Page 1

TEC3000 Color Series Field-Selectable

BACnet MS/TP or N2 Networked and

Wireless Thermostat Controllers Technical

Bulletin

www.johnsoncontrols.com

2021-01-21

LIT-12013267

Page 2

2 TEC3000 Color Series Field-Selectable BACnet MS/TP or N2 Networked and Wireless Thermostat Controllers

Technical Bulletin

Page 3

Contents

Contents

Introduction.................................................................................................................................................... 5

Product overview............................................................................................................................................ 5

Proportional Fan Coil and Individual Zone Thermostat Controllers............................................. 5

On/Off or Floating Fan Coil and Individual Zone Thermostat Controllers................................... 6

Single- or Two-Stage RTU/Heat Pump with Economizer Thermostat Controllers...................... 7

Model names and code numbers...................................................................................................... 8

Determining correct pairing of CPU Board and Base Board................................................................ 8

Wireless TEC3000 networks.......................................................................................................................... 9

Configuring a wired TEC3000 for MS/TP or N2 bus................................................................................... 9

Wiring the network.............................................................................................................................. 9

End-of-Line termination.................................................................................................................... 10

Setting the network parameters..................................................................................................... 10

Connecting the MS/TP or N2 bus.................................................................................................... 11

MS/TP or N2 thermostat controller mapping................................................................................ 12

Preparation............................................................................................................................................... 12

Adding a thermostat controller............................................................................................................. 12

Adding BACnet MS/TP points................................................................................................................. 12

Adding N2 points..................................................................................................................................... 13

MS/TP or N2 bus points tables................................................................................................................... 13

Thermostat controllers..................................................................................................................... 13

Scheduling..................................................................................................................................................... 37

Commanding objects from a supervisory controller............................................................................... 39

User lockout....................................................................................................................................... 40

Menu and submenu descriptions.............................................................................................................. 40

Setpoints............................................................................................................................................. 40

Dehumidification...................................................................................................................................... 41

Temperature............................................................................................................................................. 42

Schedule Options............................................................................................................................... 43

Display Settings................................................................................................................................. 43

Setup................................................................................................................................................... 44

General...................................................................................................................................................... 44

Input.......................................................................................................................................................... 47

Tuning........................................................................................................................................................ 48

Network Setup (present in TEC30xx-1x-000, TEC36xx-1x-000, and TEC31xx-14-000

models)...................................................................................................................................... 49

Equipment Setup............................................................................................................................... 49

General (Equipment Setup).................................................................................................................... 49

Supply Fan................................................................................................................................................. 50

Reheat........................................................................................................................................................ 51

Economizer............................................................................................................................................... 51

Heat Pump................................................................................................................................................ 51

TEC3000 Color Series Field-Selectable BACnet MS/TP or N2 Networked and Wireless Thermostat Controllers

Technical Bulletin

3

Page 4

Changeover............................................................................................................................................... 52

Commissioning......................................................................................................................................... 52

Trend.......................................................................................................................................................... 52

Status.................................................................................................................................................. 53

System Status........................................................................................................................................... 53

Control Status........................................................................................................................................... 53

Controller Info.......................................................................................................................................... 54

Comms Status (wireless TECs only)....................................................................................................... 54

Update................................................................................................................................................ 54

BAS Only Points........................................................................................................................................ 54

Troubleshooting........................................................................................................................................... 56

Related documentation............................................................................................................................... 61

Product warranty......................................................................................................................................... 62

Software terms............................................................................................................................................. 62

Patents........................................................................................................................................................... 62

Single point of contact................................................................................................................................. 62

Contact information..................................................................................................................................... 62

4

TEC3000 Color Series Field-Selectable BACnet MS/TP or N2 Networked and Wireless Thermostat Controllers

Technical Bulletin

Page 5

Introduction

This document describes how to configure the various wireless and wired TEC3000 Series

Thermostat Controllers for BACnet MS/TP or N2 networked applications, including how to:

• Connect to the MS/TP or N2 bus and map a thermostat controller into a Network Automation

Engine (NAE)

• Add a thermostat controller

• Add points

• Command and configure from an NAE

• Troubleshoot the thermostat controller

Product overview

The technologically advanced TEC3000 Series Thermostat Controllers feature a Building Automation

System (BAS) BACnet MS/TP or N2 connectivity that enables remote monitoring and programming

for efficient space temperature control. The TEC3000 Series Thermostat Controllers feature an

intuitive user interface with backlit color display that makes setup and operation quick and easy.

The programming memory of all TEC3000 Series Thermostat Controllers is non-volatile.

In addition, the configuration can be backed up to a USB drive and restored to like models to

help expedite the commissioning process. Refer to the TEC3000 Series On/Off or Floating Fan Coil

Thermostats Installation Guide (LIT-12013161), TEC3000 Series Proportional Fan Coil Thermostats

Installation Guide (LIT-12013162), or TEC3000 Series Networked and Wireless Single- or Two-Stage

Economizer Thermostat Controllers Installation Guide (LIT-12013163) for information on using the USB

drive.

The TEC3000 Series Thermostat Controllers are BACnet MS/TP, N2, or ZFR Wireless networked

devices that provide control of:

• Rooftop units (with or without economizers, dehumidification, or hot gas bypass)

• Heat pumps

• Single- and multi-stage heating and cooling equipment

• Humidification and dehumidification equipment

• Two- or four-pipe fan coils

• Cabinet unit heaters

• Local hydronic reheat valves

• Pressure-dependent Variable Air Volume (VAV) equipment with or without local reheat

• Other individual zone equipment using an on/off, floating, or proportional 0 VDC to 10 VDC

control input

Proportional Fan Coil and Individual Zone Thermostat Controllers

The TEC3000 Series Proportional Fan Coil and Individual Zone Thermostat Controllers are fieldselectable BACnet MS/TP, N2, or ZFR Wireless networked devices that provide control of:

• Local hydronic reheat valves

• Pressure-dependent VAV equipment with or without local reheat

Technical Bulletin

5TEC3000 Color Series Field-Selectable BACnet MS/TP or N2 Networked and Wireless Thermostat Controllers

Page 6

• Two- or four-pipe fan coils

• Cabinet unit heaters

• Other individual zone equipment using a proportional 0 VDC to 10 VDC control input

The networked models feature a BAS BACnet MS/TP, N2, or ZFR Wireless communication capability

that enables remote monitoring and programming for efficient space temperature control.

Some models have occupancy-sensing capability built into the device. These thermostat controllers

maximize up to 30% energy savings in high-energy usage, light commercial buildings, such as

schools and hotels. Savings occur during occupied times by using additional standby setpoints

when occupants are not in the room.

All models feature an intuitive UI with backlit display that makes setup and operation quick and

easy. Multiple fan configurations are supported for all equipment types.

• Single-speed

• Multi-speed (two or three discrete speeds)

• Variable-speed/EC motors (0 VDC to 10 VDC control)

All models contain a built-in humidity sensor to support dehumidification on two-pipe fan coil units

with reheat and four-pipe fan coil units with individual coils or single coil with heating and cooling

valves installed. When no heating is required, the thermostat controller monitors space humidity

and activates dehumidification control as necessary. Heat, reheat, or both are used as required to

prevent over-cooling while achieving humidity setpoint and maintain the space temperature. For

optimal dehumidification performance, use a fan coil unit that has a multi-speed or variable-speed

fan.

On/Off or Floating Fan Coil and Individual Zone Thermostat Controllers

The TEC3000 Series On/Off or Floating Fan Coil and Individual Zone Thermostat Controllers are

field-selectable BACnet MS/TP, N2, or ZFR Wireless networked devices that provide control of:

• Local hydronic reheat valves

• Pressure-dependent VAV equipment with or without local reheat

• Two- or four-pipe fan coils

• Cabinet unit heaters

• Other individual zone equipment using an on/off or floating control input

The networked models feature a BAS BACnet MS/TP, N2, or ZFR Wireless communication capability

that enables remote monitoring and programming for efficient space temperature control.

Some models have occupancy sensing capability built into the device. These thermostat controllers

maximize up to 30% energy savings in high-energy usage, light commercial buildings, such as

schools and hotels. Savings occur during occupied times by using additional standby setpoints.

All models feature a UI with backlit color display that makes setup and operation quick and easy.

Multiple fan configurations are supported for all equipment types.

• Single-speed

• Multi-speed (two or three discrete speeds)

• Variable-speed/EC motors (0 VDC to 10 VDC control)

All models contain a built-in humidity sensor to support dehumidification on two-pipe fan coil units

with reheat and four-pipe fan coil units with individual coils or single coil with heating and cooling

6

TEC3000 Color Series Field-Selectable BACnet MS/TP or N2 Networked and Wireless Thermostat Controllers

Technical Bulletin

Page 7

valves installed. When no heating is required, the thermostat controller monitors space humidity

and activates dehumidification control as necessary. Heat, reheat, or both are used as required to

prevent over-cooling while achieving humidity setpoint and maintain the space temperature. For

optimal dehumidification performance, use a fan coil unit with a multi-speed or variable-speed fan.

Single- or Two-Stage RTU/Heat Pump with Economizer Thermostat Controllers

The TEC3000 Series Single- or Two-Stage Economizer Thermostat Controllers are field-selectable

BACnet MS/TP, N2, or ZFR Wireless networked devices that provide control of:

• Unitary rooftop units (RTUs)

• Unitary RTUs with economizers

• Unitary RTUs with heat pumps

• Unitary RTUs with economizers and heat pumps

• Unitary RTUs with hot gas reheat

• Unitary RTUs with hot gas reheat and economizers

The networked models feature a BAS BACnet MS/TP, N2, or ZFR Wireless communication capability

that enables remote monitoring and programming for efficient space temperature control.

Some models have occupancy sensing capability built into the device. These thermostat controllers

maximize up to 30% energy savings in high-energy usage, light commercial buildings, such as

schools and hotels. Savings occur during occupied times by using additional standby setpoints.

All models feature an intuitive UI with backlit color display that makes setup and operation quick

and easy. Only the single-speed fan configuration is supported for RTU equipment types.

All models contain a build-in humidity sensor to support dehumidification on RTUs with hot gas

reheat and RTUs with auxiliary dehumidifier installed. When no heating is required, the thermostat

controller monitors the space humidity and activates dehumidification control as necessary. The

controller uses heat, reheat, or both as required to prevent over-cooling while it achieves the

humidity setpoint and maintains the space temperature.

Technical Bulletin

7TEC3000 Color Series Field-Selectable BACnet MS/TP or N2 Networked and Wireless Thermostat Controllers

