Page 1

Instruction Manual

TopClean AS

Hygienic, Self-priming

Liquid Ring Pumps

IM-AS/02.00 GB-JPAB (0412)

Page 2

CE – Declaration of conformity

Manufacturer

Johnson Pump

Box 1436

SE- 701 14 Örebro

Sweden

We declare under our sole responsibility that the product:

Pump Series AS

CE declaration of conformity (Ann.II.A, 98/37/EEC)

to wich this declaration refers, is conform to safety requirements according

to 98/37/EEC norms and amendments

Manufacturer declaration (Ann. II.B, 98/37/EEC)

cannot be operated before the machine in which is assembled, will be declared in conformity with safety requirements according to 98/37/EEC norms

and amendments.

Örebro, Sweden, 01/03/2007

Stefan Ring

Manager Quality & Environment

Page 3

Index

1.0 Introduction ...................................................................................................... 3

2.0 Symbols ...................................................................................................... 3

3.0 Safety warnings ................................................................................................ 3

4.0 Transportation, receipt and transferring of goods ....................................... 4

4.1 Transportation .............................................................................................................. 4

4.2 Receipt .......................................................................................................................... 4

4.3 Transferring .................................................................................................................. 4

5.0 Description ...................................................................................................... 5

5.1 Sound pressure level.................................................................................................... 5

6.0 Non-permitted uses.......................................................................................... 6

7.0 Installation ...................................................................................................... 6

7.1 Suction and inflow conditions .................................................................................... 6

7.2 Piping ........................................................................................................................... 6

7.3 Electrical connection ................................................................................................... 7

8.0 Operation ...................................................................................................... 7

8.1 Preliminary operations and starting .......................................................................... 7

8.2 Operating checks ......................................................................................................... 8

8.3 Extended stop .............................................................................................................. 8

8.4 Cleaning the pump ...................................................................................................... 8

9.0 Spare parts ...................................................................................................... 8

10.0 Seals ................................................................................................. 9

11.0 Disassembly and Assembly AS-series ......................................................... 10

11.1 General instructions .................................................................................................. 10

11.2 O-rings and lip seals .............................................................................................. 10

11.3 Shutdown .............................................................................................. 10

11.4 Disassembly .............................................................................................. 11

11.4.1 Removal of pump casing and impeller – AS 40, 50, 60, 65 and 80 .......... 11

11.4.2 Removal of pump casing and impeller – AS 42 and AS 52 ...................... 11

11.4.3 Seal disassembly ............................................................................................ 12

11.4.3.1 T execution ......................................................................... 12

11.4.3.2 V execution ......................................................................... 12

11.4.3.3 Q execution......................................................................... 12

11.4.4 Bearing removal ............................................................................................ 13

11.5 Assembly .............................................................................................. 13

11.5.1 Clearances .............................................................................................. 13

11.5.2 Pump assembly AS 40, 50, 60, 65................................................................. 14

11.5.3 Seal assembly .............................................................................................. 14

IM-AS/02.00 GB (0412)

1

Page 4

11.5.3.1 T execution .......................................................................... 14

11.5.3.2 V execution .......................................................................... 14

11.5.3.3 Q execution .......................................................................... 15

11.5.4 Assembly of pump casing and impeller assembly ........................................

– AS 40, AS 50, AS 60, AS 65 and AS 80 ................................................... 15

11.5.5 Pump cover and Impeller assembly – AS 42 and AS 52 ........................... 16

12.0 Spare parts lists and sectional drawings ...................................................... 17

12.1 Spare part list AS 40, 50, 60-65, 80 .......................................................................... 17

12.2 AS 40 – Execution T, Q, V........................................................................................ 18

12.3 AS 50 – Execution T, Q, V........................................................................................ 19

12.4 AS 60-65 – Execution T, Q, V .................................................................................. 20

12.5 AS 80 – Execution T, Q, V........................................................................................ 21

12.6 Spare part list AS 42, 52 ............................................................................................ 22

12.7 AS 42 – Execution T, Q, V........................................................................................ 23

12.8 AS 52 – Execution T, Q, V........................................................................................ 24

13.0 Dimensions and weights .............................................................................. 25

13.1 AS 40-50-60-65-80 with shroud 1450 rpm ............................................................... 25

13.2 AS 40-50-60-65-80 without shroud 1450 rpm ......................................................... 25

13.3 AS 42-52 with shroud 1450 rpm ............................................................................... 26

13.4 AS 42-52 with shroud 1450 rpm ............................................................................... 26

14.0 Trouble shooting chart .............................................................................. 27

15.0 Disposal of the pump .............................................................................. 28

2

IM-AS/02.00 GB (0412)

Page 5

1.0 Introduction

• Read the instructions carefully and keep them for future consultation.

• Johnson Pump reserves the right to make any changes to the documentation it

deems necessary without being obliged to update publications that have already

been issued.

•When requesting information, spare parts or assistance, always specify the pump

type and serial number in order to ensure fast and efficient service: the complete

code is given on the plate and in the purchase documents.

Serial No.

No.

kW

Nastagatan 19, Örebro, Sweden · Tel +46 (0)19 21 83 00

Name plate

2.0 Symbols

TopClean

Item

r.p.m.

Volt

Pump type

Hz

Warning: Pay great attention to the text parts indicated by this symbol.

Danger: The non-observance of instructions can cause serious damage

to persons and/or objects.

Danger:Only skilled personnel is allowed to carry out operations

concerning the electric parts.

3.0 Safety warnings

When the pump is working the following occurs:

• Electric parts are in tension.

•Mechanical parts are moving.

• Pump body, pipelines and articulations are under internal pressure. Therefore do not

remove any protection or locking, do not loosen screws or clampings, as this can

cause serious damages to persons or objects. The clamp joining the pump casing and

the cover must be well tightened and it should not be easily unscrewed by hand. The

tightening of the clamp must be carried out by means of a key and not by hand.

• Non-observance of inspection and maintenance can cause damages to persons and

objects, especially when dangerous or toxic liquids are pumped.

•When pumping liquids at a temperature over 60°C, adequate protection and

warning signals are required.

•When you buy a pump with bare shaft, motor coupling operations have to be

•Operations on the electric parts have to be carried out by skilled personnel,

• Installation must ensure adequate ventilation, in order to cool the engine, as well as

IM-AS/02.00 GB (0412)

carried out according to technical directions and law, providing adequate

rotections for joints, gear belts, etc.

according to technical directions and law, on authorisation of the responsible

installer.

enough space for maintenance operations.

3

Page 6

Before carrying out any operation which requires to disassembly of the pump

(inspection, cleaning, seal replacement, etc.), the following preliminary operations have

to be carried out:

• Switch off engine tension and disinsert electric connection.

• Close valves on suction and outlet pipelines, in order to avoid the risk of inundation.

•Use adequate protection for hands and face, if the pump contains liquids which are

hazardous to health (for example acids, solvents, etc.).

• Consider whether the liquid which flows out of the pump when disassembling is

dangerous and arrange for adequate safety measures.

4.0 Transportation, receipt and transferring of goods

4.1 Transportation

The packings of all AS pumps are defined when making the order. Unless prior arrangements

are given, goods will be packed only for transit conditions and not for long-term storage; in case

it should be necessary to store the pumps outside, you are requested to cover the pumps

appropriately in order to protect the electrical parts (motor) from rain, dust, humidity etc.

4.2 Receipt

Upon receipt of goods the integrity of the packaging must be verified in order to identify

possible damages to the content during transfer, and to claim immediately from the carrier.

Should any damage be ascertained, the following procedure must be observed:

• Collect the goods with receipt.

• Take the necessary pictures showing the damages.

• Notify the carrier of the suffered damages, by registered airmail – including the

pictures taken.

