Johnson Controls VA9104-AGA-1S, VA9104-IUA-1S, VA9104-GGA-1S, VA9104-IGA-1S Installation Instructions Manual

Page 1

VA9104-AGA-1S / VA9104-IGA-1S / VA9104-IUA-1S / VA9104-GGA-1S

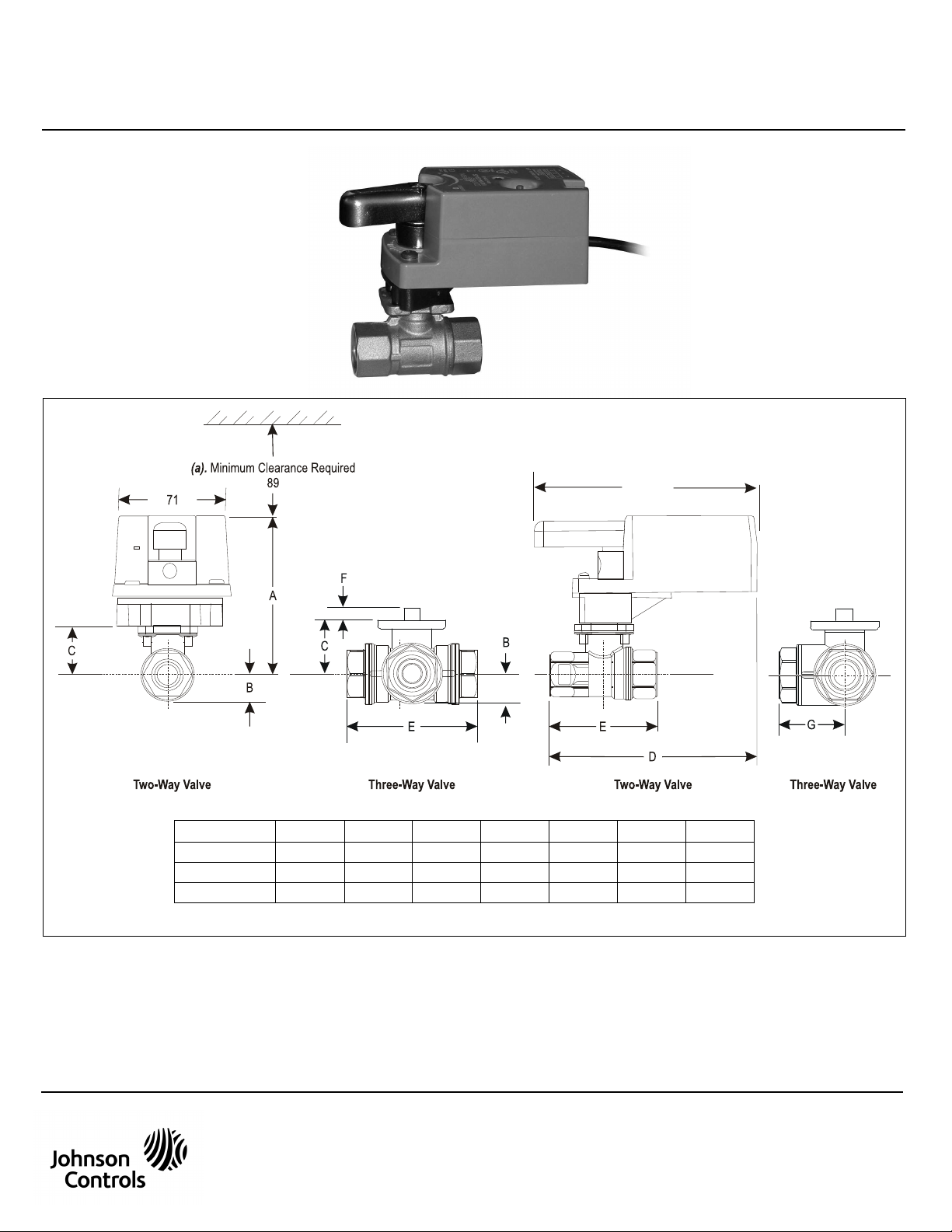

140

Valve Size (DN)*

A

B C D E F G

DN15 98 17 31 129 64 9 32

DN20 98 17 31 133 71 9 36

DN25 100 19 33 141 87 9 43

* (b). On models with the flow-characterizing disk, the disk is located in Port A. Port A must be the Valve inlet.

European Single Point of Contact: NA/SA Single Point of Contact: APAC Single Point of Contact:

JOHNSON CONTROLS

WESTENDHOF 3

45143 ESSEN

GERMANY

JOHNSON CONTROLS

507 E MICHIGAN ST

MILWAUKEE WI 53202

USA

JOHNSON CONTROLS

C/O CONTROLS PRODUCT MANAGEMENT

NO. 22 BLOCK D NEW DISTRICT

WUXI JIANGSU PROVINCE 214142 - CHINA

Electric Non-Spring Return Valve Actuators

Installation Instructions

P/N 14-88360-2331 Rev. G

Issue Date 04 2017

Figure 1: Dimensions in mm

© Copyright 2017 Johnson Controls. All rights reserved. Any unauthorized use or copying is strictly prohibited.

Johnson Controls® is registered trademark of Johnson Controls

All marks herein are the marks of their respective owners.

www.johnsoncontrols.com

Page 2

IS_VA9104-AGA-1S / VA9104-IGA-1S / VA9104-IUA-1S / VA9104-GGA-1S_14-88360-2331_Rev. G_04 2017

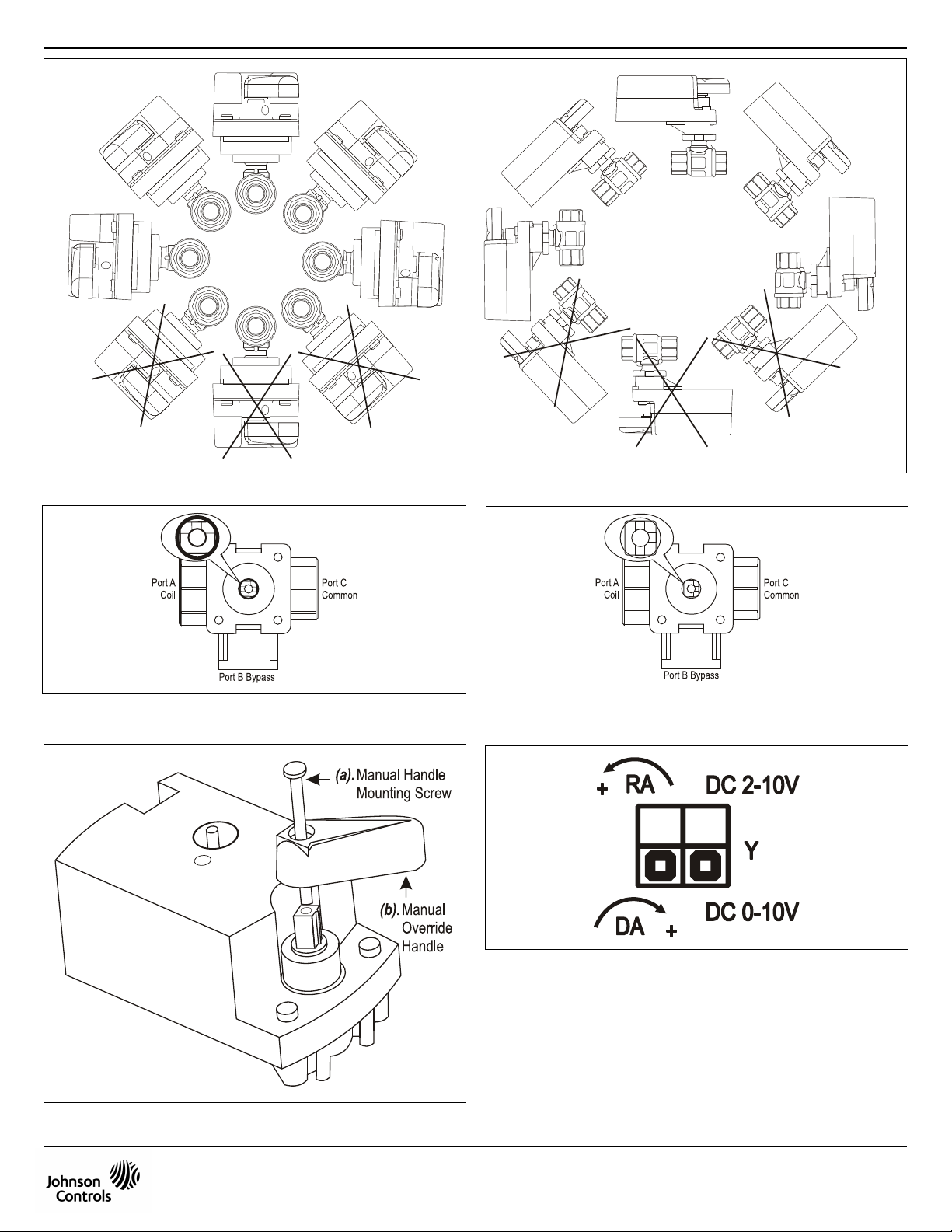

Figure 2: Mounting Positions for Chilled Water and condensing Atmosphere Applications

Figure 3: VG1000 Series 3-Way Ball Valve

(Port A Connected to Port C)

Figure 5: Installing the Handle

Figure 4: VG1000 Series 3-Way Ball Valve

(Port B Connected to Port C)

Figure 6: VA9104-GGA-1S Factory Switch Setting

This document is subject to change without notice

Page 3

IS_VA9104-AGA-1S / VA9104-IGA-1S / VA9104-IUA-1S / VA9104-GGA-1S_14-88360-2331_Rev. G_04 2017

BLU

S1

S1

ON DA

RA

OFF

AC 100...240 V 50/60 Hz

BRN ORN

BLU

AC 100...240 V 50/60 Hz

BRN ORN

1 2 3

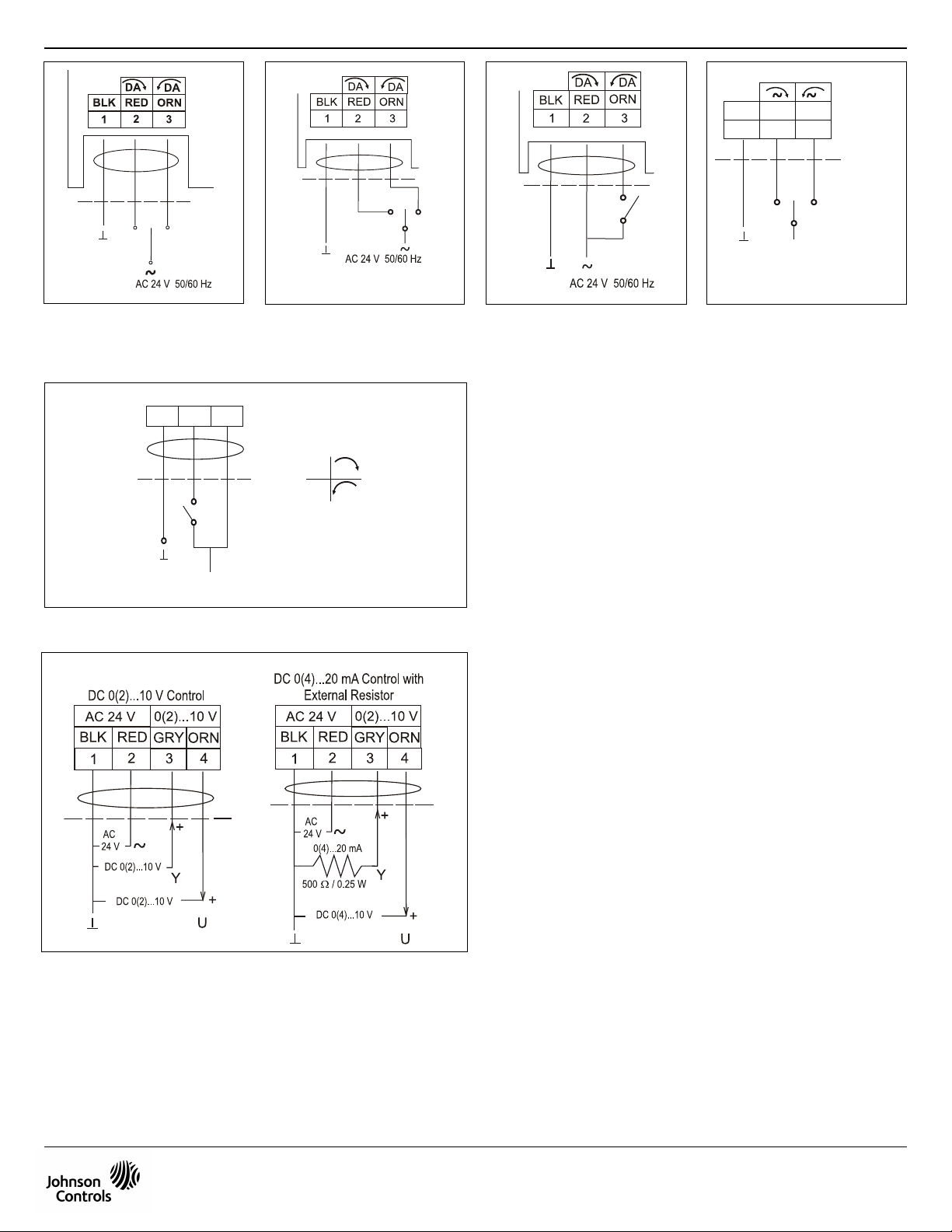

Figure 7: VA9104-AGA-1S

Control Wiring Diagram

Figure 11: VA9104-IUA-1S Control Wiring Diagram ON/OFF

Figure 8: VA9104-IGA-1S

Control Wiring Diagram Floating

Figure 9: VA9104-IGA-1S

Control Wiring Diagram ON/OFF

Figure 10: VA9104-IUA-1S

Control Wiring Diagram Floating

Figure 12: VA9104-GGA-1S Control Wiring Diagram

This document is subject to change without notice

Page 4

English

READ THIS INSTRUCTION SHEET AND THE SAFETY WARNINGS CAREFULLY

General Features

The VA9104 Series Actuators are direct-mount, non-spring return electric valve

actuators that operate on AC 24V or AC 100÷240V power supply. These synchronous,

motor-driven actuators are used to provide accurate positioning on Johnson Controls®