Page 8

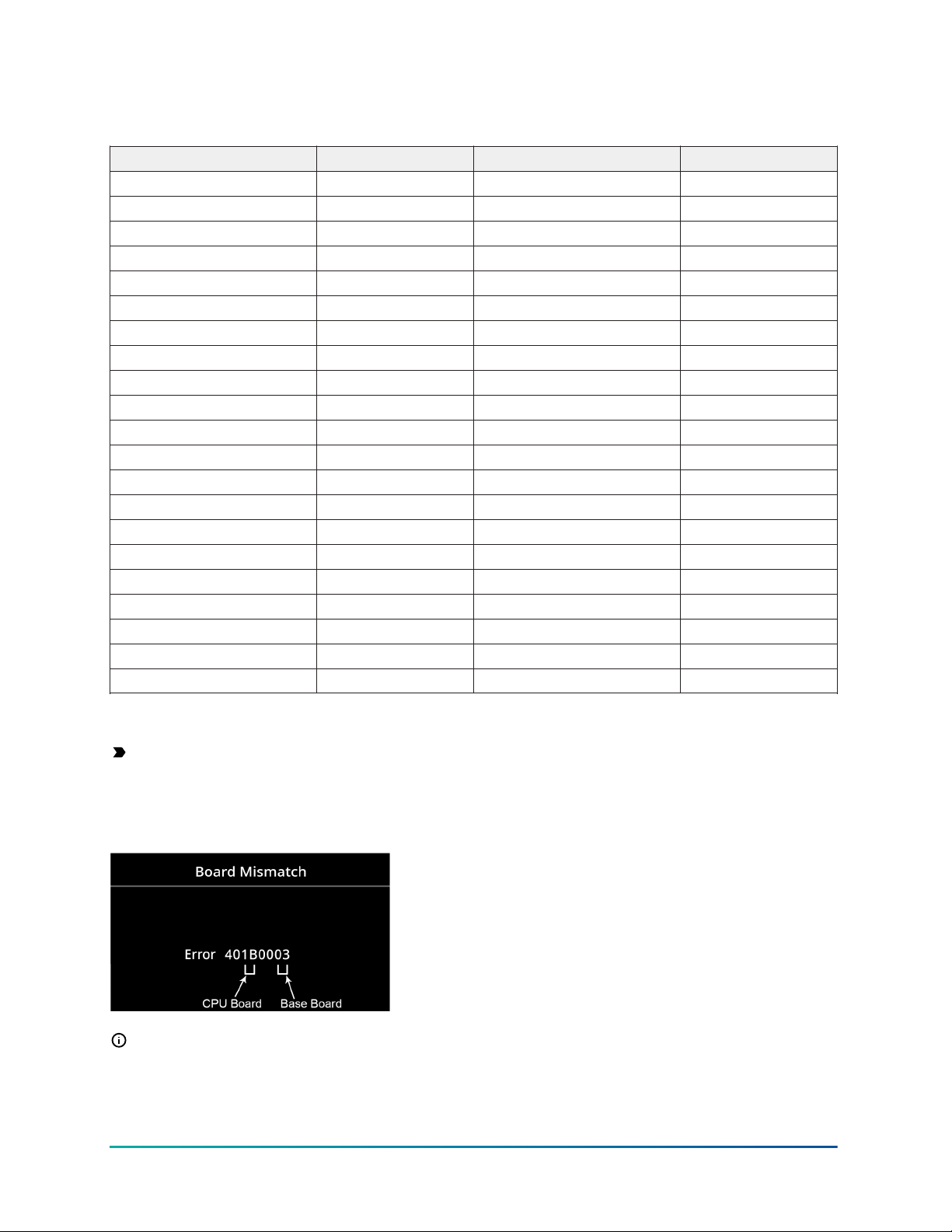

Model names and code numbers

Table 1: TEC3000 model names and code numbers

Name Code number Name Code number

TEC3012-13 30 TEC3313-14 05

TEC3012-14 31 TEC3322-13 08

TEC3012-16 33 TEC3322-14 09

TEC3013-14 35 TEC3322-16 0B

TEC3022-13 38 TEC3323-14 0D

TEC3022-14 39 TEC3330-13 10

TEC3022-16 3B TEC3330-14 11

TEC3023-14 3D TEC3330-16 13

TEC3030-13 40 TEC3331-14 15

TEC3030-14 41 TEC3612-13 18

TEC3030-16 43 TEC3612-14 19

TEC3031-14 45 TEC3612-16 1B

TEC3112-14 49 TEC3613-14 1D

TEC3113-14 4D TEC3622-13 20

TEC3122-14 51 TEC3622-14 21

TEC3123-14 55 TEC3622-16 23

TEC3130-14 59 TEC3623-14 25

TEC3131-14 5D TEC3630-13 28

TEC3312-13 00 TEC3630-14 29

TEC3312-14 01 TEC3630-16 2B

TEC3312-16 03 TEC3631-14 2D

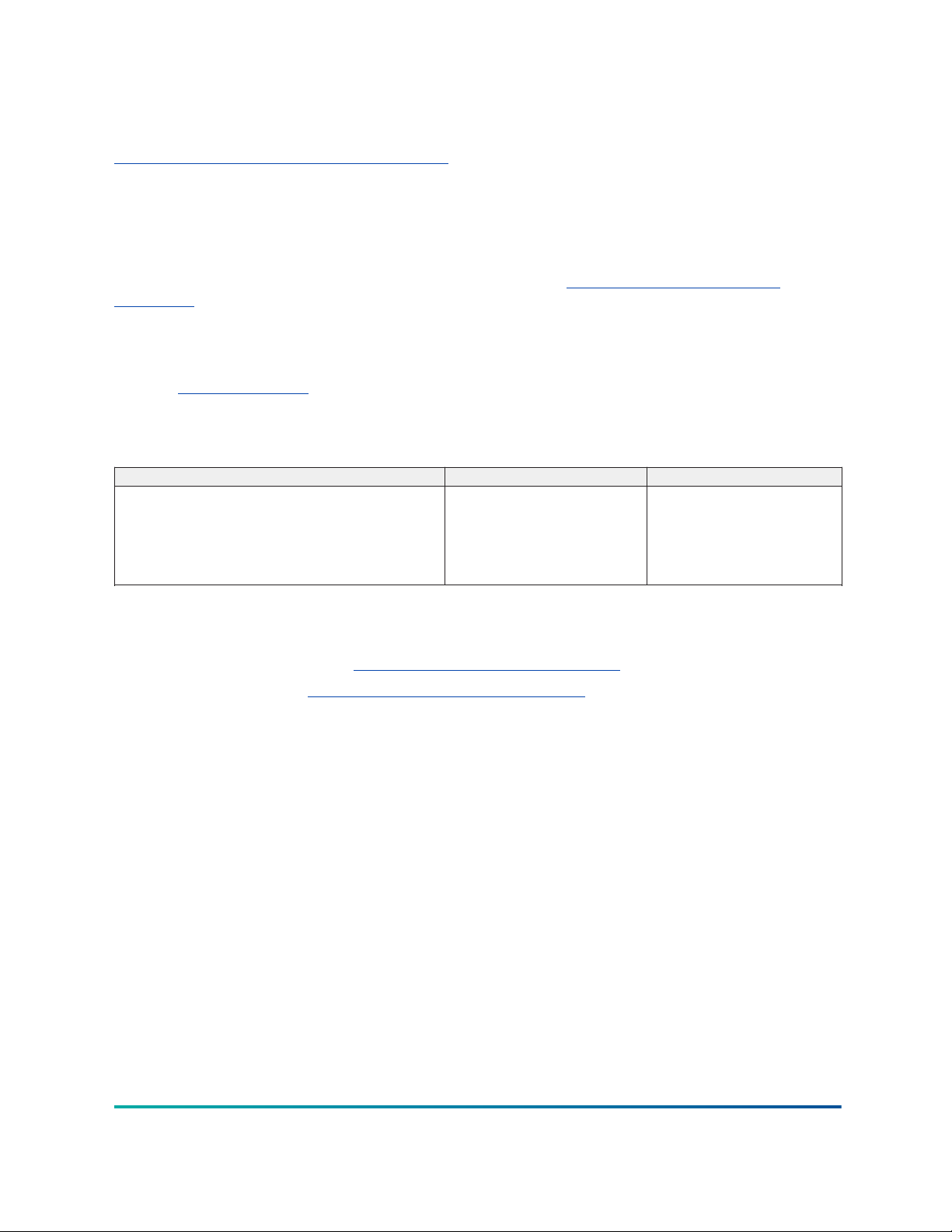

Determining correct pairing of CPU Board and Base Board

Important: Make sure you attach the cover that corresponds to its correct base. The CPU

board number needs to match the Base board number. Otherwise you encounter an operation

error after you reattach a cover and base that do not belong together, as shown in Figure 1.

Figure 1: Error code indicating mismatched boards

Note: The example shown in Figure 1 indicates a TEC3612-16 CPU board that is mounted on

the base of a TEC3312-16.

8

TEC3000 Color Series Field-Selectable BACnet MS/TP or N2 Networked and Wireless Thermostat Controllers

Technical Bulletin

Page 9

Wireless TEC3000 networks

The TEC3000 includes an embedded wireless router and can only be used on a ZFR182x or ZFR183x

Pro Series Wireless Network.

The WRG1830/ZFR183x Pro Series Wireless Field Bus System is similar to the WNC1820/ZFR182x

Series wireless system in many ways. But there are several important differences.

• The wireless networks (PANs) formed by the ZFR183x and ZFR182x systems are not

compatible.

• The ZFR182x Series Routers and TEC3000 are not field upgradeable to be compatible with the

ZFR1830 Series System.

Important: ZFR182x Pro Series Wireless System compatible TEC30xx-1x-000 models and

ZFR183x Pro Series Wireless System compatible TEC31xx-1x-000 models are not compatible

with each other and cannot be used under the same PAN ID (network address).

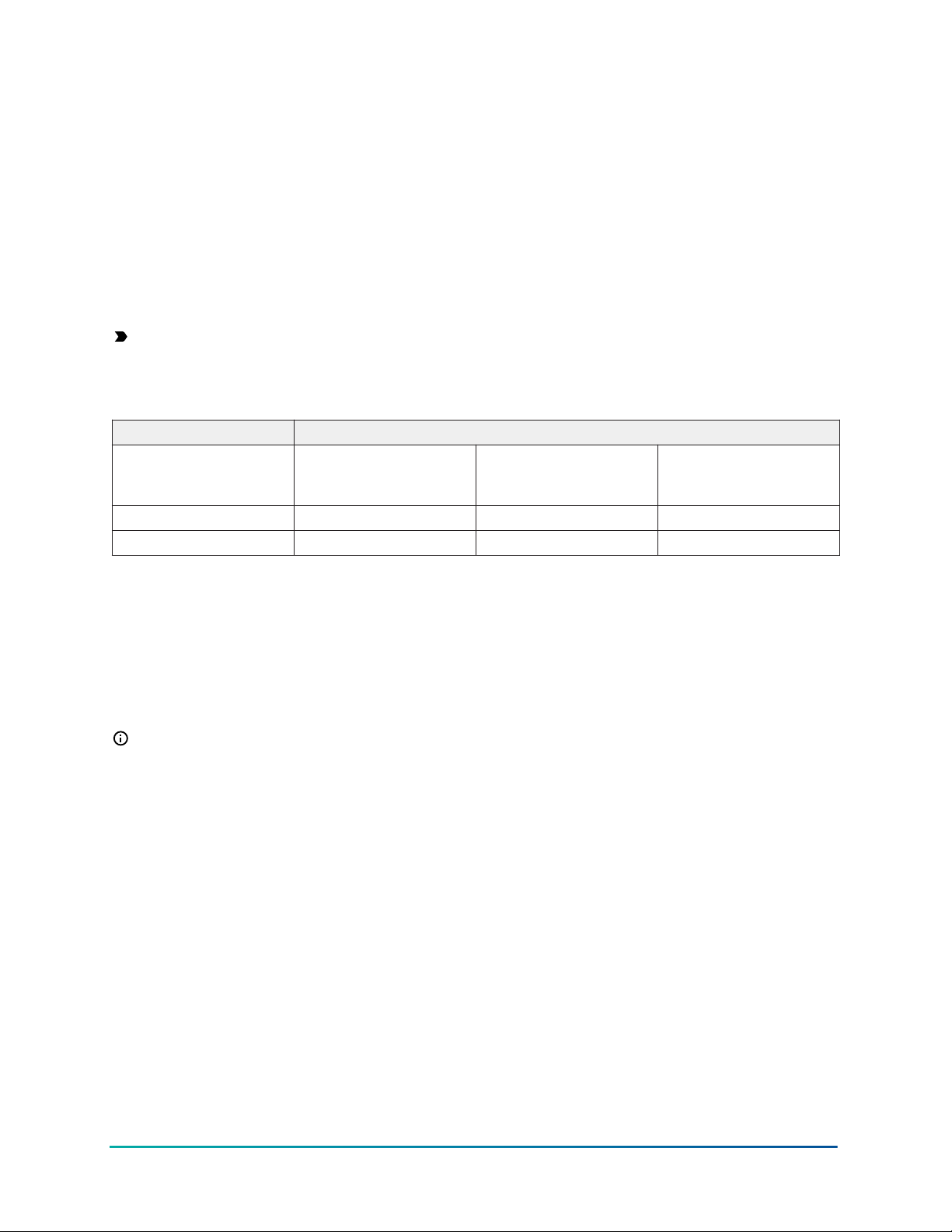

Table 2: ZFR183x Pro Series indoor transmission ranges

Range type Transmission distance

ZFR to ZFR TEC to ZFR

TEC to TEC

Recommended 250 ft (75 m) 250 ft (75 m) 50 ft (15.2 m)

Maximum, Line of Sight 1000 ft (304.8 m) 1000 ft (304.8 m) 100 ft (30 m)

WRZ to ZFR

In ZFR182x Pro Series networks, place every wireless TEC3000 within 50 ft (15 m) of at least two

other TEC3000 or ZFR182x wireless devices.

In ZFR183x Pro Series networks, place every wireless TEC3000 within 250 ft (76.2 m) of at least two

other ZFR183x Pro Series wireless TEC3000.

If any wireless TEC3000 is not within 50 ft (15 m) of a ZFR182x Pro Series, or 250 ft (76.2) of a

ZFR183x Pro Series system with other compatible wireless TEC, use compatible ZFR182x or ZFR183x

Routers as repeaters with applicable accessories to provide multiple wireless data pathways.

Note: Change the address of the wireless TEC. The address on the wireless TEC is invalid from

the factory so it must be changed when installed.

A wireless network requires a network coordinator/gateway. See the WNC1800/ZFR182x Pro Series

Wireless Field Bus System Technical Bulletin (LIT-12012356) and WRG1830/ZFR183x Pro Series Wireless

Field Bus System Technical Bulletin (LIT-12013553) for more information about the layout of a ZFR182x

or ZFR183x Pro Series Network.

Configuring a wired TEC3000 for MS/TP or N2 bus

The TEC3000 supports network connectivity to a BAS using a BACnet MS/TP or N2 bus. You select

BACnet MS/TP or N2 communication through the software.

Wiring the network

N2 and BACnet MS/TP protocols use the same physical connections for an RS-485 connection, that

requires three conductors:

• NET +

• NET -

Technical Bulletin

9TEC3000 Color Series Field-Selectable BACnet MS/TP or N2 Networked and Wireless Thermostat Controllers

Page 10

• NET COM

Connect the TEC3000 in line with other devices on the network.

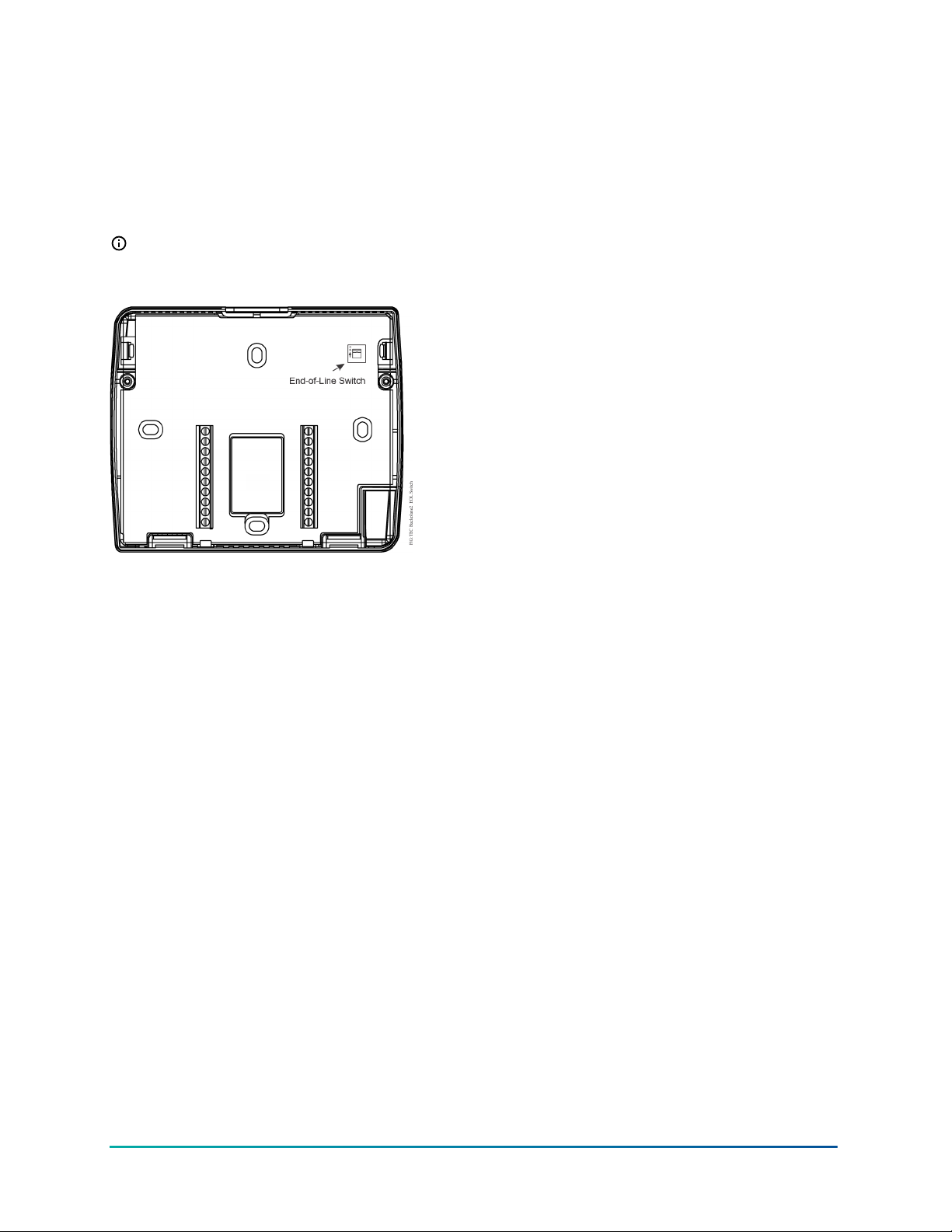

End-of-Line termination

When the TEC3000 is the last device on the bus, make sure the end-of-line (EOL) switch on the I/O

board is in the On position.

