Page 1

VA7800 Valve Actuator

VA7800 Series Electric Valve Actuators

Code No. LIT-1900558

Issued June 4, 2015

Description

The VA7800 Series of electric valve actuators

control VG7000 Series Bronze Globe Valves

in HVAC systems. The VA7800 Series

produce a minimum linear output force of

180 lb (800 N) and are ordered field mounted

or factory coupled to 1/2 through 2 in.

VG7000 Series Bronze Globe Valves. All

actuators are direct mount and available in

both spring-return and non-spring-return

models.

Spring-return models ship from the factory set

for DC 0 to 10 V Proportional Control. With a

change of DIP switch settings, this model can

be field configured to On/Off or Floating

Control. In addition to these settings, optional

auxiliary switches are also available.

Non-spring-return models are available in

AC 24 V On/Off (Floating) Control, or

DC 0 to 10 V Proportional Control. Models are

available with or without optional auxiliary

switches.

Refer to the VA7800 Series Electric Valve

Actuators Product Bulletin (LIT-12011474) for

important product application information.

Features

• Automatic Stroke Adjustment — provides

easy, quick, and precise commissioning.

• Manual Override as Standard — allows

manual positioning of valve for easy

commissioning and servicing.

• IP54 Enclosure Protection — allows

installation in a wide range of

environments.

• Unique Swing-Gate Yoke — offers fast and

secure attachment to the valve.

• Brushless Motor — ensures low energy

consumption and long life.

• Proportional Model — enables one model

to be used for various control types.

• Force-Controlled Motor Shutoff — reduces

energy consumption, wear of the actuator,

and protects the valve from excessive

forces.

• Stroke Position Indicator — gives visual

indication of valve operation, provides

automatic adjustment of stroke indicators

during first cycle of operation.

• Status Light-Emitting Diode (LED) — gives

visual indication of actuator status and

assists with diagnostic.

• Optional Integrated Auxiliary Switches —

provides adjustable switch points with line

voltage capability.

• Integral Cable with Colored Conductors —

simplifies installation and field wiring.

• Integral Connector for 3/8 in. (10mm)

Flexible Metal Conduit (FMC) — simplifies

installation and field wiring.

• Underwriters Laboratories Inc.® (UL) and

CE Compliant — provides internationally

recognized regulatory agency approval.

Repair Information

If the VA7800 Series Electric Actuator fails to

operate within specifications, replace the unit.

For a replacement actuator, contact the

nearest Johnson Controls® representative.

