Johnson Controls SA PC090 THRU 240, SA PD 180 THRU 240, PC090, PC120, PC180 Installation Manual

...Page 1

R-410A

MODELS:

7.5 - 20 Ton

60 Hertz

Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Renewal Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Agency Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Limitations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Rigging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Phasing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1 PC090 - 240 and PD180 - 240 Physical Data . . . . . . . . . . 4

2 Unit Application Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Corner Weights & Center of Gravity . . . . . . . . . . . . . . . . . 6

4 Minimum Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5 Electrical Data - Outdoor Unit - HP Without Powered

Convenience Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

6 Electrical Data - Outdoor Unit - HP With Powered

Convenience Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

PC090 Thru 240

PD180 Thru 240

TABLE OF CONTENTS

LIST OF TABLES

Electrical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Refrigerant Mains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Piping And Electrical Connections . . . . . . . . . . . . . . . . . . 17

Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Crankcase Heaters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Sequence of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Cooling Sequence Of Operation. . . . . . . . . . . . . . . . . . . . 18

Heating Sequence of Operation . . . . . . . . . . . . . . . . . . . . 20

Unit Control Board Option Setup. . . . . . . . . . . . . . . . . . . . 23

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Typical Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7 PC090, PC120 Unit Height Dimensions . . . . . . . . . . . . . 15

8 PC/PD180 & PC/PD240 Unit Height Dimensions . . . . . . 16

9 Piping and Electrical Connection Sizes . . . . . . . . . . . . . 17

10 PC090 thru 240 Unit Control Board Flash Codes . . . . . . 21

11 PD180 thru 240 Unit Control Board Flash Codes . . . . . . 22

LIST OF FIGURES

1 Corner Weights & Center Of Gravity . . . . . . . . . . . . . . . . 6

2 Typical Rigging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Typical Field Wiring Diagram - NC090 Air Handling Unit

With PC090 Heat Pump . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Typical Field Wiring Diagram - NC120 thru 240 Evaporator

Unit with PC120 thru 240 Heat Pump . . . . . . . . . . . . . . 13

5 NC120 - 240 Liquid Line Solenoid Wiring . . . . . . . . . . . 13

6 Typical Field Wiring Diagram - ND180 thru 240

Evaporator Unit with PD180 thru 240 Heat Pump . . . . . 14

7 PC090, PC120 Unit Dimensions . . . . . . . . . . . . . . . . . . 15

8 PC/PD180 & PC/PD240 Unit Dimensions and Piping

& Electrical Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . 16

9 Fan Orientation, Control Box End . . . . . . . . . . . . . . . . . 21

10 Unit Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

11 PC090 Charging Chart . . . . . . . . . . . . . . . . . . . . . . . . . . 27

12 PC120 Charging Chart . . . . . . . . . . . . . . . . . . . . . . . . . . 27

13 PC180 Charging Chart . . . . . . . . . . . . . . . . . . . . . . . . . . 28

14 PD180 Charging Chart . . . . . . . . . . . . . . . . . . . . . . . . . . 28

15 PC240 Charging Chart . . . . . . . . . . . . . . . . . . . . . . . . . . 29

16 PD240 Charging Chart . . . . . . . . . . . . . . . . . . . . . . . . . . 29

17 Typical PC090 Heat Pump Wiring Diagram . . . . . . . . . . 30

18 Typical PC120 Heat Pump Wiring Diagram . . . . . . . . . . 31

19 Typical PC180 - 240 Heat Pump Wiring Diagram . . . . . 32

20 Typical PD180 - 240 Heat Pump Wiring Diagram . . . . . 33

430645-YIM-D-0610

Page 2

430645-YIM-D-0610

Product Category

P = Split System, Condenser, HP, R-410A

Product Identifier

C = Standard Efficiency, 2-Pipe, R-410A

D = Standard Efficiency, 4-Pipe, R-410A

Nominal Cooling Capacity - MBH

090 = 7.5 Ton

120 = 10 Ton

150 = 12.5 Ton

180 = 15 Ton

240 = 20 Ton

C00 = Cooling Only

Product Options

AA = None

AB = Phase Monitor

AC = Coil Guard

AE = Phase Monitor + Coil Guard

LA = Low Ambient

LB = Low Ambient + Phase Monitor

LC = Low Ambient + Coil Guard

LD = Low Ambient + Phase Monitor

+ Coil Guard

LE = Low Ambient + Technicoat Cond. Coil

LF = Low Ambient + Technicoat Cond. Coil

+ Phase Monitor

LG = Low Ambient + Technicoat Cond. Coil

+ Coil Guard

LH = Low Ambient + Technicoat Cond. Coil

+ Phase Monitor + Coil Guard

TA = Technicoat Condenser Coil

TB = Technicoat Condenser Coil + Phase

Monitor

TC = Technicoat Condenser Coil + Coil Guard

TE = Technicoat Condenser Coil + Coil Guard

+ Phase Monitor

Installation Options

A = None

2 = 208/230-3-60

4 = 460-3-60

5 = 575-3-60

7 = 380/415-3-50

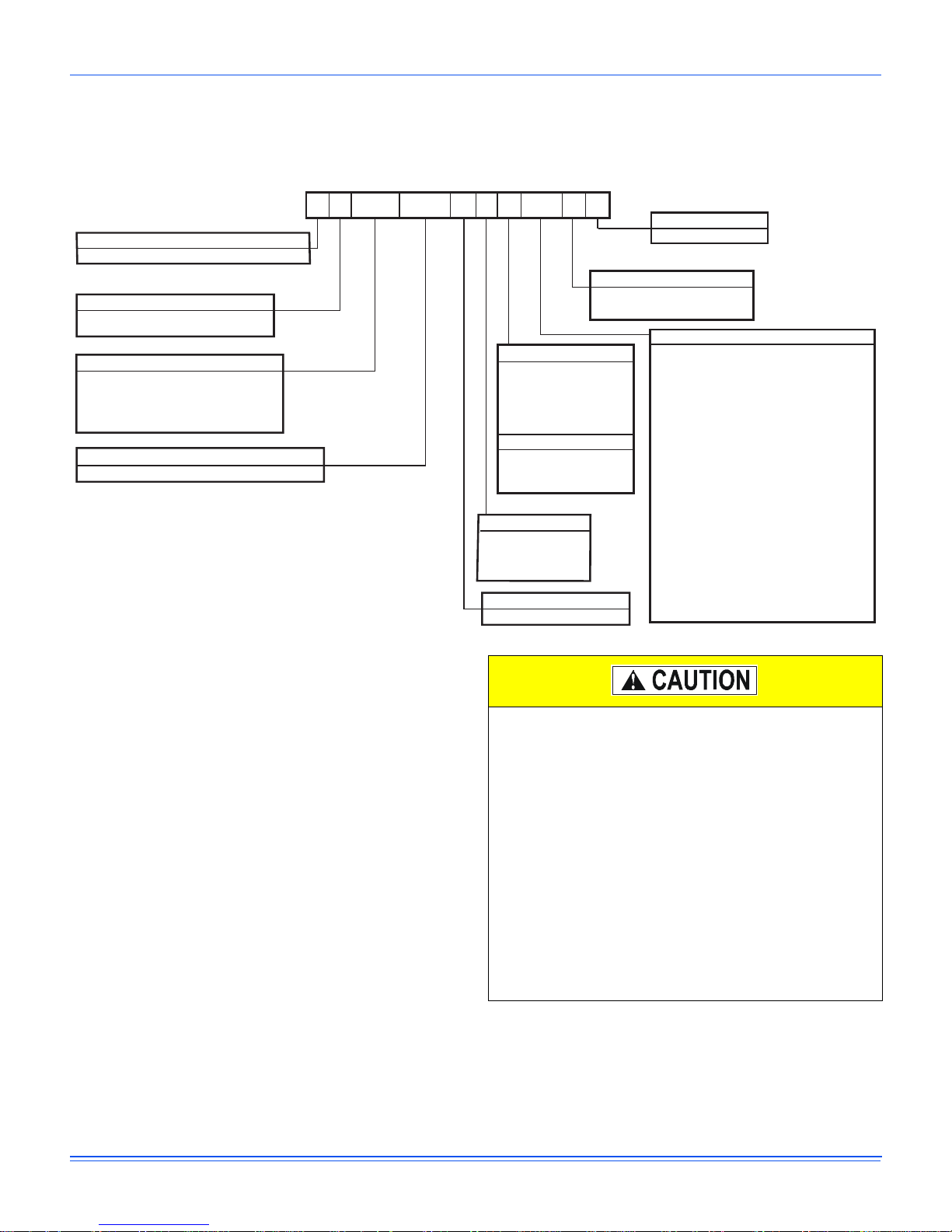

Configured Split Condenser Model Number Nomenclature

A = Standard Motor

Airflow

Product Generation

1 = First Generation

2 = Second Generation

Voltage

Heat Type & Nominal Heat Capacity

P

C

240

C00 A

2

A

AA

2

A

Product Style

A = Style A

2 = Non Pwr’d Conv Outlet

1 = Disconnect

T = Options 1 & 5

S = Options 5

D = Options 1 & 2

C = Option 2

B = Option 1

Options

5 = Pwr’d Conv Outlet

Nomenclature

General

These condensing units are designed for outdoor installation on

a roof or at ground level. Every unit is completely piped and

wired at the factory and is shipped ready for immediate

installation. Only the liquid and suction lines to the evaporator

coil, the filter drier, the thermostat wiring and the main power

wiring are required to complete the installation. Each unit is

dehydrated, evacuated, leak tested and pressure tested at 450

psig before being pressurized with a holding charge of

refrigerant R-410A for shipment and/or storage.

All controls are located in the front of the unit and are readily

accessible for maintenance, adjustment and service. All wiring

(power and control) can be made through the front of the unit.

