Page 1

UZR-xx-x, UBR-xx-x, UZD-0xxX0xx-x, UBD-0xxX0xx-x

CCS Zone/Bypass Damper Assemblies

CCS Zone/Bypass Damper Assembly

Code No. LIT-1900539

Issued July 15, 2011

Description

The Commercial Comfort System (CCS)

Zone/Bypass Damper Assemblies are zone

control and pressure control devices that

include the damper and control components in

a factory assembled configuration. The

assembly includes the round or rectangular

damper, configured Direct Digital Control

(DDC) controller, electric actuator, pressure

sensor (in the bypass damper only), National

Electrical Manufacturers' Association (NEMA)

Type 1 enclosure, and an optional control

power transformer. The controllers are

application specific, factory programmed

digital controllers that communicate via the

BACnet® Master Slave/Token-Passing (MS/

TP) Protocol. Both the zone and bypass

controllers operate as part of a larger zoning

system and provide zone and pressure control

for the appropriate mechanical equipment.

The zone damper modulates in response to

temperature variations relative to a user

defined space temperature setpoint. The

bypass damper modulates to maintain supply

duct static pressure setpoint.

Refer to the Commercial Comfort System

(CCS) Product Bulletin (LIT-12011347) for

additional product application information.

Features

• factory mounted and wired control

components reduce installation time

• fast response actuator drives the damper

from full open to full closed (90) in 60

seconds to reduce commissioning time

• continuous loop tuning provided by Pattern

Recognition Adaptive Control (PRAC)

technologies

• available in both round and rectangular

configurations

• supplemental heat for both staged and

modulated damper assemblies

• variety of additional sizes available through

special order

Repair Information

If the CCS Zone/Bypass Damper Assembly

fails to operate within its specifications, see

the Repair Parts

Contact your local Johnson Controls®

representative for a replacement unit.

table for a list of repair parts.

Round Damper Assemblies

The round damper assemblies feature superior design, solid molded damper shafts, and control enclosures. The round damper assembly

features both staged and modulated supplement heat options.

Superior Design

The round zone damper is a 22 gauge round unit. An automated manufacturing process produces damper blades to exact specifications. The

dampers are designed for low noise operation with minimal friction loss and a tight closure seal. Air valve leakage is less than 1% of rated capacity

at 3 in. wg inlet pressure.

Solid Molded Damper Shaft

The solid damper shaft is molded using a high-impact, high-strength composite material. It is designed to eliminate condensation on the extended

portion that penetrates the unit casing. The shaft allows a more secure attachment to the damper actuator, since the set screws adhere to this

material better than metal. The high impact material gives the shaft superior impact strain resistance compared to cast metal shafts. The damper

blade is mounted on the damper shaft and connected by means of an integral molded sleeve. The shaft rotates in low friction self lubricating

bearings.

Control Enclosure

The zone and bypass damper assembly include a NEMA Type 1 galvanized steel (22 gauge) enclosure for factory mounting of the direct digital

controller, damper actuator, differential pressure sensor (in bypass damper only), and an optional multi-tap primary/24 VAC secondary

transformer.

Round Damper Assembly Construction Components

Damper Part Construction Component

Frame 22-gauge galvanized steel valve body with embossed beads. Withstands 125 per hour salt spray test per ASTM B-117.

Blade Full circular closed cell gasket secured between two pieces of 22 gauge sheet metal.

Damper Shaft Molded solid damper shaft constructed of high-impact, high-strength composite material.

Bearing Low friction self-lubricating bearings

Seal Full circular closed cell gasket

Temp Limits 32 to 122°F (0 to 50°C)

The performance specifications are nomina l and con form to accep table ind ustry stand ards. For applicati ons at con ditions be yond these specification s, consult the local Jo hnson Controls office.

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2011 Johnson Controls, Inc.

1 of 6

Page 2

CCS Zone/Bypass Damper Assembly (Continued)

