Johnson Controls VA9208-BGA-3, VA9208-BAA-3, VA9208-BDC-3, VA9208-BGC-3, VA9208-GGA-3 Installation Instructions Manual

...Page 1

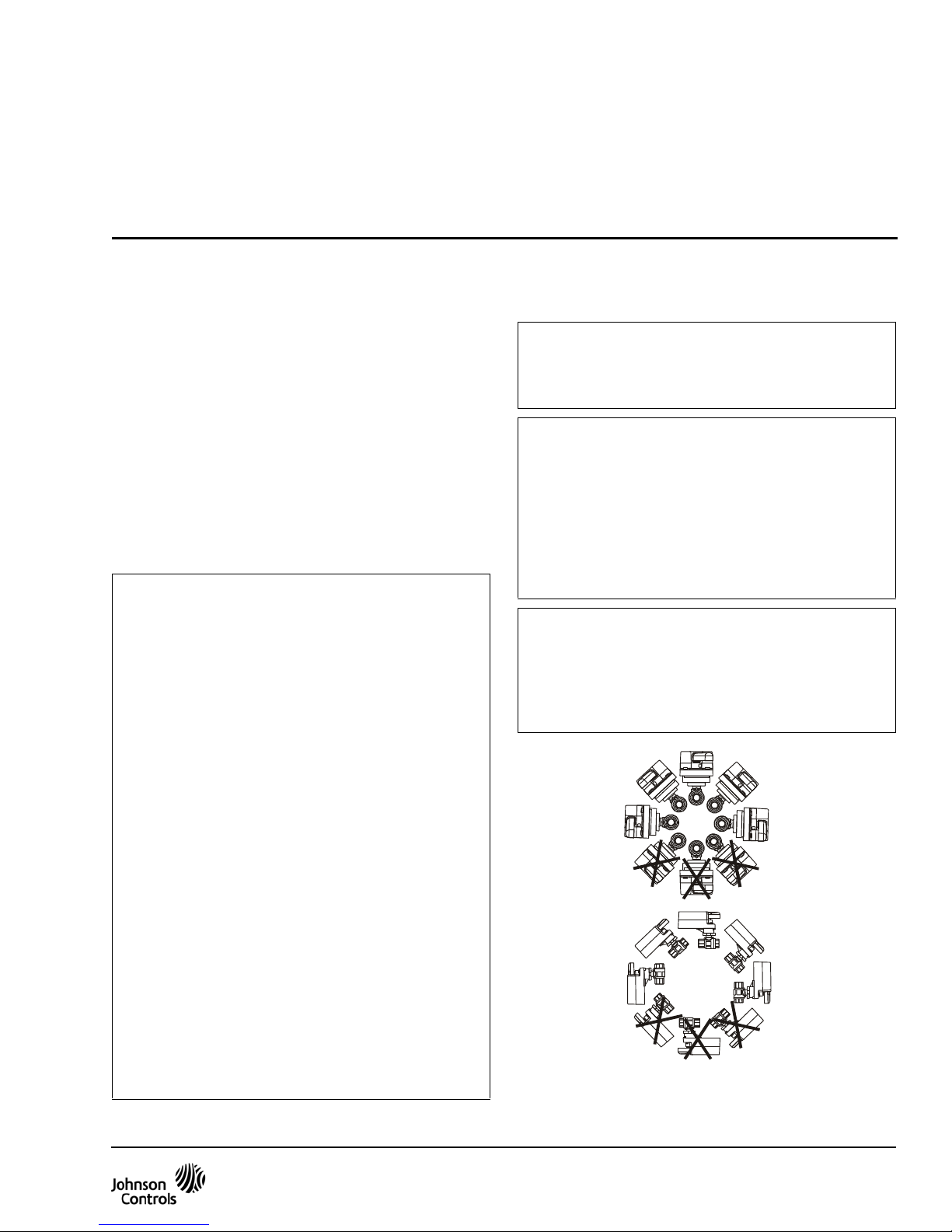

Figure 1: Mounting Positions for Chilled

Water and Condensing Atmosphere

F

I

G

:

m

n

t

p

o

s

_

H

2

O

_

a

p

p

*14137913E*

14-1379-13, Rev. E

VA9208-Bxx-x Series On/Off Electric Spring Return

Valve Actuators

Installation Instructions

VA9208-BAA-3, VA9208-BAC-3, VA9208-BDA-3

VA9208-BDC-3, VA9208-BGA-3, VA9208-BGC-3

Refer to the QuickLIT Web site for the most up-to-date version of this document.

Applications

The VA9208-Bxx-x Series On/Off Electric Spring

Return Actuator s are direct-mount valve actuators that

operate on AC 24 V power at 50/60 Hz, DC 24 V

power, AC 120 V power at 60 Hz, or AC 230 V power at

50/60 Hz. These bidirectional actuators are used to

provide two position control on Johnson Controls®

VG1000 Series 1-1/4, 1-1/2, and 2 in. (DN32, DN40,

and DN50) ball valves in Heating, V entilating, and Air

Conditioning (HVAC) applications.

