Page 1

Handheld VAV Balancing Tool

Installation Instructions

NS-ATV7003-0

Part No. 24-10211-2, Rev. C

Release 4.1

Issued October 6, 2008

Supersedes March 10, 2008

Applications

The Variable Air Volume (VAV) Balancing Tool allows

you to easily adjust and set the required parameters for

VAV applications that reside on the Metasys® system

VAV Modular Assembly (VMA) 1600 Series or Field

Equipment Controller (FEC) Series controllers.

The VAV balancing parameters display on the tool’s

Liquid Crystal Display (LCD). You use the dial and two

buttons on the tool to navigate through simple, intuitive

menus to balance the VAV box. The menus you see

are customized to the type of application residing in the

controller. The balancing operation also features an

adjustable time-out parameter that re tu rn s the to ol an d

controller to normal operation if you leave the controller

in balancing mode.

The handheld VAV Balancing Tool is lightweight and

portable. It can plug into any model of network sensor

to access the VAV controller.

The VAV Balancing Tool is compatible with the

following Metasys system BACnet® protocol devices:

• FEC loaded with a VAV application

• VMA1600 loaded with a VAV application

North American Emissions Compliance

United States

This equipment has been tested and found to comply

with the limits for a Class A digital device pursuant to

Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful

interference when this equipment is operated in a

commercial environment. This equipment generates,

uses, and can radiate radio frequency energy, and if

not installed and used in accordance with the

instruction manual, may cause harmful interference to

radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference,

in which case the user will be required to correct the

interference at his/her own expense.

Canada

This Class (A) digital apparatus meets all the

requirements of the Canadian Interference-Causing

Equipment Regulations.

Cet appareil numérique de la Classe (A) respecte

toutes les exigences du Règlement sur le matériel

brouilleur du Canada.

