Page 1

Powered by

November 2009

Eaton’s Technology

VSD Series Quick Start Guide

Open Drive

IMPORTANT: This guide is intended to provide a quick reference to

the VSD Series drive’s Application Software features for start-up,

programming and service. It does not replace the need to thoroughly

read and understand the User Manual.

Table of Contents

Description Page

NEMA Type 1/12 Open Drives (1 – 250 HP) . . . . . . . . . . . . . . 2

NEMA Type 1 IntelliPass/IntelliDisconnect Drive . . . . . . . . . 5

Enclosed NEMA Type 12/3R . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Appendix A — Main Control Board Wiring . . . . . . . . . . . . . 15

Appendix B — Interlock Damper Start Example

Using 4 – 20 mA Control Signal . . . . . . . . . . . . . . . . . . . 16

Appendix C — Interlock Damper Start Example

Using PID Duct Static Control Signal . . . . . . . . . . . . . . . 17

Appendix D — Bypass Wiring Diagram . . . . . . . . . . . . . . . . 18

Appendix E — Keypad Navigation . . . . . . . . . . . . . . . . . . . . 19

Appendix F — Main Menu Navigation . . . . . . . . . . . . . . . . . 20

Appendix G — Start-Up Wizard . . . . . . . . . . . . . . . . . . . . . . . 21

Appendix H — Static Checking . . . . . . . . . . . . . . . . . . . . . . . 25

Appendix I — Fault and Warning Codes . . . . . . . . . . . . . . . . 27

Bypass Drive

VSD Series Quick Start Guide

NEMA Type 12

General

Upon receipt of the unit, verify that the catalog number and unit

options stated on the shipping container match those stated on

the order/purchase form.

Inspect the equipment upon delivery. Report any carton damage

to the carrier prior to accepting the delivery. Have this

information noted on the freight bill. Johnson Controls is not

responsible for damage incurred in shipping.

Unpacking

Remove all packing material from the unit. Be sure to remove all

packing material from lug location. Also, make sure no packing

material is left behind that would block the airflow to the fan.

Check the unit for any signs of shipping damage. If damage to

the product is found after unpacking, report it to the freight

company. Retain the packing materials for the carrier to review.

Storage

It is recommended that the unit be stored in its original shipping

box/crate until it is to be installed.

The unit should be stored in a location where:

•

The ambient temperature is between -40°F and 158°F

(-40°C and 70°C)

•

The relative humidity is between 0% and 95%,

non-condensing

•

The environment is dry, clean, and non-corrosive

•

The unit will not be subjected to high shock or vibration

conditions

NEMA Type 3R

Technical Support Phone Numbers

Branch: 800-281-3792 (Option 1)

Third Party (ABCS/DIST): 800-445-4757 (Option 1)

LIT-1201858

For more information visit: www.johnsoncontrols.com

Mandatory Ground Wiring (See Appendix D on Page 18)

Be sure to pull low impendance ground wiring from customer

power to drive and ground wire from drive to motor.

Utility Drive Motor Ground

(Inside Motor Conduit Box)

1

Page 2

VSD Series Quick Start Guide

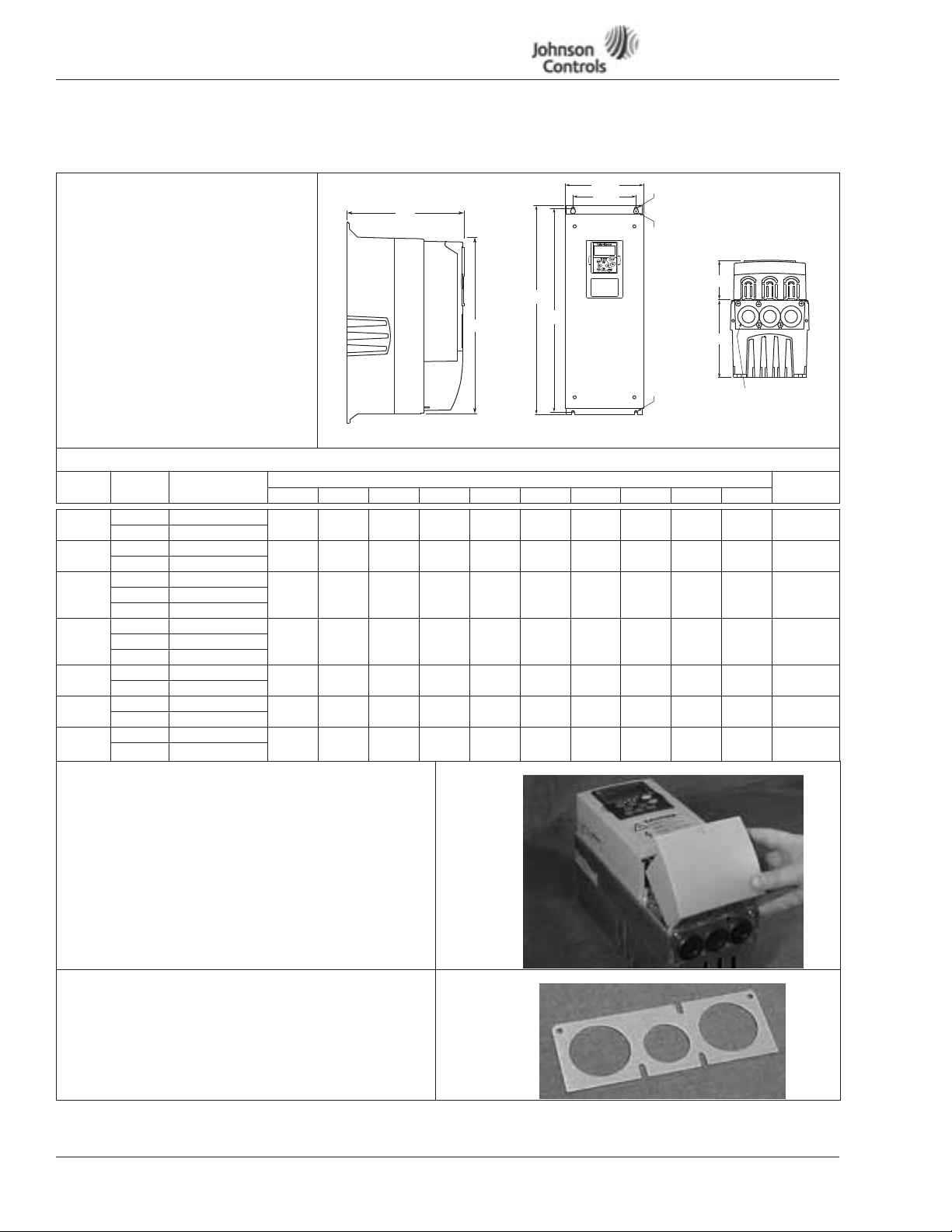

NEMA Type 1/12 Open Drives (1 – 250 HP)

Table 1: Control Wiring Instructions

Mounting Drive

1. Mount Drive

(See Table below for dimensions.)

VSD Series Open Drive Dimensions

Frame

Size

FR4 230V 3/4 – 3 12.9

FR5 230V 5 – 7-1/2 16.5

FR6 230V 10 – 15 22.0

FR7 230V 20 – 30 24.8

FR8 480V 75 – 125 29.7

FR9

FR10 480V 250 – 350 44

Voltage hp (VT) Approximate Dimensions in Inches (mm) Weight

H1 H2 H3 D1 D2 D3 W1 W2 R1 dia. R2 dia.

480V 1 – 5

480V 7-1/2 – 15

480V 20 – 30

575V 2 – 25

480V 40 – 60

575V 30 – 40

575V

480V 150 – 200 45.3

575V 100 – 150

575V 200 – 300

50 – 75

(327)

(419)

(558)

(630)

(755)

(1150)

(1120)

12.3

(313)

16.0

(406)

21.3

(541)

24.2

(614)

28.8

(732)

44.1

(1120)

33.5

(850)

Power Wiring

Notice

Do not discard the plastic bag containing the wiring plate.

2. Remove the bottom cover by rotating the cover toward

you on the base hinges, then lifting the cover away from

the base.

D1

11.5

(292)

15.4

(391)

20.4

(519)

23.3

(591)

28.4

(721)

— 14.3

— 23.6

7.5

(190)

8.4

(214)

9.3

(237)

10.1

(257)

11.3

(288)

(362)

(600)

H1

H3

H2

Figure 1:

2.5

(64)

2.7

(68)

2.7

(68)

2.7

(68)

1.3

(34)

5.4

(137)

NA NA 23.6

5.0

(126)

5.8

(148)

6.7

(171)

7.5

(189)

11.0

(279)

8.8

(224)

5.0

(128)

5.7

(144)

7.7

(195)

9.3

(237)

11.2

(285)

18.9

(480)

(600)

W1

W2

Powered by

R2

R1

R2

3.9

(100)

3.9

(100)

5.8

(148)

7.5

(190)

10.0

(255)

15.7

(400)

16.7

(425).9(23)

.5

(13)

.5

(13)

.7

(18)

.7

(18)

.7

(18)

.7

(18)

Eaton’s Technology

November 2009

D2

D3

Knockouts

Lbs. (kg)

.3

(7)

.3

(7)

.4

(9)

.4

(9)

.4

(9)

.4

(9)

.47

(12)

11

(5)

17.9

(8.1)

40.8

(18.5)

77.2

(35)

127.8

(58)

321.9

(146)

550.7

(250)

Power Wiring

3. Locate the plastic bag shipped with the drive containing

the wiring plate, and remove the wiring plate.

