Page 1

Application Note

Issue Date April 20, 2012

Connecting Serial Controllers to the P2000 Comark

Server Running Software Version 3.11

This document describes how to connect supported serial controllers to the P2000 Comark

server running software Version 3.11. P2000 supports the following serial controllers:

• S321-DIN

• D620

• D600-AP (Version PS 155B or higher)

• D620-TIU

• S320

• P900

If installing serial controllers, you may need the following equipment:

• Digi® AccelePort® serial adapter board (installed at the P2000 server)

• PC232 converter (S321-DIN and P900 controllers excluded)

• B&B Electronics RS-232 to RS-485 converter (model 485OT9L) (S321-DIN controllers

using serial communications only)

Note: The S321-DIN can use serial communications with the RS-232 to RS-485 converter,

or it can communicate via IP using the Digi One® SP converter. This document covers both

scenarios.

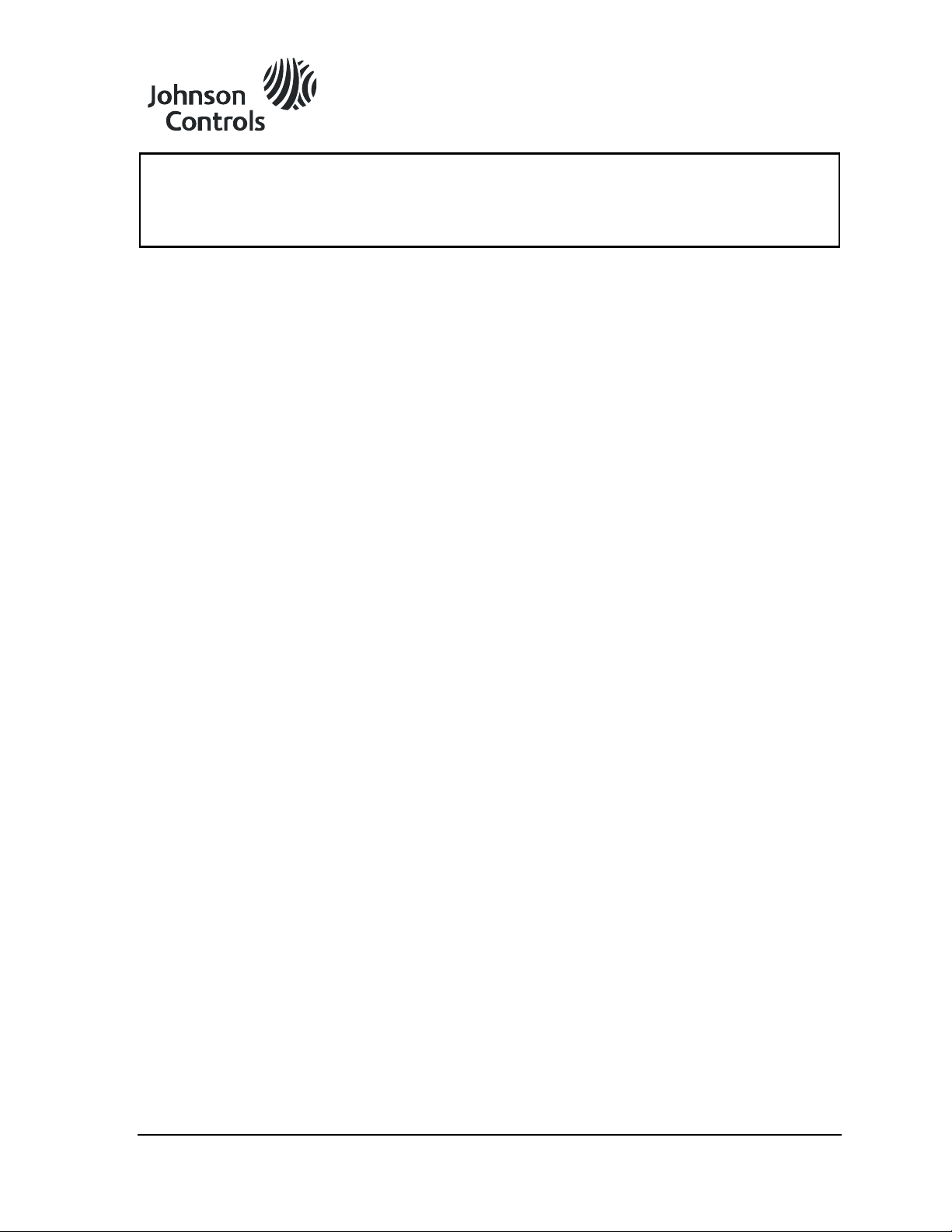

P2000 supports a controller loop configuration in which most serial controllers connect to the

server using a PC232 converter and an AccelePort connector box. See Figure 1 for an

illustration of a P2000 system component configuration with serial controllers.

