VSD Series II Variable Speed Micro Drives

VSD Series II Variable Speed Micro

Drive

Code No. LIT-1900795

Issued March 26, 2013

Description

Johnson Controls® VSD Series II Variable

Speed Micro Drives (JC-VSM II) are the next

generation of drives specifically engineered

for today’s HVAC mid-market applications.

These micro-processor-based drives have

standard features that can be programmed to

tailor the drive’s performance to suit a wide

variety of application requirements. The

JC-VSM II product line uses a 32-bit

microprocessor and insulated gate bipolar

transistors (IGBTs) that provide quiet

operation, high efficiency, and smooth

low-speed performance for three-phase

induction motors. The size and simplicity of

the JC-VSM II makes it ideal for hassle-free

installation. Models rated at 575 volts,

three-phase, 50/60 Hz are available in sizes

ranging from 1 to 7-1/2 hp. Models rated at

480 volts, three-phase, 50/60 Hz are available

in sizes ranging from 1/2 to 10 hp. Models

rated at 230 volts, single or three-phase,

50/60 Hz are available in sizes ranging from

1/4 to 3 hp, 230 V three-phase output. Models

rated at 115 volts, single-phase, 50/60 Hz are

available in 1/4 to 1-1/2 hp, 230 V

three-phase output.

The standard drive includes a digital display,

and operating and programming keys on a

visually appealing, efficient application

programming interface. The display provides

drive monitoring, as well as adjustment and

diagnostic information. The keys are used for

digital adjustment and programming of the

drive, as well as for operator control. Separate

terminal blocks for control and power wiring

are provided for customer connections.

Refer to the VSD Series II Variable Speed

Micro Drives Product Bulletin (LIT-12011813)

for important product information.

Features

• Preset Application Macros, Startup Wizard,

and Diagnostic Capabilities — allows for

quick and easy startup

• Rugged Construction — offers 122°F

(50°C) rated, conformal coated boards

• DIN Rail and Screw Mountable Chassis —

reduces installation time

• Compact, Space Saving Design — allows

for side-by-side installation resulting in less

mounting space

• Industry-Leading Efficiency — delivers

energy savings to the customer. Provides

integrated EMC filters and brake choppers

as standard features in three-phase

applications, which make the unit suitable

for commercial and industrial applications.

• IP 20 Enclosure Class Available as

Standard — offers IP21/NEMA Type 1 kits

• Temperature-Controlled Fan — ensures

extended product reliability

• RS-485/Modbus® — includes a standard

communication protocol

• PID Controller — provides stand-alone,

closed-loop control

Programmable Parameters

• Application macros: basic, pump, fan, and

high-load

• Programmable start and stop and reverse

signal logic (sinking or sourcing)

• Reference scaling

• Programmable start and stop functions

• DC brake at start and stop

• Programmable V/Hz curve

• Adjustable switching frequency

• Auto restart function after fault

• Protections and supervisions (all fully

programmable; off, warning, and fault)

• Current signal input fault

• External fault

• Fieldbus communication

• Eight preset speeds

• Analog input range selection, signal

scaling, and filtering

• PID controller

Repair Information

If a VSD Series II Variable Speed Micro Drive

fails to operate within its specifications,

contact the nearest Johnson Controls

representative.

Selection Chart (Single-phase Input, 3-Phase Output)

Code Number

Base Product VS = Variable Speed

Full Load Amperes

(VT/CT)

Voltage 0 = 120 V

Enclosure Rating 0 = IP20

Enclosure Style 4 = Single-phase (Micro Drive)

Revision # B = Rev. 2 (Americas)

Separator (—)

Communications M = Modbus

Options 00 = None

1. 120 Volts

2. 230 Volts

Series II Micro Drive prefix

1D7 = 1.7 A (1/4 hp, 0.25 kW)

2D4 = 2.4 A (1/2 hp, 0.37 kW)

2D8 = 2.8 A (3/4 hp, 0.55 kW)

3D7 = 3.7 A (1 hp, 0.75 kW)

4D8 = 4.8 A (1.5 hp, 1.1 kW)

7D0 = 7.0 A (2 hp, 1.5 kW)

9D6 = 9.6 A (3 hp, 2.2 kW)

2 = 230 V

D = Rev. 2 (Canada)

EM = EMC Filter

2

2

1,2

1,2

1,2

1,2

Note: Horsepower ratings are based on the use of a 240 V four- or six-pole squirrel-cage induction

motor and are for reference only. Select a drive where the motor current is less than or equal to the rated

continuous output current.

