Page 1

24-10239-480 Revision F

December 2017

hardware installation

S321-IP

Network Controller

Page 2

Copyright 2017

Johnson Controls

All Rights Reserved

No part of this document may be reproduced without the prior permission of Johnson Controls.

If this document is translated from the original English version by Johnson Controls, all reasonable

endeavors will be used to ensure the accuracy of translation. Johnson Controls shall not be liable

for any translation errors contained herein or for incidental or consequential damages in connection

with the furnishing or use of this translated material.

Due to continuous development of our products, the information in this document is subject to

change without notice. Johnson Controls shall not be liable for errors contained herein or for

incidental or consequential damages in connection with furnishing or use of this material. Contents

of this publication may be preliminary and/or may be changed at any time without any obligation to

notify anyone of such revision or change, and shall not be regarded as a warranty.

Other Manufacturers’ Documentation

Johnson Controls does not duplicate documentation of other equipment manufacturers. When

necessary, Johnson Controls provides documentation that supplements that of other manufacturers.

When unpacking your equipment, keep all original manufacturer documentation for future

reference.

Technical Support

For factory technical support, Johnson Controls authorized field technicians or authorized dealer

representatives can contact Global Security Solutions Technical Support by phone at

(866) 893-0423 or (414) 524-1214, or by email at support.globalsecuritysolutions@jci.com

. They

can also call the Field Support Center at (800) 524-1330 or (414) 524-5000 and use options 6, 1, 7.

End users and customers should contact their local Johnson Controls branch or authorized dealer

for any of their support needs (technical support, maintenance contracts, on-site field support,

P2000 Software Service Agreements, Service Partnerships, and so on). Visit

http://www.johnsoncontrols.com/location-finder

to find your local Johnson Controls office.

For material returns contact the branch if the material was purchased through a Johnson Controls

branch or through the Product Sales Operations Team, if ordered through the Advanced Order

Management System (AOMS) and follow the RMA process; or contact the authorized dealer

representative where the material was purchased directly.

Acknowledgment

Metasys® and Johnson Controls® are trademarks of Johnson Controls. All other company and

product names are trademarks or registered trademarks of their respective owners.

Page 3

Declarations of Conformity

United States: This equipment, S321-IP, has been tested and found to comply with the limits for a

Class A digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful interference to

radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

Canada: CAN ICES-3 (A)/NMB-3(A)

European Union: This product complies with the requirements of the EMC Directive.

This equipment must not be modified for any reason and it must be installed as stated in the

Manufacturer’s instructions. If this shipment (or any part thereof) is supplied as second-hand

equipment, equipment for sale outside the European Economic Area or as spare parts for either a

single unit or system, it is not covered by the Directives.

Page 4

UNDERWRITERS LABORATORIES COMPLIANCE VERIFICATION SHEET

The following model number is listed under Underwriters Laboratories® (UL) 1076 for Proprietary

Burglar Alarm Units and Systems and UL 294 for Access Control Systems Units and Underwriters

Laboratories of Canada ULC/ORD-C1076-86.

S321-IP

When installed at the site the following requirements must be met to comply with these standards.

1. The S321-IP shall be mounted in subassembly S300-DIN-L or S300-DIN-S.

2. The tamper switch must be enabled at all times.

3. Transient protection devices that are installed must not be removed or defeated.

4. Do not connect equipment to an AC power source that is controlled by a switch.

5. The sole use of a class 2 transformer to power the S321-IP would not provide battery

standby power.

6. The RS485 reader interfaces were not investigated by Underwriters Laboratories.

7. For a UL 294 Listed system the following Listed readers may be used.

8. Model S321-IP must use a Class 2 direct plug-in transformer rated 120 VAC input and

24 VAC, 50 VA output from one of the following manufacturers:

Basler, part number BE116450CAA or BE116450AAA

Potter Electric Signal Co. (Amseco), model XR-2450LED

Revere Industries, model RT-2450SL/M

9. UL 294 Performance Levels

Destructive Attack Level I

Endurance Level IV

Line Security Level II

Standby Power Level I

Manufacturer Models

HID Corp. 30387, 31503, 31815, 31880, 32005, 32788, 32985

5355, 5365, 5395, 5405, 5455, 6005

All models may be followed by additional suffixes

Mercury Security Corp. MR-5

Page 5

S321-IP Network Controller Hardware Installation

24-10239-480 Rev. F

1

S321-IP HARDWARE INSTALLATION

The S321-IP controller communicates with the host via Ethernet. It supports up

to two doors per unit and allows you to configure supervised 4-state inputs and

unsupervised 2-state inputs. The S321-IP controller provides power for the card

reader hardware; it does not provide power for the door locking hardware.

A

BOUT THIS DOCUMENT

This document describes S321-IP hardware installation, basic operation, and

maintenance procedures. It is divided into the following sections:

• Unpacking the Equipment on page 1

• Tools Needed on page 1

• Mounting on page 2

• Description of Signals on page 5

• Cable Requirements on page 7

• Basic Commissioning on page 10

• The S321-IP User Interface on page 16

• Technical Specifications on page 19

• Maintenance on page 20

U

NPACKING THE EQUIPMENT

Inspect the S321-IP shipping containers as soon as you receive them, with the

delivery agent present. If a container is damaged, open it immediately, inspect

the contents, and have the agent make note on the shipping document. Check

the purchase order against the packing slips to ensure the order is complete. If

the contents of a container are damaged, notify the carrier and your

Johnson Controls representative immediately. Report any discrepancies to your

Johnson Controls representative. Save the packing materials for possible return

shipments.