2

For more information visit: www.johnsoncontrols.com

LIT-1201858

Page 3

Powered by

November 2009

Eaton’s Technology

NEMA Type 1/12 Open Drives (1 – 250 HP)

Table 1: Control Wiring Instructions (continued)

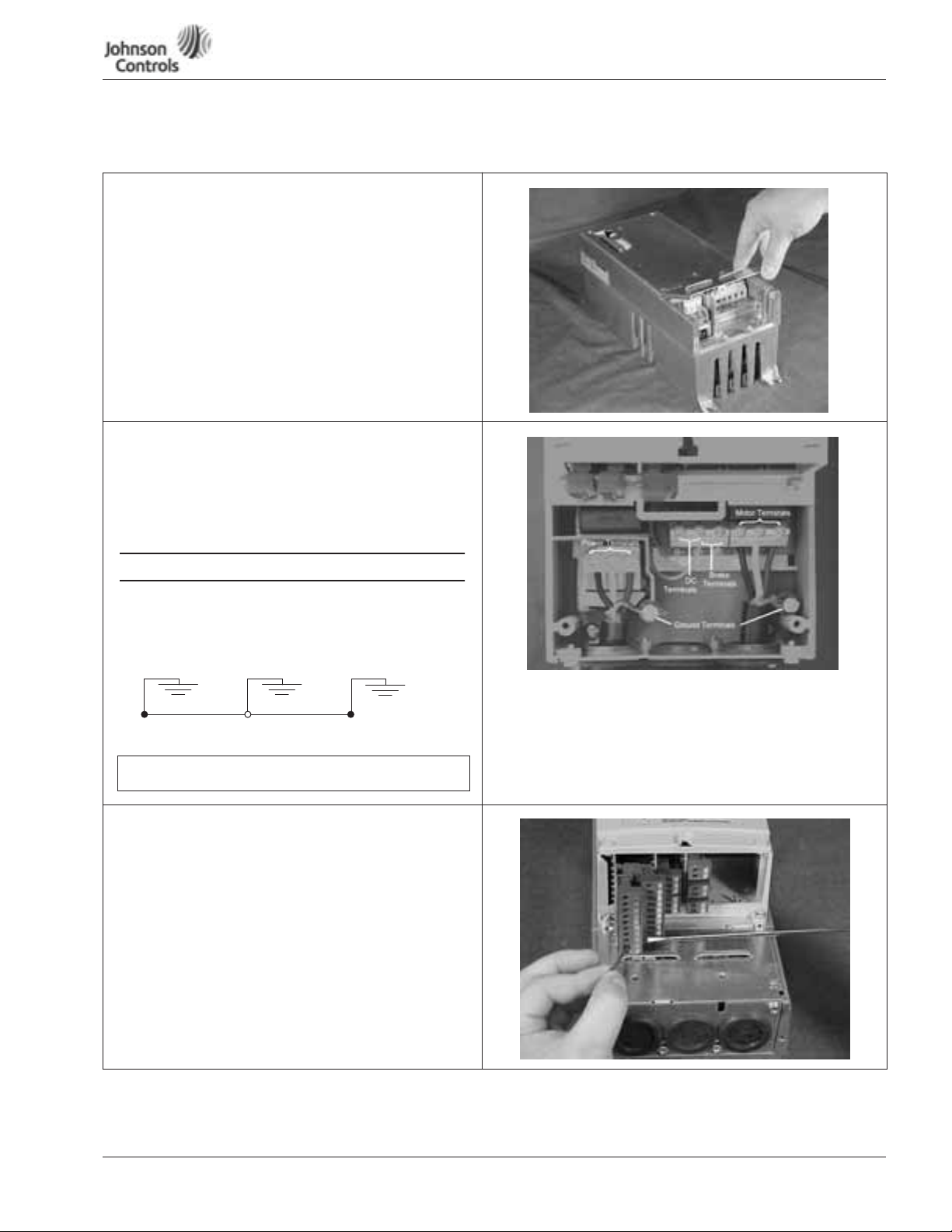

Power Wiring

4. If conduit is being used, attach the wiring plate to it.

5. Pass the motor and input power wires/cables through the

holes of the wiring plate.

6. If shielded cable is used, connect the shields of the input

line power cable and the motor cable to the motor and

power ground terminals of the VSD Series drive.

Power Wiring/Grounding

7. Wire power terminals, motor terminals, and grounding

terminals per diagram. Power and Motor leads must be in

separate conduit.

Note: Do not wire motor loads to B- B+ R-. This will cause

damage.

VSD Series Quick Start Guide

GROUND WIRING

•

Run motor cables in separate conduit.

DO NOT RUN CONTROL WIRES in same conduit

•

Cables sized per NEC.

•

Provide low impedance ground between drive and

•

motor.

Utility Drive Motor Ground

IMPORTANT: Improper grounding could result in damage to the

motor and/or drive and could void warranty

Control Wiring

8. Wire the control terminals following the details for the

specific option boards shown on the following pages.

Note: For ease of access, the option board terminal blocks can

be unplugged for wiring.

Note: If using conduit or Seal Tite for control wiring for Frame

4, you must order NEMA Type 12 kit.

(Inside Motor Conduit Box)

LIT-1201858

For more information visit: www.johnsoncontrols.com

3

Page 4

VSD Series Quick Start Guide

NEMA Type 1/12 Open Drives (1 – 250 HP)

Table 1: Control Wiring Instructions (continued)

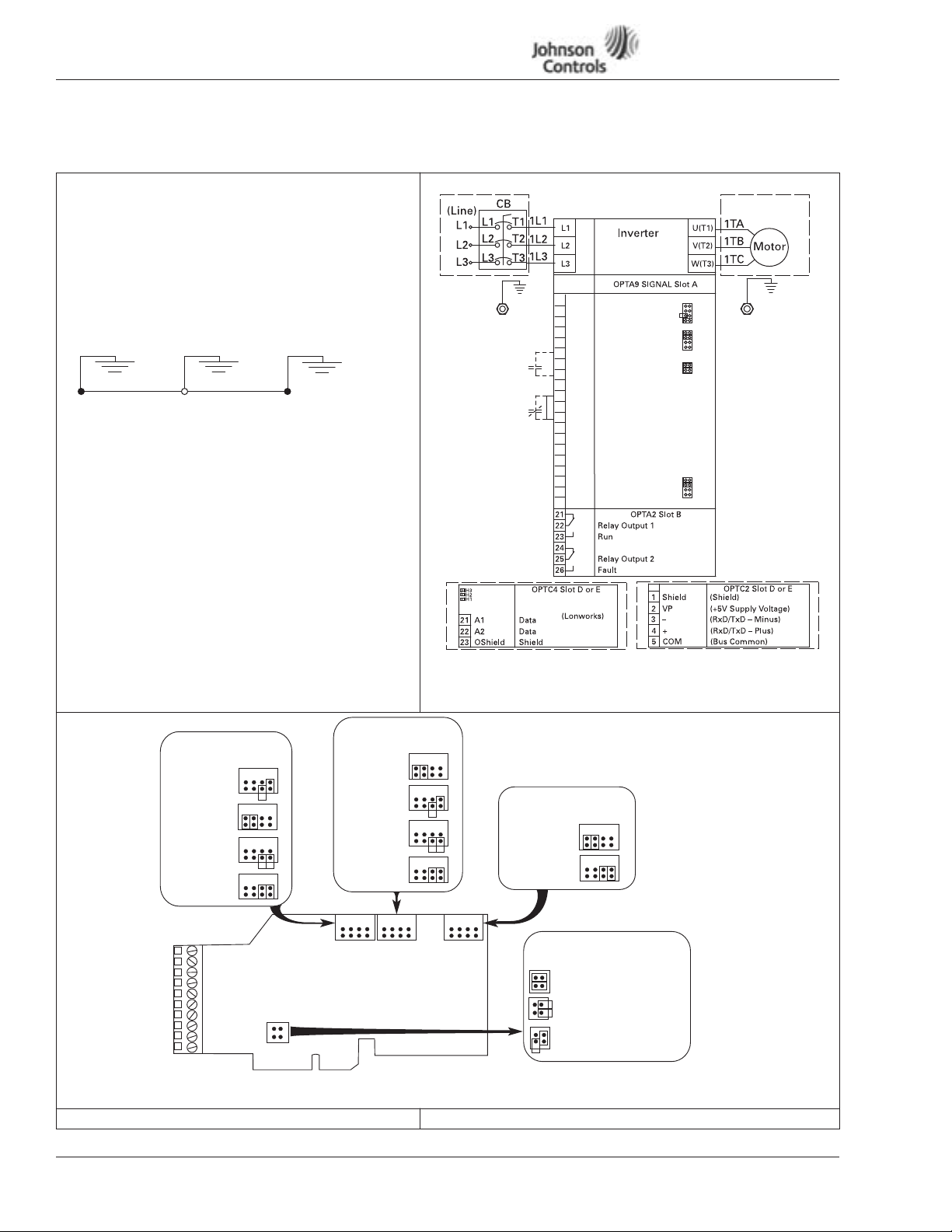

Control Wiring

9. Wire control to the OPTA9 Control Board and OPTA2.

Note: Drive default is programmed for Damper Interlock.

Note: Option Boards OPTC2 (N2/XT/SA Bus) and OPTC4

(LonWorks) are optional.

Mandatory Ground Wiring

Be sure to pull low impendance ground wiring from

customer power to drive and ground wire from drive

to motor.

Utility Drive Motor Ground

I/O Connection

Run 110 Vac and 24 Vdc Control wiring in separate

•

conduit.

Communication wire to be shielded.

•

RS-232 Keypad cable less than 20 feet.

•

(Inside Motor Conduit Box)

Incoming Power

Optional

CB

Note: Must pull

dedicated

ground wire

to drive

and motor.

1

+1DV

2

Vin+

3

GND

4

Lin+

5

Lin–

6

24Vout

7

GND

8

DIN1

9

DIN2

10

DIN3

11

CMA

12

24Vout

13

GND

14

DIN4

15

DIN5

16

DIN6

17

CMB

18

Lout+

19

Lout–

20

DO1

Powered by

Reference Output

Analog Input Voltage

(Range 0-10V DC)

I/O Ground

Analog Input Current

(Range 4-20mA)

Control Voltage Output

I/O Ground

Start/Stop

External Fault

Run Permisive Damper Interlock

DIN1-DIN3 Common

Control Voltage Output

I/O Ground

Speed Select 1

Fire Mode

Bypass Overload Fault

DIN4-DIN6 Common

Output Frequency

Analog Output

Digital Output Ready

X1

A

B

C

D

X2

A

B

C

D

X3

X6

A

B

C

D

Eaton’s Technology

November 2009

Note:

See Figure 3

for Dip X1, X2,

X3, X6 Switch

settings.

Start-Up Wizard

X1 Jumper Setting

Analog Input 1 (AI1)

0 to 10V*

Voltage Input

0 to 20 mA

Current Input

0 to 10V

(Differential)

Voltage Input

-10 to 10V

Voltage Input

A

A

A

A

Note:

Optional Communication Cards can be

supplied with the Drive or as a Field Option.

Figure 2:

X2 Jumper Setting

Analog Input 2 (AI2)

B

A

0 to 20 mA*

B

CD

CD

B

B

CD

B

C D

Current Input

0 to 10V

Voltage Input

0 to 10V

(Differential)

Voltage Input

-10 to 10V

Voltage Input

B

A

C D

X1X3X2

A

CD

B

A

CD

A

CD

B

B

A

C D

B

C D

X6

B

A

C D

X6 Jumper Setting

Analog Output 1 (A01)

B

A

0 to 20 mA*

Current Output

0 to 10V

Voltage Output

CMA and CMB Grounding

* Designates Default Jumper Settings

CD

B

A

CD

X3 Jumper Setting

CMB Connected to Ground*

CMA Connected to Ground

CMB Isolated from Ground

CMA Isolated from Ground

CMB and CMA Internally

Connected and Isolated

from Ground

Figure 3: Option Board A9 Location and Settings

See Appendix G .