V S 0 4B—M0 0 0 0

1,2

The performance specifications are nomina l and conf orm to accep table industr y standar ds. For ap plications a t condition s beyond th ese specification s, consult the local Johnson Controls o ffice.

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2013 Johnson Controls, Inc.

www.johnsoncontrols.com

1

VSD Series II Variable Speed Micro Drives (Continued)

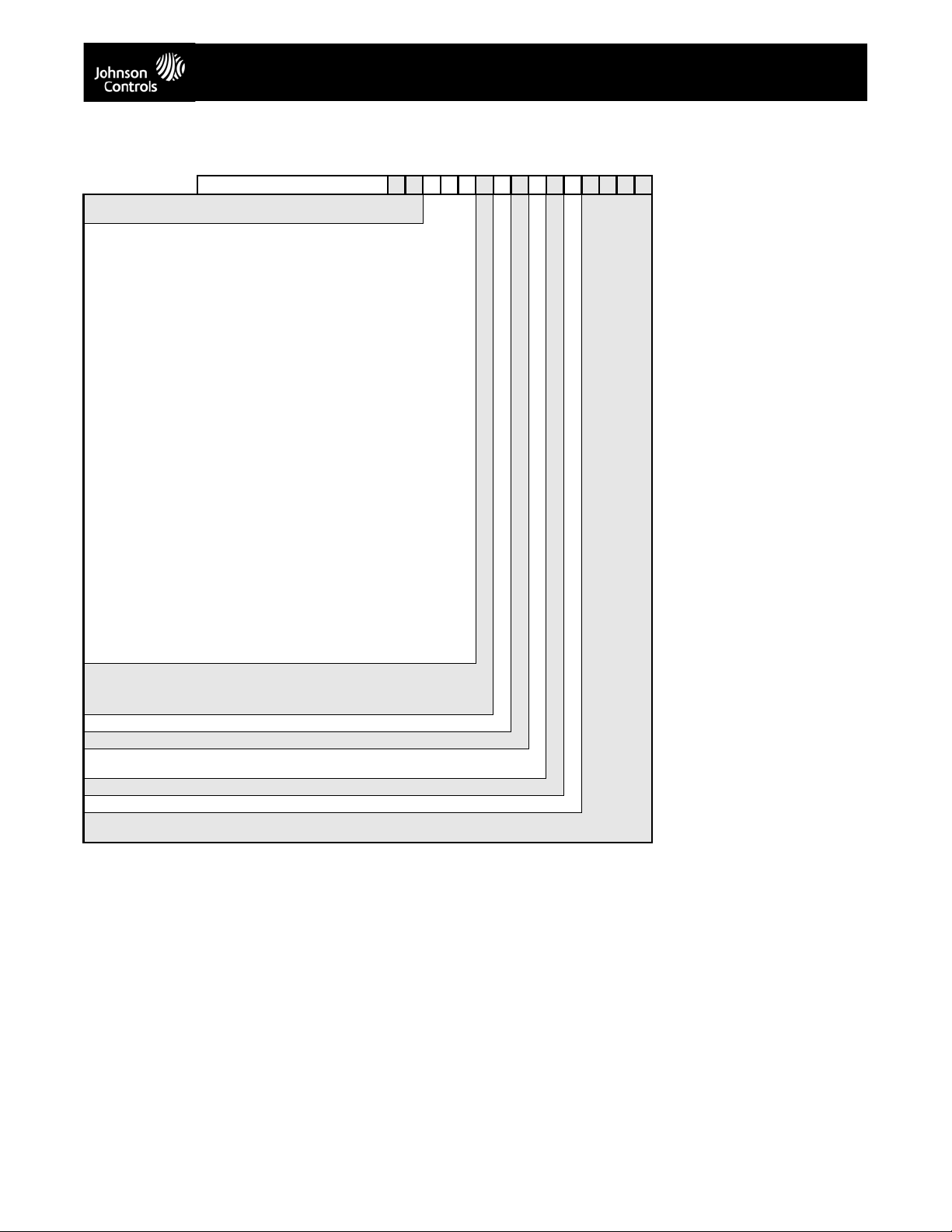

Selection Chart (3-Phase Input, 3-Phase Output)

Code Number

Base Product VS = Variable Speed

Full Load Amperes

(VT/CT)

Voltage 2 = 230 V

Enclosure Rating 0 = IP20

Enclosure Style 3 = 3-phase (Micro Drive)

Revision # B = Rev. 2 (Americas)

Separator (—)

