Johnson Controls VA78*0-HG*-2 Series, VA7810-HG*-2 Series, VA7830-HG*-2 Series, VA7810-AD*-2 Series, VA7810-AG*-2 Series Product Bulletin

...Page 1

Figure 1: VA7800 Actuator

VA7800 Series Electric Valve Actuators

Product Bulletin

VA7800 Series

Refer to the QuickLIT website for the most up-to-date version of this document.

The VA7800 Series of Electric Valve Actuators control

VG7000 Series Bronze Globe Valves in Heating,

Ventilating, an d Air Conditioning (HVAC) systems. The

V A7800 Series produces a minimum linea r output force

of 180 lb (800 N) and is ordered field mounted or

factory coupled to 1 in. and 2 in. VG7000 Series

Bronze Globe Valves with brass trim and to 1/2 in.

through 2in. VG7000 Series Bronze Globe Valves with

stainless steel trim. All actuators are direct mount and

available in both Spring Return and Non-Spri ng Return

models.

Spring Return models ship from the factory set for

DC 0 to 10 V Proportional Control. With a change of

DIP switch settings, this model can be field configured

to On/Off or Floating Control. In addition to these

settings, optional auxiliary switches are also available.

Code No. LIT-12011474

Issued June 2018

Non-Spring Return models are available in AC 24 V

On/Off (Floating) Control, or DC 0 to 10 V Proportional

Control. Models are available with or without optional

auxiliary switches.

Table 1: Features and Benefits

Features Benefits

Automatic Stroke Adjustment Provides easy, quick, and precise commissioning.

Manual Override as Standard Allows manual positioning of valve for easy commissioning and servicing.

NEMA 2 (IP54) Enclosure Protection Allows installation in a wide range of environments.

Unique Swing-Gate Yoke Offers fast and secure attachment to the valve.

Brushless Motor Ensures low energy consumption and long life.

Proportional Model Enables one model to be used for various control types.

Force-Controlled Motor Shut-Off Reduces energy consumption, wear of the actuator, and protects the valve from

excessive forces.

Stroke Position Indicator Gives visual indication of valve operation, provides automatic adjustment of

Status Light-Emitting Diode (LED) Gives visual indication of actuator status and assists with diagnostic.

Optional Integrated Auxiliary Switches Provides adjustable switch points with line voltage capability.

Integral Cable with Colored Conductors Simplifies installation and field wiring.

Integral Connector for 3/8 in. (10 mm)

Flexible Metal Conduit (FMC)

Underwriters Laboratories Inc.® (UL)

and CE Compliant

stroke indicators during first cycle of operation.

Simplifies installation and field wiring.

Provides internationally recognized regulatory agency approval.

VA7800 Series Electric Valve Actuators Product Bulletin

1

Page 2

Application Overview

IMPORTANT: The VA7800 Series Electric Valve

Actuators are intended to control saturated steam,

hot water, and chilled water flow under normal

equipment operating conditions. Where failure or

malfunction of the VA7800 Series Valve Actuator

could lead to personal injury or property damage to

the controlled equipment or other property,

additional precautions must be designed into the

control system. Incorporate and maintain other

devices, such as supervisory or alarm systems or

safety or limit controls, intended to warn o f or protect

against failure or malfunction of the VA7800 Series

V alve Actuator .

VA7810-Axx-2 Series Non-Spring Return On/ Off and Floating Point Actuator

The VA7810-AGx-2 Series Non-Spring Return

Actuators provide fail-in-place on/off or modulating

control of valves in HVAC systems. On/Off Control is

provided from a manual switch, an auxiliary switch from

a pump contactor, or a similar device. Floating Point

Control is provided from a triac or relay.

VA7810-HGx-2 Series Non-Spring Return Proportional Actuator

The VA7810-HGx-2 Series Non-Spring Return

Actuators offer fail-in-place proportional control of

valves in HVAC systems regulated by an electronic

controller . These a ctuators are configured for response

to 0 to 10 VDC, 2 to 10 VDC, 0 to 20 mA, or 4 to 20 mA.