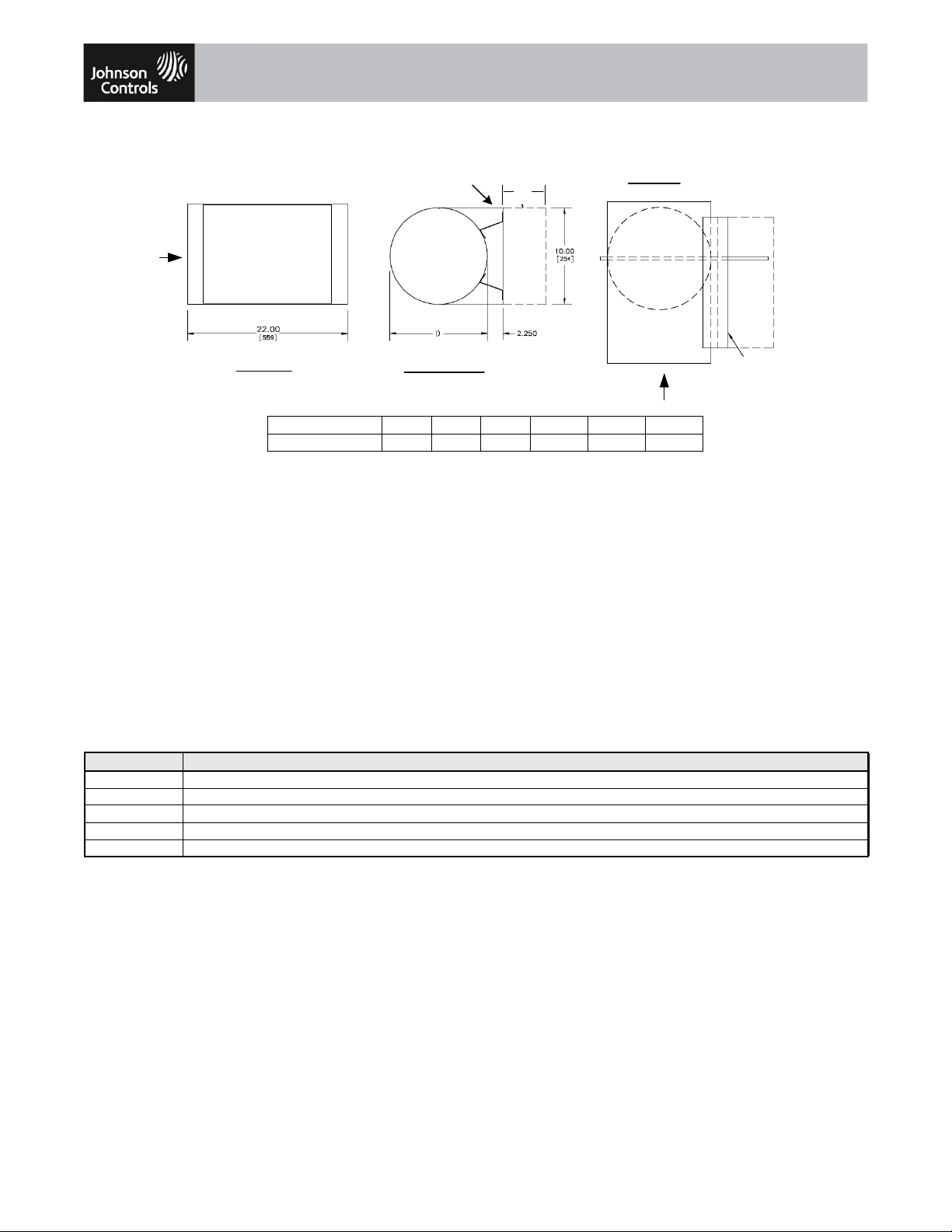

Airflow

Top View

Standard Control

Mounting Plate

Airflow

Side View

Inlet End View

Size 10 Shown

6.00

Control Enclosure

Standard

Unit Size 06 08 10 12 14 16

Dimension - D

5.88” 7.88” 9.88” 11.88” 13.88” 15.88”

Round Damper Assembly Dimensions

Round Damper Assembly Dimensions

Rectangular Damper Assemblies

Superior Design

The rectangular damper offers sturdy, steel construction with interlocking frame design. The unit frame is constructed of 5 x 1 in. (127 x 25 mm)

16-gauge galvanized steel hat channel reinforced with corner braces for structural strength equal to 13-gauge (2.28 mm). For dampers under

13 in. (330 mm), low profile 3-1/2 x 3/8 in. (89 x 10 mm) 16-gauge galvanized steel channels are located on the top and bottom frame. Damper

locks together without bolts, screws, or rivets that could shake loose. The frame corners are internally braced to reduce racking.

Damper Blades

Blades are 6 in. (152 mm) wide, 16 gauge (1.6 mm) galvanized steel approximately 6 in. (152 mm) on center with parallel action.

Damper Shaft

1/2-inch (13 mm) plated steel hex axles positively lock to blades without screws or welds. Non-stick, non-corrosive bearings assure long life and

ease of operation. Axles and bearings combine with a shake proof linkage for low maintenance operation.

