Page 1

ACCESSORY KIT INSTALLATION MANUAL

THERMAL EXPANSION VALVE KITS

R-22 – S1-1TVM2**, 1TVM7** & R-410A – S1-1TVM4**, S1-1TVM9**

FOR MODELS:

COILS - FC, MC, PC, UC, HD, HC, G4FA, G4FD & AIR HANDLERS - AH, AV, & F*FP

GENERAL INFORMATION

This thermal expansion valve (with internal check valve) is to be

used with flex coils for models listed above. This kit is required

to provide overall rated system performance improvement. The

kit can be applied to the listed indoor coils and air handlers,

both for heat pump and cooling applications.

The kit consists of a bolt-on thermal expansion valve, 2.5 feet of

thermal insulation, bulb straps or bulb clamp and this instruction.

When a TXV kit is installed, a hard start kit may be required.

Consult your product data sheet.

Refer to Tabular Data sheet for specific model TXV/match-up.

• 1TVM2, 1TVM7 series TXV kits are R-22 AC and HP.

• 1TVM4, 1TVM9 series TXV kits are for R-410A AC and HP.

INSTALLATION

To install the thermal expansion valve, use the following steps.

The coil will have to be pulled out of the casing for easy access.

1. Relieve the holding charge by pulling off the rubber cap

plug on the suction manifold line of the coil.

ID coil is under 30 psig pressure.

2. After holding charge is completely discharged, loosen and

remove the schraeder cap seal.