The VA7810-HGx-2 Series can also be custom

configured for valve sequencing. The minimum setpo int

is 0 to 6 VDC (0 to 12 mA), and maximum input signal

is 3 to 10 VDC (6 to 20 mA). A

0 to 10 VDC, or 2 to 10 VDC feedback signal is

available for position indication. The actuator features a

preset actuator position with a stem that extends or

retracts on loss of signal. However, when you select

current input, this stem feature is not available.

VA7820-HGx-2/VA7830-HGx-2 Series Spring Return Proportional Actuator

The VA7820-HGx-2 and VA7830-HGx-2 Series

Actuators are Spring Return actuators that provide

fail-safe proportional control of valves in HV AC systems

regulated by an electronic controller. In the event of

power loss, the V A7820 -HGx-2 Series Actuators spring

return with the actuator stem fully retracted and the

valve stem in the full up position. On loss of power, the

VA7830-HGx-2 Series Actuators spring return with the

actuator stem fully extended and the valve stem in the

full down position.

These actuators are configured for response to 0 to

10 VDC, 2 to 10 VDC, 0 to 20 mA, or 4 to 20 mA. Both

models of actuators can also be custom configured for

valve sequencing. Minimum setpoint is 0 to 6 VDC (0 to

12 mA) and maximum input signal is 3 to 10 VDC (6 to

20 mA). A 0 to 10, or 2 to 10 VDC feedback signal is

available for position indication. The actuator s feature a

preset actuator position with a stem that extends or

retracts, on loss of signal. When current input is

selected, this stem feature is not available.

Operation

The VA7800 Series of actuators offers up to 1 in.

(25 mm) of linear stroke for the operation of

Johnson Controls® VG7000 Series Bronze Control

Valves. The actuators interface to all threaded stem

VG7000 Valves

trim VG7000 series valves from 1/2 in. to 2 in. The

actuator should not be used on brass trim VG7000

series valves from 1/2 in. to 3/4 in.

be manually positioned by means of a 5 mm Allen

wrench.

For non-spring return actuators, engage manual

operation by inserting the Allen wrench into the

hexagonal socket and pushing down to cut off the

power to the motor. Turn the Allen wrench clockwise to

extend the actuator stem; turn the wrench

counterclockwise to retract the actuator stem.

For spring return actuators, manual operation requires

that the power be disconnected. On loss of power, the

actuator spring force moves the stem to its fail-safe

position. For manual operation, insert the Allen wrench

into the hexagonal socket and turn the wrench either

clockwise or counterclockwise depending on the

actuator model. When you reach the desired stem

position, push the wrench down and slightly rotate the

wrench in the opposite direction to lock it in position.

When power resumes, the actuator is released from its

manual position.

Note: After using manual control to position the

actuator, it is recommended that a self-calibration cycle

be performed to assure proper operation.

VA7810-AGx-2 Series Non-Spring Return On/ Off and Floating Point Actuator

The VA7810-AGx-2 Series Non-Spring Return

Actuators are offered with On/Off Control or Floating

Control. Select these controls by applying power to

different terminals located on the actuator. For a more

detailed procedure, refer to the appropriate installation

instructions for the actuator.

and can be used on all stainless steel

All actuators can

VA7800 Series Electric Valve Actuators Product Bulletin

2

Page 3

For On/Off Control, apply power continuously to

Terminal 1 (Common) and Terminal 2 (Power). From

this action, the actuator assumes its fully extended

stem position. To fully retract the stem, apply power

through the controlling device to Terminal 3. When

power is removed from Terminal 3, the actuator returns

to its fully extended position. In the event of power loss,

the actuator remains in its last position.

To enable Floating Control, wire Terminal 1 to the

common. Apply power to Terminal 2 to extend the

actuator stem, or to Terminal 3 to retract the actuator

stem. If power is removed from Terminal 2 and

Terminal 3, or in the event of complete power loss, the

actuator remains in its last position.

VA78x0-HGx-2 Series Proportional Control Actuators

The VA78x0-HGx Series Actuators operate with

Proportional Control, On/Off Control, or Floating

Control. Changes in DIP switch settings allow the

selection of Control Type, Input Signal, Input Range,

Action, actuator position at signal loss, and stroke

speed. See Table 2 for a detailed reference of DIP

switch settings.