4

For more information visit: www.johnsoncontrols.com

LIT-1201858

Page 5

November 2009

Powered by

Eaton’s Technology

VSD Series Quick Start Guide

NEMA Type 1 IntelliPass/IntelliDisconnect Drive

Circuit Breaker Endplate

Circuit Breaker

Extension Bar

Circuit Breaker

Ribbon

Cable Hinge

Output & Bypass

Contactor*

24V DC Power Supply *

Optional 3rd Input Contactor *

Contactor Overload *

Manual/Auto Reset *

24V DC Motor Overload

Terminal Block *

* IntelliPass only.

Optional 3rd Contactor S1 Switch *

(provided for drive isolation)

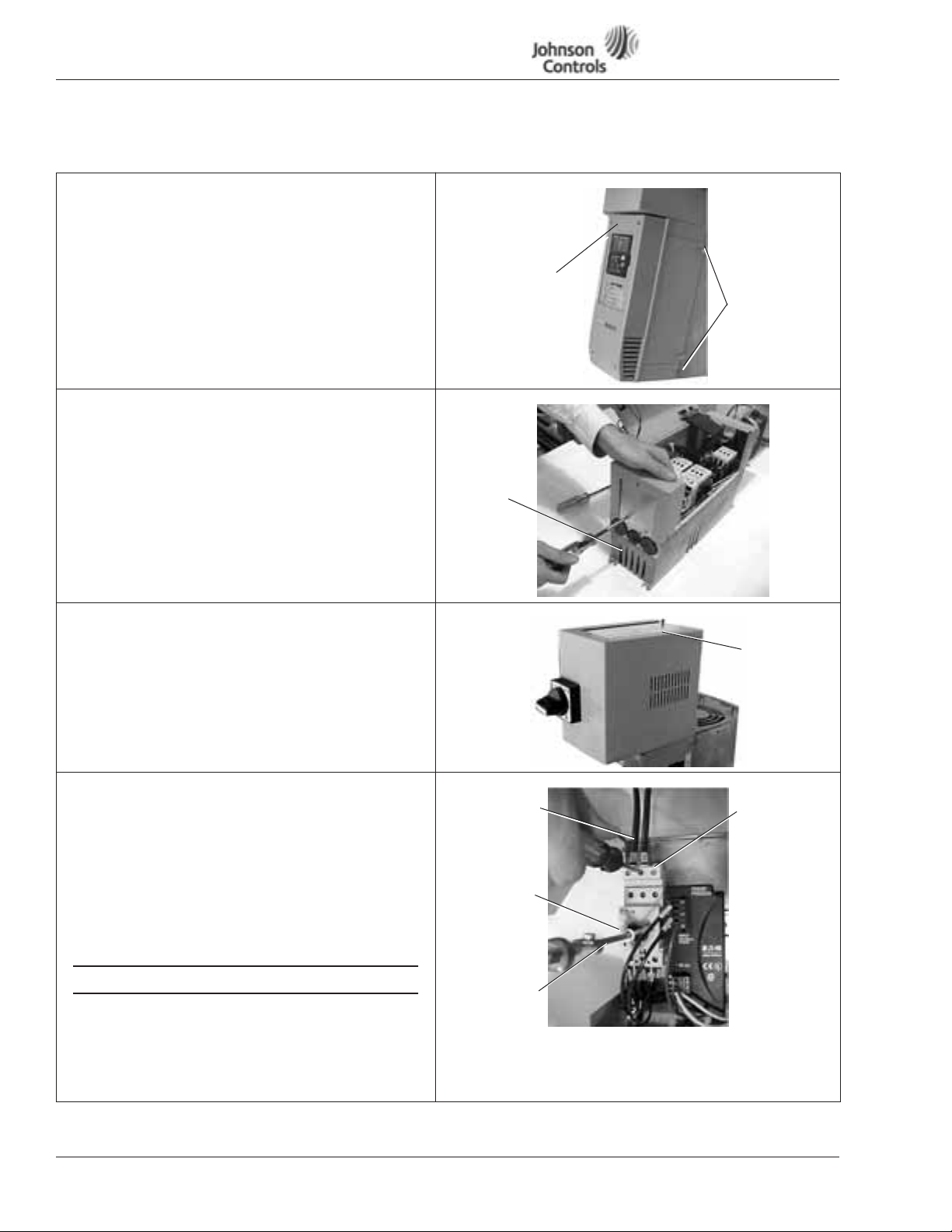

Figure 4: Identification of NEMA Type 1 Components

Figure 5: VSD Series IntelliPass/IntelliDisconnect Drive Dimensions

Ground Studs

Drive Enclosure Endplate

(located at bottom)

Table 2: VSD Series NEMA Type 1 IntelliPass/IntelliDisconnect Drive

Dimensions

Drive

Horsepower (VT)

208V, 1 – 3 hp

230V, 1 – 3 hp

480V, 1 – 7-1/2 hp

208V, 5 – 7-1/2 hp

230V, 5 – 10 hp

480V, 10 – 20 hp

208V, 10 – 20 hp

230V, 15 and 20 hp

480V, 25 – 40 hp

208V, 25 and 30 hp

230V, 25 and 30 hp

480V, 50 – 75 hp

If mounting two or more IntelliPass Drives next to each other, make sure to use the

proper spacing between the drives for hinged door operation.

Frame

Approximate

Size

Dimensions in

Inches (mm)

ABC D

FR4 5.04

FR5 5.50

FR6 7.50

FR7 9.10

(128)

(140)

(191)

(231)

18.25

(464)

23.25

(591)

29.38

(746)

37.53

(953)

13.24

(336)

13.24

(336)

15.25

(387)

15.25

(387)

Approx.

Weight

in lbs. (kg)

21 (9.5) 5.3 (134.6)

35 (15.9) 5.7 (144.8)

67 (30.4) 7.5 (190.5)

108 (49.0) 9.0 (228.6)

Distance

Between

Drives in

Inches (mm)

LIT-1201858

For more information visit: www.johnsoncontrols.com

5

Page 6

VSD Series Quick Start Guide

NEMA Type 1 IntelliPass/IntelliDisconnect Drive

Table 3: Bypass Power Wiring Instructions — NEMA Type 1

Mounting Drive

1. Mount drive per dimensions. (See Page 5 .)

2. Verify that the main power source is removed upstream.

3. Using a flat-blade screwdriver, remove the four screws

securing the outer cover of the drive and remove the

cover.

4. Using the same screwdriver, remove the two center

screws securing the side cover.

5. Make sure there is adequate room, and open the hinged

side cover.

Power Wiring

6. Using a flat-blade screwdriver, remove the screws

securing the endplate at the bottom of the drive enclosure,

and remove the endplate.

7. Using a Greenlee conduit cutter (recommended), cut one

or more holes in the endplate, located at the bottom of the

drive’s enclosure, for the motor and power leads.

Note: If bringing the power leads in through the top of the

drive’s enclosure, go to step 8. If not, proceed to step 10.

Outer Cover

Bottom

Endplate

Powered by

Eaton’s Technology

November 2009

Two Screws on

Side Cover

Power Wiring

8. Using a flat-blade screwdriver, remove the screws

securing the endplate for the circuit breaker enclosure,

and remove the endplate.

9. Using a Greenlee conduit cutter (recommended), cut one

hole in the circuit breaker endplate for the power leads.

Power Wiring

10. Calibrate the circuit breaker amperage, so it is 1.25 times

the amperage on the motor nameplate, by turning the

red set screw located below the circuit breaker extension

bar. See the circuit breaker user’s manual supplied with

the drive.

11. Connect the incoming power leads to circuit breaker

terminals labeled L1, L2 and L3. Cables sized per NEC.

12. Using the torque wrench, tighten each terminal to the

torque value found in the appropriate user’s manual

supplied with the drive.

POWER WIRING

Run cabling in separate metal conduit or wiring tray.

•

DO NOT RUN CONTROL WIRING with incoming

•

power wiring.

Provide low impedance ground connection to drive

•

chassis.

DO NOT CONNECT to B+, B-, R terminals.

•

Incoming

Power Leads

Circuit Breaker

Set Screw

Circuit Breaker

Extension Bar

Circuit Breaker

Endplate

Circuit Breaker

Terminals

6

For more information visit: www.johnsoncontrols.com

LIT-1201858

Page 7

Powered by

November 2009

Eaton’s Technology

NEMA Type 1 IntelliPass/IntelliDisconnect Drive

Table 3: Bypass Power Wiring Instructions — NEMA Type 1 (continued)

Motor Wiring

13. Use your first and second fingers and simultaneously

push down to release the two orange retaining clips (one

on each side of the 24V DC motor overload terminal

block).

14. If necessary, use a flat-blade screwdriver to carefully

remove the terminal block in a straight plane to avoid

damaging it.

Motor Wiring

15. Connect the motor leads to the motor overload terminals

labeled 1TA, 1TB and 1TC.

16. Using the appropriate metric Allen wrench (2.5 mm, 3 mm

or 4 mm), tighten each overload terminal per the

specifications in the contactor user’s manual.

MOTOR WIRING

An SAE allen wrench will damage the terminals,

and the motor overload will need to be replaced

(not covered by warranty).

17. Using the torque wrench, tighten each terminal to the

torque value found in the appropriate user’s manual

supplied with the drive.

18. Reinsert the motor overload terminal block.

Motor

Leads

VSD Series Quick Start Guide

Motor

Overload

Terminals

Grounding

19. Use a flat-blade screwdriver to connect the motor ground

wire to the ground stud (located at either the top or

bottom of the drive’s enclosure). (Mandatory) Ground

connection main power ground must be connected to

other ground screws.

GROUND WIRING

Run motor cables in separate conduit.

•

DO NOT RUN CONTROL WIRES in same conduit

•

•

Cables sized per NEC.

Provide low impedance ground between drive and

•

motor.

Utility Drive Motor Ground

IMPORTANT: Improper grounding could result in damage to the

motor and/or drive and could void warranty

LIT-1201858

(Inside Motor Conduit Box)

For more information visit: www.johnsoncontrols.com

Motor

Ground

Stud

7

Page 8

VSD Series Quick Start Guide

NEMA Type 1 IntelliPass/IntelliDisconnect Drive

Table 3: Bypass Power Wiring Instructions — NEMA Type 1 (continued)

Setting Overload

20. Lift to open the cover on the motor overload, and use a

1/8" flat-blade screwdriver to set the overload amperage to

match the value on the motor nameplate.

21. Turn the auto/manual reset (factory default is manual) on

the motor overload 90° to the auto position.

Control Wiring

22. Use a flat-blade screwdriver to carefully remove the lowvoltage I/O terminal block.

23. Insert the incoming control leads into the terminal block.

Refer to the electrical schematic supplied with the drive.