VG1000 Series DN15, DN20, and DN25 ball valves in Heating, Ventilating and Air

Conditioning (HVAC) applications.

The VA9104 Series Electric Non-Spring Return Actuators provide a running torque of 4 Nm.

IMPORTANT: Use this Actuator only to control valves under normal operating

conditions. Where failure or malfunction of the actuator could lead to personal injury

or property damage to the controlled equipment or other property, additional

precautions must be designed into the control system. Incorporate and maintain

other devices such as supervisory or alarm systems or safety or limit controls intended

to warn of, or protect against, failure or malfunction of the actuator.

Figure 1: Dimensions in mm

Installation

Figure 2: Mounting Positions for Chilled Water and condensing Atmosphere

Install the ball valve with the actuator at or above the centerline of the horizontal piping.

Mounting the Actuator

Figure 3: VG1000 Series 3-Way Ball Valve (Port A Connected to Port C)

Figure 4: VG1000 Series 3-Way Ball Valve (Port B Connected to Port C)

Figure 5: Installing the Handle

To mount the actuator to a ball valve:

1. Rotate the valve stem manually several times using an adjustable wrench to break

the torque that may have built up during long-term storage.

Then, rotate the valve stem so that Port A on the valve is open.

Note: Two-way valves in the fully open position have the index marking on the top

of the valve stem, parallel to the direction of flow. Two-way valves in the fully closed

position have the index marking perpendicular to the direction of flow. Three-way valves

feature two index markings on the top of the valve stem, with one of the index markings

parallel to the common port (see Figure 3 and Figure 4).

2. Place the handle on top of the drive shaft as shown in Figure 5.

The handle is keyed and can only be mounted in one orientation.

BEFORE INSTALLING AND SAVE IT FOR FUTURE USE

(a). Minimun Clearance Required

(b). On models with the flow-characterizing disk, the disk is located

in Port A. Port A must be the Valve inlet.

Applications

WARNING: Do not install or use this Actuator in or near environments

where corrosive substances or vapors could be present.

Exposure of the electric actuator to corrosive environments may

damage the internal components of the device, and will void the

warranty.

(a). Manual Handle Mounting Screw

(b). Manual Override Handle

IS_VA9104-AGA-1S / VA9104-IGA-1S / VA9104-IUA-1S / VA9104-GGA-1S_14-88360-2331_Rev. G_04 2017

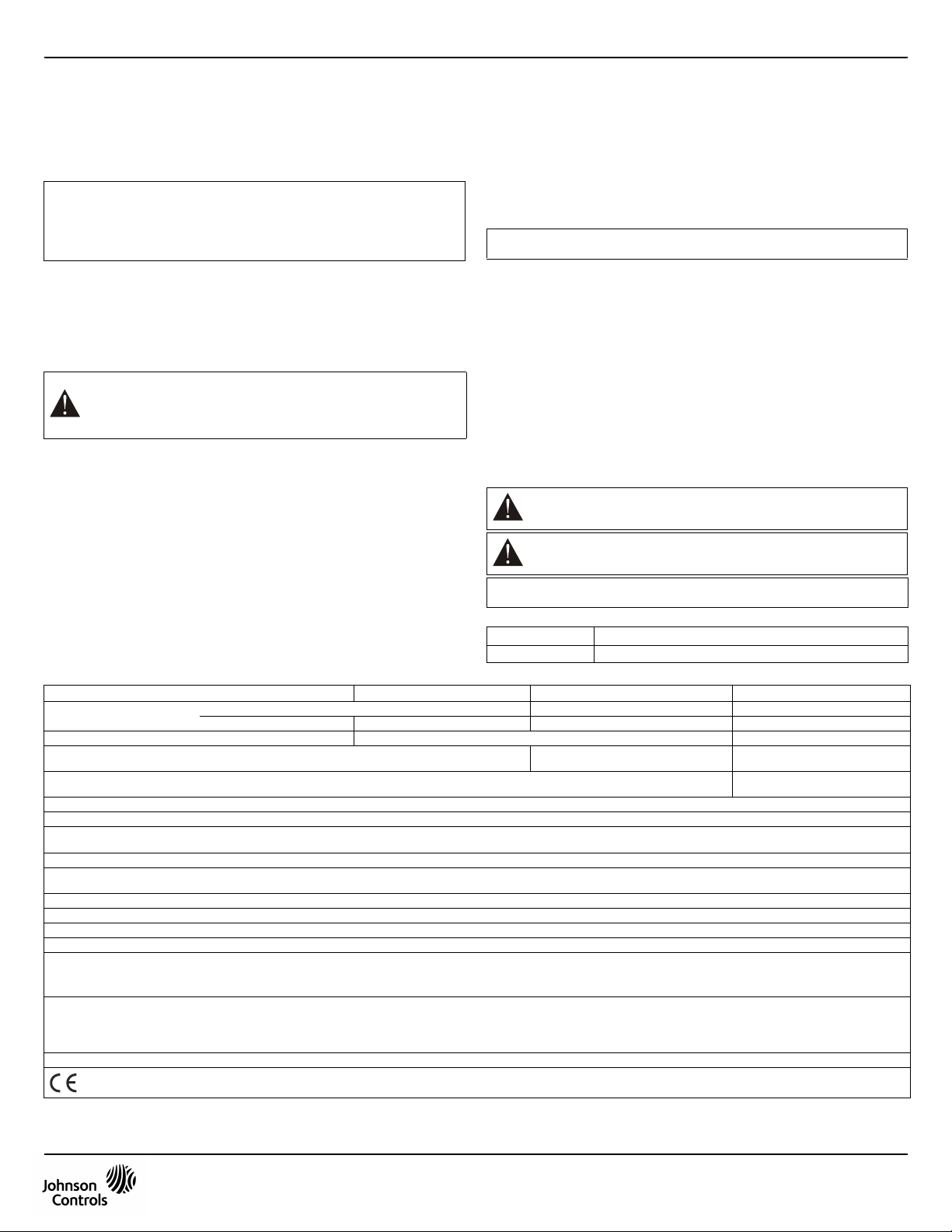

Technical Specifications

Product Codes

Power Requirements

Control Type

Input Signal

Feedback Signal

Motor Input Impedance

Running Torque

Travel Time

(for 90° of Rotation)

Rotation Range

Cycles

Audible Noise Rating

Electrical Connections

Mechanical Connections

Enclosure

Ambient Conditions

Fluid Temperature Limits

(Actuator and Valve Assembly)

Shipping Weight

Compliance

- Operating

- Storage

- Water

- Steam

VA9104-AGA-1S VA9104-IGA-1S VA-104-IUA-1S VA9104-GGA-1S

AC 24V +25%/-20% at 50/60 Hz AC 100 to 240V -15%/+10% at 50/60 Hz AC 24V +25%/-20% at 50/60 Hz

Floating Control without Timeout ON/OFF and Floating Control with Timeout Modulating

200 ohms Nominal

4 Nm

60 Seconds at 60 Hz

72 Seconds at 50 Hz

93° ±3°, CW or CCW

100,000 Full Stroke Cycles;

2,500,000 Repositions at Rated Running Torque

35 dBA Nominal at 1 m

1.2 m Polyvinyl Chloride (PVC) cable

Up to13 mm Diameter Round Damper Shafts, or 10 mm Square Damper Shafts

IP 42

-20 to 60° C; 90% RH Maximum, Noncondensing

-40 to 85° C; 90% RH Maximum, Noncondensing

VG1205 and VG1805 Series Valves: -30 to +95 °C (140 °C with M9000-561 Thermal Barrier)

Rated for Steam Service only with M9000-561 Thermal Barrier

0.5 Kg

Johnson Controls declares that these products are in compliance with the essential requirements and other relevant provisions of the

EMC Directive and Low Voltage Directive

2.1 VA 3.0 VA 7.5 VA Supply and 0.07 A 3.6 VA

AC 24 V +25%/-20% at 50/60 Hz, SELV or Class II AC 100 to 240V -15%/+10% at 50/60 Hz

3. Insert the M4 x 60 long machine screw into the hole in the handle.

Use a flat blade screwdriver to drive the screw into the drive shaft until the screw

is below the top of the handle.

4. Check that the actuator coupler and handle are in the fully counterclockwise position

as viewed from the top of the actuator. If not, press the actuator gear release

and rotate the handle until the actuator coupler is fully counterclockwise.

5. Install the valve actuator over the ball valve mounting flange.

Depending on the installation, position the assembly in any one of four 90°

increments on the valve.

Note: For proper operation, the actuator must drive the valve counterclockwise to open

Port A when viewed from above the valve.

6. To secure the actuator to the valve, use a flat blade screwdriver.

Recommended torque is 0.9 to 1.4 Nm.

IMPORTANT: Do not overtighten the manual handle mounting screw.

Overtightening may strip the threads resulting in damage to the valve stem threads.

Selecting the direction of rotation

Figure 6: VA9104-GGA-1S Factory Switch Setting

VA9104-GGA actuators are factory set for Direct Acting (DA) mode and for a DC 0 to 10

V input control signal. In DA mode, a minimum control signal drives the actuator to the

full Counterclockwise (CCW) position, and a maximum control signal drives the actuator

to the full Clockwise (CW) position.

For Reverse Acting (RA) operation, a minimum control signal drives the actuator

to the full CW position and a maximum signal drives the actuator to the full CCW

position. To change the factory settings, remove the actuator cover and adjust

the switches on the circuit board.

Wiring

Figure 7: VA9104-AGA-1S Control Wiring Diagram

Figure 8: VA9104-IGA-1S Control Wiring Diagram - Floating

Figure 9: VA9104-IGA-1S Control Wiring Diagram - ON/OFF

Figure 10: VA9104-IUA-1S Control Wiring Diagram - Floating

Figure 11: VA9104-IUA-1S Control Wiring Diagram - ON/OFF

Figure 12: VA9104-GGA-1S Control Wiring Diagram

WARNING: Risk of Electric Shock Disconnect the power supply before

making electrical connections to avoid electric shock.

WARNING: Risk of Property Damage Do not apply power to the system

before checking all wiring connections. Short circuited or improperly

connected wires may result in permanent damage to the equipment.

IMPORTANT: Make all wiring connections in accordance with local, national, and

regional regulations. Do not exceed the electrical ratings of the Actuator.

