Johnson Controls TM9V100C20MP11, TM9V100C16MP11, TM9V080C16MP11, TM9V060B12MP11, TM9V080B12MP11 User Manual

...

QUICK REFERENCE GUIDE

96%TWO STAGE MULTI-POSITION RESIDENTAL

GAS FURNACES (33” TALL)

NOTES:

1.If the furnace is equipped with NOx screens and is to be used with LP (propane) gas, the screens must be removed prior to start-up.

2.Drip leg in the gas line must be installed.

3.The furnace controls require correct polarity on the power supply and a proper ground.

4.Y & G must be connected to the control board for cooling operation.

5.External filters are required on all configurations.

6.Electrical or gas entry is available on both casing sides.

7.To measure total static pressure, add supply duct pressure to the return duct pressure, add pressure drop across the ‘A’ coil, and add pressure drop across the filter. Ignore negative signs on the readings.

8.Inlet gas pressure should be 7” w.c. for natural gas and 11” w.c. for propane. Nominal manifold gas pressure is 3.5” w.c. for natural gas and 10” w.c. for propane at max. input.

9.For downflow application the vent blower must be rotated 90 left or right as shown.

|

Airflow CFM (Bottom Return without Filters) |

|

|

Minimum Wire |

|

Maximum |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

Models |

|

|

0.5" ESP (Nominal)† |

|

|

|

|

|

Size awg @ 75' |

|

Over Current |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

One-Way |

|

Protection |

|||

|

*D-A** |

|

*C-A** |

|

*B-A** |

|

*A-B** |

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TM9V060B12MP11 |

600 |

|

|

690 |

|

|

1000 |

|

1305 |

|

|

14 |

|

|

|

|

15 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TM9V080B12MP11 |

600 |

|

|

680 |

|

|

1000 |

|

1290 |

|

|

14 |

|

|

|

|

15 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TM9V080C16MP11 |

850 |

|

|

905 |

|

|

1175 |

|

1670 |

|

|

14 |

|

|

|

|

15 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TM9V100C16MP11 |

870 |

|

|

910 |

|

|

1160 |

|

1655 |

|

|

14 |

|

|

|

|

15 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TM9V100C20MP11 |

960 |

|

1155 |

|

|

1605 |

|

2215 |

|

|

12 |

|

|

|

|

20 |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TM9V120D20MP11 |

960 |

|

1160 |

|

|

1595 |

|

2180 |

|

|

12 |

|

|

|

|

20 |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Input |

|

Total Unit |

Air Temp. Rise |

|

Air Temp. Rise |

Time For 1 ft |

3 |

Natural Gas |

|||||||||||

Models |

Rate |

|

|

|

||||||||||||||||

|

|

Amps |

|

Max Input °F |

|

|

Min Input °F |

(1030 Btu/Ft3) Seconds |

||||||||||||

|

Max |

Min |

|

|

|

|

|

|

(On Max. Rate) |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

TM9V060B12MP11 |

60,000 |

21,000 |

|

|

9 |

|

|

|

35 - 65 |

|

|

35 - 65 |

|

62 |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

TM9V080B12MP11 |

80,000 |

28,000 |

|

|

9 |

|

|

|

35 - 65 |

|

|

30 - 60 |

|

46 |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

TM9V080C16MP11 |

80,000 |

28,000 |

|

|

12 |

|

|

35 - 65 |

|

|

35 - 65 |

|

46 |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

TM9V100C16MP11 |

100,000 |

35,000 |

|

|

12 |

|

|

35 - 65 |

|

|

30 - 60 |

|

37 |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

TM9V100C20MP11 |

100,000 |

35,000 |

|

|

14 |

|

|

35 - 65 |

|

|

35 - 65 |

|

37 |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

TM9V120D20MP11 |

120,000 |

42,000 |

|

|

14 |

|

|

35 - 65 |

|

|

35 - 65 |

|

31 |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

† Other airflows are available. see Tech Guide for all CFM options.

*Cool Tap.

**Adjustment Tap.

This document does not replace the installation instructions, which must be referred to for detailed information.