3. Loosen and remove distributor cap seal.

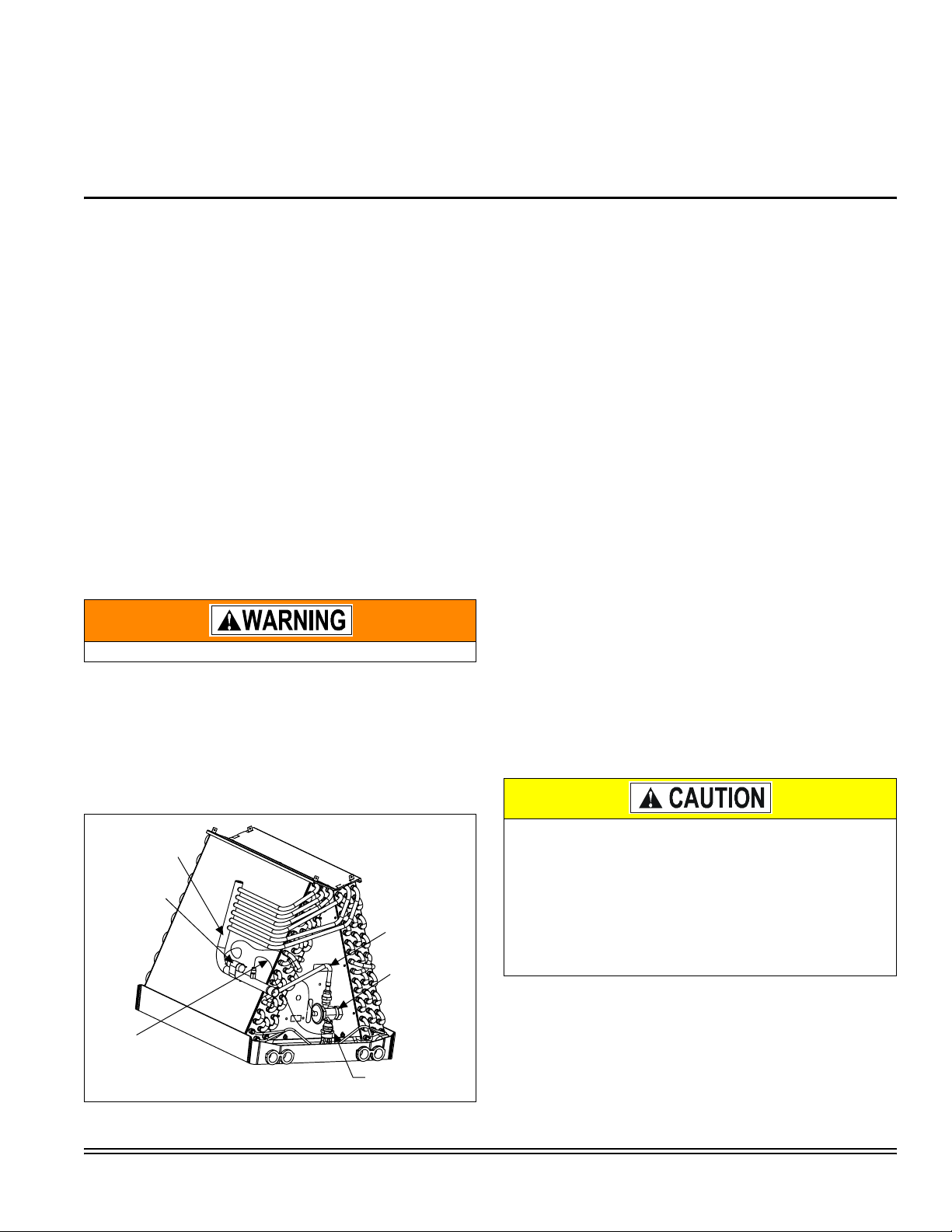

4. Install the thermal expansion valve to the orifice distributor

assembly with supplied fittings. Orient the TXV as shown in

Figure 1. Hand tighten and turn an additional

1/4 turn to seal. Do not overtighten fittings.

5. Install the liquid line to the top of the thermal expansion

valve with fitting supplied with the liquid line. Hand modify

the liquid line to align with casing opening. Hand tighten

the liquid line and an additional 1/4 turn to seal.

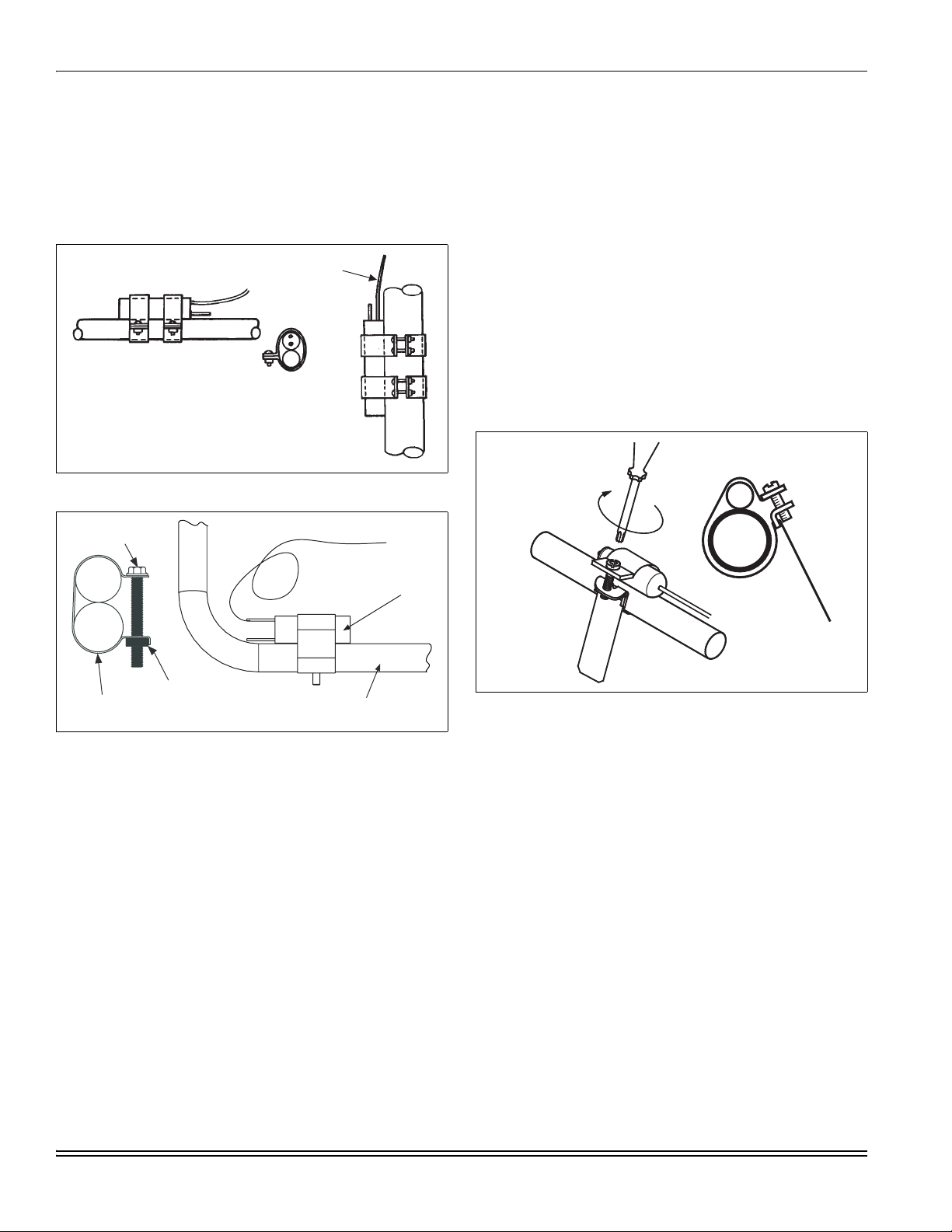

6. Install the TXV equalizer line into the vapor line as follows:

a. Hand tighten the 1/4” SAE nut to the schraeder fitting

and an additional 1/3 turn to seal.