2 Johnson Controls Unitary Products

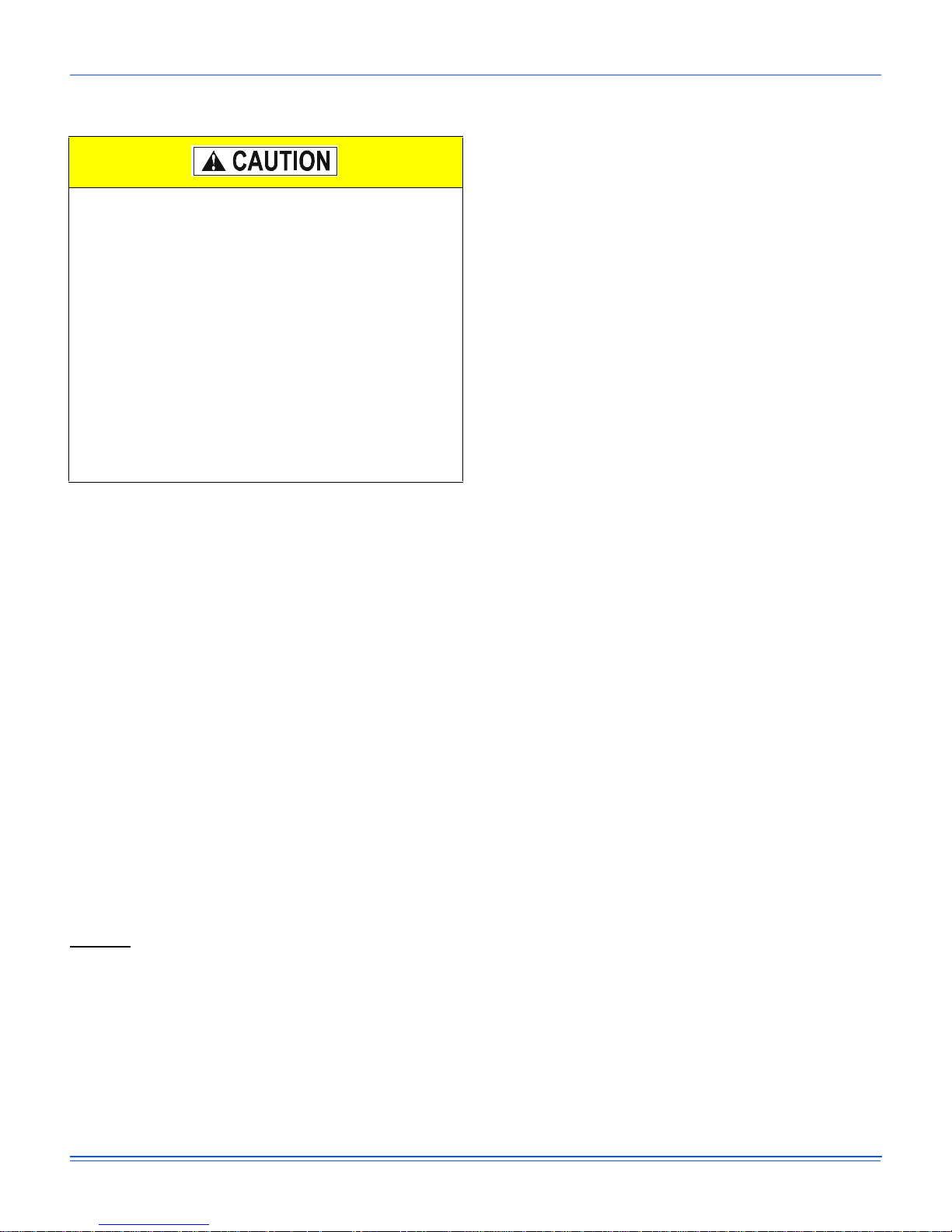

This Split-System (Air Condensing / Heat Pump / Air

Handling) unit is one component of an entire system. As

such it requires specific application considerations with

regard to the rest of the system (air handling unit, duct

design, condensing unit, refrigerant piping and control

scheme).

Failure to properly apply this equipment with the rest of

the system may result in premature failure and/or

reduced performance / increased costs. Warranty

coverage specifically excludes failures due to improper

application and Unitary Products specifically disclaims

any liability resulting from improper application.

Please refer to the equipment Technical Guide,

Installation Manual and the piping applications bulletin

247077 or call the applications department for Unitary

Products @ 1-877-UPG-SERV for guidance.

Page 3

430645-YIM-D-0610

Safety Considerations

Installer should pay particular attention to the words: NOTE,

CAUTION, and WARNING. Notes

make the installation easier. Cautions are given to prevent

equipment damage. Warnings are given to alert installer that

personal injury and/or equipment damage may result if

installation procedure is not handled properly.

Improper installation may create a condition where the

operation of the product could cause personal injury or

property damage. Improper installation, adjustment,

alteration, service or maintenance can cause injury or

property damage. Refer to this manual for assistance or

for additional information, consult a qualified contractor,

installer or service agency.

Before performing service or maintenance operations on

unit, turn off main power switch to unit. Electrical shock

could cause personal injury. Improper installation,

adjustment, alteration, service or maintenance can

cause injury or property damage. Refer to this manual.

For assistance or additional information consult a

qualified installer, service agency or the gas supplier.

are intended to clarify or

Reference

This instruction covers the installation and operation of the

basic condensing unit. For refrigerant piping installation

instructions refer to document 247077 “Application Data General Piping Recommendations for Split System Air

Conditioning and Heat Pumps”. For information on the

installation and operation of the evaporator blower units, refer

to Instruction Manual No. 508526.

All accessories come with a separate Installation Manual.

Renewal Parts

Contact your local Source 1 Center for authorized replacement

parts.

Agency Approvals

Design certified by CSA as follows:

1. For use as a cooling/heating uni t.

2. For outdoor installation only.

Inspection

As soon as a unit is received, it should be inspected for possible

damage during transit. If damage is evident, the extent of the

damage should be noted on the carrier’s freight bill. A separate

request for inspection by the carrier’s agent should be made in

writing.

This system uses R-410A Refrigerant which operates at

higher pressures than R-22. No other refrigerant may be

used in this system. Gage sets, hoses, refrigerant

containers and recovery systems must be designed to

handle R-410A. If you are unsure, consult the

equipment manufacturer. Failure to use R-410A

compatible servicing equipment may result in property

damage or injury.

This product must be installed in strict compliance with

the enclosed installation instructions and any applicable

local, state and national codes including, but not limited

to, building, electrical, and mechanical codes.

Johnson Controls Unitary Products 3

Page 4

430645-YIM-D-0610

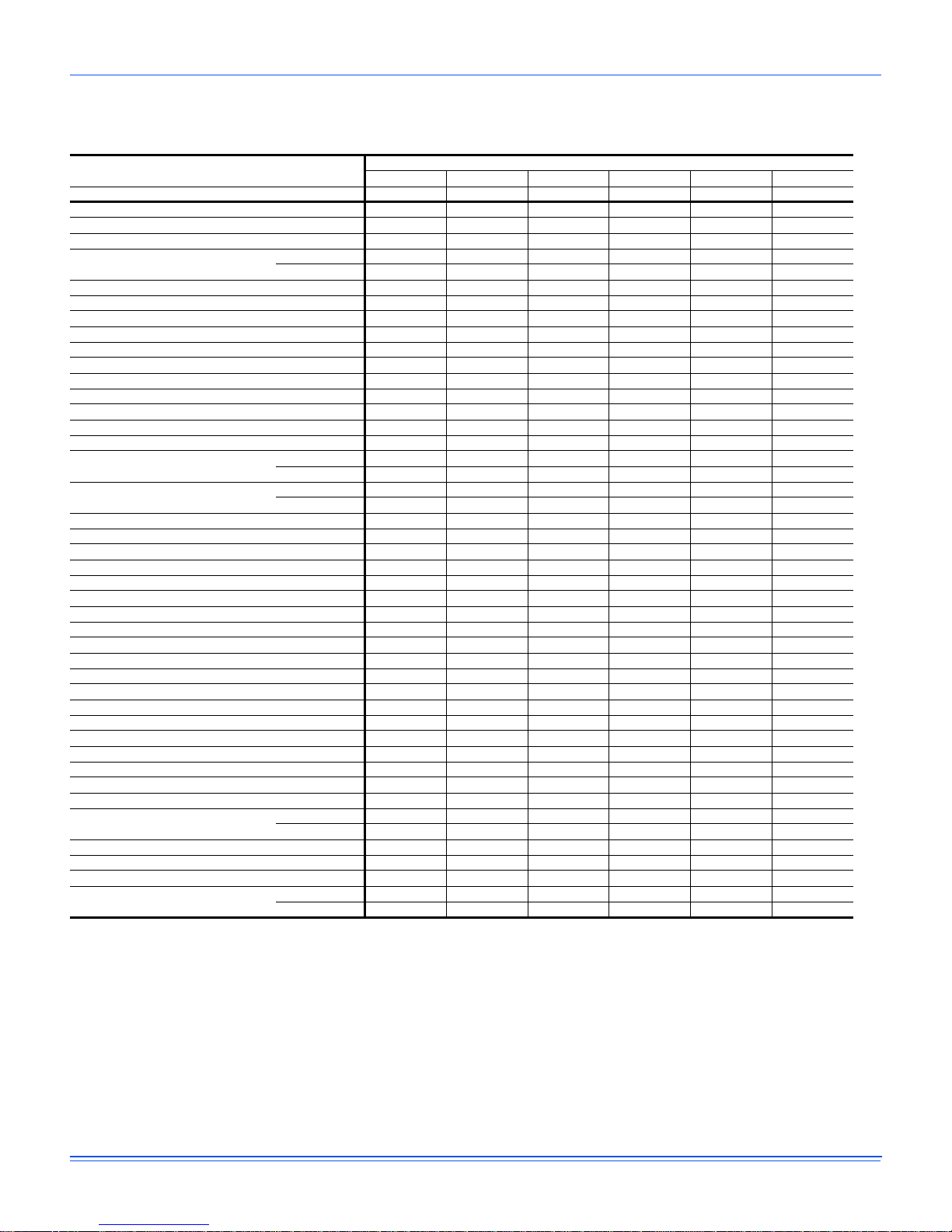

Physical Data

Table 1: PC090 - 240 and PD180 - 240 Physical Data

Component

Nominal Tonnage 7.5 10 15 15 20 20

Refrigerant type R-410A R-410A R-410A R-410A R-410A R-410A

Holding charge (lb)

Operating Charge (lb)

Length 59.1 59.1 59.1 59.1 59.1 59.1

Width 31.9 31.9 64.1 64.1 64.1 64.1

Height 44.5 50.0 44.5 44.5 50.0 50.0

Shipping 421 543 947 921 1116 1090

Operating 430 574 968 942 1152 1126

Type Single Scroll Tandem Scroll Tandem Scroll Single Scroll Tandem Scroll Single Scroll

Quantity 1 1 1212

Cooling

Nominal Capacity (Tons)

Capacity Stages

Heating

Nominal Capacity (Tons) System #1 & #2 7.5 10 15 15 20 20

Capacity Stages System #1 & #2 1 1 1111

No. Refrigeration Circuits 111212

Suction Line OD (in.) 1 1/8 1 3/8 1 5/8 1 3/8 1 5/8 1 3/8

Liquid Line OD (in.) 5/8 7/8 7/8 5/8 7/8 7/8

Face area (Sq. Ft.) 23.8 29.0 47.5 47.5 58.1 58.1

Rows 222222

Fins per inch 20 20 20 20 20 20

Tube diameter (in./MM) 0.38 / 10 0.38 / 10 0.38 / 10 0.38 / 10 0.38 / 10 0.38 / 10

Circuitry Type Interlaced Interlaced Interlaced Interlaced Interlaced Interlaced

Refrigerant Control TXV TXV TXV TXV TXV TXV

No. Fans / Diameter (in.) 2/24 2/24 4/24 4/24 4/24 4/24

Type Axial Axial Axial Axial Axial Axial

Drive type Direct Direct Direct Direct Direct Direct

No. speeds 1 1 1111

Number of motors

Motor HP (ea.) 1/3 3/4 1/3 1/3 3/4 3/4

Rotation

RPM 850 1100 850 850 1100 1100

Nominal CFM

REFRIGERANT

1

2

DIMENSIONS (inches)

WEIGHTS (lb)

COMPRESSORS

SYSTEM DATA

OUTDOOR COIL DATA

CONDENSER FAN DATA

4

3

System #1 23.9 27.5 54.0 27.0 60.0 34.0

System #2 --- --- --- 27.0 --- 34.0

System #1 7.5 10 15 7.5 20 10

System #2 --- --- --- 7.5 --- 10

System #1122121

System #2 --- --- --- 1 --- 1

System #1224242

System #2 --- --- --- 2 --- 2

System #1 7500 9800 15000 7500 19600 9800

System #2 --- --- --- 7500 --- 9800

PC090 PC120 PC180 PD180 PC240 PD240

1.0 1.0 1.0 1.0 1.0 1.0

CW CW CW CW CW CW

1. Holding Charge is the amount in the unit as shipped from the factory.

2. Includes matched evaporator unit with 25 ft of piping.

3. All Compressors include crankcase heater.

4. When viewing the shaft end of the motor.

Models

4 Johnson Controls Unitary Products

Page 5

430645-YIM-D-0610

Table 2: Unit Application Data

208/230-3-60 187/252

Voltage Variation

Min. / Max.

