Johnson Controls VS3-326D6EB-C20C, VS3-324D8DN-C21C, VS3-327D8EB-C20C, VS3-324D8EB-C20C, VS3-327D8DN-C21C Applications Manual

...Page 1

Variable Speed Drive Series III

Application manual

Effective June 2018

Supersedes March 2018

Supports Firmware Version Bundle:

DH1-V0003-JCI

Page 2

Variable Speed Drive Series III

Disclaimer of warranties and limitation of liability

The information, recommendations, descriptions, and safety notations in this document are based on Johnson Controls’

experience and judgment and may not cover all contingencies. If further information is required, a Johnson Controls sales

office should be consulted. Sale of the product shown in this literature is subject to the terms and conditions outlined in

appropriate Johnson Controls selling policies or other contractual agreement between Johnson Controls and the purchaser.

THERE ARE NO UNDERSTANDINGS, AGREEMENTS, WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING WARRANTIES

OF FITNESS FOR A PARTICULAR PURPOSE OR MERCHANTABILITY, OTHER THAN THOSE SPECIFICALLY SET OUT IN ANY

EXISTING CONTRACT BETWEEN THE PARTIES. ANY SUCH CONTRACT STATES THE ENTIRE OBLIGATION OF JOHNSON

CONTROLS. THE CONTENTS OF THIS DOCUMENT SHALL NOT BECOME PART OF OR MODIFY ANY CONTRACT

BETWEEN THE PARTIES.

In no event will Johnson Controls be responsible to the purchaser or user in contract, in tort (including negligence), strict

liability, or otherwise for any special, indirect, incidental, or consequential damage or loss whatsoever, including but not

limited to damage or loss of use of equipment, plant or power system, cost of capital, loss of power, additional expenses

in the use of existing power facilities, or claims against the purchaser or user by its customers resulting from the use of the

information, recommendations, and descriptions contained herein. The information contained in this manual is subject to change

withoutnotice.

Cover Photo: Johnson Controls Variable Speed Drive Series III

ii

VARIABLE SPEED DRIVE SERIES III LIT-12012999—June 2018 www.johnsoncontrols.com

Page 3

Support services

Support services

The goal of Johnson Controls is to ensure your greatest

possible satisfaction with the operation of our products.

We are dedicated to providing fast, friendly, and accurate

assistance. That is why we offer you so many ways to get

the support you need. Whether it is by phone, fax, or email,

you can access Johnson Controls’ support information

24hours a day, seven days a week.

Our wide range of services is listed below.

You should contact your local distributor for product pricing,

availability, ordering, expediting, and repairs.

Website

Use the Johnson Controls website to find product

information.

Website address

www.johnsoncontrols.com –> HVAC Controls –> Variable

Speed Drives

Variable Speed Drive Series III

Johnson Controls product sales operation/

technical support

Call Local Service Center Representative.

If Representative is unknown, call 1-800-482-2778 and ask

for a local service rep for programming support.

VARIABLE SPEED DRIVE SERIES III LIT-12012999—June 2018 www.johnsoncontrols.com

iii

Page 4

Variable Speed Drive Series III

Table of contents

SAFETY

Before commencing the installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Definitions and symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

Hazardous high voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

Warnings and cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

Important safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

CHAPTER 1—VARIABLE SPEED DRIVES SERIES III OVERVIEW

How to use this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Receiving and inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Real time clock battery activation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Rating label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Carton rating label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