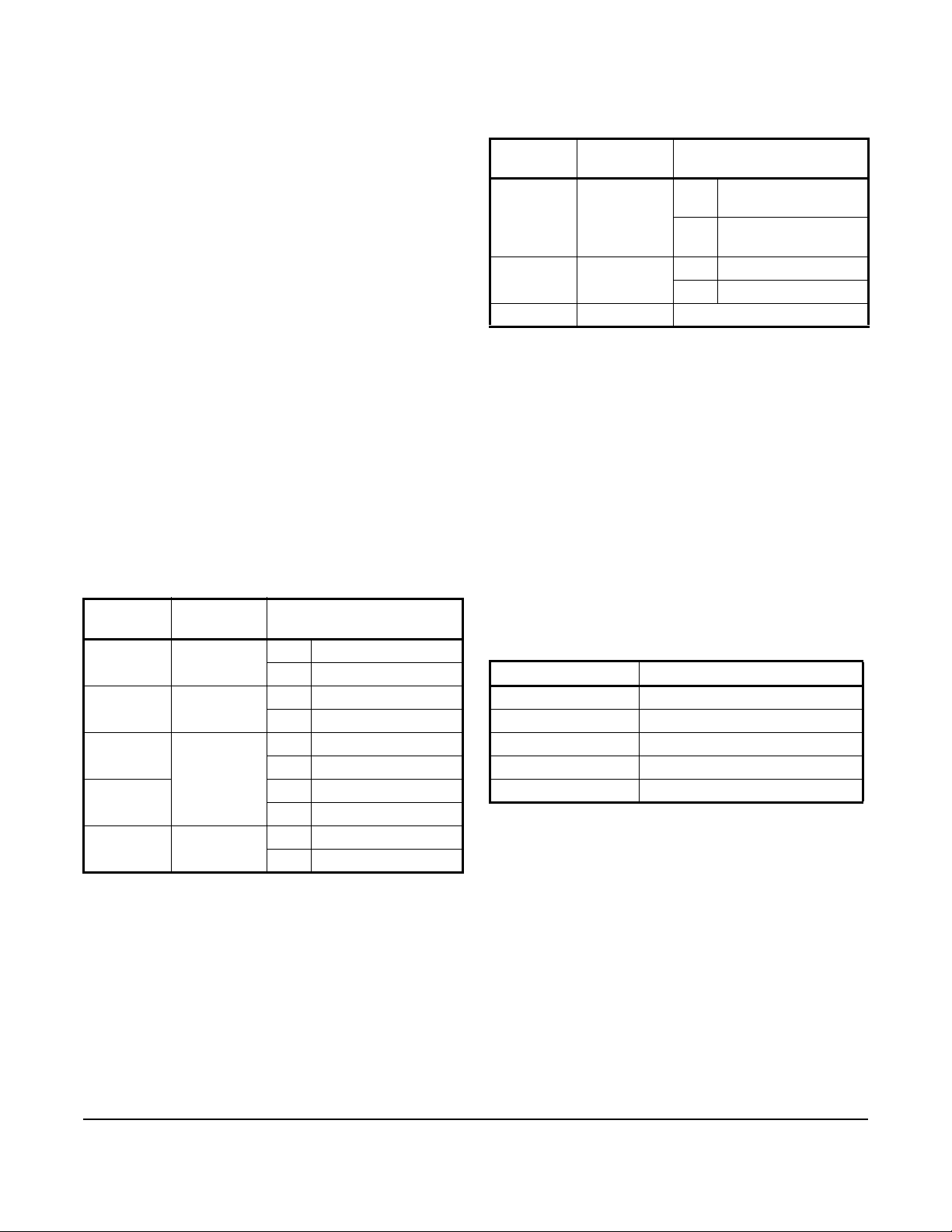

Table 2: VA78x0-HGx-2 Series Proportional

Control Actuators DIP Switch Settings

(Part 1 of 2)

DIP Switch

Number

1 Control Type ON Floating/on/off control

2 Input Signal ON Current input signal

3 Input Signal

4 ON 2 to 10 V (4 to 20 mA)

5 Action ON Reverse

Description State

OFF Proportional control

OFF Voltage input signal

ON Custom setting

Range

OFF Pre-defined setti ng

OFF 0 to 10 V (0 to 20 mA)

OFF Direct

Table 2: VA78x0-HGx-2 Series Proportional

Control Actuators DIP Switch Settings

(Part 2 of 2)

DIP Switch

Number

6 Preset

7 Stroke

8 Not Used Not Used

1. Control signal loss position preset does not operate when

you select 0 to 20 mA or custom input range control.

