Page 1

Features

•• Internal Square Root

Extractor

•• High Degree of Accuracy

•• Pneumatic Feedback

•• Movement Release Knob

to Maintain Calibration

Setting During Shipping

•• Minimal Field Calibration

Required

Pneumatic Control Manual 717.1

Pressure Section

Product Bulletin P-5219

Issue Date 1088

P-5219

Linear Velocity Transmitter

The P-5219 Linear Velocity

Transmitter is designed to

produce a linear 4.2 to 15 PSIG

(29 to 105 kPa) output signal

with respect to the calibrated

input velocity range of the

instrument. Applications for this

transmitter include constant

volume control and constant

volume differential control for

return fans on VAV systems.

Operation

The P-5219 employs a highly

sensitive differential pressure

diaphragm to compare static

and total pressure from a duct

mounted pitot tube or air flow

measuring station. The

resultant velocity pressure

signal is converted to a linear

velocity signal by an internal

square root extractor, which

eliminates the need for a

separate device.

Installation

Fig. 1: P-5219

Linear Velocity Transmitter

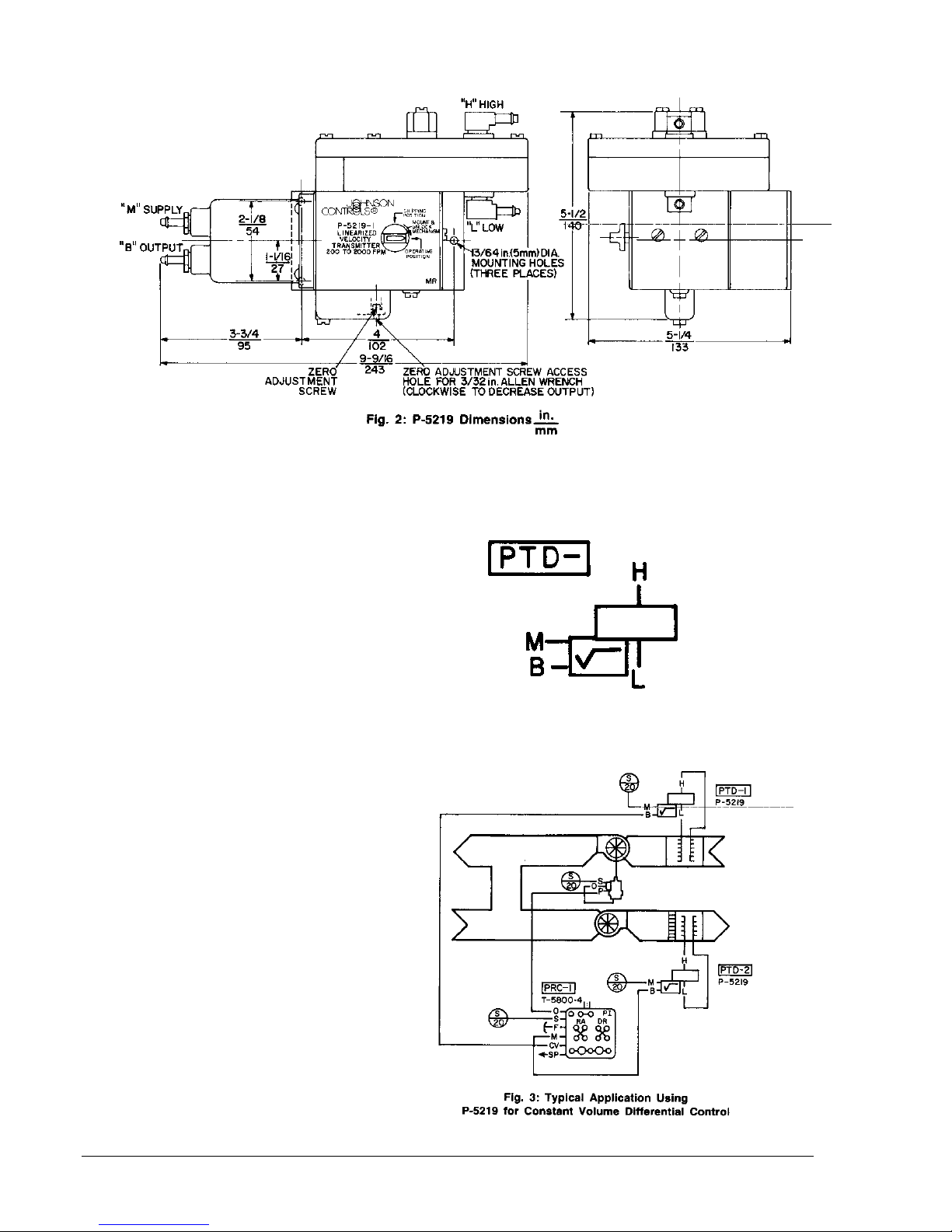

Specifications

The P-5219 should be located on

a vibration-free surface with the

diaphragm oriented within

5 angular degrees of a horizontal

plane. To install and calibrate

the P-5219, refer to Fig. 2 and

proceed as follows:

1. Secure the mounting

bracket to the surface using

© 1988 Johnson Controls, Inc. 1

Code No. LIT-7171230

Page 2

the three #8 sheet metal

screws provided, making

sure that the side of the

bracket marked “TOP” is

upward.