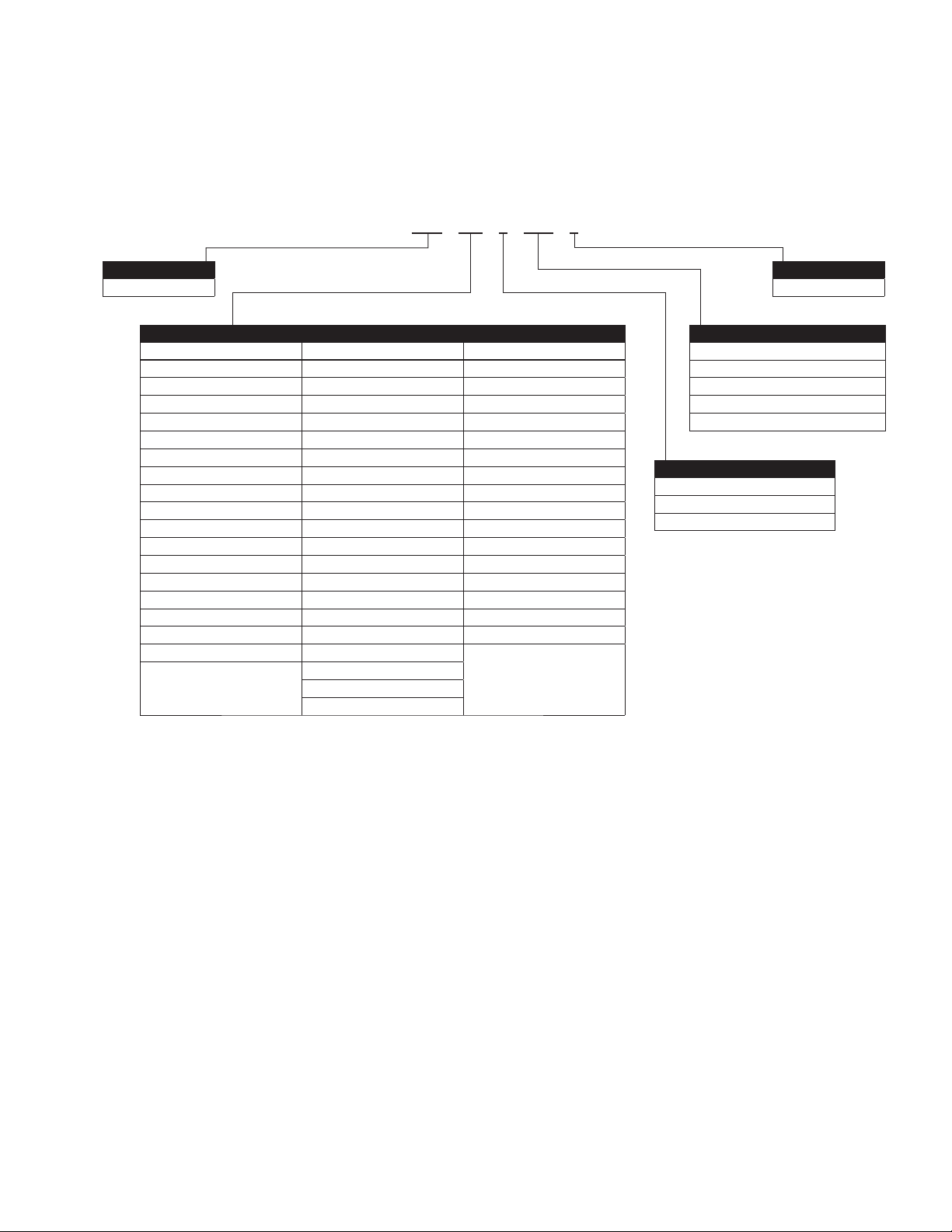

Catalog number system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

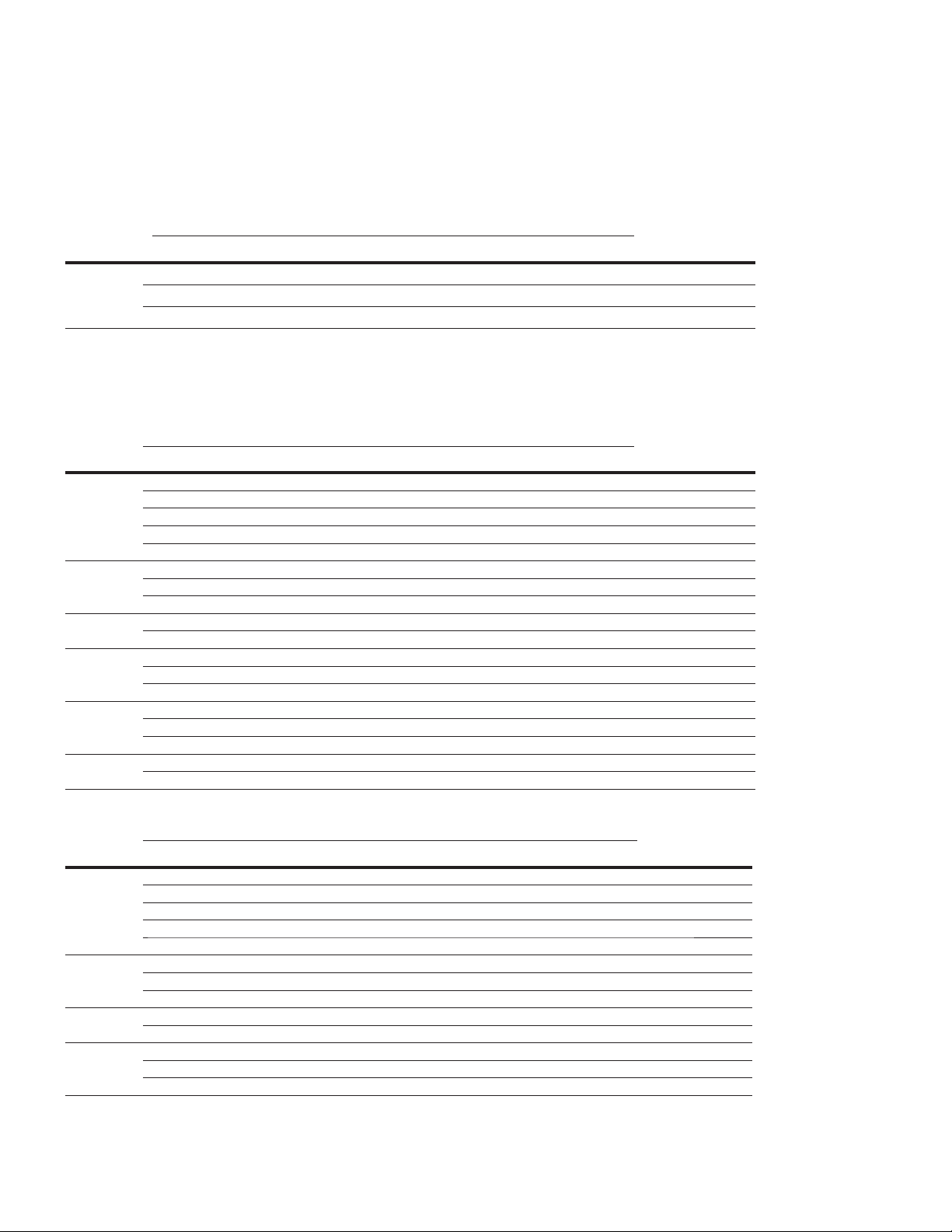

Power ratings and product selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

CHAPTER 2—KEYPAD OVERVIEW

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Keypad buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

LED lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

LCD display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

CHAPTER 3—MENU OVERVIEW

Main menu page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Menu navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Menu structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

M — Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

F — Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Pop-up fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Fault history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Fault Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

P — Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Value edit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

T—Favorite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

CHAPTER 4—STARTUP

Startup wizard page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Startup wizard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

PID and Advanced Application Mini-Wizard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

CHAPTER 5—BASIC APPLICATION

I/O controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Force open/force close selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

DIGIN selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Option board digIN selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Basic Application Control I/O configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

iv

VARIABLE SPEED DRIVE SERIES III LIT-12012999—June 2018 www.johnsoncontrols.com

Page 5

Table of contents, continued

CHAPTER 5—BASIC APPLICATION, continued

Control I/O configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Basic application—parameters list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Drive Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Motor Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Protections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

RS485 Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

EtherNet Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

CHAPTER 6 — PID APPLICATION

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

I/O controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Force open/force close selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