1

460-3-60 432/504

575-3-60 540/630

Ambient Air on Condenser Coil

Min. /Max.

2

Suction Pressure at Compressor and

Corresponding Temp. at Saturation

Min. / Max.

1.Utilization range “A” in accordance with ARI Standard 110.

2.These units can operate in an ambient temperature of

125°F providing the wet bulb temperature of the air entering the evaporator coil does not exceed 67°F. Unit can

operate to 0°F if equipped with a low ambient kit.

40°F/125°F

101.6 psig / 156.6 psig

32.0 ºF / 55.0 ºF

Installation

Limitations

These units must be installed in accordance with all national

and local safety codes. If no local codes apply, installation must

conform to the appropriate national codes. Units are designed

to meet National Safety Code Standards. If components are to

be added to a unit to meet local codes, they are to be installed

at the dealer's and/or the customer's expense.

3. The heat pump and the evaporator should be positioned to

minimize the number of bends in the refrigerant piping.

4. The heat pump should be as close to the evaporator as

practical.

5. The heat pump should not be installed where normal

operating sounds may be objectionable.

6. The evaporator should be located within the building, either

outside or inside the conditioned space.

Rooftop Locations

Be careful not to damage the roof. Consult the building

contractor or architect if the roof is bonded. Choose a location

with adequate structural strength to support the unit.

The heat pump must be mounted on level supports. The

supports can be channel iron beams or wooden beams treated

to reduce deterioration.

Minimums of two (2) beams are required to support each unit.

The beams should: (1) be positioned perpendicular to the roof

joists. (2) Extend beyond the dimensions of the section to

distribute the load on the roof. (3) Be capable of adequately

supporting the concentrated loads at the corners. These beams

can usually be set directly on the roof. Flashing is not required.

NOTE: On bonded roofs, check for special installation

requirements.

Location

Use the following guidelines to select a suitable location for

both the condensing unit and the evaporator.

1. The heat pump is designed for outdoor installation only.

2. The condenser fans are the propeller type and are not

suitable for use with ductwork in the condenser air stream.

Ground Level Locations

It is important that the units be installed on a substantial base

that will not settle, causing strain on the refrigerant lines and

possible leaks. A one-piece concrete slab with footers that

extend below the frost line is recommended. The slab should

not be tied to the building foundation, as noise will telegraph

through the slab.

Johnson Controls Unitary Products 5

Page 6

430645-YIM-D-0610

DIM X

DIM Y

LENGTH

WIDTH

C

A

B

D

CG

FRONT

RIGHT

REAR

LEFT

CG

DIM X

DIM Y

LENGTH

WIDTH

C

B

A

D

FRONT

REAR

LEFT

RIGHT

PC090, PC120

PC180, PD180,

PC240, PD240

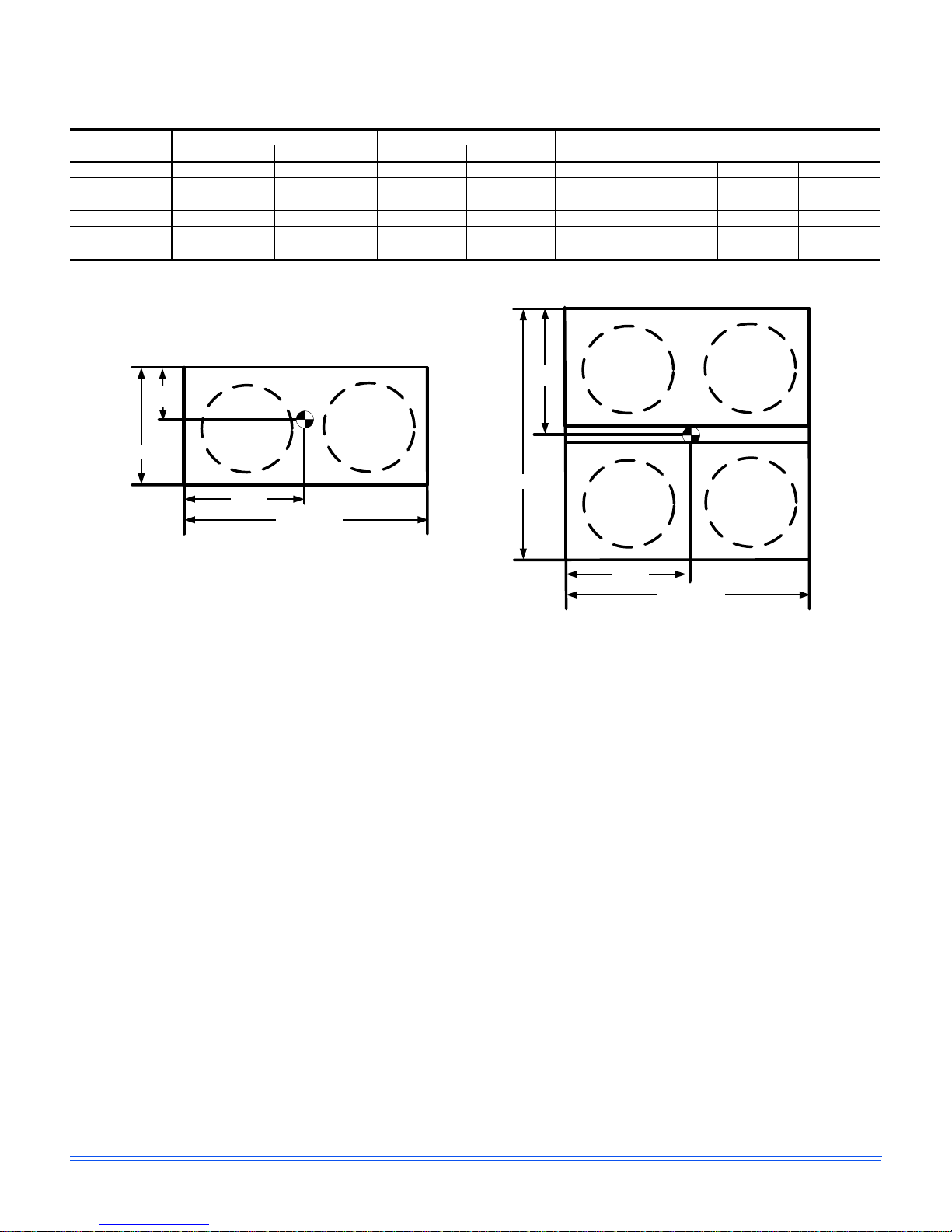

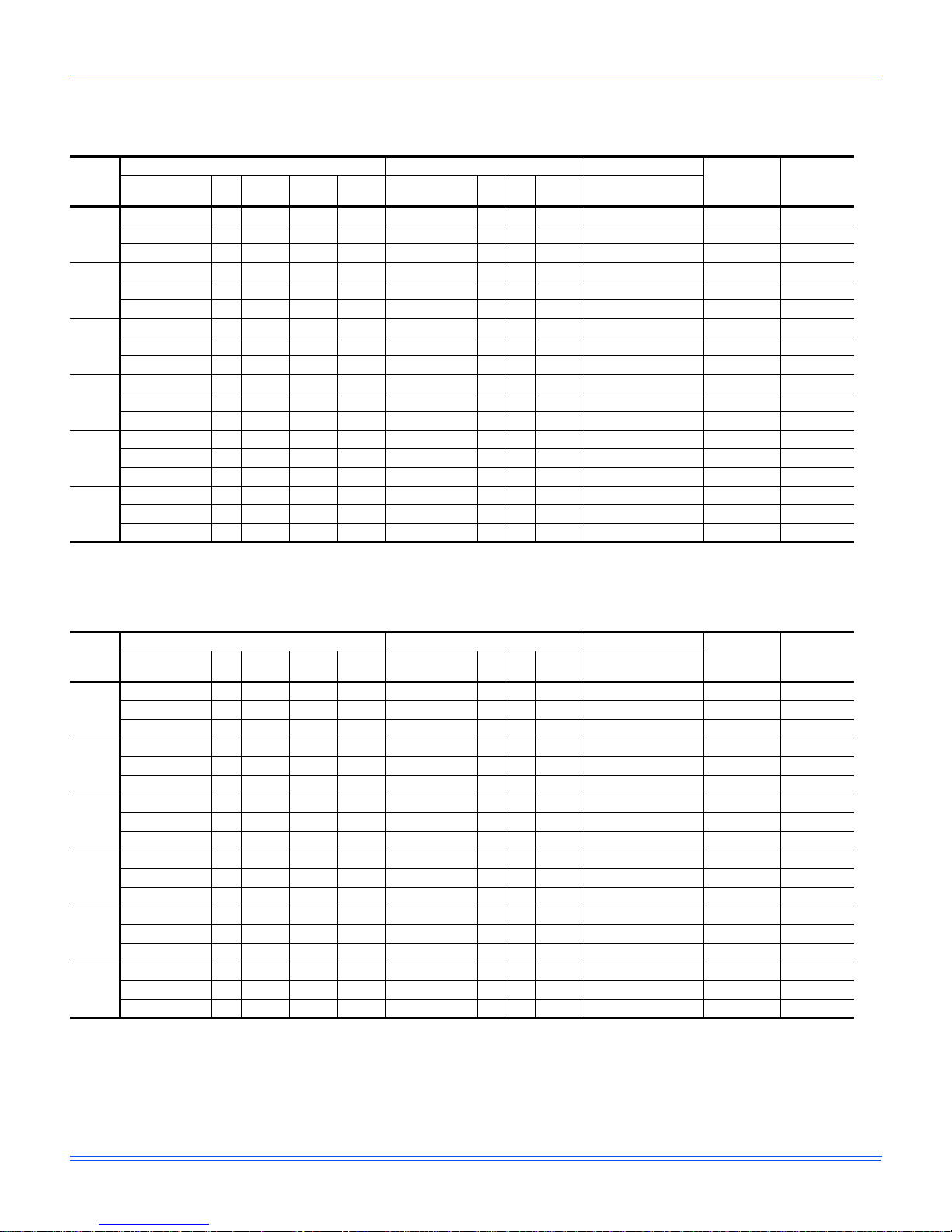

Table 3: Corner Weights & Center of Gravity

Model

PC090 421 430 17.3 33 110 130 103 87

PC120 543 574 16.4 32.3 153 161 134 127

PC180 947 968 32.5 33 266 274 217 211

PD180 921 942 34 32.5 243 275 225 199

PC240 1116 1152 32.1 30.8 300 301 276 275

PD240 1090 1126 31.2 31.8 311 295 253 267

Weight (lbs.) Center of Gravity (in.) 4 Point Load Location (lbs.)