Rectangular Damper Assembly Construction Components

Damper Part Construction Component

Frame 5 x 1 x 16 inch gauge galvanized steel hat channel reinforced with corner braces for structural strength equal to 13 gauge.

Blade 6 inches wide, 16 gauge galvanized steel approximately 6 inches on center, parallel action

Damper Shaft 1/2 inch plated steel hex axles

Bearing Corrosion resistant, molded synthetic sleeve type

Temp Limits 32 to 122°F (0 to 50°C)

The performance specifications are no minal and co nform t o acceptab le ind ustry standar ds. For appl ications at conditi ons beyond these specifications, con sult the local Johnso n Controls office.

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2011 Johnson Controls, Inc.

2 of 6

Page 3

CCS Zone/Bypass Damper Assembly (Continued)

8"x12"

8"x14"

8"x16"

10"x16"

10"x20"

14"x18"

AxB

14"x12"

16"x16"

20"x20"

30"x30"

AxB

Rectangular Damper Assembly Dimensions

Rectangular Damper Assembly Dimensions

Zone Damper Si ze

Bypass Damper Size

Selection Charts

Round Damper Assemblies

Damper Size

(Area - SqFt)

Air Velocity Through Damper (FPM) Zone Damper Airflow - CFM

750 FPM - Zone 141 254 399 577 788 1,031

1000 FPM - Zone 188 338 532 769 1,050 1,375

1250 FPM - Zone 235 423 665 961 1,313 1,718

1500 FPM - Bypass only 282 507 798 1,154 1,575 2,062

1750 FPM - Bypass only 329 592 931 1,346 1,838 2,405

2000 FPM - Bypass only 376 676 1,064 1,538 2,100 2,749

2250 FPM - Bypass only 423 761 1,197 1,730 2,363 3,094

6 inch

(0.188)

8 inch

(0.338)

10 inch

(0.532)

12 inch

(0.769)

14 inch

(1.05)

16 inch

(1.375)

The performance specifications are no minal and co nform t o acceptab le ind ustry standar ds. For appl ications at conditi ons beyond these specifications, con sult the local Johnso n Controls office.

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2011 Johnson Controls, Inc.

3 of 6

Page 4

CCS Zone/Bypass Damper Assembly (Continued)

Rectangular Damper Assemblies

Damper Size

W x H inches

(Area - SqFt)

8 x 12 inches

(0.42)

Zone Damper Assembly Bypass Damper Assembly

8 x 14

inches

(0.5)

8 x 16

inches

(0.58)

10 x 16

inches

(0.77)

10 x 20

inches

(1.00)

14 x 18

inches

(1.33)

14 x 12

inches

(0.83)

16 x 16

inches

(1.36)

20 x 20

inches

(2.25)

30 x 30

inches

(5.44)

Air Velocity Through Damper

Zone Damper Airflow - CFM

(FPM)

750 FPM - Zone 315 375 435 578 750 998 N/A N/A N/A N/A

1000 FPM - Zone 420 500 580 770 1,000 1,330 N/A N/A N/A N/A

1250 FPM - Zone 525 625 725 963 1,250 1,663 N/A N/A N/A N/A

1500 FPM - Bypass only N/A N/A N/A N/A N/A N/A 1,245 2,040 3375 8160

1750 FPM - Bypass only N/A N/A N/A N/A N/A N/A 1,453 2,380 3,938 9,520

2000 FPM - Bypass only N/A N/A N/A N/A N/A N/A 1,660 2,720 4,500 10,880

2250 FPM - Bypass only N/A N/A N/A N/A N/A N/A 1,868 3,060 5,063 12,240

Part Numbers (Part 1 of 3)

Product Code Number Description Weight

(lb)

Round Zone

Damper

Assemblies

UZR-06-0 6 in. round zone damper, actuat or, controller (no transformer) 16.3

UZR-06-1 6 in. round zone damper, actuat or, controller (120/208/240-24 VAC Transformer) 18.3

UZR-06-2 6 in. round zone damper, actuat or, controller (277/480-24 VAC Transformer) 18.3

UZR-06-3 6 in. round zone damper, Pressure Dependent (PD), actuator, controller (no transfor mer), st aged supplemen t al

UZR-06-4 6 in. round zone damper, PD, actuator, controller (120/208/240-24 VAC Transformer), staged supplemental

UZR-06-5 6 in. round zone damper, PD, actuator, controller (277/480-24 VAC Transformer), staged supplemental heat

