Page 1

V47 Series Valve

Valves and Valve Accessories

Code No. LIT-1927330

V47 Series Temperature Actuated Modulating Valve

Description

The V47 is a temperature actuated modulating

valve that regulates the flow of water or glycol

to maintain a desired temperature. Three

temperature ranges for each valve size are

available.

Many valves come with a removable bypass

plug that can be replaced by the bypass orifice

provided separately with each valve.

Valve action is open on temperature increase.

For open on temperature decrease models,

contact Application Engineering.

Refer to the V47 Series Temperature Actuated

Modulating Water Valves Product Bulletin

(LIT-125690) for important product application

information.

Selection Chart

Product Code

Number

V47AA-1C 3/8 115 to 180 Heating 11/16 x 3-1/4 0.062 STT14A-600R SET29A-622R WEL18A-602R

V47AA-2C 3/8 160 to 230 Heating 11/16 x 3-1/4 0.062 STT14A-600R SET29A-623R WEL1 8A-602R

V47AA-3C 3/8 75 to 135 Cross Ambient 11/16 x 6 0.062 STT14A-600R SET29A-601R WEL17A-601R

V47AA-26C

V47AB-2C 1/2 75 to 135 Cross Ambient 11/16 x 10

V47AB-3C 1/2 115 to 180 Heating 11/16 x 3-1/4 0.062 STT15A-602R SET29A-624R WEL18A-602R

V47AB-4C 1/2 160 to 230 Heating 11/16 x 3-1/4 0.062 STT15A-602R SET29A-625R WEL18A-602R

V47AB-5C 1/2 75 to 135 Cross Ambient 11/16 x 10 0.062 STT15A-602R SET29A-602R WEL17A-600R

V47AB-27C

V47AC-3C 3/4 115 to 180 Heating 11/16 x 3-1/4 0.062 STT16A-601R SET29A-626R WEL18A-602R

V47AC-4C 3/4 160 to 230 Heating 11/16 x 3-1/4 0.062 STT16A-601R SET29A-627R WEL18A-602R

V47AC-6C 3/4 75 to 135 Cross Ambient 11/16 x 10 0.062 STT16A-601R SET29A-604R WEL17A-600R

V47AC-8C 3/4 75 to 135 Heating 11/16 x 3-1/4 – STT1 6A-601R SET98A-621R WEL18A-602R

V47AC-40C 3/4 40 to 85 Cross Ambient 11/16 x 10 Yes

V47AD-1C 1 75 to 135 Cross Ambient 11/16 x 16-1/4 0.093 STT17A-609R SET29A-605R –

V47AD-2C 1 115 to 180 Heating 11/16 x 6 0.093 STT17A-609R SET29A-629R WEL17A-601R

V47AD-3C 1 160 to 230 Heating 11/16 x 6 0.093 STT17A-609R SET29A-630R WEL17A-601R

V47AD-19C 1 40 to 85 Cross Ambient 11/16 x 16-1/4 0.093 STT17A-609R – –

V47AE-1C 1-1/4 75 to 135 Cross Ambient 11/16 x 16-1/4 0.093 STT17A-610R SET29A-605R –

V47AE-2C 1-1/4 115 to 180 Heating 11/16 x 6 0.093 STT17A-610R SET29A-629R WEL17A-601R

V47AE-3C 1-1/4 160 to 230 Heating 11/16 x 6 0.093 STT17A-610R SET29A-630R WEL17A-601R

V47AE-13C 1-1/4 40 to 85 Cross Ambient 11/16 x 16-1/4 Yes

V47AR-1 1-1/2

V47AR-2 1-1/2

V47AR-3 1-1/2

V47AS-1 2

V47AS-2 2

V47AS-3 2

V47AS-13C 2

V47AT-1 2-1/2

V47AT-2 2-1/2

V47AT-3 2-1/2

1. Standard capillary is 6 ft (Style 4)

2. 2 ft capillary

3. Style 1 bulb (does not include 1/2 in. external NPT fitt ing)

4. 4 ft capillary

The performance specifications are nomina l and con form to accep table ind ustry stand ards. For applicati ons at con ditions be yond these specification s, consult th

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2015 Johnson Controls, Inc.

Pipe

1

Size, in.