Description State

ON Actuator Stem

Actuator

Position at

Signal Loss

Speed

OFF Actuator Stem

1

ON 76 s/in. (3 s/mm)

OFF 152 s/in. (6 s/mm)

Extends

Retracts

The VA78x0-HGx Series Actuators are a direct acting

and factory supplied set for 0 to 10 VDC Proportional

Control. Field setting options exist for standard ranges

of 0 to 20 VDC (0 to 20 mA) or 2 to 10 VDC (4 to

20 mA) control in the field. At the end of a span, the

actuator control signal has a buffer zone of 0.3 V

(0.6 mA) to ensure definite valve close-off.

You can set the actuators for custom signal ranges.

Minimum setpoint is 0 to 6 VDC (0 to 12 mA) and

maximum input signal is 3 to 10 VDC (6 to 20 mA).

Position feedback signal is also available in Table 3.

Table 3: Position Feedback Signal for

VA78x0-HGx-2 Series Proportional

Control Actuators

Input Signal Feedback Output

0 to 10 VDC 0 to 10 VDC

2 to 10 VDC 2 to 10 VDC

0 to 20 mA 0 to 10 VDC

4 to 20 mA 2 to 10 VDC

Custom Range 0 to 10 VDC

VA7800 Series Electric Valve Actuators Product Bulletin

3

Page 4

All VA78x0-HGx-2 Series Actuators feature a

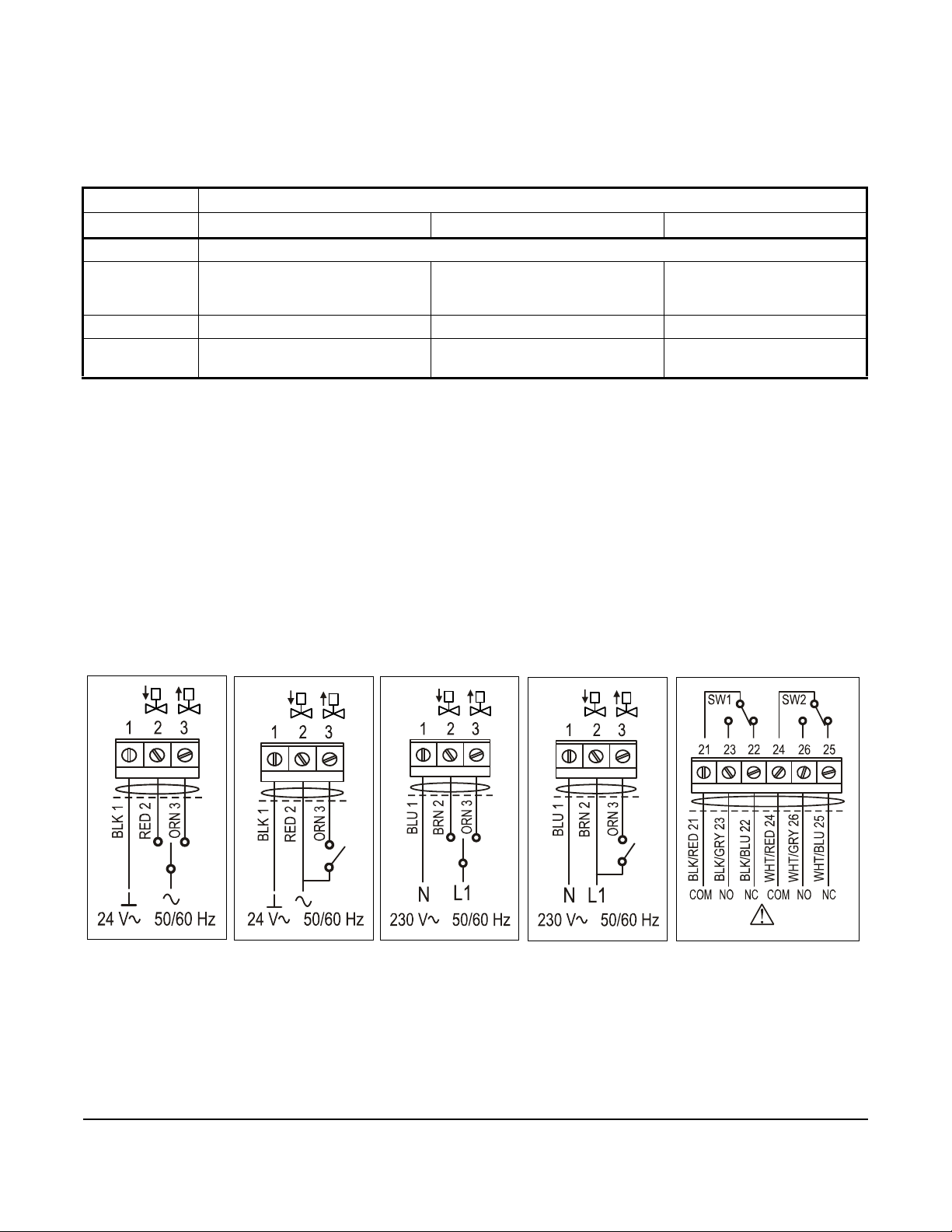

Figure 2: VA7810-Axx-2 Wiring Diagram

VA7810-AGx-2 Wired

as Floating

VA7810-AGx-2 Wired

as OPEN/CLOSE

VA7810-ADx-2 Wired

as Floating

VA7810-ADx-2 Wired

as OPEN/CLOSE

VA7810-AxC-2

Auxiliary Switches Wiring

multicolored LED that provides operational status and

failure analysis information. See Table 4 for a detailed

description of LED color indicators.

Table 4: VA78x0-HGx-2 Series Actuators LED Status and Color Indicators

LED Color

Status Green Yellow Red

Off Power off

Blink Motor running Power on after a black-out

Temporary fault, possible valve

2

sticking

Fast Blink Calibrating Input signal failure

Continuous

On

