Johnson Controls NH-07 Series, NH-10 Series, NH-15 Series, NH-20 Series, NJ-10 Series Installation Manual

...Page 1

R-410A

MODELS: NH-07 Thru -20, 2-Pipe

NJ-10 Thru -20, 4-Pipe

7.5 - 20 Ton, 60 Hertz

TABLE OF CONTENTS

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Renewal Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Agency Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Unit Application Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Physical Data Indoor Unit . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Air Discharge Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Unit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Rigging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

LIST OF TABLES

1 Unit Application Data Indoor . . . . . . . . . . . . . . . . . . . . . . . 4

2 Physical Data Indoor Unit . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Minimum Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4 Corner Weights & Center of Gravity NH/NJ Unit . . . . . . . 9

5 Accessory Operating Weight Distribution (Lbs) . . . . . . . 10

6 Electrical Data - Electric Heat . . . . . . . . . . . . . . . . . . . . . 16

7 Altitude/Temperature Correction Factors . . . . . . . . . . . . 19

8 Example Supply Air Blower Performance . . . . . . . . . . . . 20

9 RPM Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

10 NH-07 Upflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

11 NH-07 Horizontal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Duct Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Refrigerant Mains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Expansion Valve Bulb Installation. . . . . . . . . . . . . . . . . . . 13

Air System Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Electrical Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Airflow Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Airflow Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Twin Belt Drive Adjustment. . . . . . . . . . . . . . . . . . . . . . . . 29

Sequence of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Typical Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Air Handling Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

12 NH/NJ-10 Upflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

13 NH/NJ-10 Horizontal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

14 NH/NJ-15 Upflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

15 NH/NJ-15 Horizontal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

16 NH/NJ-20 Upflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

17 NH/NJ-20 Horizontal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

18 RPM Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

19 Additional Static Resistance . . . . . . . . . . . . . . . . . . . . . . 26

20 Blower Motor And Drive Data . . . . . . . . . . . . . . . . . . . . . 27

21 Unit Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

LIST OF FIGURES

1 Vertical Airflow Arrangements . . . . . . . . . . . . . . . . . . . . . 6

2 Horizontal Airflow Arrangements . . . . . . . . . . . . . . . . . . . 6

3 Typical Cabinet Clamp Assembly . . . . . . . . . . . . . . . . . . 6

4 Typical Suspension of AHU’s From Ceiling . . . . . . . . . . . 8

5 Suggested Method For Connecting Ductwork . . . . . . . . 10

6 Recommended Drain Piping . . . . . . . . . . . . . . . . . . . . . 11

7 Typical Field Wiring Diagram - NH-07 Unit . . . . . . . . . . 14

8 Typical Field Wiring Diagram - NH/NJ-10 Thru -20 Unit 15

9 NH/NJ-10 Thru -20 Liquid Line Solenoid Wiring . . . . . . 15

10 Altitude/Temperature Correction Factors . . . . . . . . . . . . 19

11 Hole Location For Pressure Drop Reading . . . . . . . . . . 27

12 Pressure Drop Across A Dry Indoor Coil vs. Supply

Air CFM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

13 Belt Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

14 Double Groove Pulley . . . . . . . . . . . . . . . . . . . . . . . . . . 29

15 Unit Dimensions NH-07 Thru -10 & NJ-10 . . . . . . . . . . 31

16 Unit Dimensions NH/NJ-15 . . . . . . . . . . . . . . . . . . . . . . 32

17 Unit Dimensions NH/NJ-20 . . . . . . . . . . . . . . . . . . . . . . 33

18 Typical Horizontal Configuration . . . . . . . . . . . . . . . . . . 34

520413-BIM-A-0209

Page 2

520413-BIM-A-0209

General

These completely assembled 7-1/2 thru 20 ton evaporator

blower units include a well insulated cabinet, a DX cooling coil

with copper tubes and aluminum fins, expansion valve(s), a distributor(s), throwaway filters, centrifugal blower(s), a blower

motor, and a small holding charge of dry nitrogen. Blower

motors and adjustable drives are factory-installed on all units.

Supplemental resistance heaters, a supply air plenum, a return

air grill, hot water coils, non-freeze steam coils, and a base are

available as accessories for field installation.

The units are shipped in the vertical position ready for field

installation.

Safety Considerations

Installer should pay particular attention to the words: NOTE,

CAUTION, and WARNING. Notes

make the installation easier. Cautions are given to prevent

equipment damage. Warnings are given to alert installer that

personal injury and/or equipment damage may result if installation procedure is not handled properly.

are intended to clarify or

Additional information on the design, installation, operation and

service of this equipment is available in the Technical Guide -

505430.

Renewal Parts

Contact your local UP Parts Distribution Center for authorized

replacement parts.

Agency Approvals

Design certified by CSA as follows:

1. For use as a (cooling coil, heat pump coil/air handler) only

with or without supplemental electric heat.

2. For indoor installation only.

Inspection

As soon as a unit is received, it should be inspected for possible

damage during transit. If damage is evident, the extent of the

damage should be noted on the carrier’s freight bill. A separate

request for inspection by the carrier’s agent should be made in

writing.

Improper installation may create a condition where the

operation of the product could cause personal injury or

property damage.

Improper installation, adjustment, alteration, service or

maintenance can cause injury or property damage.

Refer to this manual for assistance or for additional

information, consult a qualified contractor, installer or

service agency.

This system uses R-410A Refrigerant which operates at

higher pressures than R-22. No other refrigerant may be

used in this system. Gage sets, hoses, refrigerant

containers and recovery systems must be designed to

handle R-410A. If you are unsure, consult the

equipment manufacturer. Failure to use R-410A

compatible servicing equipment may result in property

damage or injury.

Reference

This instruction covers the installation and operation of evaporator blower units. For information on the operation of matching

condensing units, refer to Installation Manual - 430646 for cool

ing units and Installation Manual - 430647 for heat pumps.

This product must be installed in strict compliance with

the enclosed installation instructions and any applicable

local, state and national codes including, but not limited

to, building, electrical, and mechanical codes.

Wear safety glasses and gloves when handling

refrigerants. Failure to follow this warning can cause

serious personal injury.