2. Push the mounting release

knob in and turn it to the

“MOUNT AND UNLOCK”

position.

3. Align the pins on the bottom

front of the mounting

bracket with the slots in the

body of the P-5219. While

holding the P-5219 firmly

against the bracket, push

the mounting release knob

in and turn it to the

“OPERATING” position.

4. With the “H” and “L”

sensing lines disconnected,

furnish a 20 PSIG

(140 kPa) supply to the unit

and turn the zero

adjustment screw (using a

3/32 in. Allen head wrench)

to provide a 3 PSIG

(21 kPa) output signal.

No further field calibration

is required.

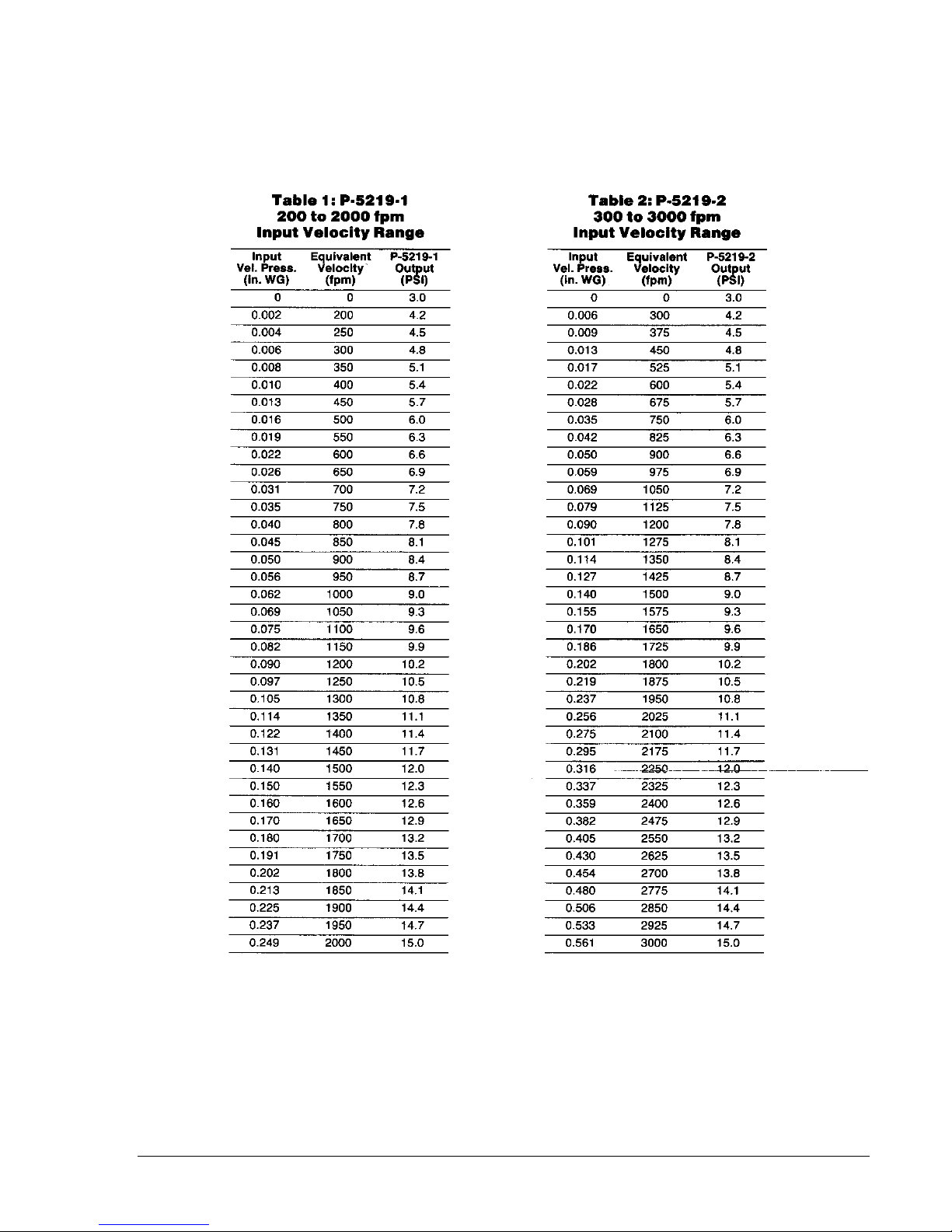

Application and Drawing

Identification

Repair Information

Field repairs must not be made.