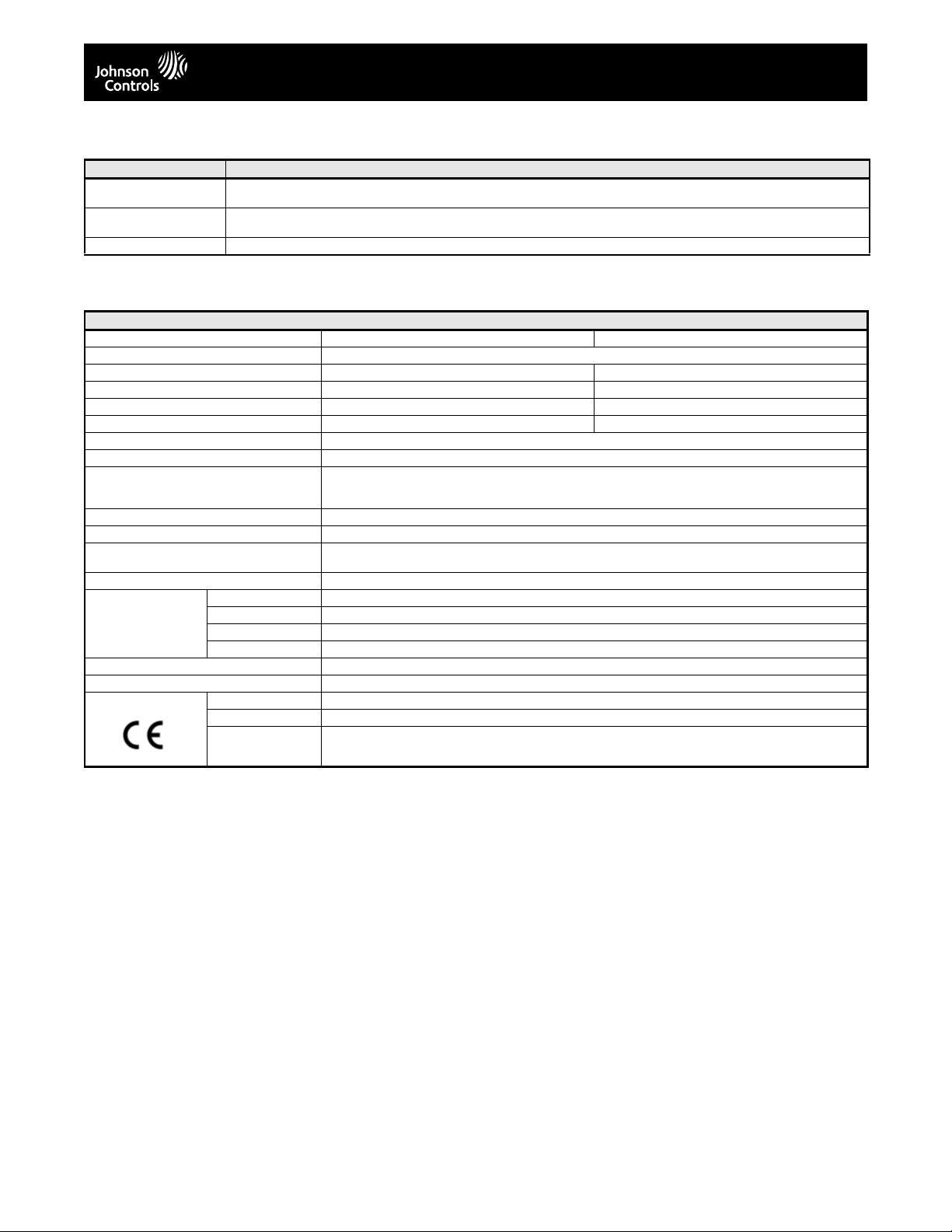

Selection Chart

Code Number Input Signal Power

Requirements

On/Off

Floating Point

Proportional 0 (2) to 10 VDC

0 (4) to 20 mA

24 VAC 50/60 Hz ± 15%

VA7810-ADC-2 ■■——■ 8 ■ —— — ■ 48 76 114

VA7810-AGA-2 ■■— ■ —3■ — — — — 48 76 114

VA7810-AGC-2 ■■— ■ —3■ —— — ■ 48 76 114

VA7810-HGA-2 ■■ ■ ■—6 ■ —— ■ —24

VA7810-HGC-2 ■■ ■ ■—6 ■ —— ■■24 / 48 38 / 76 57 / 114

VA7820-HGA-2 ■■ ■ ■—11— ■ — ■ —24

VA7820-HGC-2 ■■ ■ ■—11— ■ — ■■24

VA7830-HGA-2 ■■ ■ ■—11— — ■■ —24 / 48 38 / 76 57 / 114

VA7830-HGC-2 ■■ ■ ■—11— — ■■ ■24

1. VA78x0-HGx-2 actuators have field-selectable stroke speed; factory setting is the slowest speed.

230 VAC 50/60 Hz ± 15%

Action on Power

Failure

VA Rating

Non-Spring Return

Spring-Return Actuator

Retracted Valve Stem Full Up

Feedback Auxiliary

Spring-Return Actuator

Extended Valve Stem Full Down

0 (2) to 10 VDC

Switches

2 SPDT, 1A, 3A Resistive,

1/4 HP

Nominal Stroke Time1

(Seconds)

1/2 and 3/4 in. VG7000

(5/16 in. valve stroke)

1 and 1-1/4 in. VG7000

(1/2 in. valve stroke)

/ 48 38 / 76 57 / 114

/ 48 38 / 76 57 / 114

/ 48 38 / 76 57 / 114

/ 48 38 / 76 57 / 114

1-1/2 and 2 in. VG7000

(3/4 in. valve stroke)

The performance specifications are nominal and conform to acceptable industry standards. For applications at conditions beyond these specifications, consult the local Johnson Controls office.

