Johnson Controls VB30, VB24, VB36, VM09, VM12 Installation, Operation And Maintenance Manual

...Page 1

INDOOR PACKAGED EQUIPMENT

Installation, Operation, and Maintenance Supersedes: 145.18-IOM1 (115) Form 145.18-IOM1 (818)

HIGH EFFICIENCY VSCS SERIES

VERTICAL STACKED WATER SOURCE HEAT PUMP

LD27626

CABINET MODEL VB/VM/VS09–36

AND

CHASSIS MODEL VSCS09–36

R-410A

ISSUE DATE:

August 30, 2018

Page 2

FORM 145.18-IOM1

ISSUE DATE: 8/30/2018

IMPORTANT!

READ BEFORE PROCEEDING!

GENERAL SAFETY GUIDELINES

This equipment is a relatively complicated apparatus.

During rigging, installation, operation, maintenance,

or service, individuals may be exposed to certain components or conditions including, but not limited to:

heavy objects, refrigerants, materials under pressure,

rotating components, and both high and low voltage.

Each of these items has the potential, if misused or

handled improperly, to cause bodily injury or death. It

is the obligation and responsibility of rigging, installation, and operating/service personnel to identify and

recognize these inherent hazards, protect themselves,

and proceed safely in completing their tasks. Failure

to comply with any of these requirements could result

in serious damage to the equipment and the property in

which it is situated, as well as severe personal injury or

death to themselves and others at the site.

This document is intended for use by owner-authorized

rigging, installation, and operating/service personnel. It

is expected that these individuals possess independent

training that will enable them to perform their assigned

tasks properly and safely. It is essential that, prior to

performing any task on this equipment, this individual

shall have read and understood the on-product labels,

this document and any referenced materials. This individual shall also be familiar with and comply with

all applicable industry and governmental standards and

regulations pertaining to the task in question.

SAFETY SYMBOLS

The following symbols are used in this document to alert the reader to specific situations:

Indicates a possible hazardous situation

which will result in death or serious injury

if proper care is not taken.

Identies a hazard which could lead to

damage to the machine, damage to other

equipment and/or environmental pollution if proper care is not taken or instructions and are not followed.

Indicates a potentially hazardous situation which will result in possible injuries

or damage to equipment if proper care is

not taken.

External wiring, unless specied as an optional connection in the manufacturer’s product line, is not

to be connected inside the control cabinet. Devices such as relays, switches, transducers and controls

and any external wiring must not be installed inside the micro panel. All wiring must be in accor-

dance with the manufacturer's published specications and must be performed only by a qualied

electrician. The manufacturer will NOT be responsible for damage/problems resulting from improper

connections to the controls or application of improper control signals. Failure to follow this warn-

ing will void the manufacturer’s warranty and cause serious damage to property or personal injury.

WARNING: This product can expose you to chemicals including formaldehyde, which is known

to the state of California to cause cancer. For more information, go to www.P65Warnings.ca.gov.

2

Highlights additional information useful

to the technician in completing the work

being performed properly.

Page 3

FORM 145.18-IOM1

ISSUE DATE: 8/30/2018

CHANGEABILITY OF THIS DOCUMENT

In complying with the manufacturer's’ policy for continuous product improvement, the information contained in this document is subject to change without

notice. There is no commitment to update or provide

lifting, and operating/service personnel should verify

whether the equipment has been modified and if current

literature is available from the owner of the equipment

prior to performing any work on the equipment.

current information automatically to the manual or

product owner. Updated manuals, if applicable, can be

CHANGE BARS

obtained by contacting the nearest service office.

Revisions made to this document are indicated with a

It is the responsibility of rigging, lifting, and operating/

service personnel to verify the applicability of these

documents to the equipment. If there is any question

regarding the applicability of these documents, rigging,

line along the left or right hand column in the area the

revision was made. These revisions are to technical in-

formation and any other changes in spelling, grammar

or formatting are not included.

ASSOCIATED LITERATURE

MANUAL DESCRIPTION FORM NUMBER

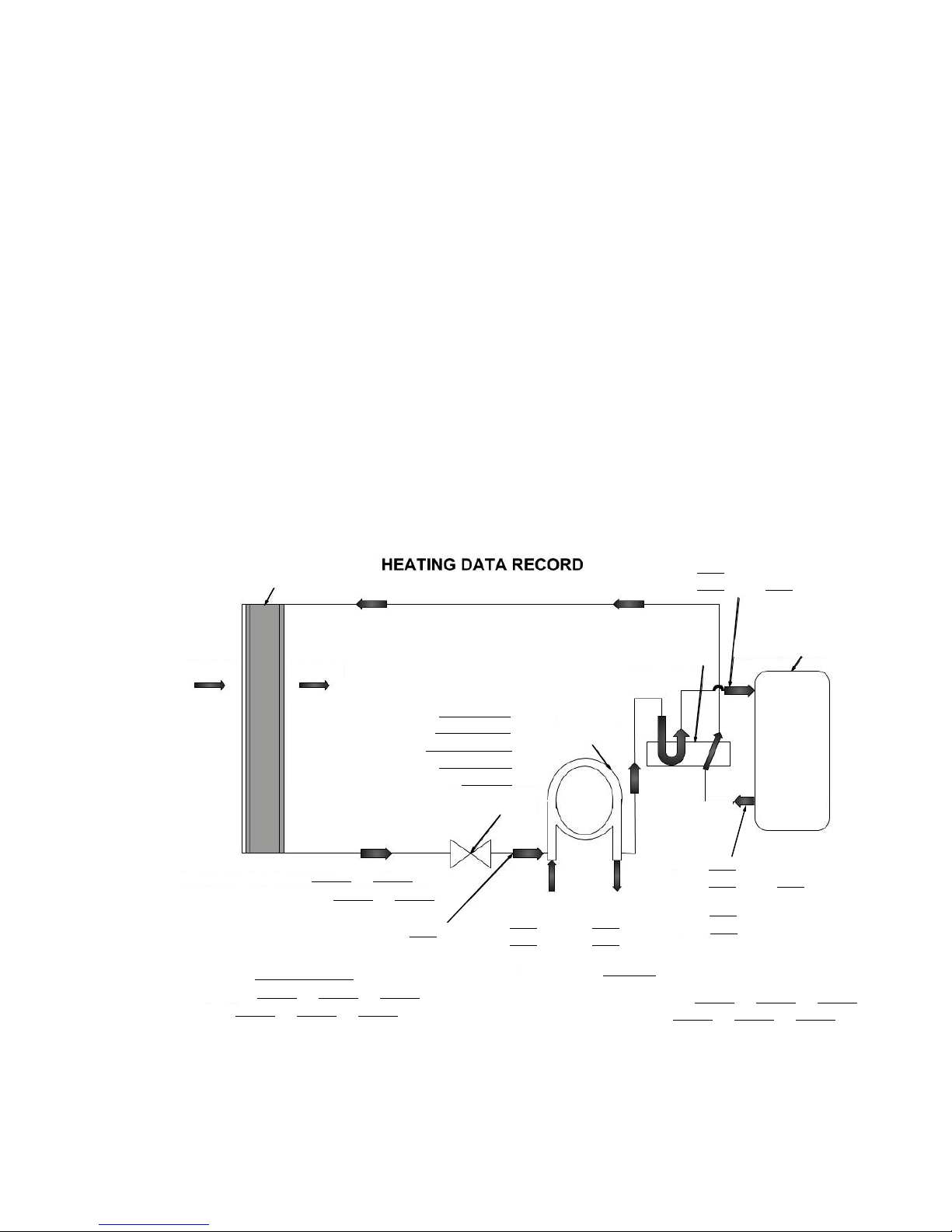

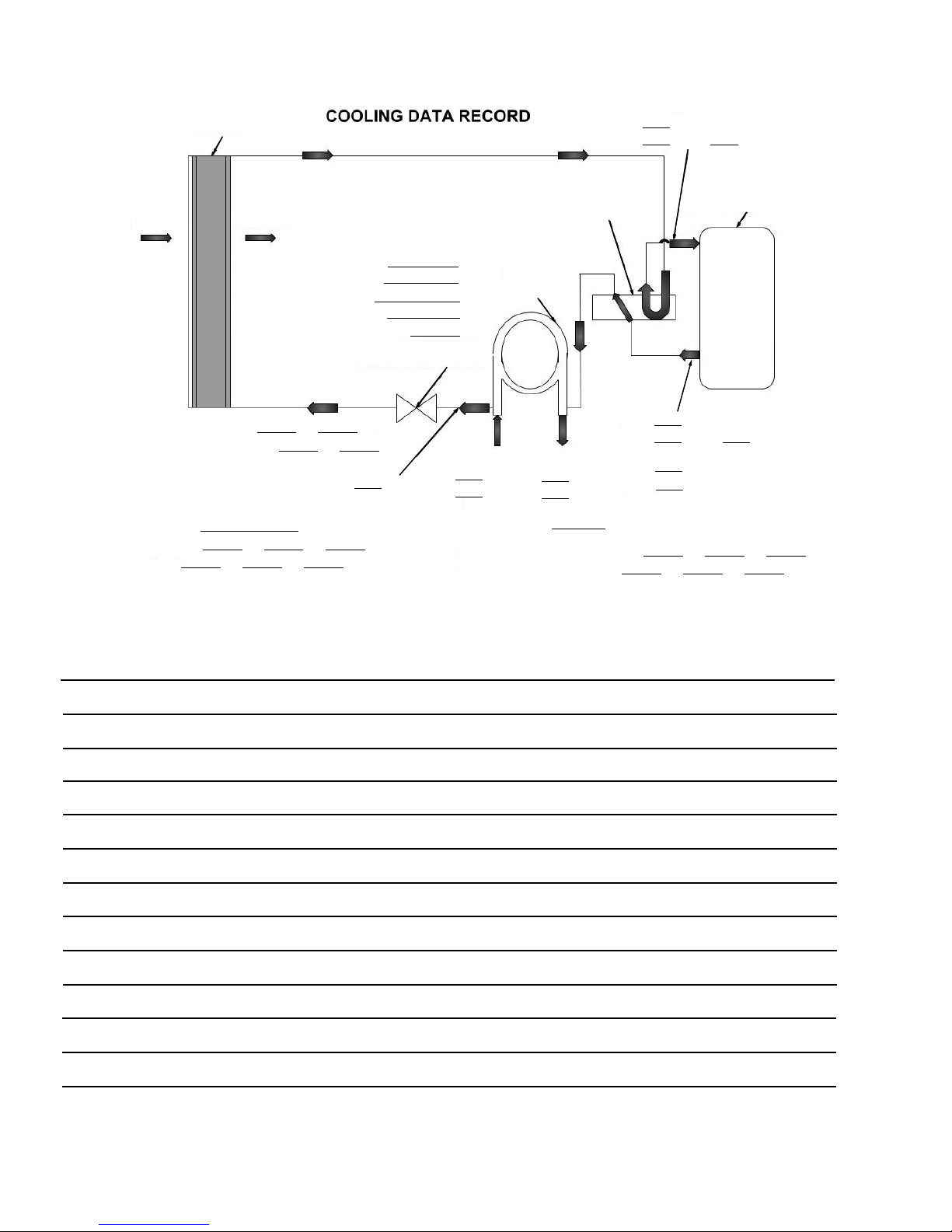

Vertical Stacked Heat Pump Start-Up and Performance Checklist 145.18-CL1

Vertical Stacked Water Source Heat Pump Heating and Cooling Data Record Sheet 145.18-CL2

