Page 1

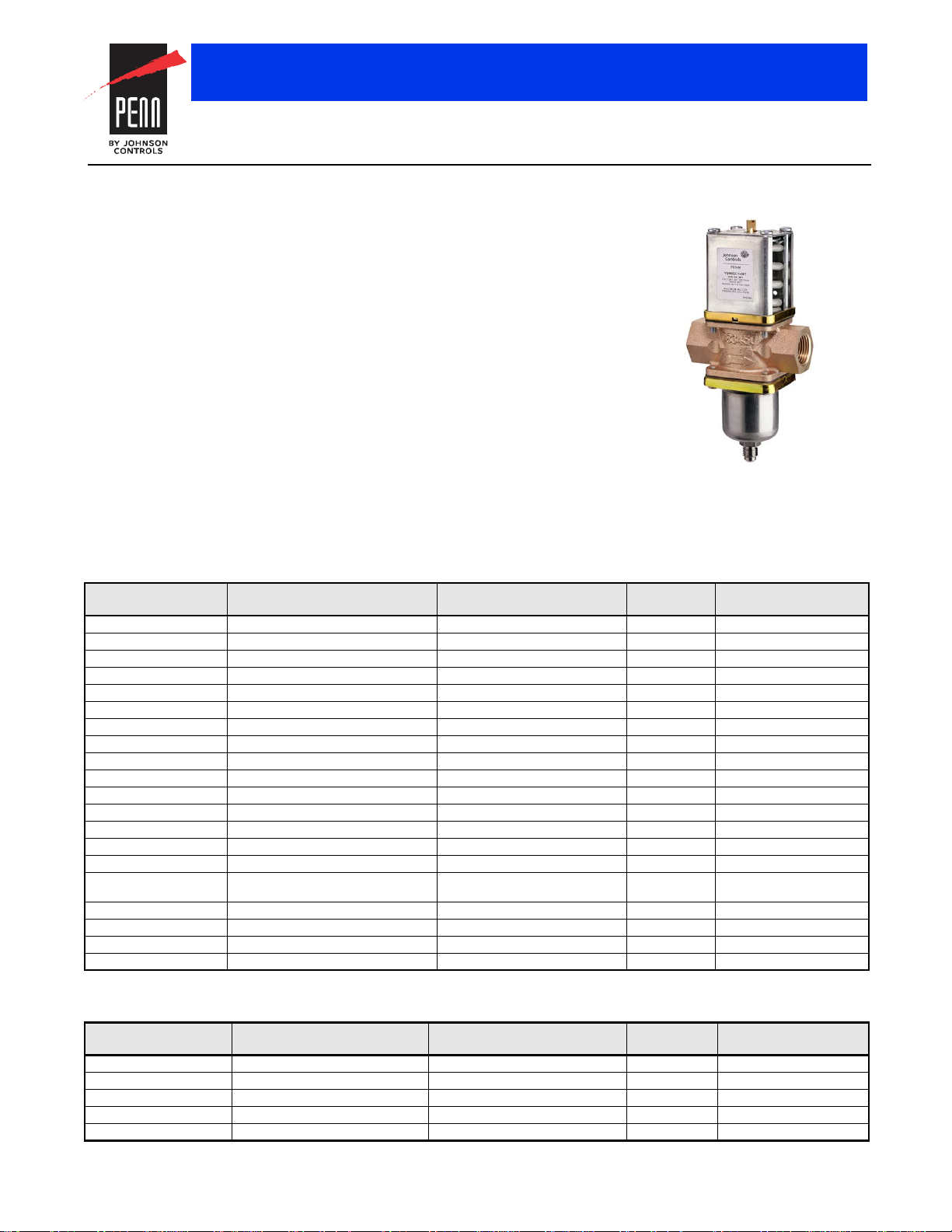

V246 Series Water-Regulating Valve

Valves and Valve Accessories

Code No. LIT-1900575

V246 Series Two-Way Pressure-Actuated Water-Regulating Valves

for High-Pressure Refrigerants

Description

The V246 Series Two-Way

Pressure-Actuated Water-Regulating Valves

for High-Pressure Refrigerants come in two

types of control action: direct acting and

reverse acting. V246 valves regulate water

flow to control refrigerant head pressure in

systems with water-cooled condensers.

The V246 Series Valves are available in 3/8 in.

through 2 in. sizes and have a maximum

allowable water pressure of 150 psig

(10.3 bar). Direct acting V246 valves have an

adjustable opening point in a refrigerant

pressure range of 200 to 400 psi

(13.8 to 27.6 bar), and reverse acting valves

have a range of 135 to 300 psi

(9.3 to 20.7 bar). V246 valves

may be used

with standard non-corrosive refrigerants.

Maritime models, which have nickel copper

(Monel®) internal parts, are available for

applications where the media may be

corrosive to the internal parts.

Selection Charts

North American Standard Production Models

Product Code Number Construction Valve Size and Connection Element Style Shipping Weight,

V246GA1-001C Direct Acting1, Commercial

V246GB1-001C Direct Acting

V246GC1-001C Direct Acting

V246GD1-001C Direct Acting

V246GE1-001C Direct Acting

V246GM1-001C Direct Acting

V246GR1-001C Direct Acting

V246GS1-001C Direct Acting

V246HA1-001C Direct Acting

V246HB1-001C Direct Acting

V246HC1-001C Direct Acting

V246HD1-001C Direct Acting

V246HE1-001C Direct Acting

V246HR1-001C Direct Acting

V246HS1-001C Direct Acting

V246KA1-001C Direct Acting

V246NA1-001C Reverse Acting

V246NB1-001C Reverse Acting

V246NC1-001C Reverse Acting

V246ND1-001C Reverse Acting

1. The range is 200 to 400 psi (13.8 to 27.6 bar).

2. The range is 135 to 300 psi (9.3 to 20.7 bar).

Low Flow

European Standard Production Models (Part 1 of 2)

Product Code Number Construction Valve Size and Connection Element Style Shipping Weight,

V246GA1A001C Direct Acting, Commercial 3/8 in. BSPP Screw, ISO228 Style 5 0.8 (1.8)

V246GB1A001C Direct Acting, Commercial 1/2 in. BSPP Screw, ISO228 Style 5 1.4 (3.0)

V246GC1A001C Direct Acting, Commercial 3/4 in. BSPP Screw, ISO228 Style 5 1.7 (3.7)

V246GD1B001C Direct Acting, Commercial 1 in. BSPT Screw, ISO 7 Style 5 4.2 (9.3)

V246GE1B001C Direct Acting, Commercial 1-1/4 in. BSPT Screw, ISO 7 Style 5 4.5 (10)

The performance specifications are nomina l and con form to accep table ind ustry stand ards. For applicati ons at con ditions be yond these specification s, consult th

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2015 Johnson Controls, Inc.