Shipping Operating X Y A B C D

Figure 1: Corner Weights & Center Of Gravity

NOTE: Front of unit is considered the side having the control

box.

Concrete piers can also support ground level units. These piers

should (1) extend below the frost line, (2) be located under each

of the section's four corners, and (3) be sized to carry the load

of the corner it supports.

On either rooftop or ground level installations, rubber padding

can be applied under the unit to lessen any transmission of

vibration.

6 Johnson Controls Unitary Products

Holes are provided in the base rails for bolting the unit to its

foundation.

For ground level installations, precautions should be taken to

protect the unit from tampering and unauthorized persons from

injury. Screws on access panels will prevent casual tampering.

Further safety precautions such as a fenced enclosure or

locking devices on the panels may be advisable. Check local

authorities for safety regulations.

Page 7

430645-YIM-D-0610

Clearances

The unit must be installed with sufficient clearance for air to

enter the condenser coils, for air discharge and for servicing

access. See Table Table 4 for clearances.

NOTE: Additional clearance is required to remove the

compressors out the back of the unit.

Table 4: Minimum Clearances

Clearance Description Distance in Inches

Overhead (Top) 120

Front 36

Rear 36

Left Side 30

Right Side 30

1

Bottom

1.In all installations where snow ac cu mulates and winter oper-

ation is expected, additional height mus t be prov id ed to

insure normal condenser airflow.

0

LENGTH OF FORKS MUST BE A MINIMUM OF 60 INCHES.

Spreaders, longer than the largest dimension across the

unit must be used across the top of the unit.

Before lifting a unit, make sure that its weight is

distributed equally on the cables so that it will lift evenly.

Do not permit overhanging structures or shrubs to

obstruct condenser air discharge.

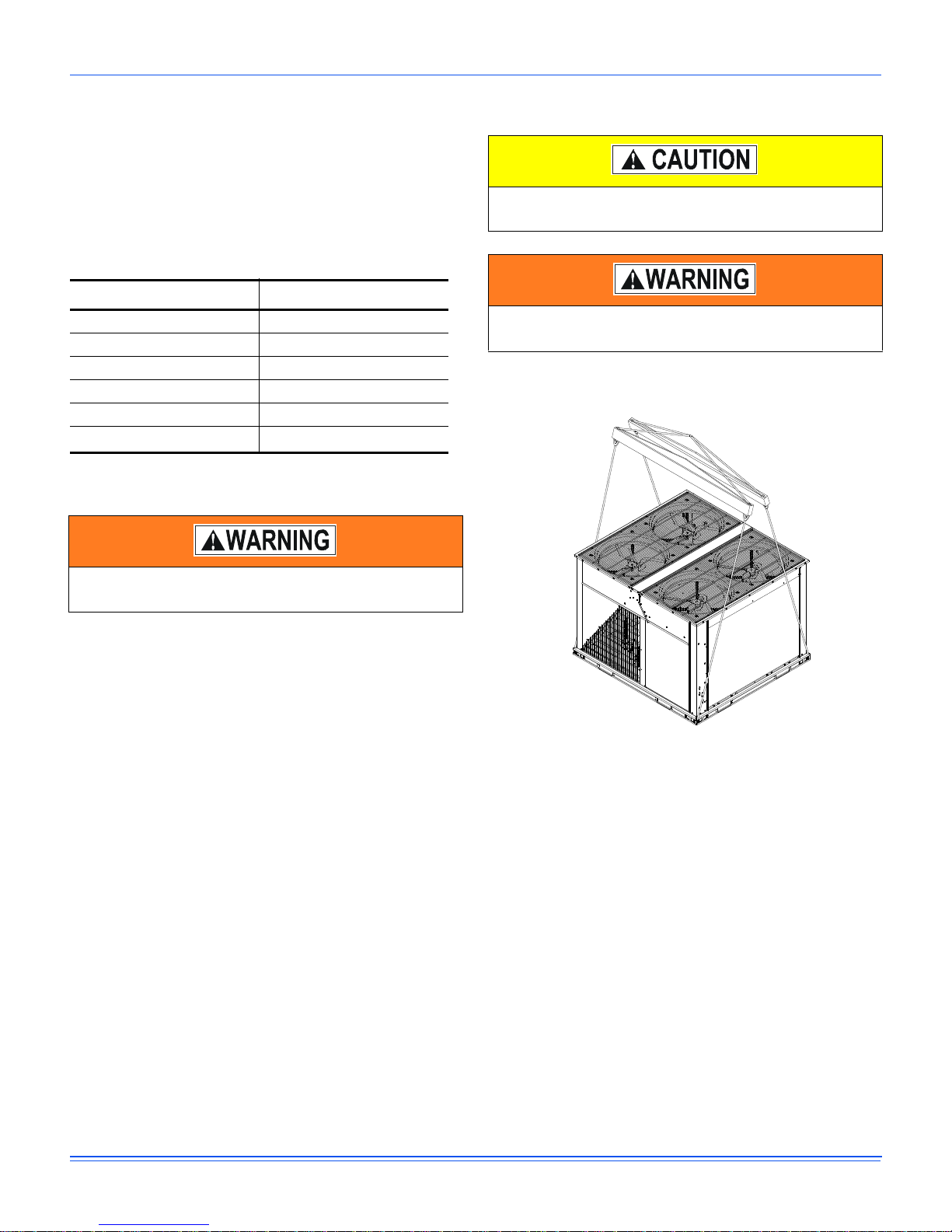

Rigging

Exercise care when moving the unit. Do not remove any

packaging until the unit is near the place of install ation. Rig the

unit by attaching chain or cable slings to the lifting holes

provided in the base rails. Spreader bars, whose length

exceeds the largest dimension across the unit, MUST be used

across the top of the unit.

The unit may be moved or lifted with a forklift. Slotted openings

in the base rails are provided for this purpose.

Figure 2: Typical Rigging

Johnson Controls Unitary Products 7

Page 8

430645-YIM-D-0610

Power Wiring

Check the available power and the unit nameplate for correct

voltage. Run the necessary number of properly sized wires to

the unit. Provide a disconnect switch (if not included with the

unit) and fusing as required (Factory disconnect is a fused

disconnect /breaker). Route the conduit through the large

knockout located near the electrical box. See Table 5 for

Electrical Data.

The disconnect switch may be bolted to the side of the unit but

not to any of the removable panels; which would interfere with

access to the unit. Make sure that no refrigerant lines will be

punctured when mounting the disconnect switch, and note that

it must be suitable for outdoor installation.

All power and control wiring must be in accordance

with National and Local electrical codes.

Do not leave the system open to the atmosphere. Unit

damage could occur due to moisture being absorbed by

the POE oil in the system. This type of oil is highly

susceptible to moisture absorption

POE (polyolester) compressor lubricants are known to cause

long term damage to some synthetic roofing materials.

Exposure, even if immediately cleaned up, may cause

embrittlement (leading to cracking) to occur in one year

or more. When performing any service that may risk

exposure of compressor oil to the roof, take precautions

to protect roofing.

Control Wiring

Route the necessary low voltage control wires from the

Simplicity™ control board to the thermostat and also between

the terminal blocks inside the heat pump and evaporator control

boxes. Refer to Figures 3 thru 6 for field wiring diagrams.

Compressors

The scroll compressors used in this product are specifically

designed to operate with R-410A Refrigerant and cannot be

interchanged.

This system uses R-410A Refrigerant which operates at

higher pressures than R-22. No other refrigerant may be

used in this system.

The compressor also uses a polyolester (POE oil), Mobil 3MA

POE. This oil is extremely hydroscopic, meaning it absorbs

water readily. POE oil can absorb 15 times as much water as

other oils designed for HCFC and CFC refrigerants. Take all

necessary precautions to avoid exposure of the oil to the

atmosphere.

Procedures which risk oil leakage include, but are not limited to,

compressor replacement, repairing refrigerant leaks, replacing

refrigerant components such as filter drier, pressure switch,

metering device or coil.

The unit is shipped with compressor mounting bolts which are

factory adjusted and ready for operation.

Do not loosen compressor mounting bolts.

Phasing

Three-phase, scroll compressors operate in only one direction.

If the scroll is drawing low amperage, has similar suction and

discharge pressures, or is producing a high noise level, the

scroll is misphased. Change the incoming line connection

phasing to obtain the proper rotation.

Scroll compressors require proper rotation to operate

properly. Failure to check and correct rotation may result

in property damage.

8 Johnson Controls Unitary Products

Page 9

Electrical Data

Table 5: Electrical Data - Outdoor Unit - HP Without Powered Convenience Outlet

Model

PC090

PC120

PC180

PD180

PC240

PD240

Power

Supply

208/230-3-60 1 25.0 39 164 208/230-1-60 1/3 2 2.1 - 3 5.5 45

460-3-60 1 12.2 19 100 460-1-60 1/3 2 1.2 - 1 7.6 25

575-3-60 1 9.0 14 78 575-1-60 1/3 2 0.9 - 13.1 20

208/230-3-60 2 18.1 28.3 137 208/230-1-60 3/4 2 3.0 - 46.8 60

460-3-60 2 9.0 14.0 62 460-1-60 3/4 2 1.6 - 2 3.5 30

575-3-60 2 6.8 10.6 50 575-1-60 3/4 2 1.4 - 1 8.0 20

208/230-3-60 2 25.0 39 164 208/230-1-60 1/3 4 2.1 - 6 4.7 80

460-3-60 2 12.2 19 100 460-1-60 1/3 4 1.2 - 3 2.2 40

575-3-60 2 9.0 14 78 575-1-60 1/3 4 0.9 - 24.0 30

208/230-3-60 2 25.0 39 164 208/230-1-60 1/3 4 2.1 - 6 4.7 80

460-3-60 2 12.2 19 100 460-1-60 1/3 4 1.2 - 3 2.2 40

575-3-60 2 9.0 14 78 575-1-60 1/3 4 0.9 - 24.0 30

208/230-3-60 2 30.1 47 225 208/230-1-60 3/4 4 3.0 - 7 9.8 100

460-3-60 2 16.7 26 114 460-1-60 3/4 4 1.6 - 4 4.0 60

575-3-60 2 12.2 19 80 575-1-60 3/4 4 1.4 - 32.9 45

208/230-3-60 2 30.1 47 225 208/230-1-60 3/4 4 3.0 - 7 9.8 100

460-3-60 2 16.7 26 114 460-1-60 3/4 4 1.6 - 4 4.0 60

575-3-60 2 12.2 19 80 575-1-60 3/4 4 1.4 - 32.9 45

1. Based on three, 75°C insulated copper conductors in conduit and ambient of 30°C.

2. Maximum fuse or maximum circuit breaker (HACR type per NEC).

Refer to NEC/NFPA No. 70, Articles 440-11, 12 for information on minimum disconnect sizing.