3

Page 4

FORM 145.18-IOM1

ISSUE DATE: 8/30/2018

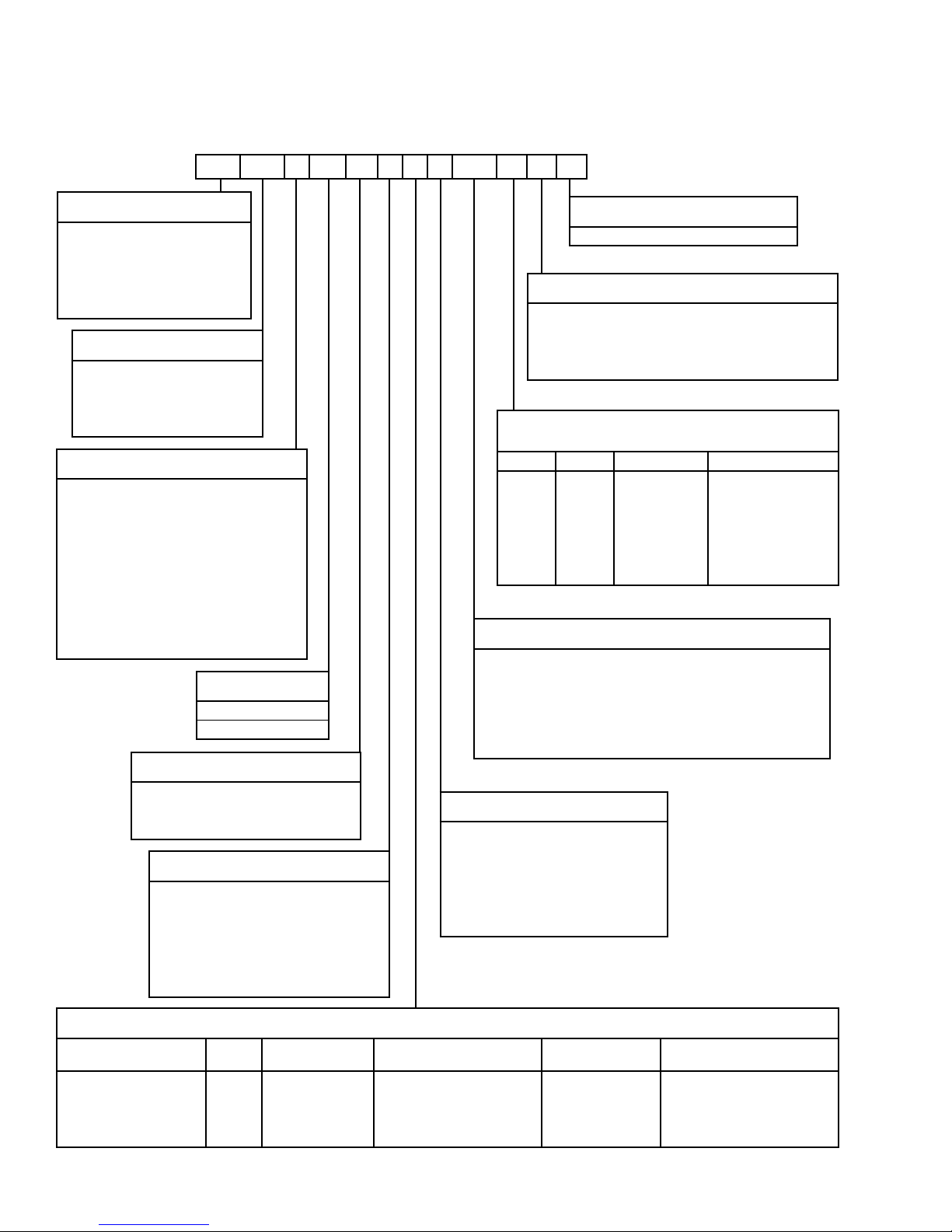

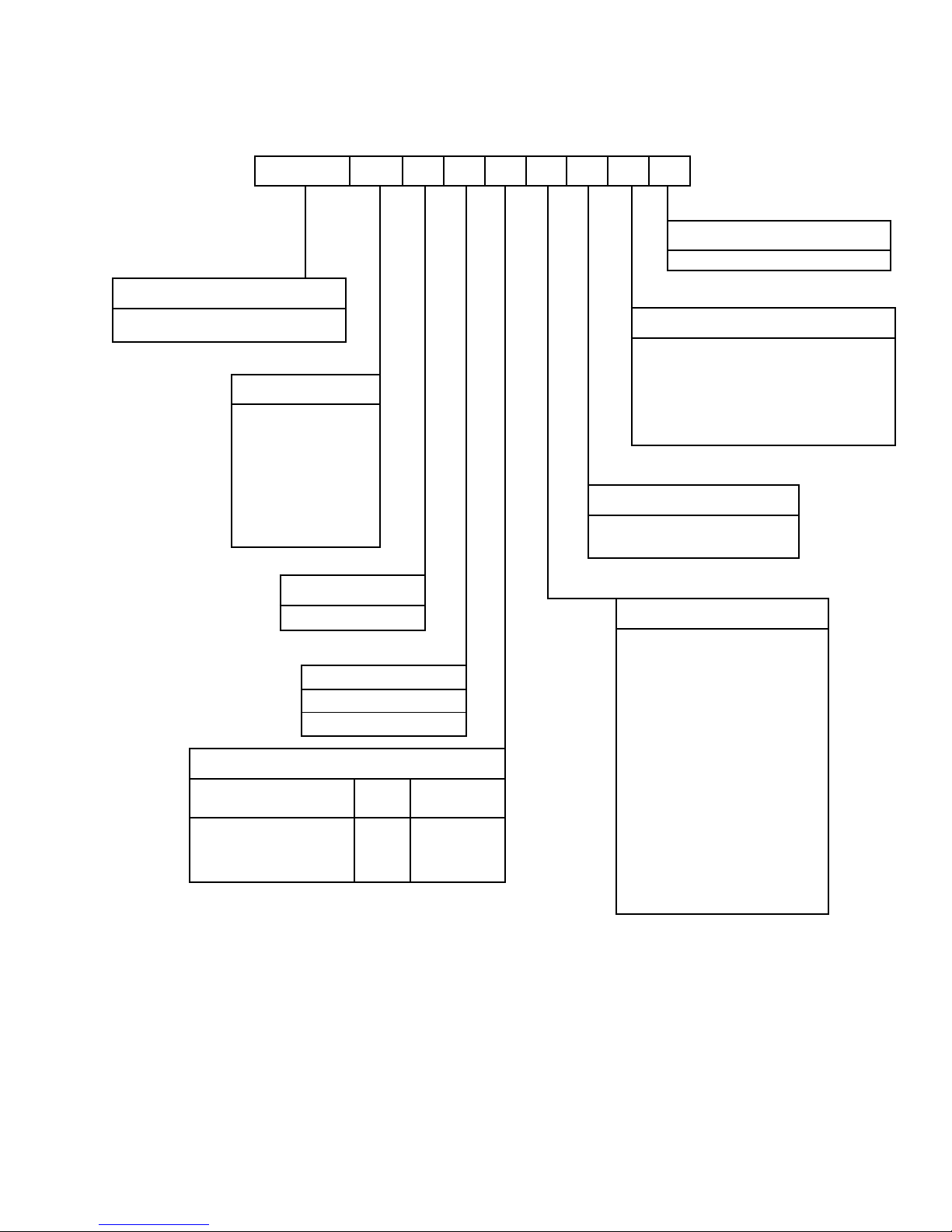

CABINET NOMENCLATURE

1, 2 3, 4 5 6 7 8 9 10 11, 12 13 14 15

VB 12 M 1 D E A 2 2T 4 0 C

PRODUCT CATEGORY

VB = Vertical Stacked Heat Pump -

Standard Cabinet Assembly

VM = Vertical Stacked Heat Pump -

Master Cabinet Assembly

VS = Vertical Stacked Heat Pump -

Satellite Cabinet Assembly

UNIT CAPACITY

09 = 0.75 TON 24 = 2 TON

12 = 1 TON 30 = 2.5 TON

15 = 1.25 TON 36 = 3 TON

18 = 1.5 TON

CONTROL OPTIONS

M = Microprocessor (MP) Control with 2-Speed

Unit Mounted Switch

2 = MP Control with 2-Speed Thermostat Control

3 = MP Control with 3-Speed Thermostat Control

P = MP Control with Surface-Mount Thermostat

Connection with Unit Mounted Switch

4 = MP Control with Surface-Mount Thermostat

Connection with 2-Speed Thermostat Control

5 = MP Control with Surface-Mount Thermostat

Connection with 3-Speed Thermostat Control

(ECM Only)

VOLTAGE

1 = 208/230-60-1

6 = 265-60-1

ELECTRICAL CONNECTION

0 = None (Terminal Block)

D = Non-Fused Disconnect

F = Disconnect with Fuses

BLOWER OPTIONS

A = PSC Blower

B = Hi-Static PSC Blower

E = ECM Blower

F = Hi-Static ECM Blower

G = ECM with Continuous Low Speed

H = Hi-Static ECM with Continuous Low Speed

DESIGN SERIES

C = Current Generation

MISCELLANEOUS OPTIONS

0 = None

S = Stainless Steel (SST) Drain Pan

F = MERV 8 Filters

C = SST Drain Pan with MERV 8 Filters

HORIZONTAL DISCHARGE OPENING

ORIENTATION

00, 0T 1H, 1T 2H, 2T 3H, 3T

X = None B = Back 1 = Left + Front 7 = Front + Left + Right

F = Front 2 = Left + Back 8 = Front + Right + Back

L = Left 3 = Left + Right 9 = Front + Left + Back

R = Right 4 = Right + Back

5 = Right + Front

6 = Back + Front

SUPPLY AIR CONFIGURATION

1H = Single Horizontal Supply 2T = Double Horizontal Supply

2H = Double Horizontal Supply

3H = Triple Horizontal Supply 3T = Triple Horizontal Supply

0T = Top Only

1T = Single Horizontal Supply

+ Top

+ Top

+ Top

00 = Field Cut (No Openings)

RISER ARRANGEMENT

1 = Right Hand Risers

2 = Left Hand Risers

3 = Back Risers

4 = Right Hand Risers with Cover

5 = Left Hand Risers with Cover

6 = Back Risers with Cover

CABINET OPTIONS

Cabinet Height

88 inches A G L R W

80 inches B H M T X

80 inches with 4-inch Stand D K P V Z

80 inches with 8-inch Stand F 2 4 6 8

No OA

Options

Left Top OA Entry

(4-inch Round)

4

Left Top OA Entry (4-inch

Round with Motorized Damper)

Right Top OA Entry

(4-inch Round)

Right Top OA Entry (4-inch

Round with Motorized Damper)

Page 5

FORM 145.18-IOM1

ISSUE DATE: 8/30/2018

1, 2, 3, 4 5, 6 7 8 9 10 11 12 13

VSCS 12 C 1 0 0 A C 0

PRODUCT CATEGORY

VSCS = Vertical Stacked Heat Pump Chassis

R-410A

UNIT CAPACITY

09 = 0.75 TON

12 = 1 TON

15 = 1.25 TON

18 = 1.5 TON

24 = 2 TON

30 = 2.5 TON

36 = 3 TON

CHASSIS NOMENCLATURE

MISCELLANEOUS OPTIONS

O = None

WATERSIDE OPTIONS

C = Standard Water Coil

B = Standard Water Coil with Low Temperature

Option

N = Cupro-Nickel Water Coil

R = Cupro-Nickel Water Coil with Low Temperature

Option

AIRSIDE OPTIONS

A = Standard Airside Coil

C = Corrosion Protective Coating

DESIGN SERIES

C = Current Generation

VOLTAGE

1 = 208/230-60-1

6 = 265-60-1

WATER VALVE & PUMP OPTIONS

VALVE OPTIONS

No Water Control Valve

Motorized 2-Way Shut-Off Valve

Motorized 3-Way Shut-Off Valve

VALVE

ONLY

Y-STRAINER

O S

M Y

N V

AUTO-FLOW REGULATOR

0 = No Flow Control Valve

B = 1.5 USGPM

C = 2.0 USGPM

D = 2.5 USGPM

E = 3.0 USGPM

F = 3.50 USGPM

H = 4.0 USGPM

J = 4.5 USGPM

K = 5.0 USGPM

L = 6.0 USGPM

M = 7.0 USGPM

N = 8.0 USGPM

P = 9.0 USGPM

R = 10.0 USGPM

5

Page 6

FORM 145.18-IOM1

ISSUE DATE: 8/30/2018

TABLE OF CONTENTS

SECTION 1 - INSTALLATION ..................................................................................................................................9

Notice and Disclaimer ......................................................................................................................................9

Disclaimer ................................................................................................................................................9

Pre-Installation .................................................................................................................................................9

Literature .................................................................................................................................................9

Shipping ..................................................................................................................................................9

Inspection and Storage .........................................................................................................................10

Preparations for Installing the Unit ........................................................................................................10

Rigging .................................................................................................................................................. 11

Cabinet Riser Installation ............................................................................................................................... 11

Placing the Cabinet ............................................................................................................................... 11

Riser Loop ...................................................................................................................................................... 16

Hoses .............................................................................................................................................................16

Electrical Wiring .............................................................................................................................................. 18

Field-Installed Power Wiring ..................................................................................................................18

Field-Installed Low Voltage Wiring ........................................................................................................18

Optional Surface Mount Thermostat Connection Wiring ....................................................................... 19

Optional Remote Mounted Thermostat Wiring ...................................................................................... 19

Optional ADA Door Mounted Thermostat .............................................................................................. 20

EC Motor (ECM) Continuous Fan .........................................................................................................20

Closet and Drywall Installation .......................................................................................................................20

Acoustic Return Air (RA) Panel ......................................................................................................................20

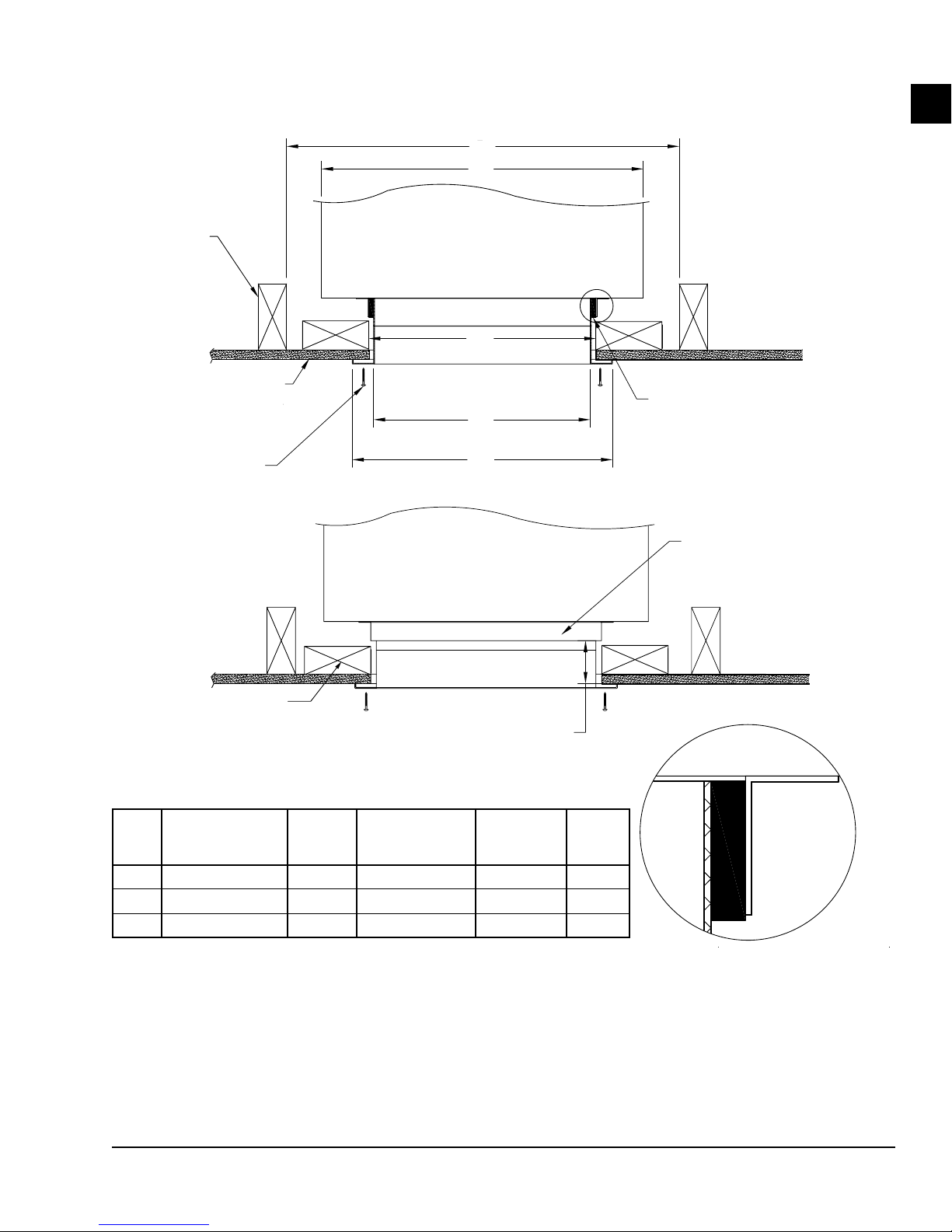

Supply Air (SA) Ductwork ............................................................................................................................... 24

Horizontal Supply Air ............................................................................................................................. 24

Top Discharge Supply Air ......................................................................................................................24

Top Mounted Fresh Air Intake ........................................................................................................................27

Top Mounted Fresh Air Intake with Motorized Damper .........................................................................27

System Flushing and Cleaning ...................................................................................................................... 28

Flushing the System .............................................................................................................................. 28

Cleaning the System .............................................................................................................................29

Chassis Installation ........................................................................................................................................32

For Units with NPSH Valve Connection and Hose Sets ........................................................................ 32

For Units with NPT Style (Tapered Pipe Thread) Valve Connection and Hoses ...................................32

SECTION 2 - OPERATION .....................................................................................................................................35

Pre-Start-Up Checklist .................................................................................................................................... 35

Initial Unit Start-Up .........................................................................................................................................35

System Loop Temperature .............................................................................................................................36

Fan Speed Adjustment ................................................................................................................................... 36

Unit Controls ................................................................................................................................................... 40

Sequence of Operation .........................................................................................................................40

Continuous Blower ................................................................................................................................40

Safety Control Reset .............................................................................................................................40

Operation Errors .................................................................................................................................... 41

Safety Controls ...................................................................................................................................... 41

Random Start ........................................................................................................................................42

Compressor Protection ..........................................................................................................................42

Microprocessor Control Unit Flash Codes .............................................................................................42

Communication ....................................................................................................................................42

6

Page 7

FORM 145.18-IOM1

ISSUE DATE: 8/30/2018

TABLE OF CONTENTS (CONT'D)

SECTION 3 - MAINTENANCE ................................................................................................................................ 43

APPENDIX ..............................................................................................................................................................45

Heating and Cooling Data Record Sheet .......................................................................................................49

R-410A Quick Reference Guide ..................................................................................................................... 51