1

, Commercial 1/2 in. NPT Screw Style 5 3.0 (1.4)

1

, Commercial 3/4 in. NPT Screw Style 5 3.7 (1.7)

1

, Commercial 1 in. NPT Screw Style 5 9.3 (4.2)

1

, Commercial 1-1/4 in. NPT Screw Style 5 10 (4.5)

1

, Commercial 1-1/4 in. Union Sweat Style 5 10 (4.5)

1

, Commercial 1-1/2 in. Flange Style 5 13.6 (6.2)

1

, Commercial 2 in. Flange Style 5 27 (12.3)

1

, Maritime 3/8 in. NPT Screw Style 5 1.8 (0.8)

1

, Maritime 1/2 in. NPT Screw Style 5 3.0 (1.4)

1

, Maritime 3/4 in. NPT Screw Style 5 4.3 (2.0)

1

, Maritime 1 in. NPT Screw Style 5 9.5 (4.3)

1

, Maritime 1-1/4 in. NPT Screw Style 5 10.3 (4.7)

1

, Maritime 1-1/2 in. ASME Flange Style 5 13.6 (6.2)

1

, Maritime 2 in. ASME Flange Style 5 27 (12.3)

1

, Commercial,

Refer to the V246 Series 2-Way

Pressure-Actuated Water-Regulating Valves

for High-Pressure Refrigerants Product

Bulletin (LIT-12011514) for important product

application information.

Features

• no close fitting or sliding parts in water

passages

• accessible range spring

• take-apart construction

• pressure-balanced design

• corrosion-resistant material for internal

parts

Repair Information

If the V246 Series Two-Way

Pressure-Actuated Water-Regulating Valve

for High Pressure Refrigerants fails to operate

within its specifications, refer to the V246

Series Two-Way Pressure-Actuated

Water-Regulating Valves for High Pressure

Refrigerants Product Bulletin (LIT-12011514)

for a list of repair parts available.

lb (kg)

3/8 in. NPT Screw Style 5 1.8 (0.8)

3/8 in. NPT Screw Style 5 1.8 (0.8)

2

, Commercial

2

, Commercial 1/2 in. NPT Screw Style 5 3.0 (1.4)

2

, Commercial 3/4 in. NPT Screw Style 5 3.7 (1.7)

2

, Commercial 1 in. NPT Screw Style 5 9.3 (4.2)

3/8 in. NPT Screw Style 5 1.8 (0.8)

kg (lb)

R-171

Page 2

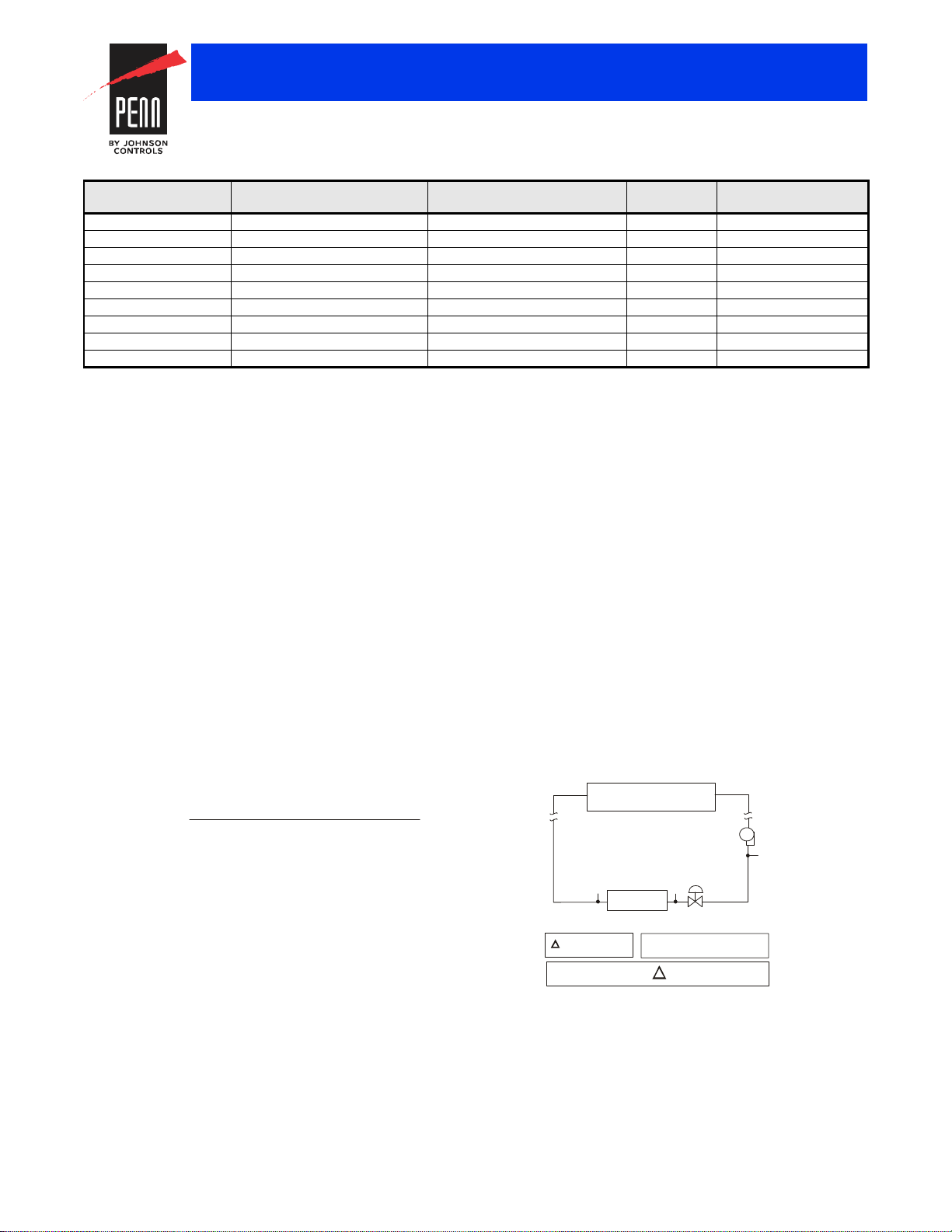

Flow Required

Flow =

(Temp. - Temp. )

Outlet Inlet

FIG:flw_e qn

Valve Opening Pressure

FIG:eqn_

opn_prs

P = P +10 psi (0.7 bar)

OPEN CLOSE

Refrigerant Head Pressure Rise

FIG

P = P - P

Available Water Pressure

Cooling Tower

P

1

P

2

P

Loss 2

2-Way

Valve

P

IN

COND

P

P

1P2

=

-

P

P

P

=

+

+ ...

FIG:2wy_prs s_dr

Valves and Valve Accessories

V246 Series Two-Way Pressure-Actuated Water-Regulating Valves for

High-Pressure Refrigerants (Continued)

European Standard Production Models (Part 2 of 2)

Product Code Number Construction Valve Size and Connection Element Style Shipping Weight,

kg (lb)

V246GR1B001C Direct Acting, Commercial 1-1/2 in. Flange, DIN2533 Style 5 6.2 (13.6)

V246GS1B001C Direct Acting, Commercial 2 in. Flange, DIN2533 Style 5 12.3 (27)

V246HA1B001C Direct Acting, Maritime 3/8 in. BSPP Screw, ISO228 Style 5 0.8 (1.8)

V246HB1B001C Direct Acting, Maritime 1/2 in. BSPP Screw, ISO228 Style 5 1.4 (3.0)

V246HC1B001C Direct Acting, Maritime 3/4 in. BSPP Screw, ISO228 Style 5 2.0 (4.3)

V246HD1B001C Direct Acting, Maritime 1 in. BSPP Screw, ISO 228 Style 5 4.3 (9.5)

V246HE1B001C Direct Acting, Maritime 1-1/4 in. BSPP Screw, ISO 228 Style 5 4.7 (10.3)

V246HR1B001C Direct Acting, Maritime 1-1/2 in. Flange, DIN86021 Styl e 5 6.2 (13.6)

V246HS1B001C Direct Acting, Maritime 2 in. Flange, DIN86021 Style 5 12.3 (27)

Valve Sizing Information

.