Note: If the EOL switch is not on the I/O board, the thermostat is a stand-alone model.

Figure 2: EOL switch positions

Setting the network parameters

All network configuration is done through the software. On the home screen, click the menu icon.

Scroll down to Network Setup for the network settings. Out of the box, the thermostat is configured

in BACnet MS/TP mode. To change to the N2 mode, select FC Comm Mode and change to N2. This

change reboots the device when you click the save icon.

10

TEC3000 Color Series Field-Selectable BACnet MS/TP or N2 Networked and Wireless Thermostat Controllers

Technical Bulletin

Page 11

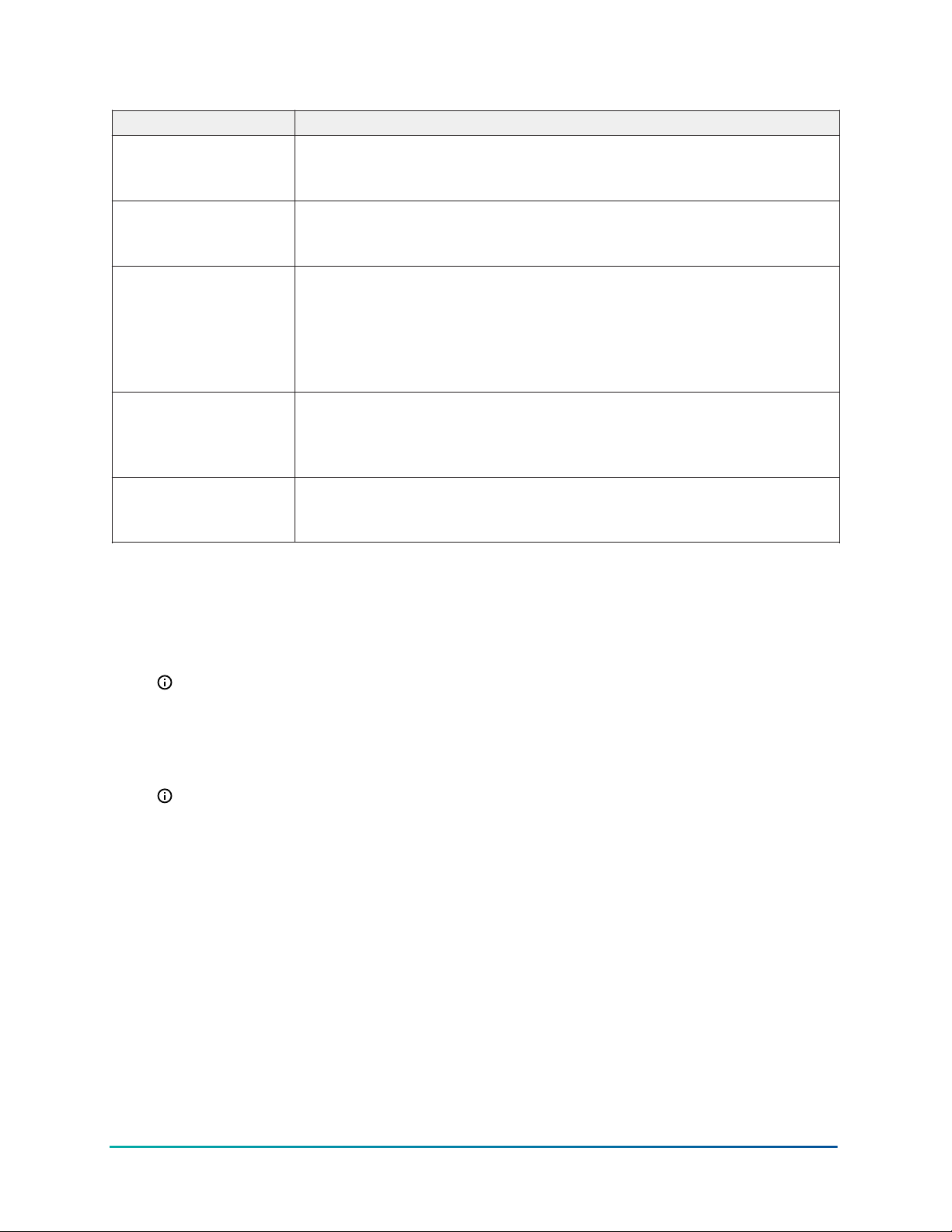

Table 3: Setup menus

Menu parameter Description

BACnet Instance ID This is the instance ID of the device on the BACnet MS/TP bus. BACnet

MS/TP systems use the instance ID for identification of the device. It can

be set from 1 to 4,194,302 and is unique to that site. The default is 1.

BACnet Device Address This is the physical MAC address of the BACnet MS/TP device on the bus.

It can be set from 4 to 127. Two devices on the same bus cannot have the

same BACnet MS/TP device address. The default is 4.

MSTP Baud Rate This is the baud rate that the TEC communicates on the network. The

default value is Auto, which allows the device to automatically detect

the baud rate of the BACnet MS/TP bus and operate at that speed. An

incorrect value causes the device to not communicate on the network,

and can potentially cause the network to fail. Options for this setting are

Auto, 1,200, 9,600, 19,200, 38,400, and 76,800 Baud.

BACnet Encoding Type This is the method of data encoding and is used by the BACnet MS/TP

bus. The default value, ISO 10646 (UCS-2), is the encoding used by the

Metasys® platform. When operating on a third-party BAS, refer to the

documentation provided with the BAS for the correct encoding type.

N2 Device Address This is the physical MAC address of the N2 device on the bus and can be

set from 1 to 255. Two devices on the same bus cannot have the same N2

device address.

Connecting the MS/TP or N2 bus

About this task: To connect the MS/TP or N2 bus, complete the following steps:

1. Set the MS/TP or N2 address of the TEC3000 Series BACnet MS/TP or N2 Network

Temperature and Humidity Thermostat Controller according to the engineering drawings.

Note: For more details on wiring the MS/TP Communications bus, refer to the MS/TP

Communications Bus Technical Bulletin (LIT-12011034).

2. Observe the polarity when connecting the bus wires to the thermostat controller.

3. After the bus wires are connected to the first thermostat controller, continue in a daisychained fashion to the next thermostat controller.

Note: The bus wiring must be twisted-pair lines. Do not run the bus wiring in the same

conduit as line voltage wiring (30 VAC or above) or other wiring that switches power to

highly inductive loads (such as contactors, coils, motors, or generators).

Result

Configure the thermostat controller for automatic baud rate detection. Do not exceed the

maximum number of devices allowed on a field bus. Ensure that the wiring terminations are set

correctly and that all communication wiring is daisy-chained with no T taps.

Technical Bulletin

11TEC3000 Color Series Field-Selectable BACnet MS/TP or N2 Networked and Wireless Thermostat Controllers

Page 12

MS/TP or N2 thermostat controller mapping

Preparation

About this task: Before you map a TEC3000 Series field-selectable BACnet MS/TP or N2 Network

Thermostat Controller into an NAE:

1. Decide which points within the thermostat controller need to be mapped. Only map the

points that need to be viewed or commanded on a regular basis. Excessive point mapping

lowers system performance. Suggested points for mapping include Zone Temp, System

Mode, Fan Mode, Manual Occupancy Mode, Occupied Heating Setpoint, Occupied Cooling

Setpoint, Unoccupied Heating Setpoint, and Unoccupied Cooling Setpoint. In addition, alarm

points may be mapped if they are used, and other points may be mapped if required. Use the

Engineering view of the MS/TP trunk on the NAE to examine infrequently used points.

Note: Set all thermostat controller configuration parameters as required before you

map the points into the NAE. If you alter any thermostat controller configuration

parameters after you mapped the points into the thermostat controller, re-map all

points individually, because some exposed points might have been added or removed.

Be careful when you map configuration parameters, because they should only be

mapped if the operator is fully familiar with their use.

2. Verify that a Field bus is defined in the NAE. BACnet MS/TP or N2 devices attach to a Field bus.

Refer to the Metasys N2 Communication Bus Technical Bulletin (LIT-636018) for instructions on

how to define a Field bus.

3. For Metasys system software earlier than Release 4.0, verify that a BACnet Integration is

defined for the Field bus. The thermostat controllers are mapped as BACnet MS/TP devices

under a Field bus BACnet Integration. Refer to the BACnet Controller Integration with NAE/

NCE Technical Bulletin (LIT-1201531) or the Metasys N2 Communication Bus Technical Bulletin

(LIT-636018) for instructions on how to define a BACnet Integration.

Note: Metasys system Release 7.0.7 or later software is required for correct support of

text strings on all network points.

Result

At this point, you can map the thermostat controller and the required points inside the thermostat

controller.

Adding a thermostat controller

You must add the thermostat controller before you can map its points. To add the thermostat

controller, select either the Field or N2 bus (depending on the selected configuration) and choose

Field Device from the Insert menu.

Assisted Definition using Auto Discovery is the easiest way to add a new thermostat controller

online; however, this method requires that the thermostat controller that you want to add is

connected and ready to communicate. Device addresses must be unique from 4 to 127 for the

BACnet MS/TP and 1 to 255 for the N2 network.

Note: Do not use the MAP-ALL functionality when you add the thermostat controller to a

Supervisory device, because this adds all TEC3000 Trend Objects which cannot be viewed in

the Supervisory device. These trends update every 15 minutes which could cause issues in the

Supervisory device.

Adding BACnet MS/TP points

You must map the required points under the thermostat controller device. To map the points, select

the thermostat controller device under the BACnet Integration (if required, refresh the tree view to

see a newly added thermostat controller device) and choose Field Point from the Insert menu.

12

TEC3000 Color Series Field-Selectable BACnet MS/TP or N2 Networked and Wireless Thermostat Controllers

Technical Bulletin

Page 13

Assisted Definition using Auto Discovery is the easiest way to add new points online; however, this

function requires that the thermostat controller that you want to map is connected and ready to

communicate. When mapping points offline, the point type must match the BACnet object type

(for example, AV, MV, BI), and the point instance number must match the point BACnet instance

number.

Adding N2 points

You must map the required points under the thermostat controller device. To map the points, select

the thermostat controller device under the N2 Integration (if required, refresh the tree view to see a

newly added thermostat controller device) and choose Field Point from the Insert menu.

Then you need to add the appropriate PRN file based on the TEC model being used as an extension

to the device. Multi-state points are defined as ADI points in the PRN file. You must map these using

either MI or MO NAE object types. Following the field point addition, object units may need further

tailoring of units and enum set values. See Table 4, Table 5 or Table 6 for the enum set values.