Compressors Outdoor Fan Motor Pwr Conv Outlet

Qty

RLA

(each)

MCC

(each)

LRA

(each)

Power

Supply

HP Qty

FLA

(each)

FLA

430645-YIM-D-0610

Minimum

Circuit

Ampacity

1

Maximum

Fuse Size

2

(A)

Table 6: Electrical Data - Outdoor Unit - HP With Powered Convenience Outlet

Compressors Outdoor Fan Motor Pwr Conv Outlet

Model

PC090

PC120

PC180

PD180

PC240

PD240

Power

Supply

208/230-3-60 1 25.0 39 164 208/230-1-60 1/3 2 2.1 10.0 45.5 60

460-3-60 1 12.2 19 100 460-1-60 1/3 2 1.2 5.0 22.6 30

575-3-60 1 9.0 14 78 575-1-60 1/3 2 0.9 4.0 17.1 25

208/230-3-60 2 18.1 28.3 137 208/230-1-60 3/4 2 3.0 10.0 56.8 70

460-3-60 2 9.0 14.0 62 460-1-60 3/4 2 1.6 5.0 28.5 35

575-3-60 2 6.8 10.6 50 575-1-60 3/4 2 1.4 4.0 22.0 25

208/230-3-60 2 25.0 39 164 208/230-1-60 1/3 4 2.1 10.0 74.7 90

460-3-60 2 12.2 19 100 460-1-60 1/3 4 1.2 5.0 37.2 45

575-3-60 2 9.0 14 78 575-1-60 1/3 4 0.9 4.0 28.0 35

208/230-3-60 2 25.0 39 164 208/230-1-60 1/3 4 2.1 10.0 74.7 90

460-3-60 2 12.2 19 100 460-1-60 1/3 4 1.2 5.0 37.2 45

575-3-60 2 9.0 14 78 575-1-60 1/3 4 0.9 4.0 28.0 35

208/230-3-60 2 30.1 47 225 208/230-1-60 3/4 4 3.0 10.0 89.8 110

460-3-60 2 16.7 26 114 460-1-60 3/4 4 1.6 5.0 49.0 60

575-3-60 2 12.2 19 80 575-1-60 3/4 4 1.4 4.0 36.9 45

208/230-3-60 2 30.1 47 225 208/230-1-60 3/4 4 3.0 10.0 89.8 110

460-3-60 2 16.7 26 114 460-1-60 3/4 4 1.6 5.0 49.0 60

575-3-60 2 12.2 19 80 575-1-60 3/4 4 1.4 4.0 36.9 45

Qty

RLA

(each)

MCC

(each)

LRA

(each)

Power

Supply

HP Qty

1. Based on three, 75°C insulated copper conductors in conduit and ambient of 30°C.

2. Maximum fuse or maximum circuit breaker (HACR type per NEC).

Refer to NEC/NFPA No. 70, Articles 440-11, 12 for information on minimum disconnect sizing.

FLA

(each)

FLA

Minimum

Circuit

Ampacity

1

Maximum

Fuse Size

2

(A)

Johnson Controls Unitary Products 9

Page 10

430645-YIM-D-0610

Refrigerant Mains

This Split-System (Air Condensing / Heat Pump / Air

Handling) unit is one component of an entire system. As

such it requires specific application considerations with

regard to the rest of the system (air handling unit, duct

design, condensing unit, refrigerant piping and control

scheme).

Failure to properly apply this equipment with the rest of

the system may result in premature failure and/or

reduced performance / increased costs. Warranty

coverage specifically excludes failures due to improper

application and Unitary Products specifically disclaims

any liability resulting from improper application.

Please refer to the equipment Technical Guide,

Installation Manual and the piping applications bulletin

247077 or call the applications department for Unitary

Products @ 1-877-UPG-SERV for guidance.

Line Sizing

When sizing refrigerant pipe for a split-system air conditioner,

check the following:

1. Suction line pressure drop due to friction.

2. Liquid line pressure drop due to friction.

3. Suction line velocity for oil return.

4. Liquid line pressure drop due to vertical rise. For certain

piping arrangements, different sizes of suction line pipe

may have to be used. The velocity of the refrigerant vapor

must always be great enough to carry the oil back to the

compressor.

5. Evaporator Located Below Condenser - On a split

system where the evaporator blower is located below the

condenser, the suction line must be sized for both pressure

drop and for oil return.

6. Condenser Located Below Evapora tor - When the

condenser is located below the evaporator blower, the

liquid line must be designed for the pressure drop due to

both friction loss and vertical rise. If the pressure drop due

to vertical rise and friction exceeds 60 psi, some refrigerant

will flash before it reaches the thermal expansion valve.

Flash gas

1. Increases the liquid line pressure loss due to friction that in

2. Reduces the capacity of the refrigerant control device

3. Erodes the seat of the refrigerant control device.

4. Causes erratic control of the refrigerant entering the

:

turn causes further flashing.

which starves the evaporator.

evaporator.

Take Adequate Precautions

Many service problems can be avoided by taking adequate

precautions to provide an internally clean and dry system and

by using procedures and materials that conform to established

standards.

Use hard drawn copper tubing where no appreciable amount of

bending around pipes or other obstructions is necessary. If soft

copper is used, care should be taken to avoid sharp bends that

may cause a restriction. Pack fiberglass insulation and a

sealing material such as permagum around refrigerant lines

where they penetrate a wall to reduce vibrations and to retain

some flexibility.

Support all tubing at minimum intervals with suitable hangers,

brackets or clamps.

Braze all copper-to-copper joints with Silfos-5 or equivalent

brazing material. Do not use soft solder. Insulate all suction

lines with a minimum of 1/2" ARMAFLEX or equivalent that

meets local codes. Liquid lines exposed to direct sunlight and/

or high temperatures must also be insulated. Never solder

suction and liquid lines together. They can be taped together for

convenience and support purposes, but they must be

completely insulated from each other.

The liquid and suction service ports on the condenser section

permit leak testing, evacuation, and partial charging of the field

piping and the evaporator without disturbing refrigerant stored

in the condenser during initial installation.

Before beginning installation of the main lines, be sure that the

evaporator section has not developed a leak in transit. Check

pressure at the Schrader valve located on the header of each

coil. If pressure still exists in the system, it can be assumed to

be leak free. If pressure DOES NOT exist the section will need

to be repaired before evacuation and charging is performed.

A bi-flow solid core filter-drier MUST be field-installed in the

liquid line of every system to prevent dirt and moisture from

damaging the system. Properly sized filter-driers are shipped

with each condensing section.

NOTE: Installing a filter-drier does not eliminate the need for

the proper evacuation of a system before it is charged.

A field-installed moisture indicating sight-glass should be

installed in the liquid line(s) between the filter-drier and the

evaporator coil. The moisture indicating sight-glass can be used

to check for excess moisture in the system.

Both condenser and evaporator sections have copper sealing

disks brazed over the end of liquid and suction connections.

The temperature required to make or break a brazed joint is

high enough to cause oxidation of the copper unless an inert

atmosphere is provided.

NOTE: Dry nitrogen should flow through the system at all times

when heat is being applied and until the joint has

cooled. The flow of nitrogen will prevent oxidation of the

copper lines during installation.

10 Johnson Controls Unitary Products

Page 11

430645-YIM-D-0610

Always punch a small hole in sealing disks before unbrazing to

prevent the pressure in the line from blowing them off. Do not

use a drill as copper shavings can enter system.

NOTE: Solenoid and hot gas bypass valves (if used) should be

opened manually or electrically duri ng brazing or

evacuating.

NOTE: Schrader valves located on unit service valves should

have their stems removed during brazing to prevent

damage to the valve and reduce system evacuation

time.

Start Installation

Start the installation of main lines at the heat pump. Verify

holding charge in unit by cracking open valve. If pressure is

present, close valve and proceed with installation. If no

pressure is present, check system for leaks.

Verify all service valves are fully seated by screwing the stems

of both valves down into the valve bodies until they stop.

Remove the Schrader valve stem and connect a low-pressure

nitrogen source to the service port on the suction line valve

body. Punch a small hole in the sealing disk; the flow of

nitrogen will prevent any debris from entering the system. Wrap

the valve body with a wet rag to prevent overheating during the

brazing process. Overheating the valve will damage the valve

seals. Unbraze the sealing disk, cool the valve body and

prepare the joint for connections of the main lines. Repeat for

the liquid line valve body.

suction sealing disks and prepare the joints for connections of

the main lines.

Connect the main liquid line to the liquid line connection on the

evaporator section, while maintaining a flow of nitrogen.

Make the suction line connection at the evaporator and run the

line to the heat pump. Connect the main suction line to the

suction line service valve connection, while maintaining a flow

of nitrogen. Cool the valve body and replace the Schrader valve

stem in the service port.

Once the brazing process is complete, leak testing should be

done on all interconnecting piping and the evaporator befo re

proper evacuation to below 500 microns is performed.

Verify evacuation with micron guage or thermocouple. Once the

line set and evaporator section is properly evacuated, the

service valves can be opened and the heat pump is now ready

to charge with the appropriate weight of refrigerant. Calculate

the correct system charge for the outdoor unit, the indoor unit

and the field line set.

Charge the system by introducing liquid refrigerant into the

liquid line through the liquid port connection. Complete adding

the refrigerant in vapor form into the suction port when the

compressor is started.

The correct refrigerant pressures are indicated as shown in

Figures 11 thru 16.

Never remove a cap from an access port unless the

valve is fully back-seated with its valve stem in the

maximum counter-clockwise position because the

refrigerant charge will be lost. Always use a refrigeration

valve wrench to open and close these service valves.

Connect the main liquid line to the liquid line service valve

connection, while maintaining a flow of nitrogen. Cool the valve

body and replace the Schrader valve stem in the service port.

Install the liquid line from the heat pump to the evaporator liquid

connection, maintaining a flow of nitrogen during all brazing

operations.

The filter-drier and sight glass must be located in the liquid line,

leaving the O.D. unit.

Connect a low-pressure nitrogen source to the Schrader valve

located on the evaporator section coil headers. Punch a small

hole in the sealing disks, the flow of nitrogen will prevent any

debris from entering the system. Unbraze both liquid and

This system uses R-410A Refrigerant which operates at

higher pressures than R-22. No other refrigerant may be

used in this system. Gage sets, hoses, refrigerant

containers and recovery systems must be designed to

handle R-410A. If you are unsure, consult the

equipment manufacturer. Failure to use R-410A

compatible servicing equipment may result in property

damage or injury.

Wear safety glasses and gloves when handling

refrigerants. Failure to follow this warning can cause

serious personal injury.

NOTE: This instruction covers the installation and operation of

the basic heat pump. For refrigerant piping installation

instructions refer to document 247077 "Application

Data - General Piping Recommendations for Split

System Air Conditioning and Heat Pumps".

Johnson Controls Unitary Products 11

Page 12

430645-YIM-D-0610

R CY1G W1 W2

THERMOSTAT

SINGLE STAGE COOLING

TWO STAGE HEATING

NOTE: Do not use a heat pump thermostat.

NOTE: Liquid line solenoid is not included or required

on 7.5 Ton Single Stage Units.

Figure 3: Typical Field Wiring Diagram - NC090 Air Handling Unit With PC090 Heat Pump

12 Johnson Controls Unitary Products

Page 13

430645-YIM-D-0610

R CY1G W1 W2

Y2

THERMOSTAT

TWO STAGE COOLING

TWO STAGE HEATING

NOTE: Do not use a heat pump thermostat.

NOTE: Liquid line solenoid is only activated during

second stage cooling operation.