24. Reinsert the I/O terminal block into the control board.

25. Verify that all other wires to the terminal block are

connected.

26. Terminate control wiring to the OPTA9 and OPTA2 board

(Terminals 1 – 26).

Powered by

Eaton’s Technology

November 2009

Auto/Manual

Reset

CONTROL WIRING

Run 110 Vac and 24 Vdc control wiring in separate

•

conduit.

•

Communication wire must be shielded.

RS-232 keypad cable must be less then 25 feet.

•

OptionalOptional

Customer

Ground

Drive

Ground

Start/Stop

Speed Select 1

Fire Mode

Bypass Overload Fault

Drive

Ground

Motor

Ground

Note: See Figure 3

for Dip X1, X2,

X3, X6 Switch

settings.

Note: Optional COMM cards can be supplied

Note: with the drive or as a field option.

Figure 6: VSD Series IntelliPass with Three Contactors

8

For more information visit: www.johnsoncontrols.com

LIT-1201858

Page 9

Powered by

November 2009

Eaton’s Technology

NEMA Type 1 IntelliPass/IntelliDisconnect Drive

able 3: Bypass Power Wiring Instructions — NEMA Type 1 (continued)

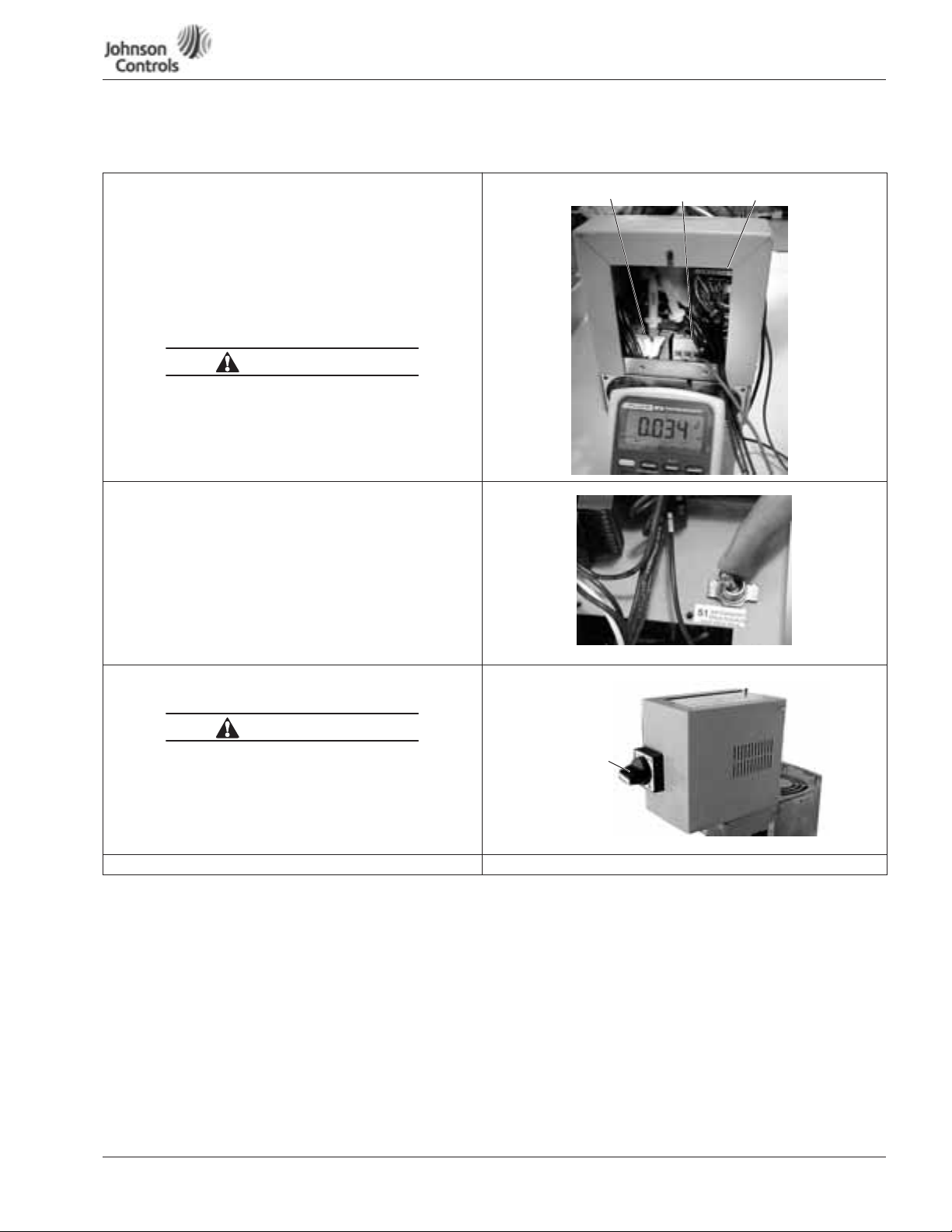

Static Check

27. Make sure power is off, and perform static checks as

described in Table 7

(for the inverter) and Table 9 (for the DC bus). Refer to

Page 25, Appendix H.

Note: Static check shown is for L3 and B+ terminals.

28. Once the pre-power static checks are completed,

reinstall the drive’s outer and side covers, tightening

all the screws.

High Voltage is present on L1, L2, L3, B-, B+, BT, T1, T2, T3.

Starting Drive

29. Make sure that the drive’s 3rd contactor S1 switch, if

present, is in the ON position (shown in OFF position).

Note: The bypass mode operates with the switch in the OFF

position, however the drive will not run. Yet the keypad

will operate.

(for the converter) , Table 8

WARNING

VSD Series Quick Start Guide

L1, L2, L3 B-, B+, BT T1, T2, T3

Starting Drive

30. Turn the circuit breaker handle in a clockwise direction.

WARNING

High Voltage

• Always work with another person.

• Be sure equipment is properly grounded.

• Wear safety glasses.

Start-Up Wizard

Circuit Breaker

Handle

See Appendix G.

LIT-1201858

For more information visit: www.johnsoncontrols.com

9

Page 10

VSD Series Quick Start Guide Powered by

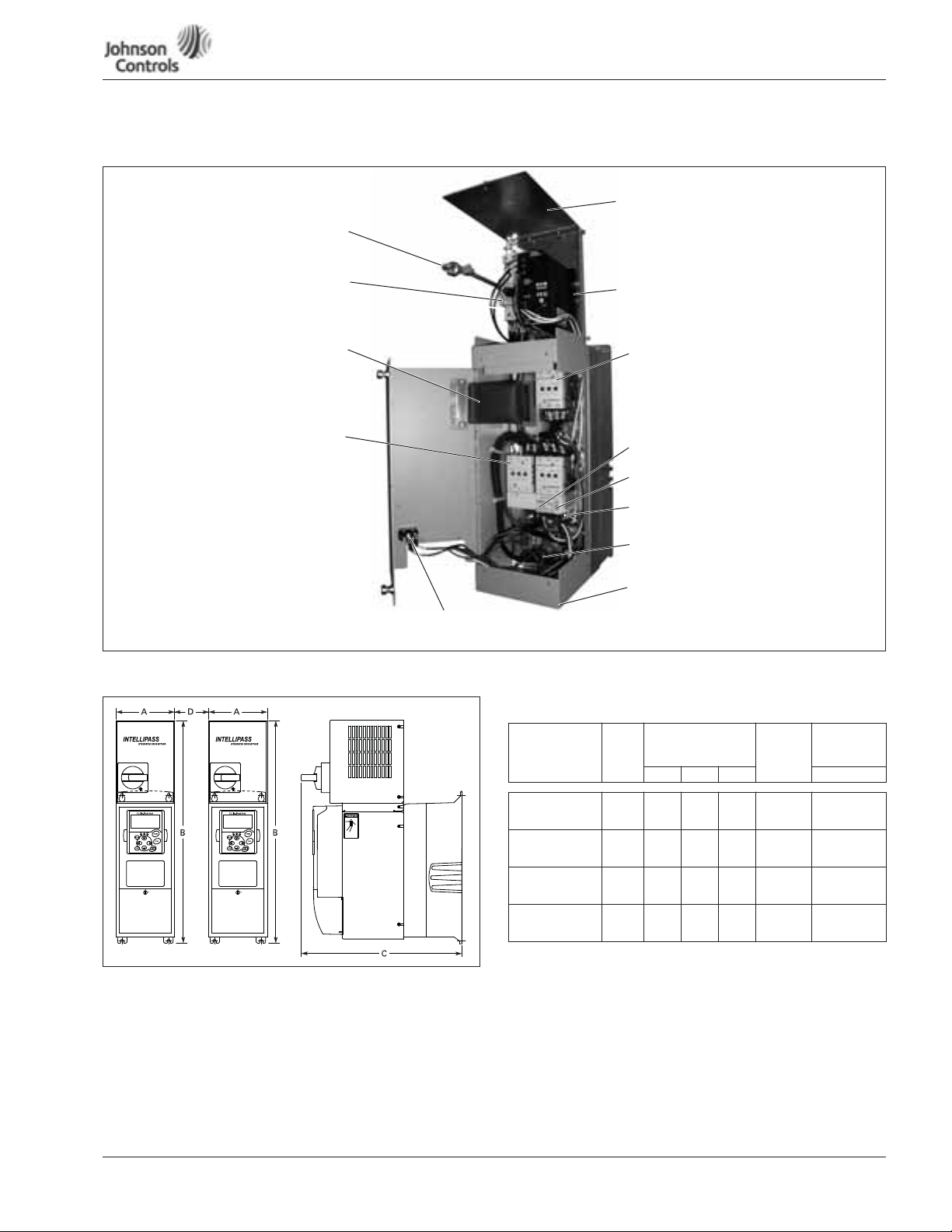

Enclosed NEMA Type 12/3R

Optional NEMA Type 3R Hood

(Hood not present on

NEMA Type 12 drive)

Power Ground Stud

Circuit Breaker

Eaton’s Technology

November 2009

Circuit Breaker

Handle

24V DC Power Supply

Optional 3rd Input Contactor

Keypad Cable

Space Heater (not on

electrical schematic)

Output & Bypass Contactor

50 hp NEMA Type 3R

480V AC Variable

Frequency Drive

(behind drive cover)

Optional 3rd Contactor S1 Switch

(provided for drive isolation)

Contactor Overload

24V DC Motor Overload

Terminal Block

Motor Ground Stud

Figure 7: Identification of NEMA Type 12 and NEMA Type 3R Components

Note: You will need to consult the electrical schematic supplied with the drive and the appropriate wiring diagram in Appendix D.