MS/TP or N2 bus points tables

Thermostat controllers

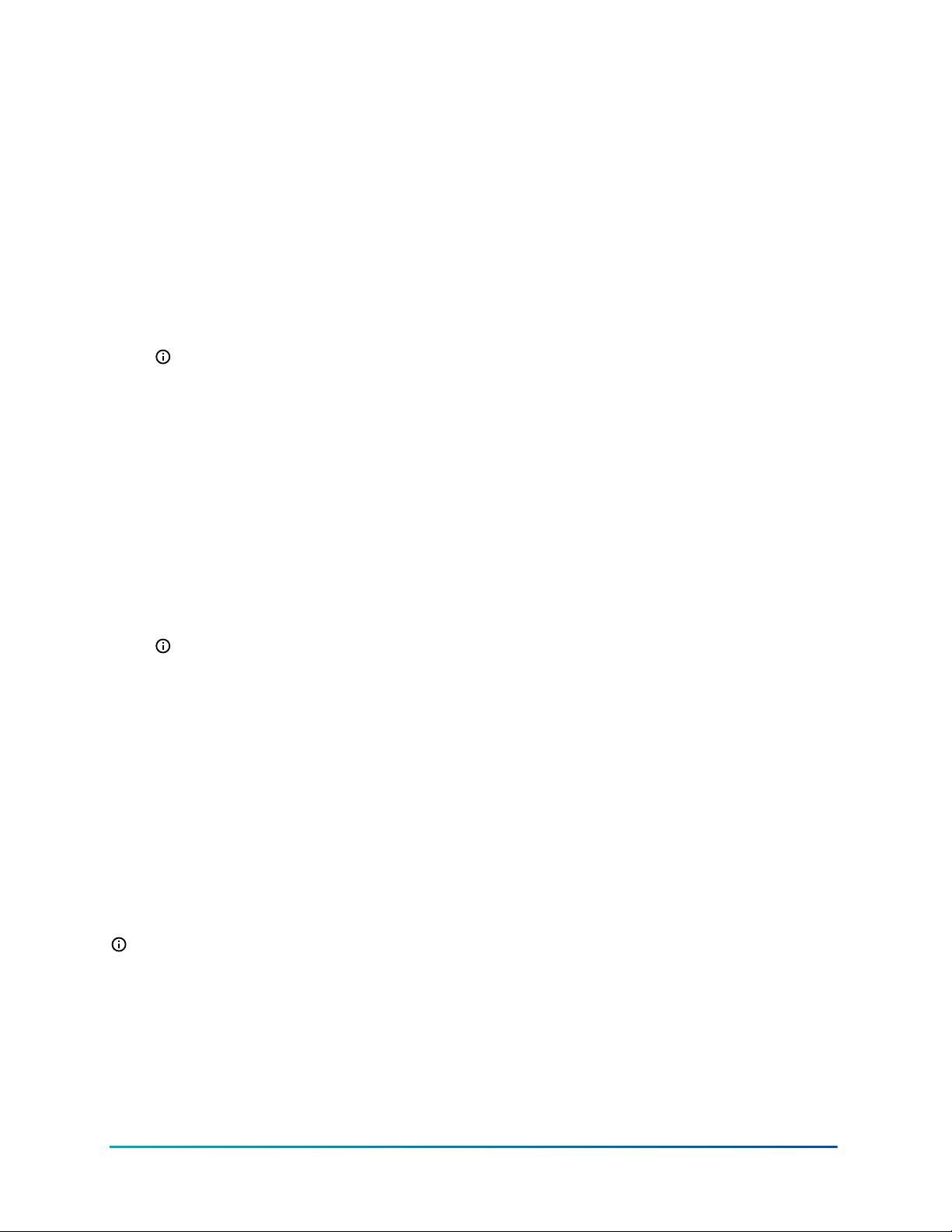

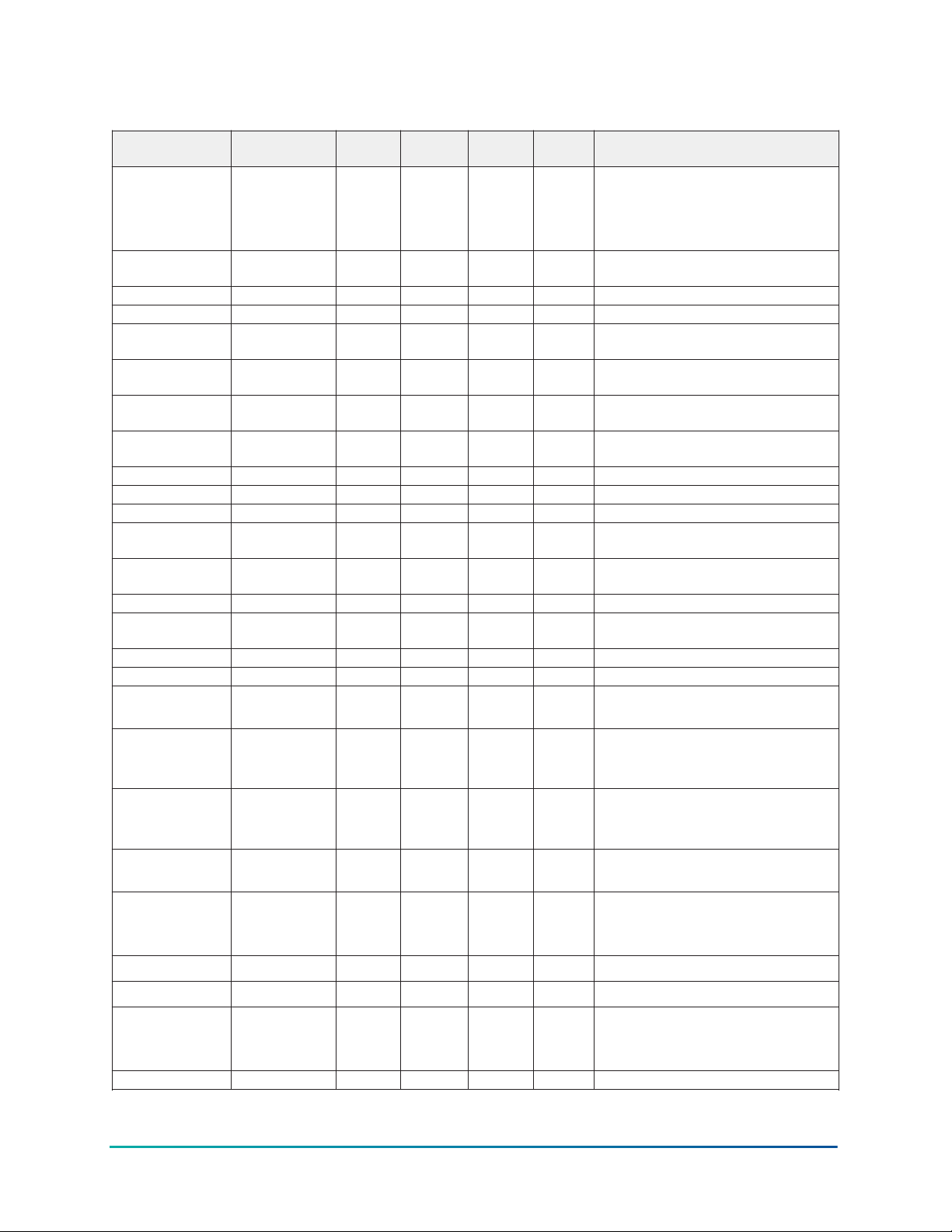

Table 4: Points for TEC3612-1x-000, TEC3613-1x-000, TEC3012-1x-000, TEC3013-1x-000,

TEC3112-14-000, and TEC3113-14-000

Point description Point name Object

type

Control Mode SYSTEM-MODE MV 29500 MI, ADI 1 TEC3000 Unit Control Mode

Unit Enable UNITEN-MODE MV 29501 MI, ADI 2 Shutdown/Enable

Occupied Cooling

Setpoint

Occupied Heating

Setpoint

Unoccupied

Cooling Setpoint

Unoccupied

Heating Setpoint

Standby Cooling

Setpoint

Standby Heating

Setpoint

Setpoint Offset WC-ADJ AV 29508 AO, ADF 7 (Negative) Max Setpoint Offset.

Hold/Run HOLDRUN-

Humidity Setpoint ZNH-SP AV 29510 AO, ADF 8 0% RH to 100% RH

CLGOCC-SP AV 29502 AO, ADF 1 60°F to 100°F (15.05°C to 37.78°C)

HTGOCC-SP AV 29503 AO, ADF 2 45°F to 85°F (7.22°C to 29.44°C)

CLGUNOCC-SP AV 29504 AO, ADF 3 60°F to 100°F (15°C to 38°C)

HTGUNOCC-SP AV 29505 AO, ADF 4 45°F to 85°F (7°C to 30°C)

CLGSTBY-SP AV 29506 AO, ADF 5 60°F to 100°F (15°C to 38°C)

HTGSTBY-SP AV 29507 AO, ADF 6 45°F to 85°F (7°C to 30°C)

MV 29509 MI, ADI 3 Hold/Run

MODE

InstanceIDPoint

type

Point

address

Unit (IP), enum set/range

1. Auto

2. Cooling

3. Heating

1. Shutdown

2. Enable

*When Occ Setpoint Select = Setpoint

Offset. Otherwise, see Table 11 for

constraints

1. Hold

2. Run

Technical Bulletin

13TEC3000 Color Series Field-Selectable BACnet MS/TP or N2 Networked and Wireless Thermostat Controllers

Page 14

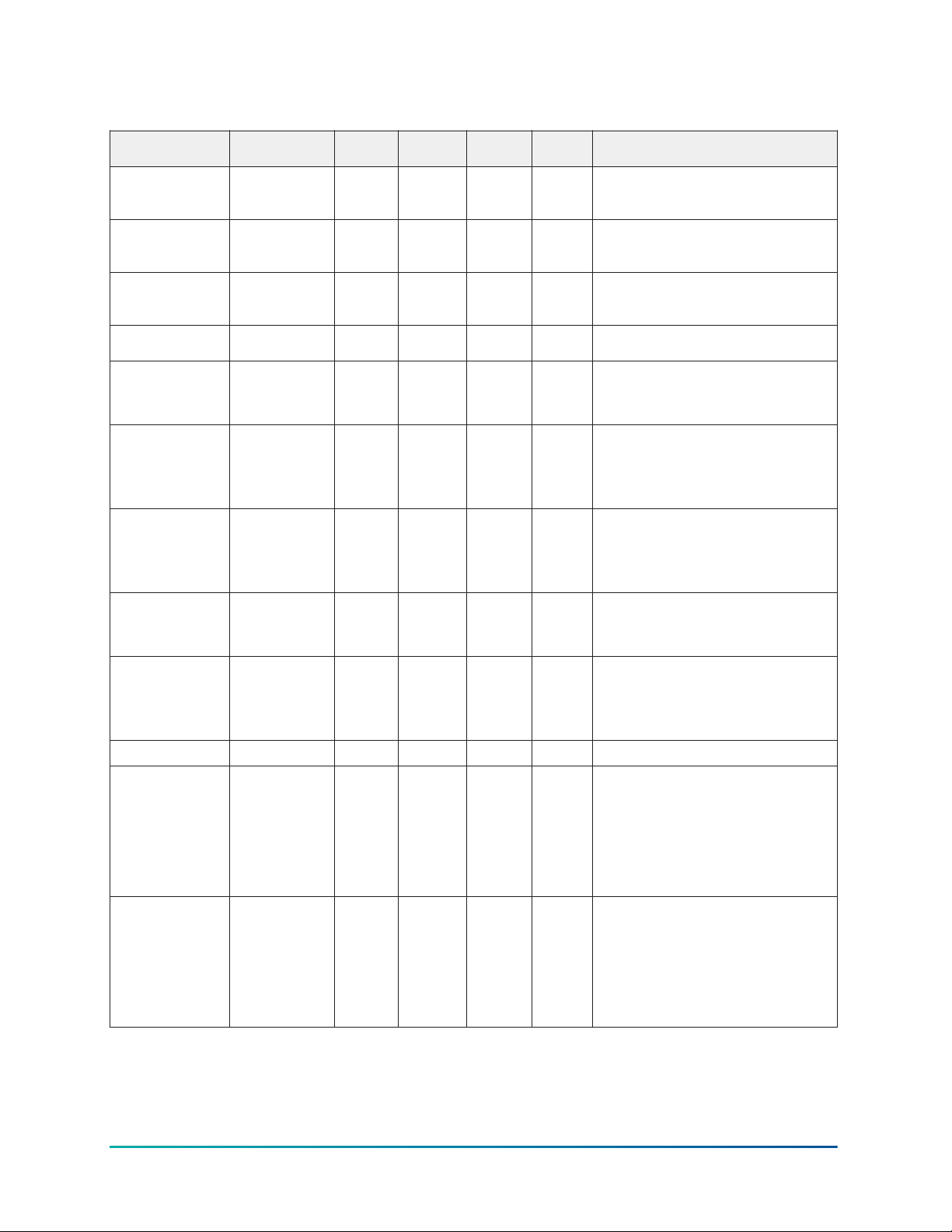

Table 4: Points for TEC3612-1x-000, TEC3613-1x-000, TEC3012-1x-000, TEC3013-1x-000,

TEC3112-14-000, and TEC3113-14-000

Point description Point name Object

type

Network Override

NET-OAT AV 29513 AO, ADF 11 -50°F to 125°F (-46°C to 52°C)

Outdoor Air

Temperature

Network Override

NET-OAH AV 29514 AO, ADF 12 0% RH to 100% RH

Outdoor Air

Humidity

Network Override

NET-SAT AV 29515 AO, ADF 13 0°F to 150°F (-18°C to 65°C)

Supply Air

Temperature

Network Override

NET-ZNH AV 29516 AO, ADF 14 0% RH to 100% RH

Zone Humidity

Reset PID Tuning TUNING-RESET MV 29517 MI, ADI 4 No/Yes

Manual Occupancy

OCCOVRD-MODE MV 29518 MI, ADI 5 UI Occ Override

Mode

Supervisor

NET-OCC MV 29519 MI, ADI 6 Occ Schedule

Occupancy

Occupancy

OCC-CONFIG MV 29520 MI, ADI 7 SE Occupancy Mode

Schedule Source

Changeover Mode CGOVR-MODE MV 29523 MI, ADI 8 TEC3000 Unit Control Mode

Passcode

PASSCODE

11

MV 29522 AI, ADF 15 00000 to 99999

Fan Mode FAN-MODE MV 29524 MI, ADI 9 TEC3000 Fan Mode

Fan Override FANOVRD-MODE MV 29525 MI, ADI 10 UI Fan Override

InstanceIDPoint

type

Point

address

Unit (IP), enum set/range

1. No

2. Yes

1. No Override

2. Occupied

3. Unoccupied

1. Occupied

2. Unoccupied

3. Standby

1. Schedule

2. External

1. Auto

2. Cooling

3. Heating

1. On

2. Auto

3. Smart

*This point only shows if the unit type

is 2-pipe or 4-pipe and the fan type is

single- or variable-speed

1. On

2. Auto

3. Quiet

*This point only shows if the unit type

is 2-pipe or 4-pipe and the fan type is

single- or variable-speed

14

TEC3000 Color Series Field-Selectable BACnet MS/TP or N2 Networked and Wireless Thermostat Controllers