© 2012 Johnson Controls, Inc. www.johnsoncontrols.com

Code No. LIT-12011743 P2000 Software Release 3.11

Page 2

2

Connecting Serial Controllers to the P2000 Comark Server Running Software Version 3.11

Figure 1: P2000 System with Serial Controllers

Connecting Serial Controllers

The following sections describe the hardware components needed to support serial

controllers (D620, D620-TIU, D600-AP, S320, and P900), including how to connect the

controllers to the system and establish communications. These components are not supplied

and must be purchased separately.

Note: This section does not include instructions for installing S321-DIN controllers. For

information on connecting these controllers, see Connecting S321-DIN Controllers on

page 13.

Note: The sections on the current loop converter do not apply to the P900 controller. For

more information on the P900 controller, refer to the P900 Installation Manual (Part No.

09-9133-01).

Preliminary – This information may change.

Page 3

Connecting Serial Controllers to the P2000 Comark Server Running Software Version 3.11

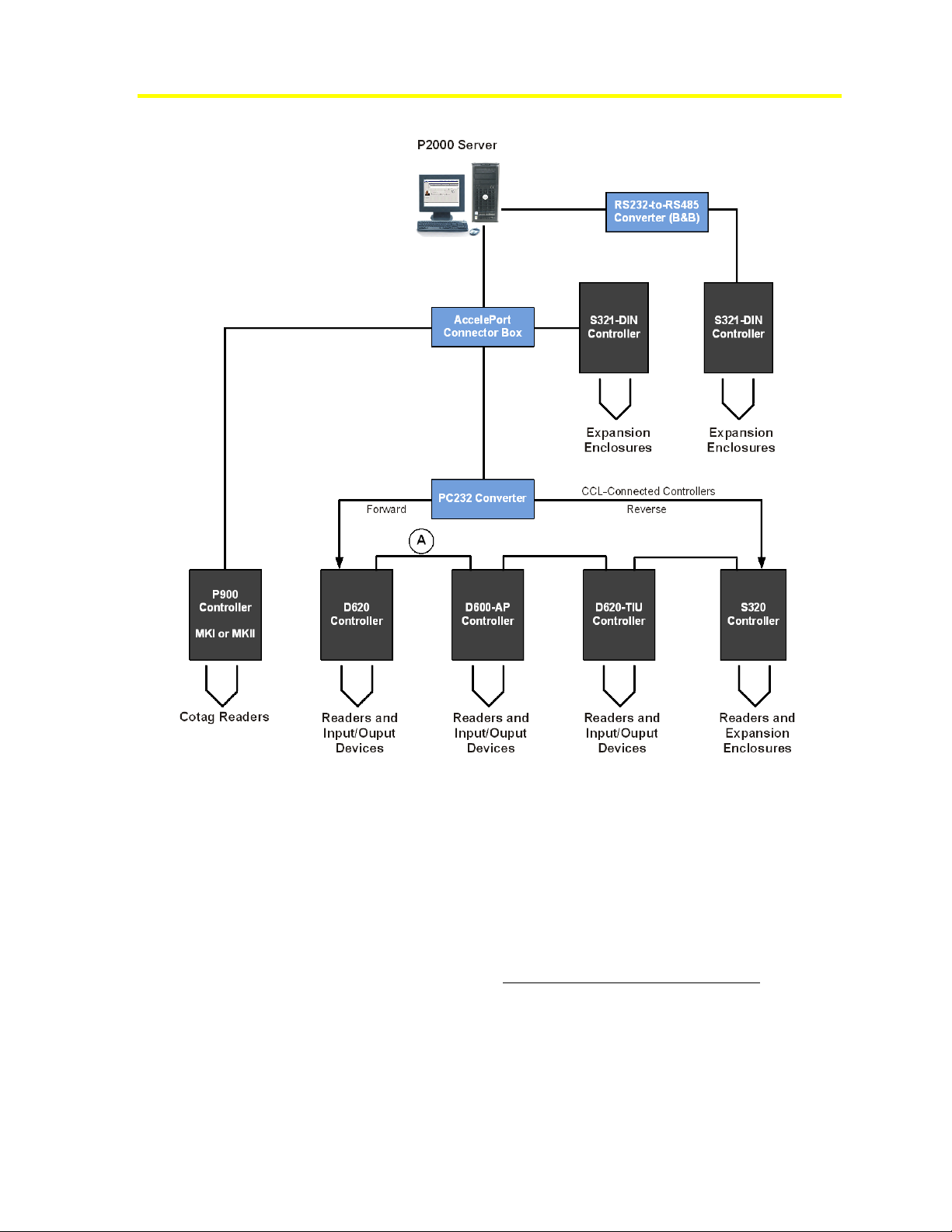

Digi PORTS/16m

Xem PCI Adapter

Installed in PCI Slot 2

DB-44 Cable

Front Side

Back Side

PC-232

Converter

Legacy

Controller

(S321/P900

Excluded)

DB-25 Female Connector

RJ-45

Connector

EBI OUT

EBI IN

Side

Panel

Connect to EBI IN

DB-25 Male Connector

Acceleport to

PC-232

To next legacy

controller

Each channel supports 16

legacy controllers

P900

Controller

To next P900 controller

For detailed information about configuring controller loop communication, refer to the

installation documentation of the serial controller.