Table 4: VSD Series NEMA Type 12 Enclosed IntelliPass Drive

Dimensions

Drive

Horsepower (VT)

208V, 1 – 15 hp

230V, 1 – 15 hp

480V, 1 – 30 hp

575V, 3 – 30 hp

208V, 20 – 30 hp

230V, 20 – 30 hp

480V, 40 – 75 hp

575V, 40 – 50 hp

208V, 40 – 60 hp

230V, 40 – 60 hp

480V, 100 – 150 hp

Floor Stands available on Box C only and can be purchased and shipped separately

as kit.

Frame

Size

FR4 – FR6

FR4 – FR6

FR4 – FR6

FR6

FR6 – FR7 B 20.92

FR8 C 30.92

Enclosure

Box

A 16.92

Approximate Dimensions in

Inches (mm)

ABC

(429.8)

(531.3)

(785.3)

29.00

(736.6)

40.00

(1016.0)

52.00

(1320.8)

18.60

(472.4)

19.10

(485.1)

19.10

(485.1)

Table 5: VSD Series NEMA Type 3R Enclosed IntelliPass Drive

Dimensions

Drive

Horsepower (VT)

208V, 1 – 15 hp

230V, 1 – 15 hp

480V, 1 – 30 hp

575V, 3 – 30 hp

208V, 20 – 30 hp

230V, 20 – 30 hp

480V, 40 – 75 hp

575V, 40 – 50 hp

208V, 40 – 60 hp

230V, 40 – 60 hp

480V, 100 – 150 hp

Floor Stands available on Box C only and can be purchased and shipped separately

as kit.

Frame

Size

FR4 – FR6 A 21.05

FR6 – FR7 B 26.31

FR8 C 37.73

Enclosure

Box

Approximate Dimensions in

Inches (mm)

ABC

(534.7)

(668.3)

(958.3)

33.00

(838.2)

46.09

(1170.7)

58.09

(1475.5)

19.57

(497.0)

20.07

(509.9)

20.08

(510.0)

NEMA Type 12

Figure 8: VSD Series Enclosed Drive Dimensions

10 For more information visit: www.johnsoncontrols.com LIT-1201858

Page 11

Powered by

Space Heater

Temperature

Setting

November 2009

Eaton’s Technology VSD Series Quick Start Guide

Enclosed NEMA Type 12/3R

Table 6: Bypass Power Wiring Instructions — NEMA Type 12/3R

Mounting Drive

1. Mount drive per dimensions. (See Page 10.)

2. Verify that the main power source is removed upstream.

3. Remove the keypad cable from the drive.

4. Remove the screws from the drive cover, and remove the

cover.

CAUTION

The circuit breaker extension bar is sharp and can cause injury.

5. Calibrate the circuit breaker amperage, so it is 1.25 times

the value on the motor nameplate, by turning the red set

screw located below the circuit breaker extension bar. See

the circuit breaker user’s manual supplied with the drive.

Keypad Cable

Circuit

Breaker

Extension Bar

Circuit

Breaker

Set Screw

Power and Ground Wiring

6. Using a Greenlee conduit cutter (recommended), cut three

holes in the drive’s enclosure for the incoming power,

motor and low-voltage control leads.

POWER WIRING

Note: Power, motor and control leads must each be

located in separate conduit.

• DO NOT RUN CONTROL WIRING in same conduit

with power wiring.

• Provide low impedance ground connection to drive

chassis.

• DO NOT CONNECT B+, B-, R terminal.

(Reserved for Braking Resistor only.)

7. Connect the incoming power leads to circuit breaker

terminals labeled L1, L2 and L3.

8. Using the torque wrench, tighten each terminal to

the torque value found in the appropriate user’s

manual supplied with the drive.

9. Connect the power ground wire to the ground stud.

Connect motor ground to ground stud.

Setting Space Heater

10. If applicable, set the space heater. See the space heater

user’s manual supplied with the drive.

Note: The space heater is used to prevent condensation from

damaging the equipment when the drive is not operating

(OFF).

Incoming

Power Leads

Power

Ground Wire

LIT-1201858

For more information visit: www.johnsoncontrols.com 11

Page 12

VSD Series Quick Start Guide Powered by

Enclosed NEMA Type 12/3R

Table 6: Bypass Power Wiring Instructions — NEMA Type 12/3R (continued)

Motor Wiring

11. Use your first and second fingers and simultaneously

push down to release the two orange retaining clips (one

on each side of the 24V DC motor overload terminal

block).

12. If necessary, use a flat-blade screwdriver to carefully

remove the terminal block in a straight plane to avoid

damaging it.

Setting Motor Overload

13. Lift to open the cover on the motor overload, and use a

1/8" flat-blade screwdriver to set the overload amperage

to match the value on the motor nameplate.

14. Turn the auto/manual reset (factory default is manual) on

the motor overload 90° to the auto position.

Bypass

Contactor

Assembly

Eaton’s Technology

November 2009

Orange

Retaining Clips

Auto/Manual

Reset

Motor Wiring

15. Connect the motor leads to the motor overload terminals

labeled 1TA, 1TB and 1TC.

16. Using the appropriate metric Allen wrench (2.5 mm, 3 mm

or 4 mm), tighten each overload terminal per the

specifications in the contactor user’s manual.

MOTOR WIRING

An SAE allen wrench will damage the terminals,

and the motor overload will need to be replaced

(not covered by warranty).

17. Using the torque wrench, tighten each terminal to

the torque value found in the appropriate user’s

manual supplied with the drive.

18. Reinsert the motor overload terminal block.

19. Connect the motor ground wire to the ground stud.

Note:

• Run motor cables in separate conduit.

• Do not run control wires in same conduit.

• Size motor leads per NEC.

• Provide low impedance ground.

Motor Leads

Bypass

Contactor

Assembly

Motor

Overload

Terminals

Motor

Ground

Stud

12 For more information visit: www.johnsoncontrols.com LIT-1201858

Page 13

Powered by

Eaton’s Technology VSD Series Quick Start Guide

November 2009

Enclosed NEMA Type 12/3R

Table 6: Bypass Power Wiring Instructions — NEMA Type 12/3R (continued)

Control Wiring

20. Use a flat-blade screwdriver to carefully remove the lowvoltage I/O terminal block.

21. Reinsert the I/O terminal block into the control board.

22. Terminate control wiring to the OPTA9 and OPTA2 board

(Terminals 1 – 26).

Note: Use 1/8" flat-blade.

CAUTION

• Run 110 Vac and 24 Vdc control wiring in separate conduit.

• Communication wire to be shielded.

• RS-232 keypad cable must be less then 25 feet (to prevent

nuisance trips).

Optional Spacer Heater

R

(DC 2)

FAN

Space Heater

Drive

Ground

Motor

Ground

Customer

Ground

Drive

Ground

(Optional)

Start/Stop

Speed Select 1

Fire Mode

Bypass Overload Fault

Note: See Figure 3

for Dip X1, X2,

X3, X6 Switch

settings.

LIT-1201858

Note: Optional COMM cards can be supplied

Note: supplied with the drive or as a field option.

Figure 9:

For more information visit: www.johnsoncontrols.com 13

Page 14

VSD Series Quick Start Guide Powered by

Enclosed NEMA Type 12/3R

Table 6: Bypass Power Wiring Instructions — NEMA Type 12/3R (continued)

Static Check

23. Use a Phillips screwdriver to remove all the faceplate

screws on the high-voltage faceplate, and remove the

faceplate.

Note: Location of the screws may vary from the drive

illustrated. There may be screws securing a bottom faceplate,

which also need to be removed.

Eaton’s Technology

November 2009

High-Voltage

Faceplate

Optional Bottom

Faceplate

Static Check

24. Make sure power is off, and perform static checks as

described in Table 7 (for the converter), Table 8

(for the inverter) and Table 9 (for the DC bus). Refer to

Page 21, Appendix H.

Note: Static check shown is for L3 and B+ terminals.

25. Once the pre-power static checks are completed,

reinstall the drive’s outer and side covers, tightening

all the screws.

WARNING

High Voltage is present on L1, L2, L3, B-, B+, BT, T1, T2, T3.

Starting Drive

26. Make sure that the drive’s 3rd contactor S1 switch, if

present, is in the ON position (shown in OFF position).

Note: The bypass mode operates with the switch in the OFF

position, however the drive will not run. Yet the keypad

will operate.

27. Reinsert the keypad cable and control board on

small drives.

Starting Drive

28. Close the drive door, and turn the circuit breaker handle in

a clockwise direction.

29. Go to Appendix E for keypad operation.

Note: If the circuit breaker latch is locked, use a flat-blade

screwdriver to turn the screw to release the handle.

L1, L2, L3 B-, B+, BT T1, T2, T3

WARNING

High Voltage

• Always work with another person.

• Be sure equipment is properly grounded.

• Wear safety glasses.

Start-Up Wizard

14 For more information visit: www.johnsoncontrols.com LIT-1201858

See Appendix G.

Page 15

Powered by

Eaton’s Technology VSD Series Quick Start Guide

November 2009

Appendix A — Main Control Board Wiring

Main Control Board Wiring Default in Slot A and B

+

Digital Input

24V DC

OPTA9 Slot A

24V DC

DI-1

DI-3

6

Close Terminal (6-8)

8

to Start VFD

10

Damper/External Interlock

Control Relay

Outputs

OPTA2 Slot B

CR Ratings

8A / 24V DC

.4A / 125V DC

.8A / 250V AC

Continuous Capacity

Analog Outputs

Analog Input

+

Com

+

–

AI-1

AI-2

12

21

22

23

24

25

26

18

19

2

3

4

5

(22-21) Opens on Run (Default)

(22-23) Closes on Run (Default)

(24-25) Opens on Fault (Default)

(25-26) Closes on Fault (Default)

AO-1

0-10V DC Factory Default Source Auto

4-20 mA Default

Setpoint Software Selectable

inStart-Up Wizard

+

Output Frequency (0-f max)

0-20 mA Default

–

500 Ω Resistor to be Added

for 0-10V DC

Applications

Remote Input

Duct Static

Building Static

Pressure Control

Temperature

Generic PI

+

24V DC

≤

2 RMS

PI Applications Using Internal Power Supply from VFD

AI+1

PI Feedback Pressure

0-10V DC Transducer

Connection

PI Feedback Pressure

4-20 mA Pressure

Transducer

2

3

12

3

4

6

0-10V DC

Com GND

24V DC

Com GND

AI+2

4-20 mA

24V DC

Figure 10: Wiring Diagrams (Default)

Out

Com

Power

Com

Out

Power

Pressure

Tra nsducer

Pressure

Tra nsducer

PI Feedback Sensor –

Used for the following

Applications

Duct Static

Building Static

Pressure Control

Temperature

Generic PI

Card is programmable for a 0 – 10V DC with change in jumper. Add X6 jumper on Board A6 from A-B to C-D.