LIST OF FIGURES

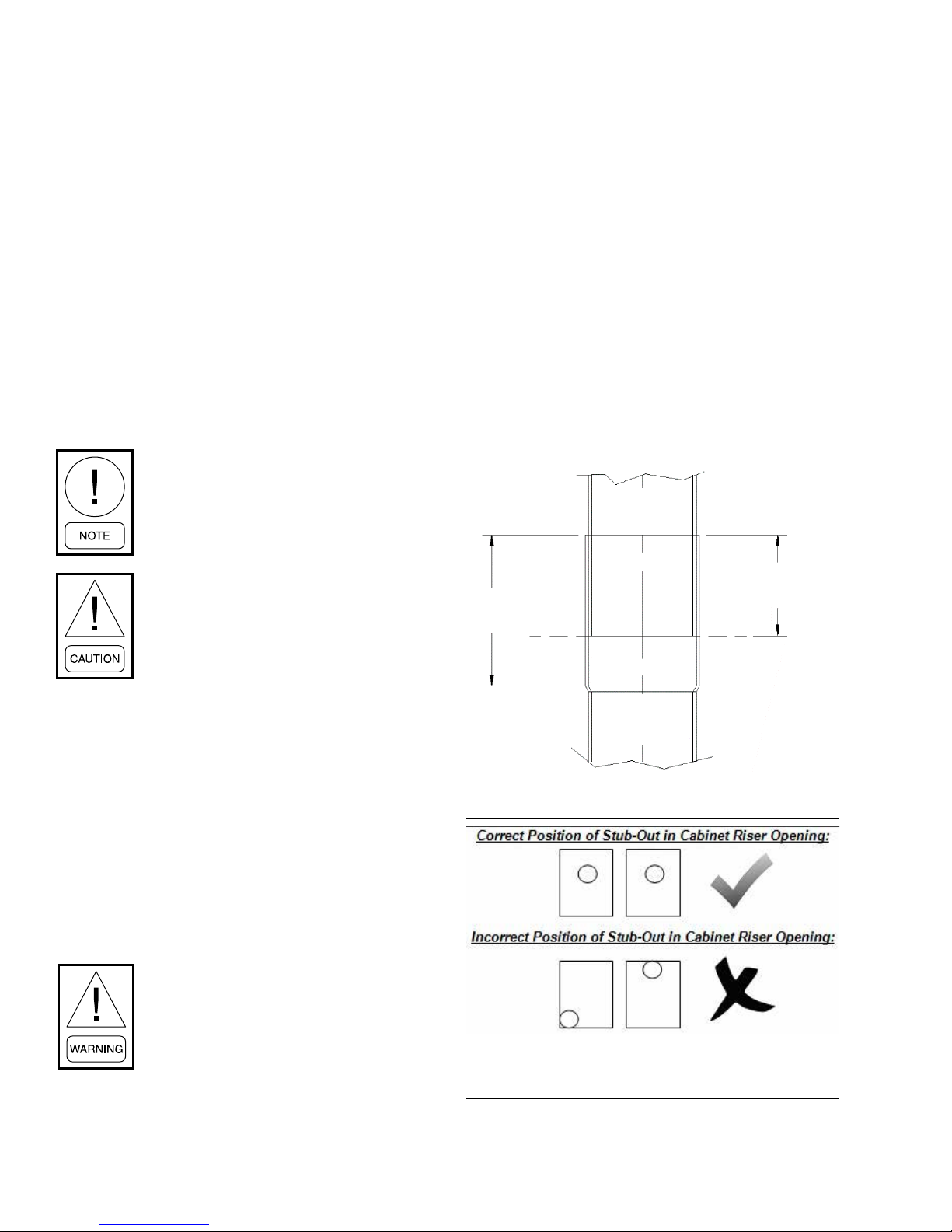

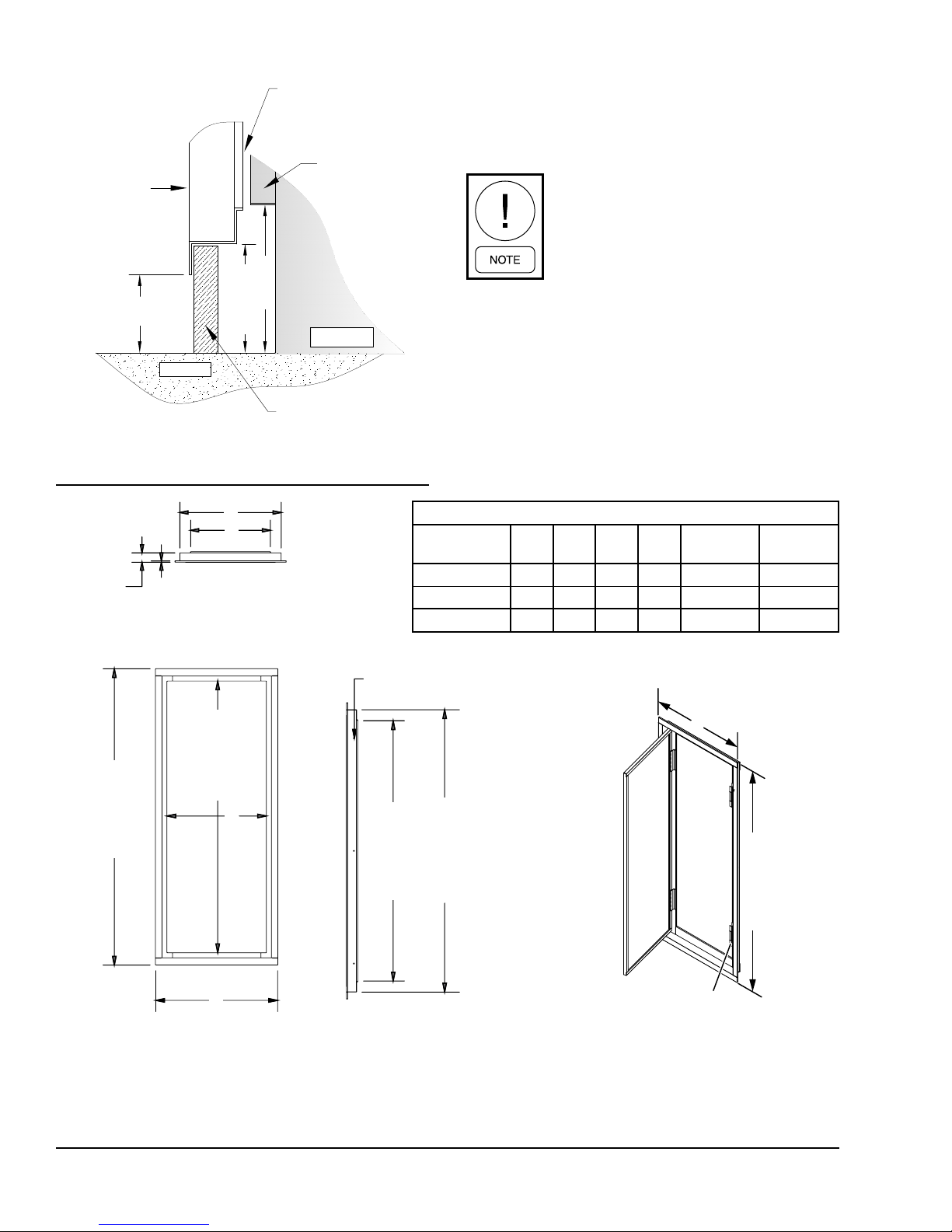

FIGURE 1 - Ideal Riser Insertion Depth ..................................................................................................................12

FIGURE 2 - Correct/Incorrect Stub-Out Positions in Cabinet Riser Opening ..........................................................12

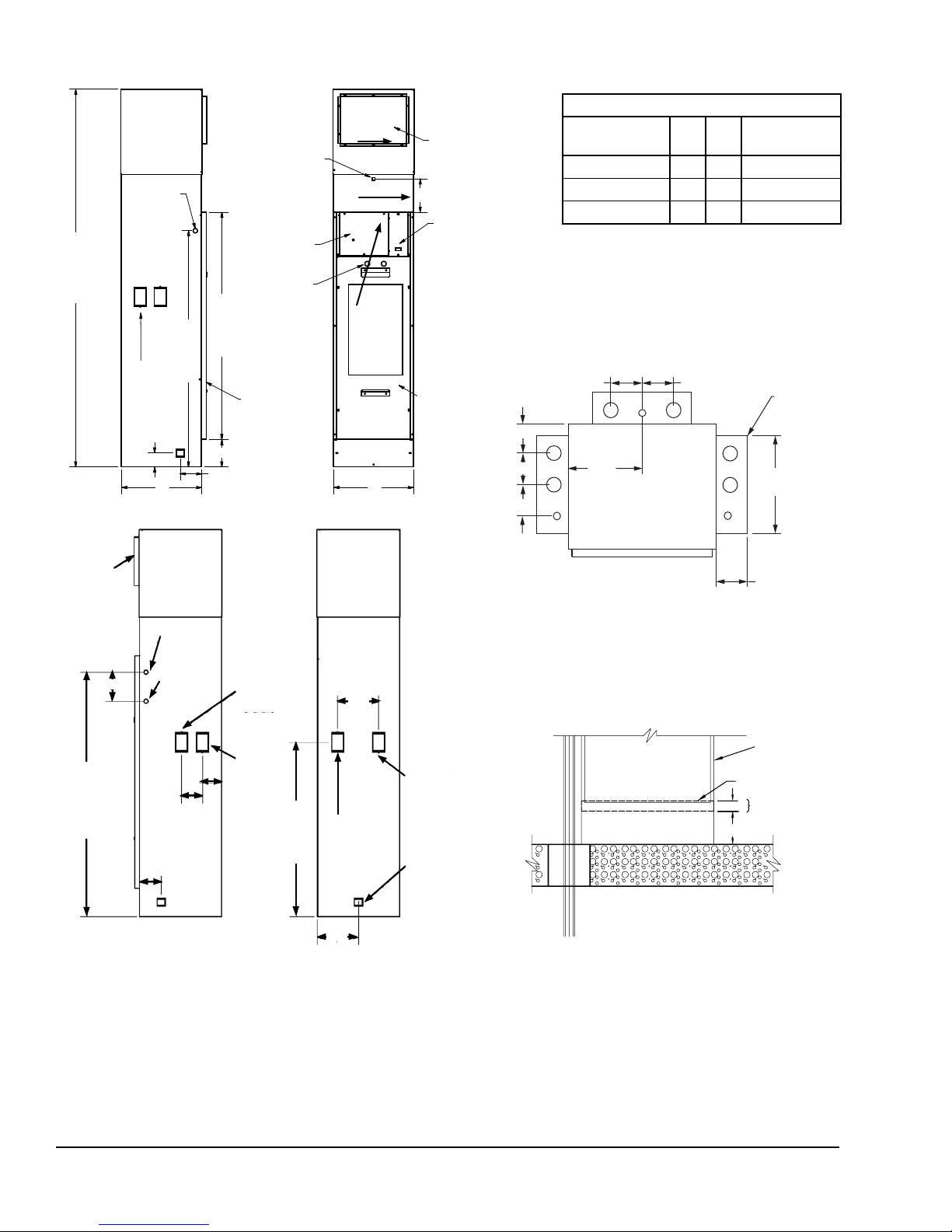

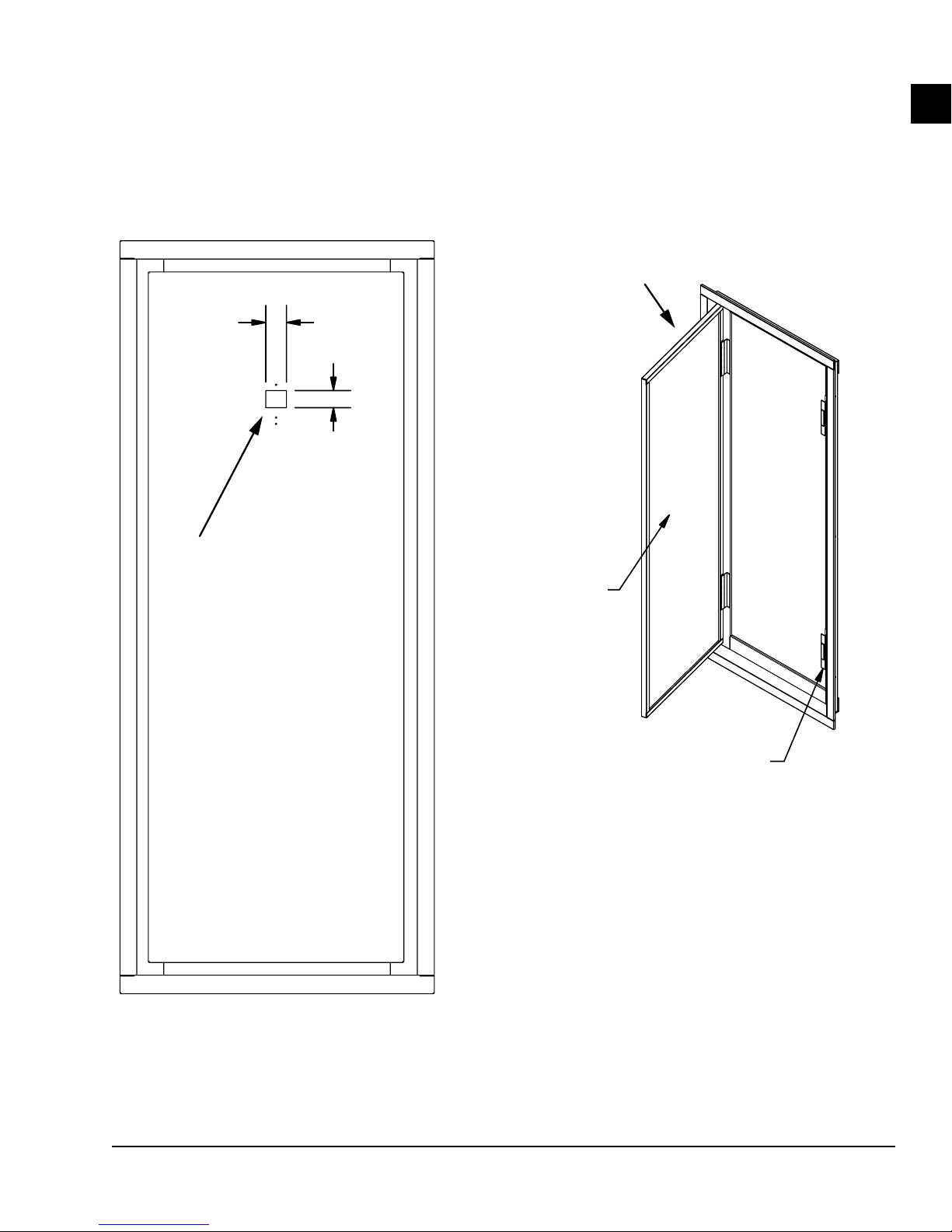

FIGURE 3 - Cabinet Unit Dimensions & Floor Sleeve Dimensions .........................................................................14