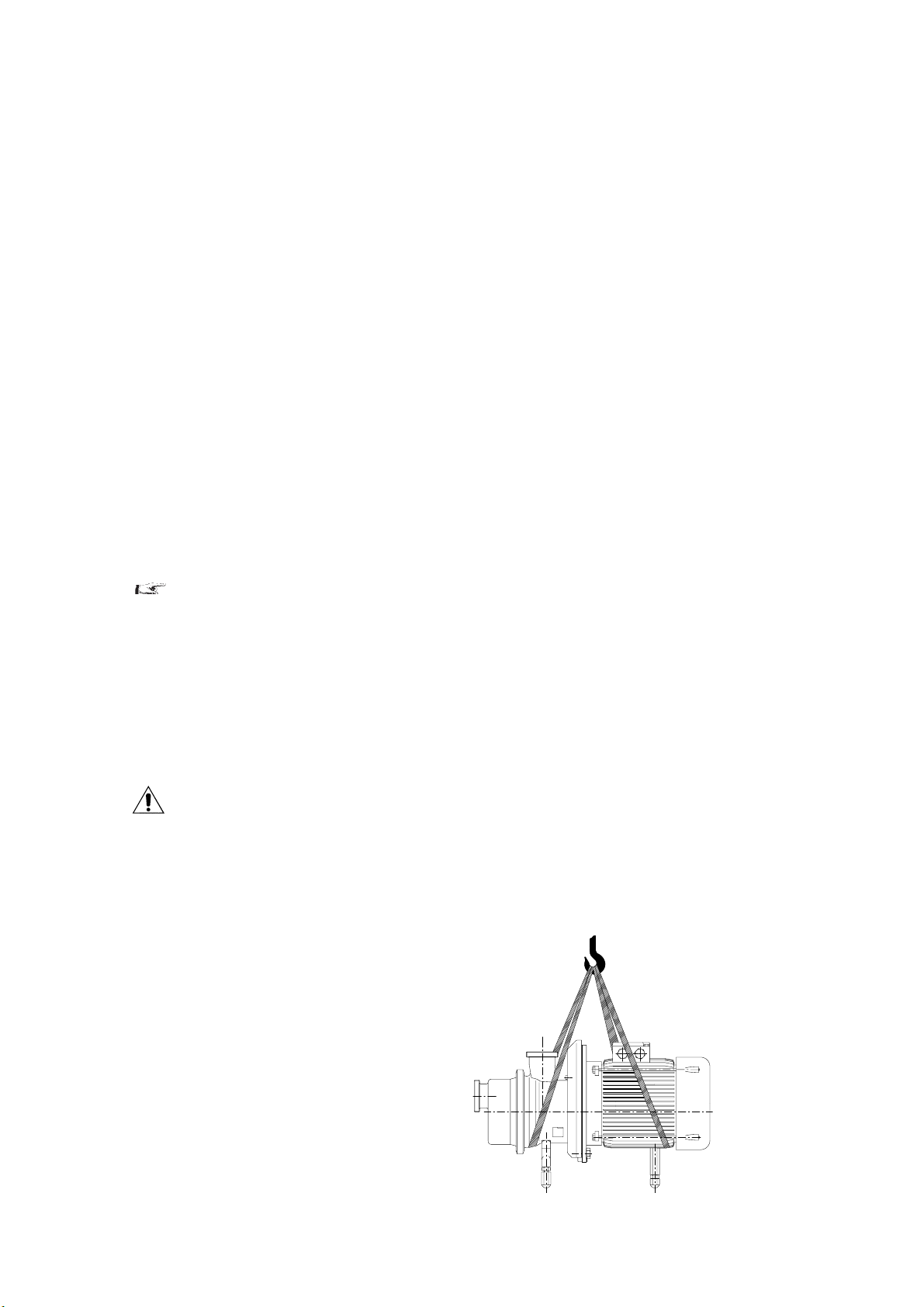

4.3 Transferring

Carry the packed pumps as close as possible to the place of installation by means of appropriate

lifting devices and unpack them. During this operation take care, as unsteady parts could fall

down.

The material used for packing (wood, paper, cellophane, etc.) should be properly disposed of,

according to the corresponding rules in force in receiver’ s country.

After unpacking the pump, use special lifting belts and move the pump-motor-set to the place

of installation; never use the eyebolts on the motor to move the pump, as the eyebolts are for

moving the motor only.

In versions complete with shroud,

take the shroud off before moving the

pump-motor-set, in order to avoid

damages.

4

IM-AS/02.00 GB (0412)

Page 7

5.0 Description

The pumps of series AS are centrifugal side channel self-priming with star-shaped impeller; the

ports are located on the longitudinal axe with the suction located on the front of the pump

cover. All models have threaded connections for fittings according to DIN 11851 standard

(unless otherwise requested). The pump front cover is easy to open to improve cleaning and

inspection operations; all models are fitted with mechanical seals and the materials used for the

components of mechanical seal are chosen according to the liquid to be pumped.

Designed in close-coupled version, fitted with indepandant standard electric motors B5 shape,

IP 55 protection (unless otherwise requested).

These pumps are designed for applications where the liquid to be pumped :

• is not subject to pollution of any kind,

• is at a temperature between -30°C and +140°C,

•must under no circumstances come into contact with the outside environment,

• is chemically aggressive.

5.1 Sound pressure level

The sound pressure level of self-priming pumps is the following (see table):

The measurement has been made by means of a phon-meter placed at 1 m distance from the pump

and at a height of 1.6 m from the ground.

Preliminary condition is that the pump is fixed correctly; the above mentioned values do not take

into account external noise sources (e.g. valves, abrupt hydraulic deflections).

Pump type dB(A)

AS 40 < 80

AS 42 81-85

AS 50 81-85

AS 52 86-90

AS 60 86-90

AS 65 86-90

AS 80 86-90

IM-AS/02.00 GB (0412)

5

Page 8

6.0 Non-permitted uses

Do not use the pump with a suction pressure greater than the specified value (0.5 times

the discharge head generated by the pump).

The pump must always be used in an environment appropriate to the level of protection

of the motor. Always check this on the motor plate before installation.

The pump may not be used in environments which require a higher level of protection or

a higher specification motor or electrical parts.

Components complying with the safety standards for the environment in question must

be used.

7.0 Installation

7.1 Suction and inflow conditions

(NPSH = Net Positive Suction Head)

NPSH of system (available NPSH)

In order to ensure that pump operation is free from cavitation, it is essential to observe

the maximum permitted suction lift ha geo max or the minimum allowable head hc geo

min. NPSH of pump (required NPSH)

The centrifugal pumps can operate correctly only if vapour has not formed inside. For

this reason the static head at the reference point for the NPSH is the centre of the

impeller, that is the point of intersection of the pump shaft axis with the vertical plane

that passes through the external points of the blade inlet corners.

NPSHnec. is the value required by the pump, expressed in metres, obtained from the

performance curve. In practice 0.5 m should be added to this value as a safety margin.