DIGIN selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Option board DigIN selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Timer channel selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Control I/O configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

PID application—parameters list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Drive Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Motor Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Protections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

PID Controller 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Feedforward . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

PID Controller 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Feedforward . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

Bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

Real Time Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

RS485 Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

EtherNet Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Variable Speed Drive Series III

VARIABLE SPEED DRIVE SERIES III LIT-12012999—June 2018 www.johnsoncontrols.com

v

Page 6

Variable Speed Drive Series III

Table of contents, continued

CHAPTER 7—ADVANCED APPLICATION PARAMETER

I/O Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

Force open/force close selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

DIGIN selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Option board digIN selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Timer channel selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Control I/O configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

Advanced application—Parameters List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

Drive Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

Motor Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

Protections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

PID Controller 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Feedforward . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

PID Controller 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Feedforward . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

Bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

Real Time Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

RS485 Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

EtherNet Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

APPENDIX A – DESCRIPTION OF PARAMETERS

Application level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

APPENDIX B – FAULT LOG

Fault codes and descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

APPENDIX C – RECOMMENDED SECURE HARDENING GUIDELINES

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Secure configuration guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

vi

VARIABLE SPEED DRIVE SERIES III LIT-12012999—June 2018 www.johnsoncontrols.com

Page 7

List of gures

Figure 1. RTC battery connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Figure 2. VS3 rating label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Figure 3. VS3 carton rating label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Figure 4. Johnson Controls Series III VSD—catalog numbering system . . . . . . . . . . .3

Figure 5. Keypad and display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Figure 6. General view of LCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Figure 7. Welcome page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Figure 8. Upgrade page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Figure 9. Auto backup page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Figure 10. Main menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Figure 11. Parent node page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Figure 12. Parameter page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Figure 13. Parameter page from favorite menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Figure 14. Fault page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Figure 15. Main menu page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Figure 16. Main menu navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Figure 17. M—Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Figure 18. Active faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Figure 19. Pop-up active faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Figure 20. Fault history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Figure 21. Parameter setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Figure 22. Parameter sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Figure 23. Down from keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Figure 24. Parameters comparison . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Figure 25. Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Figure 26. Edit parameter value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Figure 27. Parameter locked . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Figure 28. Acceleration and deceleration time . . . . . . . . . . . . . . . . . . . . . . . . . . . . .130

Figure 29. Motor parameters from ratings plate . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Figure 30. With and without reference scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . .134

Figure 31. Start forward/start reverse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .134

Figure 32. Start, stop and reverse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .135

Figure 33. Start pulse/stop pulse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .136

Figure 34. Start forward/start reverse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Figure 35. Start pulse/stop pulse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .138

Figure 36. Activation of fixed frequencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .142

Figure 37. AI1 2wire-current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .146

Figure 38. AI1 3wire-current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .146

Figure 39. AI1 4wire-current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .147

Variable Speed Drive Series III

VARIABLE SPEED DRIVE SERIES III LIT-12012999—June 2018 www.johnsoncontrols.com

vii

Page 8

Variable Speed Drive Series III

List of gures, continued

Figure 40. AI1 reference potentiometer 10V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .147

Figure 41. Analog input AI scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .147

Figure 42. AI1 signal filtering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .148

Figure 43. AI1 No signal inversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .148

Figure 44. AI1 Signal Inversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .148

Figure 45. Example of joystick hysteresis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .149

Figure 46. Example of sleep limit function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .149

Figure 47. AI2 2wire-current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .150

Figure 48. AI2 3wire-current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .150

Figure 49. AI2 4wire-current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .150

Figure 50. AI2 differential voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .150

Figure 51. AI2 pot ref . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .151

Figure 52. Supervision function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .158

Figure 53. Analog output filtering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .161

Figure 54. Analog output scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .162

Figure 55. Analog output invert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .162

Figure 56. Acceleration/Deceleration (S-shaped) . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Figure 57. DC-Braking time when stop mode = coasting . . . . . . . . . . . . . . . . . . . . .166

Figure 58. DC-Braking time when stop mode = ramp . . . . . . . . . . . . . . . . . . . . . . .166

Figure 59. Example of skip frequency area setting . . . . . . . . . . . . . . . . . . . . . . . . . 168

Figure 60. Linear and squared change of motor voltage . . . . . . . . . . . . . . . . . . . . .169

Figure 61. Programmable V/Hz curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .170

Figure 62. Motor thermal current it curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Figure 63. Motor temperature calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .173

Figure 64. Stall characteristics settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Figure 65. Stall time count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Figure 66. Setting of minimum load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175

Figure 67. Underload time counter function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175

Figure 68. Auto restart fail (try number >2.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .179

Figure 69. Setting up PID application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .183

Figure 70. Setting up PID application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .188

viii

VARIABLE SPEED DRIVE SERIES III LIT-12012999—June 2018 www.johnsoncontrols.com

Page 9

List of tables

Table 1. Common abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Table 2. Open Type /IP20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Table 3. Type 1/IP21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Table 4. Type 12/IP54 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Table 5. Open Type /IP20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Table 6. Type 1/IP21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Table 7. Type 12/IP54 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Table 8. Type 1/IP21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Table 9. Type 12/IP54 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Table 10. Keypad buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Table 11. LED state indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 12. Soft keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 13. Keypad menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Table 14. Startup wizard instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Table 14. Startup wizard instructions continued . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Table 15. PID Mini-Wizard values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Table 16. I/O connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Table 17. Drive communication ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Table 18. Basic—M1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Table 19. IO Status—M2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Table 20. Optional Boards — M3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Table 21. Energy Savings — M4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Table 22. FB Monitor Menu — M5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Table 22. FB Monitor Menu — M5 continued . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Table 23. User Defined Output — M8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Table 24. MWH Monitor — M9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Table 25. Multi-Monitoring — M10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Table 26. Basic Parameters — P1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Table 27. Basic Setting — P2.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Table 28. Digital Input — P2.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Table 28. Digital Input — P2.2, continued . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Table 29. Preset Speed — P2.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Table 30. AI1 Settings — P2.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Table 31. AI2 Settings — P2.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Table 32. Digital Output — P3.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Table 32. Digital Output — P3.1 continued . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Table 33. Supervisions — P3.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Table 33. Supervisions — P3.2 continued . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Table 34. Analog Output 1 — P3.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Table 35. Analog Output 2 — P3.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Table 36. Basic Setting — P4.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Table 37. Brake — P4.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Table 38. Skip Frequency — P4.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Variable Speed Drive Series III