Your package should contain the S321-IP controller, connectors set, a CD

containing a set of user documentation, and this manual.

T

OOLS NEEDED

Use a small, straight-blade screwdriver to secure wires in the terminal blocks.

Page 6

S321-IP Network Controller Hardware Installation

24-10239-480 Rev. F

2

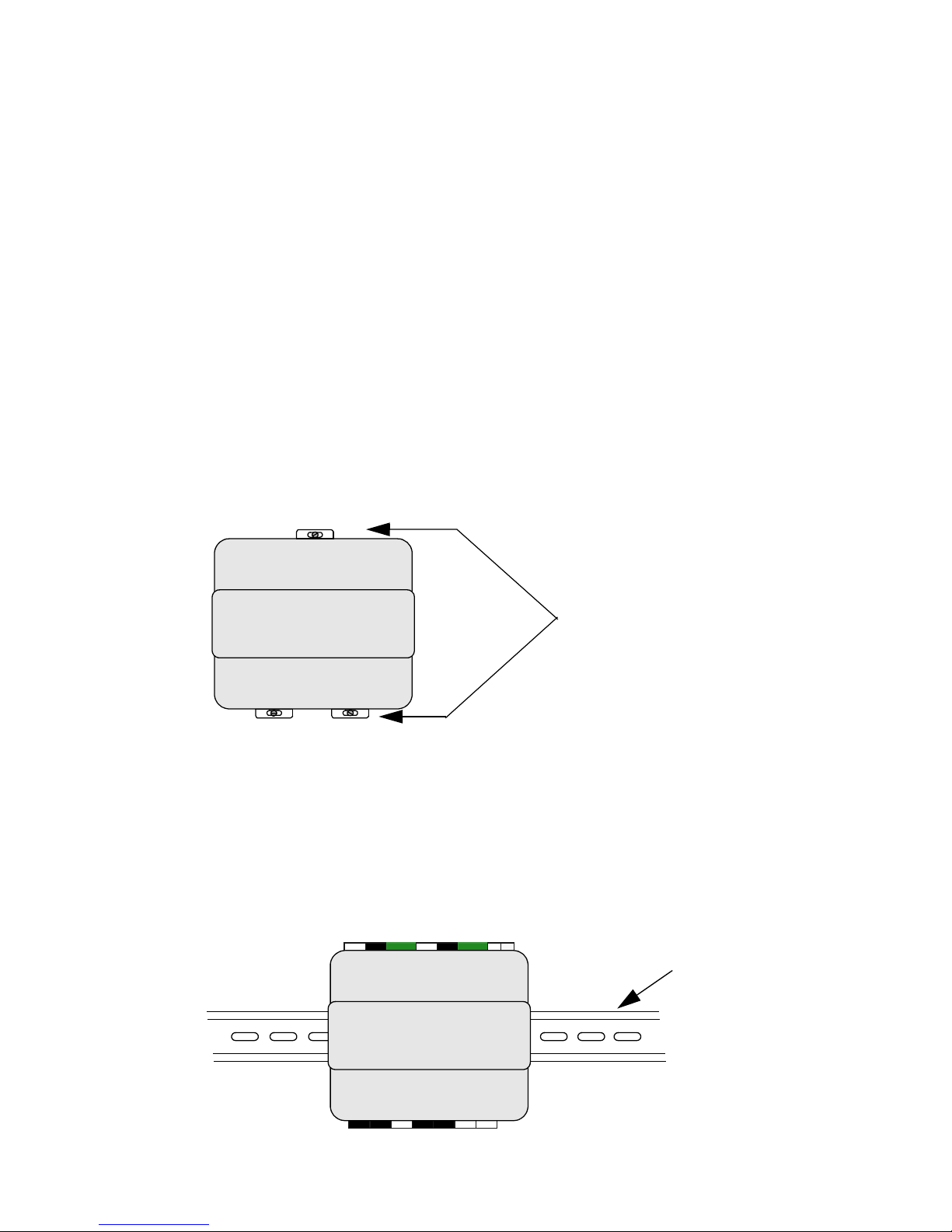

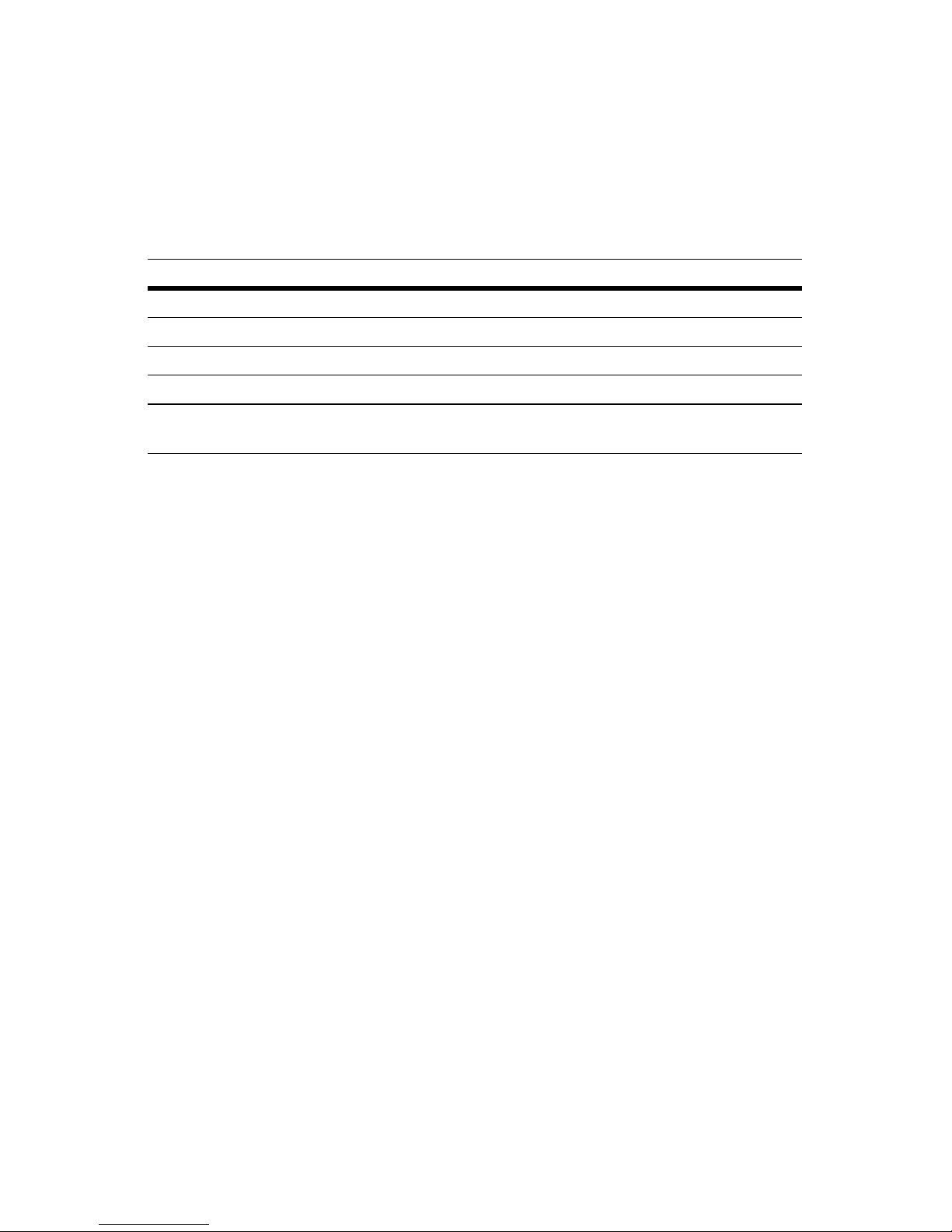

MOUNTING

You can mount the S321-IP controller on a flat surface, DIN rail, or in a

Johnson Controls’ approved enclosure (for example: S300-DIN).

For information on mounting the S321-IP in an enclosure, refer to the manual

provided with the enclosure.

To mount an S321-IP controller on a flat surface:

1. Fully extend the white clips located on the top and bottom of the

controller. You may need to remove the connectors.

2. Mount the controller to the surface with mounting screws.

3. Replace the connectors, if previously removed.

To mount an S321-IP controller on a DIN rail:

1. Fully extend the white clips located on the bottom of the controller.

You may need to remove the connectors.

2. Hook the controller on top of the rail and push in the clips.

Fully extended clips for

wall mount

(connectors are removed)

S321-IP

DIN rail

S321-IP

Page 7

S321-IP Network Controller Hardware Installation

24-10239-480 Rev. F

3

3. If you need to remove a controller from the DIN rail, reverse the

mounting sequence (pull down the bottom clips, then pull the bottom

of the controller out and lift it up.)

Power Source Requirements

Line Voltage Information

If the facility is located in an area where power lines are subject to

frequent lightning strikes, verify with the electric company that the

building transformer is equipped with surge protectors. These, as well as

a “crowbar” type of protection, can be installed at the main service

entrance if the building transformer is not equipped with lightning