Technical Bulletin

Page 15

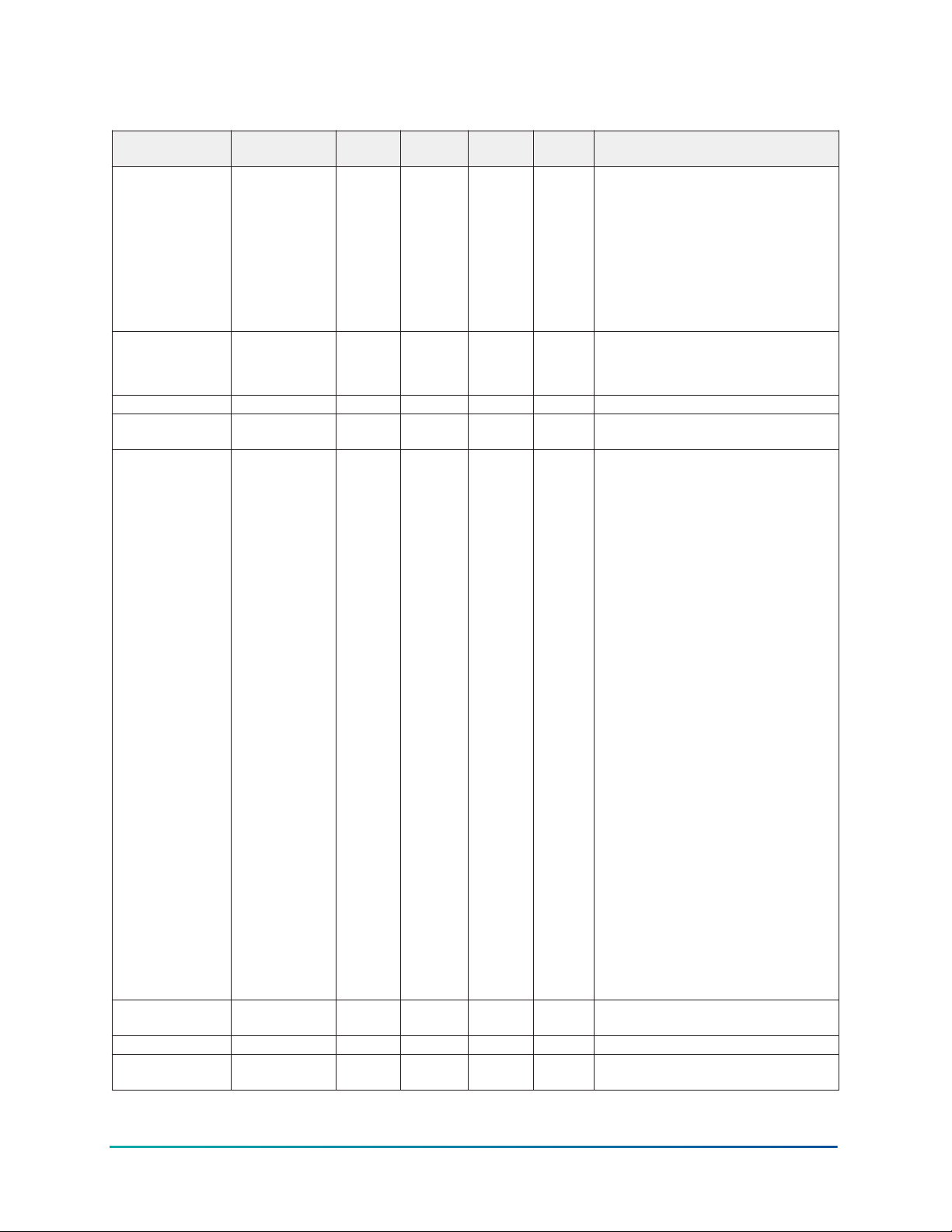

Table 4: Points for TEC3612-1x-000, TEC3613-1x-000, TEC3012-1x-000, TEC3013-1x-000,

TEC3112-14-000, and TEC3113-14-000

Point description Point name Object

type

Aux Mode AUX-MODE MV 29527 MI, ADI 11 TEC3000 Aux Mode

Units TEMP-UNITS MV 29528 MI, ADI 12 Unit Set

Max Setpoint Offset MAXSP-OFFSET AV 29529 AO, ADF 29 0 to 20 delta °F (0 to 11 delta °C)

Changeover

Setpoint

Unit Status UNIT-S MV 29700 MI, ADI 13 TEC3000 Detailed Control Status2

Operational Space

Temperature

Return Air Humidity EFF-ZNH AV 29702 AO, ADF 17 n/a

Supply Air

Temperature

CGOVR-SP AV 29530 n/a n/a 40°F to 200°F (4°C to 93°C)

EFF-ZNT AV 29701 AO, ADF 16 n/a

EFF-SAT AV 29703 AO, ADF 18 n/a

InstanceIDPoint

type

Point

address

Unit (IP), enum set/range

1. Not Used

2. Occupied NO

3. Occupied NC

4. Occupied Fan NO

5. Occupied FAN NC

6. On

7. Off

1. IP

2. SI

1. System Fault

2. Airflow Fault

3. Open Window

4. Control Off

5. Unreliable Temperature

6. Dehumidification

7. Idle

8. Cooling

9. Heating

10. Cooling Unavailable

11. Heating Unavailable

12. Cooling Unavailable due to

Changeover

13. Cooling Unavailable due to OA

Temp

14. Cooling Unavailable due to Control

Mode

15. Heating Unavailable due to

Changeover

16. Heating Unavailable due to OA

Temp

17. Heating Unavailable due to Control

Mode

18. Load Shed Active

19. Dehumidifying – Reheat

20. Dehumidifying – Fan Only

21. Dehum Unavail By Dew Point

Technical Bulletin

15TEC3000 Color Series Field-Selectable BACnet MS/TP or N2 Networked and Wireless Thermostat Controllers

Page 16

Table 4: Points for TEC3612-1x-000, TEC3613-1x-000, TEC3012-1x-000, TEC3013-1x-000,

TEC3112-14-000, and TEC3113-14-000

Point description Point name Object

type

Operational

Outdoor Air

Temperature

Active Setpoint EFF-SETPOINT AV 29705 AO, ADF 20 n/a

CV Operating

Cooling Setpoint

CV Operating

Heating Setpoint

Occupancy Status EFF-OCC MV 29708 MI, ADI 14 TEC3000 Occupancy Status

Occupancy Input

Source

Changeover State CGOVR-S n/a n/a MA, ADI 16 TEC3000 Changeover Status

Fan % Command FANSPD-% AV 29711 AO, ADF 23 0% to 100%

Fan Speed FANSPD-S MV 29712 MI, ADI 18 Supply Fan Status

Cool/Dehum PID

Control

Heat PID Cmd HTGPID-% AV 29717 AO, ADF 26 0% to 100%

Reheat PID Cmd RHPID-% AV 29720 AO, ADF 27 0% to 100%

Load Shed Active LOADSHED-EN MV 29728 MI, ADI 19 No/Yes

Load Shed Rate

Limit

Load Shed Adjust LOADSHED-RL-

Occupancy

Override Duration

EFF-OAT AV 29704 AO, ADF 19 n/a

EFFCLG-SP AV 29706 AO, ADF 21 n/a

EFFHTG-SP AV 29707 AO, ADF 22 n/a

OCCSOURCE-S MV 29709 MI, ADI 15 TEC3000 Occupancy Source

CLGPID-% AV 29714 AO, ADF 25 0% to 100%

LOADSHED-RL AV 29725 AO, ADF 30 0°F to 1°F/min (0°C to 0.5°C/min)

AV 29726 AO, ADF 31 0 to 8 delta °F (0 to 5 delta °C)

ADJ

TEMPOCC-LEN AV 29727 AO, ADF 32 0 minutes to 300 minutes

InstanceIDPoint

type

Point

address

Unit (IP), enum set/range

1. Occupied

2. Temp Occupancy

3. Unoccupied

4. Standby

5. Occupied-Override

6. Unoccupied-Override

1. Occupancy BI

2. Temp Occ BI

3. Temp Occ

4. Occ Override

5. Local Schedule

6. BAS Schedule

7. Occupancy Sensor

1. Changeover Disabled

2. Cooling Mode

3. Heating Mode

4. Supply Temperature Unreliable

1. Off

2. On

3. Low

4. Medium

5. High

1. No

2. Yes

16

TEC3000 Color Series Field-Selectable BACnet MS/TP or N2 Networked and Wireless Thermostat Controllers

Technical Bulletin

Page 17

Table 4: Points for TEC3612-1x-000, TEC3613-1x-000, TEC3012-1x-000, TEC3013-1x-000,

TEC3112-14-000, and TEC3113-14-000

Point description Point name Object

type

Lockout Level LOCL-LVL MV 29531 MI-ADI 20 States (0-2)

Unoccupied Off

UNOCC-OFF-DLY AV 29532 AO, ADF 33 0 minutes to 10 minutes

Delay

Heat Prop Band HTG-PROP-BAND AV 29535 AO, ADF 34 5 to 30 delta °F (2.8 to 16.7 delta °C)

Heat Integral Time HTG-INT-TIME AV 29536 AO, ADF 35 300 seconds to 1600 seconds

Heat Process Range HTG-PROC-

AV 29537 AO, ADF 36 10 to 100 delta °F (5.6 to 56 delta °C)

RANGE

Heat Saturation

HTG-SAT-TIME AV 29538 AO, ADF 37 60 seconds to 900 seconds

Time

Heat Time Constant HTG-TIME-

AV 29539 AO, ADF 38 360 seconds to 1440 seconds

CONST

Heat Process Dead

HTG-DEAD-TIME AV 29540 AO, ADF 39 20 seconds to 120 seconds

Time

Heat Period HTG-PERIOD AV 29541 AO, ADF 40 30 seconds to 120 seconds

Cool Prop Band CLG-PROP-BAND AV 29542 AO, ADF 41 5 to 30 delta °F (2.8 to 16.7 delta °C)

Cool Integral Time CLG-INT-TIME AV 29543 AO, ADF 42 300 seconds to 1600 seconds

Cool Process Range CLG-PROC-

AV 29544 AO, ADF 43 10 to 100 delta °F (5.6 to 56 delta °C)

RANGE

Cool Saturation

CLG-SAT-TIME AV 29545 AO, ADF 44 60 seconds to 900 seconds

Time

Cool Time Constant CLG-TIME-CONST AV 29546 AO, ADF 45 360 seconds to 1440 seconds

Cool Process Dead

CLG-DEAD-TIME AV 29547 AO, ADF 46 20 seconds to 120 seconds

Time

Cool Period CLG-PERIOD AV 29548 AO, ADF 47 30 seconds to 120 seconds

Deadband DEADBAND AV 29556 AO, ADF 55 1.4 to 3 delta °F (0.78 to 1.66 delta °C)

Min Heating

MINHTG-SP AV 29559 AO, ADF 56

Setpoint

Max Heating

MAXHTG-SP AV 29560 AO, ADF 57 Present value of Min Heating Setpoint

Setpoint

Min Cooling

MINCLG-SP AV 29561 AO, ADF 58 Present value of Max Heating Setpoint

Setpoint

Max Cooling

MAXCLG-SP AV 29562 AO, ADF 59 Min Cooling Setpoint present to 100°F

Setpoint

Occ Setpoint Select OCCSP-SEL MV 29563 AO, ADF 60 Occ Setpoint Select

Min Setpoint MIN-SP AV 29564 AO, ADF 61

Max Setpoint MAX-SP AV 29565 AO, ADF 62

Heat Cool Setpoint

Mode

HTGCLGSPMODE

MV 29566 MI, ADI 24 Heat Cool Setpoint Mode

Common Setpoint COMMON-SP AV 29567 AO, ADF 62 55°F to 90°F (12.77°C to 32.22°C)

InstanceIDPoint

type

Point

address

Unit (IP), enum set/range

1. State 0

2. State 1

3. State 2

2

45°F (7.22°C) to Max Heating Setpoint

Present Value

2

(MINHTG-SP) to present value of Min

Cooling Setpoint (MINCLG-SP)minus 1

(MAXHTG-SP) plus 1 to present value of

Max Cooling Setpoint (MAXCLG-SP)

(37.78°C)

2

1. Setpoint Offset

2. Min and Max Setpoint

3

45°F to 85°F (7°C to 30°C)

60°F to 100°F (16°C to 38°C)

3

3

1. Common Setpoint

2. Individual Setpoints

2

2

Technical Bulletin

17TEC3000 Color Series Field-Selectable BACnet MS/TP or N2 Networked and Wireless Thermostat Controllers

Page 18

Table 4: Points for TEC3612-1x-000, TEC3613-1x-000, TEC3012-1x-000, TEC3013-1x-000,

TEC3112-14-000, and TEC3113-14-000

Point description Point name Object

type

Fan Mode 2 FAN-MODE2 MV 29568 MI, ADI 27 TEC3000 Fan Mode 2

Fan Override 2 FAN-OVRD2 MV 29569 MI, ADI 28 UI Fan Override 2

Temp Control Setup TEMPCTRL-

SETUP

Control State TEMPCTRL-

SETUP2

Network Override

Zone Temperature

Signal Strength Signal Strength MV 29724 n/a n/a Wireless Signal Strength

PAO1 Output /

Cooling Valve %

Command

PAO2 Output /

Heating Valve %

Command

AO1 Output / Fan

Speed Percent

Command

NET-ZNT AV 29571 AO, ADF 63 -50°F to 120°F (-45°C to 49°C)

CLG-O AO 86914 AO, AO 1 0% to 100%

HTG-O AO 86915 AO, AO 2 0% to 100%

VSF-O AO 86905 AO, AO 3 0% to 100%

MV 29533 MI, ADI 21 TEMP_CONTROL_SETUP

MV 29570 MI, ADI 26 TEMP_CONTROL_SETUP_SUBSET

InstanceIDPoint

type

Point

address

Unit (IP), enum set/range

1. Auto

2. Smart

3. Low

4. Medium

5. High

*This point only shows if the unit type

is 2-pipe or 4-pipe and the fan type is

multispeed

1. Auto

2. Quiet

3. Low

4. Medium

5. High

*This point only shows if the unit type

is 2-pipe or 4-pipe and the fan type is

multispeed

1. Automatic PID Tuning

2. Deadband Override

3. Manual PID Tuning

4. On Off Control (available on units

with single-speed fan and On/Off

actuators configured)

1. Automatic PID Tuning

2. Deadband Override

3. Manual PID Tuning (available on

units with a multi-speed, variable

speed fan, or floating actuators

configured)

1. None

2. Weak

3. Average

4. Strong

18

TEC3000 Color Series Field-Selectable BACnet MS/TP or N2 Networked and Wireless Thermostat Controllers

Technical Bulletin

Page 19

Table 4: Points for TEC3612-1x-000, TEC3613-1x-000, TEC3012-1x-000, TEC3013-1x-000,