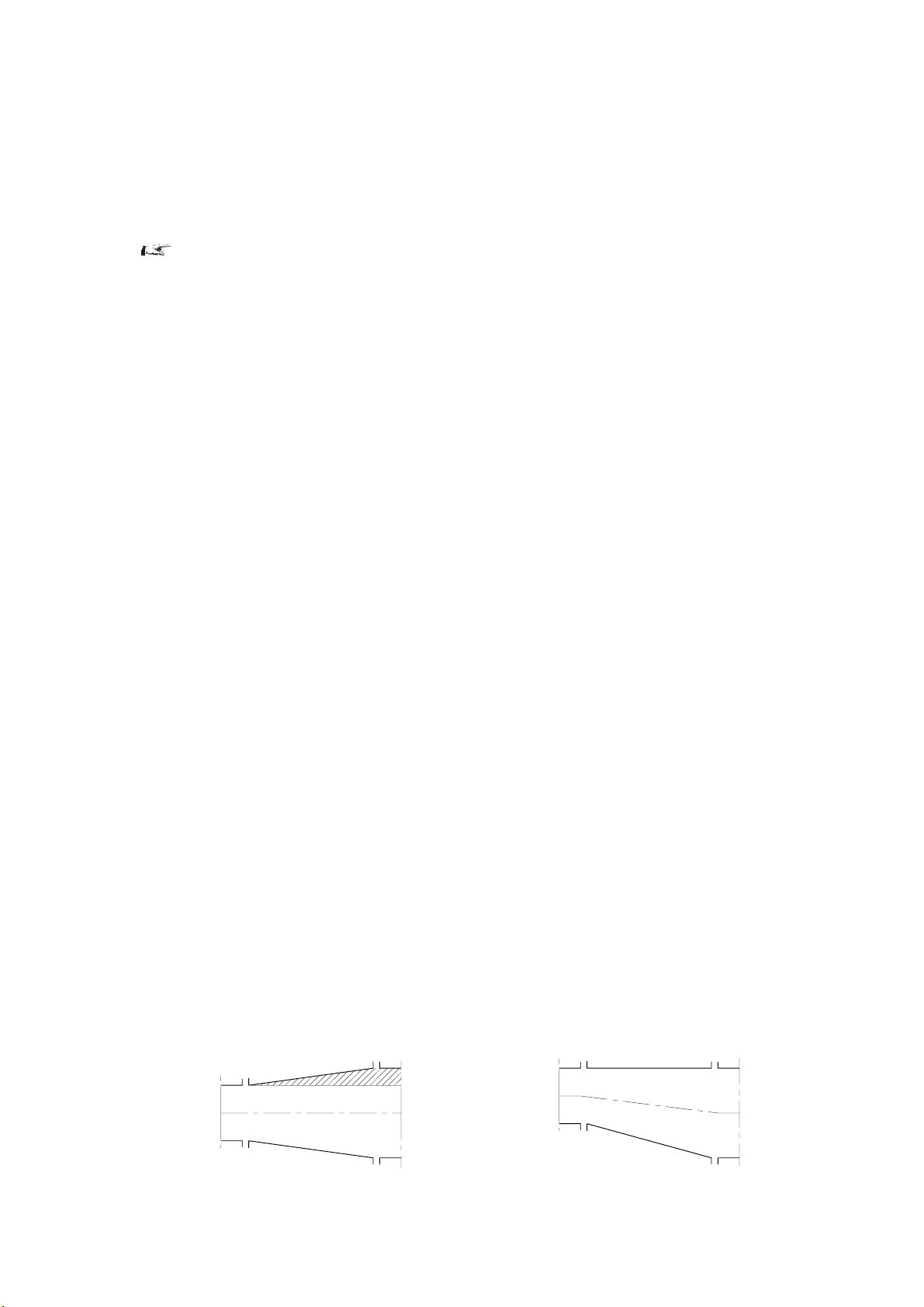

7.2 Piping

In order to prevent the creation of harmful stresses, the suction and discharge pipes must

be connected to the pump ports without the use of force. These pipes must also be

supported independently avoiding causing stresses on the pump. The internal diameter

must be the same size as the pump connections. It must in any case not be smaller to

avoid head loss and/or poor performances. Always use elbows with large radius. If the

pipe diameter changes along the line, use reduction cones, choosing the ones that are

most suitable for avoiding the formation of air pockets (Fig. 1).

The suction pipe must be as short as possible and rise as it moves towards the pump if it

is sucking from a tank, if on the other hand the pump is below the level of the liquid, the

pipe should descend slightly. If the pump is used for transporting hot liquids, fit expansion joints to compensate any expansion of the piping. The maximum velocity of the

liquid in the suction pipe must not be greater than 3 m/s. Velocities between 1 and 2 m/s

are recommended.

The suction pipe must be designed in such a way as to prevent air from entering the

pump. For this reason, when sucking from a tank located at a lower level, the pipe must

reach below the free surface of the liquid. Avoid creating obstacles which could increase

suction losses disrupting smooth fluid flow. Make sure that there are no restrictions,

NO

YES

Fig. 1

6

IM-AS/02.00 GB (0412)

Page 9

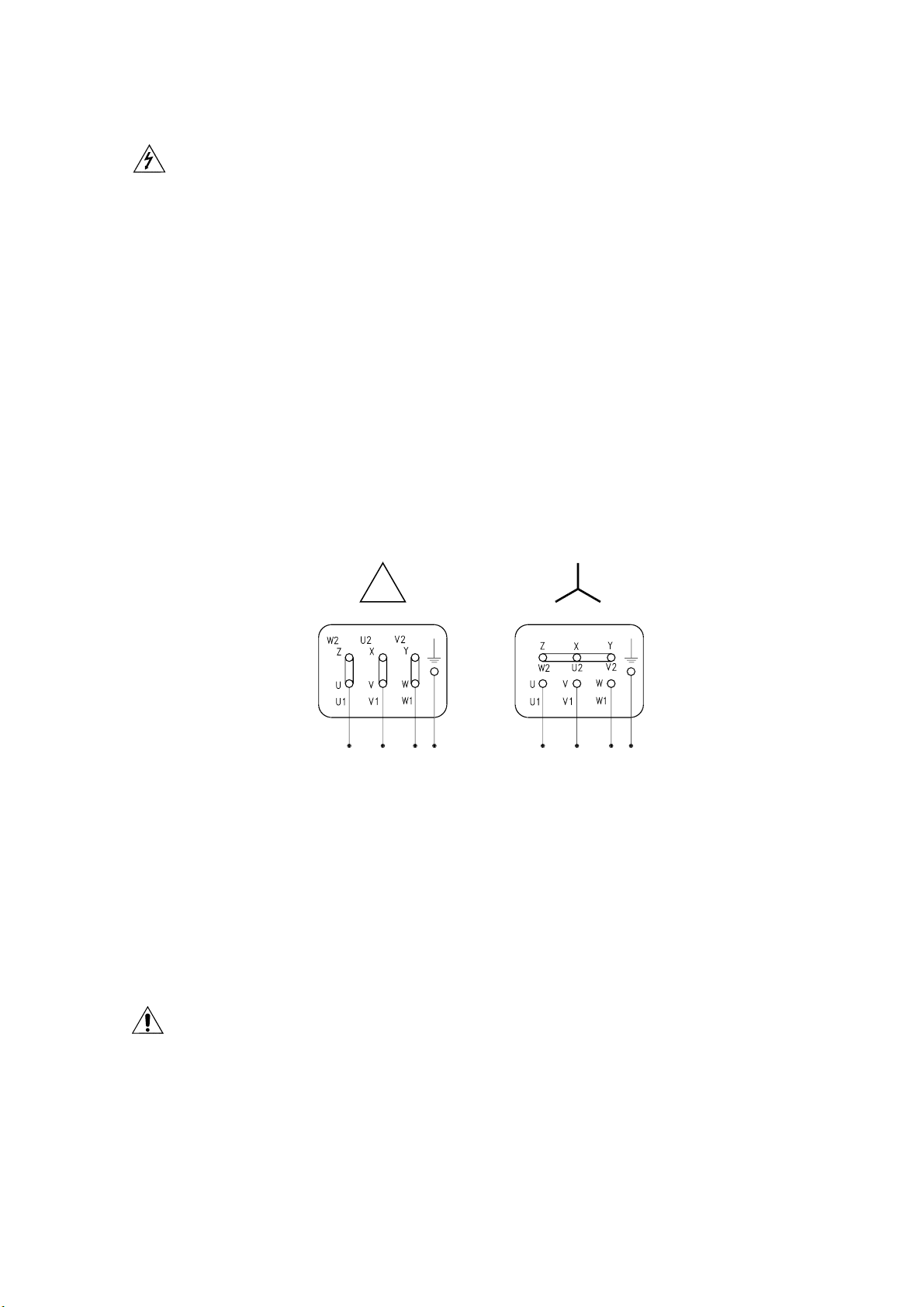

7.3 Electrical connection

Make the electrical connection only after the hydraulic connection has been completed; set up

the motor control system in conformity with the technical standards and regulations in force

(EN 60204-1): in particular a manual electric power switch must be installed with adequate

current switching capacity; devices for overcurrent and overload protection (e.g. fuses,

automatic switches, etc.) must also be fitted, plus, if necessary, a device to prevent accidental

restarting.