protection.

While lightning is one cause of power line transients, others can be

internal or external to the building environment. The general application

of transient surge suppression is low-cost insurance to ensure long life of

the equipment being installed.

Lithium Battery

The S321-IP contains a lithium battery that is used for realtime clock

backup. The lithium battery is shipped from the factory charged and

operational.

If there are no power outages, change the battery every five years. If a

power outage occurs, the battery life is approximately 30 days. Replace

with Panasonic part number CR2025 or equivalent.

Parameter Value

Power 24 W

Input voltage +12 to +28 VDC; 16 to 28 VAC

Nominal voltage +12 to +24 VDC; 16 to 24 VAC

Current 1 A at 24 V; 2 A at 12 V

Class 2 transformer (optional) See step 8 on the Underwriters Laboratories Compliance

Verification Sheet at the beginning of this manual.

Page 8

S321-IP Network Controller Hardware Installation

24-10239-480 Rev. F

4

IMPORTANT: After you replace the lithium battery (recommended every five

years or after extended use), verify that the realtime clock is correct; otherwise,

you may need to adjust the time.

To replace the lithium battery:

1. Disconnect the 24 VDC power from the S321-IP.

2. Unscrew and open the plastic enclosure.

3. With a narrow (1/8 in.) blade, carefully pry up the battery until a

portion of the battery is out of the plastic holder.

4. With your free hand gently move the battery out of the holder while

keeping the battery pried up.

5. Dispose of the old battery according to local requirements.

6. Insert the new battery into holder.

IMPORTANT: The lithium battery is polarized. Ensure the side marked ‘+’ faces

out (that is, towards you).

7. Close the plastic enclosure and secure it with the screw.

8. Re-connect the power to the S321-IP.

CAUTION: Risk of Explosion.