LIT-1201858

For more information visit: www.johnsoncontrols.com 15

Page 16

VSD Series Quick Start Guide Powered by

Appendix B — Interlock Damper Start Example

Interlock Damper Start Example Using 4 – 20 mA Control Signal

Eaton’s Technology

November 2009

10 12

To Drive Damper

Interlock Terminals

Fan

Figure 11: Interlock Damper Start Example with

Remote 4 – 20 mA Application

Step 1. Wire Load, Line, Digital In/Out per example and verify

voltage and amperage

Step 2. Static check drive SCR, IGBT, DC Bus per Static Check,

Page 20 and 21

Step 3. Start-up Wizard (Remote Input Application)

Step. 4. Set Interlock Start P1.2.1 (Programmable Options)

0. Normal start with Interlock

1. Interlock start from one D1-2….D1-6 (D1-3 Default)

2. Interlock start and timeout supervision. If feedback is

not given in timeout request, the unit will not start.

3. Delay start from Run command

Note: Interlock damper controller works in drive or bypass.

Step 5. Select Hand to test motor rotation

Step 6. To verify proper motor rotation, press start and to

increase speed in Hand mode

HOA

+

Step 7. To run in Remote Auto mode, run Remote Auto –

Hit stop

HOA

Hit twice, enter

Send START Signal from Field Controller to start drive.

Field

Controller

Terminals

Damper Actuator

Input Terminals

Figure 12: Programming Example

OPTA9 Slot A

+

4 – 20 mA

-

Run

Factory

Jumper

OPTA2 Slot B

(D1-3 Default)

4

A1-2+ Speed

A1-2- Ref

5

6

24 Vdc Control

Close Terminal

(6 – 8) to start VFD

8

D1-1

D1-3 Run Permisive

10

Damper Interlock

(Default)

24 Vdc Control

12

Voltage

22

23

Closes on Run

(Default)

8 A/24 Vdc

.8 A/125 Vac

.4 A/250 Vac

16 For more information visit: www.johnsoncontrols.com LIT-1201858

Page 17

Powered by

Eaton’s Technology VSD Series Quick Start Guide

November 2009

Appendix C — Interlock Damper Start Example

Interlock Damper Start Example Using PID Duct Static Control Signal

Max WC = 2.5”

Main WC = 0.0”

Setpt WC = 2.0“

10 12

To Drive Damper

Interlock Terminals

Fan

Set PT Keypad Default

Error

Actual PI Feedback

A1-1, 0-10 Vdc Default

Figure 13: Interlock Damper Start with PID Duct Static Example

2.50”

Water

O

H

2

Step 1. Wire load line, digital I/O per example and verify

voltage and amperage

Step 2. Static check drive SCR, IGBT, DC Bus per Static Check,

Page 20 and 21

Step 3. Start-up wizard (Duct static application)

Step 4. Select hand to check motor rotation

Step 5. Press Start and to increase speed in Hand mode

Step 6. Select Remote to run in Auto

HOA

+

HOA

Step 7. Tune PID per diagram below

Out

Com

Power

Pressure

X Drive

Damper Actuator

Input Terminals

2

3

6

OPTA9 Slot A

Actual

+

0 ñ 10 Vdc

-

24 Vdc

Factory

Jumper

OPTA2 Slot B

A1-1+ 0 ñ 10 Vdc

2

A1-1- Default

3

24 Vdc Control

6

Close Terminal

(6 ñ 8) to Start VFD

8

D1-1

10

D1-3 Run Permisive

Damper Interlock

(Default)

12

24 Vdc Control Voltage

22

23

Closed on

Run

Default

8 A/24 Vdc

.8 A/125 Vac

.4 A/250 Vac

Hand Mode (M1)

P1.1.13

A1 - 1

A1 - 2

Keypad

Motor Pot

Actual PI (M1)

Feedback

P1.1.17

A1 - 1

A1 - 2

Fieldbus

Min A1-1, A1-2

Max A1-1, A1-2

Ave A1-1, A1-2

Sensor Parameter

Adjustments

Auto Mode (M1)

P1.1.15

A1 - 1

A1 - 2

OR

Keypad

Motor Pot

Fieldbus

Sensor

Output

Signal

PI Setpoint

Figure 15: PID Flow Chart

PI

Error

Amp

PID Gain (M1)

P1.1.20

PID I-Time

P1.1.21

PID Control D

P1.1.22

PI Ref Rise T

P1.1.23

PI Ref Fall Time

P1.1.24

PI Ref Max

P1.1.19

PI Ref Min

P1.1.18

Figure 14:

Output

Frequency

P10 Parameter

Adjustments

LIT-1201858

For more information visit: www.johnsoncontrols.com 17

Page 18

VSD Series Quick Start Guide Powered by

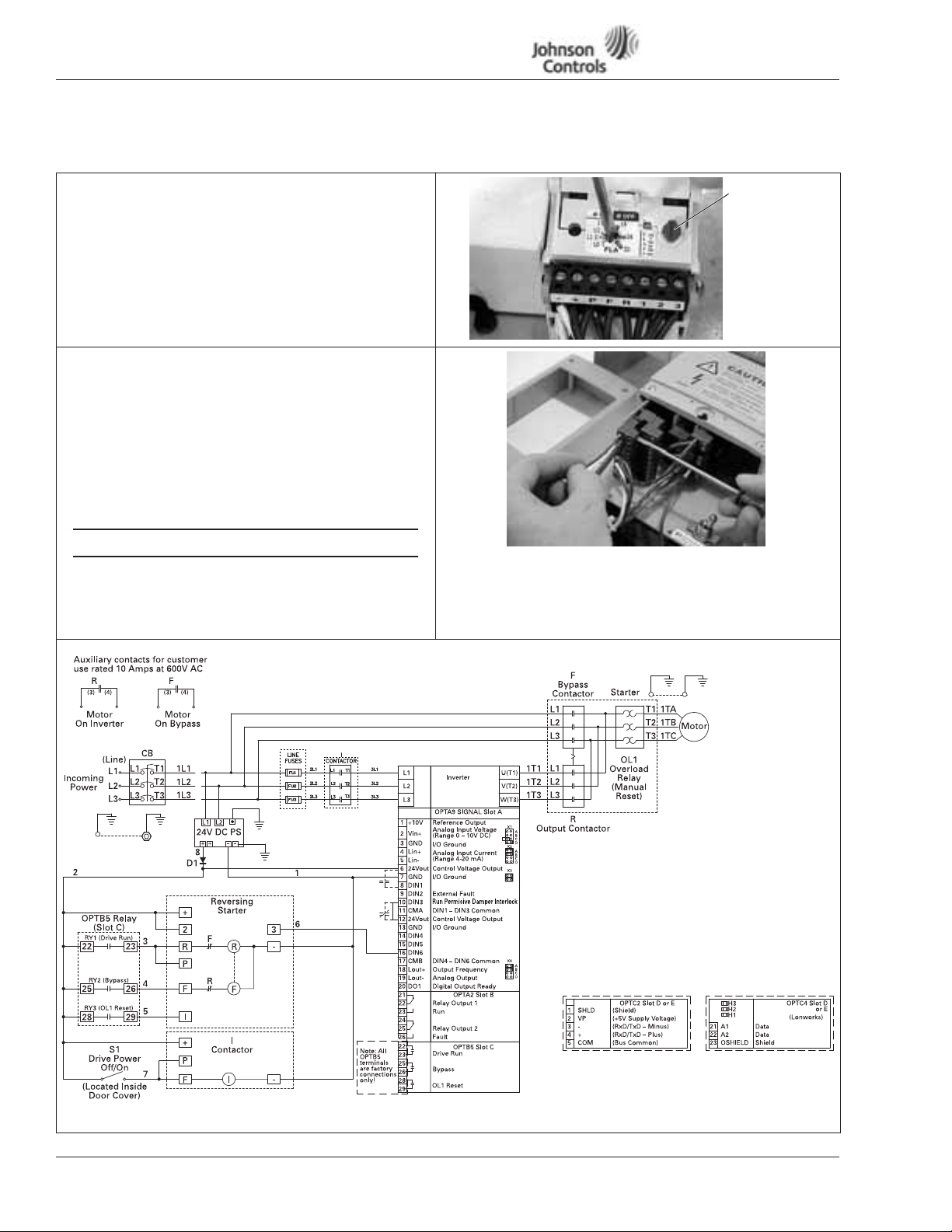

Appendix D — Bypass Wiring Diagram

Motor

Ground

Drive

Ground

B

C

A

D

X1

B

C

A

D

X2

for Dip X1, X2,

X3, X6 Switch

settings.

Note: See Figure 3

X3

B

C

A

D

X6

Eaton’s Technology

November 2009

Close Terminals 6 to 8 or 8 to 12

to Start VFD in Auto Mode.

Relays Shown in De-Energized State.

3

4

Run Motor Cables in Separate Metal Conduit or

Wire Tray.

Do Not Run with Control Wiring or Power Cables.

Cables to be Sized per NEC.

Provide Low Impedance Ground Connection Between

and Drive.

Reference Output

I/O Ground

Control Voltage Output

I/O Ground

External Fault

DIN1-DIN3 Common

Control Voltage Output

I/O Ground

Bypass Overload Fault

DIN4-DIN6 Common

Output Frequency

Analog Output

Fire Mode

DIN5

DIN6

CMB

Lout+

Digital Output Ready

Lout–

DO1

Enclosure and Motor(s) Must be Grounded.

See Instruction Manual. A continuous wire

must be run from drive to motor.

1

Jumper is Factory Installed to Enable

Start Permissive. Can be Replaced with

N/C Contact.

2

Analog Input Voltage

(Range 0-10V DC)

+1DV

Vin+

OptionalOptional

Start/Stop

Analog Input Current

(Range 4-20mA)

GND

Lin+

Lin–

24Vout

GND

DIN1

Speed Select 1

DIN2

DIN3

CMA

GND

DIN4

24Vout

Notes:

Ground

Drive

Customer

Ground

Run 110 Vac and 24 Vdc Control Wiring

in Separate Conduit.

Communication Wire to be Shielded.

Run Cabling in Separate Metal Conduit or Wire Tray.

Do Not Run With Control Wiring or Motor Cables.

Cables to be Sized per NEC.

Provide Low Impedance Ground Connection to

Drive Chassis.

Do Not Connect to B+, B-, R Terminals. These

Terminals are Used for External Braking or Single-

Incoming Power Connection Notes: Motor Connection Notes:

Phase Capacitors.

I/O Connection Notes:

RS-232 Keypad Cable Less Than 20 Feet.

Figure 16:

18 For more information visit: www.johnsoncontrols.com LIT-1201858

Page 19

Powered by

November 2009

Keypad Navigation

Eaton’s Technology VSD Series Quick Start Guide

Appendix E — Keypad Navigation

Figure 17: Keypad and Display

One Touch Operate Menu Navigation

Monitor Display

Navigation Left

Exit Operate Menu by navigating

to Programming display and

pressing ENTER button or simply

press ENTER button 1 second.