219 / Y

218 / BR

1LLS

VALVE SYS 2

BLK

BLK

C O I L

Figure 4: Typical Field Wiring Diagram - NC120 thru 240 Evaporator Unit with PC120 thru 240 Heat Pump

Figure 5: NC120 - 240 Liquid Line Solenoid Wiring

Johnson Controls Unitary Products 13

Page 14

430645-YIM-D-0610

R CY1G W1 W2

Y2

THERMOSTAT

TWO STAGE COOLING

TWO STAGE HEATING

NOTE: Do not use a heat pump thermostat.

NOTE: Liquid line solenoid is not included or required

on any 4 pipe units.

Figure 6: Typical Field Wiring Diagram - ND180 thru 240 Evaporator Unit with PD180 thru 240 Heat Pump

14 Johnson Controls Unitary Products

Page 15

LEFT

REAR

RIGHT

FRONT

RIGHT

2X (Ø 0.875)

KNOCKOUT

30.994

2X (Ø 1.375)

KNOCKOUT

CONVENIENCE

OUTLET

7.00010.000

24.000

31.758

7.000

3.883

3.664

2.933

1.664

23.000

37.000

58.500

7.000

7.000

12.126

9.876

4.751

A

2X (Ø 1.375)

KNOCKOUT

REAR LEFT

2X (Ø 0.875)

KNOCKOUT

12.000

10.000

4.875

4.132

2.382

1.882

15.53

12.70

6.26

7.52

8.98

10.60

SYSTEM 2

SYSTEM 1

FRONT

430645-YIM-D-0610

Figure 7: PC090, PC120 Unit Dimensions

NOTE: Use System 1 piping dimensions when applying a PC090/120 model system.

Table 7: PC090, PC120 Unit Height Dimensions

MODEL A

PC090 44.5

PC120 50.0

Johnson Controls Unitary Products 15

Page 16

430645-YIM-D-0610

LEFT

RIGHT

FRONT

REAR

FRONT

FRONT

(PIPING DETAIL)

RIGHT

SYSTEM 2

SYSTEM 1

7.0007.000

23.000

37.000

64.000

2X (Ø 0.875)

KNOCKOUT

2X (Ø 1.375)

KNOCKOUT

7.0007.000

23.000

37.000

59.000

30.994

11.375

9.125

4.750

4.132

3.913

3.181

1.913

A

SYSTEM 2

SYSTEM 1

16.133

13.133

17.367

18.867

20.617

22.617

Figure 8: PC/PD180 & PC/PD240 Unit Dimensions and Piping & Electrical Dimensions

NOTE: Use System 1 piping dimensions when applying a PC180/240 model system.

Table 8: PC/PD180 & PC/PD240 Unit Height Dimensions

16 Johnson Controls Unitary Products

MODEL A

PC180 44.5

PD180 44.5

PC240 50.0

PD240 50.0

Page 17

430645-YIM-D-0610

Table 9: Piping and Electrical Connection Sizes

MODEL PC090 PC120 PC180 PD180 PC240 PD240

No. Refrigeration Circuits 1 1 121 2

Suction Line OD (in.) 1 1/8 1 3/8 1 5/8 1 3/8 1 5/8 1 3/8

Liquid Line OD (in.) 5/8 7/8 7/8 5/8 7/8 7/8

Power Wiring Knockout 1 3/8 1 3/8 1 3/8 1 3/8 1 3/8 1 3/8

Control Wiring Knockout 7/8 7/8 7/8 7/8 7/8 7/8

Piping And Electrical Connections

Piping connections are made from the rear of 7.5 thru 12.5 Ton

units and from the front of 15 thru 20 Ton units. Stubouts are

provided on the suction and liquid line service valves. Piping

can be routed to the unit from the left or right side.

Electrical connections for power and control wiring are made

from the right or left side of the electrical control box. See Table

9 and Figures 7 and 8 for piping sizes and electrical knockout

details.

Start-Up

Crankcase Heaters

The crankcase heaters must be energized at least 8 hours

before starting the compressors. To energize the crankcase

heaters, the main disconnect switch must be closed. During this

8 hour period, the system switch on the room thermostat must

be “OFF” to prevent the compressor from starting. Make sure

that the bottom of the compressor is warm to the touch to prove

crankcase heater operation.

Do not attempt to start the compressor without at least 8

hours of crankcase heat or compressor damage can

occur.

Pre-Start Check

Before starting the unit, complete the following check list:

1. Have sufficient clearances been provided?

2. Has all foreign matter been removed from the interior of the

unit (tools, construction or shipping materials, etc.)?

3. Have the condenser fans been rotated manually to check

for free rotation?

4. Are all wiring connections tight?

5. Does the available power supply agree with the nameplate

data on the unit?

6. Is the control circuit transformer set for the proper voltage?

7. Have the fuses, disconnect switch and power wire been

sized properly?

8. Are all compressor mounting bolts properly secured?

9. Are any refrigerant lines touching each other or any sheet

metal surface? Rubbing due to vibration could cause a

refrigerant leak.

10. Are there any visible signs of a refrigerant leak, such as oil

residue?

11. Has the refrigeration system been leak checked,

evacuated and had the correctly calculated charge

weighted in?

12. Is any electrical wire laying against a hot refrigerant line?

Initial Start-Up

1. Supply power to the unit through the disconnect switch at

least 8 hours prior to starting the compressor.

2. Move the system switch on the thermostat to the AUTO or

COOL position.

3. Reduce the setting of the room thermostat to energize the

compressor.

4. Check the operation of the evaporator unit per the

manufacturer’s recommendations.

5. With an ammeter, check the compressor amps against the

unit data plate.

6. Check for refrigerant leaks.

7. Check for any abnormal noises and/or vibrations, and

make the necessary adjustments to correct fan blade(s)

touching shroud, refrigerant lines hitting on sheet metal,

etc.

8. After the unit has been operating for several minutes, shut

off the main power supply at the disconnect switch and

inspect all factory wiring connections and bolted surfaces

for tightness.

Johnson Controls Unitary Products 17

Page 18

430645-YIM-D-0610

Operation

Unit Control Overview

This series of heat pumps come factory equipped with

Simplicity™ controls to monitor all unit functionality and safety

controls.

Safety Controls

The Simplicity™ control board incorporates features to monitor

safety circuits as well as minimize compressor wear and

damage. An anti-short cycle delay (ASCD) is utilized to prevent

operation of a compressor too soon after its previous run. The

ASCD is initiated on unit start-up and on any compressor reset

or lockout.

The Simplicity™ control board monitors the following inputs for

each cooling system:

• A high-pressure switch is factory installed to protect

against excessive discharge pressure due to a blocked

condenser coil or a condenser fan motor failure. During

cooling operation, if a high-pressure limit switch opens,

the Simplicity™ control board will de-energize the

associated compressors and initiate the 5-minute ASCD.

If the call for cool is still present at the end of the ASCD,

the control board will re-energize the halted compressor. If

a high-pressure switch opens three times within two hours

of operation, the Simplicity™ control board will lockout the

associated system compressors and will flash an error

code (see Table 11).

• A low-pressure switch to protec t the unit against

excessively low suction pressure is standard on all

condensing units. If the low-pressure switch opens during

normal operation, the Simplicity™ control board will deenergize the compressor, initiate the ASCD, and shut

down the condenser fans. On startup, if the low-pressure

switch opens, the Simplicity™ control board will monitor

the low-pressure switch to make sure it closes within one

minute. If it fails to close, the unit will shut down the

associated compressor and begin an ASCD. If the call for

cool is still present at the end of the anti-short cycle time

delay, the control board will re-energize the halted

compressor. If a low-pressure switch opens three times

within one hour of operation, the Simplicity™ control

board will lock-out the associated compressor and flash

an error code (see Table 11).

• An ambient air switch will lock out mechanical cooling at

40F. If the product was equipped from the factory with

the low ambient option the unit will operate down to 0F. If

the unit was not ordered with the factory low amb i e nt

option a field installed low ambient kit is available.

The refrigerant systems are independently monitored and

controlled. On any fault, only the associated system will be

affected by any safety/preventive acti on . Th e oth e r refrig erant

system will continue to operate unless it is affected by the fault

as well.

Compressor Protection

In addition to the external pressure switches, the compressors

also have inherent (internal) protection. If there is an abnormal

temperature rise in a compressor, the protector will open to shut

down the compressor. The UCB incorporates features to

minimize compressor wear and damage. An Anti-Short Cycle

Delay (ASCD) is utilized to prevent operation of a compressor

too soon after its previous run. Additionally, a minimum run time

is imposed any time a compressor is energized.

The ASCD is initiated on unit start-up and on any compressor

reset or lock-out.

Flash Codes

The UCB will initiate a flash code associated with errors within

the system. Refer to UNIT CONTROL BOARD FLASH CODES

Table 11.

Reset

Remove the call for cooling, by raising thermostat setting higher

than the conditioned space temperature. This resets any

pressure or freezestat flash codes. Simplicity

minimum run time in cool. Heat pump mode shuts off

immediately.

™ only has

Sequence of Operation

Continuous Blower

By setting the room thermostat to “ON,” the low voltage control

circuit from the “R” to “G” is completed and the supply air blower

will operate continuously.

Intermittent Blower

With the room thermostat fan switch set to “AUTO” and the

system switch set to either the “AUTO” or “HEAT” settings, the

blower is energized whenever a cooling or heating operation is

requested. The blower is energized after any specified delay

associated with the operation.

When energized, the indoor blower has a minimum run time of

30 seconds. Additionally, the indoor blower has a delay of 10

seconds between operations.

Cooling Sequence Of Operation

Single-Stage Heat Pump (PC090)

A single stage thermostat is required to operate the heat pump

in cooling mode.

The reversing valve is energized during cooling mode. A

continuous 24V signal is passed through the normally closed

contacts of relay RY2 to the "O" terminal of the Defrost Control

Board (DC). The normally closed relay DR-2 within DC

energizes the solenoid (SOL) of the reversing valve.

When the thermostat calls for cooling (Y1), the Simplicity

control board (UCB) closes the coils of relay RY1 and contactor

18 Johnson Controls Unitary Products

Page 19

430645-YIM-D-0610

M1 while sending a signal to one of the "CFAN" terminals on

DC.

• Relay RY1 controls the crankcase heater (CCH1). The

normally closed contacts allow CCH1 to operate during

unit shutdown.

• Contactor M1 controls compressor COMPR1.

The output signal from the remaining "CFAN" terminal on DC

closes the coil of contactor M3.

• Contactor M3 controls outdoor fans ODFAN1 & 2.

After completing the specified time for fan on-delay, UCB closes

the coil of relay BR1.

• Relay BR1 sends a 24V signal to G1 of terminal block

TB2. It may be used to control operation of an indoor

blower.

When the call for cooling (Y1) is satisfied, the UCB disables the

signal to RY1, M1 and DC as long as the specified minimum run

time (ASCD) has elapsed.

The UCB disables the signal to BR1 after completing the fan

off-delay period.

Dual Stage Heat Pump (PC120-240)

A two stage thermostat is required to operate the heat pump in

cooling mode.

The reversing valve is energized during cooling mode. A

continuous 24V signal is passed through the normally closed

contacts of relay RY2 to the "O" terminal of the Defrost Control

Board (DC). The normally closed relay DR-2 within DC

energizes the solenoid (SOL) of the reversing valve.