Replace the battery with a lithium battery of the same type and

voltage rating. Dispose of the used battery in accordance with local,

national, and regional regulations. Failure to replace the battery with

one of the same type and voltage rating may result in an explosion

causing personal injury and property damage.

Page 9

S321-IP Network Controller Hardware Installation

24-10239-480 Rev. F

5

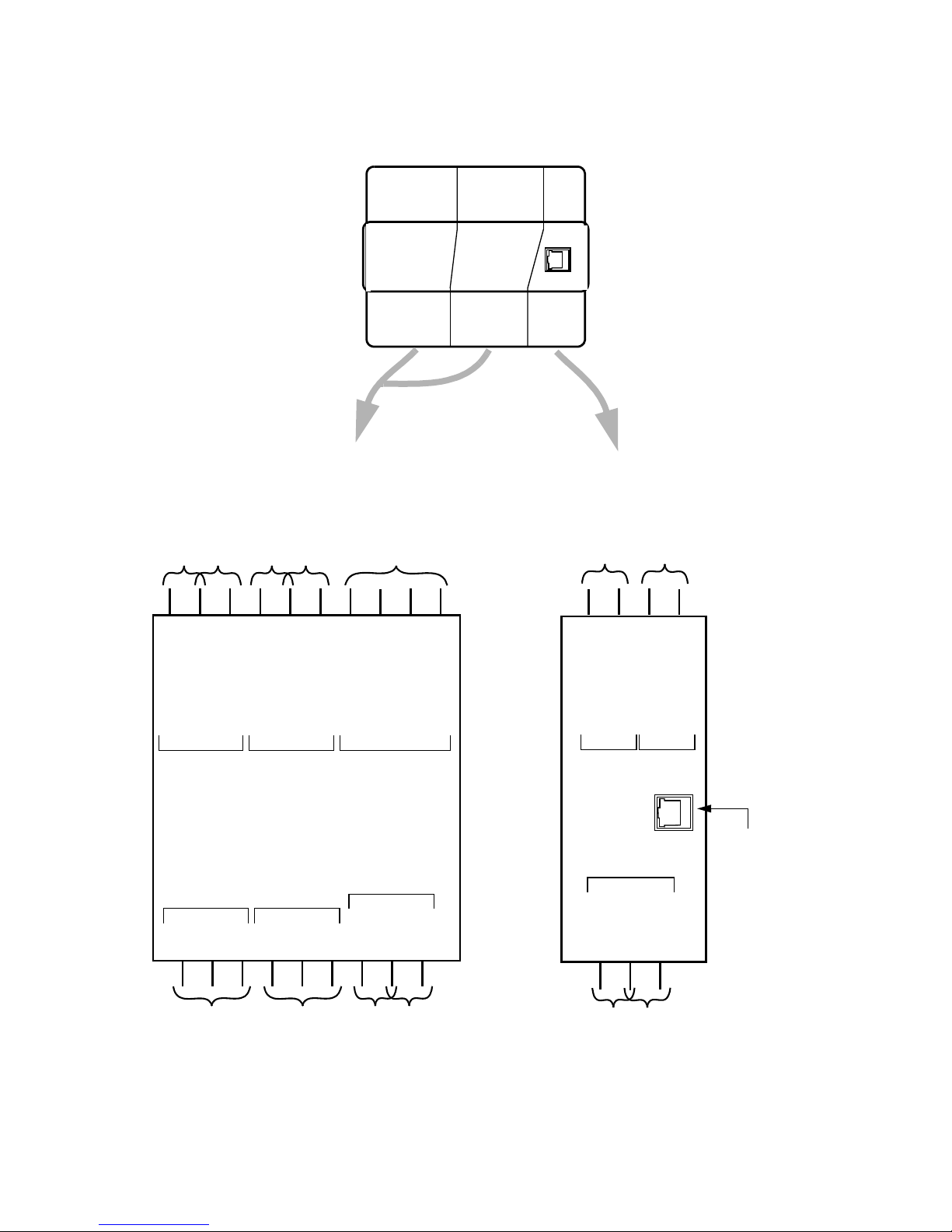

DESCRIPTION OF SIGNALS

READER n

COMNCNO

COMNCTAMP

COM

SPARE

PWR FAIL

COM

TAMP

NO

RDR n

STRIKE

RDR n

SHUNT

POWER RETURN

CAL RESISTOR

CAL RESISTOR

DATA1/Rs485+

DATA0/Rs485-

COM

POWER

GREEN LED

COM

RED LED

REX

COM

DOOR CONTACT

+12/24 VAC/VDC

RDR n

PANEL

RDR n RDR n RDR n

CAL POWER

RDR Request to

Exit Device

RDR Red Light

RDR Green Light

RDR Door

Reader

Calibration

Resistor

To the power

supply

RDR Door

Contact

RDR 1 General

Purpose Input 5

RDR 1 General

Purpose Input 6

RDR General

Purpose Input 3

RDR General

Purpose Input 4

RDR Shunt

RDR Strike

READER

1

RJ45

connector

READER

2

Page 10

S321-IP Network Controller Hardware Installation

24-10239-480 Rev. F

6

Wiegand Input

Description of Signals – DATA0 and DATA1 from each reader,

complying with the Wiegand interface specification.

Reference – These signals are referenced to logic ground (COM).

Protection – Each signal has a 6 V transient voltage suppressor between

it and COM.