Installing the AccelePort Serial Adapter

The AccelePort board is an expandable serial communication adapter that provides each

server with additional connections to serial controllers (S321-DIN controllers excluded).

Install the AccelePort board in one of the available PCI slots. After installing the AccelePort

board, connect the cable to the board’s interface. Follow the manufacturer’s documentation

for detailed instructions on installing the board.

Note: When configuring the AccelePort, name your devices as COM1, COM2, and so on.

The AccelePort does not support other names.

AccelePort to PC232 Installation

The AccelePort module provides additional RS-232 serial ports. The module is connected to

the AccelePort PCI board in the server by a DB44 RS-232 cable. Connect one end of the

DB44 cable to the AccelePort COM port, and the other DB44 end to the CPU port on the

module. See Figure 2.

3

Preliminary – This information may change.

Figure 2: AccelePort Connection (16 port model shown)

Page 4

4

Connecting Serial Controllers to the P2000 Comark Server Running Software Version 3.11

Current Loop Converter

The D620, D620-TIU, D600-AP (Version PS 155B or higher), and S320 controllers

communicate with the system via the Johnson Controls® proprietary Nodal Protocol B. The

current loop converter converts standard serial communication to Nodal Protocol B to allow

the P2000 Database Server to communicate with these controllers.

Current loop converters are available in two models:

• Model PC232-S4-1 Accommodates 4 loops and operates on 120 VAC

• Model PC232-S4-2 Accommodates 4 loops and operates on 240 VAC

Both models use the same type of enclosure for mounting. If installing only one 4-loop

converter, communication can be established with up to 64 controllers. If installing two

4-loop converters, communication can be established with up to 128 controllers. The

enclosure contains a tamper switch, transformer, EMI line filter, and current loop converter

Printed Circuit Board (PCB).