When the thermostat calls for first-stage cooling (Y1), the

Simplicity control board (UCB) closes the coils of relay RY1 and

contactor M1 while sending a signal to one of the "CFAN"

terminals on DC.

• Relay RY1 has two fu nctions. 1) control the crankcase

heater CCH1, 2) control the 24V output signal to S1 on

terminal block TB2.

• Contactor M1 controls compressor COMPR1.

The output signal from the remaining "CFAN" terminal on DC

closes the coil of contactor M3.

• Contactor M3 controls all outdoor fans.

After completing the specified time for fan on-delay, UCB closes

the coil of relay BR1.

• Relay BR1 sends a 24V signal to G1 of terminal block

TB2. It may be used to control operation of an indoor

blower.

When the thermostat calls for second-stage cooling (Y2), th e

Simplicity control board (UCB) closes the coil of relay RY2 and

contactor M2.

• Relay RY2 has two functions. 1) control the crankcase

heater CCH2, 2) control the 24V output signal to S2 on

terminal block TB2.

• Contactor M2 controls compressor COMPR2.

If the initial call for cooling requires both stages (Y1 and Y2), the

UCB will delay the second stage by 30 seconds to avoid an

excessive power inrush.

When the call for cooling (Y2) is satisfied, the UCB disables the

signal to RY2 and M2 as long as the specified minimum run

time (ASCD) has elapsed.

When the call for cooling (Y1) is satisfied, the UCB disables the

signal to RY1 and M1 as long as the specified minimum run

time (ASCD) has elapsed.

Dual Stage Heat Pump - 4 pipe (PD180-240)

A two stage thermostat is required to operate the heat pump in

cooling mode.

Both reversing valves are energized during cooling mode.

Continuous 24V signals are passed through the normally

closed contacts of relays RY2 and RY3 to the "O" terminals of

their respective Defrost Control Boards (DC1 and DC2). The

normally closed relays DR-2 within DC1 and DC2 energize the

solenoids (SOL1 and SOL2) of the reversing valves.

When the thermostat calls for first-stage cooling (Y1), the

Simplicity control board (UCB) closes the coils of relay RY1 and

contactor M1 while sending a signal to one of the "CFAN"

terminals on DC1.

• Relay RY1 has two functions. 1) control the crankcase

heater CCH1, 2) control the 24V output signal to S1 on

terminal block TB2.

• Contactor M1 controls compressor COMPR1.

The output signal from the remaining "CFAN" terminal on DC1

closes the coil of contactor M3.

• Contactor M3 controls outdoor fans ODFAN1 & 2.

After completing the specified time for fan on-delay, UCB closes

the coil of relay BR1.

• Relay BR1 sends a 24V signal to G1 of terminal block

TB2. It may be used to control operation of an indoor

blower.

When the thermostat calls for second-stage cooling (Y2), the

Simplicity control board (UCB) closes the coils of relay RY2 and

contactor M2 while sending a signal to one of the "CFAN"

terminals on DC2.

• Relay RY2 has two functions. 1) control the crankcase

heater CCH2, 2) control the 24V output signal to S2 on

terminal block TB2.

• Contactor M2 controls compressor COMPR2.

The output signal from the remaining "CFAN" terminal on DC2

closes the coil of contactor M4.

Johnson Controls Unitary Products 19

Page 20

430645-YIM-D-0610

• Contactor M4 controls outdoor fans ODFAN3 & 4.

If the initial call for cooling requires both stages (Y1 and Y2), the

UCB will delay the second stage by 30 seconds to avoid an

excessive power inrush.

When the call for cooling (Y2) is satisfied, the UCB disables the

signal to RY2 and M2 as long as the specified minimum run

time (ASCD) has elapsed.

When the call for cooling (Y1) is satisfied, the UCB disables the

signal to RY1 and M1 as long as the specified minimum run

time (ASCD) has elapsed.

Low Ambient Cooling

These units are factory equipped with low ambient switches

that work through the Simplicity control board to operate the

compressors and condenser fans normally to 40ºF ambient

temperature. The Electronic Low Ambient Controller

2LA04703000 Accessory is designed to assure safe operation

through condenser head pressure regulation down to 0ºF

ambient temperature.

Low Ambient Control Operation

• A call for cooling closes contactor M3 which energize s all

condenser fans. The Low Ambient Control starts all fans

at full speed then adjusts according to the liquid line

temperature.

Refer to the appropriate 2LA low ambient kit instructions for

additional detail on the factory or field installed low ambient kit

and its operation.

Heating Sequence of Operation

General

Heat pump models are to be matched with air handlers of

equivalent tonnage ratings. Twinning of heat pumps and air

handlers is not recommended.

A two stage thermostat is required to operate the heat pump in

heating mode.

All reversing valves are de-energized during normal heating

mode. They are energized only during cooling and defrost

modes.

The heat pump operates all compressors during a first stage

call for heating unless locked out by the Unit Control Board

(UCB).

First Stage Heating Operation

When the thermostat calls for first stage heating (W1):

• The Simplicity control board (UCB) goes into a five minute

ASCD timer delay.

• When the ASCD time delay is satisfied, the UCB closes its

internal compressor relay contact, thus energizing the

contacts of relay RY1 and contactor M1.

• Relay RY1 has two functions: 1) control the operation of

crankcase heater CCH1, and 2) control the 24V output

signal to S1 on terminal block TB2.

• Contactor M1 controls compressor COMPR1.

• Relay RY3 (RY2 for PC090 model) toggles the 24V signal

from the "O" terminal of DC to the "Y" terminal assuring

the reversing valve cannot be energized except during

defrost.

• Concurrently, a 24V signal is sent to one of the "CFAN"

terminals of DC. The output signal from the remaining

"CFAN" terminal closes the coil of contactor M3.

• Contactor M3 controls outdoor fans ODFAN1 & 2 (all

models) and ODFAN3 & 4 (PC180-240).

(PC120-240; PD180-240 models)

• After a two second delay, the UCB energizes the contacts

of relay RY2 and contactor M2.

• Relay RY2 has two functions: 1) control the operation of

crankcase heater CCH2, and 2) control the 24V output

signal to S2 on terminal block TB2.

• Contactor M2 controls compressor COMPR2.

(PD180-240 models only)

• Concurrently, a 24V signal is sent to one of the "CFAN"

terminals of defrost control board DC2. The output signal

from the remaining "CFAN" terminal closes the coil of

contactor M4.

• Contactor M4 controls outdoor fans ODFAN3 & 4.

Second Stage Heating Operation

When the thermostat calls for second stage heating (W2):

• A 24V signal passes through UCB sending an input signal

to the "W" terminal of DC. This signal passes through DC

as an output signal to the "66" terminal of TB2 to be used

as a control signal for first stage electric heat.

Emergency Heating Operation

When the thermostat calls for emergency heating (EMER):

• The UCB de-energizes all compressor relays and

contactors.

• A 24V signal passes through UCB sending an input signal

to the "W" terminal of DC. This signal passes through DC

as an output signal to the "66" terminal of TB2 to be used

as a control signal for first stage electric heat.

• The normally closed contacts of M1-AUX and M2-AUX

(PC120-240; PD180-240 models only) send a 24V output

signal to the "60" terminal of TB2 to be used as a control

signal for second stage electric heat.

20 Johnson Controls Unitary Products

Page 21

430645-YIM-D-0610

Rear

Front

Rear

Front

2

1

2

1

4

3

Defrost Operation

The defrost control board (DC) utilizes a time/temperature

defrost scheme. The DC repeats normal heating run cycles,

which must be completed, until one of the following conditions

is met and the DC enters defrost mode:

1. The DC satisfies its accumulated minimum run time. This

is factory set at 60 minutes, but is field adjustable to 30, 60

or 90 minutes.

2. The defrost switch(es) is closed. This normally open

switch is set to close at 28° F (+/-3°).

When the DC enters defrost mode, its on-board defrost relays

are powered. This energizes the reversing valve solenoid, deenergizes the condenser fan motors and energizes the unit's

optional electric heater. The DC remains in defrost mode until

either of the following two conditions are met:

1. Both of the liquid line thermostats are open. Each is set to

open at 55 degrees (+/- 3).

2. The maximum defrost run time of 10 minutes is met.

The DC also contains a set of test pins. Placing a jumper

across these pins will result in the following actions:

• If the ASCD timer is active, it is now bypassed, allowing

the compressor to run.

• If the DC is in a lockout condition, the lockout is reset.

• If the compressor is running, the DC is forced into defrost

mode. The control will remain in defrost mode as long as

the jumper is in place. When the jumper is removed, the

control will terminate defrost mode.

NOTE: The DC has two flash codes that only initiate if the

jumper between the two pressure switch terminals is

removed or broken.

Blower Operation

After completing the specified time for fan on-delay, UCB closes

the coil of relay BR1.

• Relay BR1 sends a 24V signal to G1 of terminal block

TB2. It may be used to control operation of an indoor

blower.

The UCB disables the signal to BR1 after completing the fan

off-delay period.

Figure 9: Fan Orientation, Control Box End

Table 10: PC090 thru 240 Unit Control Board Flash Codes

GREEN

FLASH CODE DESCRIPTION

On Steady This is a Control Failure -----

1 Flash

2 Flashes

3 Flashes

4 Flashes

5 Flashes

6 Flashes

7 Flashes

8 Flashes

10 Flashes

12 Flashes

13 Flashes

14 Flashes

OFF

1. Non-alarm condition.

2. Freeze - stat not applicable.

Not Applicable ----Control waiting ASCD

HPS1 Compressor Lockout Off Off Off On On

Not Applicable ----LPS1 Compressor Lockout Off Off On Off On

Not Applicable -----

FS1 Compressor Lockout

Not Applicable -----

Compressors Locked Out on Low Outdoor Air Temperature

Unit Locked Out due to Fan Overload Switch Failure Off On On Off Off

Compressor Held Off due to Low Voltage

EEPROM Storage Failure Off On On On Off

No Power or Control Failure OffOffOffOffOff

1

2

1

1

LED

16

Flashing Off Off On Off

Off Off On On On

Flashing On Off On Off

Flashing On On Off On

RED

LED

8

RED

LED

4

RED

LED

2

RED

LED

1

Johnson Controls Unitary Products 21

Page 22

430645-YIM-D-0610

Check

Alarm

History

Reset All

ASCDs for

One Cycle

Non Alarm

Condition Green

LED Flashing

Current Alarm

Flashed

Red LED

Table 11: PD180 thru 240 Unit Control Board Flash Codes

FLASH CODE DESCRIPTION

GREEN

LED

16

RED

LED

8

RED

LED

4

RED

LED

2

RED

LED

1

On Steady This is a Control Failure -----

1 Flash

2 Flashes

3 Flashes

4 Flashes

5 Flashes

6 Flashes

7 Flashes

8 Flashes

10 Flashes

12 Flashes

13 Flashes

14 Flashes

OFF

Not Applicable ----Control waiting ASCD

1

Flashing Off Off On Off

HPS1 Compressor Lockout Off Off Off On On

HPS2 Compressor Lockout Off Off On Off Off

LPS1 Compressor Lockout Off Off On Off On

LPS2 Compressor Lockout Off Off On On Off

FS1 Compressor Lockout

FS2 Compressor Lockout

2

2

Compressors Locked Out on Low Outdoor Air Temperature

1

Off Off On On On

Off On Off Off Off

Flashing On Off On Off

Unit Locked Out due to Fan Overload Switch Failure Off On On Off Off

Compressor Held Off due to Low Voltage

1

Flashing On On Off On

EEPROM Storage Failure Off On On On Off

No Power or Control Failure OffOffOffOffOff

1. Non-alarm condition.

2. Freeze - stat not applicable.

Figure 10: Unit Con trol Board

22 Johnson Controls Unitary Products

Page 23

430645-YIM-D-0610

Flash Codes

Various flash codes are utilized by the unit control board (UCB)

to aid in troubleshooting. Flash codes are distinguished by the

short on and off cycle used (approximately 200ms on and

200ms off). To show normal operation, the control board

flashes a 1 second on, 1 second off "heartbeat" during normal

operation. This is to verify that the UCB is functioning correctly.