Each application is unique and requires specific engineering data to

properly size and design a system to fulfill the appropriate

requirements. Typically, a valve is replaced with another valve of the

same size in a properly sized and engineered system. In North

America, contact Johnson Controls/PENN® Refrigeration Application

Engineering at 1-800-275-5676 to obtain specific engineering data. In

other areas, contact the local Johnson Controls® sales office to obtain

specific engineering data.

To make a rough field estimate of the size of valve for an application,

c. From the Pressure-Temperature Chart for the refrigerant

selected, read the Refrigerant Condensing Pressure (P

(operating head pressure) corresponding to the selected

condensing temperature.

d. Subtract the Valve Opening Pressure from the Refrigerant

Condensing Pressure. This gives the head pressure rise.

find the valve size needed by locating a point on a flow chart that

satisfies these requirements:

• water flow required by the condenser (Flow)

• refrigerant head pressure rise (P

• available water pressure (P

AVAIL

RISE

)

)

Follow these steps, and use the information obtained to locate a point

on one of the flowcharts that satisfies all three steps.

1. Take the water flow required by the condenser (Flow) from

information provided by the manufacturer of the condensing unit. If

the manufacturer’s information is unavailable, use the following

information to make a rough approximation of water flow in gallons

per minute (gpm) [cubic meters per hour (m

3

/hr)]:

• System Capacity (Tons of Refrigeration)

Inlet

Outlet

)

)

• Outlet Water Temperature (Temp.

• Inlet Water Temperature (Temp.

Calculate the flow using the following formula:

3. Determine the available water pressure to the valve (P

the following steps. This is the actual water pressure available to

force water through the valve.

a. Determine the inlet pressure (P

from city water mains, pumps, or other sources.

b. Pressure drop through condenser (P

water pressure between the condenser inlet and the condenser

outlet. Obtain this information from the condenser manufacturer.

c. Estimate or calculate the pressure drop through all associated

piping (P

d. Subtract the P

RISE COND OPEN

).

LOSS

COND

and P

:eqn_hd_prs sr_rs

). This is the water pressure

IN

) is the difference in

COND

from PIN. The result is P

LOSS

p

AVAIL

Tons of Refrigeration x 30

Pump

COND

) using

AVAIL

)

.

Note: If the outlet temperature is unknown, assume it to be 10F

(6C) above the inlet temperature.

2. Determine refrigerant head pressure rise above the valve opening

point (P

the following steps:

) using the Refrigerant Head Pressure Rise figure and

RISE

a. The Valve Closing Pressure (P

refrigerant pressure at the highest ambient temperature the

refrigeration equipment experiences in the Off cycle. Use a

Pressure-Temperature Chart for the refrigerant selected to find

this pressure.

b. To approximate the Valve Opening Pressure (P

about 10 psi (0.7 bar) to the Valve Closing Pressure.

Note: Add about 20 psi (1.4 bar) for 3/8 in. valves.

The performance specifications are no minal and co nform t o acceptab le ind ustry standar ds. For appl ications at condition s beyond these specifica tions, consult th

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2015 Johnson Controls, Inc.

) is equal to the

CLOSE

OPEN

), add

Condenser

Loss 1

LOSS

P= P- (P+ P)

AVAIL IN COND LOSS

Loss 2

P

Loss 1

4. Select the proper valve size from the flowcharts by locating a point

on a chart that satisfies the flow, the head pressure rise above

opening point, and the pressure drop across the valve.

Metric Conversions

Use these equations to convert between U.S. and S.I. units.

3

•1 dm

• 1 bar = 100 kPa = 0.1 MPa 1.02 kg/cm

/s = 3.6 m3/h = 15.9 U.S. gal. /min. = 13.2 U.K. gal. /min.