-

2 Johnson Controls Unitary Products

Page 3

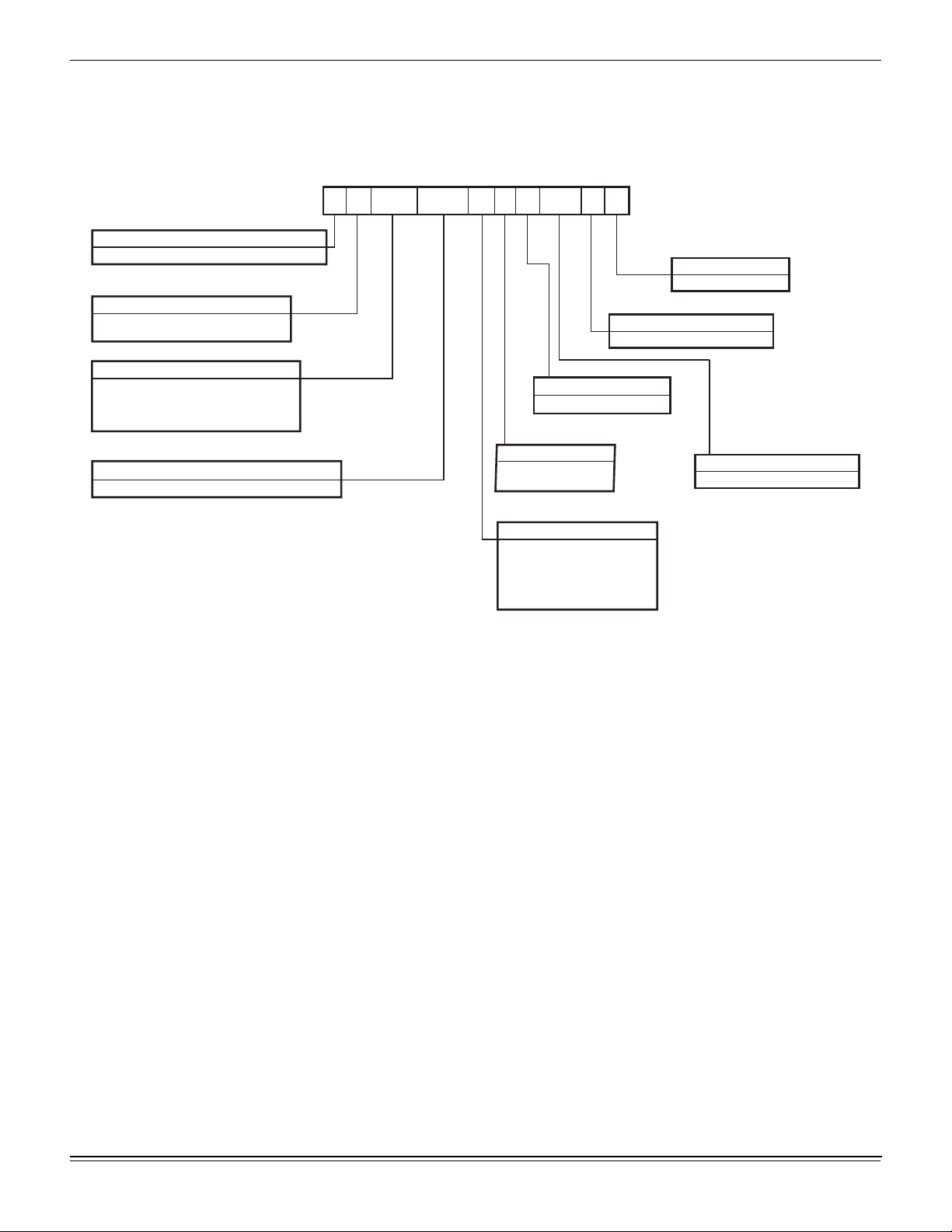

Nomenclature

Configured Split Air Handler Model Number Nomenclature

520413-BIM-A-0209

Product Category

N = Split System, Air Handler, AC & HP, R-410A

Product Identifier

H = Standard Efficiency, 2-Pipe, R-410A

J = Standard Efficiency, 4-Pipe, R-410A

Nominal Cooling Capacity - MBH

-07 = 7.5 Ton

-10 = 10 Ton

-15 = 15 Ton

-20 = 20 Ton

Heat Type & Nominal Heat Capacity

C00 = Cooling Only

N

H

-20

C00 B

S

A

A = None

Voltage

S = 208/230/460-3-60

X = 575-3-60

B = 1.5 HP Motor

C = 2.0 HP Motor

D = 3 HP Motor

E = 5 HP Motor

F = 7.5 HP Motor

2

AA

Installation Options

Airflow

A

Product Style

A = Style A

Product Generation

1 = First Generation

Product Options

AA = None

Johnson Controls Unitary Products 3

Page 4

520413-BIM-A-0209

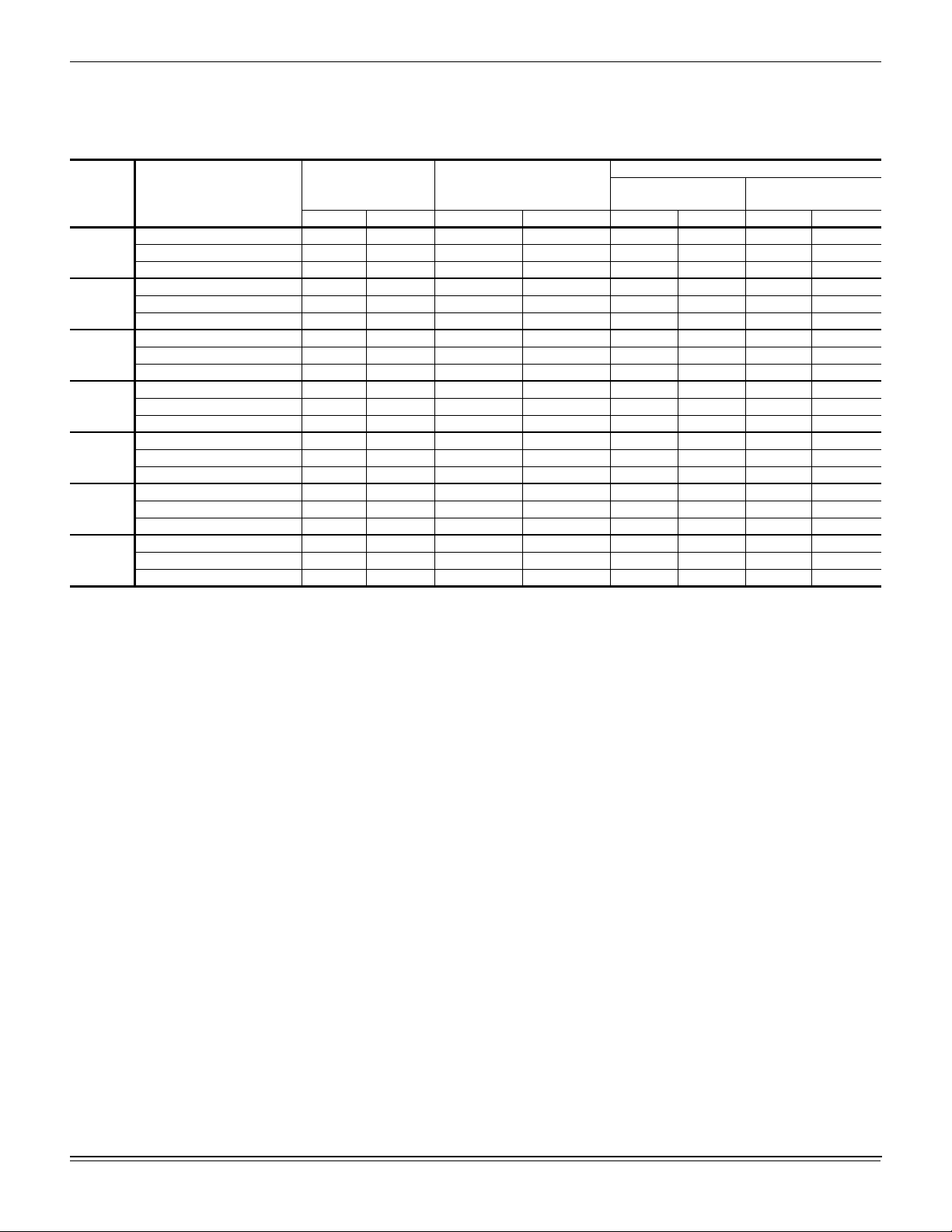

Unit Application Data

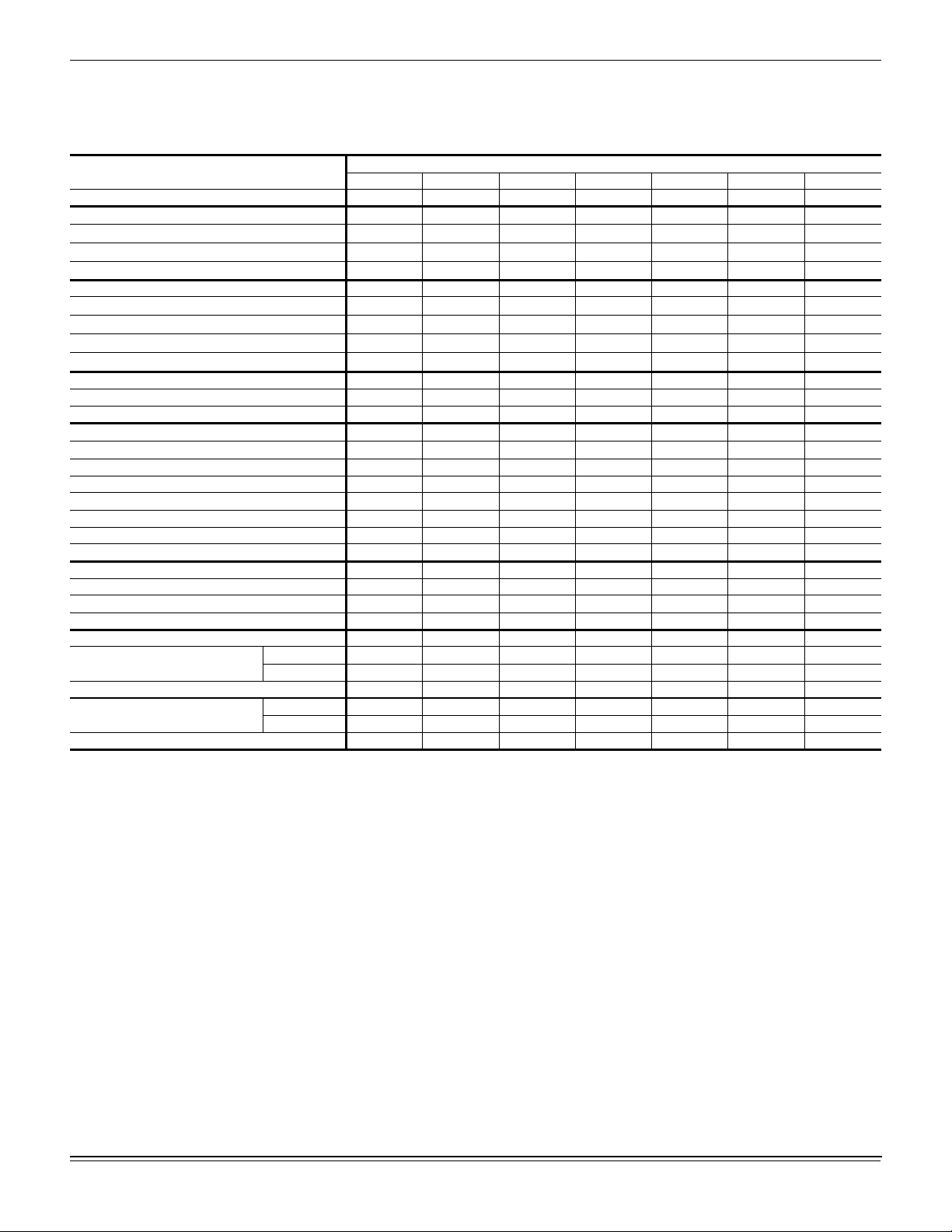

Table 1: Unit Application Data Indoor

Entering Air Temperature Degrees °F

Model Power Supply Voltage

208/230-3-60 187 253 2,250 3,750 65/57 90/77 40 80

NH-07

NH-10

NJ-10

NH-15

NJ-15

NH-20

NJ-20

1. Heating Min/Max temperatures apply to steam and hot water coils. NOTE: Do not apply steam to hot water coils.

460-3-60 414 506 2,250 3,750 65/57 90/77 40 80

575-3-60 540 630 2,250 3,750 65/57 90/77 40 80

208/230-3-60 187 253 3,000 5,000 65/57 90/77 40 80

460-3-60 414 506 3,000 5,000 65/57 90/77 40 80

575-3-60 540 630 3,000 5,000 65/57 90/77 40 80

208/230-3-60 187 253 3,000 5,000 65/57 90/77 40 80

460-3-60 414 506 3,000 5,000 65/57 90/77 40 80

575-3-60 540 630 3,000 5,000 65/57 90/77 40 80

208/230-3-60 187 253 4,500 7,500 65/57 90/77 40 80

460-3-60 414 506 4,500 7,500 65/57 90/77 40 80

575-3-60 540 630 4,500 7,500 65/57 90/77 40 80

208/230-3-60 187 253 4,500 7,500 65/57 90/77 40 80

460-3-60 414 506 4,500 7,500 65/57 90/77 40 80

575-3-60 540 630 4,500 7,500 65/57 90/77 40 80

208/230-3-60 187 253 6,000 10,000 65/57 90/77 40 80

460-3-60 414 506 6,000 10,000 65/57 90/77 40 80

575-3-60 540 630 6,000 10,000 65/57 90/77 40 80

208/230-3-60 187 253 6,000 10,000 65/57 90/77 40 80

460-3-60 414 506 6,000 10,000 65/57 90/77 40 80

575-3-60 540 630 6,000 10,000 65/57 90/77 40 80

Voltage Variation Supply Air Range CFM

Min. Max. Min. Max. Min. Max. Min. Max.

