is broken

frequency converter is broken

increase of motor temperature

mapping values to Fieldbus Process

Data Out

values for Fieldbus Process Data Out

values for Fieldbus Process Data Out

(16-bit)

PID controller: Feedback value outside

of supervision limits (and the delay if set)

PID controller: Feedback value outside

of supervision limits (and the delay if set)

Set the option board parameters again

Set the option board parameters again

Check keypad connection and possible keypad

cable

Check installation and Fieldbus master

—

• Check motor cooling and load

• Check thermistor connection (if

thermistor input is not in use it has to

be short circuited)

Check parameters in Fieldbus Data Mapping

menu

The value being mapped may be of undefined

type. Check parameters in Fieldbus Data

Mapping menu

—

—

—

22 VSD Series II LIT-12011773—October 2012 www.johnsoncontrols.com

Diagnostics

VSD Series II LIT-12011773—October 2012 www.johnsoncontrols.com 23

Diagnostics

24 VSD Series II LIT-12011773—October 2012 www.johnsoncontrols.com

Controls Group

507 E. Michigan Street

P.O. Box 423

Milwaukee, WI 53201

Powered by

Eaton Technology

© 2012 Johnson Controls

All Rights Reserved

Printed in USA

Publication No. LIT-12011773 / Z12052

October 2012

Loading...

Loading...