UZR-06-6 6 in. round zone damper, Pressure Dependent (PD), actuator, controller (no t r ansformer), modulated

UZR-06-7 6 in. round zone damper, PD, actuator, controller ( 120/208/24 0-24 VAC T ransfor mer), modulat ed supplement al

UZR-06-8 6 in. round zone damper, PD, actuator, contro ller (277/480-24 VAC T ransformer), modu lated supplement al heat

UZR-08-0 8 in. round zone damper, actuat or, controller (no transformer) 18.3

UZR-08-1 8 in. round zone damper, actuat or, controller (120/208/240-24 VAC Transformer) 20.3

UZR-08-2 8 in. round zone damper, actuat or, controller (277/480-24 VAC Transformer) 20.3

UZR-08-3 8 in. round zone damper, PD, actuator, controller (no transformer), staged supplemental heat (LC-ZEC110-0) 18.3

UZR-08-4 8 in. round zone damper, PD, actuator, controller (120/208/240-24 VAC Transformer), staged supplemental

UZR-08-5 8 in. round zone damper, PD, actuator, controller (277/480-24 VAC Transformer), staged supplemental heat

UZR-08-6 8 in. round zone damper, PD, actuator, controller (no transformer), modulated supplemental heat (LC-ZEC120-0)18.3

heat (LC-ZEC110-0)

heat (LC-ZEC110-0)

(LC-ZEC110-0)

supplemental heat (LC-ZEC120-0)

heat (LC-ZEC120-0)

(LC-ZEC120-0)

heat (LC-ZEC110-0)

(LC-ZEC110-0)

16.3

18.3

18.3

16.3

18.3

18.3

20.3

20.3

UZR-08-7 8 in. round zone damper, PD, actuator, controller ( 120/208/24 0-24 VAC T ransfor mer), modulat ed supplement al

UZR-08-8 8 in. round zone damper, PD, actuator, contro ller (277/480-24 VAC T ransformer), modu lated supplement al heat

UZR-10-0 10 in. round zone damper, actuator, controller (no transformer) 20.3

UZR-10-1 10 in. round zone damper, actuator, controller (120/208/240-24 VAC Transformer) 22.3

UZR-10-2 10 in. round zone damper, actuator, controller (277/480-24 VAC Transformer) 22.3

UZR-10-3 10 in. round zone damper, PD, actuator, controller (no transformer), staged supplemental heat (LC-ZEC110-0) 20.3

UZR-10-4 10 in. round zone damper, PD, actuator, controller (120/208/240-24 VAC Transformer), staged supplemental

UZR-10-5 10 in. round zone damper, PD, actuator, controller (277/480-24 VAC Transformer), staged supplemental heat

UZR-10-6 10 in. round zone damper, PD, actuator, controller (no transformer), modulated supplemental heat (LC-

The performance specifications are no minal and co nform t o acceptab le ind ustry standar ds. For appl ications at conditi ons beyond these specifications, con sult the local Johnso n Controls office.

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2011 Johnson Controls, Inc.

heat (LC-ZEC120-0)

(LC-ZEC120-0)

heat (LC-ZEC110-0)

(LC-ZEC110-0)

ZEC120-0)

20.3

20.3

22.3

22.3

20.3

4 of 6

Page 5

CCS Zone/Bypass Damper Assembly (Continued)

Part Numbers (Part 2 of 3)

Product Code Number Description Weight

Round Zone

Damper

Assemblies

(Cont.)

Round Bypass

Damper

Assemblies

The performance specifications are no minal and co nform t o acceptab le ind ustry standar ds. For appl ications at conditi ons beyond these specifications, con sult the local Johnso n Controls office.

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2011 Johnson Controls, Inc.

UZR-10-7 10 in. round zone damper, PD, actuator, controller (120/208/240-24 VAC Transformer), modulated

UZR-10-8 10 in. round zone damper, PD, actuator, controller (277/480-24 VAC Transformer), modulated supplemental

UZR-12-0 12 in. round zone damper, actuator, controller (no transformer) 21.3

UZR-12-1 12 in. round zone damper, actuator, controller (120/208/240-24 VAC Transformer) 23.3

UZR-12-2 12 in. round zone damper, actuator, controller (277/480-24 VAC 23.3

UZR-12-3 12 in. round zone damper, PD, actuator, controller (no transformer), staged supplemental heat (LC-ZEC110-0) 21.3

UZR-12-4 12 in. round zone damper, PD, actuator, controller (120/208/240-24 VAC Transformer), staged supplemental