Check that the main frequency and voltage and the available power are suitable for the motor

installed. All the material used for the electrical connection (cables, cable clamps, switches and

shielding) must have a suitable level of protection for the environment in which it is installed.

Be sure to use cables of sufficient cross-section for the current shown on the motor plate so as

to prevent them from overheating. Before doing anything else, make the motor’s earth

connection, using the terminal on the motor and a cable of sufficient cross-section. The cables

may be connected to the terminal board using either a delta or star arrangement. Follow the

data given on the motor plate for the main voltage, as shown in the diagram in fig 2; ensure that

the terminals are clean and tight and not under stress.

When starting, the motor’s current absorption increases briefly to 5-6 times the nominal value.

If the mains supply is unable to sustain this increase in absorption, use a star-delta starter or

other kind of device (e.g. an autotransformer).

Johnson Pump will accept no responsibility for damage to property and/or injury to persons

caused by failure to comply with technical standards and regulations in force.

Lower

voltage

Fig 2

8.0 Operation

8.1 Preliminary operations and starting

When first starting, fill the pump with liquid so as to create the pressure drop required for

suction. When starting subsequently the quantity of liquid that remains in the pump will be

sufficient to ensure self-priming even if the pipe is empty. Make sure that the pump does not

become completely empty in the event of installation under a vacuum or to a siphon. If

necessary, fit a check valve.

• Check that the pump turns freely under hand pressure.

• Check that the clamp joining the pump casing and the cover is well tightened and that

it cannot be easily unscrewed by hand. The tightening of the clamp must be carried out

by means of a key and not by hand.

Higher

voltage

• Check that the pump turns in the market direction.

• Check that any gate valves installed on the suction and discharge pipelines are open.

• Start the pump and check the turns direction; before restarting it is extremely important to

IM-AS/02.00 GB (0412)

7

Page 10

8.2 Operating checks

• If the pump does not generate the required discharge head rapidly, facilitate

priming by stopping the pump and adding liquid.

• Check that the absorption of the motor does not exceed the value specified on the

plate.

• The pump must always work smoothly and without vibrations.

•Do not operate without liquid and in any case avoid prolonged operation with the

discharge gate valve closed.

• With series AS pumps never close discharge side completely.

•Mechanical seal: check that there is no leakage along the shaft.

8.3 Extended stop

When stopping the pump for a longer time, empty the pump completely and wash it

accurately in order to avoid the formation of scales and/or encrustations. When starting

the pump again, please follow the above mentioned instructions.

8.4 Cleaning the pump

The pump does not require any special washing procedures. The washing cycles

normally used for the plant in which it is installed are quite satisfactory. When using the

pump for liquids that tend to harden or crystallize, always make sure it is washed before

periods when the machine is to be taken out of operation. This will ensure durability of

the seal and of the pump itself.

It is the user’s responsibility to ensure that the washing liquids are compatible with the

process liquid and the pump.

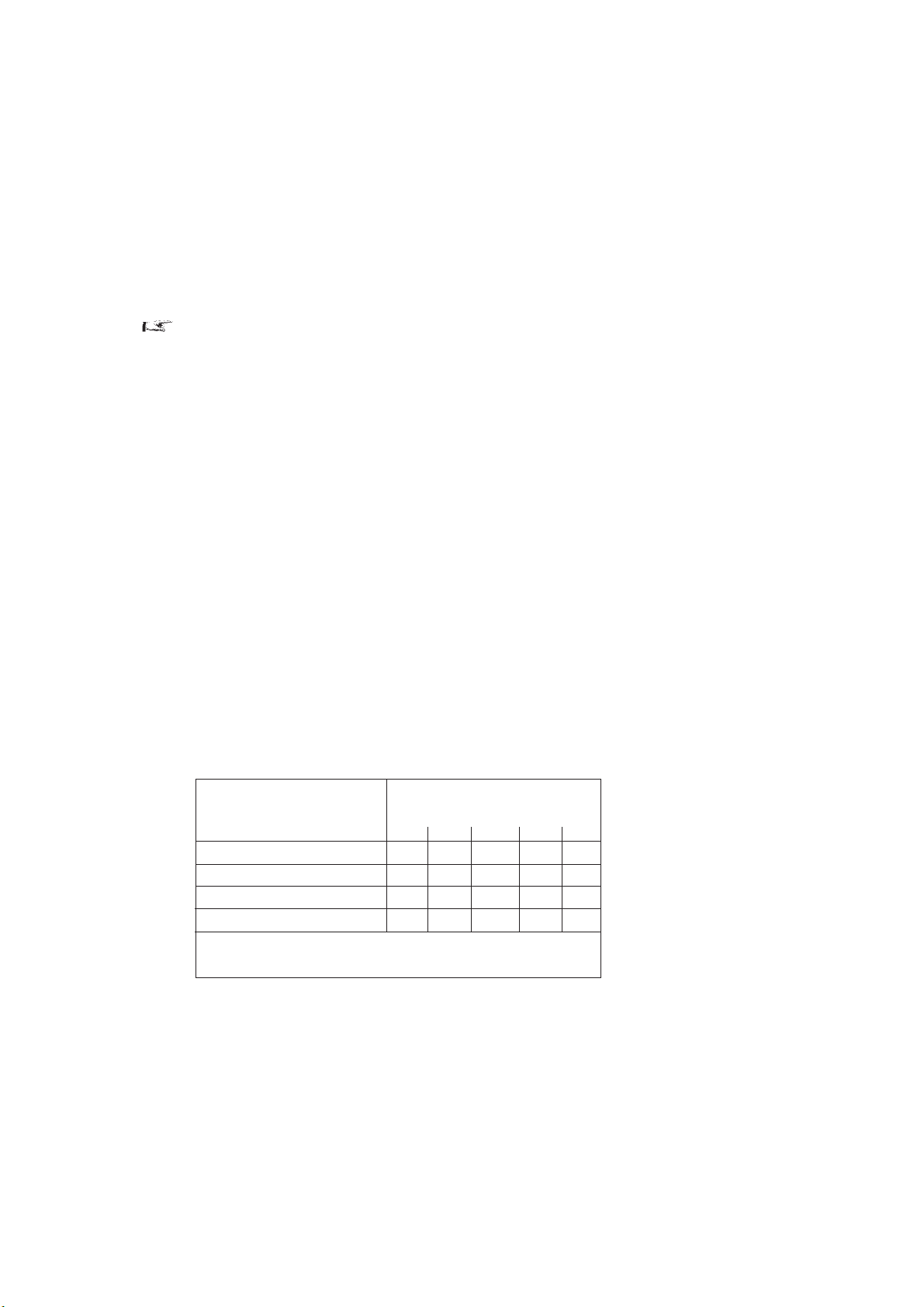

9.0 Spare parts

Denomination Number of pumps

Mechanical seal 1 2 3 4 4

Pump bearing 1 1 1 2 2

O-ring seal 2 3 5 6 7

O-ring seal nut 2 3 5 6 7

Recommended spare part for two years of operation according to the

number of pumps installed – vdma standard

Johnson Pump declines all responsibility for damage or injury resulting from the use of

non-original spare parts

(Including reserve)

12345

8

IM-AS/02.00 GB (0412)

Page 11

10.0 Seals

All centrifugal pumps of the AS series are fitted with unified mechanical seals according

to DIN 24960 - ISO 3069 standards, in order to grant the interchangeability (subject to

verification of axial space). The type of mechanical seal and material are chosen

according to the liquid to be pumped.