VARIABLE SPEED DRIVE SERIES III LIT-12012999—June 2018 www.johnsoncontrols.com

ix

Page 10

Variable Speed Drive Series III

List of tables, continued

Table 39. Analog Output 2 — P3.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Table 40. Basic Setting — P5.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Table 41. Motor — P6.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Table 42. Drive — P6.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Table 43. Communication — P6.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Table 44. Auto Restart — P6.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Table 45. Fire Mode — P9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Table 46. Basic Setting — P10.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Table 47. FB Process Data Input Sel — P12.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Table 48. FB Process Data Output Sel — P12.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Table 49. Basic Setting — P12.3.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Table 50. Modbus RTU — P12.3.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Table 51. BACnet MS/TP — P12.3.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Table 52. SA Bus — P12.3.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Table 53. Basic Setting — P12.4.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Table 54. Modbus TCP — P12.4.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Table 55. BACnet IP — P12.4.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Table 56. Basic Setting — P13.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Table 57. Version Info — P13.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Table 58. Application Info — P13.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Table 59. User Info — P13.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Table 60. Operate Mode — O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Table 61. PID application default I/O connection . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Table 62. Drive communication ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Table 63. Basic - M1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Table 64. IO Status — M2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Table 65. Optional Boards — M3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Table 66. Energy Savings — M4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Table 67. FB Monitor Menu — M5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Table 68. PID Monitor — M6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Table 69. Timer/Interval Control — M7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Table 70. User Defined Output — M8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Table 71. MWH Monitor — M9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Table 72. Multi-Monitoring — M10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Table 73. Basic Parameters — P1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Table 74. Basic Setting — P2.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Table 75. Digital Input — P2.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Table 76. Preset Speed — P2.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Table 77. AI1 Settings — P2.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Table 78. AI2 Settings — P2.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Table 79. Digital Output — P3.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

x

VARIABLE SPEED DRIVE SERIES III LIT-12012999—June 2018 www.johnsoncontrols.com

Page 11

List of tables, continued

Table 80. Supervisions — P3.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Table 81. Analog Output 1 — P3.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Table 82. Analog Output 2 — P3.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Table 83. Basic Setting — P4.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Table 84. Brake — P4.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Table 85. Skip Frequency — P4.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Table 86. Energy Savings Calc — P4.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Table 87. Basic Setting — P5.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Table 88. Second Motor Parameter — P5.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Table 89. Motor — P6.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Table 90. Drive — P6.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Table 91. Communication — P6.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Table 92. Auto Restart — P6.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Table 93. Basic Setting — P7.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

Table 94. Monitor — P7.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Table 95. Basic — P7.3.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Table 96. Setpoint 1 — P7.3.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Table 97. Setpoint 2 — P7.3.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Table 98. Basic — P7.4.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Table 99. Feedback 1 — P7.4.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Table 100. Feedback 2 — P7.4.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Table 101. Basic — P7.5.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Table 102. Feedforward 1 — P7.5.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Table 103. Feedforward 2 — P7.5.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Table 104. Basic Setting — P8.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Table 105. Monitor — P8.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Table 106. Basic — P8.3.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Table 107. Setpoint 1 — P8.3.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Table 108. Setpoint 2 — P8.3.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Table 109. Basic — P8.4.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Table 110. Feedback 1 — P8.4.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Table 111. Feedback 2 — P8.4.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

Table 112. Basic — P8.5.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

Table 113. Feedforward 1 — P8.5.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

Table 114. Feedforward 2 — P8.5.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

Table 115. Fire Mode — P9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

Table 116. Basic Setting — P10.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

Table 117. Redundant Drive — P10.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

Table 118. Interval 1 — P11.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

Table 119. Interval 2 — P11.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

Variable Speed Drive Series III

VARIABLE SPEED DRIVE SERIES III LIT-12012999—June 2018 www.johnsoncontrols.com

xi

Page 12

Variable Speed Drive Series III

List of tables, continued

Table 120. Interval 3 — P11.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

Table 121. Interval 4 — P11.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

Table 122. Interval 5 — P11.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

Table 123. Timer — P11.6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

Table 124. FB Process Data Input Sel — P12.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

Table 125. FB Process Data Output Sel — P12.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Table 126. Basic Setting — P12.3.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Table 127. Modbus RTU — P12.3.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Table 128. BACnet MS/TP — P12.3.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Table 129. Basic Setting — P12.4.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Table 130. Modbus TCP — P12.4.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Table 131. BACnet IP — P12.4.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Table 132. Basic Setting — P13.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Table 133. Version Info — P13.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Table 134. Application Info — P13.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Table 135. User Info — P13.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Table 136. Operate Mode — O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Table 137. Advanced Application Default I/O Configuration . . . . . . . . . . . . . . . . . . . .94

Table 138. Drive Communication Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

Table 139. Basic — M1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

Table 140. IO Status — M2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

Table 141. Optional Boards — M3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

Table 142. Energy Savings — M4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

Table 143. FB Monitor Menu — M5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

Table 144. PID Monitor — M6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

Table 145. Timer/Interval Control — M7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

Table 146. User Defined Output — M8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

Table 147. MWH Monitor — M9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

Table 148. Multi-Monitoring — M10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

Table 149. Basic Parameters — P1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

Table 150. Basic Setting — P2.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