Input Points

Description of Signals – The following are internally pulled up inputs:

The allowable voltage range for these signals is 0-12 VDC.

Reference – These signals are referenced to their associated COM input.

Protection – Each signal is protected with series resistors and dual

clamping diodes.

External Circuits – 4-state operation requires two external resistors and

switch circuit connected between an input point and COM. 2-state

operation requires an external switch connected between an input point

and COM. For wiring details see Wiring Input Devices on page 8.

Output Points

Description of Signals – The following are open collector outputs, with

voltage range for these signals of 0-24 VDC, limited to 50mA:

IMPORTANT: These open collector outputs can be damaged by alternating

current (AC) potentials as low as 1 VAC. Connect the LED outputs only to direct

current (DC) loads up to 24VDC.

• Reader 1 Door

Contact

• Reader 1 REX

•Reader 1 Tamper

• Reader 1 Spare

• Reader 2 Door

Contact

• Reader 2 REX

•Reader 2 Tamper

• Reader 2 Spare

• Power Panel Fail

• Panel Tamper

• Reader 1 Red LED

• Reader 1 Green LED

• Reader 2 Red LED

• Reader 2 Green LED

Page 11

S321-IP Network Controller Hardware Installation

24-10239-480 Rev. F

7

Reference – These signals are referenced to logic ground (COM).

Protection – Each signal has a 30 volt transient voltage suppressor

between it and system ground.

Relay Output Points

Description of Signals – NC, NO, and COM are the three connections to

a single pole, double throw relay. The following are the relay outputs:

Reference – The relay is a dry contact relay rated at 1 A at 24 VDC/

VAC, 25 VA maximum.

Reader Power

Description of Signals – 250 mA at 12 VDC is provided for each reader.

Protection – There is a 750 mA PTC re-settable fuse.

Network Connection

RJ45 connector – Use this connector to connect the S321-IP to the

network. The S321-IP communicates with the P2000 server via 10/

100Base-T Ethernet, using the TCP/IP protocol.

C

ABLE REQUIREMENTS

This table describes the recommended cable to use when wiring the S321-IP.

• Reader 1 Strike

• Reader 1 Shunt

• Reader 2 Strike

• Reader 2 Shunt

Description Recommended Cable Type Maximum Segment Length

S321-IP to Power

Supply

1

Listed, 18 AWG, hook-up

wire

Wire should fit within the enclosure.

S321-IP to Host Listed, Category 5, 24 AWG,

solid, 2 pair or 4 pair type.

354 ft (100 m). Cable, RJ45 connector,

and RJ45 crimp tool to be supplied by

customer.

Door Contact Belden 8442, 1 twisted,

unshielded pair, 22 AWG

500 ft. (152 m)

Door Strike and

Shunt

Belden 9740, 1 twisted,

unshielded pair, 18 AWG

Depends on power requirements of the

door strike. Do not reduce voltage to

the strike more than 10% over the 18

AWG wire, measured when energized.

Page 12

S321-IP Network Controller Hardware Installation

24-10239-480 Rev. F

8

Cable Routing

The cables should run in grounded conduit or at least 2 ft. (0.7 m) from

AC power, fluorescent lights, or other high energy sources.

IMPORTANT: Physically separate all data cables from power lines. If you use

conduit, do not run data cables in the same conduit as power cables or certain

door strike cables, for example, strike voltage greater that 42 V or Magnetic

door locks without EMI suppression.

All cables must conform with the following regulations: National

Electrical Code; NFPA 70; Local electrical codes; Canadian Electric

Code C22.1 (installations in Canada); BSI Standard BS7671, latest

edition (installations in Great Britain).

Make all cabling using good wiring practices and allow sufficient cable

length to allow service loops at cable terminations in the enclosure.

Wiring Input Devices

Tamper Switch Wiring

The tamper switch connects to a general purpose input point. To be

operational, the tamper switch must be wired to one of the unused input

points on any S321-IP in the enclosure and programmed.

Request to Exit Belden 8442, 1 twisted,

unshielded pair, 22 AWG

500 feet (152 m)

Reader Power

2

Belden 9740, 1 twisted,

unshielded pair, 18 AWG

Refer to reader manufacturer’s

specification for power requirements.

Reader Data0/

Data1

2

Belden 9744, 2 twisted,

unshielded pair, 22 AWG

500 ft. (152 m). Refer to reader

manufacturer’s specification for data

requirements.

Alarm Input Point Belden 8442, 1 twisted,

unshielded pair, 22 AWG to

each detector

500 feet (152 m)

1

When wiring more than one S321-IP, use the same type of hook-up wire and

communications wire to connect subsequent controllers.

2

Refer to reader manufacturer’s recommendations when using UL-listed readers. In the

absence of other recommendations, consider these cable specifications taking into

account the number of conductors that will actually be needed for installation.

Description Recommended Cable Type Maximum Segment Length

Page 13

S321-IP Network Controller Hardware Installation

24-10239-480 Rev. F

9

General Input Wiring

You can use the inputs as either 2-state or 4-state inputs. You must

calibrate the inputs depending on the needs of your site.

General Input Configuration

You have to configure an input before use.

The 2-state inputs, wired as shown under General Input Wiring on page 9,

must be uncalibrated. Execute an “Uncalibrate” command for each

2-state input.

The 4-state inputs, wired as shown under General Input Wiring on page 9,

must be calibrated. There are two methods available to calibrate a 4-state

input: “Calibrate” and “Calibrate with Resistor.”