Mechanical seal types conforming to DIN 24960

•T execution: Standard – Internal single mechanical seal

•V execution: External single mechanical seal with external

•Q execution: Compact double mechanical seal back-to-back,

Warning: before using the pump for any liquids other than those specified when

selecting and ordering, ensure that mechanical seals and gaskets are suitable for the new

product.

flushing/quench.

high pressure flush

IM-AS/02.00 GB (0412)

9

Page 12

11.0 Disassembly and Assembly AS-series

11.1 General instructions

Assembly and disassembly may be preformed by qualified personnel only. Always wear

appropriate safety clothing. Make sure that personnel are instructed and educated.

Insufficient or wrong assembly and disassembly can lead to the pump malfunction.

Johnson Pump is not liable for accidents and/or damage caused by non-compliance with

the guidelines.

Always work in a clean surrounding. Keep all highly sensitive parts such as seals, Orings, bearings, etc. in their original packing as long as possible.

Use a clean work surface.

Check that the parts to be used have not been damaged during transport.

Never work on the pump in operation. In case of a disassembled pump, avoid any

contact with the impeller when turning the shaft manually.

Do not forget that the pump can be started even when the pump casing has been removed for e.g. cleaning. Never run the pump without the pump casing. Follow the

instructions for shutdown before performing any maintenance or service.

After disassembly carefully clean the parts and check them for damage, especially the

mounting surfaces, and replace all damaged parts.

All parts fitted together at the disassembly must stay together when reinstalled,

especially the impeller, shaft, shim and back plate.

11.2 O-rings and lip seals

When working with lip seals or O-rings, take care not to damage them as they pass over

sharp edges of splines, threads, etc. Be sure that the O-rings are not twisted in the groove

when installing.

All O-rings and sealing lips should be lubricated with a suitable lubricant before fitting,

e.g. soap and water or silicone spray.

For O-rings made of PTFE, it is advised to heat them up in hot water before placement.

A warmed up O-ring becomes softer, thus easier to install. Be aware of that PTFE has

no thermal memory.

11.3 Shutdown

Before starting the maintenance or inspection, follow the next steps to shut down the pump.

1. Stop the pump. To prevent the motor from starting while you are working on the

pump follow the procedure below:

• Turn off the pump at the electrical cabinet.

• Set the pump circuit breaker to off.

• Switch off and lock the operating switch.

• Remove the fuse.

• Sign the electrical cabinet “danger”.

10

2. Remove, if necessary, the protection around the shaft coupling when the pump

has stopped completely.

3. Let the pump cool down to ambient temperature.

IM-AS/02.00 GB (0412)

Page 13

4. Isolate and depressurize flushing/quench system.

5. Close the inlet and discharge valves.

6. Drain and purge the pump casing and pipe work.

7. Clean the pump externally before disassembly.

11.4 Disassembly

11.4.1 Removal of pump casing and impeller – AS 40, 50, 60, 65 and 80

See sectional drawings AS40 page 18, AS 50 page 19

1. Remove the mechanical seal flushing pipes 71 on V and Q executions.

2. Remove the shroud (44) with screws (46) (if shroud is assembled).

3. Loosen screws (28) to remove the motor (50).

4. Gently pull the motor (50) away from the bearing housing (5).

5. Motor sizes up to IEC 112. If necessary remove the adjustable foot frame by

loosening the two nuts (30) and the screws (29).

6. Motor sizes larger than IEC 112. If necessary remove the adjustable foot

frame by loosening the screws (29) to remove the front foot (20), and the rear

foots (23).

7. Loosen and remove the casing clamp (9).

8. Remove the casing cover (2).

9. Unscrew the impeller nut (10) anti-clockwise and slide off the impeller (3).

10. Remove the impeller key (11).

11. Remove the clearance shims (19).

11.4.2 Removal of pump casing and impeller – AS 42 and AS 52

See sectional drawings AS 42 page 23 and AS 52 page 24

1. Remove the mechanical seal flushing pipes 71 on V and Q executions.

2. Remove the shroud (44) with screws (46) (if shroud is assembled).

3. Loosen the screws (28) to remove the motor (50).

4. Gently pull the motor (50) away from the bearing housing (5).

5. Motor sizes up to IEC 112. If necessary remove the adjustable foot frame by

loosening the two nuts (30) and the socket head screw (29).

6. Motor sizes larger than IEC 112. If necessary remove the adjustable foot

frame by loosening the socket head screw (29) to remove front foot (20), and

the rear foots (23).

7. Loosen and remove the rag bolt (38).

8. Remove the casing cover (2).

9. Remove the first impeller (3) as well as the impeller key (11).

10. Remove the inter-discharge casing (35) and the intersuction casing (34).

11. Remove the second impeller (3) as well as the impeller key (11).

IM-AS/02.00 GB (0412)

11

Page 14

11.4.3 Seal disassembly

11.4.3.1 T execution

1. AS 42 and AS 52 only. Push back the ring retainer (31) to remove the circlip (32)

from the shaft (4).

2. Remove the rotating seal half by turning the spring clockwise and at the same

time pull the spring and the seal over the shaft end. If necessary use a pair of pliers.

3. Loosen the screws (26).

4. Slowly remove the pump casing (1) from the bearing housing (5).

5. Remove the stationary seal part from its seat in the pump casing (1).

Pull off the thrower (14).

11.4.3.2 V execution

1. AS 42 and AS 52 only. Push back the ring retainer (31) to remove the circlip (32)

from the shaft (4).

2. Remove the rotating seal half by turning the spring clockwise and at the same

time pull the spring and the seal over the shaft end. If necessary use a pair of pliers.

3. Loosen the screws (26).

4. Slowly remove the pump casing (1) from the bearing housing (5).

5. Loosen the stud bolt (68)

6. Gently pull off the mechanical seal cover (65) from the pump casing (1).

7. Remove the radial seal (66) from the mechanical seal cover (65 )

11.4.3.3 Q execution

1. AS 40, 42, 60-65, 80. Loosen and remove the stud bolts (68)

AS 50, 52 on the stud bolts (62).

1. Separate the mechanical seal cover (60) from the pump casing (1) by pushing it

backwards.

2. Loosen the screws (26).

3. Pull the pump casing (1) gently from the bearing housing (5).

4. Remove the primary stationary seal from the rear of the pump casing (1).

5. Loosen the grub screws on the rotating seal

6. Slide off the rotating seals along the shaft (4).

7. Remove the mechanical seal cover (60) by gently pulling it over the shaft (4).

8. Push out the secondary stationary seal from the mechanical seal cover (60).

9. Remove the O-ring (61).

10. Pull off the thrower (14).

12

IM-AS/02.00 GB (0412)

Page 15

11.4.4 Bearing removal

1. Remove shroud adapter (43) (if assembled) by loosening the screws (45).

2. Unscrew the screws (27).

3. Remove the bearing cover (8).

4. Press out the shaft and bearing assembly from the bearing housing (5).

5. Unscrew the ring nut (17).

Press out the shaft (4) from the bearing (7).

11.5 Assembly

Remark: It is recommended to pre-assemble the pump without the seal. Shim the pump

according to the clearance table to obtain the correct impeller clearance, and thereafter

assemble the pump with seal.

Exception: AS 42 and AS 52 (two stage pumps) which have floating impellers (shim free).

11.5.1 Clearances

Defined clearances for AS – range to be shimmed

•A= Behind impeller, Clearance between Impeller and Pump casing

• B= Front of impeller, Clearance between Impeller and Cover

• C= Clearance between, Pump Casing and Cover

To remember:

C clearance is machined, B will be given depending on the shims put under A, Behind

impeller, should be correct

If problems occur concentrate on the A clearance it is the most important, if there will

be a deviation make sure that it will be at B clearance

If it is other problems please contact Johnson pump or dealer for advice.

Pump clearances defined and shimmed

AS

pumps A B C

AS 40 0.15 15

AS 50 0.15 0.15 2.85

AS60-65 0.2 0.2 2.80

AS 80 0.3 0.3 4.20

C

B

IM-AS/02.00 GB (0412)

A

13

Page 16

11.5.2 Pump assembly AS 40, 50, 60, 65

Before assembly read chapters 11.1 General Instructions and 11.2 O-rings and lip seals.