• Network Sensors connected to an FEC or

VMA1600 loaded with a VAV application

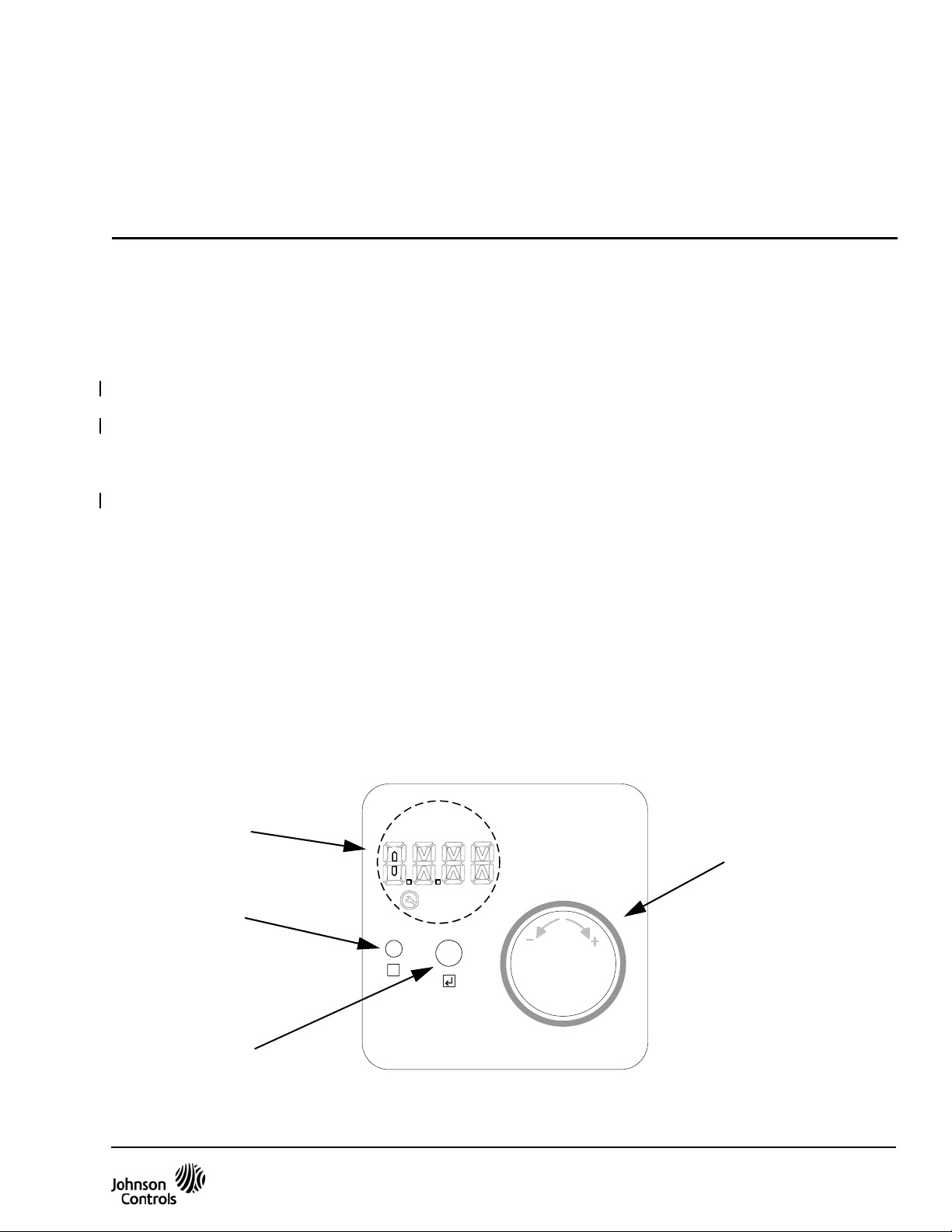

LCD with Backlight

Cancel Button

x

°F/°C

Enter Button

Figure 1: Front of the VAV Balancing Tool, 80 x 80 mm (3.2 x 3.2 in.)

Adjustment Dial

`

Handheld VAV Balancing Tool Installation Instructions 1

Page 2

Installation

Parts Included

• one handheld VAV Balancing Tool

• one 1.5 m (5 ft) retractable cable

• one laminated user guide (Metasys Balancing

Sensor User Guide [Part No. 24-10159-5])

• one padded carrying case

• one set of installation instructions

Special Tools Needed

The VAV Balancing Tool allows you to change the VAV

box parameters. To measure actual airflow and other

parameters, you need standard VAV measuring

equipment.

Do not plug the SA port cable into a standard phone

jack.

Note: Connect through the MS-ZFRCBL-0 when

connecting to a wireless-enabled VMA1600.

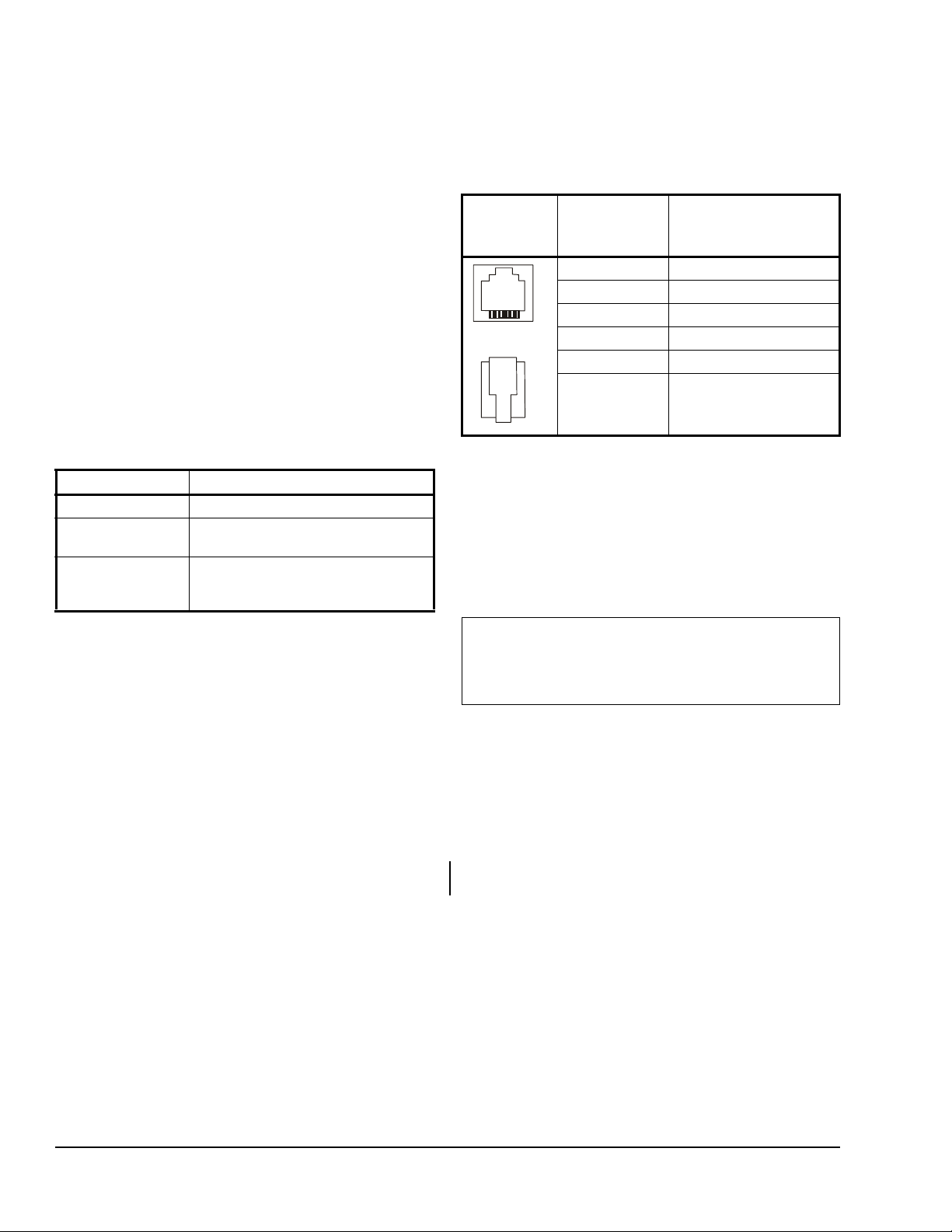

Table 2: SA Bus Port Pin Designations

Diagram Pin Number

Signal Name

(Both Ends

of Cable)

1 SA +

2 SA -

3 15 VDC Common

. . . .