• To use the Calibrate method, place the wired input in the secure state

and issue a “Calibrate” command. Use this method when the input

resistance tolerance is greater than 1% or unknown, when the cable

requirements (as described under Cable Requirements on page 7) are

not guaranteed, when the resistor value is less than 500 ohms, or when

all the inputs on an S321-IP are not wired with the same resistor

values.

• To use the Calibrate with Resistor method, install a resistor matching

the resistors wired to a 4-state input across the CAL RESISTOR

contacts, and issue a “Calibrate with Resistor” command. Use this

method when the input resistor tolerance is 1%, the cable

requirements (as described under Cable Requirements on page 7) are

guaranteed, and the resistor value is greater than 500 ohms. This

method allows an input to be calibrated before the input wiring is

completed. You can use this method to calibrate an input in any state

(alarm, secure, open, or short).

Note: The 4-state wiring requires two resistors of the same value. The

resistors can be 150-2000 Ohms, 1%, 1/4W. Recommended: 1200 Ohms.

e.g. DOOR

CONTACT

COM

e.g. DOOR

CONTACT

COM

e.g. DOOR

CONTACT

COM

2-state inputs

wiring

4-state inputs

wiring: N/O

4-state inputs

wiring: N/C

Page 14

S321-IP Network Controller Hardware Installation

24-10239-480 Rev. F

10

Ground

Every metal DIN enclosure in a Johnson Controls installation must have

its chassis bonded to a verified electrical ground (earth). Conduit ground,

cold water pipes, unbrazed joints or dissimilar metals are unacceptable

in the path of either building or supplemental ground. Where grounding is

required, connect only to the proven building electrical system ground

(earth).

B

ASIC COMMISSIONING

This section outlines the process of commissioning the S321-IP network

controller for use as a stand-alone device.

System Requirements

You need the following hardware and software to configure and operate

the S321-IP:

• Personal Computer (PC) with network connectivity running

Microsoft® Windows Server® 2008, Windows 8, Windows 7, or

Windows Vista®, 32 or 64-bit operating systems are supported

• Compatible web browser, such as Windows Internet Explorer®

Version 6.0 or higher, or Mozilla® Firefox® Version 1.0 or higher

For proper operation, cookies from the S321-IP must be allowed.

NOTE: Functionality of the browser’s Forward, Back, and Refresh buttons may

differ depending on the type of browser and the page being displayed.

Configuration Outline

Once the S321-IP and all peripheral devices are installed, you are ready to

configure the S321-IP using the controller’s embedded web interface.

Figure 1 shows a flowchart for configuring an S321-IP for use as a part of

the P2000 Security Management System (SMS). Figure 2 shows a

flowchart for configuring an S321-IP for use as a stand-alone device.

NOTE: To avoid network conflict caused by multiple controllers with the same

default name and static IP address, add and configure controllers one at a time.

Page 15

S321-IP Network Controller Hardware Installation

24-10239-480 Rev. F

11

Figure 1: S321-IP Basic Commissioning Flowchart: S321-IP with P2000 SMS

Mount, wire, and power the S321-IP

controller.

Does a DHCP

server exist on

the network?

Install the Lantronix® DeviceInstaller

software utility. Use this utility to

determine which IP address the DHCP

server assigned to the S321-IP.

Log on to the S321-IP user interface.

When logging on, use the IP address

assigned by the DHCP server or the

default controller name “s321ip”

(requires a DNS server on the network).

Log on to the S321-IP user interface

using the default static IP address of

192.168.0.1 or the default controller

name “s321ip” (when DNS service is

running).

Assign a static IP address, network

mask, and gateway to the S321-IP.

In systems with the DNS server,

assign a unique name to the controller.

Configure the following network

protocol settings, as needed: FTP,

SSL, and HTTP.

Define the P2000 host IP configuration

settings on the Configuration page

(Network menu).

Configure the S321-IP controller via the

P2000 software. Refer to the P2000

Software User Manual for instructions.

Note: Do not use local user interface to

configure the device.

You have completed the basic

commissioning of an S321-IP

controller.

Yes

No

Power off the S321-IP. Set DIP

switches #6 and #8 to ON (up). Power

on the S321-IP. Turn DIP switch #6 to

OFF (down).

Page 16

S321-IP Network Controller Hardware Installation

24-10239-480 Rev. F

12

Figure 2: Basic Commissioning Flowchart: Stand-alone S321-IP

Log on to the S321-IP user interface

using the default static IP address of

192.168.0.1 or the default controller

name “s321ip” (when DNS service is

running).

Assign a static IP address, network

mask, and gateway to the S321-IP.

In systems with the DNS server,

assign a unique name to the

controller.

Configure the following network

protocol settings, as needed: FTP,

SSL, and HTTP.

Set the current date and time at the

S321-IP controller.

Configure the S321-IP’s input/output

(I/O) point settings for two readers, one

reader with general purpose I/Os, or no

readers (all general purpose I/Os).

Add cardholder badges to the

database. If you use FTP, you can

import badge data from a spreadsheet

or from another panel. If you use the

badge enrollment feature, add names

to the cardholder records once the

badges are enrolled in the system.

Power off the S321-IP. Set DIP

switches #6 and #8 to ON (up). Power

on the S321-IP. Turn DIP switch #6 to

OFF (down).

Mount, wire, and power the S321-IP

controller.

Does a DHCP

server exist on

the network?

Install the Lantronix® DeviceInstaller

software utility. Use this utility to

determine which IP address the DHCP

server assigned to the S321-IP.