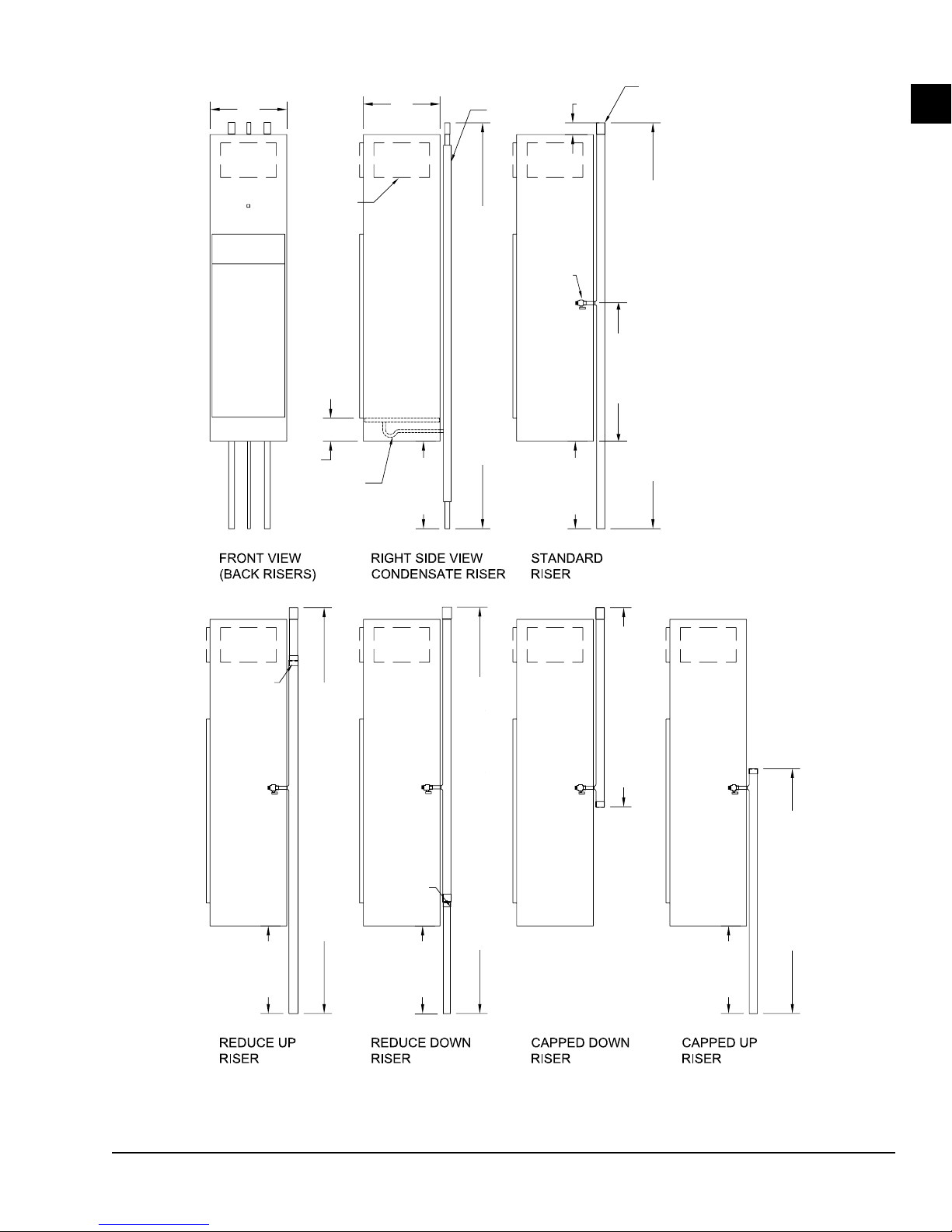

FIGURE 4 - Cabinet Riser Dimensions ...................................................................................................................15

FIGURE 5 - Standard Factory Supplied NPSH Hose Kits and Risers.....................................................................17

FIGURE 6 - Optional Field Supplied Risers with Factory Supplied NPSH Hose Kits and Shut-Off Valves .............17

FIGURE 7 - Conversion of NPT to NPSH Type Fittings (VB Units with NPT Fittings Only) ....................................18

FIGURE 8 - Field Wiring Diagram ...........................................................................................................................19

FIGURE 9 - Remote Thermostat Wiring ..................................................................................................................19

FIGURE 10 - Unit Switch Plate with ADA Thermostat Connection .......................................................................... 20

FIGURE 11 - Critical Return Air (RA) Panel with Unit Cabinet Installation Dimensions ..........................................21

FIGURE 12 - RA Panel Cross Section Installation at Floor Level ...........................................................................22

FIGURE 13 - RA Panel Dimensions ........................................................................................................................22

FIGURE 14 - Optional RA Panel with ADA Mounted Thermostat ............................................................................23

FIGURE 15 - Supply Grille with Volume Damper and 1/8-inch Neoprene Tape Applied to Perimeter ....................24

FIGURE 16 - Unit Mounted Supply Grille Installation ..............................................................................................25

FIGURE 17 - Damper Plate Fasteners ....................................................................................................................27

FIGURE 18 - Remove the Red Cover .....................................................................................................................27

FIGURE 19 - Position Black Cover..........................................................................................................................28

FIGURE 20 - System Flushing and Cleaning ..........................................................................................................29

FIGURE 21 - Fresh Air Opening without Motorized Damper – Left and Right Hand Unit Shown ...........................30

FIGURE 22 - Fresh Air Opening with Motorized Damper – Left and Right Hand Unit Shown ................................31

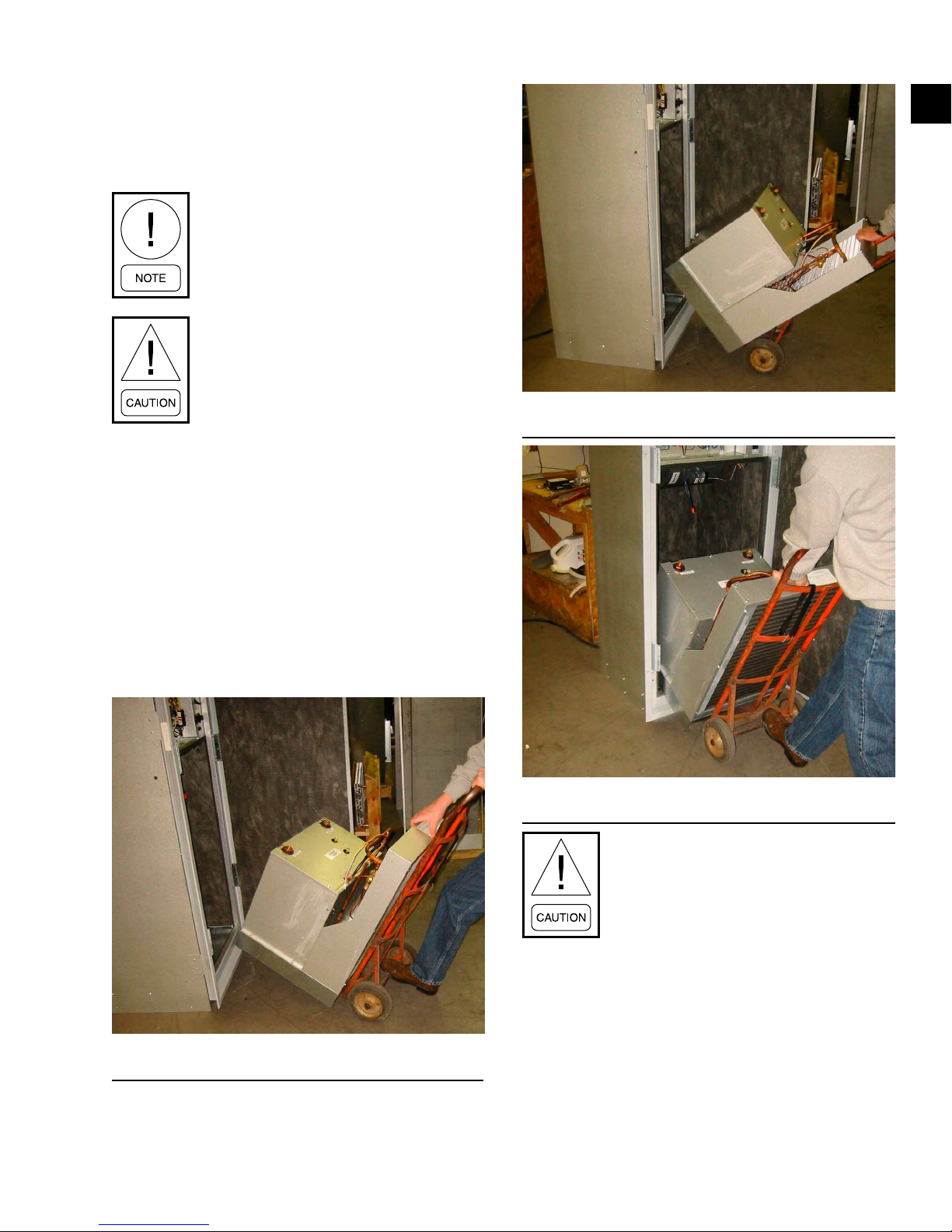

FIGURE 23 - Lift the Chassis Front .........................................................................................................................33

FIGURE 24 - Tilt the Chassis ..................................................................................................................................33

FIGURE 25 - Insert the Chassis ..............................................................................................................................33

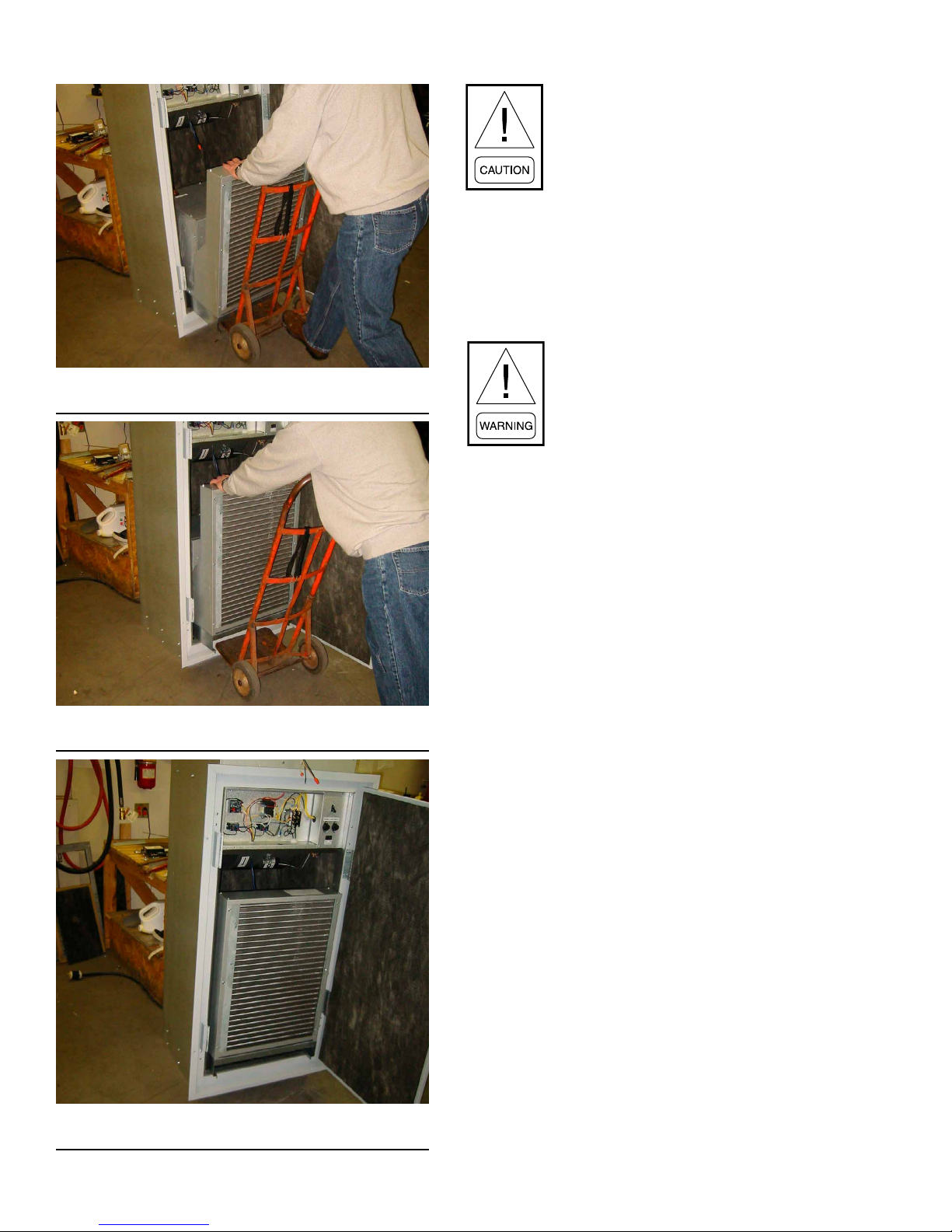

FIGURE 26 - Pivot the Chassis ...............................................................................................................................34

FIGURE 27 - Slide the Chassis ...............................................................................................................................34

FIGURE 28 - Check the Chassis .............................................................................................................................34

FIGURE 29 - PSC Motor Wiring Diagram ...............................................................................................................45

FIGURE 30 - ECM Wiring Diagram .........................................................................................................................46

FIGURE 31 - Continuous Fan with ECM Wiring Diagram .......................................................................................47

FIGURE 32 - Motorized Damper ECM Wiring Diagram ..........................................................................................48

7

Page 8

FORM 145.18-IOM1

ISSUE DATE: 8/30/2018

LIST OF TABLES

TABLE 1 - High Series Physical Data .....................................................................................................................13

TABLE 2 - Replacement Hose Gaskets ..................................................................................................................16

TABLE 3 - Chassis Hoses .......................................................................................................................................16

TABLE 4 - Typical Wire Connections ......................................................................................................................19

TABLE 5 - Unit Supply Opening Sizes ....................................................................................................................26

TABLE 6 - Unit Supply Face Velocity (FPM) ...........................................................................................................26

TABLE 7 - Operating Limits ....................................................................................................................................36

TABLE 8 - PSC Standard Blower Performance (CFM) ...........................................................................................37

TABLE 9 - PSC High Static Blower Performance (CFM) ........................................................................................37

TABLE 10 - ECM Standard Blower Performance (CFM) ........................................................................................38

TABLE 11 - ECM High Static Blower Performance (CFM) ......................................................................................38

TABLE 12 - ECM Blower Performance - All Speed Taps (CFM) ............................................................................. 39

TABLE 13 - Flash Codes ........................................................................................................................................42

8

Page 9

FORM 145.18-IOM1

ISSUE DATE: 8/30/2018

SECTION 1 - INSTALLATION

After installing the unit, show the user

how to turn off the electricity to the unit.

Point out control and switch locations for

turning off the electricity.

Ensure the user understands the importance of following all safety precautions.

NOTICE AND DISCLAIMER

This unit contains refrigerant installed by the factory

that is approved for use in the unit’s intended country

of installation or market. Distributors are only authorized to provide refrigerants that have been approved

for use in the countries or markets they serve.

The refrigerant used in this unit is identified on the

unit's nameplate and in this manual. Any additions of

refrigerant into this unit must comply with the country’s requirements with regard to refrigerant use and

should be obtained from manufacturer approved distributors. Use of unapproved refrigerant substitutes

will void all warranties and can cause injury or death.

1

Modifications may invalidate product certifications or

violate country standards. Any person or entity making

changes to the product is responsible for obtaining the

required engineering review and approval, as well as

covering certification and other related costs.

Unauthorized customer modifications to certified

products are prohibited for the following reasons:

A. Modications may create hazards that could result

in death, serious injury, or equipment damage.

B. Modications will void product warranties.

C. Modications may invalidate product certica-

tions and may violate country standards. Country

standards may require that only certied products

be used in certain applications, and modications

that result in the loss of product certication may

violate those standards.

PRE-INSTALLATION

Literature

Disclaimer

Customer modifications to certified products are prohibited. If performed without the express written approval of the manufacturer, modifications will void

all warranties (expressed or implied) and may result

in hazardous situations resulting in equipment damage,

serious physical injury or property damage, or death.

The manufacturer has certified the product as being

compliant with applicable government and/or industry

standards. Product certification is designated either on

the product itself or in the product literature. The certification mark identifies the applicable standards as

well as the Nationally Recognized Test Lab (NRTL) or

other testing facility that conducted the testing, where

applicable.

If changes are made to the product, an engineering review is required to assess the impact to the product certification. In some instances, the changes may require

that the NRTL or testing facility review and re-approve

the product by means of a field or site inspection and

certification.

Review this Installation, Operation, and Maintenance

(IOM) manual prior to installation. After installing the

unit, give this IOM to the end user. If help is needed

with any of the installation instructions or matters relating to the unit, contact the sales office where you

bought the unit. You may also refer to the unit rating

plate for a contact name.

Shipping

Cabinets and risers ship in one of the following configurations:

• Cabinets are stacked on their side with risers attached. Chassis ship on separate skids.

• Risers ship loose, packaged in boxes and sorted

by oor. Cabinets ship upright up to four per skid.

Chassis ship on separate skids.

• Risers ship loose, packaged in boxes, and sorted

by oor. Cabinets ship upright on skids with chassis inside the cabinet. Chassis electrical and water

connections are not installed. The chassis is secured to the service panel. Remove the screws before removing the service panel and chassis.

The cabinet must remain standing upright. Do not

place cabinets on their side with the chassis inside.