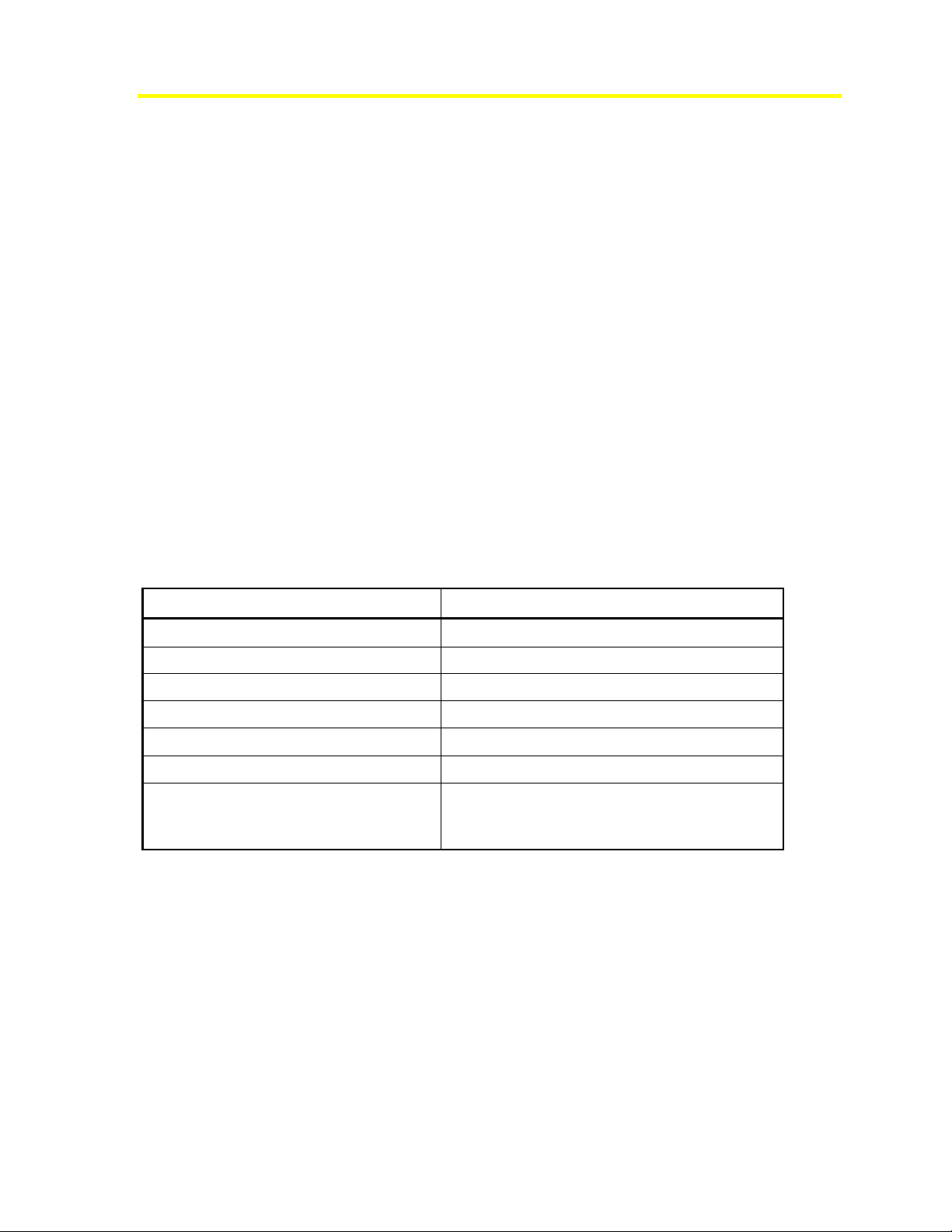

Specifications

The environmental specifications for the Field Panel Interface board are the same as for the

computers. The specifications of the current loop converter are listed in Table 1.

Table 1: Current Loop Converter Specifications

Item Specification

Number of Channels per PCBA

Input/Output

Number of Serial Controllers per Channel

Ambient Temperature

Relative Humidity

Ventilation

Power Requirements:

PC232-S4-1

PC232-S4-2

4

RS-232 to current loop and current loop to RS-232

16

32° to 122°F (0° to 50°C)

0 to 95%

Free flow of air over all exposed surfaces

120 VAC, 125 milliamps

240 VAC, 70 milliamps

PC232-S4-X Converter Installation

Install the PC232-S4-X enclosure on a wall or other mounting surface in a restricted-access

area with an ambient temperature between 32° and 122°F (0° and 50°C) and a relative

humidity between 0 and 95 percent.

Note: High heat and humidity can be harmful to electronic equipment and contributes to

early component failure. Long life and reliable operation can best be obtained by installing

the converter in an environment which is comfortable to a person.

Suggested installation locations include a locking utility closet, a crawl space, or inside a

suspended ceiling (if necessary). Install the unit so the door can swing fully open to the right.

The location must allow free flow of air over all exposed surfaces.

Preliminary – This information may change.

Page 5

Connecting Serial Controllers to the P2000 Comark Server Running Software Version 3.11

The converter can function in any position, but we recommend mounting it flat against a wall

with the hinge to the right.

To be UL-compliant, the Current Loop Converter must be located in the same room and

within 20 feet (6.1 m) of the Proprietary Station.