Log on to the S321-IP user interface.

When logging on, use the IP address

assigned by the DHCP server or the

default controller name “s321ip”

(requires a DNS server on the network).

You have completed the basic

commissioning of an S321-IP

controller.

Yes

No

Page 17

S321-IP Network Controller Hardware Installation

24-10239-480 Rev. F

13

DIP Switch Settings

The DIP switches are accessible through the front panel of the S321-IP.

The settings should be adjusted as follows (make sure you power cycle

the controller after you change any switch settings):

Figure 3: DIP Switch Settings

Determining the Controller’s IP Address on a DHCP-enabled Network

DHCP is a network protocol that automatically assigns IP addresses to

devices on a TCP/IP network. S321-IP controllers can be connected to a

DHCP network to receive their dynamic IP addresses.

If the S321-IP is connected to a DHCP network, use the Lantronix®

DeviceInstaller software utility provided on the S321-IP Network

Controller CD to determine the IP address the DHCP server assigned to

the controller.

Before determining the IP address:

1. Find out the controller’s Media Access Control (MAC) address. It is

listed on the sticker on the left side as well as top of the S321-IP. You

need to match the MAC address to the Hardware Address listed on the

utility’s user interface.

2. If needed, adjust the DIP settings for DHCP. See Figure 3 for details.

ON

1

2

3 4

5 6 7

8

For DHCP:

Switches #6 and

#8 down (OFF)

ON

1

2

3 4

5 6 7

8

ON

1 2

3 4

5 6 7

8

For Static IP:

Switch #6 down

(OFF) and switch #8

up (ON)

For Static IP

Commissioning:

Switches #6 and #8

up (ON)

ON

ONON

Note: Switch #1 must

always be up (ON)

Page 18

S321-IP Network Controller Hardware Installation

24-10239-480 Rev. F

14

To determine the IP address assigned to the S321-IP by the DHCP

server:

1. Insert the S321-IP Network Controller CD into the computer that will

run the utility.

NOTE: The S321-IP and the computer that will run the DeviceInstaller utility

must be connected to the same network interface.

2. Install the DeviceInstaller utility.

3. From the Windows taskbar, select Start>All Programs (or

Programs)>Lantronix>DeviceInstaller>DeviceInstaller to launch

the DeviceInstaller software utility.

4. When DeviceInstaller launches, the utility automatically searches for

all S321-IP controllers on the network and lists them in the right pane.

5. Locate the S321-IP controller’s MAC address under the Hardware

Address column.

6. Once you locate a match, use the IP address assigned to the controller

when logging on to the S321-IP controller’s user interface.

Page 19

S321-IP Network Controller Hardware Installation

24-10239-480 Rev. F

15

Configuring and Using a Static IP Address

Use the static IP address if the S321-IP is not connected to a DHCPenabled network.

To use a Static IP Address:

1. With the S321-IP unit powered off, adjust the DIP settings for Static

IP commissioning as follows: turn switch #6 and switch #8 up (ON).

2. Power on the unit.

3. Adjust the DIP settings for Static IP use as follows: turn switch #6

down (OFF).

4. Log on to S321-IP (see Logging On and Off).

5. Assign a new static IP address to the controller using the S321-IP user

interface. (Log in and go to Network>IP. On the IP page configure

the IP address under the Static IP Configuration section. Refer to the

S321-IP Network Controller Configuration and Operation Manual

for more information.)

6. The controller reboots automatically. The new settings will take effect

after the reboot.

Logging On and Off

You can log on to the user interface using the S321-IP controller’s current

IP address or name (in networks with the DNS server).

Page 20

S321-IP Network Controller Hardware Installation

24-10239-480 Rev. F

16

To log on to the S321-IP controller’s user interface:

1. From a web browser, enter the following URL, using either the IP

address or name of the S321-IP:

http://name (the default name is s321ip), or

http://IP Address (the default static IP address is 192.168.0.1),

2. Enter your User Name and Password. Your user name and password

are defined on the HTTP configuration page.

If accessing the S321-IP user interface for the first time, enter

the following in the exact letter case, as shown:

User Name: admin

Password: PASS

NOTE: If you cannot successfully log on to the S321-IP user interface, consult

with the Network Administrator for assistance.

3. Click OK. The Main menu options appear.

To log off from the S321-IP controller’s user interface:

1. To log off from the S321-IP user interface, click the Logout link at

the upper-right corner of any page or simply close the browser

window.

In addition, the S321-IP user interface automatically logs off

the current user if the system does not detect any activity for

20 minutes.

T

HE S321-IP USER INTERFACE

This section briefly describes the S321-IP user interface, which consists of:

Menu Bar – Each menu item on this bar reveals a different set of menu

options, which enable you to perform specific functions, such as configuring,

monitoring, or operating the S321-IP.

Menu Options – These options are a collection of functions associated with

the menu selected on the Menu bar. To select a menu option, simply click the

text link or the graphic icon next to it, if applicable (not all menu options have

an associated icon).

Page 21

S321-IP Network Controller Hardware Installation

24-10239-480 Rev. F

17

Logout Link – Click to log out of the S321-IP user interface.