1. After re aching both ends of the stroke, the input signal is recalibrated and the LED switches to green.

2. The actuato r leaves this mode only if the push button is pressed for at least 5 seconds, and the previously detected error

has been resolved.

3. This status is temporary. When the detected temperature decreases to the acceptable range, the LED switches back to

green.

Power on, motor not running Custom calibration value out of

range

1

High temperature

Generic fault

3

The actuator microprocessor carries out a failure

diagnosis when a failure has been detected. The

colored LED indicates the actuator status. When the

microprocessor dete cts that the stem has come to an

unexpected stop, it initiates a retry cycle. The retry

cycle repeats three times, and if unsuccessful, the

actuator switches to fault mode and the LED flashes

yellow. If the problem is cleare d, the actuator continu es

to function normally.

The LED also flashes yellow when power resumes

after a power loss. The LED continues to flash yellow

until the end stop is achieved or a recalibration process

is manually started.

Wiring Diagrams

Figure 2 and Figure 3 show detailed diagrams for the

wiring configurations of the VA7800 Series Electric

Valve Actuators.

VA7800 Series Electric Valve Actuators Product Bulletin

4

FIG:W IR10_a xx

Page 5

Mounting

Figure 3: VA78x0-HGx-2 Wiring Diagram

Figure 4: VG7800 Mounting

When mounting the actuator on a valve, the following

precautions are recommended:

• Never cover the actuator with insulating material.

• Allow sufficient clearance to remove the actuator.

• Mount the valve in an upright angle or at an angle

less than 90° from the vertical for fluid

temperatures up to 212°F (100°C).

• Orient the actuator so that the yoke supports are

one above the other when mounting the valve

horizontally.