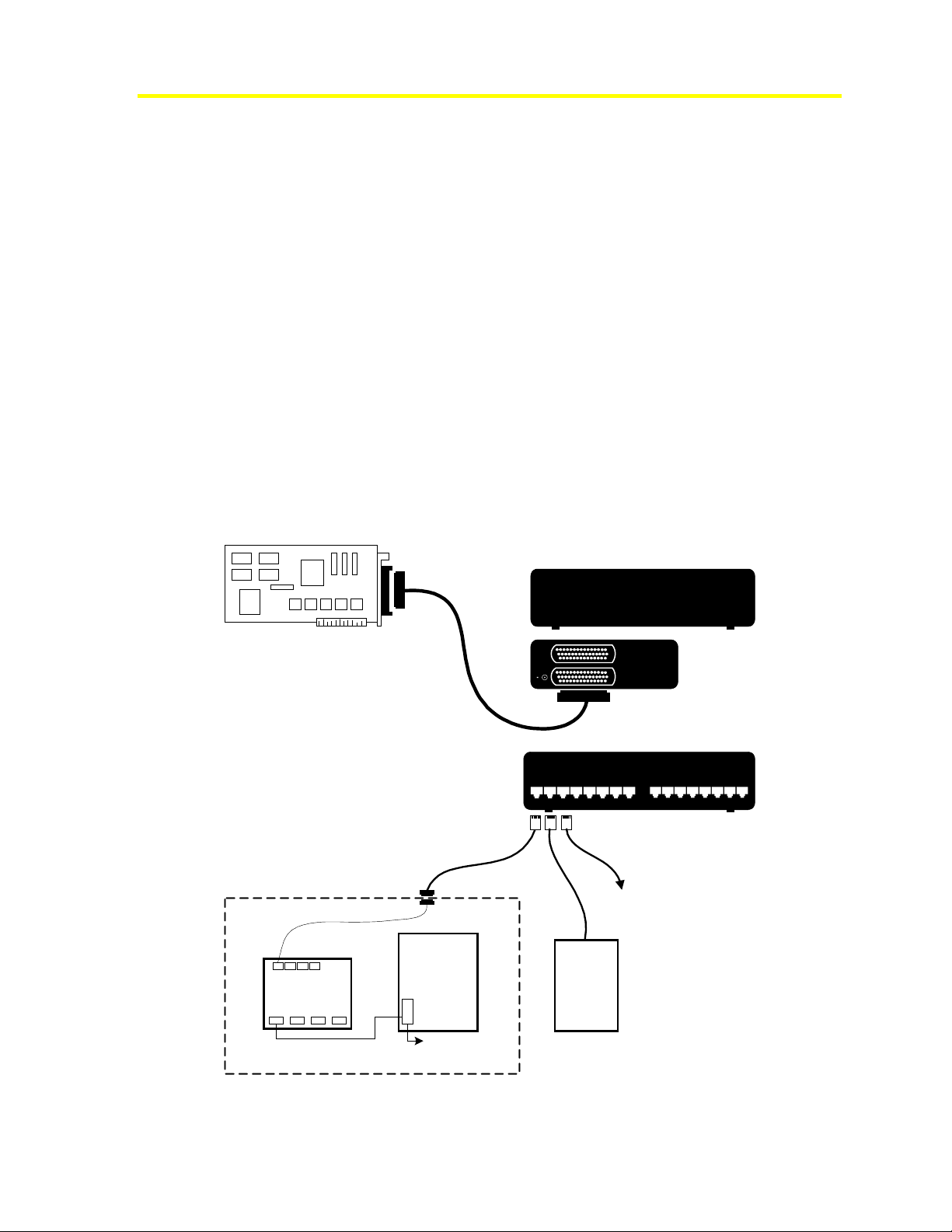

Installing the Enclosure

To meet UL requirements, the PC232-S4-X board must be installed in the enclosure supplied

for the PC232-S4-X. This enclosure has four corner holes for mounting (see Figure 3). The

diameter of these holes is 0.196 inches (4.98 mm).

The enclosure has knockout holes for cable entry. You can bring cables to the mounting

location and terminate them before or after the enclosure installation, as dictated by the

requirements of the installation.

To install the enclosure:

1. Remove the PC232-S4-X board from the enclosure by disconnecting the power cable

from J6 and the tamper switch cable from J1. Then, remove the four screws securing the

PC232-S4-X board to the enclosure.

5

2. Set aside the screws in a safe place, so you can use them to replace the board into the

enclosure.

3. Hold the enclosure in the desired location on the mounting surface and use as a template

to mark the location of the four mounting holes that correspond to the holes shown in

Figure 3.

4. Bore holes in the mounting surface at the four marks. If necessary, install hollow-wall

anchors.

5. Mount the enclosure on the wall using appropriate hardware.

6. Bring the cables to the mounting location, allowing enough excess cable for a service

loop.

7. Determine the point of entry for each cable and remove the appropriate knockout(s).

8. When using conduit, attach appropriate conduit fasteners to the conduit in the enclosure.

9. Install the PC232-S4-X board removed in Step 1.

10. Reconnect the power cable to J6 and the tamper switch cable to J1. You have completed

the enclosure installation.

Preliminary – This information may change.

Page 6

6

Connecting Serial Controllers to the P2000 Comark Server Running Software Version 3.11

Figure 3: PC232 4X Mounting Holes Location

Cabling from PC232-S4-X

All cabling must be in conformance with the National Electric Code, NFPA 70*. Observe all

local codes for specific wiring and conduit requirements. Construct cabling using good

wiring practices. All cables should be long enough to allow for service loops at their

terminations within the terminal enclosure. This allows the installer to conveniently wire the

cable connectors and plug them into the mating connectors.

* For Canadian installations, refer to the Canadian Electric Code, C22.1.

Take into account the following requirements for cable routing:

• Route power lines separately from data lines. These lines can be a standard

3-wire stranded #16 AWG UL listed/CSA approved line cord used with UL listed/CSA

approved strain relief.

• All low-level input cables (system data, alarm cables, etc.) must be shielded types and

should be in grounded conduit or at least two feet from AC power, fluorescent lights, or

other high-energy sources.

Table 2 lists the connectors in the kit supplied with one PC232-S4-X current loop converter,

and Table 3 lists the connectors supplied with two PC232-S4-X converters. Use these

connectors to construct the cables.