See the diagram below for the Main menu navigation map:

Menu Bar

Menu

Options

Logout Link

Commands

System

Info

Alarms and

Events

Main Database Network

Reboot

System

Firmware

Upgrade

Database

Operations

Logger

Operations

Output

Operations

Input

Operations

Reader/

Keypad

Operations

Badge Count

Logger Record

Count

ACM Firmware

Version

NIM Firmware

Version

Reader Info

Output Info

Schedule

Info

Input Info

Page 22

S321-IP Network Controller Hardware Installation

24-10239-480 Rev. F

18

See the diagram below for the Database menu navigation map:

Report Strike/

Reader Status

Security Level

Access and

Shunt Time

Anti Passback

Assign

Schedules

Badge ID/PIN

Badge/Reader

Override

AUX Access

Reader

Enabled

Badge Types

Name/Index

Suppression

Schedule

Daylight

Savings

Time/Date

Configuration

Report Status

Input and

Latch Enable

Name/Index

Name/Index

Flash Period

Duration

Report Status

Output Enable

Name/Index

Schedule

Enable

Define Days/

Times

Name/Index

Holiday Enable

Typ e

Month/Day/

Year

Storage Time

Last/First

Name

Badge Number

Facility Code

Assign

Schedules

Last/First

Name

Security

Level

PIN

Override

Status

Schedule

Config

Holiday

Config

Logger

Config

Badge

Config

View

Badge(s)

Main Database Network

Time/Date

Config

RDR/Keypad

Config

Input

Config

Output

Config

Debounce Time

Output Point

Link

Page 23

S321-IP Network Controller Hardware Installation

24-10239-480 Rev. F

19

See the diagram below for the Network menu navigation map:

T

ECHNICAL SPECIFICATIONS

The terminal is expected to operate at moderate temperature variation, noncondensing humidity variation, moderate vibration, and possible dust

contamination.

Item Specification

Input Power +12 to +24 VDC or 16 to 24 VAC at 24W

Reader Interface • 2-wire Wiegand (up to 256 bits)

• 12 VDC, 250 mA (typical), 500 mA (peak)

• Red indicator

• Green indicator

General Purpose Inputs Resistive load

Relay Outputs 1 A max. 0-24 VDC/VAC, 25 VA max

Red LED/Green LED

Outputs

50 mA max. 0-24 VDC.

These open collector outputs can be damaged by alternating

current (AC) potentials as low as 1 VAC. Connect the LED

outputs only to direct current (DC) loads up to 24VDC.

Communications 10/100 Base-T Ethernet using TCP/IP protocol

Certifications • FCC, Class B

•CE Mark

•C-Tick

SNMP Agent

Enable

System

Information

Community

Traps

Configuration

FTP Enable

Certificate

Private Key

Self-Signed

Certificate

IP

SNMP FTP SSL HTTP

Main Database Network

Username

and Password

Timeout

Maximum Bytes

Allowed

Admin Account

User Account

DHCP Enable

IP Address

Network Mask

Gateway

MAC Address

P2000 Host

Name

User Name

or IP

Name

P2000 Host

IP Address

Page 24

S321-IP Network Controller Hardware Installation

24-10239-480 Rev. F

20

MAINTENANCE

This section provides maintenance instructions, operational testing procedures,

and information on replacement parts.

LEDs

The S321-IP controller has 6 LEDs:

• Power (Power): On during normal operation.

• Status (STATUS): Blinks every second when unit is operational.

• Transmit (XMIT) and Receive (RCV): Indicate internal controller

activity

• Link (LINK): On when there is valid physical network connection

• Active (ACT): On during active network communication to and from

the controller.

LINK and ACT are located near the RJ45 connector.

Routine Maintenance

Perform the following routine maintenance on the S321-IP:

1. Periodically check the continuity of the grounding circuit.

2. Perform operational testing monthly (see Testing Procedure on

page 21).

3. Change the battery every five years. Replace with Panasonic part

number CR2025 or equivalent.

Mounting Specifications DIN rail

Flat surface

Dimensions 5.7 H x 5.9 W x 2.2 D inches

(14.4 cm x 15.0 cm x 5.5 cm)

Ambient Temperature 32º to 122º F (0º to 50ºC)

Humidity 10 to 85% non-condensing

Ventilation Cabinets require free movement of air over all exposed

surfaces

Item Specification

Page 25

S321-IP Network Controller Hardware Installation

24-10239-480 Rev. F

21

Impaired Performance Conditions

Testing Procedure

To check for proper operation of the S321-IP controller:

1. Verify that the “Power” LED is ON.

2. Verify that the “STATUS” LED flashes once per second.

3. Verify that the “XMIT” and “RCV” LEDs blink.

4. If the controller is connected to the network, verify that the “LINK

LED” is on.

5. Present a valid card to each reader connected to the S321-IP reader

interface and then verify that access is granted (green lamp lights).

6. Present an invalid card to each reader connected to the S321-IP reader

interface and then verify that access is denied (red lamp lights).

Replacement Parts

There are no serviceable components inside the S321-IP plastic

enclosure. Generic replacement terminal blocks can be ordered if lost.

For more information on the parts listed, refer to the applicable catalog

page.

Fuses

The S321-IP has no replaceable fuses.

Condition Information Location

Unit environment not as specified. Basic Commissioning on page 10.

Unit power and grounding not as

specified.

Power Source Requirements on page 3, General

Input Configuration on page 9.

Cable length or type not as specified. Cable Requirements on page 7.

Backup battery not replaced correctly. Lithium Battery on page 3.

Page 26

S321-IP Network Controller Hardware Installation

24-10239-480 Rev. F

22

Page 27

We welcome your comments at BE-techpubs-security@jci.com.

Security Solutions

(805) 522-5555

www.johnsoncontrols.com

Loading...

Loading...