Do not confuse this with an error flash code. To prevent

confusion, a 1-flash, flash code is not used.

Alarm condition codes are flashed on the UCB lower left Red

LED, See Figure Table 11. While the alarm code is being

flashed, it will also be shown by the other LEDs: lit continuously

while the alarm is being flashed. The total of the continuously lit

LEDs equates to the number of flashes, and is shown in the

table. Pressing and releasing the LAST ERROR button on the

UCB can check the alarm history. The UCB will cycle through

the last five (5) alarms, most recent to oldest, separating each

alarm flash code by approximately 2 seconds. In all cases, a

flashing Green LED will be used to indicate non-alarm

condition.

In some cases, it may be necessary to "zero" the ASCD for the

compressors in order to perform troubleshooting. To reset all

ASCDs for one cycle, press and release the UCB TEST/

RESET button once.

Normal Maintenance

Prior to any of the following maintenance procedures,

shut off all power to the unit, to avoid personal injury.

Periodic maintenance consists of changing or cleaning filters

and general cleaning of the outdoor coil.

FILTERS - Inspect once a month. Replace Disposable or clean

Permanent Type as necessary. DO NOT replace Permanent

Type with Disposable.

MOTORS - Outdoor fan motors are permanently lubricated and

require no maintenance.

OUTDOOR COIL - Dirt should not be allowed to accumulate on

the outdoor coil surface or other parts in the air circuit. Cleaning

should be as often as necessary to keep the coil clean. Use a

brush, vacuum cleaner attachment, or other suitable means. Be

sure that the power to the unit is shut off prior to cleaning.

Flash codes that do and do not represent alarms are listed in

Table Table 10.

Unit Control Board Option Setup

Option Byte Setup

• Enter The Option Setup Mode By Pushing The Option

Setup / Store Button, And Holding It For At Least 2

Seconds.

• The Green Status Led (Opti on Byte) Will Be Turned On

And The Red Status Led (Heat Delay) Is Turned Off.

• The 4 Led Wil l The n Show The Status Of The Labeled

Option Low Ambient Lockout.

• Press The Up Or Down Button To Change The Led Status

To Correspond To The Desired Option Setup.

• To Save The Current Displ ayed Value, Push The Option

Setup / Store Button And Hold It For At Least 2 Seconds.

When The Value Is Saved, The Green Led Will Flash A

Few Times And Then Normal Display Will Resume.

NOTE: While in either Setup mode, if no buttons are pushed for

60 seconds, the display will revert to its normal display,

exiting the Option Setup mode. When saving, the

control board only saves the parameters for the

currently displayed mode (Option Byte or Heat

Delay). (Heat Delay not applicable on these units.)

Exercise care when cleaning the coil so that the coil fins

are not damaged.

Do not permit the hot condenser air discharge to be

obstructed by overhanging structures or shrubs.

Troubleshooting

Troubleshooting of components necessarily requires

opening the electrical control box with the power

connected to the unit. Use extreme care when working

with live circuit! Check the unit nameplate for the correct

range before making any connections with line

terminals.

The wire number or color and terminal designations

referred to may vary. Check the wiring label inside the

control box access panel for the correct wiring.

Johnson Controls Unitary Products 23

Page 24

430645-YIM-D-0610

Cooling Troubleshooting Guid e

On calls for cooling, if the compressors are oper a ti n g bu t th e

supply air blower motor does not energize after a short delay

(the room thermostat fan switch is in the “AUTO” position):

1. Turn the thermostat fan switch to the ON position. If the

supply air blower motor does not energize, go to Step 3.

2. If the blower motor runs with the fan switch in the ON

position but will not run after the first compressor has

energized when the fan switch is in the AUTO position,

check the room thermostat for contact between R and G in

the AUTO position during calls for cooling.

3. If the supply air blower motor does not energize when the

fan switch is set to ON, check that line voltage is being

supplied to the contacts of the M3, contactor, and that the

contactor is pulled in. Check for loose wiring between the

contactor and the supply air blower motor.

4. If M3 is pulled in and voltage is supplied to M3, lightly touch

the supply air blower motor housing. If it is hot, the motor

may be off on internal protection. Cancel any thermostat

calls and set the fan switch to AUTO. Wait for the internal

overload to reset. Test again when cool.

5. If M3 is not pulled in, check for 24 volts at the M3 coil. If 24

volts are present at M3 but M3 is not pulled in, replace the

contactor.

6. Failing the above, if there is line voltage supplied at M3, M3

is pulled in, and the supply air blower motor still does not

operate, replace the motor.

7. If 24 volts is not present at M3, check that 24 volts is

present at the UCB supply air blower motor terminal,

“FAN”. If 24 volts is present at the FAN, check for loose

wiring between the UCB and M3.

8. If 24 volts is not present at the “FAN” terminal, check for 24

volts from the room thermostat. If 24 volts are not present

from the room thermostat, check for the following:

a. Proper operation of the room thermostat (contact

between R and G with the fan switch in the ON position

and in the AUTO position during operation calls).

b. Proper wiring between the room thermostat and the

UCB, and

c. Loose wiring from the room thermostat to the UCB

9. If 24 volts is present at the room thermostat but not at the

UCB, check for proper wiring between the thermostat and

the UCB, i.e. that the thermostat G terminal is connected to

the G terminal of the UCB, and for loose wiring.

10. If the thermostat and UCB are properly wired, replace the

UCB.

On calls for cooling, the supply air blower motor is operating but

compressor #1 is not (the room thermostat fan switch is in the

“AUTO” position):

1. If compressor #1 does not energize on a call for cooling,

check for line voltage at the compressor contactor, M1, and

that the contactor is pulled in. Check for loose wiring

between the contactor and the compressor.

2. If M1 is pulled in and voltage is supplied at M1, lightly touch

the compressor housing. If it is hot, the compressor may be

off on inherent protection. Cancel any calls for cooling and

wait for the internal overload to reset. Test again when

cool.

3. If M1 is not pulled in, check for 24 volts at the M1 coil. If 24

volts are present and M1 is not pulled in, replace the

contactor.

4. Failing the above, if voltage is supplied at M1, M1 is pulled

in, and the compressor still does not operate, replace the

compressor.

5. If 24 volts is not present at M1, check for 24 volts at the

UCB terminal, C1. If 24 volts is present, check for loose

wiring between C1 and the compressor contactor.

6. If 24 volts is not present at the C1 terminal, check for 24

volts from the room thermostat at the UCB Y1 terminal. If

24 volts is not present from the room thermostat, check for

the following:

a. 24 volts at the thermostat Y1 terminal

b. Proper wiring between the room thermostat and the

UCB, i.e. Y1 to Y1, Y2 to Y2, and

c. Loose wiring from the room thermostat to the UCB

7. If 24 volts is present at the UCB Y1 terminal, the

compressor may be out due to an open high-pressure

switch or low-pressure switch. Check for 24 volts at the

HPS1 and LPS1 terminals of the UCB. If a switch has

opened, there should be a voltage potential between the

UCB terminals, e.g. if LPS1 has opened, there will be a 24volt potential between the LPS1 terminals.

8. If 24 volts is present at the UCB Y1 terminal and none of

the protection switches have opened, the UCB may have

locked out the compressor for repeat trips. The UCB

should be flashing an alarm code. If not, press and release

the ALARMS button on the UCB. The UCB will flash the

last five alarms on the LED. If the compressor is locked

out, cancel any call for cooling. This will reset any

compressor lock outs.

NOTE: While the above step will reset any lockouts,

compressor #1 may be held off for the ASCD. See the

next step.

9. If 24 volts is present at the UCB Y1 terminal and none of

the switches are open and the compressor is not locked

out, the UCB may have the compressor in an ASCD.

Check the LED for an indication of an ASCD cycle. The

ASCD should time out within 5 minutes. Press and release

the TEST button to reset all ASCDs.

10. If 24 volts is present at the UCB Y1 terminal and the

compressor is not out due to a protective switch trip, repeat

trip lock out, or ASCD, the economizer terminals of the

UCB may be improperly wired. Check for 24 volts at the Y1

“OUT” terminal of the UCB.

11. If 24 volts is not present at the Y1 “OUT” terminal, the UCB

must be replaced. (If 24 volts is present at the Y1 OUT

terminal, check for 24 volts at the Y1 “ECON” terminal. If

24 volts is not present, check for loose wiring from the Y1

24 Johnson Controls Unitary Products

Page 25

430645-YIM-D-0610

“OUT” terminal to the Mate-N-Lock plug, the jumper in the

Mate-N-Lock plug, and in the wiring from the Mate-N-Lock

plug to the Y1 “ECON” terminal.)

12. If none of the above corrected the error, test the integrity of

the UCB. Disconnect the C1 terminal wire and jumper it to

the Y1 terminal. DO NOT jump the Y1 to C1 terminals. If

the compressor engages, the UCB has faulted.

13. If none of the above correct the error, replace the UCB.

For units with two stages of cooling: On calls for the second

stage of cooling, the supply air blower motor and compressor

#1 are operating but compressor #2 is not (the room thermostat

fan switch is in the “AUTO” position):

1. Compressor #2 will not energize simultaneously with

compressor #1 if a call for both stages of cooling is

received. The UCB delays compressor #2 by 30 seconds

to prevent a power surge. If after the delay compressor #2

does not energize on a second stage call for cooling, check

for line voltage at the compressor contactor, M2, and that

the contactor is pulled in. Check for loose wiring between

the contactor and the compressor.

2. If M2 is pulled in and voltage is supplied at M2, lightly touch

the compressor housing. If it is hot, the compressor may be

off on inherent protection. Cancel any calls for cooling and

wait for the internal overload to reset. Test again when cool.

3. If M2 is not pulled in, check for 24 volts at the M2 coil. If 24

volts is present and M2 is not pulled in, replace the

contactor.

4. Failing the above, if voltage is supplied at M2, M2 is pulled

in, and the compressor still does not operate, replace the

compressor.

5. If 24 volts is not present at M2, check for 24 volts at the

UCB terminal, C2. If 24 volts are present, check for loose

wiring between C2 and the compressor contactor.

6. If 24 volts is not present at the C2 terminal, check for 24

volts from the room thermostat at the UCB Y2 terminal. If

24 volts is not present from the room thermostat, check for

the following:

a. 24 volts at the thermostat Y2 terminal

b. Proper wiring between the room thermostat and the

UCB, i.e. Y1 to Y1, Y2 to Y2, and