For a replacement P-5219,

contact the nearest Johnson

Controls branch office.

2 P-5219 Product Bulletin

Page 3

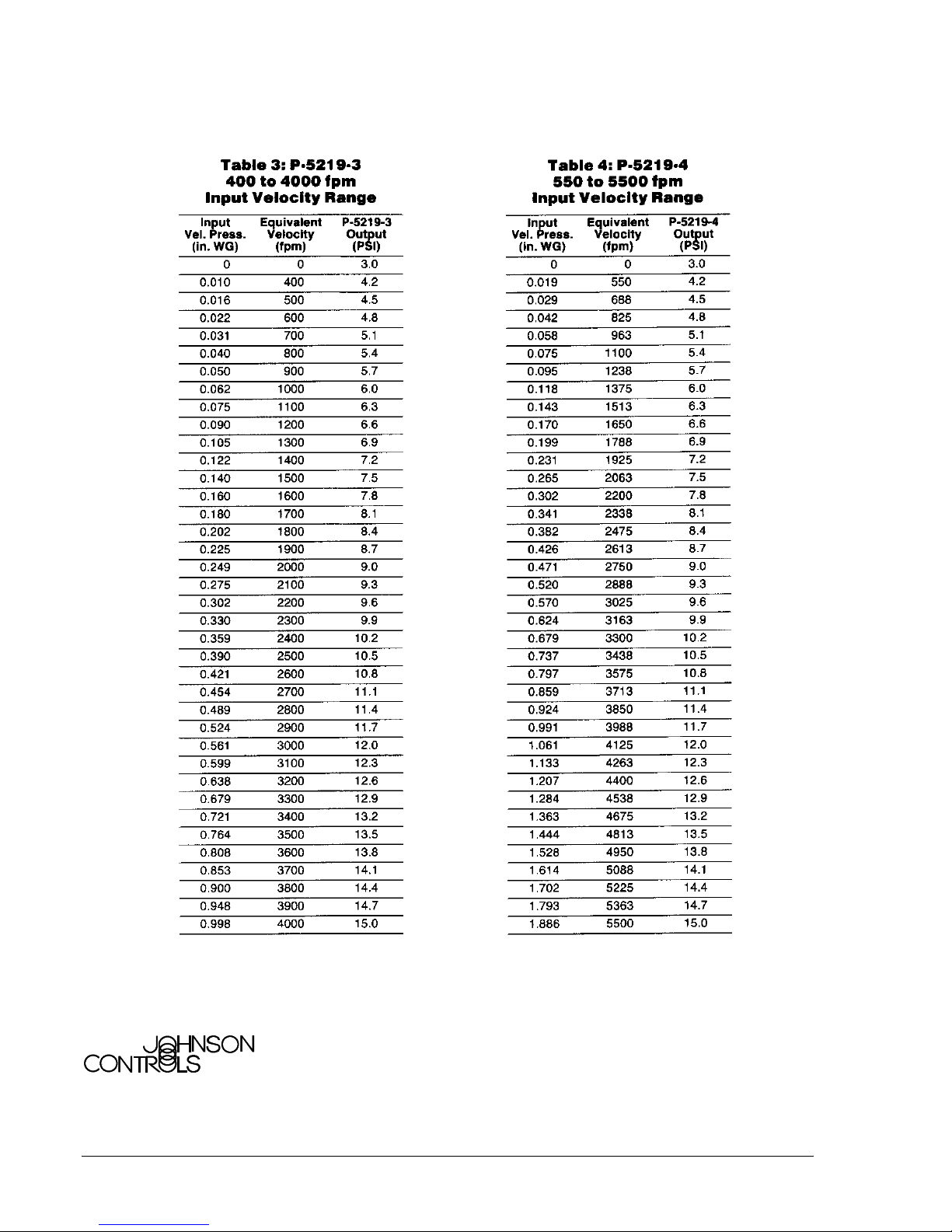

-- Velocity Data Continued on Next Page --

P-5219 Product Bulletin 3

Page 4

Controls Group

507 E. Michigan Street

P.O. Box 423 Printed in U.S.A.

Milwaukee, WI 53202

4 P-5219 Product Bulletin

Loading...

Loading...