2

3/8 20 to 65 Cross Ambient 11/16 x 6

4

1/2 40 to 85 Cross Ambient 11/16 x 10

6

6

6

6

Range

(Opening Point) °F

6

75 to 135 Cross Ambient 11/16 x 16-1/4 0.093 STT17A-610R SET29A-605R –

6

115 to 180 Heating 11/16 x 6 0.093 STT17A-610R SET29A-629R WEL17A-601R

6

160 to 230 Heating 11/16 x 6 0.093 STT17A-610R SET29A-630R WEL17A-601R

115 to 160 Heating 11/16 x 10 0.125 STT18A-600R SET29A-632R WEL17A-600R

160 to 205 Heating 11/16 x 10 0.125 STT18A-600R SET29A-633R WEL17A-600R

75 to 115 Cross Ambient 11/16 x 43 0.125 STT18A-600R SET29A-606R –

40 to 85 Cross Ambient 11/16 x 43 Yes

6

115 to 160 Heating 11/6 x 10 0.125 STT18A-601R SET29A-632R WEL17A-600R

6

160 to 205 Heating 11/6 x 10 0.125 STT18A-601R SET29A-633R WEL17A-600R

6

75 to 115 Cross Ambient 11/16 x 43 0.125 STT18A-601R SET29A-606R –

Features

• no close fitting sliding parts in water

passages

• range spring does not come in contact with

the cooling water

• easy manual flushing, if required

• valve design minimizes chatter and water

hammer

Repair Information

If the V47 Series Temperature Actuated

Modulating Valve fails to operate within its

specifications, replace the unit. For a

replacement valve, contact the nearest

Johnson

Controls®

Bulb Size, in.

(Dia. length)

3

representative.

Std Bypass

Seat Repair Kit Replacement

Orifice Dia., in.

– STT14A-600R – WEL17A-601R

3

– STT15A-602R SET29A-602R WEL17A-600R

3

5

Yes

5

5

5

5. Solid plug installed, orifice available separately

6. ASME Flange

STT15A-602R – WEL17A-600R

STT16A-601R – WEL17A-600R

STT17A-610R – –

STT18A-600R – –

Note: For more information on Bulb Wells, refer to Bulb Wells

(LIT-1922135).

Sensing Element

Bulb Well Number

Order Separately

R-157

Page 2

2

3

4

6

5

7

10

8

9

20

30

40

60

50

70

100

90

80

200

300

1136

757

379

227

349

303

265

189

151

114

76

38

34

30

26

23

19

15

11

7

3.8

-18

-14

-11

-8

-4

-1

2

36

30

24

18

12

6

0

Temperature

Rise

Above

Opening Point

(C)

o

Temperature

Rise

Above

Opening Point

(oF)

Water Flow

L/Min.

Water Flow

Gal. / Min.

2

(14)

5

(34)

10

(69)

20

(138)

30

(207)

40

(276)

50

(345)

60

(414)

3/8

1/2

3/4

1

1-1/4

1-1/2

2

2-1/2

v47_flowchart.eps

Flow Chart, V47 Valve

Ring

Gasket (Two)

Cast Iron

Flange (Two)

Hex

Nut (Eight)

Machine

Bolt (Eight)

Valves and Valve Accessories

V47 Series Temperature Actuated Modulating Valve (Continued)

Accessories (Companion Flanges and Gaskets)

Product Code Number Water Valve

Flange Gasket

(One Gasket per Package)

246-423 KIT14A-612 1-1/2 in.

246-424 KIT14A-613 2 in.

246-425 KIT14A-614 2-1/2 in.

Companion Flange Kit

(See Diagram)

Note: Flanges have NPT (National Pipe Thread).

Technical Specifications

V47 Series Temperature Actuated Modulating Valves

Maximum Bulb Temperature 20F° (-6.7 C°) above temperature range

Maximum Water Temperature 170°F (77°C)

Maximum Supply Water Pressure 150 psig (1,034 kPa)

Capillary Nylon Armor

Temperature Bulb Style 4

2

(pictured)

(1/2 in. NPT closed tank immersion)

1. For capillary length, refer to the selection chart on the previous page.

2. V47AA-26, V47AB-2, V47AB-27 — Temperature Bulb Style 1 (no 1/2 in. NPT external fitting)

1

Size (in.)

