Page 1

Two-Way, Industrial-Grade,

Non-Spring-Return, VA-90xx Series

Electrically Actuated,

High-Pressure, High-Temperature

Butterfly Valve Assemblies

Butterfly Valves and Actuators

Code No. LIT-1900151

VF Series Two-Way, Industrial-Grade, Non-Spring-Return, VA-90xx Series

Electrically Actuated, High-Pressure, High-Temperature Butterfly Valve

Assemblies

Description

VF Series Two-Way, Industrial-Grade,

Non-Spring-Return, VA-90xx Series

Electrically Actuated, High-Pressure,

High-Temperature Butterfly Valve Assemblies

are specifically designed for a wide range of

HVAC applications, including two-position and

modulating/throttling control of hot water,

chilled water, condenser water, and steam.

Refer to the VF Series High-Pressure,

High-Temperature Butterfly Valves for Steam

Service Application Note (LIT 977321) for

more information on steam applications.

These lug-style valves offer bidirectional

shutoff at full-rated American National

Standards Institute (ANSI) Class 150 and 300

operating pressures, increasing the range of

applications—particularly in high-rise building

HVAC control applications. ANSI Class 150

and 300 models are also suitable for steam

applications.

Refer to the VF Series High-Pressure,

High-Temperature Butterfly Valves Product

Bulletin (LIT-977208) for important product

application information.

Features

• compatible with all types of ANSI 150/300

slip-on and weld-neck flanges

• high-pressure, high-temperature design

• bidirectional shutoff, dead-end service

• live-loaded seat design with fully encased

O-ring

• double offset stem design

• broad range of compact pre-assembled

actuators available

• direct actuator-to-stem mounting

Repair Information

If the VF Series Butterfly Valve Assembly fails

to operate within its specifications, refer to the

VF Series High-Pressure, High-Temperature

Butterfly Valves Product Bulletin (LIT-977208)

for a list of repair parts available.