9

Page 10

SECTION 1 - INSTALLATION

FORM 145.18-IOM1

ISSUE DATE: 8/30/2018

Inspection and Storage

Store cabinets, chassis, and risers the same way they

were shipped. Ensure the storage area is dry and protected from the environment. Keep the units in their

upright position. If the risers are stored at the job site,

ensure the pipe ends are capped to prevent foreign object debris and contamination.

In areas where construction is not complete (including

dry wall, plaster, paint, and where any emission of dust

particulates or fumes from outgassing are present), all

precautions must be taken to protect the cabinet, openings, and chassis from contamination or physical damage.

Upon delivery, perform the following inspections:

1. Inspect the unit for shipment damage. Notify the

Transportation Company of any damage and note

the damage on the shipping receipt.

Rough handling may dislocate and damage internal components.

• Remove the inner service panel and manually

check the blower wheel for free rotation.

• Match the refrigeration chassis to the proper cabinets by referring to the cabinet and chassis nameplate and label information.

• Remove the chassis refrigeration access panel

(top cover) and inspect the unit. Ensure that the

refrigerant tubing is free from obvious physical

damage and kinks, and check that piping does not

touch other unit components.

• Ensure the compressor is mounted on neoprene

isolators with metal spacing sleeves inside. Secured it with nuts that are snug against the metal

spacer sleeves.

• Inspect all electrical connections. Connections

must be clean and tight at the terminals.

Do NOT use the risers to lift the cabinet

assembly.

2. Inspect the riser projections at each end of the

cabinet for misalignment or end damage that

would prevent making an acceptable connection.

3. Inspect the thermostats and other accessories that

have been shipped separately for quantity and

transit damage.

Store the refrigeration chassis in the normal upright

orientation to maintain oil in the compressor sump.

Preparations for Installing the Unit

Before installing the unit, perform the following preparations:

• Verify the model number on the unit nameplate

with the ordering and shipping information to ensure the correct unit has been shipped.

• Carefully inspect each unit before delivery to the

installation site. All cabinets may not be equipped

with the same size riser or the same air supply

grille arrangement. In most cases, each cabinet is

individually tagged for a specic location in the

building.

Do NOT install this unit outdoors.

A compressor/unit comprises a pressurized system. Never loosen threaded joints

while the system is under pressure, and

never open pressurized system parts.

Before servicing, open and tag all disconnect switches.

Do NOT install units in a flammable

environment due to the danger of an

explosion.

• Keep the cabinet sealed with the shipping materials until all plastering, painting, and construction

work is complete.

10

Page 11

FORM 145.18-IOM1

ISSUE DATE: 8/30/2018

SECTION 1 - INSTALLATION

Safety guards, shields, barriers, covers, and protective devices must not be

removed while the compressor/unit is

operating.

All safety features, disengagement, and

interlocks must be in place and function

correctly before the equipment is put into

operation. Never bypass or wire around

any safety device.

Use gloves and protective goggles where

appropriate and have a gas mask close at

hand. Use electrical protection equipment

and tools suited for electrical operations.

Personnel must be qualied according

to national safety rules and regulations.

CABINET RISER INSTALLATION

Do NOT use the risers to lift or move the

cabinets.

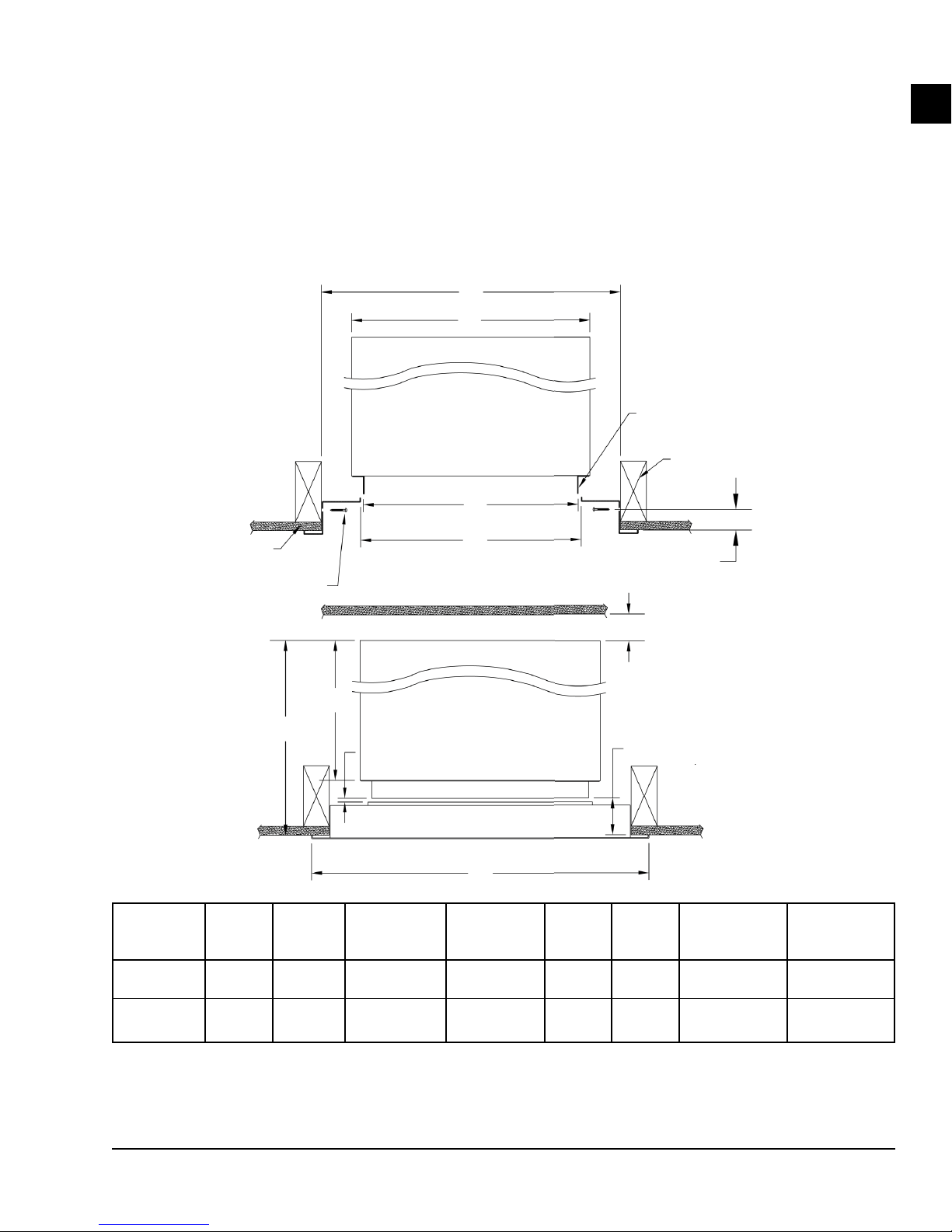

Refer to Figure 3 on page 14, which shows the

correct location of the cabinet in relation to the floor

sleeve and risers.

Risers are not designed to support or lift any part of the

cabinet. Do not use them to lift a cabinet. Risers are attached using nylon ties to allow for slight adjustments

during installation, and expansion of riser column during operation. Take care during installation to avoid

damage to risers and riser stub-outs.

Improper handling and installation of

risers could damage riser stub-outs and

valves and could result in property damage, death, or serious injury.

1

Only manufacturer- qualied personnel

should install this system. If not, it may

cause water leakage, electric shock, or

re.

Rigging

Follow all applicable regulations and

safety practices during rigging and lifting.

Prepare and follow written rigging and lifting plan.

Lifting must be directed by trained, professional rigger.

Spreader bars must be used and be long enough to prevent rigging from contacting unit. Use only the designated lift points according to unit's IOM, and use ALL

lift points.

Locate the center of gravity through trial lifts to account for possible variations in unit configuration. Use

rigging and lifting techniques that keep the unit stable

and level. Keep clear of unit when lifted.

Do not allow the risers to bottom out. Riser

stub-out should be centrally located with

the stub-out opening of the cabinet riser.

Do not allow riser stub-outs or risers to

contact cabinet sheet metal.

Do not drag risers on the oor while moving the cabinet.

When the risers are shipped loose, riser installation can

be completed before cabinet installation. When installing risers, ensure the riser stub-outs are centered in the

the cabinet openings. Ensure that the risers cannot bottom out in swage (see Figure 1 on page 12).

When risers are shipped attached to cabinets, complete

the installation of risers and cabinet at the same time.

Detaching the riser from the cabinet is unnecessary.

Placing the Cabinet

The correct location of the cabinet in relation to the

floor sleeve and risers is shown in Figure 3 on page

14. To place the cabinet correctly, perform the following steps:

11

Page 12

SECTION 1 - INSTALLATION

FORM 145.18-IOM1

ISSUE DATE: 8/30/2018

1. Place the cabinet in a horizontal position on the

oor adjacent to its installation location (when risers are attached to cabinet).

The units are designed to accommodate a maximum supply and return riser stub-out movement

of 1-1/2 inches due to expansion and contraction

(total movement of 3 inches). If the total calculated riser expansion or contraction exceeds 1-1/2

inches, the field must provide expansion compensation.

2. Install eld or factory-provided riser extensions,

if required, to the unit-mounted risers prior to

moving the cabinet into nal position.

3. Raise the cabinet upright. Lower the risers through

the oor cutout, aligning the risers into the swaged

section of the unit on the oor below.

Take extra care not to scrape or dent risers during positioning. The riser tailpiece

should insert approximately 2 inches into

the 3-inch long swaged section of the unit

below.

7. Center the risers’ horizontal stub-outs (complete

with factory-installed shut-off valves) in the cabinet slot openings. Ensure that the stub-outs are

perpendicular to the side/back panel.

8. Verify all risers are vertical and that they penetrate

the swaged joint at least 1 inch.

Factory provided risers come with a 3-inch deep

swage. Do not allow risers to completely bottom

out at 3 inches in the swage. The 3-inch swage

depth is oversized to allow for adjustments if necessary to keep riser stub-outs and valves centered

in the cabinet opening.

9. Center the riser stub-out in cabinet opening to

allow for expansion and contraction. Riser stubouts must not contact on any sheet metal opening.

Otherwise damage can occur to stub-outs, resulting in water leaks and property damage.

Top Vertical

Riser

DO NOT allow the riser tailpiece to bottom

out into the swaged section. This ensures

the correct riser positioning and com-

pensates for variations in oor-to-oor

dimensions.

4. Center the risers in the pipe chase, and level the

cabinet using shims as necessary.

5. Plumb risers in two planes to assure proper unit

operation and condensate drainage.

6. Anchor the cabinets into place using rubber isolated sheet metal angles. Approved and tested

sheet metal angles are available from factory.

It is strongly recommended to install vibration

isolation pads to reduce noise transmission into

the floor. Failure to use isolation kits could result

in loud unit operation.

Do not drill or drive screws into the cabinet in the area of the internal drain pan.

2-inch Ideal

3-inch Cup

Height

Bottom

Vertical Riser

FIGURE 1 - IDEAL RISER INSERTION DEPTH

Insertion Depth

LD23535

12

LD19017

FIGURE 2 - CORRECT/INCORRECT STUB-OUT

POSITIONS IN CABINET RISER OPENING

Page 13

FORM 145.18-IOM1

ISSUE DATE: 8/30/2018

SECTION 1 - INSTALLATION

10. Braze or solder riser joints with industry accepted

solder or brazing rod material.

The riser system must be secured to building structure. Cabinets are not designed

to support the riser system.

11. Secure the riser system at a minimum of one point

to the building structure. Cabinets are not intended to support the riser system. If the temperature

range of the system exceeds the allowed expansion and contraction limits (1-1/2 inches maximum), the installing contractor must make riser

compensation provisions.

12. Ensure that individual unit shut-off valves remain

closed until the circulating loop system is cleaned

and ushed.

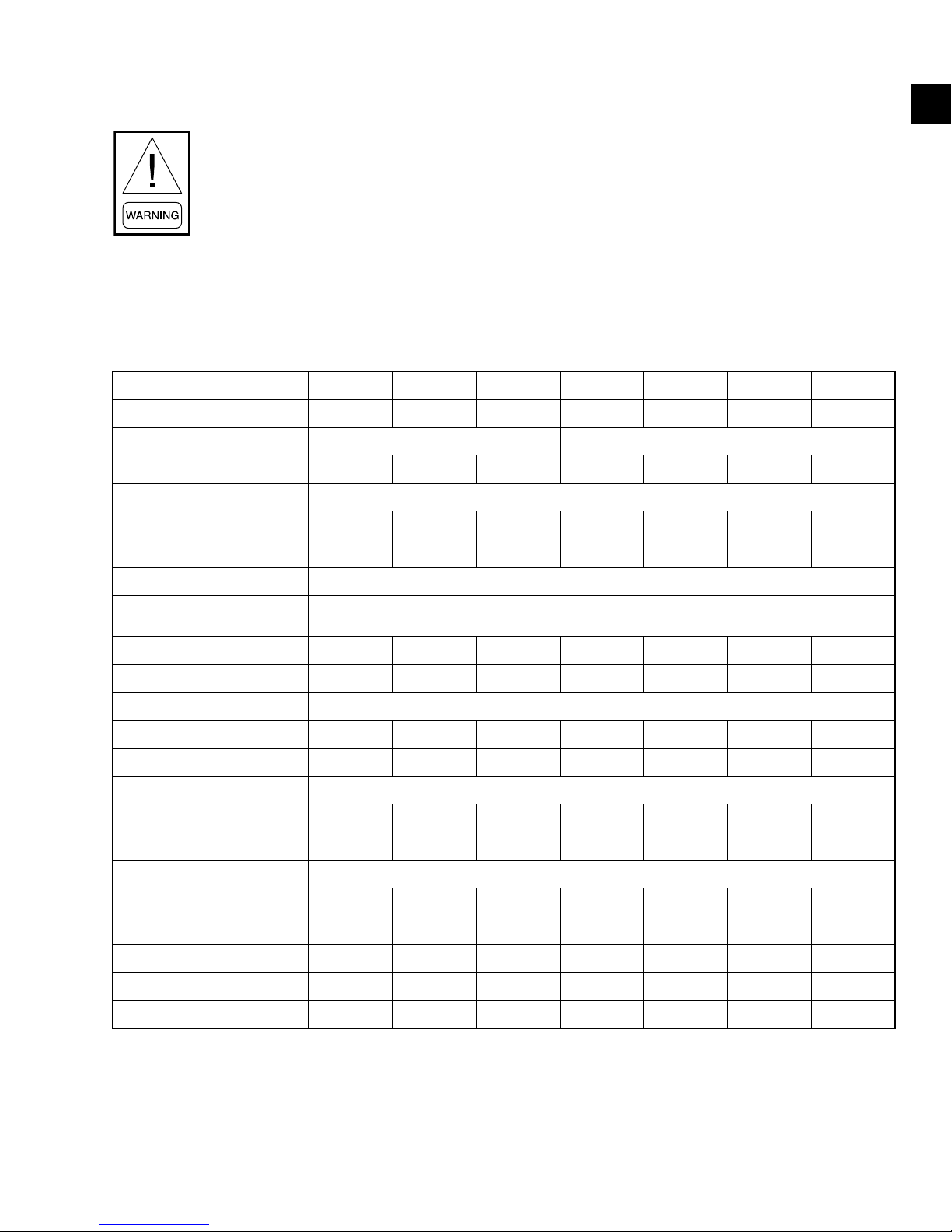

TABLE 1 - HIGH SERIES PHYSICAL DATA

HIGH SERIES MODEL 09 12 15 18 24 30 36

Nominal Cooling (ton)