Communications M = Modbus

Options 00 = None

Series II Micro Drive prefix

230 V

1D7 = 1.7 A (1/4 hp, 0.25 kW)

2D4 = 2.4 A (1/2 hp, 0.37 kW)

2D8 = 2.8 A (3/4 hp, 0.55 kW)

3D7 = 3.7 A (1 hp, 0.75 kW)

4D8 = 4.8 A (1.5 hp, 1.1 kW)

7D0 = 7.0 A (2 hp, 1.5 kW)

011 = 11.0 A (3 hp, 2.2 kW)

017 = 17.0 A (5 hp, 4 kW)

025 = 25.0 A (7.5 hp, 5.5 kW)

031 = 31.0 A (10 hp, 7.5 kW)

038 = 38.0 A (15 hp, 1 1 kW)

480V

1D3 = 1.3 A (1/2 hp, 0.37 kW)

1D9 = 1.9 A (3/4 hp, 0.55 kW)

2D4 = 2.4 A (1 hp, 0.75 kW)

3D3 = 3.3 A (1.5 hp, 1.1 kW)

4D3 = 4.3 A (2 hp, 1.5 kW)

5D6 = 5.6 A (3 hp, 2.2 kW)

7D6 = 7.6 A (4 hp, 3 kW)

9D0 = 9.0 A (5 hp, 4 kW)

012 = 12.0 A (7.5 hp, 5.5 kW)

014 = 14.0 A (10 hp, 7.5 kW)

016 = 16.0 A (10 hp, 7.5 kW)

023 = 23.0 A (15 hp, 1 1 kW)

031 = 31.0 A (20 hp, 15 kW)

038 = 38.0 A (25 hp, 18.5 kW)

575 V

1D7 = 1.7 A (1 hp, 0.75 kW)

2D7 = 2.7 A (2 hp, 1.5 kW)

3D9 = 3.9 A (3 hp, 2.2 kW)

6D1 = 6.1 A (5 hp, 4 kW)

9D0 = 9.0 A (7.5 hp, 5.5 kW)

4 = 480 V

5 = 575 V

D = Rev. 2 (Canada)

EM = EMC Filter

Note: Horsepower ratings are based on the use of a 240 V, 460 V, and 575 V four- or six-pole

squirrel-cage induction motor and are for reference only. Select a drive when the motor current is less

than or equal to the rated continuous output current.

V S 0 3B—M0 0 0 0

The performance specifications are no minal and co nform t o acceptab le ind ustry standar ds. For appl ications at condition s beyond these specifica tions, consult the local Johnson Co ntrols office.

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2013 Johnson Controls, Inc.

www.johnsoncontrols.com

2

VSD Series II Variable Speed Micro Drives (Continued)

Technical Specifications

VSD Series II Variable Speed Micro Drives (Part 1 of 2)

Input Voltage (Vin) +10%/-15% (575V units: +15%/-15%)

Input Frequency (fin) 50/60 Hz (Variation Up to 47-66 Hz)

Connection to Power Once Per Minute or Less (Typical Operation)

Output Voltage 0 to V

Continuous Output

Current

Initial Output Current Current 2 x I

Output Frequency 0 to 320 Hz

Frequency Resolution 0.01 Hz

Control Method Frequency Control (V/f) Open Loop Sensorless Vector Control

Switching Frequency 1.5 to 16 kHz; Default 6 kHz

Frequency Reference Analog Input: Resolution 0.1% (10 bit), Accuracy +/-1%

Field Weakening Point 30 to 320 Hz

Acceleration Time 0 to 3,000 s

Deceleration Time 0 to 3,000 s

Braking Torque DC Brake: 30% x T

Braking Resistor

Ambient Operating Temperature 14°F (-10°C), No Frost to 122°F (+50°C): Rated Loadability I

Storage Temperature -40 to 158°F (-40 to 70°C)

Relative Humidity 0 to 95% RH, Noncondensing, Noncorrosive,

Air Quality Chemical Vapors: IEC 721-3-3, Unit In Operation, Class 3C2;

Altitude 100% Load Capacity (No Derating) Up to 3,280 ft (1,000 m); 1% Derating for Each 328 ft (100 m) Above

Vibration 60068-2-6; 3 to 150 Hz, Displacement Amplitude 1 mm (peak) at 3 to 15.8 Hz, Maximum Acceleration Amplitude

Shock EN 50178, IEC 68-2-27 UPS Drop Test (for Applicable U PS Weights); Storage and Shipping: Ma ximum 15 G, 11 ms