Cooling

DB/WB

Heating DB

1

4 Johnson Controls Unitary Products

Page 5

520413-BIM-A-0209

Physical Data Indoor Unit

Table 2: Physical Data Indoor Unit

Component

Nominal Tonnage 7 1/2 10 10 15 15 20 20

DIMENSIONS (inches)

Length

Width

Height

WEIGHTS (lb)

Unit Shipping

Unit Operating With

Standard Motor and Drive

High Static Motor and Drive

INDOOR BLOWER (Forward Curve)

Diameter x Width 12 x 12 15 x 15 15 x 15 18 x 18 18 x 18 15 x 15 15 x 15

Quantity 1111122

NH-07 NH-10 NJ-10 NH-15 NJ-15 NH-20 NJ-20

56.0 56.0 56.0 74.5 74.5 98.5 98.5

30.0 30.0 30.0 33.0 33.0 30.0 30.0

65.0 65.0 65.0 75.0 75.0 65.0 65.0

405 512 512 681 681 874 874

381 468 468 632 632 816 816

385 492 492 661 661 854 854

INDOOR COIL

Face area (Sq. Ft.) 10.6 10.6 10.6 18.3 18.3 20.0 20.0

Rows 3443443

Fins per inch 15 15 15 15 15 15 15

Tube diameter 3/8 3/8 3/8 3/8 3/8 3/8 3/8

Circuitry Type Interfaced Interfaced Interfaced Interfaced Interfaced Interfaced Interfaced

Refrigerant Control TXV TXV TXV TXV TXV TXV TXV

Operating Charge (lb) 4 6 6 10 10 10 10

SYSTEM DATA

No. Refrigeration Circuits 1121212

Suction Line OD (in.) 1 1/8 1 3/8 1 1/8 1 5/8 1 1/8 1 5/8 1 3/8

Liquid Line OD (in.) 5/8 7/8 5/8 7/8 5/8 7/8 7/8

FILTERS

Size and Quantity Per Model (In.) 16 x 25 x 2 4 4 4 --- --- 8 8

20 x 24 x 2 --- --- --- 6 6 --- --Face area (Sq. Ft.) 11.1 11.1 11.1 20.0 20.0 22.2 22.2

Size and Quantity Per Model (In.) 16 x 25 x 4 4 4 4 --- --- 8 8

18 x 24 x 4 --- --- --- 6 6 --- ---

Face area (Sq. Ft.) 11.1 11.1 11.1 18.0 18.0 22.2 22.2

Models

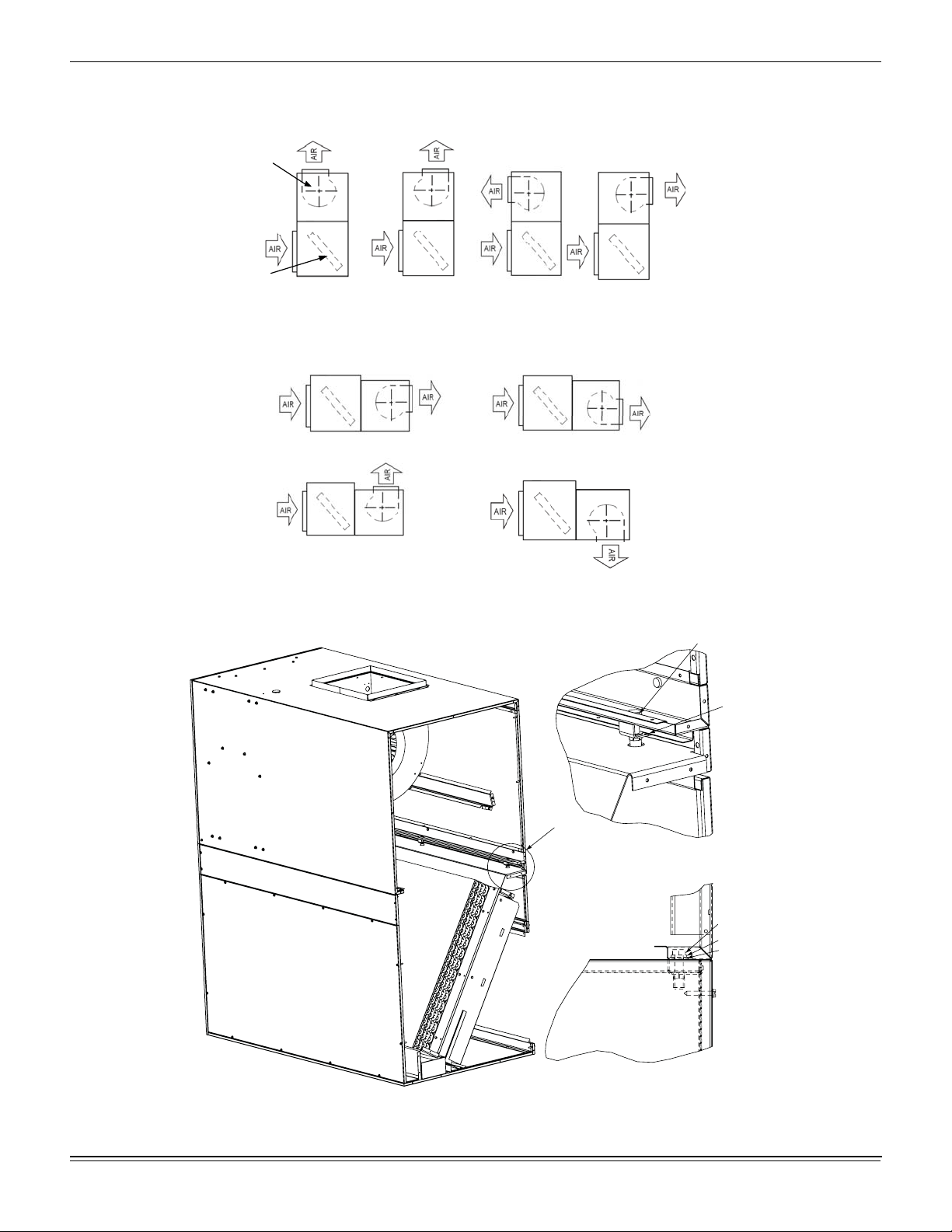

Air Discharge Conversion

6. Rotate the blower section and mate it to the hole left when

the panel was removed in Step 5.

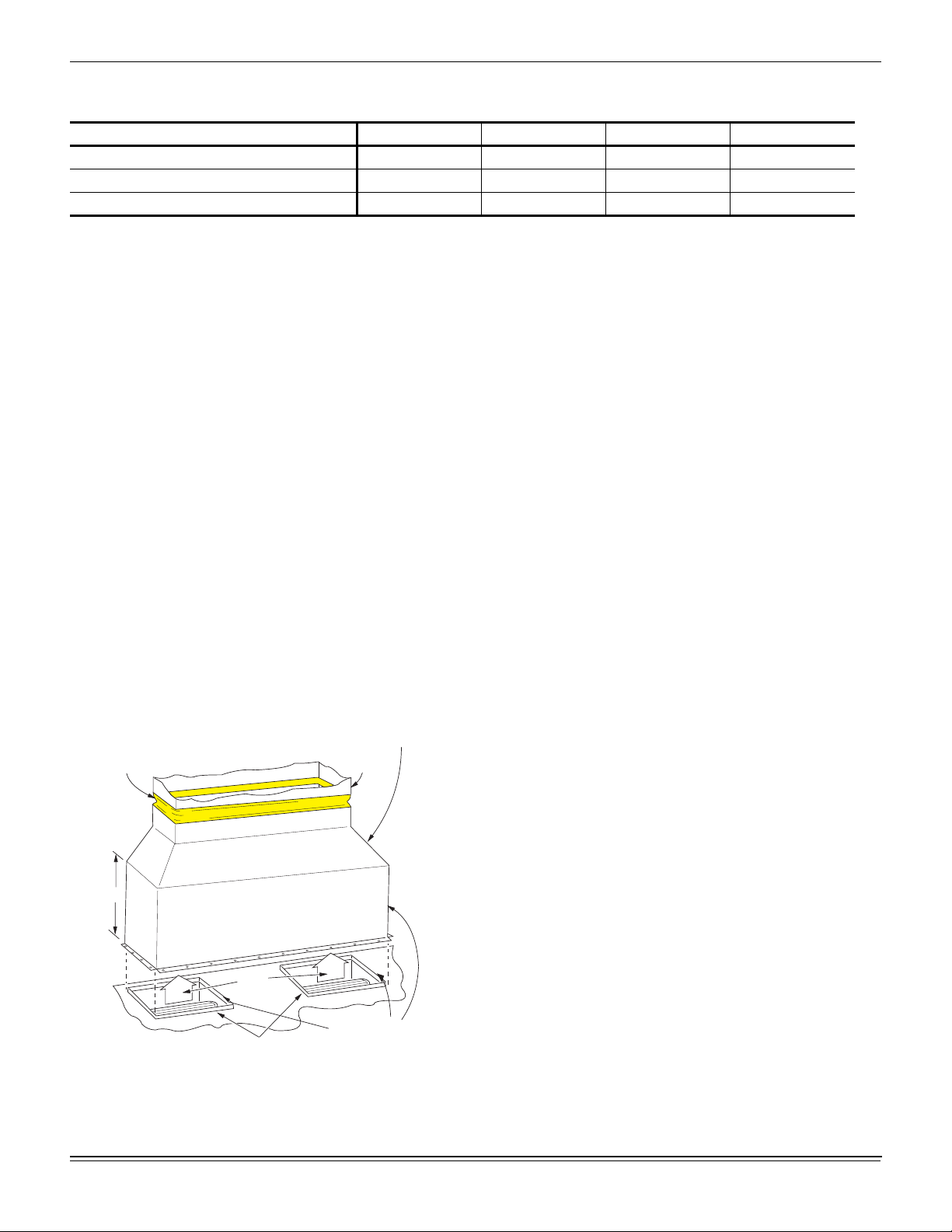

These units are shipped for Vertical Airflow operation as seen in

Figure 1 Positions 1 thru 4, but may be converted for Horizontal

Airflow operation illustrated in Figure 2 Positions 1 thru 4.

Conversion Example:

7. Bolt and clamp the two sections together.

8. Place the panel remove

1. d in Step 5 on top of the evaporator section and screw

together.

Convert Vertical Airflow Position 1 to Horizontal Airflow Position

1 as follows:

NOTE: 1 inch blower duct flange shipped with air handler.

1. Remove the front blower panel from the blower section and

set aside. This allows access to the clamps that hold the

blower section to the evaporator section.

2. Remove the bolts and clamp angles that hold the coil

section and blower section together.

3. Place the panel removed in Step 1 on top of the blower

section and screw together.