N.B. Make sure that all surfaces are clean and without damage. If necessary polish using

(600 degrees) emery cloth, lubricate all O-rings and contact surfaces with soap and water

or silicone spray.

1. Check the shaft condition – no tracks of wear etc. Clean it carefully.

2. Press the bearings (7) on to the shaft (4).

3. Assemble the ring nut (17) and tighten it.

4. Press the shaft (4) and bearing assembly into the bearing housing (5).

5. Assemble the bearing cover (8). Tighten it with the screws (27).

6. Push the thrower (14) on the shaft (4).

7. Assemble the shroud adapter (43) (if shroud should be assembled) with

screws (46).

11.5.3 Seal assembly

11.5.3.1 T execution

1. Insert the stationary seal part into the pump casing (1) by gently pushing it.

2. Assemble the pump casing (1) together with the bearing housing (5). Be careful

with the seal when sliding it over the shaft. Tighten the pump casing with the screws

(26).

3. Fit the rotating part of the seal on the shaft (4).

4. N.B. Assemble the mechanical seal carefully to avoid damages on the seal faces and

O-rings..

5. AS 42 and AS 52 only. Fit the ring retainer (31) on the shaft (4). Compress the spring

on the rotating seal with the ring retainer and lock it with the circlip (32).

11.5.3.2 V execution

1. Press the radial seal (66) into the mechanical seal cover (65).

2. Fasten the stud bolt (68) on the pump casing (1).

3. Slide the mechanical seal cover (65) on the stud bolts (68) and tighten

them.

4. Insert the stationary seal part into the pump casing (1) by gently pushing it.

5. Assemble the pump casing (1) together with the bearing housing (5). Be

careful not to damage the radial seal (66). Tighten the pump casing with screws

(26).

6. Fit the rotating part of the seal on the shaft (4).

N.B. Assemble the mechanical seal carefully to avoid damages on the seal

faces and O-rings.

7. AS 42 and AS 52 only. Fit the ring retainer (31) on the shaft (4). Compress the spring

on the rotating seal with the ring retainer and lock it with the circlip (32).

14

IM-AS/02.00 GB (0412)

Page 17

11.5.3.3 Q execution

1. Position the O-ring (61) on the mechanical seal cover (60).

2. Position the secondary stationary seal in the mechanical seal cover (60) and hexhead screws (62).

3. Slide the mechanical seal cover (60) onto the shaft (4) and position it on the back

end of the shaft.

4. Gently slide the rotating seals onto the shaft (4).

5. Check the “A” length as it is essential for an

equal working load on both seal faces,

A measures as follows:

•AS 40 = 16.0mm

•AS 50 = 17.5mm

•AS 60 = 15.5mm

•AS 65 = 15.5mm

•AS 80 = 19.5 mm

6. Tighten the grub screws on the rotating seal.

7. Fit the primary stationary seal part in the

back of the pump casing (1).

8. Assemble the pump casing (1) onto the

bearing housing (5). Be careful not to damage the seal. Tighten with the screws (26).

A

9. Fit the mechanical seal cover (60) together with the pump casing (1) and lock it

with the (62).

11.5.4 Assembly of pump casing and impeller assembly – AS 40, AS 50, AS 60, AS 65 and AS 80

1. Fit the correct clearance shims (19) (adjusted from pre-fitting)

2. Fit the impeller key (11) and push on the impeller (3).

3. Fit the O-ring (16) in the impeller nut (10) and tighten the impeller (3).

4. Assemble the O-ring (13) in the pump casing (1) groove.

5. Assemble the cover casing (2) and lock it with the casing clamp (9).

6. Motors up to size IEC 112. Fit the adjustable foot frame and lock it with the nuts

(30) and the screws (29).

7. Motor sizes larger than IEC 112. Fit the adjustable foot frame and fasten the screws

(29) for the front foot (20) and the rear foots (23).

8. Assemble the motor (50) by entering the motor shaft into the pump shaft (4) and

lock it with the screws (28).

9. Slide the shroud (44) over the motor (50) and assemble it on the adapter (43) with

the screws (46)

10. ‘‘V’’ and ‘‘Q’’ executions. Assemble the mechanical seal flushing pipes (71 and 71

respectively) on the mechanical seal cover ( 65 and 60 respectively).

IM-AS/02.00 GB (0412)

15

Page 18

11.5.5 Pump cover and Impeller assembly – AS 42 and AS 52

See drawing

1. Fit the first impeller key (11) and push on the impeller (3) on the shaft (4).

2. Fit the O-ring in the pump casing (1) groove and assemble the inter-suction casing

(34).

3. Fit the O-ring (36) in the inter-suction casing (34) and assemble the inter-discharge

casing (35).

4. Fit the second impeller key (11) and push on the impeller (3) on the shaft (4)

5. Fit the O-ring (36) in the inter-discharge casing (35). Assemble the cover casing (2)

with the rag bolts (38).

6. Motors up to size IEC 112. Fit the adjustable foot frame and lock it with the nuts

(30) and the screws (29).

7. Motor sizes larger than IEC 112 or. Fit the adjustable foot frame and fasten the

screws (29) for the front foot (20) and the rear foots (23).

8. Assemble the motor (50) by entering the motor shaft into the pump

shaft (4) and lock it with the screws (28)

9. Slide the shroud (44) over the motor (50) and assemble it on the adapter (43) with

the screws (46)

10. ‘‘V’’ and ‘‘Q’’ executions. Assemble the mechanical seal flushing pipes (71 and 71

respectively) on the mechanical seal cover ( 65 and 60 respectively).

16

IM-AS/02.00 GB (0412)

Page 19

12.0 Spare parts lists and sectional drawings

12.1 Spare part list AS 40, 50, 60-65, 80

Pos Qty Description Material

11Casing, pump CF-3M / 1.4409

1 Q 1 Casing, pump Q-execution CF-3M / 1.4409

1 V 1 Casing, pump V-execution CF-3M / 1.4409

21Cover, casing CF-3M / 1.4409

31Impeller CF-3M / 1.4409

41Shaft AISI 316 L / 1.4404

4 V 1 Shaft V-execution AISI 316 L / 1.4404

51Housing, bearing Cast iron 25 + 3%Ni

61Mechanical seal 6 Q 1 Mechanical seal, Q-execution -

71Bearing Steel

81Bearing cover Aluminum 2011

91Clamp, casing AISI 304 / 1.4301

10 1 Nut, impeller AISI 316 L / 1.4404

11 1 Key, impeller AISI 316 / 1.4401

12 1 Pin AISI 304 / 1.4301

13 1 O-ring EPDM

14 1 Thrower NBR

15 1 Shaft plug NBR

16 1 O-ring EPDM

17 1 Nut, ring Galvanized iron

18 1 Grease nipple Galvanized iron

19 2 Shim AISI 316 L / 1.4404

20 1 Foot, front CF-8 / 1.4308

21 2 Foot, adjustable AISI 304 / 1.4301

23 1 Foot, rear CF-8 / 1.4308 - AISI 304 / 1.4301

25 1 Foot, adjustable AISI 304 / 1.4301

26 4 Screw, socket head AISI 304 / 1.4301

27 3 Screw, socket head AISI 304 / 1.4301

28 4 Screw, hex-head Steel

29 2 Screw, socket head AISI 304 / 1.4301

30 2 Nut AISI 304 / 1.4301

33 1 Gaco-ring NBR

40 2 Lantern guard AISI 304 / 1.4301

43 1 Shroud, adapter AISI 304 / 1.4301

44 1 Shroud AISI 304 / 1.4301

45 3 Screw, hex-hollow AISI 304 / 1.4301

46 3 Screw, flat head AISI 304 / 1.4301

50 1 Motor-electric 60 Q 1 Mechanical seal cover Q-execution AISI 304 / 1.4301

61 Q 1 O-ring Q-execution NBR

62 Q 2 Screw, hex-head Q-execution AISI 304 / 1.4301

65 V 1 Mechanical seal cover V-execution AISI 304 / 1.4301

66 V 1 Seal, radial shaft V-execution 68 Q 2 Stud bolt Q-execution AISI 304 / 1.4301

68 V 2 Stud bolt V-execution AISI 304 / 1.4301

70 V 1 O-ring V-execution NBR

71 Q 2 Mechanical seal flushing pipe Q-execution AISI 304 / 1.4301

71 V 2 Mechanical seal flushing pipe V-execution AISI 304 / 1.4301

85 V 1 Ceramic hardened bush V-execution AISI 304 / 1.4301

86 V 1 O-ring V-execution NBR

87 V 3 Dowel V-execution AISI 304 / 1.4301

IM-AS/02.00 GB (0412)