Preliminary – This information may change.

Page 7

Connecting Serial Controllers to the P2000 Comark Server Running Software Version 3.11

One PC232-S4-X Unit

This kit is used for the installation of one PC232-S4-X board. The cable connections of the

kit complete the interface of the serial controllers to the server.

Table 2: Connector Kit (supplied with one PC232-S4-X unit)

Type Quantity Mating Connector/Function

7

Conn., 25-pin, MTA-100

DB-25 Backshell

Conn., 2-pin, MTA-100

Conn., 4-pin, MTA-100

Conn., 5-pin, MTA-100

Conn., 8-pin, MTA-100

Screw, 6-32x7/8 inch

Screw, 6-32x1/2 inch

4 Ports 1, 2, 3, and 4 on connector box

4 Covers for DB-25 connectors

1 J1 to tamper switch connector on current loop converter board

3 J3, J4, J5 on first or only current loop converter board

1 J2 on first current loop converter board

4 J7, J8, J9, J10 on first or only current loop converter board. (The

other sides of the cables made with these connectors plug into

the serial controllers.)

4 Used to mount current loop converter board to enclosure wall

6 Used to ground wire shields to enclosure wall

Two PC232-S4-X Units

This kit is used for the installation of two PC232-S4-X boards. The cable connections of the

kit complete the interface of the serial controllers to the server.

Table 3: Connector Kit (supplied with two PC232-S4-X units)

Type Quantity Mating Connector/Function

Conn., 25-pin, MTA-100

DB-25 Backshell

8 Ports 1 through 8 on connector box

8 Covers for DB-25 connectors

Conn., 2-pin, MTA-100

Conn., 4-pin, MTA-100

Conn., 5-pin, MTA-100

Conn., 8-pin, MTA-100

Screw, 6-32x7/8 inch

Screw, 6-32x1/2 inch

2 J1 to tamper switch connector on current loop converter board

6 J3, J4, J5 on both current loop converter boards

2 J2 on both current loop converter boards

8 J7, J8, J9, J10 on both current loop converter boards (The other

sides of the cables made with these connectors plug into the

serial controllers.)

8 Used to mount current loop converter board to enclosure

12 Used to ground wire shields to enclosure wall

The connectors supplied are mass termination type; attaching the cable wires to the

connectors requires special tools. The recommended tools are listed in Table 4.

Preliminary – This information may change.

Page 8

8

Connecting Serial Controllers to the P2000 Comark Server Running Software Version 3.11

Table 4: Tools Required to Install Wires in MTA Connectors

Johnson Controls

Part Number

96-0014

96-0015

96-0010-01

AMP Part

Number

58074-1 Pistol-grip Handle Assembly

58246-1 MTA-100 Modular Head (used in pistol-grip tool)

59803-1 MTA-100 Maintenance Hand Tool (inserts one wire at a time)

Tool Description

Cabling between PC232-S4-X Converter Board and Connector Box

Create the cables to connect the connector box and the PC232-S4-X converter board using

#22, 4- and 5-conductor shielded cabling. We recommend Belden® 9940 and 9941,

respectively. The cable length must not exceed 25 feet (7.6 m).

For systems with one PC232-S4-X converter board, use 4-conductor cable to connect ports 2,

3, and 4 of the FPI connector box to the PC232-S4-X PCB connectors J3, J4, and J5,

respectively. Use the 25-pin connectors supplied with the kit on ports 2, 3, and 4 of the

connector box. Use the red 4-pin connectors supplied with the kit on the PC232-S4-X PCB

end. A 5-conductor cable connects port 1 of the connector box to connector J2 on the PC232S4-X PCB. Use the remaining 25-pin connector for port 1 of the connector box and the only

red 5-pin connector for J2 of the PC232-S4-X PCB. (See Figure 4 for the wiring diagram.)

For systems with two PC232-S4-X converter boards, use 4-conductor cable to connect ports

2 through 8 of the FPI connector box to both PC232-S4-X PCB connectors J3, J4, and J5,

respectively. Use the 25-pin connectors supplied with the kit on ports 2 through 8 of the

connector box. Use the red 4-pin connectors supplied with the kit on both PC232-S4-X PCB

ends. Use a red 5-pin connector for connector J2 on the second PC232-S4-X PCB. Only four

wires connect to the 5-pin connector attaching to J2 of the second PC232-S4-X PCB. A

5-conductor cable connects port 1 of the connector box to connector J2 on the first PC232S4-X PCB. Use the remaining 25-pin connector for port 1 of the connector box and

remaining red 5-pin connector for J2 of the first PC232-S4-X PCB. (See Figure 4 for the

wiring diagram.)