Accessories

(Order Separetely)

Code Number Description

M9000-550 Mounting Hardware Replacement Kit

--- DC 0(2)...10 V Corresponds to input

Class II

DC 0(2) to 10 V or 0(4) to 20 mA

with field furnished 500 ohm resistor

span selection (DC 10V at 1 mA)

This document is subject to change without notice

1

Page 5

Français

LISEZ ATTENTIVEMENT LES PRÉSENTES INSTRUCTIONS ET LES CONSIGNES

DE SÉCURITÉ AVANT DE PROCÉDER À L’INSTALLATION ET CONSERVEZ-LES

Caractéristiques générales

Les commandes VA9104 sont des commandes électriques de vannes sans rappel par

ressort et à montage direct alimentées en AC 24 V ou AC 100÷240 V. Ces commandes

motorisées synchrones assurent un positionnement précis des vannes à bille Johnson

Controls® VG1000 DN15, DN20 et DN25 dans les applications de chauffage, ventilation

et climatisation (HVAC).

Les commandes électriques sans rappel par ressort VA9104 fonctionnent à un couple

de 4 Nm.

IMPORTANT: N’utilisez cette commande que pour réguler des vannes dans des

conditions de fonctionnement normales. Si les pannes ou défaillances de la

commande sont susceptibles d’entraîner des lésions corporelles, d’endommager

l’équipement régulé ou de provoquer d’autres dégâts matériels, on intégrera des

mesures de sécurité supplémentaires au système de régulation. On incorporera

d’autres dispositifs tels que des systèmes de surveillance ou d’alarme, ou encore des

commandes de sécurité ou de limitation, afin d’avertir ou de protéger les personnes en

cas de panne ou de défaillance de la commande.

Figure 1: Dimensions en mm

Installation

Figure 2: Positions de montage pour les applications en eau réfrigérée et

Installez la vanne à bille et la commande au niveau ou au-dessus de l’axe de la

tuyauterie horizontale.

Montage de la commande

Figure 3: Vanne à bille trois voies VG1000 (port A raccordé au port C)

Figure 4: Vanne à bille trois voies VG1000 (port B raccordé au port C)

Figure 5: Installation de la manette

Pour monter la commande sur une vanne à bille:

1. Faites tourner la tige de la vanne manuellement plusieurs fois à l’aide d’une clé

Remarque: Sur les vannes à deux voies en position entièrement ouverte, le repère

situé en haut de la tige est parallèle au sens d’écoulement. Sur les vannes à deux voies

en position entièrement fermée, ce repère est perpendiculaire au sens d’écoulement.

Les vannes à trois voies possèdent deux repères en haut de la tige, dont l’un est

parallèle au port commun (voir figure 3 et figure 4).

2. Placez la manette en haut de l’arbre de commande, comme illustré à la figure 5.

(a). Jeu minimum obligatoire

(b). Sur les modèles avec disque de caractérisation du débit, le disque est

atmosphère avec condensation

ATTENTION: N’installez pas et n’utilisez pas cette commande dans des

environnements susceptibles de renfermer des substances ou des

vapeurs corrosives, ni à proximité. L’exposition de la commande

électrique à des environnements corrosifs risque d’endommager ses

composants internes et peut ainsi annuler la garantie.

(a). Vis de fixation de la manette de commande manuelle

(b). Manette de commande manuelle de secours

réglable pour rompre le couple qui a pu se former en cas de stockage prolongé.

Faites ensuite tourner la tige de la vanne de manière à ce que son port A soit ouvert.

La manette est clavetée et ne peut être montée que dans un sens.

AUX FINS D’UTILISATION ULTÉRIEURE

situé dans le port A, qui doit correspondre à l’entrée de la vanne.

IS_VA9104-AGA-1S / VA9104-IGA-1S / VA9104-IUA-1S / VA9104-GGA-1S_14-88360-2331_Rev. G_04 2017

3. Insérez la vis usinée longue M4 x 60 dans l’orifice de la manette.

Utilisez un tournevis à lame plate pour faire pénétrer la vis dans l’arbre de commande

jusqu’à ce qu’elle se trouve sous la partie supérieure de la manette.

4. Vérifiez que le coupleur de la commande et la manette sont en position entièrement

anti-horaire, vus depuis le dessus de la commande. Si ce n’est pas le cas, appuyez

sur le dispositif de déverrouillage de l’engrenage de la commande et faites tourner la

manette jusqu’à ce que le coupleur se trouve entièrement dans le sens anti-horaire.

5. Installez la commande de la vanne sur la bride de montage de la vanne à bille.

Selon l’installation, positionnez l’ensemble au niveau de l’un des quatre incréments

de 90° sur la vanne.

Remarque: Pour que le système fonctionne convenablement, la commande doit piloter

la vanne dans le sens anti-horaire pour ouvrir le port A, vue depuis le dessus de la

vanne.

6. Pour fixer la commande sur la vanne, utilisez un tournevis à lame plate.

Le couple conseillé est de 0,9 à 1,4 Nm.

IMPORTANT: Ne serrez pas trop la vis de fixation de la manette de commande

manuelle, vous risqueriez de dénuder les filets et d’endommager le filetage de la tige

de la vanne.

Sélection du sens de rotation

Figure 6: Réglage d’usine du commutateur VA9104-GGA-1S

Les commandes VA9104-GGA sont réglées en usine pour un fonctionnement direct

(DA) et un signal de commande en entrée de 0 à 10 VDC. En mode DA, un signal de

régulation minimum place la commande en position entièrement anti-horaire et un

signal de régulation maximum la place en position entièrement horaire.

En fonctionnement inversé (RA), un signal de régulation minimum place la commande

en position entièrement horaire et un signal maximum la place en position entièrement

anti-horaire. Pour modifier les paramètres d’usine, retirez le couvercle de la commande

et réglez les commutateurs de la carte électronique.

Câblage

Figure 7: Schéma de câblage de la commande VA9104-AGA-1S

Figure 8: Schéma de câblage de la commande flottante VA9104-IGA-1S

Figure 9: Schéma de câblage de la commande marche/arrêt VA9104-IGA-1S

Figure 10: Schéma de câblage de la commande flottante VA9104-IUA-1S

Figure 11: Schéma de câblage de la commande marche/arrêt VA9104-IUA-1S

Figure 12: Schéma de câblage de la commande VA9104-GGA-1S

ATTENTION: Risque d’électrocution. Débranchez l’alimentation avant

de procéder aux raccordements électriques afin d’éviter les risques

d’électrocution.

ATTENTION: Risque de dégâts matériels. Ne mettez pas le système

sous tension avant d’avoir vérifié tous les raccordements.

Des fils en court-circuit ou mal raccordés pourraient endommager

l’équipement de façon irrémédiable.

IMPORTANT: Effectuez tous les raccordements de câblage en respectant la

réglementation locale, nationale et régionale. Ne dépassez pas les valeurs électriques

nominales de la commande.

Accessoires

(à commander séparément)

Référence Description

M9000-550 Kit de matériel de fixation de rechange

Caractéristiques techniques

Codes produits VA9104-AGA-1S VA9104-IGA-1S VA9104-IUA-1S VA9104-GGA-1S

Alimentation

Type de régulation

Signal d’entrée

Signal de feed-back

Impédance d’entrée du moteur

Couple de fonctionnement

Temps de course

(pour une rotation de 90°)

Plage de rotation

Cycles

Niveau sonore audible nominal

Raccordements électriques

Raccords mécaniques

Enceinte

Conditions ambiantes

Limites de température des fluides

(ensemble commande et vanne)

Poids d’expédition

- Fonctionnement

- Stockage

- Vapeur

Conformité

Commande flottante sans

Valeur nominale 200 ohms

4 Nm

60 s à 60 Hz

72 s à 50 Hz

93° ±3°, sens horaire ou anti-horaire

100 000 cycles à pleine course

2 500 000 repositionnements au couple de fonctionnement nominal

35 dBA nominaux à 1 m

Câble en PVC (polychlorure de vinyle) de 1,2 m

Axes de clapet ronds de diamètre max. 13 mm ou axes de clapet carrés de 10 mm max.

IP 42

-20 à 60 °C ; 90 % HR maximum, sans condensation

-40 à 85 °C ; 90 % HR maximum, sans condensation

Vannes VG1205 et VG1805: -30 à +95 °C 140 °C avec la barrière thermique M9000-561)

- Eau

Valeurs disponibles uniquement avec la barrière thermique M9000-561

0,5 kg

Johnson Controls déclare que ces produits sont conformes aux exigences essentielles et autres dispositions pertinentes de la Directive et de la Directive

basse tension.

24 VAC +25 %/-20 % à 50/60 Hz 100 à 240 VAC -15 %/+10 % à 50/60 Hz 24 VAC +25 %/-20 % à 50/60 Hz

2,1 VA 3,0 VA 7.5 VA Alimentation électrique et 0.07 A 3,6 VA

temporisation

24 VAC +25 %/-20 % à 50/60 Hz, SELV ou Classe II

Commande marche-arrêt et flottante avec temporisation Modulation

100 à 240 VAC -15%/+10% à 50/60 Hz,

--- 0(2) à 10 VDC Correspond à la sélection

Classe II

Ce document peut être sujet à modification sans préavis

0(2) à 10 VDC ou 0(4) à 20 mA

avec résistance de 500 ohms

fournie sur site

de la plage d’entrée (10 VDC à 1 mA)

2

Page 6

Deutsch

LESEN SIE DIESE ANLEITUNG UND DIE SICHERHEITSHINWEISE VOR DER

INSTALLATION SORGFÄLTIG DURCH UND BEWAHREN SIE SIE FÜR SPÄTERE

Allgemeine Merkmale

Bei den Stellantrieben der Serie VA9104 handelt es sich um direkte elektrische

Ventilstellantriebe ohne Federrücklauf, die mit 24V AC oder 100÷240V AC

Nennspannung betrieben werden. Diese synchronen, motorgesteuerten Stellantriebe

werden verwendet, um eine exakte Positionierung von Johnson Controls® Kugelventilen

der Serien VG1000 DN15, DN20 und DN25 in Heizungs-, Lüftungs- und

Klimaanlagensystemen zu gewährleisten.

Die elektrischen Stellantriebe ohne Federrücklauf der Serie VA9104 unterstützen ein

Betriebsdrehmoment von 4 Nm.

WICHTIG: Verwenden Sie diesen Stellantrieb nur, um Ventile unter normalen

Betriebsbedingungen zu steuern. Wenn der Ausfall oder eine Fehlfunktion des

Stellantriebs zu Personenschäden oder Sachbeschädigungen der gesteuerten Anlage

oder anderer Gegenstände führen könnte, müssen in dem Regelungssystem

zusätzliche Vorsichtsmaßnahmen vorgesehen werden. Bauen Sie andere Geräte ein,

wie beispielsweise Überwachungs- oder Alarmsysteme oder Sicherheits- oder

Begrenzerelemente, und achten Sie auf ihren fehlerfreien Betrieb, um vor Ausfall oder

Fehlfunktionen des Stellantriebs zu warnen oder davor zu schützen.

Abbildung 1: Abmessungen in mm

(a). Mindestabstand erforderlich

(b). Bei Modellen mit Scheibe zur Bestimmung der Flusseigenschaften

befindet sich die Scheibe in Anschluss A. Anschluss A muss der

Ventileingang sein.

Montage

Abbildung 2: Montagepositionen für Applikationen mit Kühlwasser und

Bringen Sie das Kugelventil mit dem Stellantrieb an oder oberhalb der Mittellinie der

horizontalen Rohrleitung an.

Kondensatfeuchte

ACHTUNG: Montieren oder verwenden Sie diesen Stellantrieb nicht in

Umgebungen oder in der Nähe von Umgebungen, wo korrosive

Substanzen oder Dämpfe auftreten können.

Wenn der elektrische Stellantrieb korrosiven Umgebungen ausgesetzt

ist, können die internen Komponenten des Geräts beschädigt werden

und die Garantie erlischt.

Montage des Stellantriebs

Abbildung 3: Dreiwegekugelventil der Serie VG1000

Abbildung 4: Dreiwegekugelventil der Serie VG1000

Abbildung 5: Griffmontage

Um den Stellantrieb auf einem Kugelventil zu montieren, gehen Sie wie folgt vor:

1. Drehen Sie den Ventilschaft unter Verwendung eines verstellbaren

Einmaulschlüssels mehrfach von Hand, um das Drehmoment zu lösen, das sich

möglicherweise während der langen Lagerung aufgebaut hat.

Anschließend drehen Sie den Ventilschaft so, dass Anschluss A am Ventil geöffnet ist.

Hinweis: Zweiwegeventile in vollständig geöffneter Position haben die Indexmarkierung

oben am Ventilschaft, parallel zur Flussrichtung. Zweiwegeventile in vollständig

geschlossener Position haben die Indexmarkierung senkrecht zur Flussrichtung.

Dreiwegeventile besitzen zwei Markierungen oben am Ventilschaft. Eine dieser

Markierungen steht parallel zum gemeinsamen Anschluss (siehe Abb. 3 und Abb 4).