TEC3112-14-000, and TEC3113-14-000

Point description Point name Object

4

BO1 Command /

CLGO-C BO 86908 BO, BO 1 Inactive/Active

type

BO1 Cool NO/

4

Open

BO2 Command /

FANL-C BO 86909 BO, BO 2 Inactive/Active

BO2 Fan Low

Command

BO3 Command /

FANM-C BO 86910 BO, BO 3 Inactive/Active

BO3 Fan Medium

Command

BO4 Command /

FANH-C BO 86911 BO, BO 4 Inactive/Active

BO4 Fan High

Command

BO5 Command /

HTGO-C BO 86912 BO, BO 5 Inactive/Active

BO5 Heat NO/

4

Open

5

BO6 Command /

BO6 Cool NC/Close

BO7 Command /

CLGC-C BO 87101 BO, BO 6 Inactive/Active

5

HTGC-C BO 87102 BO, BO 7 Inactive/Active

BO7 Heat NC/

5

Close

AUX Command /

AUX BO 86913 BO, BO 8 Inactive/Active

BO8 AUX

BI1 Sensor / Binary

BI1-S BI 30827 BI, BI 1 Inactive/Active

Input 1

BI2 Sensor / Binary

BI2-S BI 30828 BI, BI 2 Inactive/Active

Input 2

Schedule Schedule Schedule 10133 n/a n/a n/a

Local Occupancy LOCAL-OCC MV 6 n/a n/a Occ Schedule

Calendar Calendar Calendar 10019 n/a n/a n/a

Dehumidification

DEHUM ENABLE MV 29736 n/a n/a No/Yes

Enable

Unocc Dehum

Enable

UNOCC DEHUM

ENABLE

MV 29737 n/a n/a No/Yes

InstanceIDPoint

type

Point

address

Unit (IP), enum set/range

1. Inactive

2. Active

1. Inactive

2. Active

1. Inactive

2. Active

1. Inactive

2. Active

1. Inactive

2. Active

1. Inactive

2. Active

1. Inactive

2. Active

1. Inactive

2. Active

1. Inactive

2. Active

1. Inactive

2. Active

1. Occupied

2. Unoccupied

3. Standby

4. Not Set

1. No

2. Yes

1. No

2. Yes

Technical Bulletin

19TEC3000 Color Series Field-Selectable BACnet MS/TP or N2 Networked and Wireless Thermostat Controllers

Page 20

Table 4: Points for TEC3612-1x-000, TEC3613-1x-000, TEC3012-1x-000, TEC3013-1x-000,

TEC3112-14-000, and TEC3113-14-000

Point description Point name Object

type

Chilled

Water Supply

Temperature

Chilled

Water Supply

Temperature

Setpoint

Network

Override Chilled

Water Supply

Temperature

Outdoor Air

Humidity

Cooling Valve

Minimum Position

Cooling Valve

Starting Position

Heating Valve

Starting Position

Coil Tempering

Time

Dehumidification

Overcool Limit

Dehumidification

Sequence Mode

Dehumidification

Sequence Mode

EFF-CHWST AV 29734 n/a n/a n/a

CHWST-SP AV 29735 n/a n/a 0 to 250 deg F (-17 to 121 deg C)

NET-CHWST AV 29736 n/a n/a 0 to 250 deg F (-17 to 121 deg C)

EFF-OAH AV 29737 n/a n/a n/a

CLVVLV-MIN-POS AV 29738 n/a n/a 50% to 75%

CLGVLV-STARTPOS

HTGVLV-STARTPOS

COIL-TPR-TIME AV 29741 n/a n/a 3 minutes to 10 minutes

DEHUMOVRCLG-LIM

4PIPE-DEHUMSEQ-MODE

2PIPE-DEHUMSEQ-MODE

AV 29739 n/a n/a 50% to 100%

AV 29740 n/a n/a 50% to 100%

AV 29742 n/a n/a 1 to 5 delta deg F, delta deg C

MV 29729 n/a n/a TEC3000 FCU Dehum Seq Mode

MV 29730 n/a n/a TEC3000 Dehum Sequence

InstanceIDPoint

type

Point

address

Unit (IP), enum set/range

*This point only shows if there is neither

a CHWST sensor wired to TEC nor a

Network override value setup and

Dehum Enable is set to Enable

*This point only shows if

Dehumidification Sequence Mode is

setup as Individual Coils or 2-pipe with

reheat and Dehum Enable is set to

Enable

*This point only shows if

Dehumidification Sequence Mode is

setup as Individual Coils or 2-pipe with

reheat and Dehum Enable is set to

Enable

*This point only shows if

Dehumidification Sequence Mode is

setup as Individual Coils and Dehum

Enable is set to Enable

*This point only shows if

Dehumidification Sequence Mode is

setup as Single Coil and Dehum Enable is

set to Enable

*This point only shows if

Dehumidification Sequence Mode is

setup as Single Coil and Dehum Enable is

set to Enable

1. Individual Coils

2. Single Coil

*This point only shows if Unit Type

is 4-pipe and Dehum Enable is set to

Enable

1. Individual Coils

2. Single Coil

3. 2-Pipe With Reheat

*This point only shows if Unit Type

is 2-pipe and Dehum Enable is set to

Enable

20

TEC3000 Color Series Field-Selectable BACnet MS/TP or N2 Networked and Wireless Thermostat Controllers

Technical Bulletin

Page 21

Table 4: Points for TEC3612-1x-000, TEC3613-1x-000, TEC3012-1x-000, TEC3013-1x-000,

TEC3112-14-000, and TEC3113-14-000

Point description Point name Object

type

Scheduled

Circulation Enable

Scheduled

Circulation Only

When Occupied

Minimum Hourly

Fan Runtime

Variable Speed Fan

Circulation Setpoint

Multi Speed Fan

Circulation Setpoint

Medium Fan On

Diff Sp

Medium Fan Off

Diff Sp

High Fan On Diff Sp HIGH-FAN-ON-SP AV 29902 n/a n/a 1 to 3 delta deg F (0.55 to 1.67 delta deg

High Fan Off Diff Sp HIGH-FAN-OFF-SPAV 29903 n/a n/a 0.5 to 2 delta deg F (0.28 to 1.1 delta deg

1 The passcode cannot be changed from BAS. The passcode can only be defined by the local display or through Mobile

Access Portal (MAP) version 4.0.

2 The Occ Setpoint Select is set to the Min and Max Setpoint and Heat Cool Setpoint Mode is set to the Individual Setpoint.

3 The Occ Setpoint Select is set to the Min and Max Setpoint and Heat Cool Setpoint Mode is set to the Common Setpoint.

4 This is the output used when wired to the Normally Open (N.O.) terminal.

5 This is the output used when wired to the Normally Closed (N.C.) terminal.

SCH-CIR-EN MV 29731 n/a n/a Disable/Enable

SCH-CIR-ONLYOCC

MIN-HR-FAN AV 29743 n/a n/a 5 minutes to 30 minutes

VAR-FAN-CIR-SP AV 29744 n/a n/a 0% to 100%

MULTI-FAN-CIR-SPMV 29733 n/a n/a Sensitivity

MED-FAN-ON-SP AV 29900 n/a n/a 1 to 2 delta deg F (0.55 to 1.1 delta deg C)

MED-FAN-OFF-SP AV 29901 n/a n/a 0 to 1 delta deg F (0 to 0.55 delta deg C)

MV 29732 n/a n/a Disable/Enable

InstanceIDPoint

type

Point

address

Unit (IP), enum set/range

1. Disable

2. Enable

1. Disable

2. Enable

*This point shows Unreliable if

Scheduled Circulation Enable is set to

Disable

*This point shows Unreliable if

Scheduled Circulation Enable is set to

Disable

*This point only shows if Fan Type is

Variable Speed and Scheduled Circulation

Enable is True

1. Low

2. Medium

3. High

*This point only shows if Fan Type is

Multi Speed and Scheduled Circulation

Enable is True

*This point only shows when Fan Type is

Multi Speed and Temp Control Setup is

On Off Control

*This point only shows when Fan Type is

Multi Speed and Temp Control Setup is

On Off Control

C)

*This point only shows when Fan Type is

Multi Speed and Temp Control Setup is

On Off Control

C)

*This point only shows when Fan Type is

Multi Speed and Temp Control Setup is

On Off Control

Technical Bulletin

21TEC3000 Color Series Field-Selectable BACnet MS/TP or N2 Networked and Wireless Thermostat Controllers

Page 22

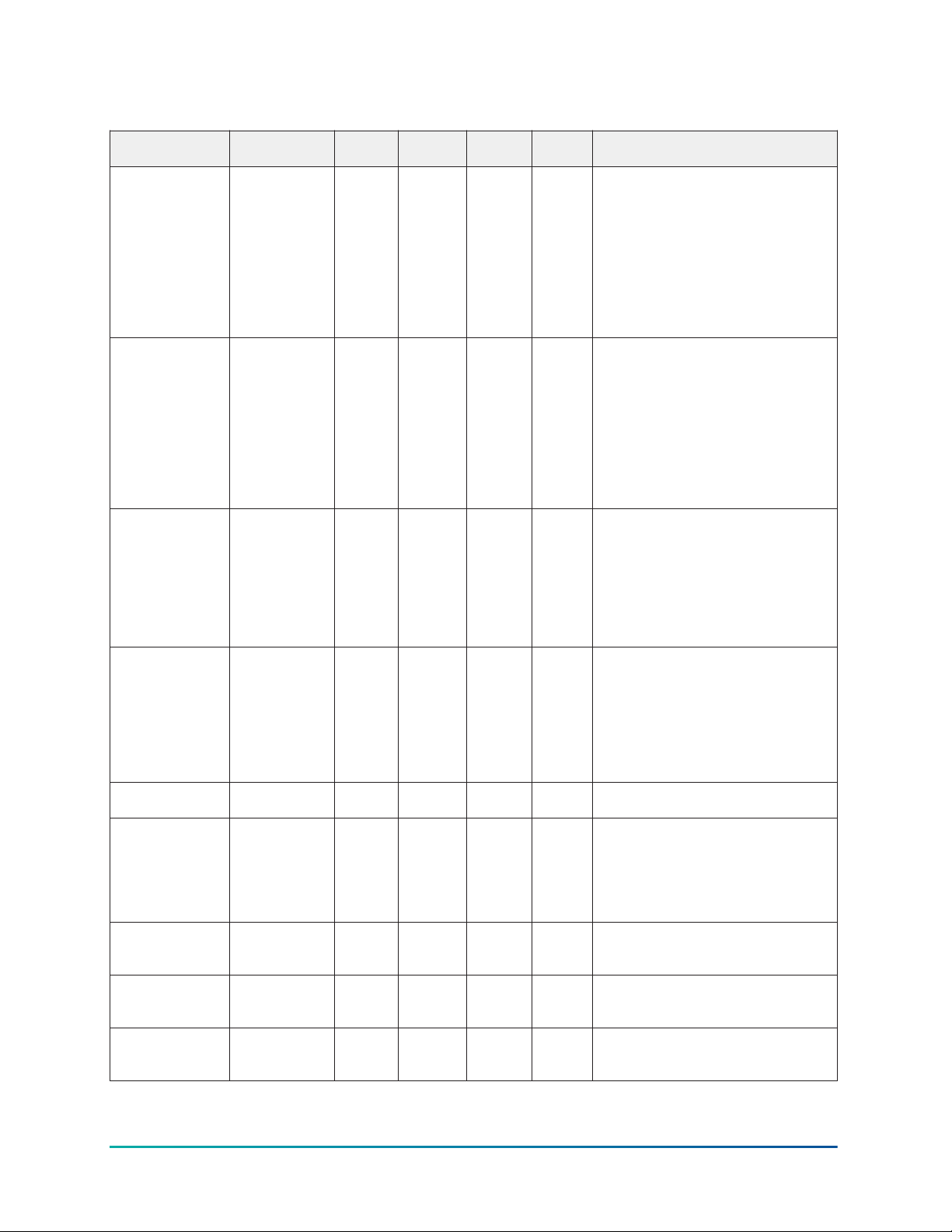

Table 5: Points for TEC3622-1x-000, TEC3623-1x-000, TEC3022-1x-000, TEC3023-1x-000,

TEC3122-14-000, and TEC3123-14-000

Point description Point name Object

type

Control Mode SYSTEM-MODE MV 29500 MI, ADI 1 TEC3000 Unit Control Mode

Unit Enable UNITEN-MODE MV 29501 MI, ADI 2 Shutdown/Enable

Occupied Cooling

Setpoint

Occupied Heating

Setpoint

Unoccupied Cooling

Setpoint

Unoccupied

Heating Setpoint

Standby Cooling

Setpoint

Standby Heating

Setpoint

Setpoint Offset WC-ADJ AV 29508 AO, ADF 7 (Negative) Max Setpoint Offset.