4. Set the blower section aside.

5. Remove the evaporator section rear panel and set aside.

Johnson Controls Unitary Products 5

Page 6

520413-BIM-A-0209

BLOWER

EVAPORATOR

COIL

POSITION

1

Figure 1: Vertical Airflow Arrangements

POSITION

2

POSITION

3

POSITION

4

POSITION

POSITION

Figure 2: Horizontal Airflow Arrangements

1

2

3

POSITION

4

3/8” x 1 1/4” Bolt

Clamp

See Detail A

Detail A

POSITION

Bolt

Lock

Flat

Washer

Detail B

Cabinet Clamp Assembly

Typical Cabinet Clamp Assembly

Figure 3: Typical Cabinet Clamp Assembly

6 Johnson Controls Unitary Products

Page 7

Unit Installation

Location

These evaporator blowers are not designed for outdoor

installation. They must be located inside a building structure,

either inside or outside the conditioned space where they are

protected from rain and other moisture.

The unit should be located as close to the condensing unit as

practical and positioned to minimize bends in the refrigerant

piping.

Units being installed vertically or horizontally can be set directly

on a floor or platform, or supported by metal or wooden beams.

Rigging

Care must be taken when moving the unit. Do not remove any

packaging until the unit is near the place of installation.

SPREADER BARS SHOULD BE USED BETWEEN THE

SLINGS TO PREVENT CRUSHING THE UNIT FRAME OR

PANELS. When preparing to move the unit, always determine

the center of gravity of the unit in order to equally distribute the

weight. Rig the unit by attaching chain or cable slings around

the bottom skid. A lift truck may be used to raise a unit to a

suspended location. Refer to Table 4 for unit weights.

520413-BIM-A-0209

Clearances

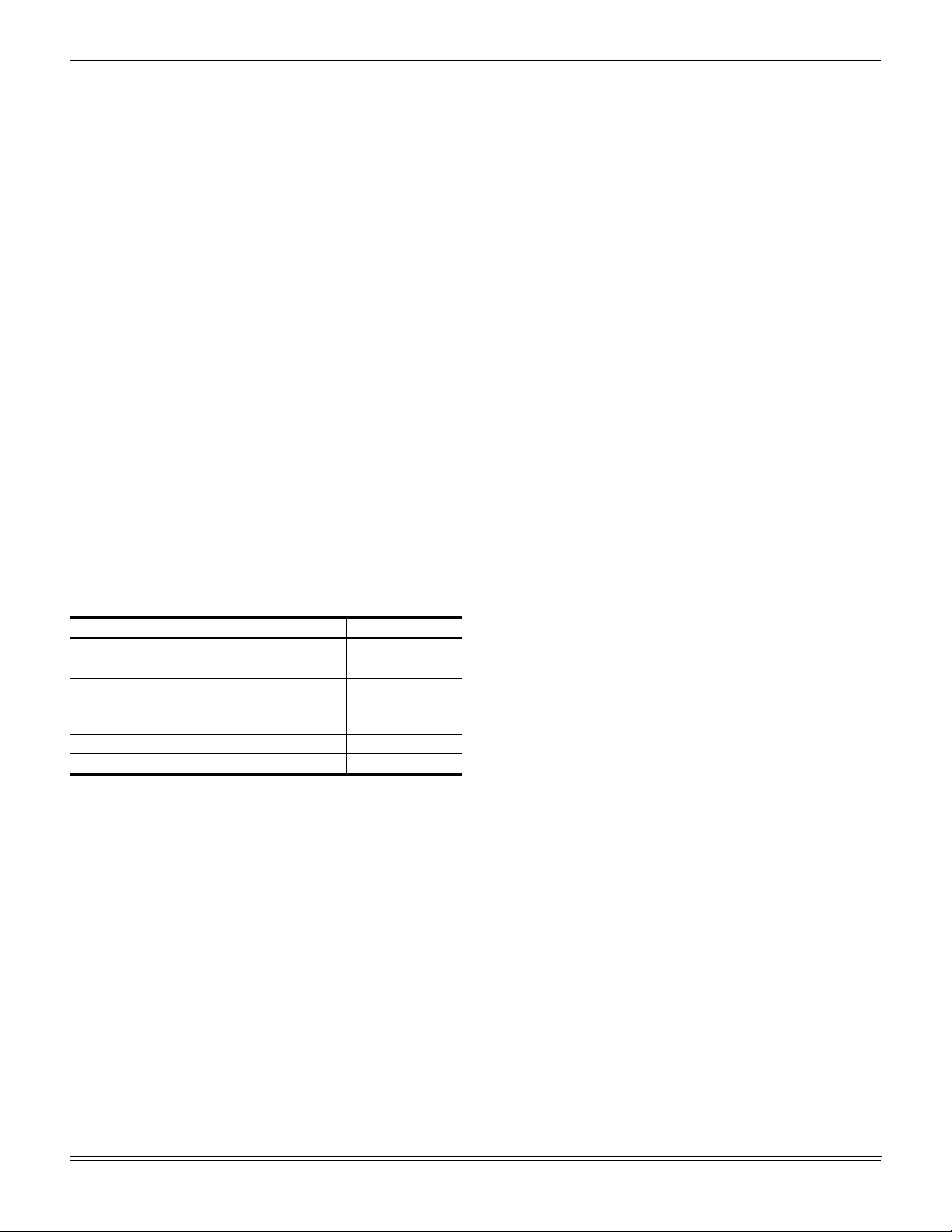

Table 3: Minimum Clearances

Minimum Clearances

Top with Supply Air Opening

Front with Return Air Opening 24”

Right Side with Access for Piping, Power &

Control Wiring Connections

Left Side 24”

3

Rear

4

Bottom

1. This dimension will vary if an electric heater, a supply air plenum or a

base is used.

2. This dimension is required for normal installation and service.

3. Although no clearance is required for service and operation, some

clearance may be required for routing the power and control wiring.

4. Allow enough clearance to trap the condensate drain line.

NOTE: If the coil has t o be removed, the blowe r section can be unbolted

and set aside and the coil can be lifted out the top of the

evaporator section.

A 24-inch clearance is required on the end with the piping

connections and the supply air blower motor to properly service

and maintain the unit.

Some clearance will also be required for the duct and power

wire connections.

1

2

24”

24”

N/A

N/A

Johnson Controls Unitary Products 7

Page 8

520413-BIM-A-0209

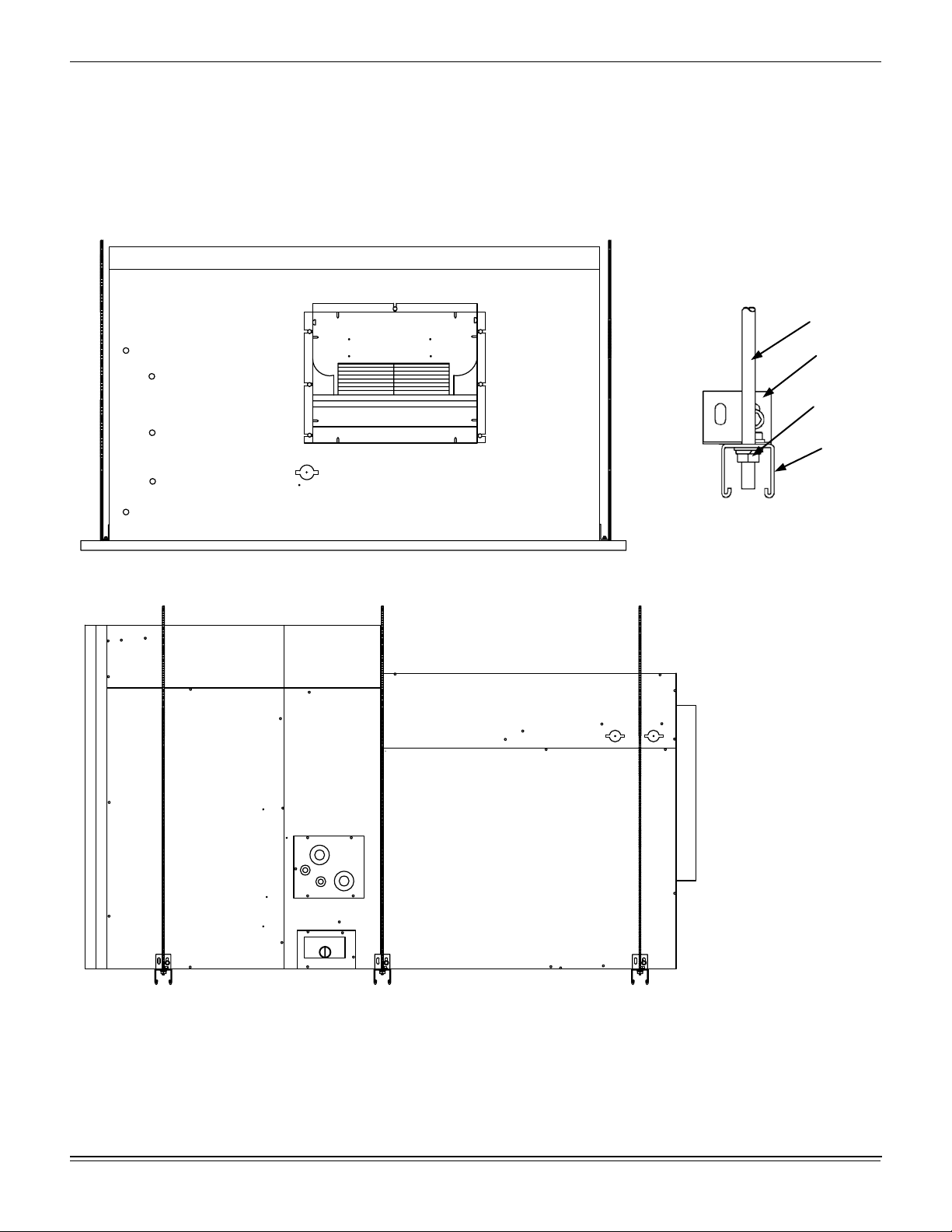

Mounting

The split air handling units can be applied in various horizontal

positions. Figure 4 shows recommended suspension rigging

using properly sized all-thread and metal c-channel. All

END VIEW

components to suspend an AHU must be field supplied. Please

refer to the units total weight, center of gravity and corner

weights (Horizontal position) shown in the appropriate table for

proper support sizing.