17

Page 20

12.2 AS 40 – Execution T, Q, V

Execution T

44

50 17 8 26 45 46 43 15 4 1 6 12 11 10 2

20 27 25 28 5 7 14 29 21 30 19 13 9 3 16

Execution Q

60 Q

61 Q 6 Q 1 Q

71 Q

68 Q

Execution V

66 V

71 V 70 V

65 V 68 V 1 V 4 V

18

IM-AS/02.00 GB (0412)

Page 21

12.3 AS 50 – Execution T, Q, V

Execution T

44

50 17 7 26 45 46 43 15 14 6 19

1121116 2

23 25 8 27 28 5 4 30 29 20 21 3 13 9 10

Execution Q Execution V

1 V

62 Q

60 Q 6 Q 1 Q

61 Q

71 Q

66 V

4 V 70 V 68 V

71 V

65 V

IM-AS/02.00 GB (0412)

19

Page 22

12.4 AS 60-65 – Execution T, Q, V

Execution T

44

50 17 7 28 45 46 43 15 14 1 6 12 16 2

25 23

Execution Q

60 Q

71 Q

23 25 8 27 26 5 4 30 29 20 21 19 3 13 9 11 10

Execution V

1 Q

66 V

71 V 1 V

20

61 Q 68 Q 6 Q

65 V 70 V 4 V 68 V

IM-AS/02.00 GB (0412)

Page 23

12.5 AS 80 – Execution T, Q, V

87 V

86 V 71 V 70 V 1 V

85 V 66 V 65 V 68 V

Execution T

50 8 26 5 45 46 43 15 14 40 1 6 9 12 4

44

16

2

23 25 17 27 28 7 18 33 30 29 20 21 3 19 13 11 10

Execution Q

61 Q

71 Q 6 Q 1 Q

60 Q 68 Q

Execution V

IM-AS/02.00 GB (0412)

21

Page 24

12.6 Spare part list AS 42, 52

Pos. Q.ty Denomination Material

11 Casing, pump CF-3M / 1.4409

1 Q 1 Casing, pump Q-execution CF-3M / 1.4409

1 V 1 Casing, pump V-execution CF-3M / 1.4409

21 Cover, casing CF-3M / 1.4409

32 Impeller CF-3M / 1.4409

41 Shaft AISI 316 L / 1.4404

4 V 1 Shaft V-execution AISI 316 L / 1.4404

51 Housing, bearing Cast iron 25 + 3%Ni

61 Mechanical seal 6 Q 1 Mechanical seal, Q-execution 71 Bearing Steel

81 Bearing cover Aluminum 2011

11 2 Key, impeller AISI 316 / 1.4401

13 1 O-ring EPDM

14 1 Thrower NBR

15 1 Shaft plug NBR

17 1 Nut, ring Galvanized iron

20 1 Foot, front CF-8 / 1.4308

21 2 Foot, adjustable AISI 304 / 1.4301

23 1/2 Foot, rear CF-8 / 1.4308 - AISI 304 / 1.4301

25 1/2 Foot, adjustable AISI 304 / 1.4301

26 4 Screw, socket head AISI 304 / 1.4301

27 3 Screw, socket head AISI 304 / 1.4301

28 4 Screw, hex-head Steel

29 2 Screw, socket head AISI 304 / 1.4301

30 2 Nut AISI 304 / 1.4301

31 1 Ring retainer AISI 316 L / 1.4404

32 1 Circlip AISI 304 / 1.4301

34 1 Inter-suction casing CF-3M / 1.4409

35 1 Inter-discharge casing CF-3M / 1.4409

36 2 O-ring EPDM

38 2 Rag bolt AISI 304 / 1.4301

39 2 Rag bolt pin AISI 304 / 1.4301

43 1 Shroud, adapter AISI 304 / 1.4301

44 1 Shroud AISI 304 / 1.4301

45 3 Screw, hex-hollow AISI 304 / 1.4301

46 3 Screw, flat head AISI 304 / 1.4301

50 1 Motor-electric 60 Q 1 Mechanical seal cover Q-execution AISI 304 / 1.4301

61 Q 1 O-ring Q-execution NBR

62 Q 2 Screw, hex-head Q-execution AISI 304 / 1.4301

65 V 1 Mechanical seal cover V-execution AISI 304 / 1.4301

66 V 1 Seal, radial shaft V-execution 68 Q 2 Stud bolt Q-execution AISI 304 / 1.4301

68 V 2 Stud bolt V-execution AISI 304 / 1.4301

70 V 1 O-ring V-execution NBR

71 Q 2 Mechanical seal flushing pipe Q-execution AISI 304 / 1.4301

71 V 2 Mechanical seal flushing pipe V-execution AISI 304 / 1.4301

22

IM-AS/02.00 GB (0412)

Page 25

12.7 AS 42 – Execution T, Q, V

Execution T

50

17 8 7 26

45

46 43 15 14

6

1

13

34

36 3 11 2

35

44

25

Execution Q

60 Q

71 Q

61 Q

23 28 27

6 Q 1 Q

68 Q

29 21

5

20 30

31 32 4

38

39

Execution V

66 V

65 V 68 V

71 V

70 V

1 V 4 V

IM-AS/02.00 GB (0412)

23

Page 26

12.8 AS 52 – Execution T, Q, V

Execution T

44

50 17

45

26

7

43 15 14 6 32

46

1

313

35 36 11 2

34

23 25 8 27 28 5 4 30 29 20 21 31 38

Execution Q

62 Q

60 Q

6 Q

1 Q

Execution V

66 V

71 V 65 V 1 V

39

24

61 Q 71 Q

4 V 70 V 68 V

IM-AS/02.00 GB (0412)

Page 27

13.0 Dimensions and weights

13.1 AS 40-50-60-65-80 with shroud 1450 rpm

K

GF

DN

A

DN

J

I1

I

Y

H

BC

C1

E1

E

L1

L

Pumps kW DN A B C C1 E E1 F G K H J I I1 Y L L1 kg

1,1 40 238 168 - 190 - 222 143 438 581 160 110 305 297 195 178 - 29

AS 40

1,5 40 238 168 - 190 - 222 143 438 581 160 110 305 297 195 178 - 31

2,2 40 298 169 - 301 - 179 143 506 649 190 110 335 354 225 225 - 45

AS 50

AS 60

AS 65

AS 80

2,2 50 298 196 - 301 - 186 175 509 684 213 115 364 377 249 225 - 50

450298 196 - 301 - 186 175 509 684 213 115 364 377 249 225 - 59

465370 216 - 301 - 186 205 499 704 212 135 392 429 257 225 - 62,5

5,5 65 370 226 324 - 226 - 225 551 776 228 135 408 445 273 225 175 75

5,5 65 370 226 324 - 226 - 225 551 776 228 135 408 445 273 225 175 76,5

7,5 65 370 226 324 - 226 - 225 551 776 228 135 408 445 273 225 175 82,5

11 80 360 267 485 - 347 - 248 851 1099 230 158 446 520 288 225 220 129

15 80 360 267 485 - 347 - 248 851 1099 230 158 446 520 288 225 220 140

Dimensions not binding – DN = DIN 11851 male threaded connection – exec. with standard IEC/EN motors