Hold/Run HOLDRUN-

Humidity Setpoint ZNH-SP AV 29510 AO, ADF 8 0% RH to 100% RH

Network Override

Outdoor Air

Temperature

Network Override

Outdoor Air

Humidity

Network Override

Supply Air

Temperature

Network Override

Zone Humidity

Reset PID Tuning TUNING-RESET MV 29517 MI, ADI 4 No/Yes

Manual Occupancy

Mode

Supervisory

Occupancy

CLGOCC-SP AV 29502 AO, ADF 1 60°F to 100°F (15.05°C to 37.78°C)

HTGOCC-SP AV 29503 AO, ADF 2 45°F to 85°F (7.22°C to 29.44°C)

CLGUNOCC-SP AV 29504 AO, ADF 3 60°F to 100°F (15°C to 38°C)

HTGUNOCC-SP AV 29505 AO, ADF 4 45°F to 85°F (7°C to 30°C)

CLGSTBY-SP AV 29506 AO, ADF 5 60°F to 100°F (15°C to 38°C)

HTGSTBY-SP AV 29507 AO, ADF 6 45°F to 85°F (7°C to 30°C)

MV 29509 MI, ADI 3 Hold/Run

MODE

NET-OAT AV 29513 AO, ADF 11 -50°F to 125 °F (-46°C to 52 °C)

NET-OAH AV 29514 AO, ADF 12 0% RH to 100% RH

NET-SAT AV 29515 AO, ADF 13 0°F to 150°F (-18°C to 65°C)

NET-ZNH AV 29516 AO, ADF 14 0% RH to 100% RH

OCCOVRDMODE

NET-OCC MV 29519 MI, ADI 6 Occ Schedule

MV 29518 MI, ADI 5 UI Occ Override

InstanceIDPoint

type

Point

address

Unit (IP), enum set/range

1. Auto

2. Cooling

3. Heating

1. Shutdown

2. Enable

*When Occ Setpoint Select = Setpoint

Offset. Otherwise, see Table 11 for

constraints

1. Hold

2. Run

1. No

2. Yes

1. No Override

2. Occupied

3. Unoccupied

1. Occupied

2. Unoccupied

3. Standby

22

TEC3000 Color Series Field-Selectable BACnet MS/TP or N2 Networked and Wireless Thermostat Controllers

Technical Bulletin

Page 23

Table 5: Points for TEC3622-1x-000, TEC3623-1x-000, TEC3022-1x-000, TEC3023-1x-000,

TEC3122-14-000, and TEC3123-14-000

Point description Point name Object

type

Occupancy

OCC-CONFIG MV 29520 MI, ADI 7 SE Occupancy Mode

Schedule Source

Changeover Mode CGOVR-MODE MV 29523 MI, ADI 8 TEC3000 Unit Control Mode

Passcode

1

PASSCODE

1

MV 29522 AI, ADF 15 00000 to 99999

Fan Mode FAN-MODE MV 29524 MI, ADI 9 TEC3000 Fan Mode

Fan Override FANOVRD-

MV 29525 MI, ADI 10 UI Fan Override

MODE

Aux Mode AUX-MODE MV 29527 MI, ADI 11 TEC3000 Aux Mode

Units TEMP-UNITS MV 29528 MI, ADI 12 Unit Set

Max Setpoint Offset MAXSP-OFFSET AV 29529 AO, ADF 29 0 to 20 delta °F (0 to 11 delta °C)

Changeover

CGOVR-SP AV 29530 n/a n/a 40°F to 200°F (4°C to 93°C)

Setpoint

InstanceIDPoint

type

Point

address

Unit (IP), enum set/range

1. Schedule

2. External

1. Auto

2. Cooling

3. Heating

1. On

2. Auto

3. Smart

*This point only shows if the unit type

is 2-pipe or 4-pipe and the fan type is

single- or variable-speed

1. On

2. Auto

3. Quiet

*This point only shows if the unit type

is 2-pipe or 4-pipe and the fan type is

single- or variable-speed

1. Not Used

2. Occupied NO

3. Occupied NC

4. Occupied Fan NO

5. Occupied Fan NC

6. On

7. Off

1. IP

2. 2 -SI

Technical Bulletin

23TEC3000 Color Series Field-Selectable BACnet MS/TP or N2 Networked and Wireless Thermostat Controllers

Page 24

Table 5: Points for TEC3622-1x-000, TEC3623-1x-000, TEC3022-1x-000, TEC3023-1x-000,

TEC3122-14-000, and TEC3123-14-000

Point description Point name Object

type

Unit Status UNIT-S MV 29700 MI, ADI 13 TEC3000 Detailed Control Status2

Operational Space

Temperature

Return Air Humidity EFF-ZNH AV 29702 AO, ADF 17 n/a

Supply Air

Temperature

Operational

Outdoor Air

Temperature

Active Setpoint EFF-SETPOINT AV 29705 AO, ADF 20 n/a

CV Operating

Cooling Setpoint

CV Operating

Heating Setpoint

Occupancy Status EFF-OCC MV 29708 MI, ADI 14 TEC3000 Occupancy Status

EFF-ZNT AV 29701 AO, ADF 16 n/a

EFF-SAT AV 29703 AO, ADF 18 n/a

EFF-OAT AV 29704 AO, ADF 19 n/a

EFFCLG-SP AV 29706 AO, ADF 21 n/a

EFFHTG-SP AV 29707 AO, ADF 22 n/a

InstanceIDPoint

type

Point

address

Unit (IP), enum set/range

1. System Fault

2. Airflow Fault

3. Open Window

4. Control Off

5. Unreliable Temperature

6. Dehumidification

7. Idle

8. Cooling

9. Heating

10. Cooling Unavailable

11. Heating Unavailable

12. Cooling Unavailable due to

Changeover

13. Cooling Unavailable due to OA

Temp

14. Cooling Unavailable due to Control

Mode

15. Heating Unavailable due to

Changeover

16. Heating Unavailable due to OA

Temp

17. Heating Unavailable due to Control

Mode

18. Load Shed Active

19. Dehumidifying – Reheat

20. Dehumidifying – Fan Only

21. Dehum Unavail By Dew Point

1. Occupied

2. Temp Occupancy

3. Unoccupied

4. Standby

5. Occupied-Override

6. Unoccupied-Override

24

TEC3000 Color Series Field-Selectable BACnet MS/TP or N2 Networked and Wireless Thermostat Controllers

Technical Bulletin

Page 25

Table 5: Points for TEC3622-1x-000, TEC3623-1x-000, TEC3022-1x-000, TEC3023-1x-000,

TEC3122-14-000, and TEC3123-14-000

Point description Point name Object

type

Occupancy Input

Source

Fan % Command FANSPD-% AV 29711 AO, ADF 23 0% to 100%

Fan Speed FANSPD-S MV 29712 MI, ADI 18 Supply Fan Status

Cool/Dehum PID

Cmd

Heat PID Cmd HTGPID-% AV 29717 AO, ADF 26 0% to 100%

Reheat PID Cmd RHPID-% AV 29720 AO, ADF 27 0% to 100%

Load Shed Active LOADSHED-EN MV 29728 MI, ADI 19 No/Yes

Load Shed Rate

Limit

Load Shed Adjust LOADSHED-ADJ AV 29726 AO, ADF 31 0 to 8 delta °F (0 to 5 delta °C)

Occupancy

Override Duration

Lockout Level LOCK-LVL MV 29531 MI, ADI 20 States (0 to 2)

Unoccupied Off

Delay

Heat Prop Band HTG-PROP-

Heat Integral Time HTG-INT-TIME AV 29536 AO, ADF 35 300 seconds to 1,600 seconds

Heat Process Range HTG-PROC-

Heat Saturation

Time

Heat Time Constant HTG-TIME-

Heat Process Dead

Time

Heat Period HTG-PERIOD AV 29541 AO, ADF 40 30 seconds to 120 seconds

Cool Prop Band CLG-PROP-

Cool Integral Time CLG-INT-TIME AV 29543 AO, ADF 42 300 seconds to 1,600 seconds

OCCSOURCE-S MV 29709 MI, ADI 15 TEC3000 Occupancy Source

CLGPID-% AV 29714 AO, ADF 25 0% to 100%

LOADSHED-RL AV 29725 AO, ADF 30 0°F to 1°F/min (0°C to 0.5°C/min)

TEMPOCC-LEN AV 29727 AO, ADF 32 0 minutes to 300 minutes

UNOCC-OFF-DLY AV 29532 AO, ADF 33 0 minutes to 10 minutes

AV 29535 AO, ADF 34 5 to 30 delta °F (2.8 to 16.7 delta °C)

BAND

AV 29537 AO, ADF 36 10 to 100 delta °F (5.6 to 56 delta °C)

RANGE

HTG-SAT-TIME AV 29538 AO, ADF 37 60 seconds to 900 seconds

AV 29539 AO, ADF 38 360 seconds to 1,440 seconds

CONST

HTG-DEAD-TIME AV 29540 AO, ADF 39 20 seconds to 120 seconds

AV 29542 AO, ADF 41 5 to 30 delta °F (2.8 to 16.7 delta °C)

BAND

InstanceIDPoint

type

Point

address

Unit (IP), enum set/range

1. Occupancy BI

2. Temp Occ BI

3. Temp Occ

4. Occ Override

5. Local Schedule

6. BAS Schedule

7. Occupancy Sensor

1. Off

2. On

3. Low

4. Medium

5. High

1. No

2. Yes

1. State 0

2. State 1

3. State 2

Technical Bulletin

25TEC3000 Color Series Field-Selectable BACnet MS/TP or N2 Networked and Wireless Thermostat Controllers

Page 26

Table 5: Points for TEC3622-1x-000, TEC3623-1x-000, TEC3022-1x-000, TEC3023-1x-000,

TEC3122-14-000, and TEC3123-14-000

Point description Point name Object

type

Cool Process Range CLG-PROC-

AV 29544 AO, ADF 43 10 to 100 delta °F (5.6 to 56 delta °C)

RANGE

Cool Saturation

CLG-SAT-TIME AV 29545 AO, ADF 44 60 seconds to 900 seconds

Time

Cool Time Constant CLG-TIME-

AV 29546 AO, ADF 45 360 seconds to 1,440 seconds

CONST

Cool Process Dead

CLG-DEAD-TIME AV 29547 AO, ADF 46 20 seconds to 120 seconds

Time

Cool Period CLG-PERIOD AV 29548 AO, ADF 47 30 seconds to 120 seconds

Deadband DEADBAND AV 29556 AO, ADF 55 1.4 to 3 delta °F (0.78 to 1.66 delta °C)

Min Heating

MINHTG-SP AV 29559 AO, ADF 56

Setpoint

Max Heating

MAXHTG-SP AV 29560 AO, ADF 57 Present value of Min Heating Setpoint

Setpoint

Min Cooling

MINCLG-SP AV 29561 AO, ADF 58 Present value of Max Heating Setpoint

Setpoint

Max Cooling

MAXCLG-SP AV 29562 AO, ADF 59 Min Cooling Setpoint present to 100°F

Setpoint

Occ Setpoint Select OCCSP-SEL MV 29563 AO, ADF 60 Occ Setpoint select

Min Setpoint MIN-SP AV 29564 AO, ADF 61

Max Setpoint MAX-SP AV 29565 AO, ADF 62

Heat Cool Setpoint

Mode

HTGCLGSPMODE

MV 29566 MI, ADI 24 Heat Cool Setpoint Mode

Common Setpoint COMMON-SP AV 29567 AO, ADF 62 55°F to 90°F (12.77°C to 32.22°C)

Fan Mode 2 FAN-MODE2 MV 29568 MI, ADI 27 TEC3000 Fan Mode 2

Fan Override 2 FAN-OVRD2 MV 29569 MI, ADI 28 UI Fan Override 2

InstanceIDPoint

type

Point

address

Unit (IP), enum set/range

2

45°F (7.22°C) to Max Heating Setpoint

2

Value

(MINHTG-SP) to present value of Min

Cooling Setpoint (MINCLG-SP)minus 1

(MAXHTG-SP) plus 1 to present value of

Max Cooling Setpoint (MAXCLG-SP)

(37.78°C)

2

1. Setpoint Offset

2. Min and Max Setpoint

3

45°F to 85°F (7°C to 30°C)

60°F to 100°F (16°C to 38°C)

3

3

1. Common Setpoint

2. Individual Setpoints

1. Auto

2. Smart

3. Low

4. Medium

5. High

*This point only shows if the unit type

is 2-pipe or 4-pipe and the fan type is

multispeed

1. Auto

2. Quiet

3. Low

4. Medium

5. High

*This point only shows if the unit type

is 2-pipe or 4-pipe and the fan type is

multispeed

2

2

26

TEC3000 Color Series Field-Selectable BACnet MS/TP or N2 Networked and Wireless Thermostat Controllers

Technical Bulletin

Page 27

Table 5: Points for TEC3622-1x-000, TEC3623-1x-000, TEC3022-1x-000, TEC3023-1x-000,

TEC3122-14-000, and TEC3123-14-000

Point description Point name Object

type

Control State TEMPCTRL-

SETUP2

Network Override

Zone Temperature

Signal Strength Signal Strength MV 29724 n/a n/a Wireless Signal Strength

Cooling Valve %

Command

Heating Valve %

Command

AO1 Output / Fan

Speed Percent

Command

BO2 Command /

BO2 Fan Low

Command

BO3 Command /

BO3 Fan Medium

Command

BO4 Command /

BO4 Fan High

Command

AUX Command /

BO8 AUX

BI1 Sensor / Binary

Input 1

BI2 Sensor / Binary

Input 2

Schedule Schedule Schedule 10133 n/a n/a n/a

Local Occupancy LOCAL-OCC MV 6 n/a n/a Occ Schedule

Calendar Calendar Calendar 10019 n/a n/a n/a

Dehumidification

Enable

NET-ZNT AV 29571 AO, ADF 63 -50°F to 120°F (-45°C to 49°C)

CLG-O AO 86907 AO, AO 5 0% to 100%

HTG-O AO 86906 AO, AO 4 0% to 100%

VSF-O AO 86905 AO, AO 3 0% to 100%

FANL-C BO 86909 BO, BO 2 Inactive/Active

FANM-C BO 86910 BO, BO 3 Inactive/Active

FANH-C BO 86911 BO, BO 4 Inactive/Active

AUX BO 86913 BO, BO 8 Inactive/Active

BI1-S BI 30827 BI, BI 1 Inactive/Active

BI2-S BI 30828 BI, BI 2 Inactive/Active

DEHUM ENABLE MV 29736 n/a n/a No/Yes

MV 29570 MI, ADI 26 TEMP_CONTROL_SETUP_SUBSET

InstanceIDPoint

type

Point

address

Unit (IP), enum set/range

1. Automatic PID Tuning

2. Deadband Override

3. Manual PID Tuning

1. None

2. Weak

3. Average

4. Strong

1. Inactive

2. Active

1. Inactive

2. Active

1. Inactive

2. Active

1. Inactive

2. Active

1. Inactive

2. Active

1. Inactive

2. Active

1. Occupied

2. Unoccupied

3. Standby

4. Not Set

1. No

2. Yes

Technical Bulletin

27TEC3000 Color Series Field-Selectable BACnet MS/TP or N2 Networked and Wireless Thermostat Controllers

Page 28

Table 5: Points for TEC3622-1x-000, TEC3623-1x-000, TEC3022-1x-000, TEC3023-1x-000,

TEC3122-14-000, and TEC3123-14-000

Point description Point name Object

type

Unocc Dehum

Enable

Chilled

Water Supply

Temperature

Chilled

Water Supply

Temperature

Setpoint

Network

Override Chilled

Water Supply

Temperature

Outdoor Air

Humidity

Cooling Valve

Minimum Position

Cooling Valve

Starting Position

Heating Valve

Starting Position

Coil Tempering

Time

Dehumidification

Overcool Limit

Dehumidification

Sequence Mode

Dehumidification

Sequence Mode

UNOCC DEHUM

ENABLE

EFF-CHWST AV 29734 n/a n/a n/a

CHWST-SP AV 29735 n/a n/a 0 to 250 deg F (-17 to 121 deg C)