MOUNTING DETAIL

All Thread

Steel Rod

Mounting

Bracket

Flat Washer /

Lock Washer

and Nut

Steel Cchannel

SIDE VIEW

Figure 4: Typical Suspension of AHU’s From Ceiling

8 Johnson Controls Unitary Products

Page 9

Table 4: Corner Weights & Center of Gravity NH/NJ Unit

Model Options

Vertical Airflow

NH-07

NH/NJ-10

NH/NJ-15

NH/NJ-20

Std. Mtr. and Drv. 357 381 30 30 102 102 88 88 68 68 68 59 59 59

High Static Mtr. and Drv. 357 385 30 30 103 103 89 89 69 69 69 60 60 60

Std. Mtr. and Drv. 422 468 30 30 125 125 109 109 84 84 84 72 72 72

High Static Mtr. and Drv. 422 492 31 29 123 132 123 115 81 85 89 83 79 76

Std. Mtr. and Drv. 560 632 36 36 139 167 178 148 90 101 115 122 108 96

High Static Mtr. and Drv. 560 661 36 35.5 143 172 189 157 93 104 118 130 114 102

Std. Mtr. and Drv. 715 816 32 48 186 212 223 195 121 132 145 152 139 127

High Static Mtr. and Drv. 715 854 32 47 190 217 238 208 124 135 148 162 148 136

Horizontal Airflow

NH-07

NH/NJ-10

NH/NJ-15

NH/NJ-20

Std. Mtr. and Drv. 357 381 15 30 102 102 88 88 68 68 68 59 59 59

High Static Mtr. and Drv. 357 385 15 30 103 103 89 89 69 69 69 60 60 60

Std. Mtr. and Drv. 422 468 15 30 125 125 109 109 84 84 84 72 72 72

High Static Mtr. and Drv. 422 492 15.5 29 123 132 123 115 81 85 89 83 79 76

Std. Mtr. and Drv. 560 632 18 36 139 167 178 148 90 101 115 122 108 96

High Static Mtr. and Drv. 560 661 18 35.5 143 172 189 157 93 104 118 130 114 102

Std. Mtr. and Drv. 715 816 16 48 186 212 223 195 121 132 145 152 139 127

High Static Mtr. and Drv. 715 854 16 47 190 217 238 208 124 135 148 162 148 136

Weight (lbs.) Center of Gravity (in.) 4 Point Load Location (lbs.) 6 Point Load Location (lbs.)

Shipping Operating X Y A B C D A B C D E F

520413-BIM-A-0209

FRONT

WIDTH

LEFT

A

A

DIM Y

F

D

DIM X

VERTICAL POSITION

B

E

LENGTH

RIGHT

CG

LEFT

B

C

WIDTH

REAR

FRONT

D

C

DIM Y

A

A

F

D

DIM X

HORIZONTAL POSITION

B

E

LENGTH

RIGHT

CG

B

C

REAR

D

C

Johnson Controls Unitary Products 9

Page 10

520413-BIM-A-0209

Table 5: Accessory Operating Weight Distribution (Lbs)

ACCESSORY

2

BASE

HOT WATER COIL

STEAM COIL

1.These weights should be added to each point load in table 4.

2.This accessory can only be applied on units installed in the vertical position.

NH-07 NH/NJ-10 NH/NJ-15 NH/NJ-20

1

25 25 30 45

35 35 45 35

30 30 35 50

Duct Connections

Ductwork should always be suspended with hangers or

supported by legs. It should never be fastened directly to the

building structure.

Allow clearance around ducts for safety in the handling of

heated air and for insulation when required.

Insulation

Ductwork insulation should meet the following criteria:

• Be used when ducts pass through an unconditioned

space in the cooling season or through an unheated

space during the heating season.

• Include a vapor barrier around the outside to prevent the

absorption of moisture.

• Be no less than 2 inches thick with a weatherproof coating

when applied to ducts exposed to outdoor conditions.

Supply Air Ducts

See Figure 5 for suggested method of connecting supply air

ductwork. Non-flammable material collars should be used to

minimize the transmission of noise and/or vibration.

DUCT

NON-FLAMMABLE

COLLAR

24"

AIR

OUTLET

BLOWER

GASKETS

(BY INSTALLER)

TRANSITION

DUCT

FLANGED DUCT

CONNECTION

(Factory Furnished,

Field Installed )

Figure 5: Suggested Method For Co nn e cti ng Ductw ork

10 Johnson Controls Unitary Products

Page 11

520413-BIM-A-0209

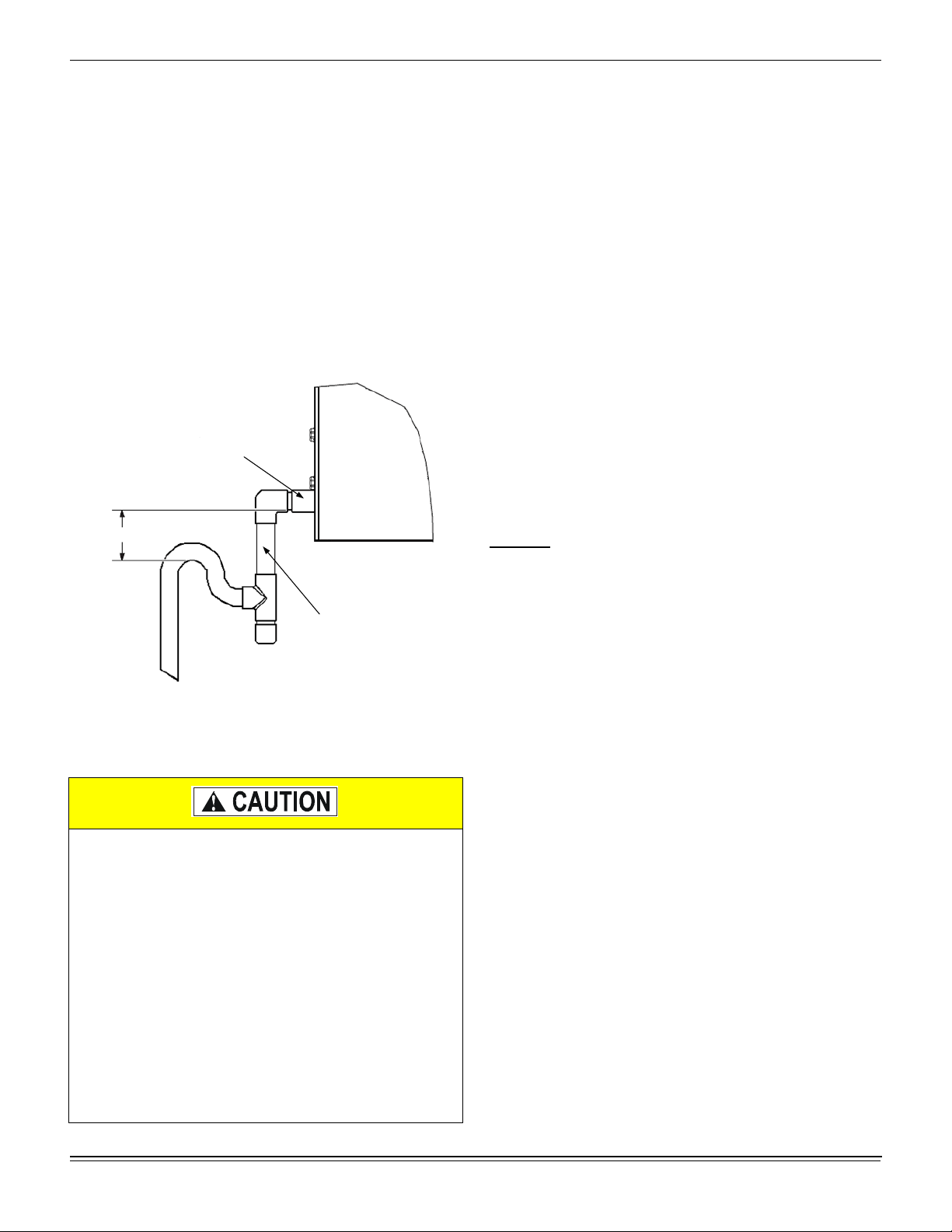

Drain Connections

All drain lines MUST be trapped and located so they will not be

exposed to freezing temperatures.

All evaporator blower units have a 3/4” PVC condensate stub at

the end of a double sloped drain pan. The drain pan is

removable and reversible, It can be unscrewed and slid out

from one side of the evaporator section and installed in the

other end.

Drain piping should be constructed as shown in Figure 6. The

3-inch dimension must equal or exceed the negative static

pressure developed by the supply air blowers. If it does not, the

condensate will not drain properly and may overflow the drain

pan.

¾” PVC

STUB

3" MINIMUM

Line Sizing

When sizing refrigerant pipe for a split-system air conditioner,

check the following:

1. Suction line pressure drop due to friction.

2. Liquid line pressure drop due to friction.

3. Suction line velocity for oil return.

4. Liquid line pressure drop due to vertical rise. For certain

piping arrangements, different sizes of suction line pipe

may have to be used. The velocity of the refrigerant vapor

must always be great enough to carry the oil back to the

compressor.

5. Evaporator Located Below Condenser - On a split

system where the evaporator blower is located below the

condenser, the suction line must be sized for both pressure

drop and for oil return.

6. Condenser Located Below Evaporator - When the

condenser is located below the evaporator blower, the

liquid line must be designed for the pressure drop due to

both friction loss and vertical rise. If the pressure drop due

to vertical rise and friction exceeds 40 psi, some refrigerant

will flash before it reaches the thermal expansion valve.

Flash gas

:

FIELD SUPPLIED

Figure 6: Recommended Drain Piping

Refrigerant Mains

This Split-System (Air Condensing / Heat Pump / Air

Handling) unit is one component of an entire system. As

such it requires specific application considerations with

regard to the rest of the system (air handling unit, duct

design, condensing unit, refrigerant piping and control

scheme).

Failure to properly apply this equipment with the rest of

the system may result in premature failure and/or

reduced performance / increased costs. Warranty

coverage specifically excludes failures due to improper

application and Unitary Products specifically disclaims

any liability resulting from improper application.

Please refer to the equipment Technical Guide,

Installation Manual and the piping applications bulletin

247077 or call the applications department for Unitary

Products @ 1-877-UPG-SERV for guidance.

1. Increases the liquid line pressure loss due to friction that in

turn causes further flashing.

2. Reduces the capacity of the refrigerant control device

which starves the evaporator.

3. Erodes the seat of the refrigerant control device.

4. Causes erratic control of the refrigerant entering the

evaporator.

Take Adequate Precautions

Many service problems can be avoided by taking adequate

precautions to provide an internally clean and dry system and

by using procedures and materials that conform to established

standards.

Use hard drawn copper tubing where no appreciable amount of

bending around pipes or other obstructions is necessary. If soft

copper is used, care should be taken to avoid sharp bends that

may cause a restriction. Pack fiberglass insulation and a

sealing material such as permagum around refrigerant lines

where they penetrate a wall to reduce vibrations and to retain

some flexibility.