Enclosure Class IP20

EMC (at default settings) Category C2, C3, and C4 (Level H): With an Internal RFI Filter Option

Emissions EMC Level Dependent: +EMC 2: EN 61800-3 (2004)

Analog Input Voltage 0 to 10 V, R = 200 kOhms Differential Resolution 0.1%; Accuracy ±1%, Dip Switch Selection (Voltage/Current)

Overcurrent Protection Trip Limit 4.0 x IH Instantaneously

Overvoltage Protection 115/230 V Series: 437 VDC; 400 V Series: 874 VDC; 575 V Series: 1048 VDC Trip Level

Undervoltage Protection 115/230 V Series: 183 VDC; 400 V Series: 333 VDC; 575 V Series: 460 VDC Trip Level

Earth Fault Protection Ground fault is tested before every start. In case of ground fault in motor or motor cable, only the frequency

Overtemperature Protection Yes

Motor Overload Protection Yes

Motor Stall Protection Yes

Motor Underload

Protection

Compliance

Warranty 30 months (parts only) from date of shipment

Reliability 500,000 hours Mean Time Between Failures (MTBF)

Weight FS1: 1.21 lb (0.55 kg)

Single-Phase Voltage/hp/Amperes

2

FS1 230 V, 1/4 to 3/4 hp, 0.25 to 0.55 kW, 1.7 to 2.8 A

1

1

in

Ambient Temperature Maximum 104°F (40°C), Overload 1.1 x IL (1 min./10 min.)

for 2 Seconds in Every 20-Second Period, Torque Depends on Motor

N

Panel Reference: Resolution 0.01 Hz

(without Brake Option)

230 V: Frame 2, 35 ohms; Frame 3, 26 ohms

480 V: Frame 2, 75 ohms; Frame 3, 54 ohms

575 V: Frame 3, 103 ohms

No Dripping Water

Mechanical Particles: IEC 721-3-3, Unit In Operation, Class 3S2

3,280 ft (1,000 m); Maximum 6,560 ft (2,000 m)

1 G at 15.8 to 150 Hz

(In Package)

converter is protected.

Yes

UL Listed File No 508C; cUL Listed, IEC, RoHS Compliant

CE Mark – Johnson Controls, Inc. declares that the VSD Series II Variable Speed Micro Drives are in compliance

with the essential requirements and other relevant provisions of EMC Directive 2004/108/EC and Low Voltage

Directive 2006/95/EC.

Safety – EN 61800-5-1

FS2: 1.54 lb (0.69 kg)

FS3: 2.18 lb (0.99 kg)

n

N

The performance specifications are no minal and co nform t o acceptab le ind ustry standar ds. For appl ications at condition s beyond these specifica tions, consult the local Johnson Co ntrols office.

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2013 Johnson Controls, Inc.

www.johnsoncontrols.com

3

VSD Series II Variable Speed Micro Drives (Continued)

VSD Series II Variable Speed Micro Drives (Part 2 of 2)

FS2 120 V, 1/4 to 1 hp, 0.25 to 0.75 kW, 1.7 to 3.7 A

230 V, 1 to 2 hp, 0.75 to 1.5 kW, 1.7 to 7 A

FS3 120 V , 1.5 hp, 1.1 kW, 1.7 to 3.7 A

230 V, 3 hp, 2.2 kW, 4.8 A

Three-Phase Volta ge/hp/Amperes

FS1 230 V, 1/4 to 1 hp, 0.25 to 0.75 kW, 1.7 to 3.7 A

480 V, 1/2 to 1.5 hp, 0.37 to 1.1 kW, 1.3 to 3.3 A

FS2 230 V, 1.5 to 2 hp, 1.1 to 1.5 kW, 4.8 to 7 A

480 V, 2 to 3 hp, 1.5 to 2.2 kW, 4.3 to 5.6 A

FS3 230 V, 3 hp, 2.2 kW, 11 A

480 V, 3 to 10 hp, 3 to 7.5 kW, 7.6 to 16 A

575 V, 1 to 7.5 hp, 0.75 to 5.5 kW, 1.7 to 9 A

1. The exception is 115 V single-phase in, 230 V 3-phase out.

2. Frame 2 and Frame 3, 3-phase drives are equipped with a brake chopper circuit.

The performance specifications are nomina l and conf orm to accep table industr y standar ds. For ap plications a t condition s beyond th ese specification s, consult the local Johnson Controls o ffice.

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2013 Johnson Controls, Inc.

www.johnsoncontrols.com

4

Loading...

Loading...