The VA9208 Series Electric Spring Return Actuators

provide a running torque of 70 lb·in. (8 N·m). Integral

line voltage auxiliary switches, available only on the

VA9208-xxC-3 models, indicate end-stop position, or

perform switching functions within the selected rotation

range.

IMPORTANT: Use this VA9208-Bxx-x Series On/

Off Electric Spring Return Actuator only to control

equipment under normal operating conditions.

Where failure or malfunction of the electric actuator

could lead to personal injury or property damage to

the controlled equipment or other pr op er ty,

additional precautions must be designed into the

control system. Incorporate and maintain other

devices, such as supervisory or alarm systems or

safety or limit controls, intended to warn of or protect

against failure or malfunction of the electric actuator.

Part No. 14-1379-13, Rev. E

Issued October 2017

Installation

Install the ball valve with the actuator at or above the

center line of the horizontal piping (see Figure 1).

IMPORTANT: In steam applications, install the

valve with the stem horizontal to the piping. Failure

to follow this precaution may shorten the life of the

actuator.

IMPORTANT: Before specifying VA9208 Series

Electric Spring Return Valve Actuators for plenum

applications, verify acceptance of exposed plastic

materials in plenum areas with the local building

authority. Building codes for plenum requirements

vary by location. Some local building authorities

accept compliance to UL 1995, Heating and Cooling

Equipment, while others use different acceptance

criteria.

IMPORTANT: Do not install or use this VA9208

Series Electric Spring Return Valve Actuator in or

near environments where corrosive subst an ce s or

vapors could be present. Exposure of the actuator to

corrosive environments may damage the device’s

internal components, and will void the warranty.

IMPORTANT : Utiliser ce V A9208-Bxx-x Series On/

Off Electric Spring Return Actuator uniquement po ur

commander des équipements dans des conditions

normales de fonctionnement. Lorsqu'une défaillance

ou un dysfonctionnement du electric actuator risque

de provoquer des blessures ou d'endommager

l'équipement contrôlé ou un autre équipement, la

conception du système de contrôle doit intégrer des

dispositifs de protection supplémentaires. Veiller

dans ce cas à intégrer de façon permanente

d'autres dispositifs, tels que des systèmes de

supervision ou d'alarme, ou des dispositifs de

sécurité ou de limitation, ayant une fonction

d'avertissement ou de protection en cas de

défaillance ou de dysfonctionnement du electric

actuator.