Support all tubing at minimum intervals with suitable hangers,

brackets or clamps.

Braze all copper-to-copper joints with Silfos-5 or equivalent

brazing material. Do not use soft solder. Insulate all suction

lines with a minimum of 1/2" ARMAFLEX or equivalent. Liquid

lines exposed to direct sunlight and/or high temperatures must

also be insulated. Never solder suction and liquid lines

together. They can be taped together for convenience and

Johnson Controls Unitary Products 11

Page 12

520413-BIM-A-0209

support purposes, but they must be completely insulated from

each other.

The liquid and suction service ports on the condenser section

permit leak testing, evacuation, and partial charging of the field

piping and the evaporator without disturbing refrigerant stored

in the condenser during initial installation.

Before beginning installation of the main lines, be sure that the

evaporator section has not developed a leak in transit. Check

pressure at the Schrader valve located on the header of each

coil. If pressure still exists in the system, it can be assumed to

be leak free. If pressure DOES NOT exist the section will need

to be repaired before evacuation and charging is performed.

A filter-drier MUST be field-installed in the liquid line of every

system to prevent dirt and moisture from damaging the system.

Properly sized filter-driers are shipped with each condensing

section.

NOTE: Installing a filter-drier does not eliminate the need for

the proper evacuation of a system before it is charged.

A field-installed moisture indicating sight-glass should be

installed in the liquid line(s) between the filter-drier and the

evaporator coil. The moisture indicating sight-glass can be used

to check for excess moisture in the system or used as a visual

means to verify refrigerant charge.

Both condenser and evaporator sections have copper sealing

disks brazed over the end of liquid and suction connections.

The temperature required to make or break a brazed joint is

high enough to cause oxidation of the copper unless an inert

atmosphere is provided.

connections of the main lines. Repeat for the liquid line valve

body.

Never remove a cap from an access port unless the

valve is fully back-seated with its valve stem in the

maximum counter-clockwise position because the

refrigerant charge will be lost. Always use a refrigeration

valve wrench to open and close these service valves.

Connect the main liquid line to the liquid line connection on the

condenser section, while maintaining a flow of Nitrogen. Cool

the valve body and replace the Schraded valve stem on the

service port of the liquid line service valve.

Install the liquid line from the condensing unit to the evaporator

liquid connection, maintaining a flow of nitrogen during all

brazing operations.

The filter-drier and sight glass must be located in this line, close

to the evaporator.

Connect a low-pressure nitrogen source to the Schrader valve

located on the evaporator section coil headers. Drill a small

hole in the sealing disks, the flow of Nitrogen will prevent any

debris from entering the system. Unbraze both liquid and

suction sealing disks and prepare the joints for connections of

the main lines.

Connect the main liquid line to the liquid line connection on the

evaporator section, while maintaining a flow of Nitrogen.

NOTE: Dry Nitrogen should flow through the system at all

times when heat is being applied and until the joint has

cooled. The flow of Nitrogen will prevent oxidation of

the copper lines during installation.

Always drill a small hole in sealing disks before unbrazing to

prevent the pressure in the line from blowing them off.

NOTE: Solenoid and hot gas bypass valves (if used) should be

opened manually or electrically duri ng brazing or

evacuating.

NOTE: Schrader valves located on unit service valves should

have their stem removed during brazing to prevent

damage to the valve.

Start Installation

Start Installation of main lines at the condensing section. Verify

the service valves are fully seated by screwing the stem of both

valves down into the valve body until it stops. Remove the

Schraded valve stem and connect a low-pressure nitrogen

source to the service port on the suction line valve body. Drill a

small hole in the sealing disk; the flow of Nitrogen will prevent

any debris from entering the system. Wrap the valve body with

a wet rag to prevent overheating during the brazing process.

Overheating the valve will damage the valve seals. Unbraze the

sealing disk, cool the valve body and prepare the joint for

Make the suction line connection at the evaporator and run the

line to the condensing unit. Connect the main suction line to the

suction line connection on the condenser section, while

maintaining a flow of Nitrogen. Cool the valve body and replace

the Schraded valve stem on the service port of the liquid line

service valve.

Once the brazing process is complete, leak testing should be

done on all interconnecting piping and the evaporator befo re

proper evacuation to 500 microns is performed. Once the line

set and evaporator section is properly evacuated the service

valves can be opened and the condensing unit is now ready to

charge with the appropriate weight of refrigerant.

The correct refrigerant pressures are indicated as shown in

Figures 10 through 13.

12 Johnson Controls Unitary Products

Page 13

This system uses R-410A Refrigerant which operates at

higher pressures than R-22. No other refrigerant may be

used in this system. Gage sets, hoses, refrigerant

containers and recovery systems must be designed to

handle R-410A. If you are unsure, consult the

equipment manufacturer. Failure to use R-410A

compatible servicing equipment may result in property

damage or injury.

520413-BIM-A-0209

wired to operate in a similar fashion as described on pages 14

and 15.

NOTE: See Liquid Line Solenoid Wiring on page 15.

Air System Adjustment

Refer to Tables 8 thru 18 to adjust the air system.

Electrical Connections

The electric box ships complete with contractor, transformer,

relays, circuit breaker and terminal block for making field

connections.

Refer to Typical Unit Wiring Diagrams.

Wear safety glasses and gloves when handling

refrigerants. Failure to follow this warning can cause

serious personal injury.

NOTE: This instruction covers the installation and operation of

the basic condensing unit. For refrigerant piping

installation instructions refer to document 247077

"Application Data - General Piping Recommendations

for Split System Air Conditioning and Heat Pumps".

Expansion Valve Bulb Installation

Thermal expansion valve bulbs on the blower units are not

factory-installed in its final locati o n s ; Th ey are only temporarily

taped for shipment. The bulb for system one must be fastened

in a 4 o'clock and/or 8 o'clock position to the system one suction

line leaving the evaporator coil after piping connections are

made. Repeat the procedure for system two, locating the bulbs

in a 4 o'clock and/or 8 o'clock position to the system two suction

line. Use the bulb clamps from the bag taped to the suction

connection inside the blower unit.

NOTE: Ensure the TXV bulbs are not crossed between

systems. Undesirable performance and possible

compressor damage may occur.

Liquid Line Solenoids

Install a power supply to meet the requirements listed in

Electric Data Table 6.

Provide a disconnect switch and fusing as required.

Install interconnecting control wiring between condensing

section, evaporator blower and room thermostat.

The unit is shipped with factory installed, normally closed, liquid

line solenoid valves. When the solenoid coil is energized with a

24-volt signal, the valve will open.

During brazing operations, the valves should be placed in the

OPEN position by removing the stem cap with a 9/16” wrench,

then rotating the exposed valve stem inward (CLOCKWISE),

approximately 10-12 full turns (from the fully CLOSED position),

using a 4” adjustable wrench.

The valve stems should be returned to the CLOSED

(COUNTER-CLOCKWISE) position prior to the unit’s operation.

The sequence of operation applies to the PC/PD and YC/YD

condensing units and NH/NJ air handlers when applied as a

matched system. Non-matched systems will have to be field

Johnson Controls Unitary Products 13

Page 14

520413-BIM-A-0209

S1

G1

S1 G1

S2

S2

G2

C

CG2

Figure 7: Typical Field Wiring Diagram - NH-07 Unit

SINGLE STAGE

THERMOSTAT

14 Johnson Controls Unitary Products

Page 15

S1

S1

G1

G1

S2

S2

G2

G2

520413-BIM-A-0209

C

C

Figure 8: Typical Field Wiring Diagram - NH/NJ-10 Thru -20 Unit

Figure 9: NH/NJ-10 Thru -20 Liquid Line Solenoid Wiring

Johnson Controls Unitary Products 15

Page 16

520413-BIM-A-0209

Electrical Data

Table 6: Electrical Data - Electric Heat

Supply

Motor HP Power Supply

208-3-60 5.0

230-3-60 5.0

1.5

460-3-60 2.5

575-3-60 2.0

208-3-60 6.3

230-3-60 6.3

2.0

460-3-60 3.2

575-3-60 2.4

Blower

Motor

FLA Model KW Stages Amps

Electric Heat Option

NH-07C00B

None --- --- --- 11.3 15

10 KW 7.5 1 20.8 32.1 35

16 KW 12 2 33.4 44.6 45

26 KW 19.5 2 54.2 65.5 70

36 KW 27 2 75.1 86.3 90

None --- --- --- 11.3 15

10 KW 10 1 24.1 35.3 40

16 KW 16 2 38.5 49.7 50

26 KW 26 2 62.5 73.8 80

36 KW 36 2 86.6 97.9 100

None --- --- --- 5.6 15

10 KW 10 1 12.0 17.7 20

16 KW 16 2 19.2 24.9 25

26 KW 26 2 31.3 36.9 40

36 KW 36 2 43.3 48.9 50

None --- --- --- 4.5 15

10 KW 10 1 9.6 14.1 15

16 KW 16 2 15.4 19.9 20

26 KW 26 2 25.0 29.5 30

36 KW 36 2 34.6 39.1 40

NH-07C00C, NH/NJ-10C00C

None --- --- --- 14.2 15

10 KW 7.5 1 20.8 35.0 40

16 KW 12 2 33.4 47.5 50

26 KW 19.5 2 54.2 68.4 70

36 KW 27 2 75.1 89.2 90

None --- --- --- 14.2 15

10 KW 10 1 24.1 38.2 40

16 KW 16 2 38.5 52.7 60

26 KW 26 2 62.5 76.7 80

36 KW 36 2 86.6 100.8 110

None --- --- --- 7.2 15

10 KW 10 1 12.0 19.2 20

16 KW 16 2 19.2 26.4 30

26 KW 26 2 31.3 38.5 40

36 KW 36 2 43.3 50.5 60

None --- --- --- 5.4 15

10 KW 10 1 9.6 15.0 20

16 KW 16 2 15.4 20.8 25

26 KW 26 2 25.0 30.4 35

36 KW 36 2 34.6 40.0 45

MCA

(Amps)

1

Max Fuse

Breaker

(Amps)

3

Size

2

/

16 Johnson Controls Unitary Products

Page 17

Table 6: Electrical Data - Electric Heat (Continued)