(Anschluss A mit Anschluss C verbunden)

(Anschluss B mit Anschluss C verbunden)

(a). Montageschraube für den Handgriff

(b). Griff für die Handbetätigung

REFERENZZWECKE AUF

IS_VA9104-AGA-1S / VA9104-IGA-1S / VA9104-IUA-1S / VA9104-GGA-1S_14-88360-2331_Rev. G_04 2017

2. Bringen Sie den Griff oben am Achsenschaft an, wie in Abbildung 5 gezeigt.

Der Griff ist speziell gekennzeichnet und kann nur in einer Richtung montiert werden.

3. Setzen Sie die lange Metallgewindeschraube M4x60 in die Bohrung im Griff ein.

Drehen Sie die Schraube mit Hilfe eines Flachkopfschraubendrehers in den

Achsenschaft, bis sie unter der Griffoberseite verschwunden ist.

4. Stellen Sie sicher, dass der Stellantriebsadapter und der Griff vollständig gegen den

Uhrzeigersinn stehen, wenn man von der Oberseite des Stellantriebs darauf blickt.

Andernfalls drücken Sie die Antriebsentriegelung des Stellantriebs und drehen den

Griff, bis der Stellantriebsadapter vollständig gegen den Uhrzeigersinn positioniert ist.

5. Bringen Sie den Ventilstellantrieb über dem Montageflansch des Kugelventils an.

Platzieren Sie den Bausatz abhängig von der jeweiligen Montage in einem von vier

90°-Schritten auf dem Ventil.

Hinweis: Damit der Stellantrieb richtig funktioniert, muss er das Ventil gegen den

Uhrzeigersinn drehen, um Anschluss A zu öffnen (Sicht von oben auf das Ventil).

6. Um den Stellantrieb am Ventil zu sichern, verwenden Sie einen

Flachkopfschraubendreher. Das empfohlene Drehmoment beträgt 0,9 bis 1,4 Nm.

WICHTIG: Ziehen Sie die Montageschraube für den Handgriff nicht zu fest an.

Durch das Überdrehen können die Gewinde brechen, was zu einer Beschädigung der

Gewinde am Ventilschaft führt.

Wahl der Drehrichtung

Abbildung 6: VA9104-GGA-1S Werksseitige Schalterstellungen

VA9104-GGA-Stellantriebe sind werksseitig auf direktwirkenden Betrieb (DA, Direct

Acting) und für ein Eingangssteuersignal von 0 bis 10 V DC eingestellt. Im DA-Modus

steuert ein minimales Steuersignal den Stellantrieb vollständig gegen den

Uhrzeigersinn, und ein maximales Steuersignal steuert den Stellantrieb vollständig im

Uhrzeigersinn.

Für den RA-Betrieb (Reverse Acting, Umkehrbetrieb) steuert ein minimales Steuersignal

den Stellantrieb vollständig im Uhrzeigersinn, und ein maximales Signal steuert den

Stellantrieb vollständig gegen den Uhrzeigersinn. Um die Werkseinstellungen zu

verändern, entfernen Sie die Abdeckung des Stellantriebs und passen die Schalter auf

der Platine an.

Anschluss

Abbildung 7: VA9104-AGA-1S-Steuerung Schaltplan

Abbildung 8: VA9104-IGA-1S-Steuerung Schaltplan - 3-Punkt

Abbildung 9: VA9104-IGA-1S-Steuerung Schaltplan - AUF/ZU

Abbildung 10: VA9104-IUA-1S-Steuerung Schaltplan - 3-Punkt

Abbildung 11: VA9104-IUA-1S-Steuerung Schaltplan - AUF/ZU

Abbildung 12: VA9104-GGA-1S-Steuerung Schaltplan

ACHTUNG: Stromschlaggefahr – Trennen Sie das Gerät von der

Stromversorgung, bevor Sie elektrische Verbindungen einrichten, um

einen Stromschlag zu vermeiden.

ACHTUNG: Risiko von Sachschäden – Setzen Sie das System erst dann

unter Spannung, wenn Sie alle verdrahteten Verbindungen überprüft

haben. Kurzgeschlossene oder fehlerhaft angeschlossene Drähte

können zu einer dauerhaften Beschädigung der Anlage führen.

WICHTIG: Nehmen Sie alle Verdrahtungsverbindungen gemäß lokaler, nationaler und

regionaler Vorschriften vor. Überschreiten Sie keinesfalls die elektrischen Kennwerte

des Stellantriebs.

Zubehör

Teilenummer Beschreibung

M9000-550 Austauschbausatz Montagehardware

(separat zu bestellen)

Technische Daten

Produktnamen

Leistungsaufnahme AC 24V +25 %/-20 % bei 50/60 Hz AC 100 bis 240V -15%/+10 % bei 50/60 Hz AC 24V +25 %/-20 % bei 50/60 Hz

Steuerungstyp 3-Punkt-Steuerung ohne Zeitabschaltung AUF/ZU- oder 3-Punkt-Steuerung mit Zeitabschaltung Modulierende Steuerung

Eingangssignal AC 24 V +25 %/-20 % bei 50/60 Hz, SELV oder Klasse II

Feedback-Signal --- --- ---

Motoreingangsimpedanz 200 Ohm nominal

Betriebsdrehmoment 4 Nm

Laufzeit

(für 90° Drehung)

Drehbereich 93° ±3°, im Uhrzeigersinn oder gegen den Uhrzeigersinn

Zyklen

Schallpegelmessung 35 dBA nominal bei 1 m

Elektrische Anschlüsse 1,2 m PVC-Kabel (Polyvinylchlorid)

Mechanische Anschlüsse Bis zu 13 mm Durchmesser für runde Klappenachsen oder 10 mm für Vierkant-Klappenachsen

Gehäuse IP 42

Umgebungsbedingungen

Grenzwerte für die

Flüssigkeitstemperatur

(Stellantrieb und Ventilbausatz)

Versandgewicht 0,5 kg

Konformität

- im Betrieb -20 bis 60 °C; 90 % relative Luftfeuchtigkeit, nicht kondensierend

- Lagerung -40 bis 85 °C; 90 % relative Luftfeuchtigkeit, nicht kondensierend

- Wasser Ventile der Serien VG1205 und VG1805: -30 bis +95 °C (140 °C mit M9000-561 Wärmeschutz)

- Dampf Für Dampf Anwendungen zugelassen nur mit M9000-561 Wärmeschutz

VA9104-AGA-1S VA9104-IGA-1S VA9104-IUA-1S VA9104-GGA-1S

2,1 VA 3,0 VA 7.5 VA Nennspannung und 0.07 A 3,6 VA

AC 100 bis 240V -15%/+10% bei 50/60 Hz

60 Sekunden bei 60 Hz

72 Sekunden bei 50 Hz

100.000 volle Hubzyklen;

2.500.000 Neupositionierungen beim Nenndrehmoment für den Betrieb

Johnson Controls erklärt, dass diese Produkte konform sind mit den wesentlichen Anforderungen und sonstigen anwendbaren Bestimmungen der EMVRichtlinie und der Niederspannungsrichtlinie

Klasse II

DC 0(2) bis 10 V oder 0(4) bis 20 mA

mit vor Ort bereitgestelltem

Widerstand mit 500 Ohm

DC 0(2)...10 V Entspricht dem

ausgewählten Eingangssignalbereich

(DC 10V bei 1 mA)

Änderungen des Dokuments vorbehalten

3

Page 7

Italiano

LEGGERE ATTENTAMENTE QUESTE ISTRUZIONI E LE AVVERTENZE PRIMA

DELL'INSTALLAZIONE E CONSERVARLE PER USO FUTURO

Funzioni generali

Gli attuatori della serie VA9104 sono attuatori per valvole elettrici, senza ritorno a molla,

a montaggio diretto che funzionano con un'alimentazione AC di 24 V o AC 100÷240V.

Questi attuatori sincroni a motore sono usati per il posizionamento corretto nelle valvole

a sfera DN15, DN20 e DN25 Johnson Controls® della serie VG1000 in applicazioni

HVAC (Heating, Ventilating and Air Conditioning, ovvero riscaldamento, ventilazione e

condizionamento dell'aria).

Gli attuatori elettrici, senza molla di ritorno, della serie VA9104 offrono una coppia di

funzionamento di 4 Nm.

IMPORTANTE: Utilizzare questi attuatori per controllare le valvole in condizioni di

funzionamento normali. Qualora un guasto o un malfunzionamento dell'attuatore possa

provocare lesioni personali o danni all'apparecchiatura controllata o altri danni materiali,

è necessario adottare precauzioni aggiuntive nel sistema di controllo. Includere e

gestire altri dispositivi, ad esempio sistemi di supervisione o di allarme oppure controlli

di limitazione o sicurezza che hanno lo scopo di avvisare o proteggere da guasti o

malfunzionamenti dell'attuatore.

Figura 1: Dimensioni in mm

Installazione

Figura 2: Posizioni di montaggio per applicazioni ad acqua refrigerata e di

Installare la valvola a sfera con l'attuatore posizionato in corrispondenza o sopra la linea

centrale della tubazione orizzontale.

Montaggio dell'attuatore

Figura 3: Valvola a sfera a tre vie serie VG1000 (porta A connessa alla porta C)

Figura 4: Valvola a sfera a tre vie serie VG1000 (porta B connessa alla porta C)

Figura 5: Installazione della maniglia

Per montare l'attuatore su una valvola a sfera:

1. Ruotare lo stelo della valvola diverse volte utilizzando una chiave inglese regolabile

Nota: Nelle valvole a due vie in posizione completamente aperta, il contrassegno sulla

parte superiore dello stelo della valvola è parallelo alla direzione del flusso. Nelle valvole

a due vie in posizione completamente chiusa, il contrassegno è perpendicolare alla

direzione del flusso. Nelle valvole a tre vie sono presenti due contrassegni nella parte

superiore dello stelo della valvola, uno dei quali è parallelo alla porta comune (vedere

figure 3 e 4).

2. Posizionare la maniglia sulla parte superiore dell'albero motore, come mostrato nella

(a). Distanza minima richiesta

(b). Nei modelli dotati di disco di caratterizzazione del flusso, il disco si trova

nella porta A. La porta A deve essere l'entrata della valvola.

condensazione

AVVERTENZA: Non installare o utilizzare questo attuatore all'interno o in

prossimità di ambienti in cui possono essere presenti sostanze o vapori

corrosivi.

L'esposizione dell'attuatore ad ambienti corrosivi può danneggiare i

componenti interni del dispositivo e rendere nulla la garanzia.

(a). Vite di montaggio maniglia manuale

(b). Maniglia comando manuale

per rompere la coppia che potrebbe essersi creata durante il periodo di

immagazzinaggio.

Quindi, ruotare lo stelo della valvola in modo da aprire la porta A sulla valvola.

figura 5.

La maniglia è inchiavettata e può essere montata con un solo orientamento.

IS_VA9104-AGA-1S / VA9104-IGA-1S / VA9104-IUA-1S / VA9104-GGA-1S_14-88360-2331_Rev. G_04 2017

3. Inserire la vite senza dado M4 x 60 nel foro della maniglia.

Utilizzare un cacciavite a punta piatta per avvitare la vite nell'albero motore fino a

quando la vite non si trova sotto la parte superiore della maniglia.

4. Verificare che il giunto dell'attuatore e la maniglia si trovino nella posizione di fondo in

senso antiorario, nella vista da sopra l'attuatore. In caso contrario, premere la leva di

sblocco del movimento dell'attuatore e ruotare la maniglia fino a quando il giunto

dell'attuatore non si trova nella posizione di fondo in senso antiorario.

5. Installare l'attuatore per valvole sopra la flangia di montaggio della valvola a sfera.

In base all'installazione, posizionare l'assieme in uno dei quattro incrementi di 90°

sulla valvola.

Nota: Per il corretto funzionamento, l'attuatore deve guidare la valvola in senso

antiorario per aprire la porta A, nella vista da sopra la valvola.

6. Per fissare l'attuatore alla valvola, utilizzare un cacciavite a punta piatta.

La coppia consigliata è compresa tra 0,9 e 1,4 Nm.

IMPORTANTE: Non serrare troppo la vite di montaggio della maniglia manuale.

In caso contrario, i filetti potrebbero strapparsi e causare danni alla filettatura dello stelo

della valvola.