NET-CHWST AV 29736 n/a n/a 0 to 250 deg F (-17 to 121 deg C)

EFF-OAH AV 29737 n/a n/a n/a

CLVVLV-MINPOS

CLGVLV-STARTPOS

HTGVLV-STARTPOS

COIL-TPR-TIME AV 29741 n/a n/a 3 minutes to 10 minutes

DEHUMOVRCLG-LIM

4PIPE-DEHUMSEQ-MODE

2PIPE-DEHUMSEQ-MODE

MV 29737 n/a n/a No/Yes

AV 29738 n/a n/a 50% to 75%

AV 29739 n/a n/a 50% to 100%

AV 29740 n/a n/a 50% to 100%

AV 29742 n/a n/a 1 to 5 delta deg F, delta deg C

MV 29729 n/a n/a TEC3000 FCU Dehum Seq Mode

MV 29730 n/a n/a TEC3000 Dehum Sequence

InstanceIDPoint

type

Point

address

Unit (IP), enum set/range

1. No

2. Yes

*This point only shows if there is neither

a CHWST sensor wired to TEC nor a

Network override value setup and

Dehum Enable is set to Enable

*This point only shows if

Dehumidification Sequence Mode is

setup as Individual Coils or 2-pipe with

Reheat and Dehum Enable is set to

Enable

*This point only shows if

Dehumidification Sequence Mode is

setup as Individual Coils or 2-pipe with

Reheat and Dehum Enable is set to

Enable

*This point only shows if

Dehumidification Sequence Mode is

setup as Individual Coils and Dehum

Enable is set to Enable

*This point only shows if

Dehumidification Sequence Mode is

setup as Single Coil and Dehum Enable is

set to Enable

*This point only shows if

Dehumidification Sequence Mode is

setup as Single Coil and Dehum Enable is

set to Enable

1. Individual Coils

2. Single Coil

*This point only shows if Unit Type is 4pipe and Dehum Enable is set to Enable

1. Individual Coils

2. Single Coil

3. 2-Pipe With Reheat

*This point only shows if Unit Type is 2pipe and Dehum Enable is set to Enable

28

TEC3000 Color Series Field-Selectable BACnet MS/TP or N2 Networked and Wireless Thermostat Controllers

Technical Bulletin

Page 29

Table 5: Points for TEC3622-1x-000, TEC3623-1x-000, TEC3022-1x-000, TEC3023-1x-000,

TEC3122-14-000, and TEC3123-14-000

Point description Point name Object

type

Scheduled

Circulation Enable

Scheduled

Circulation Only

When Occupied

Minimum Hourly

Fan Runtime

Variable Speed Fan

Circulation Setpoint

Multi Speed Fan

Circulation Setpoint

1 The passcode cannot be changed from BAS. The passcode can only be defined by the local display or through MAP

version 4.0.

2 The Occ Setpoint Select is set to the Min and Max Setpoint and Heat Cool Setpoint Mode is set to the Individual Setpoint.

3 The Occ Setpoint Select is set to the Min and Max Setpoint and Heat Cool Setpoint Mode is set to the Common Setpoint.

SCH-CIR-EN MV 29731 n/a n/a Disable/Enable

SCH-CIR-ONLYOCC

MIN-HR-FAN AV 29743 n/a n/a 5 minutes to 30 minutes

VAR-FAN-CIR-SP AV 29744 n/a n/a 0% to 100%

MULTI-FAN-CIR-SPMV 29733 n/a n/a Sensitivity

MV 29732 n/a n/a Disable/Enable

InstanceIDPoint

type

Point

address

Unit (IP), enum set/range

1. Disable

2. Enable

1. Disable

2. Enable

*This point shows Unreliable if

Scheduled Circulation Enable is set to

Disable

*This point shows Unreliable if

Scheduled Circulation Enable is set to

Disable

*This point only shows if Fan Type is

Variable speed and Scheduled Circulation

Enable is True

1. Low

2. Medium

3. High

*This point only shows if Fan Type is

Multi Speed and Scheduled Circulation

Enable is True

Technical Bulletin

29TEC3000 Color Series Field-Selectable BACnet MS/TP or N2 Networked and Wireless Thermostat Controllers

Page 30

Table 6: Points for TEC3630-1x-000, TEC3631-1x-000, TEC3030-1x-000, TEC3031-1x-000,

TEC3130-14-000, and TEC3131-14-000

Point description Point name Object

type

Unit Status UNIT-S MV 29700 MI, ADI 13 TEC3000 Detailed Control Status 2

Operational Space

Temperature

Eff Outdoor Air

Temperature

Active Setpoint EFF-

CV Operating Cooling

Setpoint

CV Operating Heating

Setpoint

Occupancy Status EFF-OCC MV 29708 MI, ADI 14 TEC3000 Occupancy Status

EFF-ZNT AV 29701 AI, ADF 16 n/a

EFF-OAT AV 29704 AI, ADF 19 n/a

AV 29705 AI, ADF 20 n/a

SETPOINT

EFFCLG-SP AV 29706 AI, ADF 21 n/a

EFFHTG-SP AV 29707 AI, ADF 22 n/a

InstanceIDN2 point

type

Point

address

Enum Set/Range

1. System Fault

2. Airflow Fault

3. Open Window

4. Control Off

5. Unreliable Temperature

6. Dehumidification

7. Idle

8. Cooling

9. Heating

10. Cooling Unavailable

11. Heating Unavailable

12. Cooling Unavailable due to

Changeover

13. Cooling Unavailable due to OA

Temp

14. Cooling Unavailable due to Control

Mode

15. Heating Unavailable due to

Changeover

16. Heating Unavailable due to OA

Temp

17. Heating Unavailable due to Control

Mode

18. Load Shed Active

19. Dehumidifying – Reheat

20. Dehumidifying – Fan Only

21. Dehum Unavail By Dew Point

1. Occupied

2. Temp Occupancy

3. Unoccupied

4. Standby

5. Occupied-Override

6. Unoccupied-Override

30

TEC3000 Color Series Field-Selectable BACnet MS/TP or N2 Networked and Wireless Thermostat Controllers

Technical Bulletin

Page 31

Table 6: Points for TEC3630-1x-000, TEC3631-1x-000, TEC3030-1x-000, TEC3031-1x-000,

TEC3130-14-000, and TEC3131-14-000

Point description Point name Object

type

Occupancy Input

OCCSOURCE-SMV 29709 MI, ADI 15 TEC3000 Occupancy Source

Source

Econ Command OAD-O AV 86905 AO, AO 3 n/a

Cool Cmd CLGPID-% AV 29714 AI, ADF 25 0% to 100%

Cool Stage 1 Y1-C BO 86911 BO, BO 4 Inactive/Active

Cool Stage 2 Y2-C BO 86910 BO, BO 3 Inactive/Active

Heat Cmd HTGPID-% AV 29717 AI, ADF 26 0% to 100%

Heat Stg 1 W1OB-C BO 86912 BO, BO 7 Inactive/Active

Heat Stg 2 W2SUP-C BO 86908 BO, BO 6 Inactive/Active

Manual Occupancy

Override

Supervisory

OCCOVRD-

MV 29518 MO, ADI 5 UI Occ Override

MODE

NET-OCC MV 29519 MO, ADI 6 Occ Schedule

Occupancy

Occupancy

OCC-CONFIG MV 29520 MO, ADI 7 SE Occupancy Mode

Configuration Source

Passcode

1

PASSCODE

1

AV 29522 AI, ADF 15 0000 to 9999

Fan Mode FAN-MODE MV 29524 MO, ADI 9 TEC3000 Fan Mode

InstanceIDN2 point

type

Point

address

Enum Set/Range

1. Occupancy B1

2. Temp Occ B1

3. Temp Occ

4. Occ Override

5. Local Schedule

6. BAS Schedule

7. Occupancy Sensor

1. Inactive

2. Active

1. Inactive

2. Active

1. Inactive

2. Active

1. Inactive

2. Active

1. No Override

2. Occupied

3. Unoccupied

1. Occupied

2. Unoccupied

3. Standby

4. Not Set

1. Schedule

2. External

1. On

2. Auto

3. Smart

*This point only shows if the unit type is 2

pipe or 4 pipe and the fan type is singleor variable-speed

Technical Bulletin

31TEC3000 Color Series Field-Selectable BACnet MS/TP or N2 Networked and Wireless Thermostat Controllers

Page 32

Table 6: Points for TEC3630-1x-000, TEC3631-1x-000, TEC3030-1x-000, TEC3031-1x-000,

TEC3130-14-000, and TEC3131-14-000

Point description Point name Object

type

Fan Override FANOVRD-

MODE

Aux Mode AUX-MODE MV 29527 MO, ADI 11 TEC3000 Aux Mode

Temperature Units TEMP-UNITS MV 29528 MO, ADI 12 Unit Set

Max Setpoint Offset MAXSP-

OFFSET

B1 Sensor BI1-S BI 30827 BI, BI 1 Inactive/Active

B2 Sensor BI2-S BI 30828 BI, BI 2 Inactive/Active

BO2 Command FAN-C BO 86909 BO, BO 2 Inactive/Active

Load Shed Active LOADSHED-ENMV 29728 MO, ADI 19 No/Yes

Load Shed Rate limit LOADSHEDRL AV 29725 AO, ADF 30 0°F to 1°F (-17.78°C to -17.22°C)

Load Shed Adjust LOADSHED-

ADJ

Fan Speed Status FANSPD-S MV 29712 MI, ADI 18 Supply Fan Status

Local Occupancy LOCAL-OCC MV 6 n/a Occ Schedule

MV 29525 MO, ADI 10 UI Fan Override

AV 29529 AO, ADF 29 0°F to 20°F (0°C to -11°C)

AV 29726 AO, ADF 31 0°F to 8°F (-17.78°C to -13.33°C)

InstanceIDN2 point

type

Point

address

Enum Set/Range

1. On

2. Auto

3. Quiet

*This point only shows if the unit type is 2

pipe or 4 pipe and the fan type is singleor variable-speed

1. Not Used

2. Occupied NO

3. Occupied NC

4. Occupied Fan NO

5. Occupied Fan NC

6. On

7. Off

1. IP

2. SI

1. Inactive

2. Active

1. Inactive

2. Active

1. Inactive

2. Active

1. No

2. Yes

1. Off

2. On

3. Low

4. Medium

5. High

1. Occupied

2. Unoccupied

3. Standby

4. Not Set

32

TEC3000 Color Series Field-Selectable BACnet MS/TP or N2 Networked and Wireless Thermostat Controllers

Technical Bulletin

Page 33

Table 6: Points for TEC3630-1x-000, TEC3631-1x-000, TEC3030-1x-000, TEC3031-1x-000,

TEC3130-14-000, and TEC3131-14-000

Point description Point name Object

type

Control Mode SYSTEM-

MODE

Unit Enable UNITEN-

MODE

Common Setpoint COMMON-SP AV 29567 AI, ADF 62 55°F to 90°F (12.77°C to 32.22°C)

Occupied Cooling

Setpoint

Occupied Heating

Setpoint

Unoccupied Cooling

Setpoint

Unoccupied Heating

Setpoint

Standby Cooling

Setpoint

Standby Heating

Setpoint

Setpoint Offset WC-ADJ AV 29508 AO, ADF 7 (Negative) Max Setpoint Offset

Hold/Run HOLDRUN-MDMV 29509 MO, ADI 3 Hold/Run

Reset PID Tuning TUNING-

Network Override

Outdoor Air

Temperature

Network Override

Outdoor Air Humidity

Network Override

Zone Humidity

Network Override

Supply Air

Temperature

Supplemental %

Command

Economizer PID CMD OADPID-% AV 29713 AO, ADF 24 0% to 100%

Schedule Schedule Schedule 10133 n/a n/a n/a

Calendar Calendar Calendar 10019 n/a n/a n/a

Temporary

Occupancy Duration

Unoccupied Off Delay UNOCC-OFF-

CLGOCC-SP AV 29502 AO, ADF 1 60°F to 100°F (15.05°C to 37.78°C)

HTGOCC-SP AV 29503 AO, ADF 2 45°F to 85°F (7.22°C to 29.44°C)

CLGUNOCC-SPAV 29504 AO, ADF 3 60°F to 100°F (15.05°C to 37.78°C)

HTGUNOCC-SPAV 29505 AO, ADF 4 45°F to 85°F (7.22°C to 29.44°C)

CLGSTBY-SP AV 29506 AO, ADF 5 60°F to 100°F (15.05°C to 37.78°C)

HTGSTBY-SP AV 29507 AO, ADF 6 45°F to 85°F (7.22°C to 29.44°C)

RESET

NET-OAT AV 29513 AI, ADF 11 -50°F to 125°F (-45.55°C to 51.66°C)

NET-OAH AV 29514 AI, ADF 12 0% RH to 100% RH

NET-ZNH AV 29516 AI, ADF 14 0% RH to 100% RH

NET-SAT AV 29515 AIO, ADF 13 0°F to 150°F (-17.78°C to 65.56°C)

SUPHTPID-% AV 29723 AO, ADF 28 0% to 100%

TEMPOCCLEN

DELAY

MV 29500 MO, ADI 1 TEC3000 Unit Control Mode

MV 29501 MO, ADI 2 Shutdown/Enable

MV 29517 MO, ADI 4 No/Yes

AV 29727 AO, ADF 32 0 minutes to 300 minutes

AV 29534 AO, ADF 33 0 minutes to 10 minutes

InstanceIDN2 point

type

Point

address

Enum Set/Range

1. Auto

2. Cooling

3. Heating

1. Shutdown

2. Enable

*When Occ Setpoint Select = Setpoint

Offset Otherwise, see Table 11 for

constraints

1. Hold

2. Run

1. No

2. Yes

Technical Bulletin

33TEC3000 Color Series Field-Selectable BACnet MS/TP or N2 Networked and Wireless Thermostat Controllers

Page 34

Table 6: Points for TEC3630-1x-000, TEC3631-1x-000, TEC3030-1x-000, TEC3031-1x-000,

TEC3130-14-000, and TEC3131-14-000

Point description Point name Object

type

Occ Setpoint Select OCCSP-SEL MV 29563 MO, ADI 23 Occ Setpoint Select

Heat Cool Setpoint

Mode