2

= 0.987 atm 14.5 psi

R-172

Page 3

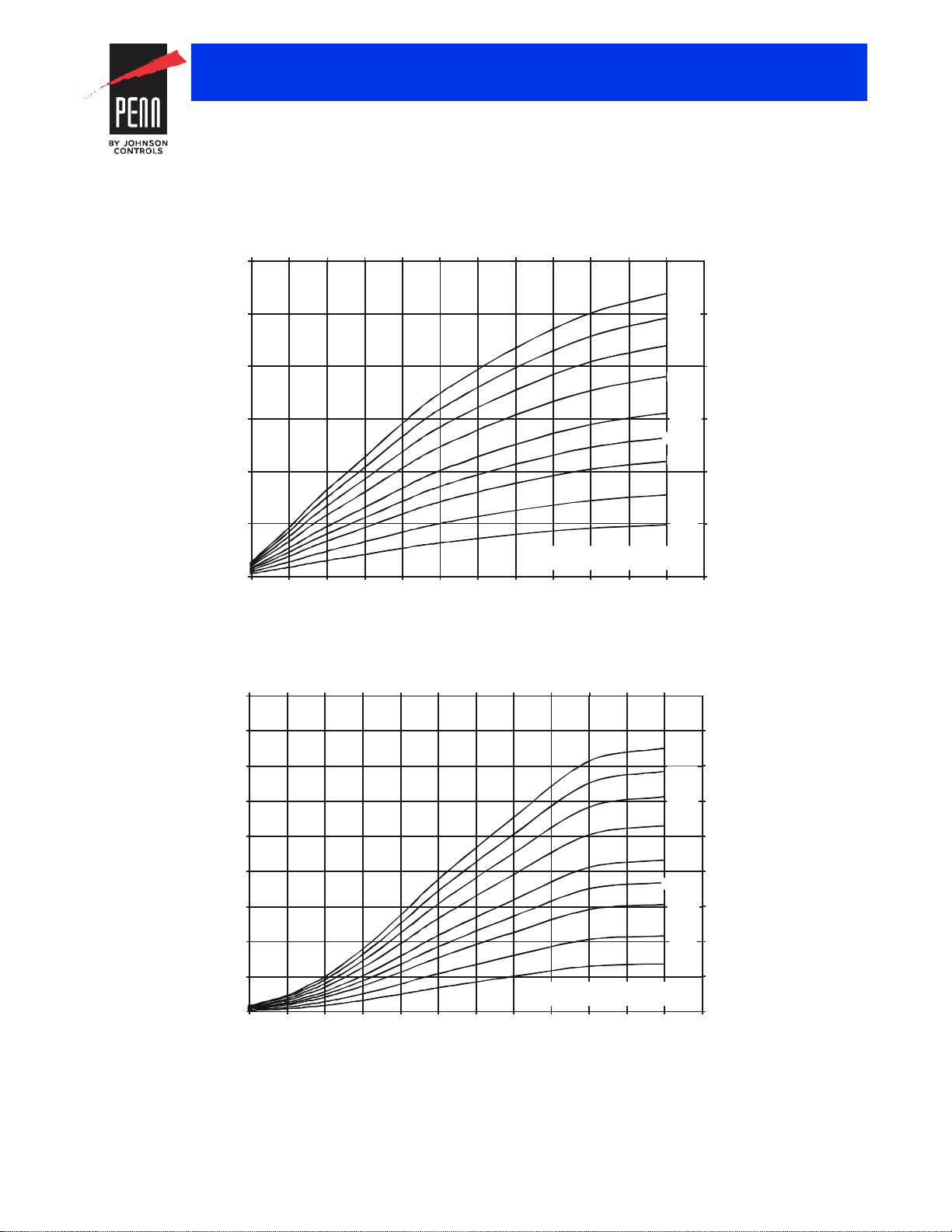

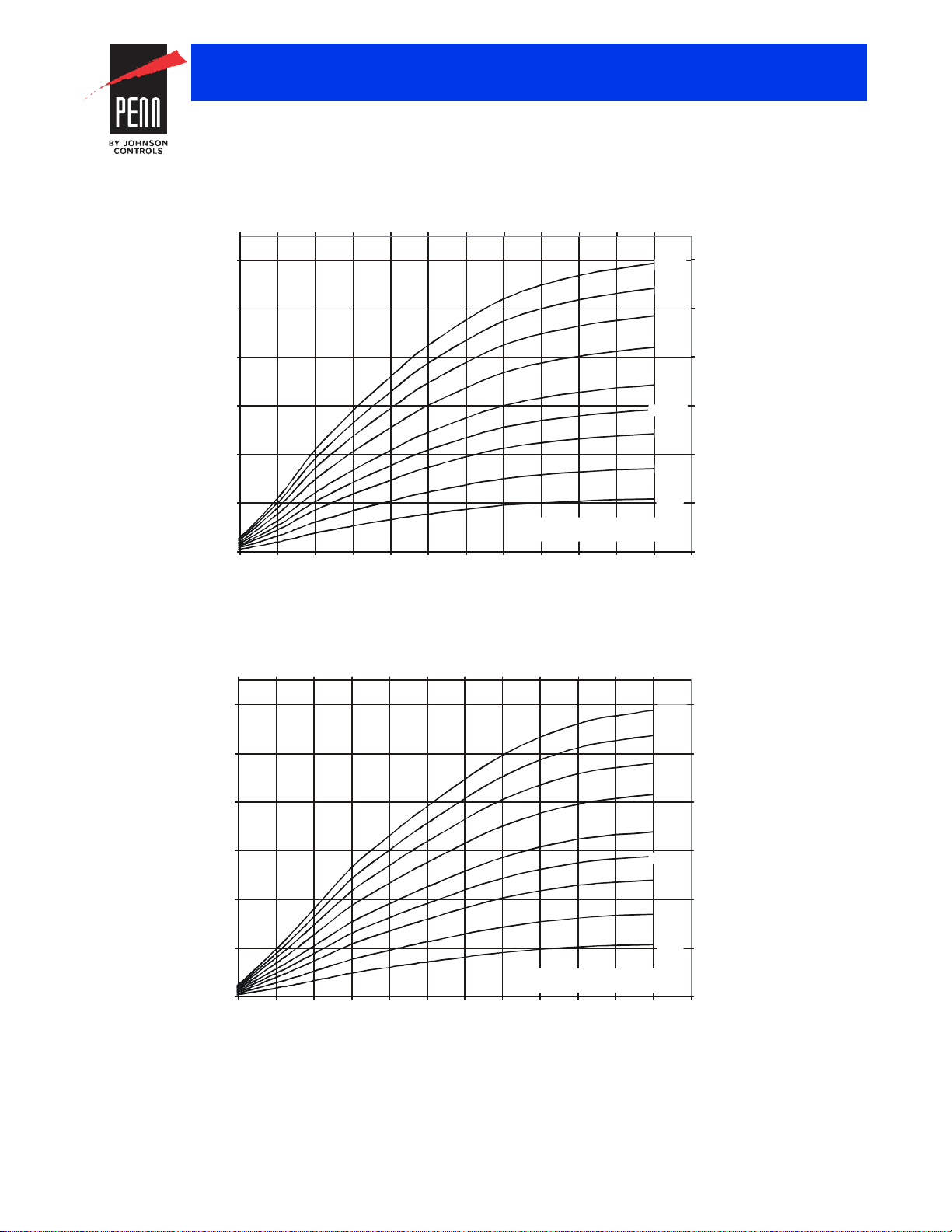

3/8 in. Direct Acting Low-Flow Valve Flowchart

0.7 1.4 2.1 2.8 3.5 4.2 4.9 5.5 6.2 6.9 7.6 8.3

0.0

0.1

0.2

0.3

0.5

0.6

0.0

0.5

1.0

1.5

2.0

2.5

3.0

10 20 30 40 50 60 70 80 90 100 110 120 130

Refrigerant Head Pressure Above Opening P

Rise

( psig )

10 (0.7)

5 (0.3)2 (0.1)

P

Avail

Pressure Drop Through Valve

psig(bar)

40 (2.8)

30 (2.1)

50 (3.4)

60 (4.1)

14.5 (1.0)

20 (1.4)

FIG:V246_3.8 in. Low graph

Refrigerant Head Pressure Above Opening P

Rise

( bar )

Flow

(gpm)

Flow

(m /hr)

3

3/8 in. Direct Acting Valve Flowchart

0.7 1.4 2.1 2.8 3.5 4.2 4.9 5.5 6.2 6.9 7.6 8.3

0.0

0.5

0.9

1.4

1.8

2.3

2.7

3.2

3.6

0

2

4

6

8

10

12

14

16

18

10 20 30 40 50 60 70 80 90 100 1 10 120 130

Refrigerant Head Pressure Above Opening P

Rise

( psig )

10 (0.7)

5 (0.3)

2 (0.1)

P

Avail

Pressure Drop Through Valve

psig (bar)

40 (2.8)

30 (2.1)

50 (3.4)

60 (4.1)

14.5 (1.0)

20 (1.4)

FIG:V246_3.8 in. graph

Flow

(gpm)

Flow

(m /hr)

3

Refrigerant Head Pressure Above Opening P

Rise

( bar )

Valves and Valve Accessories

V246 Series Two-Way Pressure-Actuated Water-Regulating Valves for

High-Pressure Refrigerants (Continued)

V246 Flowcharts

The maximum recommended differential water pressure across a valve is 60 psig (4.1 bar).

The performance specifications are no minal and co nform t o acceptab le ind ustry standar ds. For appl ications at condition s beyond these specifica tions, consult th

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2015 Johnson Controls, Inc.