Compressor Type Rotary Scroll

Refrigerant Charge (oz) 21 25 34 38 44 48 50

Air Coil-Type Enhanced Copper Tubes, Enhanced Aluminum Fins

Face Area (sq ft) 1.46 1.56 2.35 2.35 2.63 3.33 3.33

1

0.75 1.0 1.25 1.5 2.0 2.5 3.0

1

Rows/FPI 2/146 3/14 3/14 3/14 3/14 3/14 3/14

Water Coil-Type Enhanced Surface Co-Axial

Standard Blower/Motor

Diameter x Width (inches) 9x4T 9x4T 9x7T 9x7T 9x7 9x8 9x8

Motor HP 0.10 0.10 0.17 0.17 0.25 0.33 0.50

Hi-Static Blower/Motor DWDI Forward-Curved Centrifugal/PSC Direct Drive

Diameter x Width (inches) 9x4T 9x4T 9x7T 9x7T 10x7T 10x8T 10x8T

Motor HP 0.10 0.10 0.17 0.17 0.25 0.33 0.50

EC Motor (ECM) Blower/Motor DWDI Forward-Curved Centrifugal/ECM Direct Drive

Diameter x Width (inches) 9x4T 9x4T 9x7T 9x7T 10x7T 9x8 9x8

Motor HP 0.33 0.33 0.33 0.33 0.33 0.50 0.50

Hi-Static ECM Blower/Motor DWDI Forward-Curved Centrifugal/ECM Direct Drive

Diameter x Width (inches) 9x4T 9x4T 9x7T 9x7T 10x7T 10x8T 10x8T

Motor HP 0.33 0.33 0.33 0.33 0.33 0.50 0.50

Filter Quantity/Size (inches) 1/14x25x1 1/14x25x1 1/16x30x1 1/16x30x1 1/16x30x1 1/20x30x1 1/20x30x1

Cabinet Weight (lb)

2

Double Width Double Inlet (DWDI) Forward-Curved Centrifugal/Permanent Split Capacitor

(PSC) Direct Drive

130 130 145 145 150 175 175

Chassis Weight (lb) 70 75 95 100 140 155 160

NOTE:

1. Nominal capacity is calculated in accordance with ARI/ISO Standard 13256-1 for water loop application.

2. Cabinet weight is approximate and does not include the weight of the risers.

13

Page 14

SECTION 1 - INSTALLATION

7/8-inch

Control

Entrance

80

inches

or 88

inches

Riser

Opening

KnockOuts (All

3 Sides)

3 inches

50 inches

B A

Left View

Optional 24V

Connection for

Surface Mount/

Remote Mounted

Thermostat

Electrical Box

Service

Pass-Thru

48 inches

Return Air

Flange Standard

1 inch

6 inches

4.5 inches

Hoses

Front View

Optional

Front Supply

Opening

7 inches

Switch Plate with

2 Speed Fan

Switch (Optional:

Disconnect/Fuses,

ADA Molex

Connector)

Chassis

Service

Panel

4 inches

4.25 inches

4.25 inches

4.25 inches

R

S

D

FORM 145.18-IOM1

ISSUE DATE: 8/30/2018

CABINET DIMENSIONS (INCHES)

MODEL A B

RA FLANGE

WIDTH (C)

09–18 17 17 16

15–24 20 20 19

30–36 24 24 23

Back

Optional

Riser

Cover

Shown

13.25

inches

Right

A/2

4.25 inches

R

S

D

R

S

D

1-inch

Supply

Duct

Flange

6 in.

50.5 inches

7/8-inch

OD Power

Entrance

7/8-inch

OD Control

Entrance

4.25

inches

4.5 inches

Right View

4 in.

Supply Riser

Opening

Return

Riser

Opening

inches

Supply Riser

Opening

36 inches

A/2

Back View

8.5

Return Riser

Opening

Condensate

Riser Opening

Left

Top View Front

R - Return Riser

S - Supply Riser

D - Drain Riser

4-5/16 inches

VSHP Cabinet

Drain Pan

Do not penetrate

1.50

this area with

drills or screws

4.75

NOTES

1. Supply, return, and condensate riser openings are pre-punched on all sides and eld convertible. Cut tabs to remove the knock-out.

2. Supply and return openings are 4 inches x 2.5 inches. During riser installation, ensure the stub-out is centered in supply and return openings.

3. Condensate P-trap is accessible from the front by removing the bottom cover plate.

4. Riser and shut-off location is measured from base of cabinet and does not include the stand height.

FIGURE 3 - CABINET UNIT DIMENSIONS & FLOOR SLEEVE DIMENSIONS

14

LD27627

Page 15

FORM 145.18-IOM1

ISSUE DATE: 8/30/2018

SECTION 1 - INSTALLATION

A

Return Air

Opening

Optional

Supply

Opening

6 in.

P-Trap

B

Insulation

Shut-Off

Ball Valve

3 in.

Supply

and

Return

Risers

Allow for 2-inch Insertion

into Swage End

1

36 inches

Condensate Riser (Max. 120 inches)

Supply and Return Riser (Max. 120 inches)

As Req'd

As Req'd

Reducer

Reducer

Reduce Up Riser (Max. 120 inches)

As Req'd

NOTE

Riser shut-off valve is measured from base of cabinet and does not include the stand height.

As Req'd

Reduce Down Riser (Max. 120 inches)

FIGURE 4 - CABINET RISER DIMENSIONS

Capped Down Riser

Capped Up Riser

As Req'd

LD19330

15

Page 16

SECTION 1 - INSTALLATION

FORM 145.18-IOM1

ISSUE DATE: 8/30/2018

RISER LOOP

5. Install the following parts at the base of each supply and return riser to enable system ushing, balancing, and servicing:

• Drain valve

• Shut-off/balancing valves

• Flow indicators

• Drain tees

6. Install strainers at the inlet of each circulating

pump.

7. Insulate loop water piping that runs through unconditioned areas of the building or outside the

building.

When the loop water temperature is maintained

between nominal operating limits of 60.0–90.0°F,

piping does not sweat or suffer undue heat loss at

conditioned space temperatures.

8. Install vents in piping loop as required to bleed

residual air from the piping system during lling

and servicing.

9. Determine the riser shut-off valves and hose kits

required for job specic site conditions:

a. Factory-supplied risers come with the appro-

priate hose kits with NPSH type fittings (see

Figure 5 on page 17). Before attaching

NPSH type hoses, check that the female end

gasket is not missing and is free of damage

or debris. See Table 2 for information on re-

placement gaskets for NPSH hose kits.

b. For field-supplied risers, it is recommended

to order the appropriate NPSH type field

hose kits from the factory, complete with

shut-off valves. Shut-off valves are to be

field sweat connected to risers (see Figure 6

on page 17).

c. Legacy chassis with NPT type connections

and matching risers with NPT shut-off valve

connections require a special hose kit. The kit

comes complete with a NPT to NPSH swivel adapter on the shut-off valve and chassis

connection to mate with factory hoses (see

Figure 7 on page 18.

TABLE 2 - REPLACEMENT HOSE GASKETS

PART NUMBER DESCRIPTION

VSGK-UFHW-050 1/2-inch Rubber Gasket

VSGK-UFHW-075 3/4-inch Rubber Gasket

HOSES

Ensure the correct hose set is matched with the compatible unit size (see Table 3). Instal the NPSH factory-

provided hoses by completing the following steps:

1. Inspect for missing or damaged hose gasket. See

Table 2 for replacement gasket part numbers.

2. Tighten by hand the screw connections to the

male NPSH tting on the shut-off valve. Hold the

ferrule stationary when tightening.

3. Tighten using a backup wrench a 1/4 turn further.

Do not overtighten.

When installing hoses, do not apply a

twist or torque load on the hose.

When tightening hoses, hold the ferrule

stationary by hand while tightening the

screw connections. Avoid tight bends, or

water ow and high pressure drops may

occur.

Hose gasket does not require extreme

tightening to obtain a seal. DO NOT

OVERTIGHTEN, or damage to gasket or

sealing surface will occur. Do not apply

thread sealant.

Hoses must be hand tightened, then further tightened for roughly another 1/4

turn. Check for leaks before tightening

any further. Do not apply excessive force;

rubber gaskets might get damaged.

Always use a back-up wrench when tightening hoses to valves. Otherwise, valve

solder joint may fail, leading to property

damage or serious injury.

TABLE 3 - CHASSIS HOSES

CHASSIS MODEL HOSE TYPE

09–18 1/2-inch NPSH Female-Female

24–36 3/4-inch NPSH Female-Female

16

Page 17

FORM 145.18-IOM1

ISSUE DATE: 8/30/2018

SECTION 1 - INSTALLATION

1

1/2-INCH OR 3/4-INCH MALE NPSH BALL VALVE

1/2-INCH OR 3/4-INCH NPSH THREADS

1/2-INCH OR 3/4-INCH FLEXIBLE CONNECTOR HOSE

(24 INCHES LONG)

GASKET

GASKET

1/2-INCH OR 3/4-INCH NPSH THREADS

1/2-INCH OR 3/4-INCH MALE NPSH

NOTE

National Pipe Straight Hose (NPSH) connection

FIGURE 5 - STANDARD FACTORY SUPPLIED NPSH HOSE KITS AND RISERS

1/2-INCH OR 3/4-INCH WATER PIPE STUB-OUT

1/2-INCH OR 3/4-INCH SWEAT TO MALE NPSH BALL VALVE

1/2-INCH OR 3/4-INCH NPSH THREADS

1/2-INCH OR 3/4-INCH FLEXIBLE CONNECTOR HOSE

(24 INCHES LONG)

1/2-INCH OR 3/4-INCH NPSH THREADS

1/2-INCH OR 3/4-INCH MALE NPSH

LD18126

FIGURE 6 - OPTIONAL FIELD SUPPLIED RISERS WITH FACTORY SUPPLIED NPSH HOSE KITS AND SHUT-

OFF VALVES

NOTE

National Pipe Straight Hose (NPSH) connection

LD18127

17

Page 18

SECTION 1 - INSTALLATION

HANDLE MUST BE

FACING THE BOTTOM

1/2-INCH OR 3/4-INCH FPT BALL VALVE

(FACTORY OR FIELD PROVIDED)

FEMALE SWIVEL

1/2-INCH OR 3/4-INCH NPSH THREADS

GASKET INCLUDED

WITH HOSE

ADAPTER MPT TO NPSH

INCLUDED WITH HOSE

GASKET INCLUDED

WITH HOSE

FORM 145.18-IOM1

ISSUE DATE: 8/30/2018

1/2-INCH OR 3/4-INCH FLEXIBLE

CONNECTOR HOSE (24 INCHES LONG)

FEMALE SWIVEL

1/2-INCH OR 3/4-INCH NPSH THREADS

ADAPTER MPT TO NPSH

INCLUDED WITH HOSE

CHASSIS WATER CONNECTION

1/2-INCH OR 3/4-INCH FPT

(FACTORY PROVIDED)

NOTE

National Pipe Straight Hose (NPSH) connection

FIGURE 7 - CONVERSION OF NPT TO NPSH TYPE FITTINGS (VB UNITS WITH NPT FITTINGS ONLY)

ELECTRICAL WIRING

Lock all electrical power supply switches

in the OFF position before installing the

Use copper conductors only! Failure

to use copper conductors can result in

equipment damage.

unit. Failure to disconnect power supply

may result in electrical shock or even

death.

Verify that the available unit power supply is compat-

Field-Installed Power Wiring

ible with the unit’s nameplate rating. Ensure the breaker is properly sized as per the nameplate. The line volt-

Power wiring to the equipment must conform to National Electrical Codes (NEC), local electrical codes,

age supply enters through the right side of the cabinet

at the 7/8-inch power entrance knock-out.

and must be performed by a licensed electrician.

Connect to the line side of the factory-installed termi-

Provide each unit with its own separate electrical circuit, means of circuit protection, and electrical disconnect switch. Follow current NEC ANSI/NFPA 70, CSA

nal block. Unit terminals are not designed to accept

other types of conductors. Failure to use copper conductors may result in equipment damage.

C22.1 C.E.C. Part 1, and state and local codes.

Failure to provide these shut-off means

could cause electrical shock or re, resulting in damage, injury, or death.

Field-Installed Low Voltage Wiring

Select a location for room thermostat, away from supply

air registers, on draft-free interior wall that is far from

lights, television, direct sunlight, or other heat sources.

LD27628

18

Locate thermostat away from supply

drafts. Ensure the back of the thermostat

is sealed and protected from air drafts.

Short cycling can result in damage to

the unit.

Page 19

FORM 145.18-IOM1

ISSUE DATE: 8/30/2018

SECTION 1 - INSTALLATION

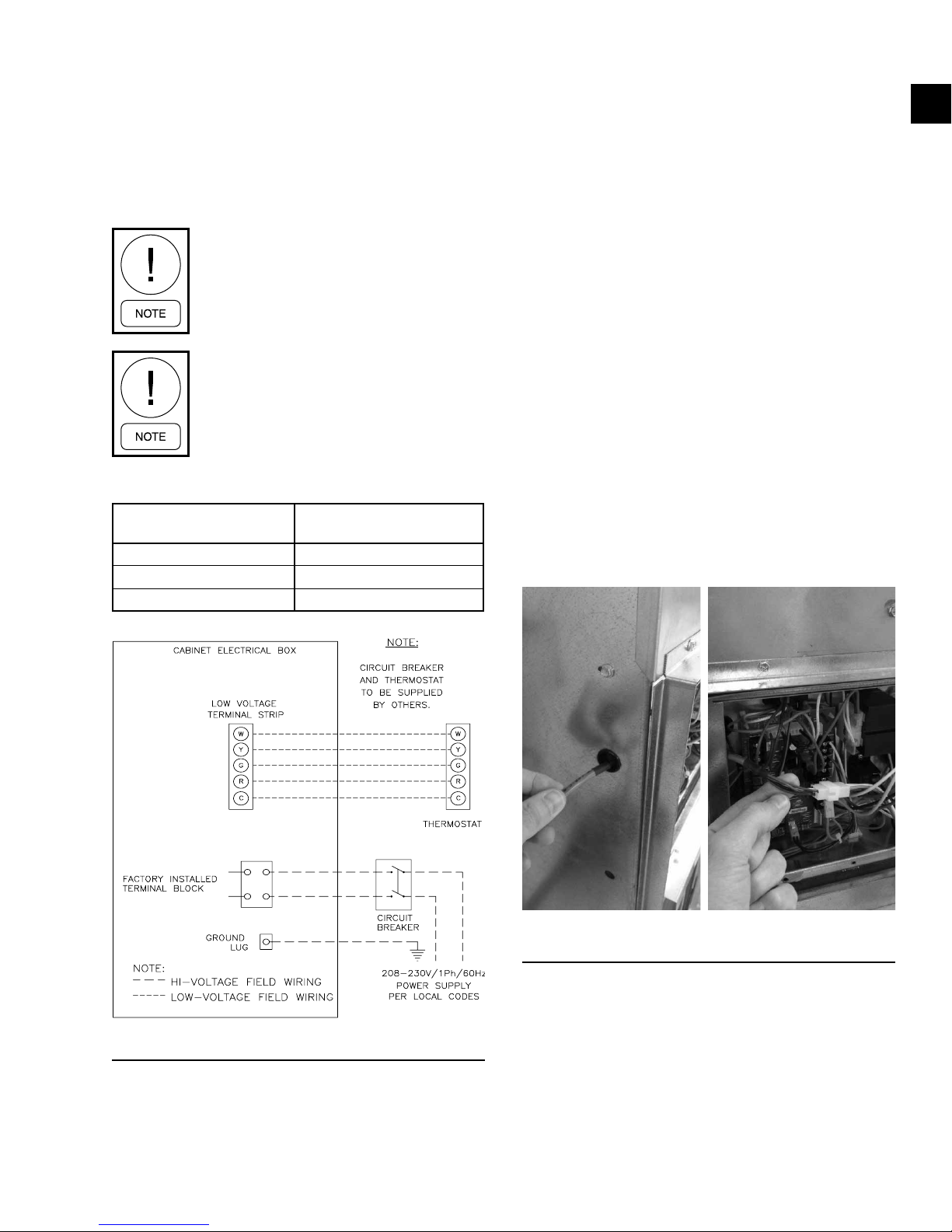

Install the thermostat by connecting the remote thermostat wiring to microprocessor board low voltage

terminal strip. See Figure 8 for typical wiring connections.