|

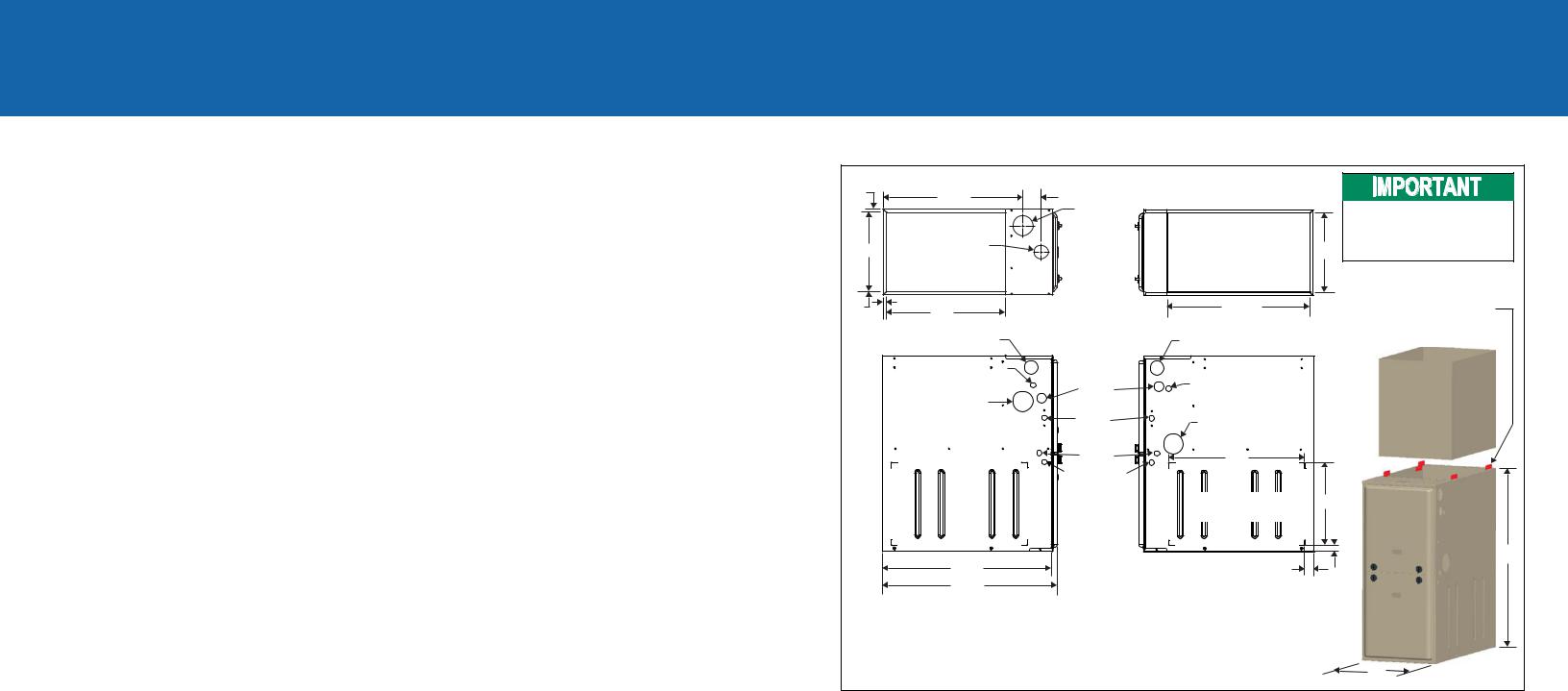

SUPPLY END |

|

2” Diameter |

RETURN END |

.56” |

|

|

|

|

23.8” |

3” |

Vent Connection |

|

|

|

|

|||

|

|

|

Outlet |

|

|

B |

Combustion |

|

|

|

Air Inlet |

|

|

|

|

|

|

|

|

.56” |

|

.56” |

|

24.25” |

|

20” |

|

||

|

|

|

|

|

|

|

Combustion Air Inlet |

|

Combustion Air Inlet |

|

|

Condensate Drain |

Gas Pipe |

|

|

|

(Downflow) |

Condensate Drain |

|

|

|

Entry |

||

|

|

|

(Downflow) |

|

|

|

Vent Connection |

|

|

|

|

Electrical |

|

|

|

|

Outlet |

|

|

|

|

Entry |

Vent Connection |

|

|

|

|

||

|

|

|

|

|

|

|

|

Condensate |

Outlet |

|

|

|

|

|

|

|

|

Drain |

23” |

|

|

|

Thermostat |

|

|

|

|

Wiring |

|

|

|

|

|

Optional Return Air |

|

|

|

|

Cutout (Either side) |

|

|

28.5” |

|

1.5” |

|

|

29.5” |

|

|

|

|

LEFT SIDE |

|

RIGHT SIDE |

Follow all national and local codes and standards in addition to this document. The installation must comply with regulations of the serving gas supplier, local building, heating, plumbing, and other codes. In absence of local codes, the installation must comply with national codes and all authorities having jurisdiction.

DURING INSTALLATION, DOORS MUST REMAIN ON FURNACE WHEN MOVING

BOR LIFTING.

Clips can be flipped into the up position for coil cabinet or plenum attachment

A-COIL

14”

1”

1”

33”

AFRONT

LED INDICATOR

Slow Green Flash - Normal operation in standby mode. Slow Amber Flash - Normal operation with call for cooling. Two Amber Flashes - Normal operation with call for heat.

Three Amber Flashes - Normal operation, burner is on at end of thermostat cycle.

Six Amber Flashes - Normal operation with call for heat pump heating.

Any Red Flash - Fault condition. NOTE: 4 or 5 flashes may indicate a blown fuse on the circuit board.

Subject to change without notice. Printed in U.S.A. |

*438336* |

438336-URG-A-0209 |

|

Copyright © 2009 by Johnson Controls, Inc. All rights reserved. |

Supersedes: Nothing |

||

|

|||

|

|

|

Johnson Controls Unitary Products

5005 York Drive

Norman, OK 73069

CLEARANCES

Application |

Upflow |

Downflow |

Horizontal |

Top |

1" |

0" |

0" |

|

|

|

|

Vent |

0" |

0" |

0" |

|

|

|

|

Rear |

0" |

0" |

0" |

|

|

|

|

Side |

0" |

0" |

1" |

|

|

|

|

Front* |

0" |

0" |

0" |

|

|

|

|

Floor |

Combustible |

Combustible1 |

Combustible |

Closet |

Yes |

Yes |

Yes |

|

|

|

|

Line Contact |

No |

No |

Yes |

|

|

|

|

1. For combustible floors only when used with special sub-base.

*24" clearance in front and 18" on side recommended for service access.

All furnaces approved for alcove and attic installation.

DIMENSIONS

Cabinet Size |

A (in) |

B (in) |

All 'B' Cabinet Furnaces |

17-1/2" |

16-3/8" |

|

|

|

All 'C' Cabinet Furnaces |

21" |

19-7/8" |

|

|

|

All 'D' Cabinet Furnaces |

24-1/2" |

23-3/8" |

|

|

|

Loading...

Loading...