Selezione della direzione di rotazione

Figura 6: VA9104-GGA-1S Impostazione interruttore predefinita

Gli attuatori VA9104-GGA sono preimpostati per la modalità DA (Direct Acting) e per un

segnale di controllo di ingresso DC da 0 a 10 V. Nella modalità DA, un segnale di

controllo minimo guida l'attuatore nella posizione di fondo in senso antiorario, mentre un

segnale di controllo massimo guida l'attuatore nella posizione di fondo in senso orario.

Nel funzionamento RA (Reverse Acting), un segnale di controllo minimo guida

l'attuatore nella posizione di fondo in senso orario, mentre un segnale di controllo

massimo guida l'attuatore nella posizione di fondo in senso antiorario. Per modificare le

impostazioni predefinite, rimuovere la copertura dell'attuatore e regolare gli interruttori

sulla scheda.

Cablaggio

Figura 7: VA9104-AGA-1S Schema di cablaggio controllo

Figura 8: VA9104-IGA-1S Schema di cablaggio controllo - Flottante

Figura 9: VA9104-IGA-1S Schema di cablaggio controllo - ON/OFF

Figura 10: VA9104-IUA-1S Schema di cablaggio controllo - Flottante

Figura 11: VA9104-IUA-1S Schema di cablaggio controllo - ON/OFF

Figura 12: VA9104-GGA-1S Schema di cablaggio controllo

AVVERTENZA: Rischio di scossa elettrica. Scollegare l'alimentazione

prima di eseguire le connessioni elettriche per evitare il rischio di

scosse elettriche.

AVVERTENZA: Rischio di danni alla proprietà. Non alimentare il sistema

prima di aver controllato tutte le connessioni. Fili cortocircuitati o non

correttamente collegati possono causare danni permanenti

all'apparecchiatura.

IMPORTANTE: Effettuare tutti i cablaggi in conformità alle normative locali, nazionali e

regionali. Non superare le caratteristiche nominali elettriche dell'attuatore.

Accessori

(ordinati separatamente)

Codice Descrizione

M9000-550

Kit di montaggio hardware sostitutivo

Specifiche tecniche

Codici prodotti

Requisiti di alimentazione AC 24 V +25% / -20% a 50/60 Hz AC 100 a 240 V -15%/+10% a 50/60 Hz AC 24 V +25% / -20% a 50/60 Hz

Tipo di controllo Controllo flottante senza timeout Controllo ON/OFF e flottante senza timeout Modulante

Segnale di ingresso AC 24 V +25% / -20% a 50/60 Hz, SELV o Classe II AC 100 a 240 V -15%/-10% a 50/60 Hz,

Segnale di feedback --- --- --- DC 0(2)...10 V Corrisponde all'ampiezza

Impedenza di ingresso motore 200 ohm nominale

Coppia di funzionamento 4 Nm

Tempo corsa

(per una rotazione di 90°)

Intervallo di rotazione 93° ±3°, senso orario o antiorario

Cicli 100.000 cicli a corsa completa;

Classificazione rumore

percepibile

Connessioni elettriche Cavo PVC (Polyvinyl Chloride) di 1,2 m

Connessioni meccaniche Alberi della serranda tondi fino a 13 mm, o alberi della serranda quadrati fino a 10 mm.

Contenitore IP 42

Condizioni ambientali

Limiti di temperatura del fluido

(assieme attuatore e valvola)

Peso di spedizione 0,5 Kg

- Funzionamento Da -20 a 60 °C; 90% umidità relativa massima, senza condensa

- Conservazione Da -40 a 85 °C; 90% umidità relativa massima, senza condensa

- Acqua Valvole serie VG1205 e VG1805: da -30 a +95 °C (140 °C con Barriera Termica M9000-561)

- Vapore Approvato per applicazioni con vapore solo con Barriera Termica M9000-561

Conformità

VA9104-AGA-1S VA9104-IGA-1S VA9104-IUA-1S VA9104-GGA-1S

2,1 VA 3,0 VA 7.5 VA alimentazione e 0.07 A 3,6 VA

SELV Classe II

60 secondi a 60 Hz

72 secondi a 50 Hz

2.500.000 riposizionamenti alla coppia di funzionamento stimata

35 dBA nominale a 1 m

Johnson Controls dichiara che questi prodotti sono conformi ai requisiti fondamentali ed altre relative disposizioni della Direttiva EMC e della Direttiva bassa

tensione

DC 0(2) - 10 V o 0(4) - 20 mA

con resistenza di 500 ohm

del segnale di ingresso selezionata

(DC 10 V a 1 mA)

Questo documento può essere soggetto a modifiche senza preavviso

4

Page 8

Español

ANTES DE LA INSTALACIÓN, LEA ATENTAMENTE ESTAS INSTRUCCIONES Y

LAS ADVERTENCIAS DE SEGURIDAD, Y CONSÉRVELAS PARA SU USO FUTURO

Características generales

Los actuadores de la serie VA9104 son actuadores eléctricos de montaje directo con

válvula de retroceso sin muelle que funcionan a 24 VAC o 100÷240 VAC fuente de

alimentación. Estos actuadores sincrónicos accionados por motor se utilizan para

facilitar una colocación precisa en las válvulas esféricas Johnson Controls® DN15,

DN20 y DN25 de la serie VG1000 en aplicaciones de calefacción, ventilación y aire

acondicionado.

Los actuadores eléctricos de retroceso sin muelle de la serie VA9104 proporcionan un par

de funcionamiento de 4 Nm.

IMPORTANTE: Utilice este actuador únicamente para controlar las válvulas en

condiciones normales de funcionamiento. En el caso de que un fallo o un

funcionamiento defectuoso del actuador puedan provocar lesiones personales o daños

en el equipo controlado o en otros objetos, se deben diseñar precauciones adicionales

en el sistema de control. Incorpore y realice el mantenimiento de otros dispositivos,

como sistemas de alarma o supervisión, o bien controles de límites o de seguridad, con

el fin de advertir de fallos o de un funcionamiento defectuoso del actuador y proteger de

ellos.

Figura 1: Dimensiones en mm

Instalación

Figura 2: Posiciones de montaje para aplicaciones en atmósfera con

Instale la válvula esférica con el actuador a la altura de la línea central de la

canalización horizontal o por encima de esa línea.

Montaje del actuador

Figura 3: Válvula esférica de tres vías de la serie VG1000 (lumbrera A conectada

Figura 4: Válvula esférica de tres vías de la serie VG1000 (lumbrera B conectada

Figura 5: Instalación del mango

Para montar el actuador en una válvula esférica:

1. Gire manualmente el vástago de la válvula varias veces con una llave ajustable para

Nota: Las válvulas de dos vías en posición completamente abierta presentan la marca

indicadora encima del vástago de la válvula, en paralelo a la dirección del caudal. Las

válvulas de dos vías en posición completamente cerrada presentan la marca indicadora

en posición perpendicular a la dirección del caudal. Las válvulas de tres vías presentan

dos marcas indicadoras encima del vástago de la válvula, con una de las marcas

indicadoras orientada en paralelo a la lumbrera común (consulte la figura 3 y la figura 4).

(a). Holgura mínima necesaria

(b). En los modelos con disco de caracterización de flujo, el disco se

encuentra en la lumbrera A. La lumbrera A debe corresponder a la

entrada de la válvula.

condensación y agua refrigerada

ADVERTENCIA: No instale ni utilice este actuador en entornos en los

que pudiera haber vapores o sustancias corrosivas ni en sus

inmediaciones.

La exposición del actuador eléctrico a entornos corrosivos podría dañar

los componentes internos del dispositivo y anular la garantía.

a la lumbrera C)

a la lumbrera C)

(a). Tornillo de montaje manual del mango

(b). Mango de control manual

neutralizar el par que pueda haberse generado durante un almacenamiento de larga

duración.

A continuación, gire el vástago de la válvula de manera que la lumbrera A de la

válvula quede abierta.

IS_VA9104-AGA-1S / VA9104-IGA-1S / VA9104-IUA-1S / VA9104-GGA-1S_14-88360-2331_Rev. G_04 2017

2. Coloque el mango encima del eje impulsor, tal como se muestra en la figura 5.

El mango está acuñado y sólo se puede montar en una orientación.

3. Introduzca el tornillo largo para metales M4 x 60 en el orificio del mango.

Utilice un destornillador plano para introducir el tornillo en el eje impulsor hasta que

se encuentre por debajo de la parte superior del mango.

4. Compruebe que el acoplador del actuador y el mango se encuentran en posición de

giro completo en sentido contrario al de las agujas del reloj si se mira desde encima

del actuador. Si no es así, pulse la palanca de liberación del engranaje y gire el

mango hasta que el acoplador del actuador quede en posición de giro contrario al

sentido de las agujas del reloj.

5. Instale el actuador de válvula sobre la brida de montaje de la válvula esférica.

En función de la instalación, coloque el conjunto en cualquiera de los cuatro pasos

de 90° en la válvula.

Nota: Para un funcionamiento correcto, el actuador debe empujar la válvula en sentido

contrario al de las agujas del reloj para abrir la lumbrera A si se mira desde encima de la

válvula.

6. Para fijar el actuador a la válvula, utilice un destornillador plano.

Se recomienda un par de entre 0,9 y 1,4 Nm.

IMPORTANTE: No apriete excesivamente el tornillo de montaje del mango de control

manual. Si se aprieta excesivamente, se podría dañar la rosca del vástago de válvula.

Selección de la dirección de giro

Figura 6: Configuración de interruptores de fábrica del VA9104-GGA-1S

Los actuadores VA9104-GGA están configurados de fábrica para el modo de acción

directa (DA) y para una señal de control de entrada de 0 a 10 VDC. En el modo DA, una

señal mínima de control lleva al actuador a la posición de giro completo en sentido

contrario al de las agujas del reloj, mientras que una señal de control máxima lleva al

actuador a la posición de giro completo en el sentido de las agujas el reloj.

Para el funcionamiento de acción inversa (RA), una señal de control mínima lleva al

actuador a la posición de giro completo en el sentido de las agujas del reloj, y una señal

máxima lleva al actuador a la posición de giro completo en sentido contrario al de las

agujas del reloj. Para cambiar la configuración de fábrica, retire la cubierta del actuador

y ajuste los interruptores en la placa del circuito.

Cableado

Figura 7: Diagrama de cableado de control del VA9104-AGA-1S

Figura 8: Diagrama de cableado de control del VA9104-IGA-1S - flotante

Figura 9: Diagrama de cableado de control del VA9104-IGA-1S – ON/OFF

Figura 10: Diagrama de cableado de control del VA9104-IUA-1S - flotante

Figura 11: Diagrama de cableado de control del VA9104-IUA-1S – ON/OFF

Figura 12: Diagrama de cableado de control del VA9104-GGA-1S

ADVERTENCIA: Riesgo de descarga eléctrica. A fin de evitar descargas

eléctricas, desconecte la fuente de alimentación antes de establecer

conexiones.

ADVERTENCIA: Riesgo de daños materiales. No conecte a la corriente el

sistema antes de comprobar todas las conexiones del cableado. La

presencia de cables cortocircuitados o mal conectados puede dañar el

equipo de forma permanente.

IMPORTANTE: Realice todas las conexiones de cableado según las normativas

locales, nacionales y regionales. No exceda los márgenes de las especificaciones

eléctricas del actuador.