VA9208-Bxx-x Series On/Off Electric Spring Return Valve Actuators Installation

1

Instructions

Page 2

Special Tools Needed

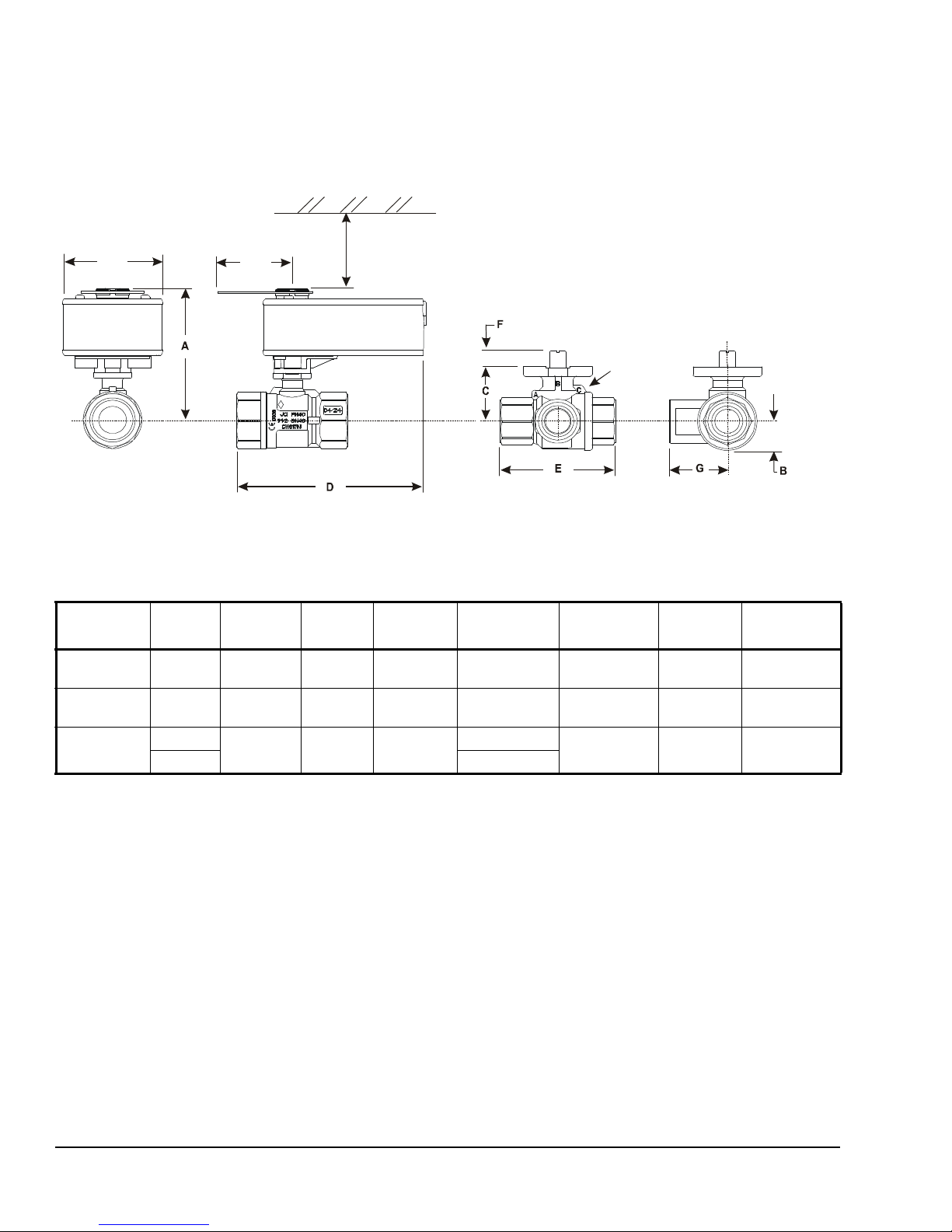

Figure 2: Spring Return VA9208 Actuated VG1241, VG1245, VG1841, and VG1845 Series Ball Valve

Dimensions, in. (mm)

3-29/32

(99)

2-7/8

(73)

Port Marking

Locations

F

I

G

:

V

A

9

2

0

8

X

_

d

i

m

s

3-1/2 (89)

Clearance Required

• Digital voltmeter

• T-2 0 T ORX® driver

Dimensions

Valve Actuat or

See Figure 2 and Table 1 for valve actuator

dimensions.

Table 1: VA9208 Actuated VG1241, VG1245, VG1841, and VG1845 Series Ball Valve Dimensions, in. (mm)

Valve Size

in. (DN)

1-1/4

(DN32)

1-1/2

(DN40)

2 (DN50) 2-way 5-17/32

1. Port A must always be connected to the coil (see Figure 2).

Valve

1

Style

All 5-5/32

All 5-5/16

3-way 7-7/8 (200)

ABC D E F G

(131)

(135)

(140)

1-1/32

(26)

1-9/64

(29)

1-15/32

(37)

1-23/32

7-5/32 (182) 3-15/16 (100) 11/32 (9) 1-31/32 (50)

(44)

1-57/64

7-3/8 (187) 4-21/64 (110) 11/32 (9) 2-11/64 (55)

(48)

2-1/8 (54) 7-19/32 (193) 4-27/32 (123) 11/32 (9) 2-27/64 (62)

VA9208-Bxx-x Series On/Off Electric Spring Return Valve Actuators Installation Instructions2