UZR-12-5 12 in. round zone damper, PD, actuator, controller (277/480-24 VAC Transformer), staged supplemental heat

UZR-12-6 12 in. round zone damper, PD, actuator, controller (no transformer), modulated supplemental heat (LC-

UZR-12-7 12 in. round zone damper, PD, actuator, controller (120/208/240-24 VAC Transformer), modulated

UZR-12-8 12 in. round zone damper, PD, actuator, controller (277/480-24 VAC Transformer), modulated supplemental

UZR-14-0 14 in. round zone damper, actuator, controller (no transformer) 22.3

UZR-14-1 14 in. round zone damper, actuator, controller (120/208/240-24 VAC Transformer) 24.3

UZR-14-2 14 in. round zone damper, actuator, controller (277/480-24 VAC Transformer) 24.3

UZR-14-3 14 in. round zone damper, PD, actuator, controller (no transformer), staged supplemental heat (LC-ZEC110-0) 22.3

UZR-14-4 14 in. round zone damper, PD, actuator, controller (120/208/240-24 VAC Transformer), staged supplemental

UZR-14-5 14 in. round zone damper, PD, actuator, controller (277/480-24 VAC Transformer), staged supplemental heat

UZR-14-6 14 in. round zone damper, PD, actuator, controller (no transformer), modulated supplemental heat (LC-

UZR-14-7 14 in. round zone damper, PD, actuator, controller (120/208/240-24 VAC Transformer), modulated

UZR-14-8 14 in. round zone damper, PD, actuator, controller (277/480-24 VAC Transformer), modulated supplemental

UZR-16-0 16 in. round zone damper, actuator, controller (no transformer) 25.3

UZR-16-1 16 in. round zone damper, actuator, controller (120/208/240-24 VAC Transformer) 27.3

UZR-16-2 16 in. round zone damper, actuator, controller (277/480-24 VAC Transformer) 27.3

UZR-16-3 16 in. round zone damper, PD, actuator, controller (no transformer), staged supplemental heat (LC-ZEC110-0) 25.3

UZR-16-4 16 in. round zone damper, PD, actuator, controller (120/208/240-24 VAC Transformer), staged supplemental

UZR-16-5 16 in. round zone damper, PD, actuator, controller (277/480-24 VAC Transformer), staged supplemental heat

UZR-16-6 16 in. round zone damper, PD, actuator, controller (no transformer), modulated supplemental heat (LC-

UZR-16-7 16 in. round zone damper, PD, actuator, controller (120/208/240-24 VAC Transformer), modulated

UZR-16-8 16 in. round zone damper, PD, actuator, controller (277/480-24 VAC Transformer), modulated supplemental

UBR-10-0 10 in. round zone damper, actuator, controller (no transformer) 20.6

UBR-10-1

UBR-10-2 10 in.

UBR-12-0 12 in. round zone damper, actuator, controller (no transformer) 21.6

UBR-12-1 12 in. round zone damper, actuator, controller (120/208/2 40-24 VAC Transformer) 23.6

UBR-12-2 12 in. round zone damper, actuator, controller (277/480-24 VAC Transformer) 23.6

UBR-14-0 14 in. round zone damper, actuator, controller (no transformer) 22.6

UBR-14-1 14 in. round zone damper, actuator, controller (120/208/240-24 VAC Transformer) 24.6

UBR-14-2 14 in. round zone damper, actuator, controller (277/480-24 VAC Transformer) 24.6

UBR-16-0 16 in. round zone damper, actuator, controller (no transformer) 25.6

UBR-16-1 16 in. round zone damper, actuator, controller (120/208/240-24 VAC Transformer) 27.6

UBR-16-2 16 in. round zone damper, actuator, controller (277/480-24 VAC Transformer) 27.6

supplemental heat (LC-ZEC120-0)

heat (LC-ZEC120-0)

heat (LC-ZEC110-0)

(LC-ZEC110-0)

ZEC120-0)

supplemental heat (LC-ZEC120-0)

heat (LC-ZEC120-0)

heat (LC-ZEC110-0)

(LC-ZEC110-0)

ZEC120-0)

supplemental heat (LC-ZEC120-0)

heat (LC-ZEC120-0)

heat (LC-ZEC110-0)

(LC-ZEC110-0)

ZEC120-0)

supplemental heat (LC-ZEC120-0)

heat (LC-ZEC120-0)

10 in. round zone damper, actuator, controller (120/208/240-24 VAC Tr ansformer) 22.6

round zone damper, actuator, controller (277/480-24 VAC Transformer) 2 2.6

(lb)