R-173

Page 4

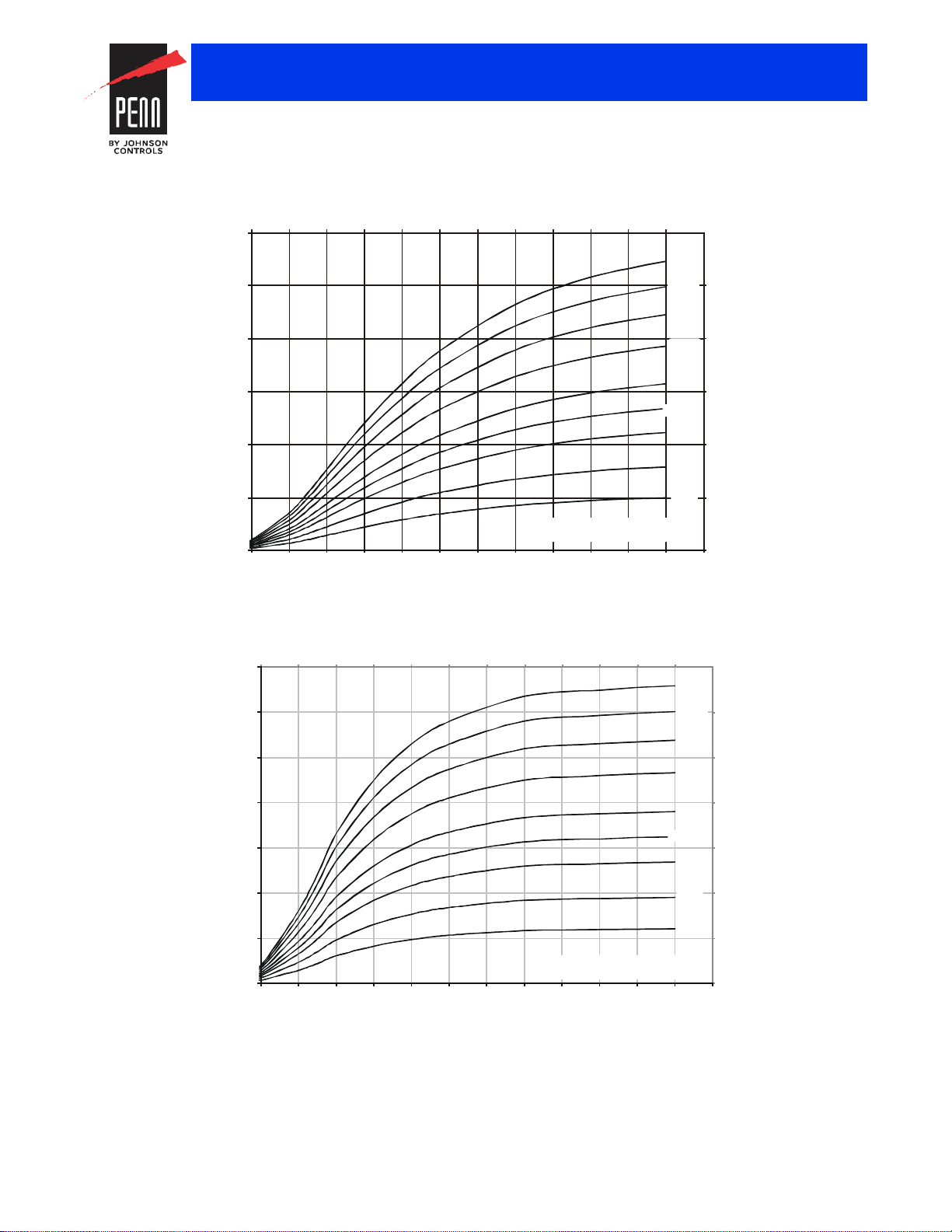

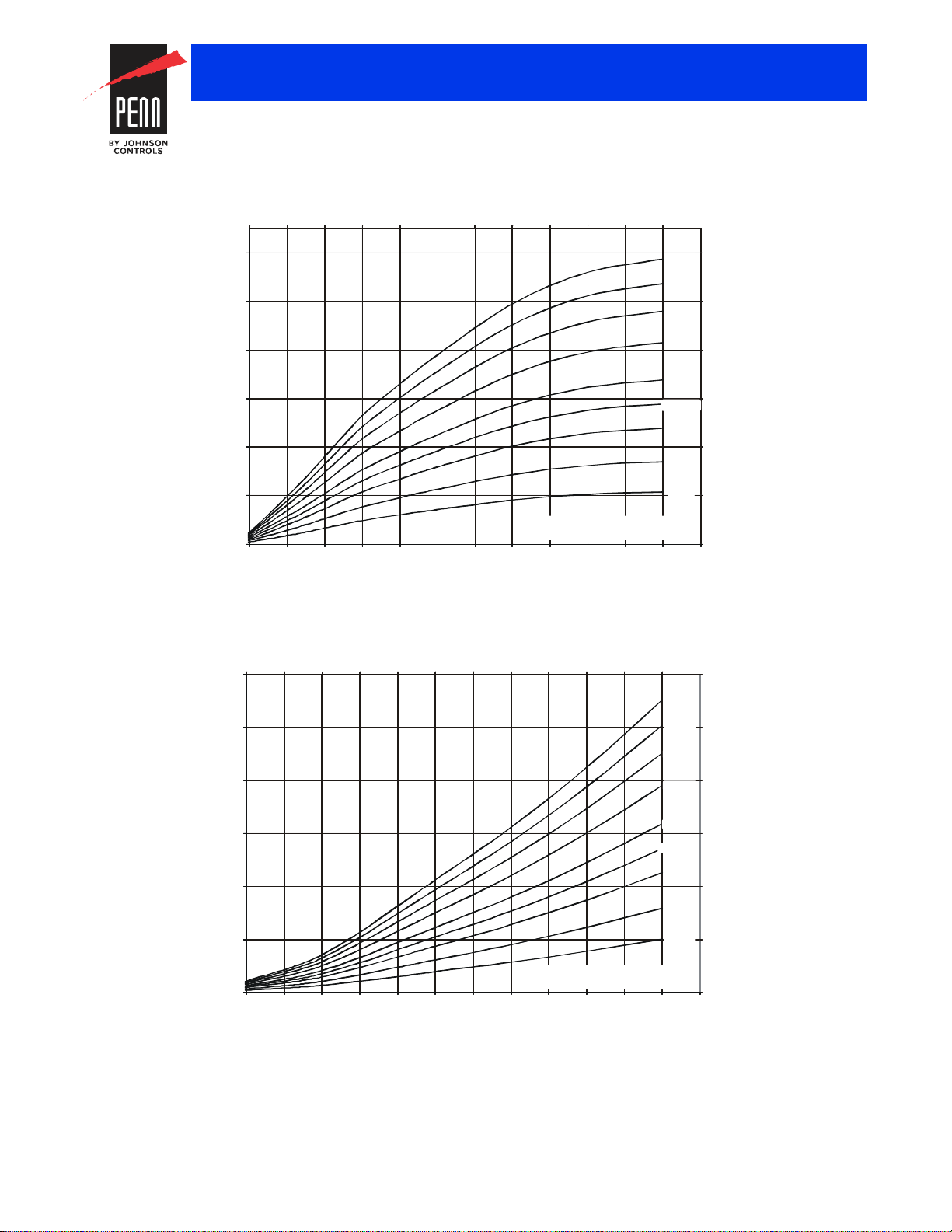

1/2 in. Direct Acting Valve Flowchart

0.7 1.4 2.1 2.8 3.5 4.2 4.9 5.5 6.2 6.9 7.6 8.3

0.0

1.1

2.3

3.4

4.5

5.7

0

5

10

15

20

25

30

10 20 30 40 50 60 70 80 90 100 110 120 130

Refrigerant Head Pressure Above Opening P

Rise

( psig )