• Install the valve with the stem horizontal and

insulate the pipe to minimize heat transfer to the

actuator for fluid temperatures above 212°F

(100°C).

FIG:MT_7800

VA7800 Series Electric Valve Actuators Product Bulletin

5

Page 6

Ordering Information

Contact the nearest Johnson Controls representative

and specify the desired product code number from

Table 5.

Table 5: VA-78x0-xxx-2 Series Electric Valve Actuators

Code Number Input Signal Power

On/Off

Floating Point

VA7810-ADC-2

VA7810-AGA-2

VA7810-AGC-2

VA7810-HGA-2

VA7810-HGC-2

VA7820-HGA-2

VA7820-HGC-2

VA7830-HGA-2

VA7830-HGC-2

X X --- --- X 8 X --- --- --- X 48 76 114

X X --- X --- 3 X --- --- --- --- 48 76 114

X X --- X --- 3 X --- --- --- X 48 76 114

X X X X --- 6 X --- --- X --- 24/48 38/76 57/114

X X X X --- 6 X --- --- X X 24/48 38/76 57/114

X X X X --- 11 --- X --- X --- 24/48 38/76 57/114

X X X X --- 11 --- X --- X X 24/48 38/76 57/114

X X X X --- 11 --- --- X X --- 24/48 38/76 57/114

X X X X --- 11 --- --- X X X 24/48 38/76 57/114

Proportional 0 (2) to 10 VDC

0 (4) to 20 mA

Requirements

24 VAC 50/60 Hz ± 15%

230 VAC 50/60 Hz ± 15%

Action on Power

Failure

VA Rating

Non-Spring Return

Spring Return Actuator

Retracted Va lve Ste m F ull Up

Feedback Auxiliary

Spring Return Actuator

Extended Valve Stem Full Down

0 (2) to 10 VDC

Switches

2 SPDT, 1A, 3A Resis tive,

1/4 HP

Nominal Stroke Time

(Seconds)

1/2 and 3/4 in. VG7000

(5/16 in. valve stroke)

1 and 1-1/4 in. VG7000

(1/2 in. valve stroke)

1

1-1/2 and 2 in. VG7000

(3/4 in. valve stroke)

1. VA 78 x0-HGx-2 actuators have field selectable stroke spee d ; fact or y setting is the slowest speed.

Repair Information

If a V A78x0-xxx-2 Seri es Electric Valve Actuator fails to

operate within specifications, replace th e un it. F or a

replacement actuator, contact the nearest

Johnson Controls representative.

Table 6: Accessories Ordering Information

Product Code Number Description

V-9999-BC1 Mounting Kit to Mount VA-715x, VA-720x, VA78xx, or VA-4233 Series Electric Actuators

to Barber Coleman® 1/2 through 1-1/4 Inch VB-9xxx Valve Bodies

V-9999-HW1 Mounting Kit to Mount VA-715x, VA-720x, VA78xx, or VA-4233 Series Electric Actuators

to Honeywell® V5011A, F, and G, 1/2 through 3 Inch Single-Seated and V5013F

Three-Way Valves

VA7800 Series Electric Valve Actuators Product Bulletin

6

Page 7

Dimensions

Figure 5: Dimensions, in. (mm)

8.35 (212

)

4.56 (116)

9.6 (244)

5.9 Minimum(150)

VA7800 Series Electric Valve Actuators Product Bulletin

7

Page 8

Technical Specifications

Table 7: VA7810-AGx-2 and VA7810-ADx-2 Series On/Off (Floating) Electric Non-Spring Return Valve

Actuators

Model VA7810-AGx-2 VA7810-ADx-2

Thrust Force 180 lb (800 N) minimum

Power Supply AC 24 V (AC 19 to 30 V) at 50/60 Hz,

Class 2

Transformer Sizing 3 VA 8 VA

Input Signal AC 24 V (AC 19 to 30 V) at 50/60 Hz AC 230 V (AC 195 to 265 V) at 50/60

Feedback N/A N/A

Auxiliary Switch Rating Two Single-Pole, Double-Throw (SPDT), AC 230 V, 3.0 A Resistive, 1/4 hp

Stroke 5/16 to 1 in. (8 to 25 mm)