Accesorios

(se encargan por separado)

Número de código Descripción

M9000-550 Kit de reemplazo de hardware de montaje

Especificaciones técnicas

Códigos de producto

Requisitos energéticos 24 VCA +25%/-20% a 50/60 Hz 100 a 240 VCA -15%/+10% a 50/60 Hz 24 VCA +25%/-20% a 50/60 Hz

Tipo de control Control flotante sin tiempo de espera Control ON/OFF y flotante con tiempo de espera Modulación

Señal de entrada 24 VCA +25%/-20% a 50/60 Hz, Clase II o SELV

Señal de retroalimentación

(feedback)

Impedancia de entrada del motor 200 ohmios (nominal)

Par de funcionamiento 4 Nm

Tiempo de recorrido

(para rotación de 90°)

Rango de giro 93° ±3°, a la derecha o a la izquierda

Ciclos 100.000 ciclos de carrera completos;

Nivel de potencia audible 35 dBA (nominal) a 1 m

Conexiones eléctricas Cable de cloruro de polivinilo (PVC) de 1,2 m

Conexiones mecánicas Ejes reguladores redondos de hasta 13 mm de diámetro o ejes reguladores cuadrados de 10 mm

Caja IP 42

Condiciones ambientales

Límites de la temperatura

del fluido (conjunto de actuador

y válvula)

Peso de envío 0,5 kg

- En funcionamiento -20 a 60 °C; 90% HR máxima, sin condensación

- Almacenamiento -40 a 85 °C; 90% HR máxima, sin condensación

- Agua Válvulas de las series VG1205 y VG1805: -30 a +95 °C (140 °C con M9000-561 Barrera térmica)

- Vapor Aprobado para su uso con vapor sólo con M9000-561 Barrera Térmica

Conforme con

VA9104-AGA-1S VA9104-IGA-1S VA9104-IUA-1S VA9104-GGA-1S

2,1 VA 3,0 VA

--- --- --- 0(2) a 0,10 VCC - Corresponde al intervalo

60 segundos a 60 Hz

72 segundos a 50 Hz

2.500.000 reposiciones al par de funcionamiento nominal

Johnson Controls declara que estos productos cumplen los requisitos esenciales y demás disposiciones aplicables de la directiva EMC y la directiva

europea de baja tensión

7.5 VA

alimentación

100 a 240 VCA -15%/+10% a 50/60 Hz

y 0.07 A

Clase II

0(2) a 10 VCC o 0(4) a 20 mA

con resistencia de 500 ohmios

de entrada seleccionado (10 VCC a 1 mA)

3,6 VA

suministrada de campo

Este documento está sujeto a cambios sin previo aviso

5

Page 9

Nederlands

LEES DIT INSTRUCTIEBLAD EN DE VEILIGHEIDSWAARSCHUWINGEN

ZORGVULDIG VOORDAT DE INSTALLATIE WORDT UITGEVOERD, EN BEWAAR

DIT MATERIAAL ZODAT U HET IN DE TOEKOMST OOK NOG KUNT RAADPLEGEN

Algemene functies

De bekrachtigers van de serie VA9104 zijn direct te monteren, niet-geveerde elektrische

retourklepbekrachtigers die werken op een AC-voeding van 24 V of AC-voeding van

100÷240 V. Deze synchrone bekrachtigers met motoraandrijving worden gebruikt voor

accurate positionering van kogelkleppen in de VG1000-serie DN15, DN20 en DN25 van

Johnson Controls® in HVAC-toepassingen voor verwarming, ventilatie en

luchtbehandeling.

De VA9104-serie elektrische niet-veerretourbekrachtigers bieden een actief draaimoment

van 4 Nm.

BELANGRIJK: Gebruik deze bekrachtiger alleen voor de regeling van kleppen onder

normale bedrijfsomstandigheden. Wanneer de bekrachtiger niet goed of helemaal niet

werkt en dit persoonlijk letsel of beschadigingen van de apparatuur of andere

eigendommen tot gevolg kan hebben, moeten aanvullende voorzorgsmaatregelen in

het regelsysteem worden ingebouwd. Zorg voor andere apparaten zoals bewakings- of

alarmeringssystemen of beveiligings- of begrenzingsmechanismen die waarschuwen

bij, of bescherming bieden tegen, het uitvallen van de bekrachtiger.

Figuur 1: Afmetingen in mm

Installatie

Figuur 2: Montageposities voor toepassingen met gekoeld water en

Installeer de kogelklep met de bekrachtiger op of boven de hartlijn van het horizontale

buizenstelsel.

De bekrachtiger monteren

Figuur 3: Driewegkogelklep VG1000-serie (poort A aangesloten op poort C)

Figuur 4: Driewegkogelklep VG1000-serie (poort B aangesloten op poort C)

Figuur 5: De hendel installeren

De bekrachtiger monteren aan een kogelklep:

1. Draai de klepstang diverse keren handmatig met behulp van een verstelbare sleutel

Opmerking: Tweewegkleppen in de volledig geopende positie hebben de

indexmarkering aan de bovenkant van de klepstang, parallel aan de stroomrichting.

Tweewegkleppen in de volledig gesloten positie hebben de indexmarkering loodrecht op

de stroomrichting. Driewegkleppen hebben twee indexmarkeringen aan de bovenkant

van de klepstang, met een van de indexmarkeringen parallel aan de

gemeenschappelijke poort (zie Figuur 3 en Figuur 4).

2. Plaats de hendel aan de bovenkant van de aandrijfas, zoals in Figuur 5 is afgebeeld.

(a). Minimaal vereiste speling

(b). Op modellen met de stroomkenmerkschijf, bevindt de schijf zich

in poort A. Poort A moet de klepingang zijn.

condenserende atmosfeer

WAARSCHUWING: Installeer of gebruik deze bekrachtiger niet in of bij

omgevingen met mogelijk bijtende stoffen of dampen.

Bij blootstelling van de bekrachtiger aan corroderende omgevingen

kunnen de interne onderdelen van het apparaat beschadigd raken en

vervalt de garantie.

(a). Hendelmontageschroef voor handmatig

(b). Hendel voor handmatige wijziging

om het draaimoment te verbreken dat tijdens de langdurige opslag mogelijk is

ontstaan.

Draai de klepstang vervolgens zó, dat poort A op de klep open is.

De hendel is voorzien van een sleutel en kan maar in één richting worden

gemonteerd.

IS_VA9104-AGA-1S / VA9104-IGA-1S / VA9104-IUA-1S / VA9104-GGA-1S_14-88360-2331_Rev. G_04 2017

3. Steek de lange machineschroef (M4 x 60) in het gat in de hendel.

Gebruik een platte schroevendraaier om de schroef in de aandrijfas te draaien tot de

schroef zich onder de bovenkant van de hendel bevindt.

4. Controleer of het koppelstuk van de bekrachtiger en de hendel zich in de volledige

linksompositie bevinden, gezien vanaf de bovenkant van de bekrachtiger. Zo niet,

druk dan op de ontgrendeling van de transmissie van de bekrachtiger en draai de

hendel tot het koppelstuk van de bekrachtiger zich in de volledige linksompositie

bevindt.

5. Installeer de klepbekrachtiger over de montageflens van de kogelklep.

Plaats de constructie, afhankelijk van de installatie, in 90° of een veelvoud daarvan

op de klep.

Opmerking: Voor een goede werking moet de bekrachtiger de klep linksom aandrijven

om poort A te openen, gezien vanaf de bovenkant van de klep.

6. Voor de bevestiging van de bekrachtiger aan de klep gebruikt u een platte

schroevendraaier. Aanbevolen draaimoment is 0,9 tot 1,4 Nm.

BELANGRIJK: Draai de hendelmontageschroef voor handmatig niet te strak aan.

Te strak aandraaien kan de schroefdraad onbruikbaar maken, en zo ook de

schroefdraad van de kleptstang beschadigen.

De draairichting selecteren

Figuur 6: VA9104-GGA-1S - fabrieksinstelling voor schakelaars

VA9104-GGA-bekrachtigers zijn in de fabriek ingesteld op de DA-modus (Direct Acting)

en op een DC-ingangregelsignaal van 0 tot 10 V. In de DA-modus zorgt een minimaal

regelsignaal voor aandrijving van de bekrachtiger tot de volledige linksompositie en een

maximaal regelsignaal voor aandrijving van de bekrachtiger tot de volledige

rechtsompositie.

In de RA-modus (Reverse Acting) zorgt een minimaal regelsignaal voor aandrijving van

de bekrachtiger tot de volledige rechtsompositie en een maximaal regelsignaal voor

aandrijving van de bekrachtiger tot de volledige linksompositie. U kunt de

fabrieksinstellingen wijzigen door de afdekking van de bekrachtiger te verwijderen en de

schakelaars op de printplaat aan te passen.

Bedrading

Figuur 7: Bedradingsschema voor VA9104-AGA-1S

Figuur 8: Bedradingsschema voor VA9104-IGA-1S - variabel

Figuur 9: Bedradingsschema voor VA9104-IGA-1S - AAN/UIT

Figuur 10: Bedradingsschema voor VA9104-IUA-1S - variabel

Figuur 11: Bedradingsschema voor VA9104-IUA-1S - AAN/UIT

Figuur 12: Bedradingsschema voor VA9104-GGA-1S

WAARSCHUWING: Risico van elektrische schokken Schakel voordat u

elektrische verbindingen maakt de voeding uit, om elektrische

schokken te voorkomen.

WAARSCHUWING: Risico van beschadiging van eigendommen

Controleer alle bedradingen en aansluitingen voordat u de voeding naar

het systeem inschakelt. Kortsluitingen of verkeerd aangesloten

bedradingen kunnen permanente schade aan de apparatuur tot gevolg

hebben.

BELANGRIJK: Sluit alle bedradingen aan conform plaatselijke, landelijke en

regionale voorschriften. Blijf binnen de nominale elektrische waarden van de

bekrachtiger.

Accessoires

(apart te bestellen)

Codenummer Beschrijving

M9000-550

Montagekit vervangende hardware

Technische specificaties

Productcodes

Voedingsvereisten AC 24 V +25%/-20% bij 50/60 Hz AC 100 tot 240 V -15%/+10% bij 50/60 Hz AC 24 V +25%/-20% bij 50/60 Hz

Regeltype Variabele regeling zonder time-out AAN/UIT- en variabele regeling zonder time-out Proportioneel

Ingangssignaal AC 24 V +25%/-20% bij 50/60 Hz, SELV of klasse II AC 100 tot 240 V -15%/+10% bij 50/60 Hz

Feedbacksignaal --- --- --- DC 0(2)...10 V komt overeen met selectie

Motoringangsimpedantie 200 ohm nominaal

Actief draaimoment 4 Nm

Uitslagtijd

(voor draaihoek van 90°)

Draaibereik 93° ±3°, rechtsom of linksom

Cycli 100.000 cycli met volledige uitslag;

Nominale geluidswaarde 35 dBA nominaal op 1 m

Elektrische aansluitingen 1,2 m PVC-kabel

Mechanische aansluitingen Tot 13 mm diameter voor ronde demperassen, of 10 mm voor vierkante demperassen

Behuizing IP 42

Omgevingsomstandigheden

Vloeistoftemperatuurbereik

(klep en bekrachtiger)

Transportgewicht 0,5 kg

Voorschriften en normen

- In bedrijf -20 tot 60 °C; maximaal 90% RH, niet-condenserend

- Opslag -40 tot 85 °C; maximaal 90% RH, niet-condenserend

- Water Kleppen uit VG1205- en VG1805-serie: -30 tot +95 °C (140 °C met M9000-561 thermische barrière)

- Stoom Geschat voor stoom alleen M9000-561 Thermische Barrière

VA9104-AGA-1S VA9104-IGA-1S VA9104-IUA-1S VA9104-GGA-1S

2,1 VA 3,0 VA 7,5 VA Voeding en 0,07 A 3,6 VA

klasse II

60 seconden bij 60 Hz

72 seconden bij 50 Hz

2.500.000 positiewijzigingen bij nominaal actief draaimoment

Johnson Controls verklaart dat deze producten voldoen aan de essentiële vereisten en andere relevante bepalingen van de EMC-richtlijn en de richtlijn voor

laagspanning.

DC 0(2) tot 10 V of 0(4) tot 20 mA met in

veld gegenereerde weerstand van 500 ohm

van ingangbereik (DC 10 V bij 1 mA)

Dit document kan zonder kennisgeving worden gewijzigd

6

Page 10

Svenska

LÄS DET HÄR INSTRUKTIONSBLADET OCH SÄKERHETSANVISNINGARNA

NOGGRANT INNAN DU INSTALLERAR MODULEN OCH SPARA DEM FÖR

Allmänna funktioner

Ställdonen i VA9104-serien är elektriska ventilställdon utan fjäderåtergång som

direktmonteras och som fungerar med AC 24 V eller AC 100÷240 V Spänningsmatning.

De synkrona, motordrivna ställdonen används för att ge korrekta inställningar på

Johnson Controls® kulventiler DN15, DN20 och DN25 i VG1000-serien i värme-,

ventilations- och luftkonditioneringssystem (HVAC).

De elektriska ställdonen utan fjäderåtergång i VA9104-serien ger ett synkront moment

på 4 Nm.

VIKTIGT! Använd bara ställdonet för att styra ventiler under normala driftförhållanden.

Om felaktiga funktioner hos ställdonet kan leda till skador på person, den styrda

utrustningen eller annan egendom, måste ytterligare säkerhetsfunktioner integreras i

styrsystemet. Installera och underhåll andra enheter, till exempel övervaknings- eller

larmsystem eller säkerhets- eller begränsningskontroller som är avsedda att varna för,

eller skydda mot, fel hos ställdonet.

Figur 1: Mått i mm

(a). Minsta avstånd

(b). På modeller med flödespåverkande skiva finns skivan i port A.