20.3

22.3

23.3

23.3

21.3

23.3

23.3

24.3

24.3

22.3

24.3

24.3

27.3

27.3

25.3

27.3

27.3

5 of 6

Page 6

CCS Zone/Bypass Damper Assembly (Continued)

Part Numbers (Part 3 of 3)

Product Code Number Description Weight

Rectangular

Zone Damper

Assemblies

UZD-008X012-0 8 x 12 in zone damper with actuator, controller (no transformer) 5.3

UZD-008X012-1 8 x 12 in. zone damper, actuator, controller (120/208/240-24 VAC Transformer) 7.3

UZD-008X012-2 8 x 12 in. zone damper, actuator, controller (277-480-24 VAC Transformer) 7.3

UZD-008X014-0 8 x 14 in. zone damper with actuator, controller (no transformer) 6.0

UZD-008X014-1 8 x 14 in. zone damper, actuator, controller (120/208/240-24 VAC Transformer) 8.0

UZD-008X014-2 8 x 14 in. zone damper, actuator, controller (277-480-24 VAC Transformer) 8.0

UZD-008X016-0 8 x 16 in zone damper with actuator, controller (no transformer) 6.6

UZD-008X016-1 8 x 16 in. zone damper, actuator, controller (120/208/240-24 VAC Transformer) 8.6

UZD-008X016-2 8 x 16 in. zone damper, actuator, controller (277-480-24 VAC Transformer) 8.6

UZD-010X016-0 10 x 16 in zone damper with actuator, controller (no transformer) 7.9

UZD-010X016-1 10 x 16 in. zone damper, actuator, controller (120/208/240-24 VAC Transformer) 9.9

UZD-010X016-2 10 x 16 in. zone damper, actuator, controller (277-480-24 VAC Transformer) 9.9

UZD-010X020-0 10 x 20 in. zone damper, actuator, controller (no transformer) 9.6

UZD-010X020-1 10 x 20 in. zone damper, actuator, controller (120/208/240-24 VAC Transformer) 11.6

Accessories

Product Code

Number

TE-68NT-0N00S Wall Temperature Sensor, 1k ohm, Nickel with Temporary Occupancy Button

TE-68NT-1N00S Wall Temperature Sensor, 1k ohm, Nickel with Temporary Occupancy Button and Warmer/Cooler Adjustment

FTG18A-600R Static Pressure Remote Mounted Sensing Probe

Description

(lb)

Repair Parts

Product Code

Number

Y65T54-0 40 VA Control Power Transformer (120/208/240 - 24 VAC)

Y65F13-0 40 VA Control Power Transformer (277/480 - 24 VAC)

M9104-AGA-3S Damper Actuator, 35 lb·in, Floating Control

263G-005-JC6 B ypass DP transducer 0.5–4.5 VDC, 0–5 in. w.c.

LC-ZEC100-0 Zone damper control board - Replacement

LC-ZEC110-0 Zone Equipment Controller with Staged Supplement Heat

LC-ZEC120-0 Zone Equipment Controller with Modulated Supplemental Heat

LC-BYP100-0 Bypass Damper Control Board - Replacement

Description

Technical Specifications

Bypass DP Transducer

Product Code Number 263G-005-JC6

Power Requirement 5.0 VDC

Pressure Range 0–5.0 in. W.C.

Overpressure limit 15.0 in. W.C.

Output Voltage 0.5–4.5 VDC into Load Impedance of 25,000 ohm

Accuracy Linearity: ±1.0% Full Span Maximum

Dimensions

(Height x Width x Depth)

Product Code Number M9104-AGA-3S

Power Requirement 24 VAC +25%/-20% at 50 to 60 Hz, 2.1 VA Supply, Class 2

Control Type Floating Control without Timeout

Input Signal 24 VAC +25%/-20% at 50 to 60 Hz, 2.1 VA Supply, Class 2

Running Torque 35 lb⋅in

Dimensions

(Height x Width x Depth)

Hysteresis: ±0.05% Full Span Maximum

1 x 2-3/4 x 2-1/2 in. (25.4 x 68.8 x 63.5 mm)

Damper Actuator

5.2 x 2.8 x 2.3 in. (132.08 x 71.1 x 58.4 mm)

The performance specifications are no minal and co nform t o acceptab le ind ustry standar ds. For appl ications at conditi ons beyond these specifications, con sult the local Johnso n Controls office.

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2011 Johnson Controls, Inc.

6 of 6

Loading...

Loading...