Stroke Speed 5/16 in. stroke: 48 seconds

1/2 in. stroke: 76 seconds

3/4 in. stroke: 114 seconds

Ambient Operating Conditions 23 to 131°F (-5 to 55°C); 10 to 90% RH Noncondensing

Enclosure Rating NEMA 2 (IP54)

Electrical Connection 48 in. (1.2 m) UL 758 Type AWM Halogen Free Cable with 18 AWG

(0.85 mm

Dimensions 9.6 x 4.56 x 8.35 in. (244 x 116 x 212 mm)

Materials Gearbox and Yoke Die Cast Aluminum

Cover Resin ABS/PC - UL94-V0

Stem Stainless Steel

Coupler Brass

Life Cycles 100,000 full stroke cycles

Shipping Weight 5.4 lb (2.5 kg)

Compliance United States UL 60730 Listed Type 1 Enclosure, CCN XAPX, File E194024

Canada UL 60730-1 Listed Type 1 Enclosure, CCD XAPX7, File E194024

Europe CE Mark - Johnson Controls, Inc. declares that this product is in compliance

with the essential requirements and other relevant provisions of the

EMC directive and the Low Voltage Directive.

2

) Conductors and 0.25 in. (6 mm) Ferrule Ends

AC 230 V (AC 195 to 265 V) at 50/60

Hz

Hz

VA7800 Series Electric Valve Actuators Product Bulletin

8

Page 9

Table 8: VA7810-HGx-2 Series Proportional Electric Non-Spring Return Valve Actuators

Model VA7810-HGx-2

Thrust Force 180 lb (800 N) minimum

Power Supply AC 24 V (AC 19 to 30 V) at 50/60 Hz, Class 2

Transformer Sizing 6 VA

Input Signal Switch Selectable:

Proportional: DC 0 to 10 V, DC 2 to 10 V, 0 to 20 mA or 4 to 20 mA

Programmable Proportional:

Start Point: 0 to 6 VDC (0 to 12 mA)

End Point: 3 to 10 VDC (6 to 20 mA) with 3 VDC (6 mA) minimum span

On/Off (Floating): AC 24 V at 50/60 Hz

Switch Selectable Direct or Reverse Action with signal increase

Switch Selectable preset actuator position on loss of signal

Control Input Impedance Voltage Input: 100k ohm

Current Input: 120 ohm

Feedback DC 0 (2) to 10 V corresponds to input range

Auxiliary Switch Rating SPDT, AC 230 V, 3.0 A Resistive, 1/4 hp

Stroke 5/16 to 1 in. (8 to 25 mm)

Stroke Speed (Switch Selectable) Sl ow (Fa cto ry Setting) 5/16 in. stroke: 48 seconds

1/2 in. stroke: 76 seconds

3/4 in. stroke: 114 seconds

Fast 5/16 in. stroke: 24 seconds

1/2 in. stroke: 38 seconds

3/4 in. stroke: 57 seconds

Ambient Operating Conditions 23 to 131°F (-5 to 55°C); 10 to 90% RH Noncondensin g

Ambient Storage Conditions -40 to 176°F (-40 to 80°C); 5 to 95% RH Noncondensing

Enclosure Rating NEMA 2 (IP54)

Electrical Connection 48 in. (1.2 m) UL 758 Type AWM Halogen Free Cable with 18 AWG

(0.85 mm

Dimensions 9.6 x 4.56 x 8.35 in. (244 x 116 x 212 mm)

Materials Gearbox and Yoke Die Cast Aluminum

Cover Resin ABS/PC - UL94-V0

Stem Stainless Steel

Coupler Brass

Life Cycles 100,000 full stroke cycles

Shipping Weight 5.4 lb (2.5 kg)

Compliance United States UL 60730 Listed Type 1 Enclosure, CCN XAPX, File E194024

Canada UL 60730-1 Listed Type 1 Enclosure, CCN XAPX7, File E194024

Europe CE Mark - Johnson Controls, Inc. declares that this product is in compliance

with the essential requirements and other relevant provisions of the

EMC directive and the Low Voltage Directive.