Table 151. Digital Input — P2.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Table 152. Preset Speed — P2.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Table 153. Preset Speed — P2.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Table 154. Preset Speed — P2.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Table 155. Digital Output — P3.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

Table 156. Supervisions — P3.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Table 157. Supervisions — P3.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Table 158. Analog Output 2 — P3.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

Table 159. Logic Function — P3.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

Table 160. Basic Setting — P4.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

Table 161. Brake — P4.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Table 162. Skip Frequency — P4.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

xii

VARIABLE SPEED DRIVE SERIES III LIT-12012999—June 2018 www.johnsoncontrols.com

Page 13

List of tables, continued

Table 163. Energy Savings Calc — P4.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Table 164. Basic Setting — P5.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

Table 165. Second Motor Parameter — P5.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

Table 166. Motor — P6.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Table 167. Drive — P6.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Table 168. Communication — P6.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Table 169. Auto Restart — P6.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Table 170. Basic Setting — P7.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Table 171. Monitor — P7.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

Table 172. Basic — P7.3.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Table 173. Setpoint 1 — P7.3.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Table 174. Setpoint 2 — P7.3.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Table 175. Basic — P7.4.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Table 176. Feedback 1 — P7.4.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Table 177. Feedback 2 — P7.4.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Table 178. Basic — P7.5.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Table 179. Feedforward 1 — P7.5.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Table 180. Feedforward 2 — P7.5.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Table 181. Basic Setting — P8.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Table 182. Monitor — P8.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Table 183. Basic — P8.3.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Table 184. Setpoint 1 — P8.3.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Table 185. Setpoint 2 — P8.3.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Table 186. Basic — P8.4.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Table 187. Feedback 1 — P8.4.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Table 188. Feedback 2 — P8.4.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Table 189. Basic — P8.5.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

Table 190. Feedforward 1 — P8.5.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

Table 191. Feedforward 2 − P8.5.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

Table 192. Fire Mode − P9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

Table 193. Basic Setting — P10.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

Table 194. Redundant Drive — P10.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

Table 195. Interval 1 — P11.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

Table 196. Interval 2 — P11.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

Table 197. Interval 3 — P11.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

Table 198. Interval 4 — P11.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

Table 199. Interval 5 — P11.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

Table 200. Timer — P11.6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

Table 201. FB Process Data Input Sel — P12.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

Table 202. FB Process Data Output Sel — P12.2 . . . . . . . . . . . . . . . . . . . . . . . . . .123

Table 203. Basic Setting — P12.3.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

Table 204. Modbus RTU — P12.3.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

Table 205. BACnet MS/TP — P12.3.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

Variable Speed Drive Series III

VARIABLE SPEED DRIVE SERIES III LIT-12012999—June 2018 www.johnsoncontrols.com

xiii

Page 14

Variable Speed Drive Series III

List of tables, continued

Table 206. SA Bus — P12.3.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

Table 207. Basic Setting — P12.4.1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

Table 208. Modbus TCP — P12.4.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

Table 209. BACnet IP — P12.4.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

Table 210. Basic Setting — P13.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

Table 211. Version Info — P13.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .128

Table 212. Application Info — P13.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .129

Table 213. User Info — P13.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .129

Table 214. Operate Mode - O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .129

Table 215. Active faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .210

Table 216. History faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

xiv

VARIABLE SPEED DRIVE SERIES III LIT-12012999—June 2018 www.johnsoncontrols.com

Page 15

Safety

WARNING!

DANGEROUS ELECTRICAL VOLTAGE!

Before commencing the installation

•

Disconnect the power supply of the device

•

Ensure that devices cannot be accidentally restarted

•

Verify isolation from the supply

•

Earth and short circuit the device

•

Cover or enclose any adjacent live components

•

Only suitably qualified personnel in accordance with

EN 50110-1/-2 (VDE 0105 Part 100) may work on this

device/system

•

Before installation and before touching the device ensure

that you are free of electrostatic charge

•

The functional earth (FE, PES) must be connected to

the protective earth (PE) or the potential equalization.

The system installer is responsible for implementing this

connection

•

Connecting cables and signal lines should be installed so

that inductive or capacitive interference does not impair

the automation functions

•

Install automation devices and related operating elements

in such a way that they are well protected against

unintentional operation

•

Suitable safety hardware and software measures should

be implemented for the I/O interface so that an open

circuit on the signal side does not result in undefined

states in the automation devices

•

Ensure a reliable electrical isolation of the extra-low

voltage of the 24 V supply. Only use power supply units

complying with IEC 60364-4-41 (VDE 0100 Part 410) or

HD384.4.41 S2

•

Deviations of the input voltage from the rated value must

not exceed the tolerance limits given in the specifications,

otherwise this may cause malfunction and dangerous

operation

•

Emergency stop devices complying with IEC/EN 60204-1

must be effective in all operating modes of the automation

devices. Unlatching the emergency-stop devices must not

cause a restart

•

Devices that are designed for mounting in housings or

control cabinets must only be operated and controlled

after they have been installed and with the housing

closed. Desktop or portable units must only be operated

and controlled in enclosed housings

Variable Speed Drive Series III

•

Measures should be taken to ensure the proper restart

of programs interrupted after a voltage dip or failure.

Thisshould not cause dangerous operating states even for

a short time. If necessary, emergency-stop devices should

be implemented

•

Wherever faults in the automation system may cause

injury or material damage, external measures must be

implemented to ensure a safe operating state in the

event of a fault or malfunction (for example, by means of

separate limit switches, mechanical interlocks, and so on)

•

Depending on their degree of protection, adjustable

frequency drives may contain live bright metal parts,

moving or rotating components, or hot surfaces during

and immediately after operation

•

Removal of the required covers, improper installation,

or incorrect operation of motor or adjustable frequency

drive may cause the failure of the device and may lead to

serious injury or damage

•

The applicable national accident prevention and safety

regulations apply to all work carried out on live adjustable

frequency drives

•

The electrical installation must be carried out in

accordance with the relevant regulations (for example,

with regard to cable cross sections, fuses, PE)

•

Transport, installation, commissioning, and maintenance

work must be carried out only by qualified personnel

(IEC 60364, HD 384 and national occupational

safetyregulations)

•

Installations containing adjustable frequency drives must

be provided with additional monitoring and protective

devices in accordance with the applicable safety

regulations. Modifications to the adjustable frequency

drives using the operating software are permitted

•

All covers and doors must be kept closed during operation

•

To reduce hazards for people or equipment, the user must

include in the machine design measures that restrict the

consequences of a malfunction or failure of the drive

(increased motor speed or sudden standstill of motor).