Cabling between PC232-S4-X and the Serial Controllers

Construct the cables to connect the PC232-S4-X and the serial controllers using #22, two

twisted pair cabling (Belden 8723 recommended). See Figure 4 for the wiring diagram. The

diagram shows the pin-to-pin connections for the serial controllers. The maximum cable

length is 4,000 feet (1,219 m) total loop distance.

Install a Lightning Transient Suppressor at each end of every cable between the PC232-S4-X

and the serial controller that is exposed to an area where lightning may strike directly or

nearby. This includes any above-ground cable runs between buildings. We recommend the

Johnson Controls Model TS10/TS11 Transient Suppressor for this purpose.

Preliminary – This information may change.

Page 9

Connecting Serial Controllers to the P2000 Comark Server Running Software Version 3.11

Tamper Switch

Install the wires in the cable from the tamper switch into the two-pin connector provided in

the connector kit, and plug the connector into J1 of the first or only PC232-S4-X converter

board. If using two PC232-S4-X units, only a single tamper switch connection is needed.

Fuses

The fuse located in the PC232-S4-X PCBs is 1 A, 3AG, SloBlo (Littelfuse® PN 313001).

Current Loop Converter, Routine Maintenance

• Vacuum the current loop converter every six months, or more often if the unit is located

in a dusty environment.

• Check the continuity of the grounding circuit periodically.

Testing Communications

This test assumes that all hardware and software is installed. (Refer to the P2000

Server/Workstation Software Installation Manual [Part No. 24-10618-120] for instructions.)

Monitor the status of loops, controllers, and terminals by using the P2000 System Status

window (located in the System menu). Refer to the P2000 Software User Manual (Part No.

24-10618-147) for more information.

9

Use visual checks to help verify that the system is working properly. Use the two wiring

diagrams, in Figure 4 and Figure 5, as troubleshooting aids.

• LED2 through LED9 on the PC232 PCB flicker when operating correctly.

• If the LEDs on the PC232 PCB do not flicker, verify that all cables are constructed

correctly and securely attached.

• If LED1 is lit, the board is receiving power. If not, verify power is flowing from the main

source to the PC232.

Preliminary – This information may change.

Page 10

10

Connecting Serial Controllers to the P2000 Comark Server Running Software Version 3.11

Figure 4: Interconnect: I/O Converter to Current Loop Converter

Preliminary – This information may change.

Page 11

Connecting Serial Controllers to the P2000 Comark Server Running Software Version 3.11

11

Figure 5: Current Loop Converter to Terminal Controller

Grounding and Connectors

This section provides instructions for grounding cable shields for data and low voltage

installations. Follow these guidelines for electromagnetic compatibility (EMC) conformity

and improved system reliability.

• Every unit in a Johnson Controls system’s installation must have its chassis connected to

a verified electrical ground (earth). In all cases, the pertinent national wiring codes apply.

• National Electrical Code NFPA 70 must be followed for installations in the USA.

• Canadian Electrical Code C22.1 must be followed for installations in Canada.

• BSI Standard BS7671 (latest edition) must be followed for installations in Great Britain.

Additional information is given in the Johnson Controls Installer’s Code of Practice

(FAN 1196).

Important: Conduit ground, cold water pipes, unbrazed joints, and dissimilar metals are

unacceptable in the path of either building or supplemental ground. Where grounding is

required, connect only to the proven building electrical system ground (earth).

Preliminary – This information may change.

Page 12

12

Connecting Serial Controllers to the P2000 Comark Server Running Software Version 3.11

Data and Low Voltage Installations

The following sections describe recommended grounding of D-type connectors and

grounding requirements in the U.S.A. and Europe. The following notes apply to all

installations described in the Grounding and Connectors section and subsections.

1. Strip back the outer cover of the cable to reveal the cable’s screen.

2. Cut back the screen so it just enters the enclosure.

Connect cable screens at both ends when connecting cables to user peripherals (such as

printers).

3. The drain wire that extends from the screen-type shield must be kept as short as possible

(typically 2.5 cm or 1 inch). Connect a lug to the end of the wire and screw securely to

the wall of the enclosure or the nearest stud.

4. All internal ground (earth) bonding straps must be left intact after installation.

5. Check that grounding points are clean and free from paint or corrosion.

D-Type Connectors

All D-type connectors must use an Electromagnetic Interference (EMI) shielded shroud.

Verify good contact occurs when connecting D-type connector shrouds to cable shields.

Figure 6 shows a critical contact throughout the 360 degrees of the cable’s screen at the point

of entry to the shell. To ensure a good fit, strip the cable’s outside layer back to reveal the

metal shield and extend the shield to the very edge of the metal shroud’s connector. If the

shield does not fit snugly, apply metallic tape to ensure a firm contact.