Port A måste vara ventilingång.

FRAMTIDA BRUK

IS_VA9104-AGA-1S / VA9104-IGA-1S / VA9104-IUA-1S / VA9104-GGA-1S_14-88360-2331_Rev. G_04 2017

Installation

Figur 2: Monteringslägen för kylt vatten och kondenserande atmosfärsystem

Installera kulventilen med ställdonet vid eller ovanför den horisontella rörledningens

mittlinje.

VARNING! Ställdonet får inte installeras eller användas i eller i närheten

av miljöer där det kan finnas frätande ämnen eller ångor.

Om ställdonet utsätts för frätande miljöer kan enhetens interna

komponenter skadas och garantin upphör då att gälla.

Montera ställdonet

Figur 3: Trevägs kulventil i VG1000-serien (port A ansluten till port C)

Figur 4: Trevägs kulventil i VG1000-serien (port B ansluten till port C)

Figur 5: Installera handtaget

Så här monteras ställdonet på en kulventil:

1. Rotera ventilstången manuellt flera gånger med hjälp av en skiftnyckel för att bryta

Obs! På tvåvägsventiler i helt öppet läge finns indexmarkeringen uppe på

ventilstången, parallellt med flödesriktningen. På tvåvägsventiler i helt stängt läge finns

indexmarkeringen lodrätt mot flödesriktningen. Trevägsventiler har två indexmarkeringar

uppe på ventilstången. En av indexmarkeringarna är parallell med den gemensamma

porten (se figur 3 och figur 4).

(a). Monteringsskruv för manuellt handtag

(b). Handtag för manuell åsidosättning

vridmomentet som kan ha byggts upp under förvaringen.

Rotera sedan ventilstången så att port A på ventilen är öppen.

Tekniska specifikationer

Produktkoder

Spänningskrav

Styrningstyp

Ingångssignal

Signal för återkoppling

Impedans för motoringång

Synkront moment

Rörelsetid (för 90° rotering)

Rotationsområde

Cykler

Klassificering av hörbart brus

Elektriska anslutningar

Mekaniska anslutningar

Kåpa IP 42

Omgivningsförhållanden

– I drift

– Förvaring

Vätsketemperaturgränser

(ställdon och ventil

hopmonterade)

– Vatten

– Ånga

Transportvikt

VA9104-AGA-1S VA9104-IGA-1S VA9104-IUA-1S VA9104-GGA-1S

AC 24 V +25 %/–20 % vid 50/60 Hz AC 100 till 240 V -15 %/+10 % vid 50/60 Hz AC 24 V +25 %/–20 % vid 50/60 Hz

Flytande styrning utan tidsutlösning PÅ/AV-styrning och flytande styrning med tidsutlösning Modulering

200 ohm nominellt

4 Nm

60 sekunder vid 60 Hz

72 sekunder vid 50 Hz

93° ±3°, medsols eller motsols

100 000 kompletta cykler,

2 500 000 förflyttningar vid angivet synkront moment

35 dBA nominellt vid 1 m

1,2 m PVC-kabel

Runda spjällaxlar, upp till 13 mm diameter eller fyrkantiga spjällaxlar, 10 mm

–20...60 °C, 90 % maximal luftfuktighet, icke-kondenserande

–40...85 °C, 90 % maximal luftfuktighet, icke-kondenserande

Ventiler i VG1205- och VG1805-serien: –30... +95 °C (140 °C med M9000-561 värme Barrier)

Märk för Steam Tjänsten endast med M9000-561 Thermal Barrier

0,5 kg

2,1 VA 3,0 VA 7.5 VA ström och 0.07 3,6 VA

AC 24 V +25 %/–20 % vid 50/60 Hz, SELV eller klass II

--- --- --- DC 0(2) till 10 V motsvarar vald räckvidd

2. Placera handtaget ovanpå drivaxeln enligt bilden i figur 5.

Handtaget är nycklat och kan bara monteras i en riktning.

3. Sätt in maskinskruven M4 × 60 i hålet i handtaget.

Använd en spårmejsel och skruva in skruven i drivaxeln tills den är nedanför

handtagets ovansida.

4. Kontrollera att ställdonskopplaren och handtaget är i helt motsols läge sett från

ställdonets ovansida. Om de inte är det trycker du på ställdonets frikopplingsknapp

och roterar handtaget tills ställdonskopplaren är i helt motsols läge.

5. Installera ventilställdonet över kulventilens monteringsfläns.

Beroende på installationen placerar du anordningen i något av de fyra 90° stegen på

ventilen.

Obs! Ställdonet måste driva ventilen motsols till den öppna porten A sett från ventilens

ovansida för att det ska fungera korrekt.

6. Fäst ställdonet vid ventilen med hjälp av en spårmejsel.

Rekommenderat vridmoment är 0,9 till 1,4 Nm.

VIKTIGT! Skruva inte åt monteringsskruven för det manuella handtaget för hårt.

Skruvens och ventilstångens gängor kan skadas.

Välja roteringsriktning

Figur 6: Brytarens fabriksinställning för VA9104-GGA-1S

VA9104-GGA-ställdonen är fabriksinställda för direktdrift (DA) och en styringångssignal

på DC 0 till 10 V. I direktverkande läge (DA) drivs ställdonet till helt motsols läge av en

minimal styrsignal och till helt medsols läge av en maximal styrsignal.

I bakåtverkande läge (RA) drivs ställdonet till helt medsols läge av en minimal styrsignal

och till helt motsols läge av en maximal styrsignal. Ändra fabriksinställningarna genom

att ta bort ställdonets lock och justera brytarna på kretskortet.

Kabeldragning

Figur 7: Illustration kabeldragning för VA9104-AGA-1S

Figur 8: Illustration kabeldragning – flytande styrning för VA9104-IGA-1S

Figur 9: Illustration kabeldragning – PÅ/AV-styrning för VA9104-IGA-1S

Figur 10: Illustration kabeldragning – flytande styrning för VA9104-IUA-1S

Figur 11: Illustration kabeldragning – PÅ/AV-styrning för VA9104-IUA-1S

Figur 12: Illustration kabeldragning för VA9104-GGA-1S

VARNING! Risk för elektriska stötar. Undvik elektriska stötar genom att

koppla från strömkällan innan de elektriska anslutningarna görs.

VARNING! Risk för skador på egendom. Strömsätt inte systemet innan

alla kabelanslutningar har kontrollerats. Kortslutna eller felaktigt

anslutna kablar kan orsaka bestående skador på utrustningen.

VIKTIGT! Gör alla kabelanslutningar i enlighet med lokala, nationella och regionala

regler. Överskrid inte den elektriska klassificeringen för ställdonet.

Tillbehör

(beställs separat)

Kodnummer Beskrivning

M9000-550

AC 24 V +25 %/–20 % vid 50/60 Hz,

Utbytessats med monteringsbeslag

klass II

DC 0(2) till 10 V eller 0(4) till 20 mA

med installerad resistor på 500 ohm

för ingång (DC 10 V vid 1 mA)

Överensstämmelse

Johnson Controls uppger att dessa produkter överensstämmer med kraven och andra relevanta bestämmelser i EMC-direktiv och lågspänningsdirektiv

Det här dokumentet kan ändras utan föregående meddelande

7

Page 11

Česky

PŘED INSTALACÍ SI POZORNĚ PŘEČTĚTE TYTO POKYNY A BEZPEČNOSTNÍ

Všeobecné charakteristiky

Servopohony řady VA9104 jsou elektrické ventilové servopohony s nepružinovým

zpětným chodem určené pro přímou montáž a napájené AC 24 V AC 100÷240V

napájení. Tyto synchronní motorové pohony se používají k zajištění přesného

nastavování polohy kulových ventilů Johnson Controls® řady VG1000 o velikostech

DN15, DN20 a DN25 ve vzduchotechnických aplikacích (HVAC).

Elektrické servopohony s nepružinovým zpětným chodem řady VA9104 poskytují točivý

moment 4 Nm.

DŮLEŽITÉ: Tento servopohon používejte pouze k ovládání ventilů při běžných

provozních podmínkách. V případech, kdy by porucha nebo nesprávná funkce

servopohonu mohla mít za následek úraz osob nebo poškození ovládaného zařízení či

jiného majetku, musí být v regulačním systému navržena dodatečná preventivní

opatření. Do systému je vhodné začlenit a udržovat v něm další zařízení, jako

například dohlížecí nebo výstražné systémy a ovládací prvky mezních hodnot nebo

zabezpečení, určené k varování či ochraně v případě závady nebo chybné funkce

elektrického servopohonu.

Obr. 1: Rozměry v mm

Instalace

Obr. 2: Montážní polohy pro aplikace ve studené vodě a kondenzující

Namontujte kulový ventil se servopohonem na nebo nad středovou čáru vodorovného

potrubí.

Montáž servopohonu

Obr. 3: Trojcestný kulový ventil řady VG1000 (otvor A připojen k otvoru C)

Obr. 4: Trojcestný kulový ventil řady VG1000 (otvor B připojen k otvoru C)

Obr. 5: Montáž rukojeti

Postup při montáži servopohonu na kulový ventil:

1. Otočte několikrát ručně dříkem ventilu pomocí nastavitelného klíče, aby došlo k

uvolnění momentu, který mohl vzniknout při dlouhodobém skladování.

Poté otočte dřík ventilu tak, aby se otevřel otvor A ventilu.

Poznámka: Dvoucestné ventily mají v plně otevřené poloze značku indexu na horní

straně dříku ventilu, rovnoběžně se směrem průtoku. V plně uzavřené poloze mají

dvoucestné ventily značku indexu kolmo ke směru průtoku. Trojcestné ventily mají dvě

označení indexu na horní straně dříku ventilu, přičemž jedna z indexových značek je

rovnoběžná se společným otvorem (viz Obrázek 3 a Obrázek 4).

2. Umístěte rukojeť na horní část hnacího hřídele tak, jak je znázorněno na Obrázku 5.

Rukojeť je opatřena klínem a lze ji namontovat pouze v jednom směru.

VAROVÁNÍ A USCHOVEJTE JE PRO POZDĚJŠÍ POUŽITÍ

(a). Minimální požadovaná vůle

(b). U modelů s kotoučem pro nastavení průtokové charakteristiky je tento

kotouč umístěn v otvoru A. Otvor A musí být vstupním otvorem ventilu.

atmosféře

UPOZORNĚNÍ: Neinstalujte a nepoužívejte tento servopohon v

prostředích s možným výskytem korozivních látek nebo výparů.

Vystavení elektrického servopohonu účinkům korozivního prostředí

může způsobit poškození vnitřních součástí zařízení a je důvodem ke

ztrátě platnosti záruky.

(a). Upevňovací šroub rukojeti

(b). Rukojeť pro ruční přestavení

IS_VA9104-AGA-1S / VA9104-IGA-1S / VA9104-IUA-1S / VA9104-GGA-1S_14-88360-2331_Rev. G_04 2017

Technické údaje

Kódy produktů

Napájení

Typ regulace

Vstupní signál

Signál zpětné vazby

Vstupní impedance motoru

Točivý moment

Doba zdvihu

(pro otočení o 90°)

Rozsah otáčení

Počet cyklů

Hlučnost

Elektrická připojení

Mechanická připojení

Kryt IP 42

Podmínky prostředí

Mezní hodnoty teplot tekutin

(sestava servopohonu a ventilu)

Přepravní hmotnost

Shoda s požadavky

norem a smìrnic

– Provozní

– Při skladování

– Voda

– Pára

VA9104-AGA-1S VA9104-IGA-1S VA9104-IUA-1S VA9104-GGA-1S

AC 24 V +25 %/-20 % při 50/60 Hz AC 100 až 240 V +25 %/-20 % při 50/60 Hz AC 24 V + 25 %/-20 % při 50/60 Hz

Astatická regulace bez časového

jmenovitá 200 ohmů

4 Nm

60 sekund při 60 Hz

72 sekund při 50 Hz

93° ±3°, ve směru nebo proti směru hodinových ruček

100 000 cyklů s plným zdvihem,

2 500 000 polohových posunutí při jmenovitém točivém momentu

Jmenovitá 35 dBA ve vzdálenosti 1 m

Kabel z polyvinylchloridu (PVC) o délce 1,2 m

Kulaté hřídele klapek o průměru do 13 mm nebo čtyřhranné hřídele klapek do 10 mm

-20 až 60 °C; max. relativní vlhkost 90 %, bez kondenzace

-40 až 85 °C; max. relativní vlhkost 90 %, bez kondenzace

Ventily řady VG1205 a VG1805: -30 až +95 °C (140 °C s M9000-561 tepelné bariéry)

Jsou urceny pro parní služby pouze s M9000-561 tepelné bariéry

0,5 kg

Johnson Controls prohlašuje, že tyto výrobky jsou v souladu se základními požadavky a ostatními odpovídajícími ustanoveními směrnice

EMC a směrnice o nízkonapěťových zařízeních

2,1 VA 3,0 VA 7,5 VA Napájení a 0.07 A 3,6 VA

limitu

AC 24 V + 25 %/-20 % při 50/60 Hz, třída II nebo SELV AC 100 až 240 V -15 %/+10 % při 50/60 Hz,

--- --- --- DC 0(2)...10 V Odpovídá výběru

Astatická regulace a regulace zapínáním/vypínáním s časovým limitem Modulace

3. Vložte dlouhý montážní šroub M4 x 60 do otvoru v rukojeti.

Pomocí plochého šroubováku zarazte šroub do hnacího hřídele tak, aby byl pod

horním okrajem rukojeti.