Companion Flange Kit

Metric Conversion

°F °C

20 to 65 -6 to 18

40 to 85 4 to 29

75 to 115 24 to 46

75 to 135 24 to 57

115 to 160 46 to 71

115 to 180 46 to 82

160 to 205 71 to 96

160 to 230 71 to 110

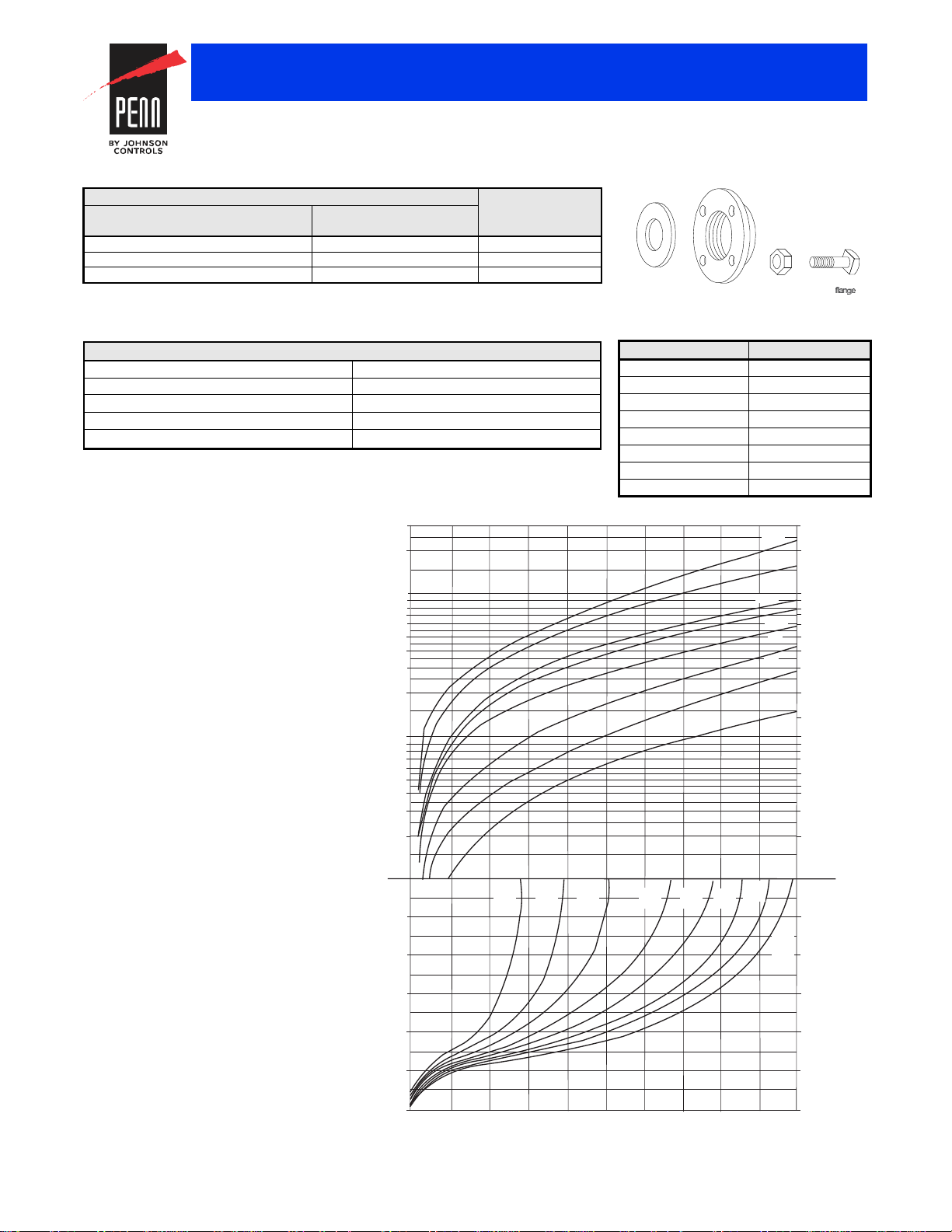

V47 Valve Sizing Information

To Select Water Valve Size, see the flow chart for

selection of water valves. Carefully follow the steps

as outlined below.

1 Determine the maximum water flow required.

Draw a horizontal line through this flow across the

upper half of the flow chart.

2 Use the following method to determine the

temperature rise above the opening point.

a Valve closing point is the highest temperature

at which it is desired to have no flow through the

valve.

b Valve opening point is about 5F° above the

closing point.

c Determine the temperature the valve is to

maintain, this is the operating temperature.

d Subtract the opening temperature from the

operating temperature. This is the temperature

rise above the opening point.

3 Determine the available system pressure for use

with the valve by the following appropriate

method:

Open System:

Available System Pressure = Inlet Pressure condenser pressure drop - friction losses in piping.

Closed System:

Available System Pressure = Inlet Pressure static head - condenser pressure drop-friction

losses in piping.

The available system pressure is represented by

the curve in the lower half of the flow chart.

4 In the lower half of the flow curve, draw a

horizontal line from the temperature above the

opening point (Step 2d) to the available system

pressure (Step 3). If the point falls between two

pressure drop curves, use the curve to the left

(this gives an automatic factor of safety).

5 From this point, draw a vertical line until it

intersects the flow line from Step 1.

6 If the intersection falls on a valve size curve, this is

the valve size.

7 If the intersection falls between two curves, use

the curve to the left for the required valve size.

The performance specifications are no minal and co nform t o acceptab le ind ustry standar ds. For appl ications at condition s beyond these specifica tions, consult th

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2015 Johnson Controls, Inc.

R-158

Loading...

Loading...