10 (0.7)

5 (0.3)

2 (0.1)

P

Avail

Pressure Drop Through Valve

psig(bar)

40 (2.8)

30 (2.1)

50 (3.4)

60 (4.1)

14.5 (1.0)

20 (1.4)

FIG:V246_0.5 in. graph

Refrigerant Head Pressure Above Opening P

Rise

( bar )

Flow

(gpm)

Flow

(m /hr)

3

3/4 in. Direct Acting Valve Flowchart

0.7 1.4 2.1 2.8 3.5 4.2 4.9 5.5 6.2 6.9 7.6 8.3

0.0

1.1

2.3

3.4

4.5

5.7

6.8

0

5

10

15

20

25

30

35

10 20 30 40 50 60 70 80 90 100 110 120 130

Refrigerant Head Pressure Above Opening P

Rise

( psig )

10 (0.7)

5 (0.3)

2 (0.1)

P

Avail

Pressure Drop Through Valve

psig (bar)

40 (2.8)

30 (2.1)

50 (3.4)

60 (4.1)

14.5 (1.0)

20 (1.4)

FIG:V246_0.75 in. graph

Refrigerant Head Pressure Abov e O pening P

Rise

( bar )

Flow

(gpm)

Flow

(m /hr)

3

Valves and Valve Accessories

V246 Series Two-Way Pressure-Actuated Water-Regulating Valves for

High-Pressure Refrigerants (Continued)

The performance specifications are no minal and co nform t o acceptab le ind ustry standar ds. For appl ications at condition s beyond these specifica tions, consult th

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2015 Johnson Controls, Inc.

R-174

Page 5

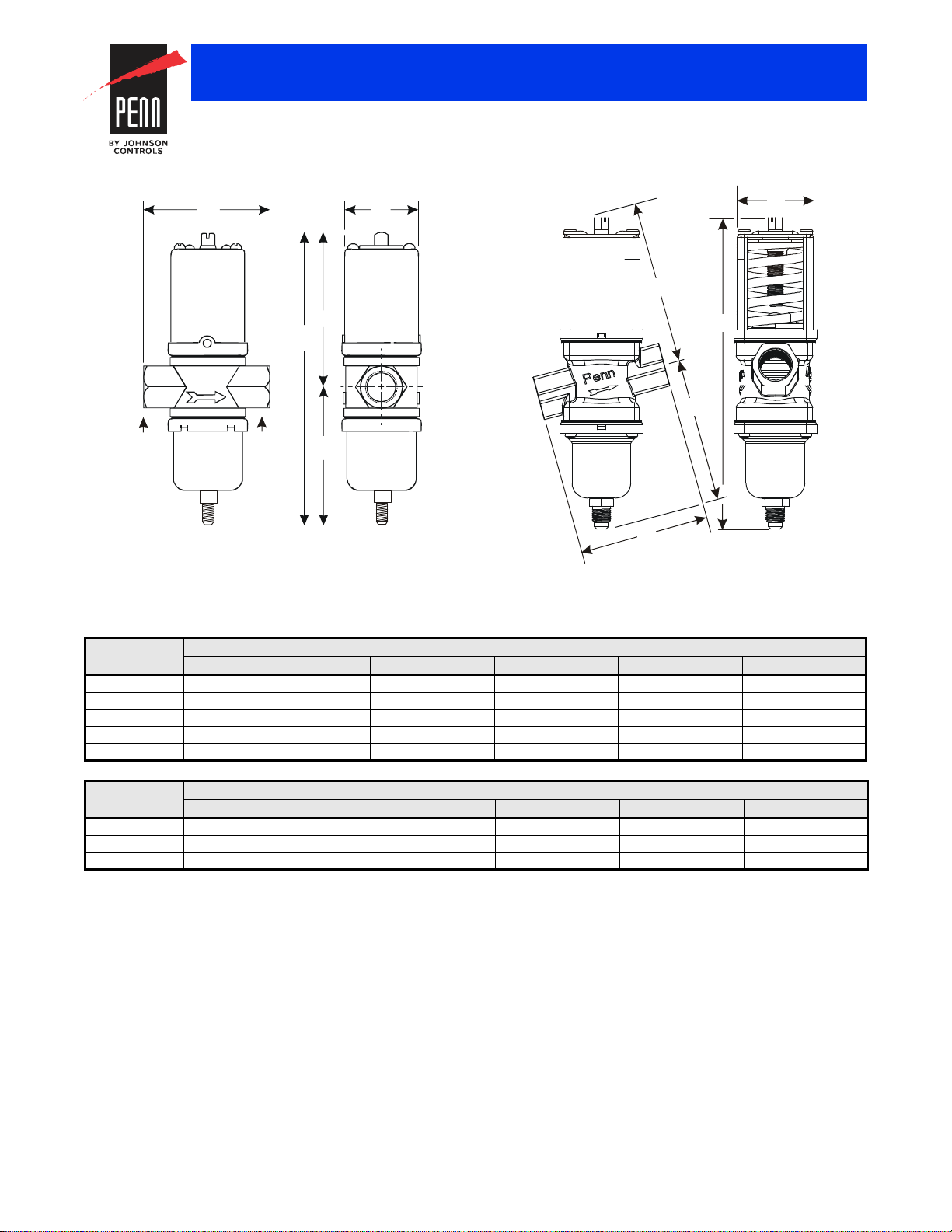

1 in. Direct Acting Valve Flowchart

0.7 1.4 2.1 2.8 3.5 4.2 4.9 5.5 6.2 6.9 7.6 8.3

0.0

2.3

4.5

6.8

9.1

11.4

13.6

0

10

20

30

40

50

60

10 20 30 40 50 60 70 80 90 100 110 120 130

Refrigerant Head Pressure Above Opening P

Rise

( psig )

10 (0.7)

5 (0.3)

2 (0.1)

P

Avail

Pressure Drop Through Valve

psig (bar)

40 (2.8)

30 (2.1)

50 (3.4)

60 (4.1)

14.5 (1.0)

20 (1.4)

FIG:V246_1.0 in. graph

Refrigerant Head Pressure Above Opening P

Rise

( bar )

Flow

(gpm)

Flow

(m /hr)

3

1-1/4 in. Direct Acting Valve Flowchart

0.7 1.4 2.1 2.8 3.5 4.2 4.9 5.5 6.2 6.9 7.6 8.3

0.0

4.5

9.1

13.6

18.2

22.7

27.3

0

20

40

60

80

100

120

10 20 30 40 50 60 70 80 90 100 110 120 130

Refrigerant Head Pressure Above Opening P

Rise

( psig )

10 (0.7)

5 (0.3)

2 (0.1)

P

Avail

Pressure Drop Through Valve

psig(bar)

40 (2.8)

30 (2.1)

50 (3.4)

60 (4.1)

14.5 (1.0)

20 (1.4)

FIG:V246_1.25 in. graph

Refrigerant Head Pressure Above Opening P

Rise

( bar )

Flow

(gpm)

Flow

(m /hr)

3

Valves and Valve Accessories

V246 Series Two-Way Pressure-Actuated Water-Regulating Valves for

High-Pressure Refrigerants (Continued)

The performance specifications are no minal and co nform t o acceptab le ind ustry standar ds. For appl ications at condition s beyond these specifica tions, consult th

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2015 Johnson Controls, Inc.