Actuators

Actuators

Actuators

Actuators

Pneumatic Damper

Pneumatic Damper

Buttery Valves and

Buttery Valves and

Selection Chart

Valve Code

Number

Two-Way, Normally Closed — ANSI Class 300 Flanges

VFC-025ZE 2-1/2 160 100 550 VFC-025ZE-723D VFC-025ZE-703N VFC-025ZE-725D4 VFC-025ZE-705N4

VFC-030ZE 3 185 155 VFC-030ZE-723D VFC-030ZE-703N VFC-030ZE-725D4 VFC-030ZE-705N4

VFC-040ZE 4 375 315 VFC-040ZE-723D VFC-040ZE-703N VFC-040ZE-725D4 VFC-040ZE-705N4

VFC-050ZE 5 790 500 VFC-050ZE-725D VFC-050ZE-705N VFC-050ZE-725D4 VFC-050ZE-705N4

VFC-060ZE 6 1,000 710 VFC-060ZE-726D VFC-060ZE-706N VFC-060ZE-727D4 VFC-060ZE-707N4

VFC-080ZE 8 2,000 1,360 VFC-080ZE-727D VFC-080ZE-707N VFC-080ZE-727D4 VFC-080ZE-707N4

VFC-100ZE 10 2,650 1,740 VFC-100ZE-927D VFC-100ZE-907N

VFC-120ZE 12 4,000 2,500 VFC-120ZE-928D VFC-120ZE-908N

VFC-140ZE 14 4,100 2,600 VFC-140ZE-928D VFC-140ZE-908N

Two-Way, Normally Closed — ANSI Class 150 Flanges

VFC-025VE 2-1/2 160 100 240 VFC-025VE-722D VFC-025VE-702N VFC-025VE-722D4 VFC-025VE-702N4

VFC-030VE 3 185 155 VFC-030VE-722D VFC-030VE-702N VFC-030VE-722D4 VFC-030VE-702N4

VFC-040VE 4 375 315 VFC-040VE-722D VFC-040VE-702N VFC-040VE-722D4 VFC-040VE-702N4

VFC-050VE 5 790 500 VFC-050VE-724D VFC-050VE-704N VFC-050VE-725D4 VFC-050VE-705N4

VFC-060VE 6 1,350 750 VFC-060VE-725D VFC-060VE-705N VFC-060VE-725D4 VFC-060VE-705N4

VFC-080VE 8 2,800 1,590 VFC-080VE-726D VFC-080VE-706N VFC-080VE-727D4 VFC-080VE-707N4

VFC-100VE 10 4,300 2,430 VFC-100VE-727D VFC-100VE-707N VFC-100VE-727D4 VFC-100VE-707N4

VFC-120VE 12 6,650 3,750 VFC-120VE-728D VFC-120VE-708N

VFC-140VE 14 7,650 4,300 VFC-140VE-927D VFC-140VE-907N

VFC-160VE 16 9,800 5,510 VFC-160VE-928D VFC-160VE-908N

1. Maximum closeoff pressure for ANSI Class 300 valves is 740 psig (5,102.1 kPa) for fluid temperatures below 100°F (37.8°C), and 550 psig (3,790 kPa) for fluid

temperatures at 250°F (121.1°C). Maximum steam pressure is 150 psig (1,034.2 kPa) for on/off service, and 50 psig (344.8 kPa) for proportional service.

2. Maximum closeoff pressure for ANSI Class 150 valves is 285 psig (1,965 kPa) for fluid temperatures below 100°F (37.8°C), and 240 psig (1,654.8 kPa) for fluid

temperatures at 250°F (121.1°C). Maximum steam pressure is 150 psig (1,034.2 kPa) for on/off service, and 50 psig (344.8 kPa) for proportional service.

Actuator AC 120 V Powered Actuator AC 24 V Powered Actuator

Size,

in.

Cv at

90°

Cv at

70°

Closeoff

Pressure,

psig

1

2

On/Off 0 to 10 VDC

Proportional

On/Off 0 to 10 VDC

Proportional

The performance specifications are nomina l and con form to accep table ind ustry stand ards. For applicati ons at con ditions be yond these specification s, consult th

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2014 Johnson Controls, Inc.

V–285

Page 2

VF Series Two-Way, Industrial-Grade, Non-Spring-Return, VA-90xx Series Electrically

Actuated, High-Pressure, High-Temperature Butterfly Valve Assemblies (Continued)