Acknowledgement password

Freq Ref Up

Freq Ref Down

value if defined.

Monitor Display

Navigation Right

Password ?

Note!

HOA OFF-MODE OR HAND-MODE

• Up and down arrows are used to

adjust speed setpoint

HOA AUTO-MODE

• Up and down arrows are used to

adjust PI-Setpoint

Programming Menu *

M1 Parameters

M2 Keypad Control

M3 Active Faults

M4 Fault History

M5 System Menu

M6 Expander Boards

M7 Monitor

Return to Operate

Note!

While in Programming

Menu the display will

automatically return to

default Operate Menu

display after 1 minute

of inactivity. (Time can

be adjusted with

Parameter P5.6.3).

or time delay

LIT-1201858

* See User Manual (LIT-1201828) for complete parameter list.

Figure 18: Operate Menu Navigation

For more information visit: www.johnsoncontrols.com 19

Page 20

VSD Series Quick Start Guide Powered by

Appendix F — Main Menu Navigation

Eaton’s Technology

November 2009

Main Menu Navigation

+

+

Menu Navigation:

Up Arrow

The up arrow advances

to the next menu item.

For example, pressing the

up arrow once will

advance from M1 to M2.

Down Arrow

The down arrow backs up to

the previous menu item.

For example, pressing the

down arrow once will back

up from M2 to M1.

Right Arrow

The right arrow will advance

to the next level in the menu.

For example, pressing the

right arrow once will

advance from M2 to R2.1.

Left Arrow

The left arrow will back up

one level in the menu structure.

For example, pressing the

left arrow once will back

up from R2.1 to M2.

+

+

+

+

+

+

M1 Programming

G1.1

. . .

G1.x

M2 Keypad Control

R2.1 Keypad Reference

. . .

P2.x Stop Button Active

M3 Active Faults

A3.1 Active Fault 1

T3.1.1 Operation Days

. . .

T3.1.13 Zero Speed

. . .

A3.x Active Fault x

M4 Fault History

H4.1 Most Recent Fault

T4.1.1 Operation Days

. . .

T4.1.13 Zero Speed

. . .

H4.1.x Oldest Saved Fault

M5 System Menu

S5.1 Language

S5.2 Application

S5.3 Copy Parameters

S5.4 Compare Parameters

S5.5 Security

S5.6 Keypad Settings

S5.7 Hardware Settings

S5.8 System Information

M6 Expander Boards

G6.1 Slot A Board

. . .

G6.5 Slot E Board

M7 Monitor

V7.1 Actual Speed

V7.2 Output Frequency

V7.3 Speed Setpoint

V7.4 Motor Speed

V7.5 Motor Current

V7.6 Motor Torque

V7.7 Motor Power

V7.8 Motor Voltage

V7.9 DC-Bus Voltage

V7.10 Unit Temperature

V7.11 Motor Temperature

V7.12 (A) AI-1

V7.13 (A) AI-2

V7.14 DI-1 DI-2 DI-3

V7.15 DI-4 DI-5 DI-6

V7.16 DO-1 RO-1 RO-2

V7.17 (A) AO-1

V7.18 ActFaultCode

V7.19 ActWarnCode

V7.20 Status Word

V7.21 PI-Setpoint

V7.22 PI-Input

V7.23 PI-Error

V7.24 PI-Output

V7.25 RO-1 RO-2 RO-3

G7.26 Multimonitor

M8 Operate Mode

O1 Output Frequency

O2 Actual Speed

. . .

Ox Motor Temperature

See Figure 3.

Parameter Menu Structure Example

M1 Programming Menu

+

G1.1 Quick Setup

+

G1.2 Input Signals

+

G1.3 Output Signals

+

G1.4 Drive Control

+

G1.5 Prohibit Frequency

+

G1.6 Motor Control

+

G1.7 Protections

G1.8 Fieldbus

+

G1.9 PI-Control

+

G1.10 Preset Speed

+

Figure 20: Parameter Menu Structure Example

P1.1.1 Minimum Frequency

P1.1.2 Maximum Frequency

. . .

P1.1.26 PI-Contr. I-Time

P1.2.1 Start Mode

P1.2.2 Intlk Timeout

. . .

P1.2.15 Setpoint Scale Max

P1.3.1 (A) AO-1 Function

P1.3.2 (A) AO-1 Filter

. . .

P1.3.21 Start Relay OFF Delay

P1.4.1 Start Function

P1.4.2 Stop Function

P1.4.3 Brake Choppper

P1.5.1 Range 1 Low Limit

. . .

P1.5.13 PH Acc/Dec Ramp

P1.6.1 Motor Control Mode

P1.6.2 V/Hz Optimization

. . .

P1.6.12 Identification

P1.7.1 Input Phase Supv

P1.7.2 4 mA Fault Response

. . .

P1.7.19 Automatic Restart

P1.8.1 FB Data Out 1

P1.8.2 FB Data Out 2

. . .

P1.8.8 FB Data Out 8

P1.9.1 Setpoint Min

P1.9.2 Setpoint Max

. . .

P1.9.14 Auto S-Curve Time

P1.10.1 Preset Speed 1

P1.10.2 Preset Speed 2

. . .

P1.10.7 Preset Speed 7

Figure 19: Main Menu Navigation

20 For more information visit: www.johnsoncontrols.com LIT-1201858

Page 21

Powered by

Eaton’s Technology VSD Series Quick Start Guide

November 2009

Appendix G — Start-Up Wizard

Start-Up Wizard

Duct Static, Building Static, Pressure Control, Temperature Control, Generic PI

Upon initial power up, the Start-Up Wizard guides the commissioner through the basic VSD Series setup.

The Start-Up Wizard may be set to function upon power up by setting parameter P5.5.3, or by pressing the

STOP/RESET button for 5 seconds while in the “Operate Menu”. The display will read “Start-Up Wizard

Activate!” after 5 seconds.

Start of the Start-Up Wizard

Language selection

Duct, Building, Pressure, Temperature, Generic PI

By pressing

By pressing

US/Metric units are used only in Duct,

Building, Pressure and Temperature applications.

Motor Name Plate current in Amps

XX.X A – Default will vary depending

on drive size

Motor Name Plate voltage in Volts

XXX V – Default is same as drive nominal

voltage

setup will start

the setup will be stopped

*

start up wizard

press enter

language

english

application

remote input

setup starts

press enter

US/ metric units

us

motor Np current

XX.X A

motor Np voltage

XXX V

Continued

1Steps:

2

3

4

5

6

7

Figure 21: Start-Up Wizard Navigation (1 of 3)

Note: Use for changing parameter. Then press ENTER to save and move forward.

LIT-1201858

For more information visit: www.johnsoncontrols.com 21

Page 22

VSD Series Quick Start Guide Powered by

Eaton’s Technology

November 2009

8Steps:

9

10

11

12

13

14

15

motor NP freq

60.00 Hz

motor NP rpm

1720 rpm

min. frequency

12.00 Hz

max. frequency

60.00

AUTO ACCEL Time

60.0s

AUTO DECEL time

60.0s

PI-input source

(a) ai-1

sensor min. scale

XXX.X

Motor Name Plate Frequency

default 60.00 Hz

Motor Name Plate Speed

1720 rpm

Drive Minimum Output Frequency

default 12.00 Hz

Drive Maximum Output Frequency

default 60.00 Hz

Acceleration time from zero to Max. Frequency,

when running in auto mode and PI-regulator is not active.

default 60.0 seconds

Deceleration time from Max. Frequency to zero,

when in auto mode and drive is stopped.

default 60.0 seconds

PI Input/Feedback Auto source, when PI is active:

AI-1 (0-10V DC); AI-2 (0-20 mA); Fieldbus

default AI-1

PID Input/Feedback device min. value

This value corresponds to the min. value of the sensor

output and to P1.2.10 or P1.2.14

(not available in Remote Input and Generic PI applications)

16

17

18

AI-1 Min.

0.0%

sensor max. scale

XXX.X

AI-1 Max.

100.00%

Continued

Figure 22: Start-Up Wizard Navigation (2 of 3)

Analog Input 1 min. value

0.00% = 0V

(not available in Remote Input and Generic PI applications)

PID Input/Feedback device max. value

This value corresponds to the max. value of the sensor

output and to P1.2.11 or P1.2.15

(not available in Remote Input and Generic PI applications)

Analog Input 1 max. value

100.00% = 10V

(not available in Remote Input and Generic PI applications)

22 For more information visit: www.johnsoncontrols.com LIT-1201858

Page 23

November 2009

Powered by

Eaton’s Technology VSD Series Quick Start Guide

19Steps:

20

21

22

23

PI-contr. p-gain

0.10

PI-contr I-time

30.00

PI-stpt

repeat setup?

NO yes

setup done

press enter

When keypad is used for copying

parameters to or from another drive

new keypad

press enter

copy parameters

NO yes

PI control gain value

default will vary depending on application

PI control integration time

default 30.00 second

PI Setpoint if source is fieldbus

(not available in Remote Input application)

Jump to

*

copy from keypad

NO yes

downloading . . .

wait. . .

copy to keypad

NO yes

uploading . . .

wait. . .

operate menu

default page

Figure 23: Start-Up Wizard Navigation (3 of 3)

Note: Start-Up Wizard can be cancelled with the STOP/RESET button. If pressed, the text “EXIT?” is shown

on the display along with “No” and “Yes”.

Note: In Pressure Control application, inverse selection is an option.

LIT-1201858

For more information visit: www.johnsoncontrols.com 23

Page 24

VSD Series Quick Start Guide Powered by

Remote Input Application

The Remote Input application uses a slightly different Start-Up Wizard:

1 4 6 10Steps: to , and to are exactly the same.

Eaton’s Technology

November 2009

New

Steps:

Skip to

Step:

12

13

14

15

22

Figure 24: Remote Input Start-Up Wizard

acceleration time

60 s

deceleration time

60 s

start srce auto

DI-1 start

stpt source auto

(a) ai-1

Acceleration time from min. Frequency

to max. Frequency

Deceleration time from max. Frequency

to min. Frequency

Keypad

DI-Start

I/O 3 wire

Fieldbus

(A) AI-1

(A) AI-2

Keypad StPt

Fieldbus

Start source location

Set point of Auto Source

24 For more information visit: www.johnsoncontrols.com LIT-1201858

Page 25

Powered by

November 2009

Eaton’s Technology VSD Series Quick Start Guide

Appendix H — Static Checking

Static Checking

Static checking tests the integrity of the power-carrying components (diodes, capacitors

and IGBTs) within the drive assembly. Performing these static checks ensures that no

damage occurred during shipping or installation that could cause a failure when the drive

is powered.

Make sure there is no power to the drive before proceeding with any of the static checks.