These measures include:

• Other independent devices for monitoring safety-related

variables (speed, travel, end positions, and so on)

• Electrical or non-electrical system-wide measures

(electrical or mechanical interlocks)

• Never touch live parts or cable connections of

the adjustable frequency drive after it has been

disconnected from the power supply. Due to the charge

in the capacitors, these parts may still be live after

disconnection. Fit appropriate warning signs

VARIABLE SPEED DRIVE SERIES III LIT-12012999—June 2018 www.johnsoncontrols.com

xv

Page 16

Variable Speed Drive Series III

Definitions and symbols

WARNING

This symbol indicates high voltage. It calls your

attention to items or operations that could be

dangerous to you and other persons operating

this equipment. Read the message and follow the

instructions carefully. This symbol is the “Safety Alert

Symbol”. It occurs with either of two signal words:

CAUTION or WARNING, as described below.

WARNING

Indicates a potentially hazardous situation which, if not

avoided, can result in serious injury or death.

CAUTION

Indicates a potentially hazardous situation which, if not

avoided, can result in minor to moderate injury, or serious

damage to the product. The situation described in the

CAUTION may, if not avoided, lead to serious results.

Important safety measures are described in CAUTION

(as well as WARNING).

Hazardous high voltage

WARNING

Motor control equipment and electronic controllers are

connected to hazardous line voltages. When servicing

drives and electronic controllers, there may be exposed

components with housings or protrusions at or above

line potential. Extreme care should be taken to protect

against shock.

Warnings and cautions

This manual contains clearly marked cautions and warnings

which are intended for your personal safety and to avoid

any unintentional damage to the product or connected

appliances. Please read the information included in cautions

and warnings carefully.

WARNING

The relay outputs and other I/O-terminals may have

a dangerous control voltage present even when

disconnected from mains.

WARNING

Be sure not to plug the Ethernet/BACnet/IP cable to

the terminal under the keypad! This might harm your

personal computer.

WARNING

Be sure not to plug the Modbus TCP cable to the

terminal under the keypad! This might harm your

personal computer.

CAUTION

Remove external control signal before resetting the fault to

prevent unintentional restart of the drive.

Stand on an insulating pad and make it a habit to use

only one hand when checking components. Always

work with another person in case an emergency occurs.

Disconnect power before checking controllers or performing

maintenance. Be sure equipment is properly grounded.

Wear safety glasses whenever working on electronic

controllers or rotating machinery.

xvi

VARIABLE SPEED DRIVE SERIES III LIT-12012999—June 2018 www.johnsoncontrols.com

Page 17

Important safety information

Hazardous high voltage

Variable Speed Drive Series III

Important warnings

WARNING

The components of the power unit are live when the

AC drive is connected to mains potential. Coming into

contact with this voltage is extremely dangerous and

may cause death or severe injury.

WARNING

The motor terminals U, V, W and the brake resistor

terminals are live when connected to mains, even if

themotor is not running.

WARNING

After disconnecting the AC drive from the mains,

waituntil the indicators on the keypad go out (if no

keypad is attached see the indicators on the cover).

Wait 5 more minutes before doing any work on

the connections. Do not open the cover before this

time hasexpired. After expiration of this time, use a

measuring equipment to absolutely ensure that no

voltage is present. Always ensure absence of voltage

before starting any electrical work!

WARNING

The control I/O-terminals are isolated from the mains

potential. However, the relay outputs and other I/Oterminals may have a dangerous control voltage present

even when disconnected from mains.

WARNING

Before connecting the AC drive to mains, confirm that

the front and cable covers of drive are closed.

WARNING

During a ramp stop (see the Application Manual), the

motor is still generating voltage to the drive. Therefore,

do not touch the components of the AC drive before the

motor has completely stopped. Wait until the indicators

on the keypad go out (if no keypad is attached see

the indicators on the cover). Wait additional 5 minutes

before starting any work on the drive.

WARNING

AC drive is meant for fixed installations only.

WARNING

Do not perform any measurements when the AC drive is

connected to the mains.

WARNING

The ground leakage current of AC drives exceeds 3.5

mA AC. According to standard EN61800-5-1, a reinforced

protective ground connection must be ensured.

WARNING

If the AC drive is used as a part of a machine, the machine

manufacturer is responsible for providing the machine

with a supply disconnecting device (EN 60204-1).

WARNING

Only spare parts delivered can be used.

WARNING

At power-up, power brake or fault reset the motor will

start immediately if the start signal is active, unless the

pulse control for Start/Stop logic has been selected.

Furthermore, the I/O functionalistic (including start

inputs) may change if parameters, applications or

software are changed. Disconnect, therefore, the motor

if an unexpected start can cause danger.

WARNING

The motor starts automatically after automatic fault

reset if the auto restart function is activated. See the

Application Manual for more detailed information.

WARNING

Prior to measurements on the motor or the motor cable,

disconnect the motor cable from the AC drive.

WARNING

Do not touch the components on the circuit boards.

Static voltage discharge may damage the components.

WARNING

Check that the EMC level of the AC drive corresponds to

the requirements of your supply network.

VARIABLE SPEED DRIVE SERIES III LIT-12012999—June 2018 www.johnsoncontrols.com

xvii

Page 18

Variable Speed Drive Series III

Additional cautions

CAUTION

The AC drive must always be grounded with an grounding

conductor connected to the grounding terminal marked

with. The ground leakage current exceeds 3.5 mA AC.