6 16 1

4 +15 VDC

5 No Connection

6 No Connection

Accessories

Table 1: Products and Accessories (Order

Separately)

Code Number Description

NS-A TV7003-0 Handheld VAV Balancing Tool

MS-BTCVT-700 Cable replacement set; includes one

1.5 m (5 ft) retractable cable

MS-ZFRCBL-0 Wire harness with connectors for use

with some wireless enabled field

controllers.

Wiring

Wiring Consideration and Guidelines

Observe the following guidelines when wiring the

VAV Balancing Tool:

• Do not allow the VAV Balancing Tool to hang from

the cable connection.

• Provide some slack in the cable between the VAV

Balancing Tool and the controller or network

sensor.

Power Supply, Network, and Communication Connections

SA Bus Port

The Sensor-Actuator Bus (SA Bus) port on the

V AV Balancing Tool is a 6-pin, RS-485 port designed to

connect the VAV Balancing Tool to an accessible SA

Bus port on a Master-Slave/Token-Passing (MS/TP)

device. The MS/TP device is typically the network

sensor on the VAV controller SA Bus, using the cable

assembly provided. The SA Bus port is a straight

through, one-to-one connection (not a crossover). The

maximum allowable cable length is 100 ft.

6-pin

Connecting the VAV Balancing Tool

Observe the following guidelines and procedures when

connecting the VAV Balancing Tool to your system.

1. Connect one male end of the supplied cable to the

VAV Balancing Tool.

2. Connect the other end of the cable to the controller

or network sensor.

IMPORTANT: The VAV Balancing Tool has a

dedicated MS/TP bus address of 198. Only one VA V

Balancing Tool can be connected to the MS/TP bus

per physical trunk on the system.

Setup and Adjustments

The VAV Balancing Tool device itself requires no

commissioning.

Operation

Using the VAV Balancing Tool

Once the VAV Balancing Tool is physically connected

to the SA bus of the VMA or FEC controller, you can

use the tool to balance the VAV box. Refer to the VAV

Balancing Tool Technical Bulletin (LIT-12011087).

Repair Information

Do not open the VAV Balancing Tool housing. The VAV

Balancing Tool has no user-serviceable parts inside.

The VAV Balancing Tool requires no periodic field

maintenance.

Handheld VAV Balancing Tool Installation Instructions2

Page 3

Technical Specifications

Handheld VAV Balancing Tool

Product Code NS-ATV7003-0

Power Requirements 15 VDC Nominal, provided through the SA Bus Port; Consumption is 1.35 watts maximum

Terminations 6-Position Modular Jack

Transmission Speed Serial Communication (SA Bus)

9600, 19.2k, 38.4k, or 76.8k bps

Sensor Addressing Fixed Address of 198

Cable 1.5 m (5 ft) retractable cable

Ambient

Conditions

Compliance United States UL Listed, File E107241, CCN PAZX7, Under UL 916, Energy Management

Dimensions 80 x 80 x 250 mm (3.2 x 3.2 x1.0 in.)

Shipping Weight 0.165 kg (0.365 lb)

Operating 0 to 50°C (32 to 122°F); 5 to 95% RH, Noncondensing; 30°C (86°F) Maximum Dew Point

Storage -40 to 85°C (-40 to 185°F); 5 to 95% RH, Noncondensing

FCC Compliant to CFR 47, Part 15, Subpart B, Class A

Canada UL Listed, File E107241, CCN PAZX7, Under CSA C22.2 No. 205, Signal Equipment

Industry Canada, ICES-003

Europe CE Mark, EMC Directive 89/336/EEC;

EN61000-6-3 (2001) Generic Emission Standard for Residential and Light Industry;

EN61000-6-2 (2001) Generic Immunity Standard for Heavy Industrial Environment

Australia and

New Zealand

C-Tick Mark, Australia/NZ Emissions Compliant

The performance specifications are nominal and conform to acceptable industry standard. For application at conditions beyond these

specifications, consult the local Johnson Controls® office. Johnson Controls, Inc. shall not be liable for damages resulting from

misapplication or misuse of its products.

Building Efficiency

507 E. Michigan Street, Milwaukee, WI 53202

Metasys® and Johnson Controls® are registered trademarks of Johnson Controls, Inc.

All other marks herein are the marks of their respective owners. © 2008 Johnson Controls, Inc.

Handheld VAV Balancing Tool Installation Instructions 3

Published in U.S.A. www.johnsoncontrols.com

Loading...

Loading...