R-175

Page 6

1-1/2 in. Direct Acting Valve Flowchart

0.7 1.4 2.1 2.8 3.5 4.2 4.9 5.5 6.2 6.9 7.6 8.3

0.0

4.5

9.1

13.6

18.2

22.7

27.3

0

20

40

60

80

100

120

10 20 30 40 50 60 70 80 90 100 110 120 130

Refrigerant Head Pressure Above Opening P

Rise

( psig )

10 (0.7)

5 (0.3)

2 (0.1)

P

Avail

Pressure Drop Through

Valve psig(bar)

40 (2.8)

30 (2.1)

50 (3.4)

60 (4.1)

14.5 (1.0)

20 (1.4)

FIG:V246_1.5 in. graph

Refrigerant Head Pressure Above Opening P

Rise

( bar )

Flow

(gpm)

Flow

(m /hr)

3

2 in. Direct Acting Valve Flowchart

0.7 1.4 2.1 2.8 3.5 4.2 4.9 5.5 6.2 6.9 7.6 8.3

0.0

4.5

9.1

13.6

18.2

22.7

27.3

0

20

40

60

80

100

120

10 20 30 40 50 60 70 80 90 100 110 120 130

Refrigerant Head Pressure Above Opening P

Rise

( psig )

10 (0.7)

5 (0.3)

2 (0.1)

P

Avail

Pressure Drop Through Valve psi

(bar)

40 (2.8)

30 (2.1)

50 (3.4)

60 (4.1)

14.5 (1.0)

20 (1.4)

FIG:V246_2 in. graph

Refrigerant Head Pressure Above Opening P

Rise

( bar )

Flow

(gpm)

Flow

(m /hr)

3

Valves and Valve Accessories

V246 Series Two-Way Pressure-Actuated Water-Regulating Valves for

High-Pressure Refrigerants (Continued)

The performance specifications are no minal and co nform t o acceptab le ind ustry standar ds. For appl ications at condition s beyond these specifica tions, consult th

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2015 Johnson Controls, Inc.

R-176

Page 7

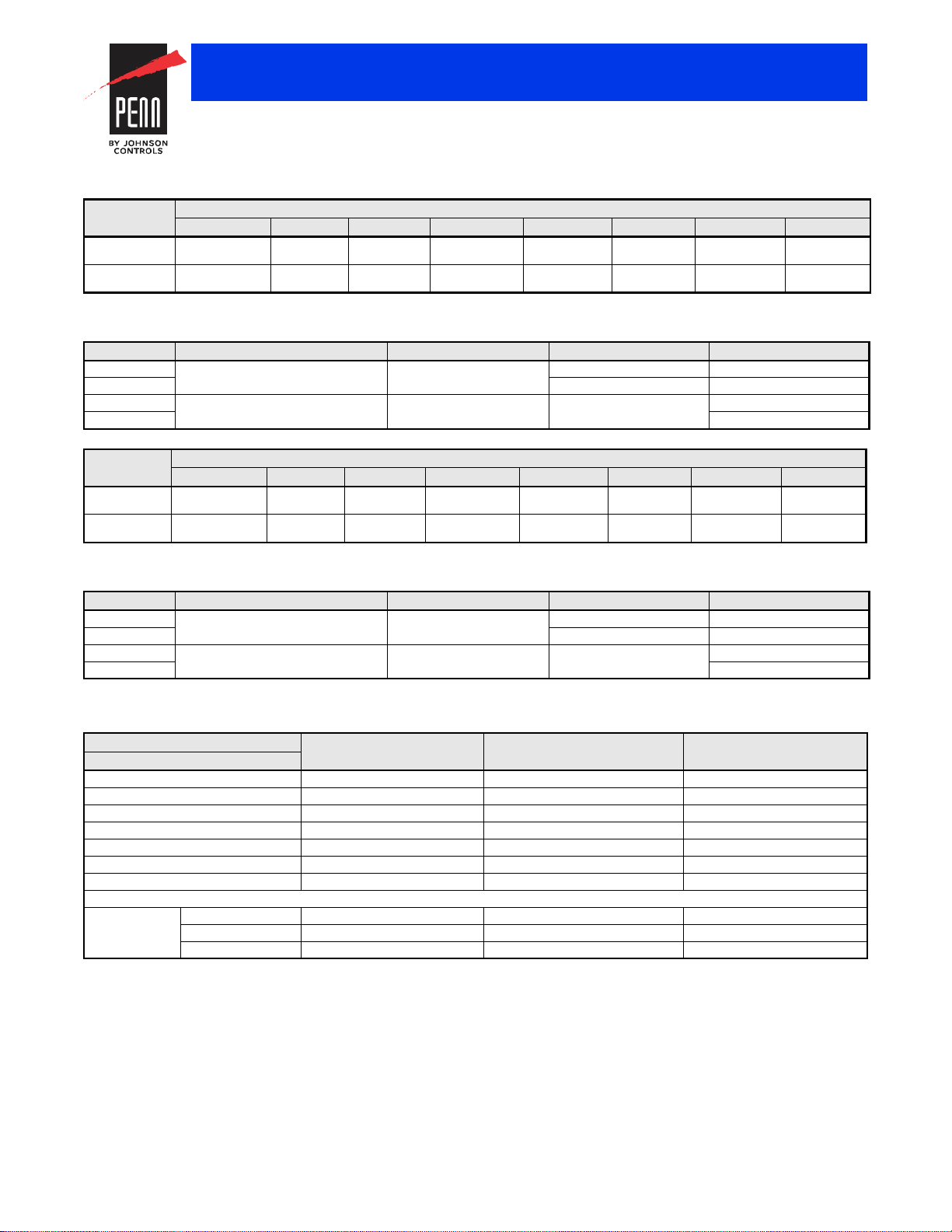

V246 Screw Connection Valves Dimensions

FIG:V246_thrdd

V246 Angle-Body Screw Connection Valves Dimensions

D

E

A

FIG:V24 6_anglbdy

Dimensions

Valves and Valve Accessories

V246 Series Two-Way Pressure-Actuated Water-Regulating Valves for

High-Pressure Refrigerants (Continued)

A

B

B

D

C

C

Port 1

Port 2

E

V246 Screw Connection Valves Dimensions

Valve Size Dimensions in Inches (Millimeters)

A B C D E

3/8 in. 2-5/8 (67) 1-5/8 (41) 6-1/2 (166) 3-1/2 (89) 3 (77)

1/2 in. 3-1/16 (78) 2 (51) 7-3/16 (182) 3-13/16 (96) 3-3/8 (86)

3/4 in. 3-3/8 (86) 2-3/16 (55) 8 (203) 4-3/16 (106) 3-13/16 (98)

1 in. 4-3/4 (121) 2-13/16 (71) 10-1/2 (267) 5-15/16 (151) 4-9/16 (116)

1-1/4 in. 4-3/4 (121) 2-13/16 (71) 10-7/8 (276) 6-1/8 (156) 4-3/4 (121)

V246 Angle-Body Screw Connection Valves Dimensions

Valve Size Dimensions in Inches (Millimeters)

A B C D E

3/8 in. 2-3/4 (70) 1-5/8 (41) 6-15/16 (176) 3-5/8 (92) 3-1/8 (80)

1/2 in. 3-1/8 (80) 2 (51) 7-1/2 (191) 3-7/8 (98) 3-1/2 (88)

3/4 in. 3-9/16 (90) 2-1/8 (55) 8-9/16 (217) 4-5/16 (1 10) 4 (101)

The performance specifications are no minal and co nform t o acceptab le ind ustry standar ds. For appl ications at condition s beyond these specifica tions, consult th

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2015 Johnson Controls, Inc.