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2015 Johnson Controls, Inc.

www.johnsoncontrols.com

1

Page 2

VA7800 Series Electric Valve Actuators (Continued)

Accessories

Code Number Product Description

V-9999-BC1 Mounting Kit to Mount VA-715x, VA-720x, VA78xx, or VA-4233 Series Electric Actuators to Barber Coleman® 1/2 through 1-1/4 Inch

V-9999-HW1 Mounting Kit to Mount VA-715x, VA-720x, VA78xx, or VA-4233 Series Electric Actuators to Honeywell® V5011A, F, and G, 1/2 through

M9000-200 Commissioning Tool

VB-9xxx Valve Bodies

3 Inch Single-Seated and V5013F Three-Way Valves

Technical Specifications

VA7810-AGx-2 and -ADx-2 Series On/Off (Floating) Electric Non-Spring-Return Valve Actuators

Model VA7810-AGx-2 VA7810-ADx-2

Thrust Force 180 lb (800 N) Minimum

Power Supply AC 24 V (AC 19 to 30 V) at 50/60 Hz, Class 2 AC 230 V (AC 195 to 265 V) at 50/60 Hz

Transformer Sizing 3 VA 8 VA

Input Signal AC 24 V (AC 19 to 30 V) at 50/60 Hz AC 230 V (AC 195 to 265 V) at 50/60 Hz

Feedback N/A N/A

Auxiliary Switch Rating Two Single-Pole, Double-Throw (SPDT), AC 230 V, 3.0 A Resistive, 1/4 hp

Stroke 5/16 to 1 in. (8 to 25 mm)

Stroke Speed 5/16 in. Stroke: 48 Seconds

Ambient Operating Conditions 23 to 131°F (-5 to 55°C); 10 to 90% RH Noncondensing

Enclosure Rating NEMA 2 (IP54)

Electrical Connection 48 in. (1.2 m) UL 758 Type AWM Halogen-Free Cable with 18 AWG (0.85 mm

Dimensions 9.6 x 4.56 x 8.35 in. (244 x 116 x 212 mm)

Materials Gearbox and Yoke Die Cast Aluminum

Cover Resin ABS/PC - UL94-V0

Stem Stainless Steel

Coupler Brass

Life Cycles 100,000 Full Stroke Cycles

Shipping Weight 5.4 lb (2.45 kg)

Compliance

United States UL 60730 Listed Type 1 Enclosure, CCN XAPX, File E194024

Canada UL 60730-1 Listed Type 1 Enclosure, CCD XAPX7, File E194024

Europe CE Mark - Johnson Controls, Inc. declares that this product is in compliance with the essential requirements and

1/2 in. Stroke: 76 Seconds

3/4 in. Stroke: 114 Seconds

2

Ferrule Ends

other relevant provisions of the EMC directive 2004/108/EC and the Low Voltage Directive 2006/95/EC.

) Conductors and 0.25 in. (6 mm)

The performance specifications are nominal and conform to acceptable industry standards. For applications at conditions beyond these specifications, consult the local Johnson Controls office.

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2015 Johnson Controls, Inc.

www.johnsoncontrols.com

2

Page 3

VA7800 Series Electric Valve Actuators (Continued)

VA7810-HGx-2 Series Proportional Electric Non-Spring-Return Valve Actuators

Model VA7810-HGx-2

Thrust Force 180 lb (800 N) Minimum

Power Supply AC 24 V (AC 19 to 30 V) at 50/60 Hz, Class 2

Transformer Sizing 6 VA

Input Signal Switch Selectable:

Control Input Impedance Voltage Input: 100k ohm

Feedback DC 0 (2) to 10 V Corresponds to Input Range

Auxiliary Switch Rating SPDT, AC 230 V, 3.0 A Resistive, 1/4 hp

Stroke 5/16 to 1 in. (8 to 25 mm)

Stroke Speed (Switch Selectable) Slow (Factory Setting) 5/16 in. Stroke: 48 Seconds

Ambient Operating Conditions 23 to 131°F (-5 to 55°C); 10 to 90% RH Noncondensing

Ambient Storage Conditions -40 to 176°F (-40 to 80°C); 5 to 95% RH Noncondensing

Enclosure Rating NEMA 2 (IP54)

Electrical Connection 48 in. (1.2 m) UL 758 Type AWM Halogen-Free Cable with 18 AWG (0.85 mm

Dimensions 9.6 x 4.56 x 8.35 in. (244 x 116 x 212 mm)

Materials Gearbox and Yoke Die Cast Aluminum

Cover Resin ABS/PC - UL94-V0

Stem Stainless Steel

Coupler Brass

Life Cycles 100,000 Full Stroke Cycles

Shipping Weight 5.4 lb (2.45 kg)

Compliance

United States UL 60730 Listed Type 1 Enclosure, CCN XAPX, File E194024

Canada UL 60730-1 Listed Type 1 Enclosure, CCN XAPX7, File E194024

Europe CE Mark - Johnson Controls, Inc. declares that this product is in compliance with the essential requirements and