4. Zkontrolujte, zda přípojka servopohonu i rukojeť jsou v krajní poloze proti směru

hodinových ruček při pohledu od horní strany servopohonu. Není-li tomu tak,

stiskněte tlačítko uvolnění převodu servopohonu a otočte rukojetí, dokud nebude

přípojka servopohonu v krajní poloze proti směru hodinových ruček.

5. Namontujte ventilový servopohon na montážní objímku kulového ventilu.

V závislosti na instalaci umístěte sestavu na ventil do kterékoli ze čtyř poloh v krocích

90°.

Poznámka: Při správné funkci musí servopohon otočit ventil proti směru hodinových

ruček, aby došlo k otevření otvoru A, při pohledu na ventil shora.

6. Upevněte servopohon k ventilu pomocí plochého šroubováku.

Doporučený utahovací moment činí 0,9 až 1,4 Nm.

DŮLEŽITÉ: Upevňovací šroub rukojeti nepřetahujte.

Přetažení může způsobit poškození závitů a poškodit také závity dříku ventilu.

Volba směru otáčení

Obr. 6: VA9104-GGA-1S – Tovární nastavení spínačů

Servopohony VA9104-GGA jsou z výroby nastaveny na režim Přímého chodu (DA) a

vstupní signál regulace DC 0 až 10 V. V režimu DA minimální signál regulace přestaví

servopohon do krajní polohy proti směru hodinových ruček (CCW) a maximální signál

regulace přestaví servopohon do krajní polohy ve směru hodinových ruček (CW).

Při provozu v režimu zpětného chodu (RA) minimální signál regulace přestavuje

servopohon do krajní polohy ve směru hodinových ruček a maximální signál regulace

přestavuje servopohon do krajní polohy proti směru hodinových ruček. Chcete-li změnit

výrobní nastavení, demontujte kryt servopohonu a upravte nastavení spínačů na desce

plošných spojů.

Zapojení

Obr. 7: VA9104-AGA-1S – Schéma zapojení regulace

Obr. 8: VA9104-IGA-1S – Schéma zapojení regulace – astatická

Obr. 9: VA9104-IGA-1S – Schéma zapojení regulace – zapínáním/vypínáním

Obr. 10: VA9104-IUA-1S – Schéma zapojení regulace – astatická

Obr. 11: VA9104-IUA-1S – Schéma zapojení regulace – zapínáním/vypínáním

Obr. 12: VA9104-GGA-1S – Schéma zapojení regulace

UPOZORNĚNÍ: Nebezpečí zasažení elektrickým proudem. Před

manipulací s elektrickým připojením odpojte kabel napájení, aby

nedošlo k úrazu elektrickým proudem.

UPOZORNĚNÍ: Nebezpečí poškození majetku. Před zapnutím napájení

systému zkontrolujte všechna zapojení. Krátká spojení a nesprávně

připojené kabely mohou mít za následek trvalé poškození zařízení.

DŮLEŽITÉ: Všechna zapojení kabelů musí odpovídat místním, národním a dalším

příslušným předpisům. Nepřekračujte jmenovité elektrické hodnoty servopohonu.

Příslušenství

(k samostatnému objednání)

Kódové číslo Popis

M9000-550 Náhradní sada upevňovacího materiálu

třída II

DC 0(2) až 10 V nebo 0(4) až 20 mA

s odporem 500 ohmů s polem

vstupního rozsahu (DC 10 V při 1 mA)

Tento dokument podléhá změnám bez předchozího upozornění

8

Page 12

Polski

PRZED INSTALACJĄ NALEŻY UWAŻNIE PRZECZYTAĆ TĘ INSTRUKCJĘ I

OSTRZEŻENIA DOTYCZĄCE BEZPIECZEŃSTWA ORAZ ZACHOWAĆ JE W CELU

Informacje ogólne

Siłowniki zaworowe VA9104 bez sprężynowego urządzenia powrotnego są montowane

bezpośrednio i są zasilane napięciem 24 V AC od AC 100÷240V zasilanie.

Synchroniczne siłowniki o napędzie elektrycznym są używane do precyzyjnego

pozycjonowania zaworów kulowych DN15, DN20 i DN25 z serii VG1000 firmy Johnson

Controls® w systemach ogrzewania, wentylacji i klimatyzacji (HVAC).

Siłowniki VA9104 bez sprężynowego urządzenia powrotnego mają moment obrotowy 4 Nm.

WAŻNE: Siłownika należy używać tylko do sterowania urządzeniami w normalnych

warunkach pracy. Jeśli awaria lub wadliwe działanie siłownika mogłoby doprowadzić

do obrażeń ciała lub uszkodzenia urządzenia sterowanego, względnie innego

wyposażenia, w systemie sterowania należy zastosować dodatkowe środki

ostrożności. W takim wypadku należy zainstalować i utrzymywać inne urządzenia, na

przykład systemy nadzorcze lub alarmowe, regulatory zabezpieczające lub

ograniczające, służące do ostrzegania lub zabezpieczenia przed awarią bądź

wadliwym działaniem siłownika.

Rysunek 1: Wymiary w mm

Instalacja

Rysunek 2: Montaż w przypadku zastosowań do zimnej wody i powietrza z

Zamontuj zawór kulowy wraz z siłownikiem na osi poziomego przewodu rurowego lub

powyżej.

Montaż siłownika

Rysunek 3: Trójdrożny zawór kulowy VG1000 (szczelina A połączona ze szczeliną C)

Rysunek 4: Trójdrożny zawór kulowy VG1000 (szczelina B połączona ze szczeliną C)

Rysunek 5: Instalowanie uchwytu

Aby przymocować siłownik do zaworu kulowego:

1. Obróć ręcznie trzpień zaworu kilka razy przy użyciu klucza nastawnego, aby

Uwaga: W przypadku zaworów dwudrożnych w położeniu całkowicie otwartym

oznaczenia wskaźników są umieszczone w górnej części trzpienia zaworu równolegle

do kierunku przepływu. W przypadku zaworów dwudrożnych w położeniu całkowicie

zamkniętym oznaczenia wskaźników są umieszczone prostopadle do kierunku

przepływu. Zawory trójdrożne mają dwa oznaczenia wskaźników w górnej części

trzpienia zaworu, a jedno z oznaczeń jest umieszczone równolegle do szczeliny

wspólnej (zobacz rysunki 3 i 4).

2. Umieść uchwyt nad wałem czynnym, jak pokazano na rysunku 5.

(a). Wymagany minimalny odstęp

(b). W przypadku modeli z tarczą charakterystyki przepływu tarcza znajduje

się w szczelinie A. Szczelina A musi być otworem wlotowym zaworu.

kondensacją

OSTRZEŻENIE: Siłownika nie należy instalować w miejscach, w których

występują substancje albo opary powodujące korozję, ani w ich pobliżu.

Narażenie elektrycznego siłownika na korozję może uszkodzić

wewnętrzne elementy urządzenia i spowodować utratę gwarancji.

(a). Wkręt do montażu uchwytu ręcznego

(b). Uchwyt do obsługi ręcznej

przełamać moment obrotowy, który mógł powstać w wyniku długiego

przechowywania.

Następnie obróć trzpień zaworu w taki sposób, aby szczelina A zaworu była otwarta.

Uchwyt jest kluczowany i może zostać zamocowany tylko w jednym położeniu.

PÓNIEJSZEGO UŻYCIA

IS_VA9104-AGA-1S / VA9104-IGA-1S / VA9104-IUA-1S / VA9104-GGA-1S_14-88360-2331_Rev. G_04 2017

Dane techniczne

Kody produktów

Zasilanie

Typ sterowania

Sygnał wejściowy

Sygnał sprzężenia zwrotnego

Impedancja wejściowa

silnika

Moment obrotowy

Czas przejścia

(dla obrotu 90°)

Zakres obrotu

Cykle

Poziom słyszalnego szumu

Połączenia elektryczne

Połączenia mechaniczne

Obudowa IP 42

Warunki otoczenia

— Przechowywanie

Limity temperatury cieczy

(siłownik z zaworem)

Ciężar wysyłkowy

Dane dotyczące

zgodności

— Praca

— Woda Zawory VG1205 i VG1805: od -30 do +95 °C (140 ° C-561 M9000 z przekładką termiczną)

— Para wodna Przystosowane do pracy z parą wodną tylko M9000-561 z przegrodą termiczną

VA9104-AGA-1S VA9104-IGA-1S VA9104-IUA-1S VA9104-GGA-1S

24 V AC +25%/-20% przy 50/60 Hz 100 do 240 V AC -15%/+10% przy 50/60 Hz

Sterowanie astatyczne bez przerw Sterowanie ON/OFF i astatyczne z przerwami Modulacja

200 omów (znamionowa)

4 Nm

60 sekund przy 60 Hz

72 sekundy przy 50 Hz

93° ±3°, w prawo lub w lewo

60 000 pełnych cykli skoku

2 500 000 zmian położenia przy znamionowym momencie obrotowym

35 dBA przy 1 m (znamionowy)

Kabel PCW 1,2 m

Wałki okrągłe przepustnicy o średnicy maksymalnej 13 mm lub wałki kwadratowe przepustnicy o średnicy 10 mm

Od –20 do 60°C; maksymalna wilgotność względna 90%, bez kondensacji

Od –40 do 85°C; maksymalna wilgotność względna 90%, bez kondensacji

0,5 kg

Firma Johnson Controls oświadcza, że niniejsze produkty są zgodne z istotnymi wymaganiami i innymi odpowiednimi przepisami zawartymi w

Dyrektywie dot. zgodności elektromagnetycznej i niskich napięć

2,1 VA 3,0 VA 7,5 VA Zasilanie i 0,07 A 3,6 VA

24 V AC +25%/-20% przy 50/60 Hz, SELV lub klasa II 100 do 240 V AC -15%/+10% przy 50/60 Hz,

--- --- ---

3. Włóż długi wkręt do części metalowych M4 x 60 do otworu w uchwycie.

Przykręcaj wkręt do wału czynnego przy użyciu wkrętaka płaskiego do momentu,

gdy wkręt znajdzie się poniżej górnej powierzchni uchwytu.

4. Upewnij się, że łącznik siłownika i uchwyt mają położenie odwrotne do ruchu

wskazówek zegara, patrząc z perspektywy górnej płaszczyzny siłownika. Jeśli nie,

naciśnij zwalniacz przekładni siłownika i obróć uchwyt do momentu, gdy łącznik

siłownika będzie mieć położenie całkowicie przeciwne do ruchu wskazówek zegara.

5. Zainstaluj siłownik zaworu nad kołnierzem do mocowania zaworu kulowego.

W zależności od położenia instalacji umieść zestaw na zaworze w jednej z czterech

pozycji odległych od siebie o 90°.

Uwaga: W celu prawidłowego działania siłownik musi napędzać zawór w kierunku

przeciwnym do otwartej szczeliny A, patrząc znad zaworu.

6. Aby przymocować siłownik do zaworu, należy użyć wkrętaka płaskiego.

Zalecany moment obrotowy wynosi od 0,9 do 1,4 Nm.

WAŻNE: Nie należy przekręcać wkrętu do montażu uchwytu ręcznego.

Przekręcenie może spowodować zdarcie gwintu i uszkodzenie gwintu trzpienia

zaworu.

Wybór kierunku obrotów

Rysunek 6: Ustawienie fabryczne przełącznika VA9104-GGA-1S

Siłowniki VA9104-GGA są ustawione fabrycznie do pracy w trybie bezpośrednim (DA,