Page 3

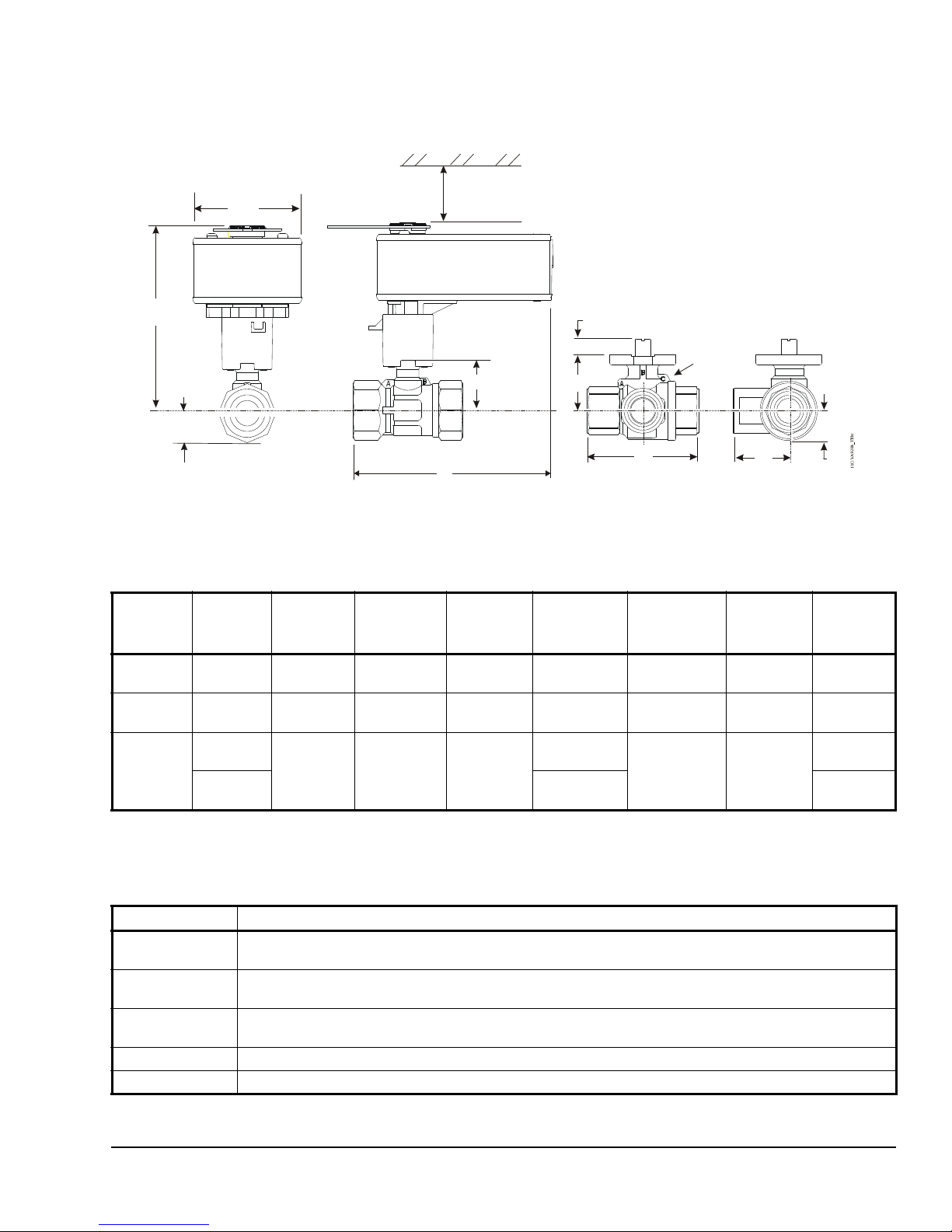

Valve Actuator with Thermal Barr ier

Figure 3: Spring Return VA9208 Actuated VG1241, VG1245, VG1841, and VG1845 Series Ball Valve

with Optional M9000-561 Thermal Barrier Installed Dimensions, in. (mm)

3-29/32

(99)

A

B

3-1/2 (89)

Clearance Req ui red

GCFBC

E

Port Marking

Locations

D

See Figure 3 and Table 2 for valve actuator dimensions

with optional M9000-561 Thermal Barrier insta lled.

Table 2: VA9208 Actuated VG1241, VG1245, VG1841, and VG1845 Series Ball Valve with Optional

M9000-561 Thermal Barrier Installed Dimensions, in. (mm)

Valve

Size in.

Valve

Style

ABC D E FG

1

(DN)

1-1/4

(DN32)

1-1/2

(DN40)

2 (DN50) 2-way 9-31/32

1. Port A must always be connected to the coil (See Figure 2).

All 9-17/64

(235)

All 9-15/16

(240)

(244)

1-1/32 (26) 1-23/32

7-1/4 (184) 3-15/16 (100) 11/32 (9) 1-31/32

(44)

1-9/64 (29) 1-57/64

7-7/16 (189) 4-21/64 (110) 11/32 (9) 2-11/64

(48)

1-15/32 (37) 2-1/8 (54) 7-11/16

(195)

(50)

(55)

4-27/32 (123) 11/32 (9) N/A

3-way 7-7/8 (200) 2-27/64

(62)

Accessories

Table 3: Accessories (Order Separately)

Code Number Description

M9000-560 Ball Valve Linkage Kit for applying M9203 and M9208 Series Actuators to VG1000 Series Valves

M9000-561 Thermal Barrier Extends M(VA)9104, M(VA)9203, and M(V A)9208 Series Electric Spring Return Actuator

M9000-341 Weathershield Kit for VG1000 Series Ball Valve application of M(VA)9104, M(VA)9203, and M(VA)9208

M9220-604 Replacement Manual Override Cranks with Long Crank Radius: 2.83 in. (72 mm) (Quantity 5)

M9208-605 Replacement Manual Override Cranks with Short Crank Radius: 1.83 in. (46.5 mm) (Quantity 5)

(Quantity 1)

Applications to Include Low Pressure Steam (Quantity 1)

Series Electric Spring Return Actuators (Quantity 1)

VA9208-Bxx-x Series On/Off Electric Spring Return Valve Actuators Installation Instructions 3