Supply

Motor HP Power Supply

208-3-60 9.6

230-3-60 9.6

3.0

460-3-60 4.7

575-3-60 3.6

208-3-60 14.0

230-3-60 14.0

5.0

460-3-60 7.0

575-3-60 5.2

208-3-60 14.0

230-3-60 14.0

5.0

460-3-60 7.0

575-3-60 5.2

Blower

Motor

FLA Model KW Stages Amps

10 KW 7.5 1 20.8 42.4 45

16 KW 12 2 33.4 55.0 60

26 KW 19.5 2 54.2 75.8 80

36 KW 27 2 75.1 96.7 100

10 KW 10 1 24.1 45.7 50

16 KW 16 2 38.5 60.1 70

26 KW 26 2 62.5 84.1 90

36 KW 36 2 86.6 108.2 110

10 KW 10 1 12.0 22.6 25

16 KW 16 2 19.2 29.8 30

26 KW 26 2 31.3 41.8 45

36 KW 36 2 43.3 53.9 60

10 KW 10 1 9.6 17.7 20

16 KW 16 2 15.4 23.5 25

26 KW 26 2 25.0 33.1 35

36 KW 36 2 34.6 42.7 45

10 KW 7.5 1 20.8 52.3 60

16 KW 12 2 33.4 64.9 70

26 KW 19.5 2 54.2 85.7 90

36 KW 27 2 75.1 106.6 110

50 KW 37.6 2 104.2 135.7 150

10 KW 10 1 24.1 55.6 60

16 KW 16 2 38.5 70.0 70

26 KW 26 2 62.5 94.0 100

36 KW 36 2 86.6 118.1 125

50 KW 50 2 120.3 151.8 175

10 KW 10 1 12.0 27.8 30

16 KW 16 2 19.2 35.0 35

26 KW 26 2 31.3 47.0 50

36 KW 36 2 43.3 59.1 60

50 KW 50 2 60.1 75.9 80

10 KW 10 1 9.6 21.3 25

16 KW 16 2 15.4 27.1 30

26 KW 26 2 25.0 36.7 40

36 KW 36 2 34.6 46.3 50

50 KW 50 2 48.1 59.8 60

20 KW 15 1 41.7 73.2 80

32 KW 24 2 66.7 98.2 100

52 KW 39.1 2 108.4 139.9 150

20 KW 20 1 48.1 79.6 80

32 KW 32 2 77.0 108.5 110

52 KW 52 2 125.1 156.6 175

20 KW 20 1 24.1 39.8 40

32 KW 32 2 38.5 54.2 60

52 KW 52 2 62.5 78.3 80

20 KW 20 1 19.2 30.9 35

32 KW 32 2 30.8 42.5 45

52 KW 52 2 50.0 61.7 70

NH/NJ-10C00D, NH/NJ-15C00D

None --- --- --- 21.6 25

None --- --- --- 21.6 25

None --- --- --- 10.6 15

None --- --- --- 8.1 15

None --- --- --- 31.5 35

None --- --- --- 31.5 35

None --- --- --- 15.8 20

None --- --- --- 11.7 15

None --- --- --- 31.5 35

None --- --- --- 31.5 35

None --- --- --- 15.8 20

None --- --- --- 11.7 15

Electric Heat Option

NH/NJ-15C00E

NH/NJ-20C00E

MCA

(Amps)

520413-BIM-A-0209

1

Max Fuse

Breaker

(Amps)

3

Size

2

/

Johnson Controls Unitary Products 17

Page 18

520413-BIM-A-0209

Table 6: Electrical Data - Electric Heat (Continued)

Supply

Motor HP Power Supply

208-3-60 19.2

230-3-60 19.2

7.5

460-3-60 9.6

575-3-60 7.8

1. Minimum Circuit Ampacity.

2. Dual Element, Time Delay Type.

3. HACR type per NEC.

Blower

Motor

FLA Model KW Stages Amps

None --- --- --- 43.2 45

20 KW 15 1 41.7 84.9 90

32 KW 24 2 66.7 109.9 110

52 KW 39.1 2 108.4 151.6 175

None --- --- --- 43.2 45

20 KW 20 1 48.1 91.3 100

32 KW 32 2 77.0 120.2 125

52 KW 52 2 125.1 168.3 175

None --- --- --- 21.6 25

20 KW 20 1 24.1 45.7 50

32 KW 32 2 38.5 60.1 70

52 KW 52 2 62.5 84.1 90

None --- --- --- 17.6 20

20 KW 20 1 19.2 36.8 40

32 KW 32 2 30.8 48.3 50

52 KW 52 2 50.0 67.6 70

Electric Heat Option

NH/NJ-20C00F

MCA

(Amps)

2

3

(Amps)

/

Size

1

Max Fuse

Breaker

CFM Static Pressure and Power-Altitude and Temperature

Corrections

The information below should be used to assist in application of

product when being applied at altitudes at or exceeding 1000

feet above sea level.

The air flow rates listed in the standard blower performance

tables are based on standard air at sea level. As the altitude or

temperature increases, the density of air decreases. In order to

use the indoor blower tables for high altitude applications,

certain corrections are necessary.

A centrifugal fan is a "constant volume" device. This means

that, if the rpm remains constant, the CFM delivered is the

same regardless of the density of the air. However, since the air

at high altitude is less dense, less static pressure will be

generated and less power will be required than a similar

application at sea level. Air density correction factors are shown

in Table 7 and Figure 10.

18 Johnson Controls Unitary Products

Page 19

520413-BIM-A-0209

Table 7: Altitude/Temperature Correction Factors

Air

Temp.

40 1.060 1.022 0.986 0.950 0.916 0.882 0.849 0.818 0.788 0.758 0.729

50 1.039 1.002 0.966 0.931 0.898 0.864 0.832 0.802 0.772 0.743 0.715

60 1.019 0.982 0.948 0.913 0.880 0.848 0.816 0.787 0.757 0.729 0.701

70 1.000 0.964 0.930 0.896 0.864 0.832 0.801 0.772 0.743 0.715 0.688

80 0.982 0.947 0.913 0.880 0.848 0.817 0.787 0.758 0.730 0.702 0.676

90 0.964 0.929 0.897 0.864 0.833 0.802 0.772 0.744 0.716 0.689 0.663

100 0.946 0.912 0.880 0.848 0.817 0.787 0.758 0.730 0.703 0.676 0.651

0 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000

1.100

1.050

1.000

0.950

0.900

0.850

0.800

Correction Factor

0.750

0.700

0.650

Altitude (Ft.)

Sea Level

1000 ft

2000 ft

3000 ft

4000 ft

5000 ft

6000 ft

7000 ft

8000 ft

9000 ft

10000 ft

0.600

40 50 60 70 80 90 100

Air Temperature (ºF)

Figure 10: Altitude/Temperature Correction Factors

The examples below will assist in determining the airflow

performance of the product at altitude.

Example 1: What are the corrected CFM, static pressure, and

BHP at an elevation of 5,000 ft. if the blower performance data

is 6,000 CFM, 1.5 IWC and 4.0 BHP?

Solution: At an elevation of 5,000 ft. the indoor blower will still

deliver 6,000 CFM if the rpm is unchanged. However, the

Altitude/Temperature Correction Factors table must be used to

determine the static pressure and BHP. Since no temperature

data is given, we will assume an air temperature of 70°F. The

table shows the correction factor to be 0.832.

Corrected static pressure = 1.5 x 0.832 = 1.248 IWC

Corrected BHP = 4.0 x 0.832 = 3.328

Example 2: A system, located at 5,000 feet of elevation, is to

deliver 6,000 CFM at a static pressure of 1.5". Use the unit

blower tables to select the blower speed and the BHP

requirement.

Solution: As in the example above, no temperature

information is given so 70°F is assumed.

The 1.5" static pressure given is at an elevation of 5,000 ft. The

first step is to convert this static pressure to equivalent sea level

conditions.

Sea level static pressure = 1.5 / .832 = 1.80"

Enter the blower table at 6000 sCFM and static pressure of

1.8". The rpm listed will be the same rpm needed at 5,000 ft.

Suppose that the corresponding BHP listed in the table is 3.2.

This value must be corrected for elevation.

BHP at 5,000 ft. = 3.2 x .832 = 2.66

Johnson Controls Unitary Products 19

Page 20

520413-BIM-A-0209

Drive Selection

1. Determine Upflow or Horizontal supply duct Application.

2. Determine desired airflow.

3. Calculate or measure the amount of external static pressure.

4. Using the operating point, determined from steps 1, 2 & 3, locate this point on the appropriate supply air blower performance

table. (Linear interpolation may be necessary.)

5. Noting the RPM and BHP from step 4, locate the appropriate motor and/or drive on the RPM selection table.

6. Review the BHP compared to the motor options available. Select the appropriate motor and, or drive.

7. Review the RPM range for the motor options available. Select the appropriate drive if multiple drives are available for the

chosen motor.

8. Determine turns open to obtain the desired operation point.

Example

1. 3250 CFM

2. 1.4 iwg

3. Using the supply air blower performance table below, the following data point was located: 1100 RPM & 1.8 BHP.

4. Using the RPM selection table below, Model X is found.

5. 1.8 BHP exceeds the maximum continuous BHP rating of the 1.5 HP motor. The 2 HP motor is required.

6. 1100 RPM is within the range of the 2 HP drives.

7. Using the 2 HP motor and drive, 1 turn open will achieve 1128 RPM.

Airflow Performance

Example Supply Air Blower Performance

Available External Static Pressure - IWG

(CFM)

3000 696 0.9 757 1.1 822 1.2 891 1.3 961 1.3 1019 1.5 1077 1.6 1135 1.8

3250 729 1.1 790 1.3 855 1.4 924 1.5 984 1.6 1042 1.7 1100 1.8 1159 2.0

3500 766 1.3 826 1.5 892 1.6 953 1.6 1010 1.8 1069 1.9 1127 2.0

RPM Selection

Unit Model HP

X

0.20.40.60.81.01.21.41.61.82.0

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Standard 1.5 HP & Drive High Static 2 HP & Drive

Max

BHP

Std. 1.5 1.73 1VL40 AK69 N/A 690 743 796 849 902 955

HS 2 2.30 1VL40 AK56 N/A 863 929 995 1062 1128 1194

Motor

Sheave

Blower

Sheave

6 Turns

Open

5 Turns

Open

4 Turns

Open

3 Turns

Open

2 Turns

Open

1 Turn

Open

Fully

Closed

20 Johnson Controls Unitary Products

Page 21

520413-BIM-A-0209

Airflow Performance

Table 8: NH-07 Upflow

Available External Static Pres sure - IWG

(CFM)

2250 754 0.8 828 0.9 902 1.0 988 1.1 1051 1.3 1116 1.4 1183 1.5

2500 707 0.8 777 0.9 851 1.0 925 1.1 996 1.3 1059 1.4 1124 1.5 1191 1.7

2750 735 0.9 805 1.1 879 1.2 953 1.3 1012 1.4 1076 1.6 1141 1.7

3000 705 1.0 767 1.1 837 1.2 911 1.3 973 1.5 1035 1.6 1099 1.7 1164 1.9

3250 741 1.1 802 1.3 872 1.4 947 1.5 1002 1.7 1064 1.8 1127 2.0

3500 780 1.4 842 1.5 912 1.6 974 1.8 1035 1.9 1097 2.1 1161 2.2

3750 823 1.6 884 1.7 954 1.9 1012 2.0 1072 2.2 1134 2.3 Exceeds BHP Limitations

1. Airflow performance includes dry evaporator coil. See Static Resistance table for additional applications.

2. See RPM Selection table to determine desired motor sheave setting and to determine the maximum continuous BHP.

3. kW = BHP x 0.746 ÷ nameplate rated motor efficiency.