Ensure that the control wiring between the thermostat

and the unit’s terminations does not exceed 1 ohm.

Resistance in excess of 1 ohm may cause

component damage due to insufcient AC

voltage supply.

Check all loads and conductors for

grounds, shorts, or miswiring. Do not run

the low voltage wiring in the same conduit

with the high voltage power wiring.

TABLE 4 - TYPICAL WIRE CONNECTIONS

RECOMMENDED WIRE

SIZE (GAUGE)

20 50

18 75

16 125

MAXIMUM LOW VOLTAGE

WIRE LENGTH (FEET)

Optional Surface Mount Thermostat

Connection Wiring

For applications where the thermostat is mounted directly above the return air (RA) panel, select cabinet

control option P (for example, VB12P). The thermostat

Molex pigtail harness (shipped loose) is field wired to

thermostat terminals. The Molex connector clips to the

panel-mounted, mating Molex connector on unit cabinet that is located 7 inches above the electrical box. See

optional 24V surface mount connection in Figure 3 on

page 14.

Optional Remote Mounted Thermostat Wiring

For units ordered with an extended thermostat harness

option, the thermostat is remote mounted. A specific,

plenum rated extended harness length can be ordered.

Use low voltage 7/8-inch knock-out on the side of the

unit at the electrical box to field wire the low voltage

thermostat wiring. Using a plastic bushing to pass the

harness inside electrical box to the factory wired mating Molex harness (see Figure 9). The thermostat pigtail Molex harness ships loose for field wiring to the

thermostat terminals.

1

FIGURE 8 - FIELD WIRING DIAGRAM

LD27629 LD27630

FIGURE 9 - REMOTE THERMOSTAT WIRING

LD19520

19

Page 20

SECTION 1 - INSTALLATION

Optional Disconnect

FORM 145.18-IOM1

ISSUE DATE: 8/30/2018

CLOSET AND DRYWALL INSTALLATION

To avoid potential vibration and noise issues, the RA panel should not contact any

part of the unit cabinet or sleeve. Maintain

a sufcient gap between RA panel frame

and cabinet.

Optional ADA Molex

Connection

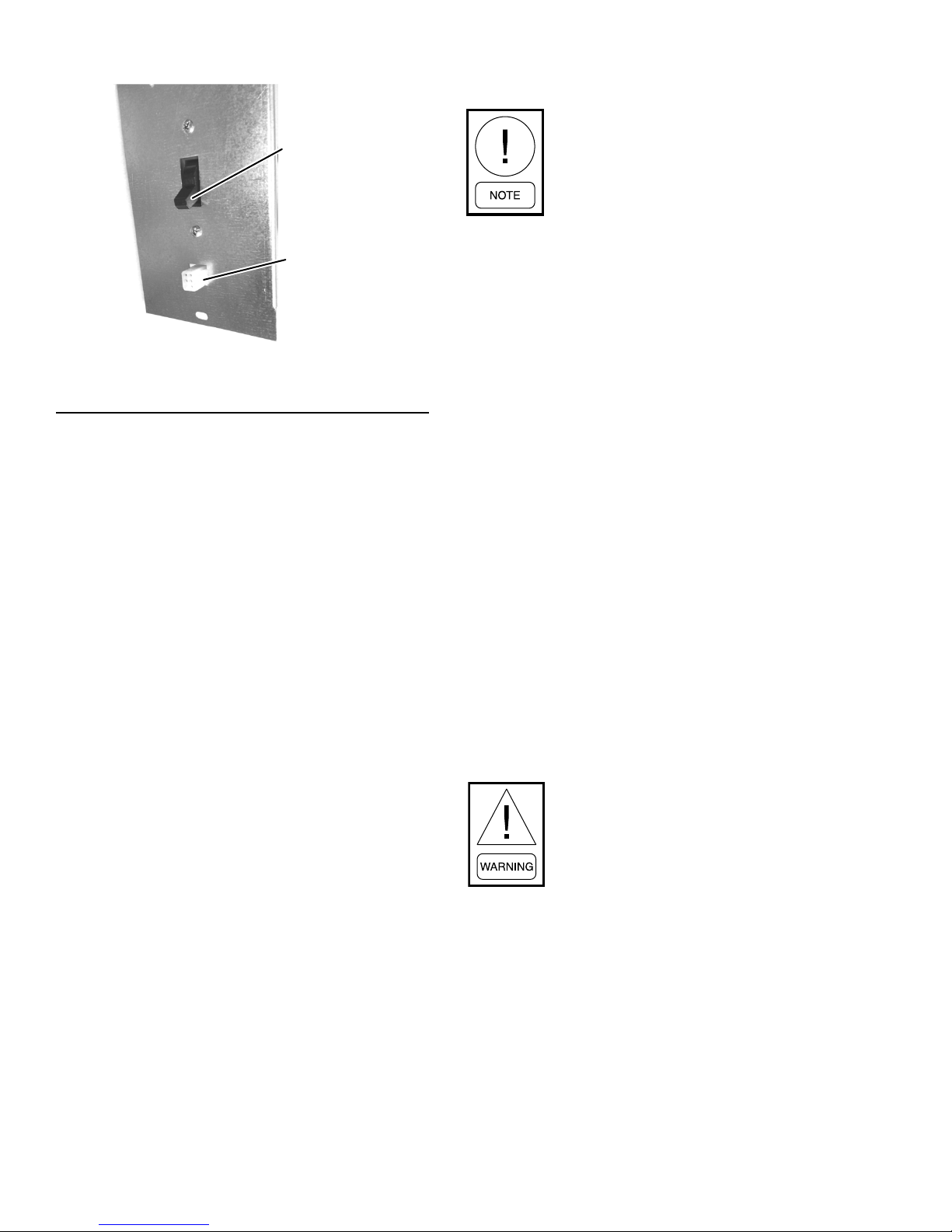

LD27631

FIGURE 10 - UNIT SWITCH PLATE WITH ADA

THERMOSTAT CONNECTION

Optional ADA Door Mounted Thermostat

For units ordered with the Americans with Disabilities

Act (ADA) thermostat option to meet ADA requirements, the thermostat is located on the RA panel door

at a height of 48 inches from the base of the cabinet.

Unit is supplied with a custom RA door panel with

thermostat mounting holes, unit switch plate with a

Molex connector, and an ADA Molex pigtail harness.

See Acoustic Return Air (RA) Panel on page 20 and

Figure 14 on page 23.

Wire leads from the ADA thermostat harness are field

wired to thermostat terminals. The Molex end of the

ADA thermostat harness is field connected to the surface mounted Molex connector at unit switch plate.

Mount the thermostat using the factory provided 1/4inch number 8 screws. The ADA thermostat harness is

plenum rated. It hangs behind the RA door. For chassis

servicing, unclip harness from unit switch plate.

EC Motor (ECM) Continuous Fan

This option features a factory wired continuous low

speed fan circuit. Because of the five available motor

speed taps, the EC motor (ECM) offers an ideal range

for supporting continuous low speed fan.

Build a closet enclosure for the cabinet that incorporates the RA panel size while maintaining a sufficient

gap between the closet and cabinet. This prevents the

cabinet from contacting the RA panel and closet enclosure. Refer to Acoustic Return Air (RA) Panel on page

20, Figure 11 on page 21, and Figure 12 on page

22.

1. Cover the supply and return openings with plastic or cardboard before installing drywall around

cabinet. This prevents dust or debris from entering

the unit components.

2. Install the drywall using conventional construction methods. Do not fasten studs or drywall directly to the cabinet surface. Space the framing

members according to the RA access and the type/

quantity of supply air (SA) outlets. See Figure 11

on page 21 and Figure 12 on page 22.

3. Install sheetrock around unit cabinet by securing

the drywall to the building construction studs.

4. Cut holes around the SA and RA openings to allow access to the unit chassis, unit controls, and

the SA connection.

5. Vacuum all dust and construction debris from the

unit drain pan, electrical box, and discharge plenum after cutting out the supply/returns openings.

To prevent electrical shorts and drain pan

leaks, DO NOT penetrate unit components when driving screws near the unit

control box or drain pan. Do not allow

screws or nails to penetrate chassis, risers,

electrical junction boxes, conduits, or to

interfere with chassis removal.

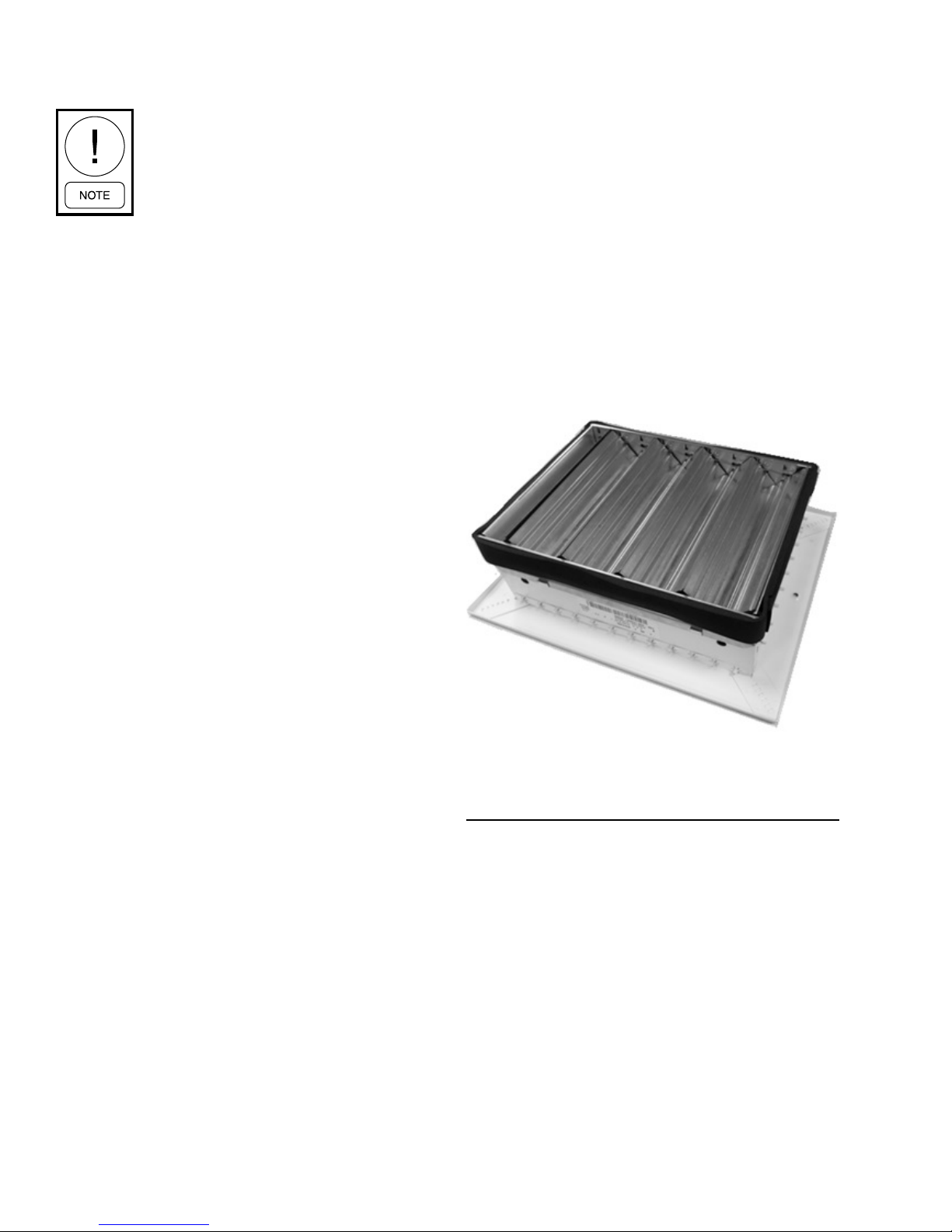

ACOUSTIC RETURN AIR (RA) PANEL

The fan runs continuously on the low fan speed setting

even if there is no demand for cooling or heating. The

continuous fan is controlled by a dry contact to provide

interlocking to energy recovery ventilator (ERV) or

room occupancy control. See Figure 28 on page 46

for electrical schematics.

20

RA panels are painted standard appliance white. Carefully unpack RA panels from their shipping box. RA

panels with optional key locks require the key locks

to be field installed to the slot in the panel door. ADA

RA door panels come with an opening and pilot holes

mounting a thermostat. The ADA harness for wiring

the thermostat and connecting to the unit is shipped

loose with the thermostats.

Page 21

FORM 145.18-IOM1

ISSUE DATE: 8/30/2018

SECTION 1 - INSTALLATION

1. Locate the drywall opening at a distance from

the unit so that it prevents the RA panel from

contacting the unit sleeve. See Figure 11 on page

21 and Figure 12 on page 22.

2. Center the RA panel throat opening to the unit

cabinet RA ange opening.

3. Fasten the RA panel to frame opening using the

screws provided. See Figure 11 on page 21.

D

E

Vertical Stack Cabinet

Top View

B

0.5-inch Drywall

6 x Fasteners

C

Figure 14 on page 23 shows the opening for mounting an ADA compliant thermostat at 48 inches above

floor. Note that location of the opening on the door

changes if the cabinet is ordered with a stand. A left

hand opening door is shown. The RA panel with ADA

is not reversible. It must be ordered in either a left or

right-hand opening configuration, determined by the

location of the door hinge.

Return Air Flange

Standard = 1 inch

Optional OA Fresh Air = 4.25 inches

Wall Stud

1-3/16 inch

(Drywall to Fastener

Based on 0.5-inch Drywall

1

F

Vertical Stack Cabinet Top View

G

Min. 1/8-inch, Max. 3/8-inch Gap

(RA Flange Must Not Contact

Acoustic Door Frame)

A

UNIT

SIZE

09/12/15/18 25 3/4 19 19 1/4 23 3/4 ± 1/8 20 20

24/30/36 29 3/4 23 23 1/4 27 3/4 ± 1/8 24 24

NOTE

All dimensions are in inches.

A

(PANEL

WIDTH)

B

(SLEEVE

WIDTH)

C

(R/A PANEL

OPENING)

D

(ROUGH IN

WIDTH)

E

(UNIT

WIDTH)

DEPTH)

H

Rear Closet to Cabinet Back:

No Risers = 0.5-inch Minimum

With Risers = 5-inch Minimum

2.25-inch Minimum

(Unit Sleeve to Drywall)

F

(UNIT

G

(NO OA

OPTION)

23 1/4 MIN

23 1/2 MAX

27 1/4 MIN

27 1/2 MAX

G

(OA OPTION)

27 1/4 MIN

27 1/2 MAX

31 1/4 MIN

31 1/2 MAX

FIGURE 11 - CRITICAL RETURN AIR (RA) PANEL WITH UNIT CABINET INSTALLATION DIMENSIONS

LD19500

21

Page 22

SECTION 1 - INSTALLATION

FORM 145.18-IOM1

ISSUE DATE: 8/30/2018

RA flange must not

contact door frame

Acoustical

1-inch RA flange

Panel Door

Frame

2.5 inches

6 inches

3.75 inches

Cabinet

Floor

Closet Drywall

FIGURE 12 - RA PANEL CROSS SECTION

INSTALLATION AT FLOOR LEVEL

B

B

C

C

1.92

1.92

0.28

0.28 inches

inches

Figure 12 on page 22 shows a cutaway view for a

standard cabinet with no stand. Add the stand height to

the cabinet to obtain the correct dimension of the RA

panel from floor.