R-177

Page 8

V246 Union Sweat Connection Valves Dimensions

E

D

C

A

Port 1

Port 2

FIG:V246_unnbdy

V246 Flange Valve Dimensions

FIG:flng_b dy

A

B

C

D

E

F

G

H

Valves and Valve Accessories

V246 Series Two-Way Pressure-Actuated Water-Regulating Valves for

High-Pressure Refrigerants (Continued)

B

V246 Union Sweat Connection Valves Dimensions

Valve Size Dimensions in Inches (Millimeters)

A B C D E

1-1/4 in. 4-3/4 (121) 2-13/16 (71) 10-7/8 (276) 6-1/8 (156) 4-3/4 (121)

The performance specifications are no minal and co nform t o acceptab le ind ustry standar ds. For appl ications at condition s beyond these specifica tions, consult th

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2015 Johnson Controls, Inc.

R-178

Page 9

Valves and Valve Accessories

V246 Series Two-Way Pressure-Actuated Water-Regulating Valves for

High-Pressure Refrigerants (Continued)

V246 Flange Valve, Commercial Service - Dimensions

Valve

Size

1-1/2 in. 5-5/16

2 in. 6-5/8

1. The dimensions on the European versions are 5-29/32 in. (150 mm).

2. The dimensions on the European versions are 6-1/2 in. (165 mm).

A B C D E F G H

(135)

(168)

9/16

(14)

5/8

(16)

V246 Flange Valve, Commercial Service - Flange Specifications

Valve Size Regional Version Number of Holes Hole Size Bolt Circle

1-1/2 in. North American 4 5/8 in. (16 mm) 3-7/8 in. (98 mm)

2 in. 3/4 in. (19 mm) 4-3/4 in. (121 mm)

1-1/2 in. European, DIN2533 Flanges 4 18 mm 110 mm

2 in. 125 mm

V246 Flange Valve, Maritime Service - Dimensions

Valve

Size

1-1/2 in. 5-5/16

2 in. 6-3/8

1. The dimensions on the European versions are 5-29/32 in. (150 mm).

2. The dimensions on the European versions are 6-1/2 in. (165 mm).

A B C D E F G H

(135)

(162)

9/16

(14)

5/8

(16)

6-1/8

(156)

7-1/8

(181)

V246 Flange Valve, Maritime Service - Flange Specifications

Valve Size Regional Version Number of Holes Hole Size Bolt Circle

1-1/2 in. North American 4 5/8 in. (16 mm) 3-7/8 in. (98 mm)

2 in. 3/4 in. (19 mm) 4-3/4 in. (121 mm)

1-1/2 in. European, DIN86021 Flanges 4 18 mm 110 mm

2 in. 125 mm

Dimensions in Inches (Millimeters)

6-1/8

(156)

7-1/8

(181)

4-3/4

(121)

6-1/8

(156)

Dimensions in Inches (Millimeters)

4-3/4

(121)

6-1/8

(156)

10-7/8

(276)

13-1/4

(336)

10-7/8

(276)

13-1/4

(337)

5-1/4

(133)

6-3/16

(157)

5-1/4

(133)

6

(152)

1

2

1

2

2-5/8

(67)

3-1/2

(89)

2-5/8

(67)

3-1/2

(89)

1-7/8

(48)

2-1/4

(57)

1-7/8

(48)

2-3/4

(70)

Materials

North American V246 Materials

Nominal Valve Size: 3/8 in. to 3/4 in.

Material

Body Cast brass Cast iron/rust resisting finish Cast bronze

Seat Aluminum Bronze Aluminum bronze Monel

Disc BUNA-N BUNA-N BUNA-N

Disc Cup Brass Brass Monel

Disc Stud Brass Brass Monel

Stem/Extension Sleeve Brass Brass Monel

Diaphragms Nylon reinforced BUNA-N Nylon reinforced BUNA-N Nylon reinforced BUNA-N

Refrigerant Contact

Pressure

Element

The performance specifications are no minal and co nform t o acceptab le ind ustry standar ds. For appl ications at condition s beyond these specifica tions, consult th

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2015 Johnson Controls, Inc.

Cup 300 Series stainle ss st eel 300 Series stainless steel 300 Series stainless steel

Bellows 300 Series stainless steel 300 Series st ainless steel 300 Series stainless steel

Bellows Ring Steel/nickel plated Steel/nickel plated Steel/nickel plated

(Commercial)

1 in. to 2 in.

(Commercial)

Maritime (All Sizes)

R-179

Page 10

Valves and Valve Accessories

V246 Series Two-Way Pressure-Actuated Water-Regulating Valves for

High-Pressure Refrigerants (Continued)

European V246 Materials

Nominal Valve Size: 3/8 in. to 3/4 in.

Material

Body Hot forged brass Cast iron/rust resisting finish Cast bronze

Seat Aluminum bronze A luminum bronze Monel

Disc BUNA-N BUNA-N BUNA-N

Disc Cup Brass B rass Monel

Disc Stud Brass B rass Monel

Stem/Extension Sleeve Brass Brass Monel

Diaphragms Nylon reinforced BUNA-N Nylon reinforced BUNA-N Nylon reinforced BUNA-N

(Commercial)

Refrigerant Contact

Pressure Element Cup 300 Series stainless steel 300 Series stainless steel 300 Series stainless steel

Bellows 300 Series stainless steel 300 Series stainless steel 300 Series stainless steel

Bellows Ring Steel/nickel plated Steel/nickel plated Steel/nickel plated

1 in. to 2 in.

(Commercial)

Maritime (All sizes)

Technical Specifications

Factory-Set Opening Point Direct Acting 200 psig (13.8 bar), Reverse Acting 165 psig (11.4 bar)

Maximum Working Pressure 630 psig (43.4 bar)

Opening Point Adjustment Range Direct Acting 200 to 400 psi (13.8 to 27.6 bar), Reverse Acting 135 to 300 psi (9.3 to 20.7 bar)

Media 150 psig (10.3 bar) Maximum,

V246 Series 2-Way Pressure-Actuated Water-Regulating Valves for High-Pressure Refrigerants

-4F to 170F (-20C to 77C) glycol/water or liquids with low freezing points that are compatible with valve materials

The performance specifications are no minal and co nform t o acceptab le ind ustry standar ds. For appl ications at condition s beyond these specifica tions, consult th

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2015 Johnson Controls, Inc.

R-180

Loading...

Loading...