7. Install the TXV bulb to the vapor line near the equalizer

line, using the bulb clamp(s) furnished with the TXV

assembly. Ensure the bulb is making maximum contact.

See Figure 2 for proper bulb location. See Figure 3 for

clamp assembly on 1TVM valve.

a. Bulb should be installed on a horizontal run of the

vapor line if possible. The bulb should be installed on

top of the line.

b. If bulb installation is made on a vertical run, the bulb

should be located at least 16 inches from any bend,

and on the tubing sides opposite the plane of the

bend. The bulb should be positioned with th e bulb tail

at the top, so that the bulb acts as a reservoir.

c. Bulb should be in sulated using thermal insulation pro -

vided to protect it from the effect of the surrounding

ambient temperature. Cover completely to insulate

from air-stream.

8. Slide the coil in the cabinet and install the tubing connect

plate. Soak the heat shield in water and slid e it in place

using the suction and liquid line holes provided.

9. Align the suction and liquid line sets to the suctio n and liquid tubing and wrap the liquid and suction tubi ng with wet

rag before brazing.

Dry nitrogen should always be supplied through the

VAPOR

LINE

THERMAL

EXPANSION

VALVE BULB

(Cover completely

with insulation

provided)

LIQUID

LINE

THERMAL

EXPANSION

VALV E

tubing while it is being brazed, because the temperature is high enough to cause oxidation of the copper

unless an inert atmosphere is provided. The flow of

dry nitrogen should continue until the joint has coole d.

Always use a pressure regulator and safety valve to

insure that only low pressure dry nitrogen is introduced

into the tubing. Only a small flow is necessary to displace air and prevent oxidation.

All connections to be brazed are copper-to-copper and should

be brazed with a phosphorous-copper alloy material such as

TXV

EQUALIZER

LINE

DISTRIBUTOR

BODY

Silfos-5 or equivalent. DO NOT use soft solder.

Nitrogen can be introduced through the Schraeder access

(located at the OD unit connection of the refrigerant line). The

Schraeder core can be removed before connecting the source

of nitrogen, but should be reinstalled prior to the evacuation and

FIGURE 1: Kit Installation in System

charging of the refrigerant lines and ID coil.

Johnson Controls Unitary Products 166806-UAI-H-0408

Page 2

10. Braze the line set to the units

11. Leak check refrigerant lines and indoor coil connections. If

leak free, remove leak check charge, reinstall any

Schraeder cores that were removed from the outdoor unit

and evacuate refrigerant lines and ID coil. Evacuate

through the Schraeder access valves of the liquid and

vapor service valves on OD unit.

TAIL

END

UP

*

ROTATE BULB TO KEEP

TAILAT BOTTOM

VERTICAL

RISER

FIGURE 2: Correct Bulb Locations

SCREW

12. After the interconnecting refrigerant lines, TXV assembly

and ID coil have been evacuated, the liquid and vapor line

valves at the OD unit can be opened to release the refrigerant charge into the complete system. The proper procedure for opening these valves is covered in the OD unit

installation instructions.

13. The OD unit factory refrigerant charge includes the charge

for 15 feet of interconnecting vapor and liquid lines. If interconnecting lines are longer than 15 feet, additional charge

must be added for the length. You may refer to “Refrigerant

Piping Guide” for line sets over 25 ft. The OD unit installation instructions list the charge required per foot of liquid/

vapor lines. Also, some indoor coil matches may require

additional charge. This charge is also listed in the OD unit

installation instruction. The additional charge should be

introduced into the system by means of a calibrated charging cylinder or other means of accurately weighing the

refrigerant.

MAX. 3 FT-LB (4 Nm)

TORX 25 WITH SLOT

2

CLAMP

NUT

SUCTION

LINE

FIGURE 3: Clamp Attachment for 1TVM (Option 1)

TXV BULB

1

FIGURE 4: Clamp Attachment for 1TVM (Option 2)

Subject to change without notice. Printed in U.S.A. 166806-UAI-H-0408

Copyright © 2008 by Johnson Controls, Inc. All rights reserved. Supersedes: 166806-UAI-G-0108

Johnson Controls Unitary Products

5005 York Drive

Norman, OK 7306

Loading...

Loading...