The two curved parts of the shroud are shown in Figure 6 making contact with the flat plate

of the shroud. Tighten the two remaining screws to ensure a firm fit.

Preliminary – This information may change.

Page 13

Connecting Serial Controllers to the P2000 Comark Server Running Software Version 3.11

Figure 6: Example of D-Type Connector Grounding

13

Connecting S321-DIN Controllers

The S321-DIN controller provides interface control for access and security devices

associated with a door. The key features of the S321-DIN include:

• Support for RS-485 bus communications at 4800, 9600, 19,200, or 38,400 (default) (auto

baud rate detection at the controller)

• Improved RS-485 bus polling algorithm

• Two-door access control input/output interface

• One general-purpose input and output per terminal

The S321-DIN can communicate with the P2000 server in one of the following

configurations:

• Serial communications using a B&B Electronics RS-232 to RS-485 converter (model

485OT9L)

• IP network communications using the Digi One SP serial-to-Ethernet converter

The following subsections provide instructions for installing the previous converters. For

additional instructions on installing and configuring the S321-DIN controller, refer to its

documentation.

For TCP/IP networking information associated with the P2000 system, refer to the P2000

Comark Server Hardware Installation Instructions (Part No. 24-10618-112).

Preliminary – This information may change.

Page 14

14

Connecting Serial Controllers to the P2000 Comark Server Running Software Version 3.11

Serial Installation with the B&B Electronics RS-232 to RS-485 (Model 485OT9L)

Converter

This device converts RS-232 signals to RS-485 signals and must be used when installing an

S321-DIN controller in a serial configuration.

To install the converter:

1. Change the switch settings on the converter to match the baud rate of the host computer.

See Table 5.

Table 5: Baud Rate Selection

Baud Switch 1 Switch 2 Switch 3 Switch 4 R21 Time out (ms)

1200

2400

4800 ON

96001

19,200

38,400

1. Default setting

OFF OFF OFF OFF 820k Ω 9.0

OFF OFF OFF OFF 410k Ω 4.5

OFF OFF OFF Not Used 2.2

OFF

OFF OFF

OFF OFF OFF

ON

OFF OFF Not Used 1.1

ON

OFF Not Used 0.6

ON

Not Used 0.3

2. Set the remaining switch positions for RS-485 Half-Duplex operation and termination

according to Table 6.

Table 6: Remaining Switch Settings

Switch 5 Switch 6 Switch 7 Switch 8

ON ON ON

OFF

3. Ensure JP1 is on SD pins.

4. Using Belden 5341FE (18 AWG, shielded, 2 twisted pair) or equivalent cable, wire the

pins from the S321-DIN serial port to the converter’s terminal block according to Figure 7.

Figure 7: RS-232 to RS-485 Converter Connections

Preliminary – This information may change.

Page 15

Connecting Serial Controllers to the P2000 Comark Server Running Software Version 3.11

15

Network Installation with the Digi One SP Converter

The Digi One SP device enables an S321-DIN controller to connect to an IP network via the

controller’s serial port. See Figure 8.

Figure 8: S321-DIN Controller in an IP Network Configuration

To install the converter:

1. Change the DIP switch settings on the bottom of the Digi One SP converter according to

Figure 9 and Table 7.

Figure 9: Digi One SP Converter DIP Switch Settings

Table 7: Digi One SP Converter DIP Switch Positions

DIP Switch Position

1

2

Down/OFF

Down/OFF

3 Up/ON

4

Preliminary – This information may change.

Down/OFF

Page 16

16

Connecting Serial Controllers to the P2000 Comark Server Running Software Version 3.11

2. Using Belden 9773 (18 AWG, shielded, 3 twisted pair) or equivalent cable, wire the pins

from the S321-DIN serial port to a DB-9F connector according to Figure 10 and Table 8.

Figure 10: Digi One SP Connections

Table 8: Digi One SP DB-9F Connections

S321-DIN Wiring Base DB-9F Connector

+RS485

-RS485

REF

PIN 2

PIN 3

PIN 6

PIN 9

PIN 5

3. Connect the DB-9F connector to the Digi One SP’s DB-9M connector.

4. Run an Ethernet cable from the Digi One SP to your network connection.

5. Connect the power cable to the Digi One SP and run to an appropriate 110/240 VAC

power source.

To install the driver for the Digi One SP and configure the device, download the driver and

configure the software according to the screen captures located at:

ftp://cardkey:cardkey2000@ftp2.johnsoncontrols.com/cardkey-out/S321/DigiOneSP%20(Working%20Driver)/

Important: Do not install the driver provided with the Digi One SP or on the Digi Web site.

Use only the driver provided on the Johnson Controls File Transfer Protocol (FTP) site.

Preliminary – This information may change.

Loading...

Loading...