Page 4

Mounting

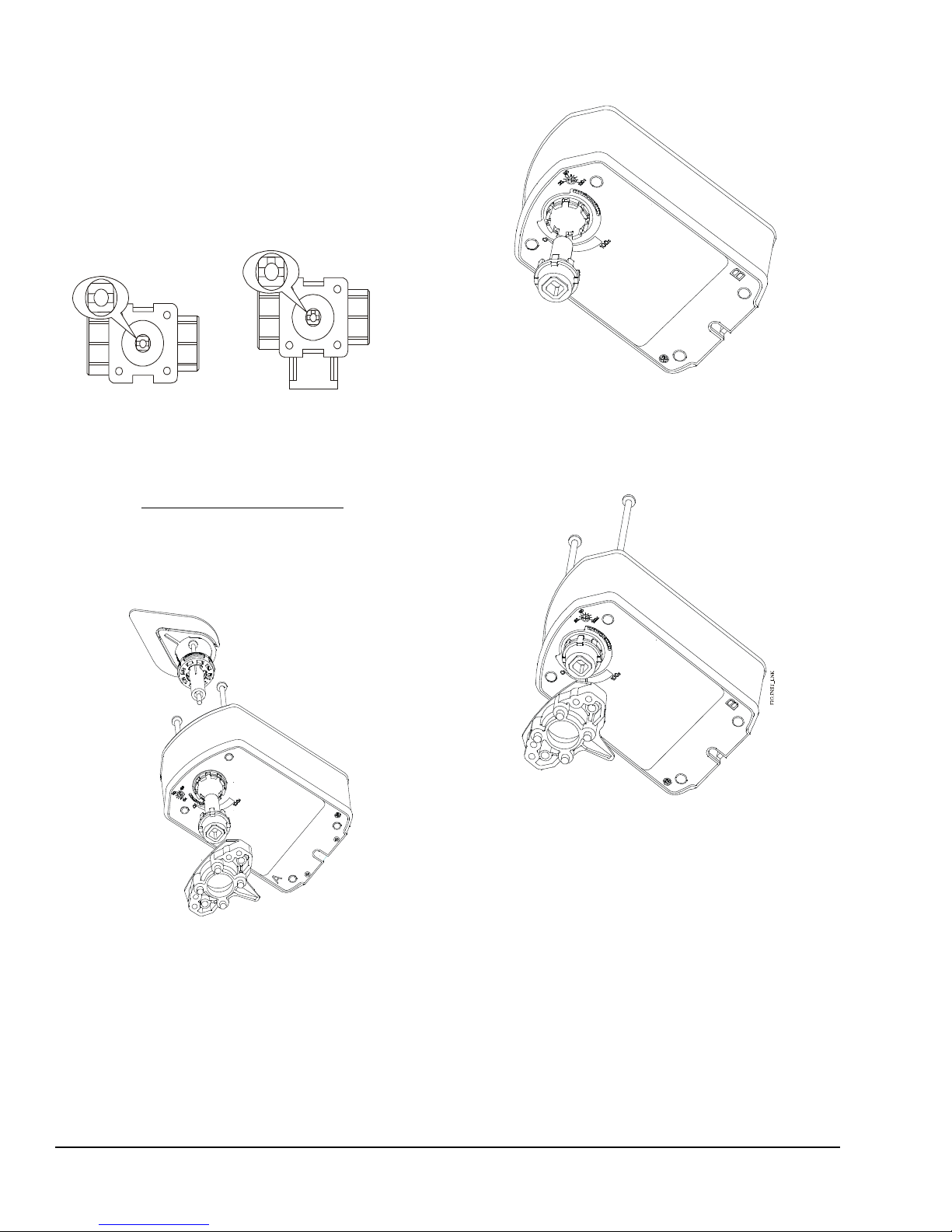

Figure 4: Positioning the Valve Stem

F

I

G

:

V

G

1

0

0

0

3 Way2 Way

Figure 5: Removing the Linkage

F

I

G

:

R

M

V

_

L

N

K

Figure 6: Inserting the Drive

F

I

G

:

D

R

V

_

S

H

F

T

_

B

Figure 7: Installing the Linkage

Mounting the Actuator to Spring Return Port A

(Coil) Open

To mount the actuator to Spring Return Port A (Coil)

open:

1. Turn the valve stem to the position outlined in

Figure 4.

2. Mount optional M9000-561 Thermal Barrier to the

valve if fluid temperature exceeds 212°F (100°C).

See the Mounting the Thermal Barrier

more information.

Note: Proceed to Step 7 if the ball valve linkage is on

actuator Side B.

section for

4. Insert the drive shaft into Side B (Figure 6).

5. Install linkage base on Side B using the two

#10-14 x 2.75 in. long screws (Figure 7). The

recommended torque is 20 to 24 lb·in.

(2.3 to 2.7 N·m).

3. Remove the linkage from Side A (Figure 5).

VA9208-Bxx-x Series On/Off Electric Spring Return Valve Actuators Installation Instructions4

Page 5

6. Insert fixed pointer and M4x0.7x83 mm long screw

Figure 8: Installing the Fixed

Pointer

F

I

G

:

F

X

P

T

_

A

Figure 9: Mount the Actuator

F

I

G

:

M

N

T

_

A

C

T

A

Figure 10: Positioning the Valve Stem

F

I

G

:

V

G

1

0

0

0

s

d

B

2 Way

3 Way

Figure 11: Removing the Linkage

into the Side A actuator hub. Direct the arrow on

the pointer to 100% (Figure 8).

7. Install the actuator on the ball valve (Figure 9).

Tighten the actuator mou nting screw to a to rque of

10 to 12 lb·in. (1.1 to 1.4 N·m) and snap the large

adjustable pointer into place.

Mounting the Actuator to Spring Return Port A

(Coil) Closed

To mount the actuator to spring return port A (coil)

closed:

1. Turn the valve stem to the position outlined in

Figure 10.

2. Mount optional M9000-561 Thermal Barrier to the

valve if fluid temperature exceeds 212°F (100° C) .

See the Mounting the Thermal Barrier

more information.

Note: Proceed to Step 7 if the ball valve linkage is on

actuator Side A.

3. Remove the linkage from Side B (Figure 11).

section for

VA9208-Bxx-x Series On/Off Electric Spring Return Valve Actuators Installation Instructions 5

Page 6

4. Insert the drive shaft into Side A (Figure 12).

Figure 12: Inserting the Drive

Figure 13: Installing the Linkage

F

I

G

:

l

n

k

g

A

Figure 14: Installing the Fixed Pointer

Figure 15: Mount the Actuator

5. Install linkage base on Side A using the two

#10-14 x 2.75 in. long screws (Figure 13). The

recommended torque is 20 to 24 lb·in.