13.2 AS 40-50-60-65-80 without shroud 1450 rpm

K

F

DN

G

A

DN

J

I

Y

H

Weight

Pumps kW DN A B C D E F G K H J I Y L M N O kg

1,1 40 200 296 100 9 22 143 380 523 90 110 235 125 140 - - - 26

AS 40

1,5 40 200 296 125 9 22 143 380 523 90 110 235 125 140 - - - 28

2,2 40 250 308 140 12 18 143 416 559 100 110 245 135 160 - - - 41

2,2 50 250 343 140 12 18 175 419 594 100 115 251 136 160 - - - 45

AS 50

AS 60

AS 65

AS 80

450250 351 140 12 18 175 441 616 112 115 263 148 190 - - - 54

465250 372 140 12 20 205 431 636 112 134 293 159 190 - - - 57

5,5 65 300 412 140 12 20 204 492 696 132 134 312 179 216 - - - 68

5,5 65 300 412 140 12 20 204 492 696 132 134 312 179 216 - - - 69,5

7,5 65 300 423 178 12 20 215 492 707 132 134 312 179 216 - - - 76

11 80 350 555 210 14 23 248 677 925 160 190 376 218 254 - - - 118

15 80 350 555 254 14 23 248 677 925 160 190 376 218 254 - - - 129

Dimensions not binding – DN = DIN 11851 male threaded connection – exec. with standard IEC/EN motors

IM-AS/02.00 GB (0412)

B

C

E

D

L

Weight

25

Page 28

13.3 AS 42-52 with shroud 1450 rpm

K

F

DN

B

G

C1 E1

CE

A

DN

J

I1

I

Y

H

L

L1

Weight

Pumps kW DN A B C C1 E E1 F G K H J I I1 Y L L1 kg

2,2 40 298 220 - 231 - 203 205 520 725 190 110 335 354 225 225 - 56

AS 42

340298 220 - 231 - 203 205 520 725 190 110 335 354 225 225 - 60

AS 52 5,5 50 370 258 292 - 267 - 237 580 817 230 115 381 417 266 225 - 85

Dimensions not binding – DN = DIN 11851 male threaded connection – exec. with standard IEC/EN motors

13.4 AS 42-52 with shroud 1450 rpm

K

F

DN

B

G

*

C

E

D

Pumps kW DN A B C D E F G K H J I Y L M N O kg

2,2 40 250 365 140 12 18 200 416 616 100 110 245 135 160 - - - 51

AS 42

340250 365 140 12 18 200 416 616 100 110 245 135 160 - - - 55

AS 52 5,5 50 300 454 140 12 20 237 502 739 132 115 283 168 216 - - - 77

Dimensions not binding – DN = DIN 11851 male threaded connection – exec. with standard IEC/EN motors

A

DN

H

L

Weight

J

I

Y

26

IM-AS/02.00 GB (0412)

Page 29

14.0 Trouble shooting chart

The pump does not prime

• Air has entered the suction piping; check the seals on the fittings and tighten them

sufficiently.

• Suction pipe not submerged in liquid.

• Clearances between impeller/cover and impeller/body have increased. Check and

correct.

• No liquid in the pump. Introduce liquid.

• Reduce loss of suction head; reduce the suction height.

• Formation of air pockets; eliminate and if necessary fit a valve on discharge.

No flow

• Pump not primed; (see point 8 and previous point).

• Pump turning in wrong direction.

• Suction port obstructed.

• On-off valves closed.

Insufficient flow

• Increased system back pressure on discharge side; increase piping diameter.

• Air entering mechanical seal; check its condition.

• Viscosity of fluid greater than that specified in the order. Contact manufacturer.

• Clearances between impeller/cover and impeller/body have increased. Check and

correct.

Loss of head

• Back pressure on discharge side has fallen; throttle the suction pipe.

• Clearances between impeller/cover and impeller/body have increased. Check and

correct.

Increase in absorbed power

• Flow rate is lower than required.

• Pump is turning at higher speed.

• The impeller does not turn freely. Check it.

• Viscosity and/or specific weight are higher than stated.

• Bearings are not in good condition.

Increase in absorbed current

• The power required has increased (see previous point).

• Main voltage value has fallen.

• There is a fault in the electrical system.

IM-AS/02.00 GB (0412)

27

Page 30

15.0 Disposal of the pump

For disposing the pump please observe the following instructions:

• Disconnect electrical and hydraulic connections according to technical rules and laws in

force.

• Disassemble all components of the pump for separate dismantling; wash the components

and clean the structure accurately.

The main components of the pump are made from the following materials:

• Pump casing, cover,

impeller, S.S. AISI 316L

shaft, impeller nut

• Elastomeres NBR, EPDM, Viton, Teflon

• Motor Aluminium, Cast iron, Copper

Components made from amianthus or lead are not used in our production.

The components of the pump should be properly disposed of, according to the corresponding

rules in force in receiver’s country.

}

28

IM-AS/02.00 GB (0412)

Page 31

Johnson Pump Industry Group

National Sales

Organisations

AUSTRALIA

Johnson Pump (Australia) Pty. Ltd.

Tel. +61 (0)7 3899 9933

Fax +61 (0)7 3899 8574

BELGIUM

Johnson Pump N.V./S.A.

Tel. +32 (0)2 422 15 50

Fax +32 (0)2 422 15 59

DENMARK

Johnson Pumper A/S

Tel. +45 43 52 24 00

Fax +45 43 52 15 77

FINLAND

Johnson Pump Oy

Tel. +358 (0)9 348 3800

Fax +358 (0)9 348 38495

FRANCE

Johnson Pompes

Tel. +33 (0)1 39 20 50 00

Fax +33 (0)1 39 56 54 22

GERMANY

Johnson Pumpen GmbH

Tel. +49 (0)5731 480 80

Fax +49 (0)5731 414 00

ITALY

Johnson Pump Italiana S.r.l.

Tel. +39 039 604 14 63

Fax +39 039 604 90 97

NETHERLANDS

Johnson Pump B.V.

Tel. +31 (0)592 37 67 67

Fax +31 (0)592 37 67 06

Johnson Pump Horticulture

Tel. +31 (0)174 51 84 10

Fax +31 (0)174 51 84 44

NORWAY

Johnson Pump Norway

Tel. +47 22 74 08 40

Fax +47 22 22 70 30

SPAIN

Johnson Pump España, S.L.

Tel. +34 972 58 08 01

Fax +34 972 58 08 03

Sales Office:

Madrid: Tel. +34 91 888 79 22

SWEDEN

Johnson Pump Svenska AB

Tel. +46 (0)19 21 83 70

Fax +46 (0)19 27 23 18

SWITZERLAND

Johnson Pumpen AG

Tel. +41 (0)43 477 71 22

Fax +41 (0)43 477 71 20

UNITED KINGDOM

JP Pumps Ltd.

Tel. +44 (0)1293 55 34 95

Fax +44 (0)1293 52 46 35

Northern Regional Office:

Bradford: Tel. +44 (0)1274 74 56 10

Fax +44 (0)1274 74 56 11

Business Units

BELGIUM

Johnson Pump Brussels N.V.

Tel. +32 (0)53 60 27 15

Fax +32 (0)53 60 27 01

INDIA

Johnson Pump (India) Ltd.

Tel. +91 (0)79 287 03 11

Fax +91 (0)79 287 25 22

NETHERLANDS

Johnson Pump Water B.V.

Tel. +31 (0)592 37 67 67

Fax +31 (0)592 37 67 60

SWEDEN

Johnson Pump Industry AB

Tel. +46 (0)19 21 83 00

Fax +46 (0)19 27 23 72

www.johnson-pump.com

Johnson Pump Industry AB

Nastagatan 19. P.O. Box 1436, SE-701 14 Örebro, Sweden. Tel. +46 (0)19 21 83 00. Fax +46 (0)19 27 23 72. E-mail: Industry.se@johnson-pump.com.

Web: www.johnson-pump.com

Loading...

Loading...