According to EN61800-5-1, one or more of the following

conditions for the associated protective circuit shall be

satisfied:

a) The protective conductor shall have a cross-sectional

area of at least 10 mm

2

Cu or 16 mm2 Al, through its

total run

b) Where the protective conductor has a cross-sectional

area of less than 10 mm2 Cu or 16 mm2 Al, a second

protective conductor of at least the same

cross-sectional area shall be provided up to a point

where the protective conductor has a cross-sectional

area not less than 10 mm

2

Cu or 16 mm2 Al

c) Automatic disconnection of the supply in case of loss

of continuity of the protective conductor. The

cross-sectional area of every protective grounding

conductor that does not form part of the supply cable

or cable enclosure shall, in any case, be not less than:

•

2.5 mm2 if mechanical protection is provided or

•

4 mm2 if mechanical protection is not provided.

The ground fault protection inside the AC drive

protects only the drive itself against ground faults in

the motor or the motor cable. It is not intended for

personal safety. The ground fault protection inside

the AC drive protects only the drive itself against

ground faults in the motor or the motor cable. It is

notintended for personal safety. Due to the high

capacitive currents present in the AC drive, fault

current protective switches may not function properly.

Do not perform any voltage withstand tests on any

part of the drive. There is a certain procedure according

to which the tests shall be performed. Ignoring this

procedure may result in damagedproduct.

xviii

VARIABLE SPEED DRIVE SERIES III LIT-12012999—June 2018 www.johnsoncontrols.com

Page 19

Sécurité

AVERTISSEMENT !

TENSION ÉLECTRIQUE DANGEREUSE !

Avant de commencer l’installation

•

Débrancher l’alimentation de l’appareil

•

S’assurer que les dispositifs ne peuvent pas être

accidentellement redémarrés

•

Vérifier l’isolement de l’alimentation

•

Mettre l’appareil à la terre et le protéger contre les

courts-circuits

•

Couvrir ou enfermer tout composant sous tension

adjacent

•

Seul le personnel qualifié conformément à la norme EN

50110-1/-2 (VDE 0105 Partie 100) peut travailler sur cet

appareil/ce système

•

Avant l’installation et avant de toucher l’appareil, s’assurer

de ne porter aucune charge électrostatique

•

La terre fonctionnelle (FE, PSE) doit être raccordée à la

terre de protection (PE) ou la compensation de potentiel.

L’installateur du système a la responsabilité d’assurer

cette connexion

•

Les câbles de connexion et les lignes de signal doivent

être installés de façon à ce que les interférences

capacitives ou inductives ne compromettent pas les

fonctions d’automatisation

•

Installer les appareils d’automatisation et les éléments de

fonctionnement associés de manière à ce qu’ils soient

bien protégés contre tout fonctionnement accidentel

•

Des dispositifs de sécurité matériels et logiciels

appropriés doivent être utilisés en rapport avec l’interface

des E/S afin qu’un circuit ouvert sur le côté signal

ne résulte pas en états indéfinis dans les dispositifs

d’automatisation

•

Assurer une isolation électrique fiable sur le côté tension

extra basse de l’alimentation 24 V. Utiliser uniquement

des blocs d’alimentation conformes à la norme CEI

60364-4-41 (VDE 0100, partie 410) ou HD384.4.41 S2

•

Les écarts entre la tension d’entrée et la tension

nominale ne doivent pas dépasser les limites de

tolérance indiquées dans les spécifications, au risque de

provoquer un mauvais fonctionnement et une utilisation

dangereuse du système

•

Les dispositifs d’arrêt d’urgence conformes à la

norme CEI/EN 60204-1 doivent être efficace dans

tous les modes de fonctionnement des dispositifs

d’automatisation. Le déverrouillage des dispositifs d’arrêt

d’urgence ne doit pas entraîner un redémarrage

Variable Speed Drive Series III

•

Les dispositifs conçus pour un montage dans des boîtiers

ou armoires de commande ne doivent être utilisés et

contrôlés qu’après avoir été installés et avec le boîtier

fermé. Les unités de bureau ou portatives ne doivent être

utilisées et contrôlées que dans leurs boîtiers fermés

•

Des mesures doivent être prises pour assurer un bon

redémarrage des programmes interrompus après une

chute ou une panne de tension. Ceci ne doit pas causer

des états de fonctionnement dangereux, même pour un

court laps de temps. Si nécessaire, des dispositifs d’arrêt

d’urgence doivent être utilisés

•

Quand des défaillances du système d’automatisation

peuvent entraîner des blessures ou des dommages

matériels, des mesures externes doivent être appliquées

pour assurer un état de fonctionnement sans danger

en cas de panne ou de mauvais fonctionnement

(par exemple au moyen de disjoncteurs séparés, de

verrouillages mécaniques, etc.)

•

En fonction de leur degré de protection, les

entraînements à fréquence variable peuvent contenir des

pièces métalliques sous tension, des composants rotatifs

ou en mouvement et des surfaces brûlantes, pendant le

fonctionnement et immédiatement après l’arrêt

•

Le retrait des protections requises, une installation

incorrecte ou un mauvais fonctionnement du moteur ou

de l’entraînement à fréquence variable peuvent causer la

défaillance de l’appareil et entraîner des blessures graves

et des dommages importants

•

La réglementation nationale applicable en matière de

sécurité et de prévention des accidents s’applique à tous

les travaux effectués sur les entraînements à fréquence

variable sous tension

•

L’installation électrique doit être effectuée conformément

aux réglementations applicables (par exemple, en ce

qui concerne les sections transversales des câbles, les

fusibles, la mise à la terre de protection)

•

Le transport, l’installation, la mise en service et

les travaux de maintenance doivent être effectués

uniquement par un personnel qualifié (IEC 60364, HD384

et règles de sécurité du travail)

•

Les installations contenant des entraînements à

fréquence variable doivent être équipées de dispositifs

de surveillance et de protection, conformément aux

réglementations applicables en matière de sécurité. Les

modifications des entraînements à fréquence variable

réalisées à l’aide du logiciel d’exploitation sont autorisées

•

Toutes les protections et les portes doivent être

maintenues fermées pendant le fonctionnement

VARIABLE SPEED DRIVE SERIES III LIT-12012999—June 2018 www.johnsoncontrols.com

xix

Page 20

Variable Speed Drive Series III

•

Pour réduire les risques d’accidents et de dommages

matériels, l’utilisateur doit inclure dans la conception de

la machine des mesures limitant les conséquences de

panne ou de mauvais fonctionnement de l’entraînement

(augmentation de la vitesse ou arrêt soudain du moteur).