For maximum return airow, the ush

mounted acoustic panel must be centered

vertically and horizontally over the RA

opening of the cabinet. SA duct collar

extensions may be required to prevent

short cycling.

LD27621

ALL DIMENSIONS ARE IN INCHES

MODEL A B C D

VSCS09–12 22.75 20.50 16.25 18.50 20.75 52.75

VSCS15–24 25.75 23.50 19.25 21.50 23.75 52.75

VSCS30–36 29.75 27.50 23.25 25.50 27.75 52.75

ROUGH-IN

WIDTH

ROUGH-IN

HEIGHT

Mounting Holes x 6

Mounting Holes x 6

52.50

50.5 inches

56.75

54.75 inches

D

D

50.25

54.50

(54 3/4" ROUGH-IN

48.25 inches

52.5 inches

WALL OPENING)

(52.75-inch Rough-In Wall Opening)

A

A

NOTES:

1. Acoustic panel is powder coated in appliance white

2. Acoustic panel can be installed on the right hand side or left hand side.

3. See Figure 11 on page 21 for additional RA panel and cabinet installation information.

FIGURE 13 - RA PANEL DIMENSIONS

A

Magnetic Catches x 2

Magnetic

Catches x 2

54.75 inches

LD19319C

22

Page 23

FORM 145.18-IOM1

ISSUE DATE: 8/30/2018

1.5 inches

1.50

1.25 inches

1.25

Left Hand Opening Shown

LEFT HAND OPENING SHOWN

SECTION 1 - INSTALLATION

1

Thermostat mounting location,

Thermostat mounting location,

Cut-out for routing

cut-out for routing ADA thermostat

ADA thermostat harness

harness

0.5-inch Insulation

1/2" Insulation

Magnetic Catches x 2

Magnetic Catches x 2

Notes:

- Powder coated in 'Appliance White'

NOTES:

- Inside panel lined with 1/2" acoustical insulation

1. Powder coated in appliance white

- Hinged panel complete with magnetic latches

2. Inside panel lined with 0.5-inch acoustical insulation

- Panel comes either Left or Right hand opening

3. Hinged panel complete with magnetic latches

4. Panel comes either left or right hand opening

LD19320

FIGURE 14 - OPTIONAL RA PANEL WITH ADA MOUNTED THERMOSTAT

LD19320

23

Page 24

SECTION 1 - INSTALLATION

FORM 145.18-IOM1

ISSUE DATE: 8/30/2018

SUPPLY AIR (SA) DUCTWORK

Ensure there is no direct contact between

cabinet sheet metal parts and drywall en-

closure. This includes RA and SA anges.

Failure to follow these instructions will

negatively affect unit sound performance.

Horizontal Supply Air

A 2-inch duct flange (field provided) may be required

to eliminate supply air recirculation when shallow profile, single deflection supply grilles are installed at the

cabinet discharge openings. If the discharge from the

cabinet is not ducted completely into the conditioned

space, air can recirculate into the RA opening from the

space inside the drywall enclosure.

Manufacturer supplied grilles have a clearance of a 1/4

inch around the perimeter to fit inside the unit supply

flange. Other grille manufacturers could have different

clearances that should be verified.

Field supplied gasket must be applied in order to prevent air recirculation and vibration transfer when supply grilles are mounted to unit supply opening. When

mounting supply grilles with optional volume damper

directly to cabinet supply flange, the volume damper

fits inside the cabinet supply flange. It is recommended

to apply 1/8-inch neoprene tape (field supplied) around

the perimeter of the volume damper prior to inserting

it into the supply opening. See Figure 15 on page 24

for an example. This assists in reducing noise transmission and air recirculation into the unit closet.

For ducted openings, connect the unit supply opening

to the supply ductwork using a watertight flexible duct

connector. This minimizes the transmission of operating sounds through the supply ductwork. Elbows with

turning vanes or splitters are recommended to minimize air noise due to turbulence and to help reduce

static pressure.

Top Discharge Supply Air

Units that are installed with a top discharge should be

connected to the supply ductwork with a watertight

flexible connector. This minimizes the transmission

of operating sounds through the supply ductwork. Elbows with turning vanes or splitters are recommended

to minimize air noise due to turbulence and to help reduce static pressure.

For information on available unit horizontal and top

supply openings see Table 5 and Table 6 on page 26.

Recommended face velocity at the outlet supply grille

is 300–500 FPM. Table 6 gives face velocity at the unit

supply openings in relation to Table 5. To calculate the

face velocity at the supply grille, take the FPM from

Table 6 and divide by the supply grille area factor.

LD27622

FIGURE 15 - SUPPLY GRILLE WITH VOLUME

DAMPER AND 1/8-INCH NEOPRENE TAPE

APPLIED TO PERIMETER

24

Page 25

FORM 145.18-IOM1

ISSUE DATE: 8/30/2018

WALL STUD

Wall Stud

D

E

VERTICAL STACK CABINET

Vertical Stack Cabinet

Top View

TOP VIEW

Optional Opposed Blade Damper

A

Louvered Supply Grille

Detail A

DETAIL A

SECTION 1 - INSTALLATION

1

0.5-inch Drywall

1/2”

DRYWALL

B

MOUNTING SCREWS

Mounting Screws

VERTICAL STACK CABINET

Vertical Stack Cabinet

Optional Framing Studs

for Supply Opening

FOR SUPPLY OPENING

UNIT

15–24 X B=X - 0.5 C=X + 1.75 23 3/4 ± 1/8 20

30–36 X B=X - 0.5 C=X + 1.75 27 3/4 ± 1/8 24

NOTES:

(SUPPLY GRILLE

SIZE

NOMINAL WIDTH)

9–18 X B=X - 0.5 C=X + 1.75 20 3/4 ± 1/8 17

1. All dimensions are in inches and typical for factory supplied grilles only.

2. Check dimensions for eld-supplied grilles because dimensions can be different.

OPTIONAL

FRAMING STUDS

A

B

(GRILLE

WIDTH)

(UNIT SUPPLY DUCT FLANGE

(Unit Supply Duct Flange

TO 1/2” DRYWALL FACE)

to 0.5-inch Drywall Face)

C

(GRILLE

FLANGE WIDTH)

C

Top View

TOP VIEW

2.25-inch Minimum

2-1/4” MIN.

D

(ROUGH IN

WIDTH)

(UNIT

WIDTH)

E

1/8” THICK FIELD SUPPLIED

1/8-inch Thick Field Supplied

GASKET TAPE

Gasket Tape Applied Around

APPLIED AROUND

Full Perimeter of Supply

FULL PERIMETER OF

Grilled with Volume Damper

SUPPLY GRILLE WITH

VOLUME DAMPER

FACTORY SUPPLIED

Factory Supplied

1” DUCT FLANGE

1-inch Duct Flange

DETAIL A

Detail A

FIGURE 16 - UNIT MOUNTED SUPPLY GRILLE INSTALLATION

LD19321

25

Page 26

SECTION 1 - INSTALLATION

FORM 145.18-IOM1

ISSUE DATE: 8/30/2018

TABLE 5 - UNIT SUPPLY OPENING SIZES

HORIZONTAL OPENINGS

SINGLE HORIZONTAL DOUBLE HORIZONTAL

MODEL

NO TOP

OPENING

TOP OPENING

NO TOP

OPENING

TOP OPENING

9 14W x 12H 14W x 6H 14W x 8H Not Available Not Available 12 x 8

12 14W x 14H 14W x 6H 14W x 10H Not Available Not Available 12 x 8

15 16W x 14H 14W x 6H 14W x 10H Not Available 14W x 8H 14 x 12

18 Not Available 14W x 6H 14W x 12H 14W x 6H 14W x 10H 14 x 12

24 Not Available 14W x 10H 16W x 14H 14W x 6H 14W x 10H 14 x 12

30 Not Available 14W x 6H 20W x 14H 14W x 6H 16W x 12H 18 x 16

36 Not Available 14W x 10H Not Available 14W x 6H 16W x 14H 18 x 16

NOTES:

1. Unit mounted supply grilles are supplied as double-deection type.

2. Grilles for unequal airow applications (for example, unit mounted plus ducted supply) are provided with integral opposed blade dampers.

3. All grilles are supplied in standard appliance white painted nish.

4. Grilles are shipped loose for eld installation upon completion of cabinet/ductwork/drywall installation.

5. Top opening size does not change. When combined with any other discharge arrangement, it is included in determining horizontal opening

grille size.

6. Openings marked Not Available result in face velocities outside the recommended 300–500 FPM range.

7. Hi-static blower option or single horizontal discharge openings with unit mounted supply grille are not recommended.

TRIPLE

HORIZONTAL

NO TOP

OPENING

TOP OPENING

TABLE 6 - UNIT SUPPLY FACE VELOCITY (FPM)

HORIZONTAL OPENINGS

MODEL

SINGLE HORIZONTAL DOUBLE HORIZONTAL

NO TOP

OPENING

TOP OPENING

NO TOP

OPENING

TOP OPENING

9 291 272 219 Not Available Not Available 510

12 316 344 221 Not Available Not Available 645

15 354 314 283 Not Available 236 471

18 Not Available 391 294 294 235 587

24 Not Available 397 273 364 291 729

30 Not Available 416 276 339 269 538

36 Not Available 410 Not Available 385 261 610

NOTES:

1. Tabulated face velocities do not account for supply grille free area factor. Face velocities at supply grille are higher depending on grille type.

2. Face velocities are based on the nominal rated CFM and feet per minute (FPM).

3. Face velocities are calculated by taking the average across all openings. Tabulated top opening face velocity is only for units with single

top opening and no horizontal openings.

TRIPLE

HORIZONTAL

NO TOP

OPENING

TOP OPENING

26

Page 27

FORM 145.18-IOM1

ISSUE DATE: 8/30/2018

SECTION 1 - INSTALLATION

TOP MOUNTED FRESH AIR INTAKE

The optional fresh air intake provides a 4-inch round

duct connection on top of the unit (see Figure 23 on

page 31 for right and left hand version). The fresh

air is discharged upstream of the direct expansion (DX)

coil through the discharge collector box.

Do not allow incoming air to bypass the

DX coil, otherwise, damage to the unit

may occur.

Units can be selected with the fresh air opening located

on the top left or right hand side for ease of installation.

It is recommended that applications requiring 10% or

more outdoor air utilize a pressurized fresh air system.

Unit cabinet static pressure at the RA opening is not

designed to draw 10% or more in passive fresh air systems.

The fresh air duct inside the unit is insulated to protect

the unit from condensation in the event of high humidity air. However excessively moist fresh air over prolonged periods can result in condensate inside unit or

closet.

During transportation, handling or installation of the cabinet, excessive handling

can cause an inner black plastic cover to

come loose and jam the actuator, preventing the damper from opening.

During start-up, check that the damper is opening when

the unit fan is running. It can take 20 seconds to fully

open. If the damper opens, the unit is operating as intended. If the damper fails to open, the cause is likely a

loose cover preventing actuator from rotating. Remove

the actuator to service the damper.

Removing the Actuator

1. Remove the damper plate:

a. Look underneath the top of the RA flange to

notice the damper assembly.

b. Remove the seven fasteners holding the

damper plate (see Figure 19 on page 28).

c. Drop the plate and disconnect the quick-con-

nect terminals from the harness.

2. Remove the red cover from the actuator body (see

Figure 18 on page 27).

1

To avoid condensate developing inside

ducts and equipment, it is recommended

to pretreat fresh air with a high humidity

ratio before it enters the unit assembly

through ERVs or make-up air units.

The unit comes with a 4-1/4 inch RA sleeve. Front

supply openings come with a 4-1/4 inch supply plaster

flange.

Top Mounted Fresh Air Intake with Motorized

Damper

This include the same features as the top mounted fresh

air intake option with the addition of a motorized damper assembly inside the discharge collector box similar

(see Figure 23 on page 31).

The damper assembly can be easily removed for servicing (see Removing the Actuator on page 27). The

motorized damper assembly opens during FAN ON operation. See Figure 28 on page 46 for the electrical

schematic. For other control options, please contact the

factory.

LD23557

FIGURE 17 - DAMPER PLATE FASTENERS

LD23558

FIGURE 18 - REMOVE THE RED COVER

27

Page 28

SECTION 1 - INSTALLATION

LD23559

FORM 145.18-IOM1

ISSUE DATE: 8/30/2018

SYSTEM FLUSHING AND CLEANING

After the piping system is complete, and before connecting the refrigeration chassis, flush and clean the

risers This ensures a proper start-up and continued efficient operation of the system (see Figure 20 on page

29).

Flushing the System

1. Ensure the supply and return riser shut-off valves

are closed at each unit.

2. Using exible hoses or piping, connect the supply

and return stub-outs in the unit located at the end

of the riser run(s).

If the building has more than ten floors, connect

the supply and return stub-outs in the last two

units to divide the water flow and reduce pressure

drop at the pump (see Figure 20 on page 29).

LD23560

FIGURE 19 - POSITION BLACK COVER

3. If the black cover is loose, position it in place and

slide it back onto the actuator (see Figure 19 on

page 28).

4. Secure the red cover back over the actuator assembly.

5. Ensure the plastic tabs are secured to the metal

body bracket.

6. Connect the quick-connect terminals, and insert

the damper assembly into the discharge collector

box.

7. Fasten the assembly using the seven fasteners.

3. Open the shut-off valves in the units that have had

the supply and return risers interconnected.

4. Fill the water circulation system with clean water from the make-up water supply. Ensure the air

vents are open during initial lling. Do not allow

the system to overow.

5. Close the air vents, and start the circulating pump.

6. Ensure that all air is bled from the system by

cracking each air vent.

Make-up water must be available in sufcient volume to replace the volume occupied by the air that is bled off.

7. When all the air is vented and the water is circulating under pressure, check the entire system for

leaks. Repair any leaks as required.

8. Raise the temperature to approximately 85.0°F

by setting the loop temperature controls. Visually

check for any leaks that may have occurred due to

the increased heat. Repair any leaks as required.

9. Open the drain at the lowest point in the system.

The make-up water ow rate must be

equal to the rate of the drain bleed.

28

Page 29

FORM 145.18-IOM1

to chassis

Hose or piping

Riser

Return

Riser

ISSUE DATE: 8/30/2018

SECTION 1 - INSTALLATION

10. Continue to bleed the system until the water leaving the drain is clear, no less than 2 hours.

11. Completely drain the piping system.

Cleaning the System

1. After the initial ushing, chemically clean the

system. Repeat the method in Flushing the System

on page 28 to rell the system and circulate the

cleaning solution.

It is recommended to use the services of a professional water treatment company for the type of

solution to be used and the duration of the cleaning application.

2. Once the cleaning process is complete, shut off

the circulating pump and completely drain the

system.

3. Rell the system with clean water to prepare for

refrigeration chassis connection and system startup.

It is recommended that a professional water treatment company perform ongoing

maintenance of the water loop including

chemical analysis and ushing, if necessary. The water loop testing should be performed at intervals recommended by the

professional water treatment consultant.

Stub-outs to

Stub-outs

chassis

Hose or piping

connecting

supply & return

connecting supply

runouts

and return runouts

1

It is recommended that the water loop

testing be performed at least once a year.

Standard practice is once a month or

quarterly.

The customer is responsible for completing adequate water loop maintenance

over the lifespan of the units. Otherwise,

damage to the units may occur.

Supply

Supply

Riser

Return

Riser

LD19685

FIGURE 20 - SYSTEM FLUSHING AND CLEANING

29

Page 30

SECTION 1 - INSTALLATION

CABINET DIMENSIONS (INCHES)

MODEL A B C

09–12 17 8 12

15–24 20 12 14

30–36 24 16 18

1. Optional fresh air option comes with 2.5-inch RA ange.

2. Optional front supply opening comes with 2.5-inch duct ange.

3. All other openings come with standard 1-inch duct ange.