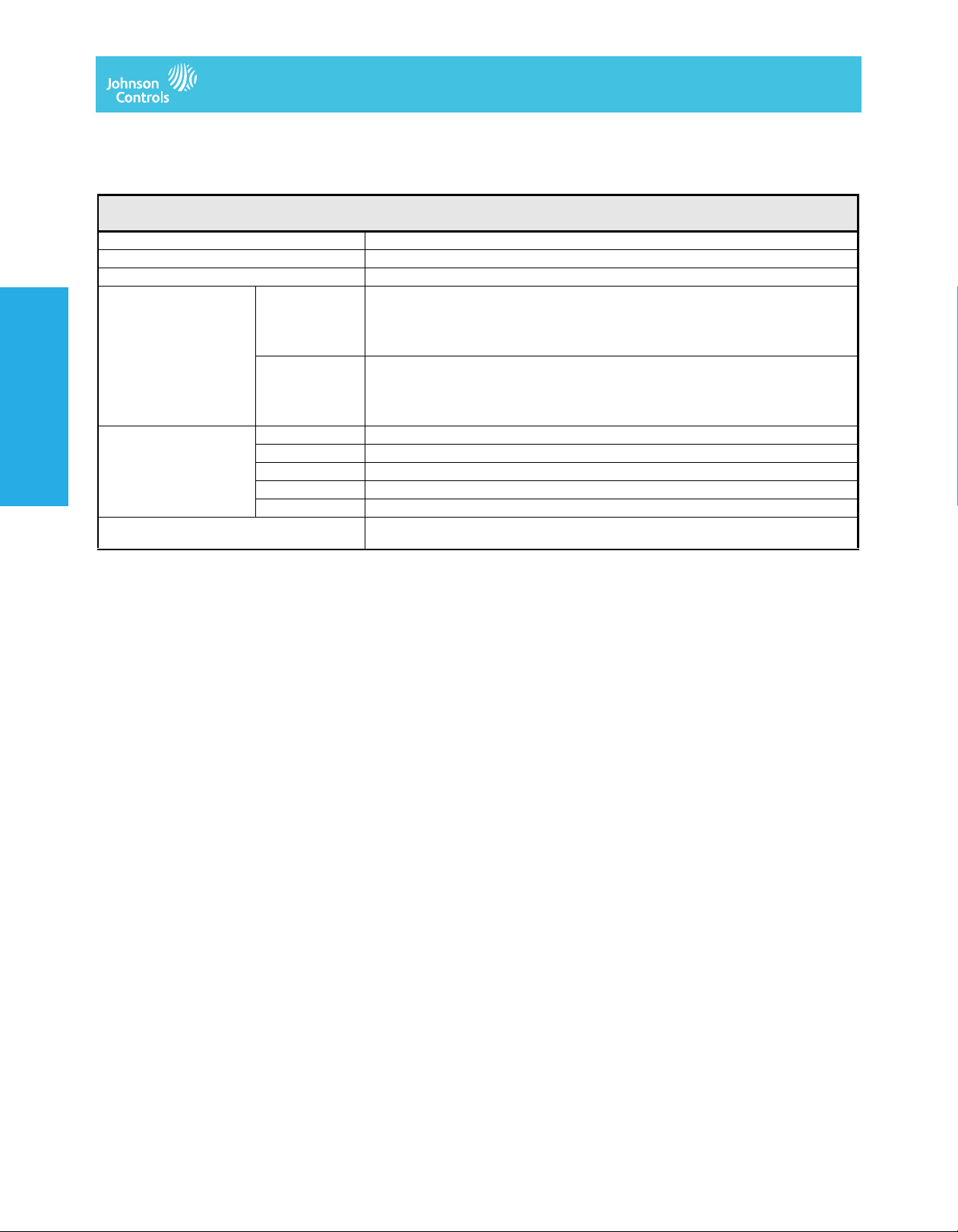

Technical Specifications

Service Hot, Chilled, or Condenser Water, and Steam

Body Styles and Sizes Two-Way, 2-1/2 through 16 in., Fully Lugged

Fluid Temperature Limits -20 to 500°F (-29 to 260°C)

Maximum Closeoff Pressure 2-1/2 through 16 in.

Actuators

Actuators

Materials Body Carbon Steel, ASTM A216 GR WCB/A516 GR 70

Pneumatic Damper

Buttery Valves and

Ambient Storage Temperature Limits -20 to 150°F (-29 to 66°C);

1. Refer to the VF Series High-Pressure, High-Temperature Butterfly Valves Product Bulletin (LIT-977208) for actuator specifications.

2. Types V and Z valves are rated for 150 psig (1,034 kPa) saturate d steam at 366°F (186°C) for two-p osition a pplications, a nd 50 p sig (345 kPa) saturated steam

at 297°F (147°C) for modulating applications. Refer to the VF Series High-Pressure, High-Temperature Butterfly Valves for Steam Service Application Note

(LIT-977321) for more information.

3. For 18 in. or larger ANSI Class 150 valves and 16 in. or larger ANSI Class 300 valves, consult the local Johnson Controls® office.

4. The preferred orientation of the seat retainer in dead-end service is against the flange.

5. For pressures between 550 and 740 psig (3,790 and 5,099 kPa), consult the local Johnson Controls office.

Butterfly Valves and Actuators

VF Series Two-Way, Industrial-Grade, Non-Spring-Return, VA-90xx Series Electrically Actuated,

High-Pressure, High-Temperature Butterfly Valve Assemblies

2

3

ANSI Class 150

Valves (Type V)

2-1 / 2 through 14 in.

ANSI Class 300

Valves (Type Z)

Disc Stainless Steel, ASTM A 351 GR CF8M

Seat Assembly RTFE with Silicone Rubber O-Ring

Seat Retainer Carbon Steel, ASTM A516 GR 70

Stem 17-4 PH Stainless Steel, ASTM A564-Type 630

240 psig (1,654 kPa) at 250°F (121°C)

Fluid Temperature, Bidirectional

240 psig (1,654 kPa) at 250°F (121°C)

Fluid Temperature, Dead-End Service

550 psig (3,790 kPa) at 250°F (121°C)

Fluid Temperature, Bidirectional

550 psig (3,790 kPa) at 250°F (121°C)

Fluid Temperature, Dead-End Service

Preferably 40 to 85°F (4 to 29°C)

3

3, 4

3, 5

3, 4, 5

1

The performance specifications are nomina l and con form to accep table ind ustry stand ards. For applicati ons at con ditions be yond these specification s, consult th

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2014 Johnson Controls, Inc.

V–286

Loading...

Loading...