Ces mesures comprennent :

• Autres dispositifs indépendants de surveillance des

variables en rapport avec la sécurité (vitesse, voyages,

positions d’extrémité, etc.)

• Mesures électriques ou non électriques appliquées à

l’ensemble du système (verrouillages électriques ou

mécaniques)

• Ne jamais toucher les pièces sous tension ni les

connexions des câbles de l’entraînement à fréquence

variable après leur déconnexion de l’alimentation. En

raison de la charge dans les condensateurs, ces pièces

peuvent être encore sous tension après la déconnexion.

Installer les panneaux d’avertissement appropriés

Lire ce manuel en entier et s’assurer de bien comprendre

les procédures avant de tenter d’installer, de configurer,

d’utiliser et d’effectuer tout travail d’entretien sur cet

entraînement à fréquence variable manejar.

Haute tension dangereuse

AVERTISSEMENT

L’équipement de contrôle du moteur et les contrôleurs

électroniques sont branchés sur des tensions secteur

dangereuses. Lors de l’entretien des entraînements

et des contrôleurs électroniques, il peut y avoir

des composants exposés avec des boîtiers ou des

protubérances au niveau du potentiel du réseau ou

au-dessus. Toutes les précautions doivent être prises

pour se protéger contre les chocs électriques.

•

Se tenir sur un tapis isolant et prendre l’habitude

de n’utiliser qu’une seule main pour vérifier

lescomposants

•

Toujours travailler avec une autre personne lorsqu’une

situation d’urgence se produit

•

Débrancher l’alimentation avant de vérifier les

contrôleurs ou d’effectuer des travaux d’entretien

•

S’assurer que l’équipement est correctement relié à

la terre

•

Porter des lunettes de sécurité lors des travaux sur les

contrôleurs électroniques ou les machines rotatives

Dé nitions et symboles

AVERTISSEMENT

Ce symbole indique une haute tension. Il attire

l’attention sur les éléments ou les opérations qui

pourraient être dangereux pour les personnes utilisant

cet équipement. Lire attentivement le message et suivre

attentivement les instructions.

Ce symbole est le « symbole d’alerte de sécurité ».

Il accompagne les deux termes d’avertissement suivants:

MISE EN GARDE ou AVERTISSEMENT, comme décrit

ci-dessous.

AVERTISSEMENT

Indique une situation potentiellement dangereuse qui, si

elle n’est pas évitée, peut entraîner des blessures graves

ou la mort.

MISE EN GARDE

Indique une situation potentiellement dangereuse qui, si

elle n’est pas évitée, peut entraîner des blessures légères

à modérées et d’importants dégâts matériels. La situation

décrite dans la MISE EN GARDE peut, si elle n’est pas

évitée, entraîner des conséquences graves. Des mesures

de sécurité importantes sont décrites dans les MISES EN

GARDE (ainsi que dans les AVERTISSEMENTS).

AVERTISSEMENT

Les composants de la section d’alimentation de

l’entraînement restent sous tension après la coupure

de la tension d’alimentation. Après la déconnexion de

l’alimentation, attendre au moins cinq minutes avant

de retirer le couvercle pour permettre la décharge des

condensateurs du circuit intermédiaire.

Prêter attention aux avertissements signalant

desdangers !

DANGER

5 MIN

AVERTISSEMENT

Risque de choc électrique – risque de blessures !

Effectuer le câblage uniquement si l’unité n’est plus

sous tension.

AVERTISSEMENT

Ne pas effectuer de modifications sur l’entraînement CA

lorsqu’il est connecté à l’alimentation secteur.

xx

VARIABLE SPEED DRIVE SERIES III LIT-12012999—June 2018 www.johnsoncontrols.com

Page 21

Avertissements et mises en garde

Variable Speed Drive Series III

AVERTISSEMENT

S’assurer de mettre l’appareil à la terre en suivant

les instructions de ce manuel. Les unités non mises

à la terre peuvent causer des chocs électriques et

desincendies.

AVERTISSEMENT

Cet équipement ne doit être installé, réglé et entretenu

que par un personnel d’entretien électrique qualifié

connaissant la construction et le fonctionnement de ce

type d’équipement, ainsi que les risques encourus. Le

non-respect de cette précaution peut entraîner la mort

ou des blessures graves.

AVERTISSEMENT

Les composants à l’intérieur de l’entraînement sont

sous tension lorsque l’entraînement est branché

à l’alimentation. Le contact avec cette tension est

extrêmement dangereux et peut causer la mort ou des

blessures graves.

AVERTISSEMENT

Les bornes de phase (L1, L2, L3), les bornes du moteur

(U, V, W) et les bornes de résistance de liaison CC/

frein (DC-, DC+/R+, R-) sont sous tension lorsque

l’entraînement est branché à l’alimentation, même si le

moteur ne tourne pas. Le contact avec cette tension est

extrêmement dangereux et peut causer la mort ou des

blessures graves.

AVERTISSEMENT

Même si les bornes E/S de commande sont isolées

de la tension secteur, les sorties de relais et les autres

bornes E/S peuvent présenter une tension dangereuse

même lorsque l’entraînement est débranché. Le contact

avec cette tension est extrêmement dangereux et peut

causer la mort ou des blessures graves.

AVERTISSEMENT