Proportional: DC 0 to 10 V, DC 2 to 10 V, 0 to 20 mA or 4 to 20 mA

Programmable Proportional:

Start Point: 0 to 6 VDC (0 to 12 mA)

End Point: 3 to 10 VDC (6 to 20 mA) with 3 VDC (6 mA) Minimum Span

On/Off (Floating): AC 24 V at 50/60 Hz

Switch Selectable Direct or Reverse Action with Signal Increase

Switch Selectable Preset Actuator Position on Loss of Signal

Current Input: 120 ohm

1/2 in. Stroke: 76 Seconds

3/4 in. Stroke: 114Seconds

Fast 5/16 in. Stroke: 24 Seconds

Ferrule Ends

other relevant provisions of the EMC directive 2004/108/EC and the Low Voltage Directive 2006/95/EC.

1/2 in. Stroke: 38 Seconds

3/4 in. Stroke: 57 Seconds

2

) Conductors and 0.25 in (6 mm)

The performance specifications are nominal and conform to acceptable industry standards. For applications at conditions beyond these specifications, consult the local Johnson Controls office.

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2015 Johnson Controls, Inc.

www.johnsoncontrols.com

3

Page 4

VA7800 Series Electric Valve Actuators (Continued)

VA7820-HGx-2 / VA7830-HGx-2 Series Proportional Electric Spring-Return Valve Actuators

Model VA7820-HGx-2 / VA7830-HGx-2

Thrust Force 180 lb (800 N) Minimum

Power Supply AC 24 V (AC 19 to 30 V) at 50/60 Hz, Class 2

Transformer Sizing 11 VA

Input Signal Switch Selectable:

Control Input Impedance Voltage Input: 100k ohm

Feedback DC 0 (2) to 10 V Corresponds to Input Range

Auxiliary Switch Rating SPDT, AC 230 V, 3.0 A Resistive, 1/4 hp

Stroke 5/16 to 1 in. (8 to 25 mm)

Stroke Spee d Slow (Factory Setting) 5/16 in. Stroke: 48 Seconds

Ambient Operating Conditions 23 to 131°F (-5 to 55°C); 10 to 90% RH Noncondensing

Ambient Storage Conditions -40 to 176°F (-40 to 80°C); 5 to 95% RH Noncondensing

Enclosure Rating NEMA 2 (IP54)

Electrical Connection 48 in. (1.2 m) UL 758 Type AWM Halogen-Free Cable with 18 AWG (0.85 mm

Dimensions 9.6 x 4.56 x 8.35 in. (244 x 116 x 212 mm)

Materials Gearbox and Yoke Die Cast Aluminum

Cover Resin ABS/PC - UL94-V0

Stem Stainless Steel

Coupler Brass

Life Cycles 100,000 Full Stroke Cycles

Shipping Weight 7.3 lb (3.3 kg)

Compliance

United States UL 60730 Listed Type 1 Enclosure, CCN XAPX, File E194024

Canada UL 60730-1 Listed Type 1 Enclosure, CCN XAPX7, File E194024

Europe CE Mark - Johnson Controls, Inc. declares that this product is in compliance with the essential requirements

Proportional: DC 0 to 10 V, DC 2 to 10 V, 0 to 20 mA or 4 to 20 mA

Programmable Proportional:

Start Point: 0 to 6 VDC (0 to 12 mA)

End Point: 3 to 10 VDC (6 to 20 mA) with a 3 VDC (6 mA) Minimum Span

On/Off (Floating): AC 24 V at 50/60 Hz

Switch Selectable Direct or Reverse Action with Signal Increase

Switch Selectable Reset Actuator Position on Loss of Signal

Current Input: 120 ohm

1/2 in. Stroke: 76 Seconds

3/4 in. Stroke: 114 Seconds

Fast 5/16 in. Stroke: 24 Seconds

Ferrule Ends

and other relevant provisions of the EMC directive 2004/108/EC and the Low Voltage Directive 2006/95/EC.

1/2 in. Stroke: 38 Seconds

3/4 in. Stroke: 57 Seconds

2

) Conductors and 0.25 in. (6 mm)

The performance specifications are nominal and conform to acceptable industry standards. For applications at conditions beyond these specifications, consult the local Johnson Controls office.

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2015 Johnson Controls, Inc.

www.johnsoncontrols.com

4

Loading...

Loading...