(2.3 to 2.7 N·m).

6. Insert fixed pointer and M4x0.7x83 mm long screw

into the Side B actuator hub. Direct the arrow on

the pointer to 0% (Figure 14).

7. Install the actuator on the ball valve (Figure 15).

Tighten the actuator mounting scr ew to a torq ue of

10 to 12 lb·in. (1.1 to 1.4 N·m) and snap the large

adjustable pointer into place.

VA9208-Bxx-x Series On/Off Electric Spring Return Valve Actuators Installation Instructions6

Page 7

Mounting the Thermal Barrier

Figure 16: Optional M9000-561 Thermal Barrier

Barrier

Drive

Shaft

Machine Screws

Flange

Nuts

Figure 17: Installing the Drive

Shaft into the Thermal Barrier

Figure 18: Installing the

Barrier

F

I

G

:

i

n

_

a

c

t

Figure 16 shows the optional M9000-561 Thermal

Barrier.

To mount the optional thermal barrier:

1. Install the thermal barrier drive shaft into the

thermal barrier by aligning the tab on the drive

shaft with the slot on the thermal barrier

(Figure 17).

3. Mount the thermal barrier onto the valve using the

four included M5x16 mm machine screws and four

M5 flange nuts. Tighten the screws to a

recommended torque of 21 to 25 lb·in.

(2.4 to 2.8 N·m) (Figure 18).

2. Rotate the drive shaft to align marks on the top of

the thermal drive shaft with matching marks on the

valve stem.

4. Proceed to actuator mounting instructions. Follow

the same steps as mounting directly to the valve

when mounting the actuator to the thermal barrier.

Note: Depending on your application, you may

position the assembly in any of the four 90° increments

on the valve.

Manual Override

Use only the supplied manual override crank to

reposition the actuator hub when using the manual

override feature.

IMPORTANT: Applying excessive torque to the

manual override or operating the manual override

with a power tool may damage the internal

components of the actuator and cause premature

failure.

To reposition the actuator hub, proceed as follows:

1. De-energize the actuator.

2. Insert the hex end of the manual override crank

into the manual override adjustment point on the

face of the actuator.

3. Rotate the manual override crank in the direction

indicated by the arrow on the label.

VA9208-Bxx-x Series On/Off Electric Spring Return Valve Actuators Installation Instructions 7

Page 8

4. The actuator requires 8-1/2 manual override crank

!

!

!

rotations from the full spring return position to fully

reposition the actuator hub. At the end of travel, the

rotation resistance increases. Do not force the

manual crank past this point.

5. While holding the manual crank in the wound

position, rotate and hold the red lock shaft

approximately 10° then release the manual crank

to lock the actuator hub in place.

Note: Insert and slightly rotate the manual crank

in the direction indicated by the arrow on the label

to unlock the actuator hub. Alte rnately, the actuator

hub automatically unlocks when power is applied

to the actuator, and returns the actuator to normal

drive and spring return operation.

Wiring

WARNING: Risk of Electric Shock.

Disconnect or isolate all power supplies

before making electrical connections.

More than one disconnection or isolation

may be required to completely

de-energize equipment. Contact with

components carrying hazardous voltage

can cause electric shock and may result

in severe personal injury or death.

AVERTISSEMENT : Risque de

décharge électrique.

Débrancher ou isoler toute alimentation

avant de réaliser un raccordement

électrique. Plusieurs isolations et

débranchements sont peut-être

nécessaires pour -couper entièrement

l'alimentation de l'équipement. Tout

contact avec des composants porteurs

de tensions dangereuses risque

d'entraîner une décharge électrique et de

provoquer des blessures graves, voire

mortelles.

CAUTION: Risk of Property Damage.

Do not apply power to the system before

checking all wiring connections. Short

circuited or improperly connected wires

may result in permanent damage to the

equipment.

MISE EN GARDE : Risque de dégâts

matériels.

Ne pas mettre le système sous tension

avant d'avoir vérifié tous les raccords de

câblage. Des fils formant un court-circuit

ou connectés de façon incorrecte

risquent d'endommager

irrémédiablement l'équipement.

CAUTION: Risk of Property Damage.

Insulate and secure each unused wire

lead before applying power to the

actuator. Failure to insulate and secure

each unused wire lead may result in

property damage.

MISE EN GARDE : Risque de dégâts

matériels.

Isoler et protéger chaque fil non utilisé

avant de mettre l'actuator sous tension.

Le non-respect de cette obligation

d'isolation et de protection de chaque fil

non utilisé risque d'entraîner des dégâts

matériels.

IMPORTANT: Make all wiring connections in

accordance with the National Electrical Code and

local regulations. Use proper Electrostatic Discharge

(ESD) precautions during installation and servicing

to avoid damaging the electronic circuits of the

actuator.