After checking each set of terminals, zero out the multimeter by touching the metal tips of

the red (positive) and black (negative) leads to each other.

Note: Set the multimeter to the diode function, and check each power terminal

consecutively with each DC bus terminal as indicated in Table 7.

Table 7: Static Checks of Converter

DC Bus Terminal Power Terminal Multimeter

L1 L2 L3

Reading

B+ (1st Overload Check)

Insert red (+) multimeter lead.

B- (2nd Overload Check)

Insert black (-) multimeter lead.

B- (1st Voltage Check)

Insert red (+) multimeter lead.

B+ (2nd Voltage Check)

Insert black (-) multimeter lead.

Insert black (-)

multimeter lead.

Insert red (+)

multimeter lead.

Insert black (-)

multimeter lead.

Insert red (+)

multimeter lead.

Insert black (-)

multimeter lead.

Insert red (+)

multimeter lead.

Insert black (-)

multimeter lead.

Insert red (+)

multimeter lead.

Insert black (-)

multimeter lead.

Insert red (+)

multimeter lead.

Insert black (-)

multimeter lead.

Insert red (+)

multimeter lead.

.OL

.OL

.25 – .55V DC

(±10%)

.25 – .55V DC

(±10%)

Note: Set the multimeter to the diode function, and check each motor terminal

consecutively with each DC bus terminal as indicated in Table 8.

Table 8: Static Checks of Inverter

DC Bus Terminal Motor Terminal on Contactor if Bypass or Output Contactor Multimeter

T1 T2 T3

B+ (1st Overload Check)

Insert red (+) multimeter lead.

B- (2nd Overload Check)

Insert black (-) multimeter lead.

B- (1st Voltage Check)

Insert red (+) multimeter lead.

B+ (2nd Voltage Check)

Insert black (-) multimeter lead.

Insert black (-)

multimeter lead.

Insert red (+)

multimeter lead.

Insert black (-)

multimeter lead.

Insert red (+)

multimeter lead.

Insert black (-)

multimeter lead.

Insert red (+)

multimeter lead.

Insert black (-)

multimeter lead.

Insert red (+)

multimeter lead.

Insert black (-)

multimeter lead.

Insert red (+)

multimeter lead.

Insert black (-)

multimeter lead.

Insert red (+)

multimeter lead.

Reading

.OL

.OL

.25 – .40V DC (±10%)

.25 – .40V DC (±10%)

LIT-1201858

For more information visit: www.johnsoncontrols.com 25

Page 26

VSD Series Quick Start Guide Powered by

Eaton’s Technology

November 2009

Appendix H — Static Checking, continued

Note: Set the multimeter to the ohm function, and check the power gµround terminal and

DC bus terminals as indicated in Table 9.

Note: Frame 6 and larger use a “Hybrid” rectifier section. “Shown in Service Manual.”

Readings will be different when taking measurements from (B+) DC.

Table 9: Static Checks of DC Bus

DC Bus Terminal DC Bus Terminal (B-) Ground Terminal (Power) Multimeter Reading

B+ (Overload Check)

Insert red (+) multimeter lead.

B+ (1st Ohm Check)

Insert black (-) multimeter lead.

B- (2nd Ohm Check)

Insert black (-) multimeter lead.

Insert black (-) multimeter lead. Not used. .OL

Not used. Insert red (+) multimeter lead. O.L

Not used. Insert red (+) multimeter lead. O.L

Figure 25 is a detailed schematic to aid in performing the static checks.

Continuity Test to Ground

Test L1, L2, L3 to ground.

T1, T2, T3 to ground.

This should read .OL ohms.

Figure 25: Schematic for Static Checks (Sample for Frames 4 and 5)

26 For more information visit: www.johnsoncontrols.com LIT-1201858

Page 27

Powered by

Eaton’s Technology VSD Series Quick Start Guide

November 2009

Appendix I — Fault and Warning Codes

Table 10: Fault and Warning Codes/Solutions

Fault

Code Fault Possible Cause Solution

1 Overcurrent VSD Series drive has detected a high current (>4xI

2 Overvoltage The DC-link voltage has exceeded its high limit due to:

3 Ground (Earth) Fault Current sensing indicates that the sum of motor phase

5 Charging Switch The charging switch was open, when the START

6 Emergency stop An Emergency stop signal was received from one of the

7 Saturation trip • defective component

8 System fault • component failure

9 Undervoltage DC-link voltage is less than the minimum safe operating

10 Input line supervision Input line phase is low or missing. Check the utility supply voltage, cables and connections.

11 Output phase supervision Current sensing indicates that there is no current in one

12 Brake chopper supervision • no brake resistor installed

13 VSD Series under-

14 VSD Series overtemperature Heatsink temperature is over 90°C. An overtemperature warning is issued when the heatsink

15 Motor stalled • motor or load mechanical failure

16 Motor overtemperature • motor is overloaded

17 Motor underload • mechanical or load problem

22

23

25 Microprocessor watchdog

temperature

EEPROM checksum fault • Parameter save fault

fault

output due to:

• sudden heavy load increase

• short in the motor

• short in the cables to the motor

• unsuitable motor

• too short a deceleration time

• high voltage levels or surges in the utility supply

currents is not zero.

• insulation failure in motor or motor cables

command was given due to:

• faulty operation

• component failure

digital inputs

• motor or motor cable short

• faulty operation

Note: exceptional fault data record, see Active Fault Menu

for more information

voltage limit

• most probable cause: too low a utility supply voltage

• VSD Series internal fault

motor phase

• brake resistor is broken

• brake chopper failure

Heatsink temperature is under -10°C Provide supplemental heating or relocate the VSD Series

• load too high

• stall parameter settings incorrect

• motor overheating has been detected by VSD Series •

motor temperature model

• underload parameter settings incorrect

• faulty operation

• component failure

• faulty operation

• component failure

) in its

Check loading.

n

Check motor.

Check cables.

Make the deceleration time longer.

Use brake chopper and brake resistor (standard on some

models, available as options on others).

Correct utility supply voltage (level is too high).

Add input impedance to limit surges.

Check motor and motor cables.

Reset the fault and restart. Should the fault re-occur,

contact your Johnson Controls distributor.

Determine reason for the Emergency stop and remedy it.

Cannot be reset from the keypad.

Switch off power.

IF THE PROBLEM IS NOT IN THE MOTOR OR ITS CABLES,

DO NOT RE-CONNECT POWER!

Contact your Johnson Controls distributor.

If this fault appears simultaneously with Fault 1, check the

motor and motor cables.

Reset the fault and restart. Should the fault re-occur,

contact your Johnson Controls distributor.

If there was a supply voltage loss or dip, reset the fault

and restart the VSD Series drive. Check the supply

voltage. If it was within specification at the time of the

fault, an internal failure has occurred. Contact your

Johnson Controls distributor.

Check the motor cables, connections and motor.

Check the brake resistor. If the resistor is ok, the chopper

is faulty. Contact your Johnson Controls distributor.

drive to a warmer location.

temperature exceeds 85°C, a fault occurs at 90°C. Check

for the correct amount and unrestricted flow of cooling

air.

Check the heatsink for dust or dirt buildup.

Check the highest ambient temperature level.

Make sure that the switching frequency is not set too high

in relation to the ambient temperature and motor load.

Check the motor, mechanical system and load level.

Confirm the stall parameter settings.

Decrease the motor load.

If no motor overload exists, check the temperature model

parameters.

Check the motor, check for a loose belt, broken coupling

or load problems.

Confirm underload parameter settings.

Upon reset of this fault, the VSD Series drive will

automatically reload the parameter default settings.

Check all parameter settings after reset. If the fault

reoccurs, contact your Johnson Controls distributor.

Reset the fault and restart. If the fault reoccurs, contact

your Johnson Controls distributor.

LIT-1201858

For more information visit: www.johnsoncontrols.com 27

Page 28

Appendix I — Fault and Warning Codes, continued

Table 10: Fault and Warning Codes/Solutions (continued)

Fault

Code Fault Possible Cause Solution

26 Start-up prevented Start-up of the drive has been prevented. Check Start Enable/Interlock settings.

29 Thermistor fault The thermistor input of an option board has detected a

31 IGBT temperature hardware IGBT Inverter Bridge overtemperature protection has

32 Fan cooling The VSD Series cooling fan did not start when

high motor temperature

detected high short term overload current

commanded

34 CAN bus communication Sent message not acknowledged Ensure that there is another device on the bus with the

36 Control unit Control unit cannot control the power unit and vise-versa Change control unit.

37 Device change • option board changed

• different power rating of drive

38 Device added • option board added

• drive of different power rating added

39 Device removed • option board removed

• drive removed

40 Device unknown Unknown option board or drive Contact your Johnson Controls distributor.

41 IGBT temperature software IGBT Inverter Bridge overtemperature protection has

42 Brake resistor

overtemperature

43 Encoder fault Note: the exceptional Fault data record. See Active Fault

detected high short term overload current

Brake resistor overtemperature protection has detected

excessive braking

Menu for more information. Additional codes:

1 Encoder 1 channel A is missing

2 Encoder 1 channel B is missing

3 Both encoder 1 channels are missing

4 Encoder reversed

50 Analog input I

(for signal range 4 to 20 mA)

< 4 mA

in

Current at the analog input is

< 4 mA

• control cable is broken or loose

• signal source has failed

51 External fault Digital input set as an external fault input has been

52 Keypad communication fault The connection between the control keypad and the VSD

53 Communication bus fault The data connection between the communication bus

triggered.

Series drive has been lost.

master and the communication bus board has failed

54 Slot fault Defective option board or slot Check that the board is properly installed and seated in

82 BypassOverLoad The motor has been overloaded while connected to the

bypass

Check the motor cooling and the motor loading.

Check the thermistor connection.

(If the thermistor input of an option board is not being

used, it must be short-circuited.)

Check loading.

Check motor size.

Contact your Johnson Controls distributor.

appropriate configuration.

Reset.

Note: No fault time data record!

Reset.

Note: No fault time data record!

Reset.

Note: No fault time data record!

Check loading.

Check motor size.

Set the deceleration time longer.

Use an external brake resistor.

Check encoder channel connections.

Check the encoder board.

Check the current loop, signal source and wiring.

Check source of trigger.

Check keypad connection and keypad cable.

Check installation.

If installation is correct, contact your Johnson Controls

distributor.

slot. If installation is correct, contact your Johnson

Controls distributor.

Decrease the motor load.

Disable the Current Imbalance feature – see the IT.

manual.

Controls Group

507 E. Michigan Street

P.O. Box 423

Milwaukee, WI 53201

Powered by

Eaton’s Technology

© 2009 Johnson Controls

All Rights Reserved

Printed in USA

LIT-1201858

www.johnsoncontrols.com

November 2009

Loading...

Loading...