2

) Conductors and 0.25 in (6 mm) Ferrule Ends

VA7800 Series Electric Valve Actuators Product Bulletin

9

Page 10

Table 9: VA7820-HGx-2 / VA7830-HGx-2 Series Proportional Electric Spring Return Valve Actuators

Model VA7820-HGx-2 / VA7830-HGx-2

Thrust Force 180 lb (800 N) minimum

Power Supply AC 24 V (AC 19 to 30 V) at 50/60 Hz, Class 2

Transformer Sizing 11 VA

Input Signal Switch Selectable:

Proportional: DC 0 to 10 V, DC 2 to 10 V, 0 to 20 mA or 4 to 20 mA

Programmable Proportional:

Start Point: 0 to 6 VDC (0 to 12 mA)

End Point: 3 to 10 VDC (6 to 20 mA) with a 3 VDC (6 mA) minimum span

On/Off (Floating): AC 24 V at 50/60 Hz

Switch Selectable Direct or Reverse Action with signal increase

Switch Selectable reset actuator position on loss of signal

Control Input Impedance Voltage Input: 100k ohm

Current Input: 120 ohm

Feedback DC 0 (2) to 10 V corresponds to input range

Auxiliary Switch Rating SPDT, AC 230 V, 3.0 A Resistive, 1/4 hp

Stroke 5/16 to 1 in. (8 to 25 mm)

Stroke Speed Slow (Factory Setting) 5/16 in. stroke: 48 seconds

1/2 in. stroke: 76 seconds

3/4 in. stroke: 114 seconds

Fast 5/16 in. stroke: 24 seconds

1/2 in. stroke: 38 seconds

3/4 in. stroke: 57 seconds

Ambient Operating Conditions 23 to 131°F (-5 to 55°C); 10 to 90% RH Noncondensing

Ambient Storage Conditions -40 to 176°F (-40 to 80°C); 5 to 95% RH Noncondensing

Enclosure Rating NEMA 2 (IP54)

Electrical Connection 48 in. (1.2 m) UL 758 Type AWM Halogen Free Cable with 18 AWG

(0.85 mm

Dimensions 9.6 x 4.56 x 8.35 in. (244 x 116 x 212 mm)

Materials Gearbox and Yoke Die Cast Aluminum

Cover Resin ABS/PC - UL94-V0

Stem Stainless Steel

Coupler Brass

Life Cycles 100,000 full stroke cycles

Shipping Weight 7.3 lb (3.3 kg)

Compliance United States UL 60730 Listed Type 1 Enclosure, CCN XAPX, File E194024

Canada UL 60730-1 Listed Type 1 Enclosure, CCN XAPX7, File E194024

Europe CE Mark - Johnson Controls, Inc. declares that this product is in compliance

with the essential requirements and other relevant provisions of the

EMC directive and the Low Voltage Directive.

2

) Conductors and 0.25 in. (6 mm) Ferrule Ends

The performance specifications are nominal and conform to acceptable industry standards. For application at conditions beyond these

specifications, consult the local Johnson Controls office. Johnson Controls, Inc. shall not be liable for damages resulting from

misapplication or misuse of its products.

VA7800 Series Electric Valve Actuators Product Bulletin

10

Page 11

Metasys® and Johnson Controls® are registered trademarks of Johnson Controls, Inc.

All other marks herein are the marks of their respective owners. © 2018 Johnson Controls, Inc.

Building Efficiency

507 E. Michigan Street, Milwaukee, WI 53202

European Single Point of Contact: NA/SA Single Point of Contact: APAC Single Point of Contact:

JOHNSON CONTROLS

WESTENDHOF 3

45143 ESSEN

GERMANY

JOHNSON CONTROLS

507 E MICHIGAN ST

MILWAUKEE WI 53202

USA

JOHNSON CONTROLS

C/O CONTROLS PRODUCT

MANAGEMENT

NO. 22 BLOCK D NEW DISTRICT

WUXI JIANGSU PROVINCE 214142

CHINA

VA7800 Series Electric Valve Actuators Product Bulletin

Published in U.S.A. www.johnsoncontrols.com

11

Loading...

Loading...