VA9208-Bxx-x Series On/Off Electric Spring Return Valve Actuators Installation Instructions8

Page 9

See Figure 19 and Figure 20 to wire the applicable

Figure 19: Control Wiring Diagrams

AC 120 V 60 Hz

L1N

WHT BLK

2

1

AC 230 V 50 /60 Hz

L1N

BLU BRN

2

1

AC 24 V 50 /60

DC 24 V

RED

BLK

2

1

+

-

~

F

I

G

:

S

_

w

i

r

i

n

g

Figure 20: Optional Auxiliary Switch Wiring

F

I

G

:

A

X

_

S

W

C

T

H

COM NC

NO

COM

NC

NO

Figure 21: Adding Flexible Metal Conduit

VA9208-Bxx-3 Series model.

Using Conduit

All VA9208 Series Actuators accept 3/8 in. (10 mm)

trade size flexible metal conduit.

1. Feed the actuator cables through the field supplied

conduit.

2. Push the conduit into the holes in the actuator and

secure it with the supplied 10-32 x 9/16 in. screws,

as illustrated in Figure 21. The product label marks

the position of holes for the screws. Drive the

screws through the product label in the marked

positions. Drive the screwhead flush with the plate

to secure the conduit.

IMPORTANT: Careful workmanship is required to

secure flexible metal conduit. Cut the conduit end

perpendicular to its axis. Insert the cut end into the

bottom of the holes in the actuator and hold the

conduit in place while securing it with the screws

provided. Check a completed installation by pulling

on the conduit to ensure its retention.

VA9208-Bxx-x Series On/Off Electric Spring Return Valve Actuators Installation Instructions 9

Page 10

Setup and Adjustments

!

Figure 22: Switch Trip Point Settings

FIG:S

W_TRP

Auxiliary Switch (VA9208-xxC-3 Models)

The VA9208-xxC-3 models include two integral

auxiliary switches with a switch adjuster accessible on

either face of the actuator (Figure 20). The factory

setting for Auxiliary Switch No. 1 is 83% closing, and

the nominal setting for Auxiliary Switch No. 2 is 10%

opening (relative to the 0 to 100% rotation range as

printed on the product label). See the Technical

Specifications table for the auxiliary switch ratings.

WARNING: Risk of Electric Shock and

Property Damage.

Insulate and secure each unused wire

lead before applying power to the

actuator. Failure to insulate and secure

each unused wire lead may result in

property damage, electric shock, and

severe personal injury or death.

AVERTISSEMENT : Risque de

décharge électrique et dégâts

matériels.

Isoler et protéger chaque fil non utilisé

avant de mettre l'actuator sous tension.

Le non-respect de cette obligation

d'isolation et de protection de chaque fil

non utilisé risque d'entraîner des dégâts

matériels, des décharges électriques et

des blessures graves, voire mortelles.

The switch point of Auxiliary Switch No. 1 is fixed. The

switch point of Auxiliary Switch No. 2 is independently

and continuously adjustable from 74 to 5% position.

For the most accurate switch positioning, see Figure22

and use the method in the following example. To

change the switch point of Auxiliary Switch No. 2,

proceed as follows:

Note: The switch is factory set to trip when the

actuator reaches the 10% position.

2. Rotate the switch adjuster until it points to the

desired switch point.

3. Connect Auxiliary Switch No. 2 to a power source

or an ohmmeter and apply power to the actuator.

The actuator moves to the fully open position and

holds while power is applied.

4. Observe the switch point. If required, repeat Step 1

through Step 3.

Repair Information

A number of replacement parts are available; see

Table 3 for more details. If an VA9208 Series

Electric Spring Return Actuator fails to operate within

its specifications, replace the unit. For a replacement

electric actuator , contact the nearest Johnson Controls

representative.

1. Position the actuator in the full spring return

position.

Technical Specifications

VA9208-Bxx-x Series On/Off Electric Spring Return Actuator (Part 1 of 3 )

Power

Requirements

VA9208-Bxx-x Series On/Off Electric Spring Return Valve Actuators Installation Instructions10

-BGx Models AC 24 V (AC 18 V to 30 V) at 50/60 Hz: Class 2 (North America) or Safety

-BAx Models AC 120 V (AC 102 V to 132 V) at 60 Hz: 0.05 A Running, 0.03 A Holding

-BDx Models AC 230 V (AC 198 V to 264 V) at 50/60 Hz: 0.04 A Running, 0.03 A Holding

Extra-Low Voltage (SELV) (Europe), 6.1 VA Running, 1.2 VA Holding Position

DC 24 V (DC 21.6 V to 28.8 V): Class 2 (North America) or SELV (Europe)

3.5 W Running, 0.5 W Holding Position

Minimum Transformer Size: 7 VA per Actuator

Position

Position

Page 11

VA9208-Bxx-x Series On/Off Electric Spring Return Actuator (Part 2 of 3 )

Auxiliary Switch

Rating

Spring Return Direction is Selectable with Mounting Position of Actuator:

Rated Torque Power On

Rotation Range Maximum Full Stroke: 95°

Rotation Time for

90 Degrees of

Travel

Life Cycles 60,000 Full Stroke Cycles with 70 lb·in. (8 N·m) Load

Audible Noise

Rating

Electrical

Connections

Conduit Connections Integral Connectors for 3/8 in. (10 mm) Flexible Metal Conduit

Fluid

Temperature

Limits

Ambient

Conditions

Enclosure Rating NEMA 2 (IP54) for all Mounting Directions

-xxC Models Two Single-Pole, Double-Throw (SPDT), Double-Insulated Switches with Gold

over Silver Contacts:

AC 24 V, 50 VA Pilot Duty

AC 120 V, 5.8 A Resistive, 1/4 hp, 275 VA Pilot Duty

AC 240 V, 5.0 A Resistive, 1/4 hp, 275 VA Pilot Duty

Actuator Face Labeled A is Away from Valve: CCW Spring Return

Actuator Face Labeled B is Away from Valve: CW Spring Return

70 lb·in. (8 N·m) All Operating Temperatures

(Running)

Power Off

(Spring Returning)

Power On

(Running)

Power Off

(Spring Returning)

70 lb·in. (8 N·m) at Standard Operating Te mperatures

53 lb·in. (6 N·m) at Extended Operating Temperatures

55 to 71 Seconds for 0 to 70 lb·in. (8 N·m) Load, at all Operating Conditions

60 Seconds Nominal at Full Rated Load (0.25 rpm)

13 to 26 Seconds for 0 to 70 lb·in. (8 N·m) Load, at Room Temperature

21 Seconds Nominal at Full Rated Load

39 Seconds Maximum with 70 lb·in. (8 N·m) Load, at -4°F (-20°C)

108 Seconds Maximum with 53 lb·in. (6 N·m) Load at -40°F (-40°C)

Power On

<47 dBA at 70 lb·in. (8 N·m) Load, at a Distance of 39-13/32 in. (1 m)

(Running)

Power On

<20 dBA at a Distance of 39-13/32 in. (1 m)

(Holding)

Power Off

<52 dBA at 70 lb·in. (8 N·m) Load, at a Distance of 39-13/32 in. (1 m)

(Spring Returning)

Bxx-3 Models 48 in. (1.2 m) UL 758 Type AWM Halogen Free Cable with 18 AWG

2

) Conductors and 1/4 in. (6 mm) Ferrule Ends

2

) Conductors and 1/4 in. (6 mm) Ferrule Ends

Auxiliary Switches

(-xxC Models)

VG12x1 and VG18x1

(0.85 mm

48 in. (1.2 m) UL 758 Type AWM Halogen Free Cable with 18 AWG

(0.85 mm

23 to 203°F (-5 to 95°C), Not Rated for Steam Service

Series

VG12x5 and VG18x5

-22 to 212°F (-30 to 100°C), Not Rated for Steam Service

Series

VG12x5 and VG18x5

Series with

-22 to 284°F (-30 to 140°C) water; 15 psig (103 kPa) at 250°F (121°C)

Saturated Steam

M9000-561 Thermal

Barrier Installed

Standard Operating -4 to 140°F (-20 to 60°C); 90% RH Maximum, Noncondensing

Extended Operating -40 to 4°F (-40 to -20°C); 90% RH Maximum, Noncondensing

Storage -40 to 185°F (-40 to 85°C); 95% RH Maximum, Noncondensing

VA9208-Bxx-x Series On/Off Electric Spring Return Valve Actuators Installation Instructions 11

Page 12

Metasys® and Johnson Controls® are registered trademarks of Johnson Controls

All other marks herein are the marks of their respective owners. © 2017 Johnson Controls

Building Technologies & Solutions

507 E. Michigan Street, Milwaukee, WI 53202

VA9208-Bxx-x Series On/Off Electric Spring Return Actuator (Part 3 of 3 )

Compliance United States UL Listed, CCN XAPX, File E27734; to UL 60730-1A: 2003-08, Ed. 3.1,

Automatic Electrical Controls for Household and Similar Use; and

UL 60730-2-14: 2002-02, Ed. 1, Part 2 Particular Requirements for Electric

Actuators

Canada UL Listed, CCN XAPX7, File E27734; to UL 60730-1:02-CAN/CSA: July 2002,

3rd Ed., Automatic Electrical Controls for Household and Similar Use; and

CSA C22.2 No. 24-93 Temperature Indicating and Regulating Equipment

Europe CE Mark – Johnson Controls declares that this product is in compliance with

Australia and New

Zealand

Shipping Weight -BGC Models 3.8 lb (1.7 kg)

-BAC and -BDC

Models

-BGA Models 3.4 lb (1.5 kg)

-BAA and -BDA

Models

European Single Point of Contact: NA/SA Single Point of Contact: APAC Single Point of Contact:

JOHNSON CONTROLS

WESTENDHOF 3

45143 ESSEN

GERMANY

the essential requirements and other relevant provisions of the EMC Directive

and the Low Voltage Directive.

RCM Mark, Australia/NZ Emissions Compliant

4.2 lb (1.9 kg)

3.8 lb (1.7 kg)

JOHNSON CONTROLS

507 E MICHIGAN ST

MILWAUKEE WI 5320 2

USA

JOHNSON CONTROLS

C/O CONTROLS PRODUCT

MANAGEMENT

NO. 22 BLOCK D NEW DISTRICT

WUXI JIANGSU PROVINCE 214142

CHINA

VA9208-Bxx-x Series On/Off Electric Spring Return Valve Actuators Installation Instructions12

Published in U.S.A. www.johnsoncontrols.com

Loading...

Loading...