Table 9: NH-07 Horizontal

(CFM)

2250 747 0.8 816 0.9 889 1.0 954 1.2 1013 1.3 1071 1.5 1128 1.6

2500 703 0.8 768 0.9 837 1.0 909 1.1 977 1.2 1036 1.4 1094 1.5 1151 1.7

2750 728 0.9 793 1.0 862 1.1 934 1.2 998 1.4 1056 1.5 1114 1.7

3000 696 0.9 757 1.1 822 1.2 891 1.3 961 1.4 1019 1.6 1077 1.7 1135 1.9

3250 729 1.1 790 1.3 855 1.4 924 1.5 984 1.6 1042 1.8 1100 1.9 1159 2.1

3500 766 1.3 826 1.5 892 1.6 953 1.6 1010 1.9 1069 2.0 1127 2.2

3750 806 1.6 867 1.7 932 1.8 984 1.9 1041 2.1 1099 2.3 Exceeds BHP Limitations

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Std. 1.5 HP & Field

Supplied Drive

Standard 1.5 HP & Drive High Static 2 HP & Drive

Available External Static Pres sure - IWG

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Std. 1.5 HP & Field

Supplied Drive

Standard 1.5 HP & Drive High Static 2 HP & Drive

1. Airflow performance includes dry evaporator coil. See Static Resistance table for additional applications.

2. See RPM Selection table to determine desired motor sheave setting and to determine the maximum continuous BHP.

3. kW = BHP x 0.746 ÷ nameplate rated motor efficiency.

Johnson Controls Unitary Products 21

Page 22

520413-BIM-A-0209

Table 10: NH/NJ-10 Upflow

Available External Static Pressure - IWG

(CFM)

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Std. 2 HP & Field

Supplied Drive

2500 671 0.8 728 0.9 788 1.0 853 1.1 926 1.3 975 1.5 1026 1.6 1077 1.7

2750 684 0.9 741 1.0 801 1.1 866 1.2 933 1.4 982 1.6 1032 1.7 1084 1.8

3000 701 1.0 757 1.1 817 1.3 882 1.4 941 1.5 991 1.7 1041 1.8 1092 2.0

3250 664 1.0 719 1.1 776 1.3 836 1.4 903 1.5 952 1.7 1002 1.8 1052 2.0

3500 685 1.1 741 1.3 797 1.4 858 1.5 917 1.7 966 1.9 1015 2.0 1066 2.2

3750 653 1.1 709 1.3 764 1.4 821 1.6 884 1.7 933 1.9 982 2.0 1031 2.2 1082 2.3

4000 679 1.3 735 1.5 790 1.6 847 1.8 903 1.9 952 2.1 1001 2.3 1050 2.4

4250 707 1.5 762 1.6 818 1.8 875 1.9 924 2.1 973 2.3 1022 2.5 1072 2.7

4500 737 1.7 792 1.9 850 2.0 899 2.2 948 2.4 997 2.6 1046 2.8

4750 768 1.9 824 2.1 877 2.2 926 2.5 975 2.7 1024 2.9 1073 3.0

5000 801 2.1 856 2.3 906 2.5 956 2.8 1005 3.0 1053 3.2 High Static 3 HP & Field Supplied Drive

1. Airflow performance includes dry evaporator coil. See Static Resistance table for additional applications.

2. See RPM Selection table to determine desired motor sheave setting and to determine the maximum continuous BHP.

3. kW = BHP x 0.746 ÷ nameplate rated motor efficiency.

Standard 2 HP & Drive High Static 3 HP & Drive

Table 11: NH/NJ-10 Horizonta l

Available External Static Pressure - IWG

(CFM)

2500 686 0.8 730 0.9 778 0.9 840 1.0 917 1.3 964 1.5 1011 1.6 1060 1.7

2750 698 0.9 742 1.0 790 1.0 852 1.1 924 1.4 971 1.6 1019 1.7 1067 1.9

3000 714 1.0 758 1.1 806 1.1 868 1.2 935 1.6 981 1.7 1029 1.9 1078 2.0

3250 684 1.0 734 1.2 778 1.2 826 1.3 902 1.6 948 1.7 995 1.9 1042 2.0

3500 707 1.2 757 1.3 801 1.4 849 1.4 917 1.7 964 1.9 1010 2.0 1058 2.2

3750 669 1.2 734 1.4 784 1.5 828 1.6 890 1.7 936 1.9 982 2.1 1029 2.2 1076 2.4

4000 699 1.4 764 1.6 814 1.7 858 1.8 910 2.0 956 2.1 1002 2.3 1049 2.4

4250 732 1.6 798 1.8 847 1.9 887 2.0 933 2.2 978 2.4 1025 2.5 1071 2.7

4500 769 1.8 834 2.0 884 2.1 911 2.3 957 2.4 1003 2.6 1049 2.8

4750 808 2.1 874 2.3 891 2.3 937 2.5 983 2.7 1029 2.9 1075 3.1

5000 850 2.3 873 2.4 919 2.6 965 2.8 1011 3.0 1057 3.2 High Static 3 HP & Field Supplied Drive

0.20.40.60.81.01.21.41.61.82.0

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Std. 2 HP & Field

Supplied Drive

Standard 2 HP & Drive High Static 3 HP & Drive

1. Airflow performance includes dry evaporator coil. See Static Resistance table for additional applications.

2. See RPM Selection table to determine desired motor sheave setting and to determine the maximum continuous BHP.

3. kW = BHP x 0.746 ÷ nameplate rated motor efficiency.

22 Johnson Controls Unitary Products

Page 23

520413-BIM-A-0209

Table 12: NH/NJ-15 Upflow

Available External Static Pressure - IWG

(CFM)

0.20.40.60.81.01.21.41.61.8

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Std. 3 HP & Field Supplied Drive Standard 3 HP & Drive High Static 5 HP & Drive

4500 583 1.1 634 1.3 688 1.5 738 1.9 782 2.3 827 2.6

4750 592 1.2 643 1.4 700 1.8 744 2.1 788 2.4 833 2.7

5000 602 1.2 653 1.4 707 1.9 751 2.2 795 2.6 840 2.9

5250 613 1.3 664 1.5 716 2.1 759 2.4 804 2.7 848 3.1

5500 577 1.1 625 1.4 676 1.6 725 2.3 768 2.6 813 2.9 857 3.2

5750 590 1.2 638 1.4 689 1.7 735 2.5 778 2.8 822 3.1

6000 603 1.3 651 1.6 702 2.3 745 2.7 789 3.0 833 3.3

6250 617 1.5 664 1.7 714 2.6 757 2.9 801 3.2 845 3.5

6500 587 1.4 631 1.6 679 1.8 726 2.8 769 3.1 813 3.4 857 3.8

6750 601 1.6 645 1.8 693 2.0 739 3.0 782 3.4 826 3.7

7000 616 1.8 660 2.0 710 2.9 753 3.3 796 3.6 839 3.9

7250 632 2.1 675 2.3 725 3.2 767 3.6 810 3.9 854 4.2

7500 647 2.3 691 2.5 740 3.5 782 3.9 825 4.2 High Static 5 HP & Field Supplied Drive

1. Airflow performance includes dry evaporator coil. See Static Resistance table for additional applications.

2. See RPM Selection table to determine desired motor sheave setting and to determine the maximum continuous BHP.

3. kW = BHP x 0.746 ÷ nameplate rated motor efficiency.

Table 13: NH/NJ-15 Horizonta l

Available External Static Pressure - IWG

(CFM)

4500 585 1.5 634 1.6 687 1.8 735 2.0 780 2.5 827 2.7 875 2.9

4750 595 1.6 644 1.7 697 1.9 741 2.4 787 2.7 834 2.9

5000 605 1.7 655 1.8 708 2.0 749 2.6 795 2.9 842 3.1

5250 617 1.8 666 2.0 719 2.1 757 2.8 804 3.1 851 3.3

5500 582 1.8 629 1.9 678 2.1 731 2.3 767 3.0 813 3.2 860 3.4

5750 594 1.9 642 2.1 691 2.2 737 2.4 778 3.2 824 3.4 871 3.7

6000 608 2.1 655 2.2 705 2.4 744 3.1 789 3.4 835 3.7

6250 622 2.2 670 2.4 719 2.6 756 3.3 801 3.6 847 3.9

6500 589 2.2 637 2.4 684 2.6 733 2.7 769 3.6 814 3.9 860 4.1

6750 604 2.4 652 2.6 699 2.8 738 3.5 782 3.8 827 4.1 873 4.4

7000 620 2.6 667 2.8 715 3.0 752 3.8 796 4.1 841 4.4

7250 636 2.8 683 3.0 731 3.2 766 4.1 811 4.4 856 4.7

7500 652 3.0 700 3.2 738 4.0 781 4.4 825 4.7 High Static 5 HP & Field Supplied Drive

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Std. 3 HP & Field Supplied Drive Standard 3 HP & Drive High Static 5 HP & Drive

1. Airflow performance includes dry evaporator coil. See Static Resistance table for additional applications.

2. See RPM Selection table to determine desired motor sheave setting and to determine the maximum continuous BHP.

3. kW = BHP x 0.746 ÷ nameplate rated motor efficiency.

Johnson Controls Unitary Products 23

Page 24

520413-BIM-A-0209

Table 14: NH/NJ-20 Upflow

Available External Static Pres sure - IWG

(CFM)

6000 732 2.2 789 2.6 846 2.9 900 3.1 959 4.0 1008 4.5 1056 4.9 1102 5.2 1146 5.3

6250 685 1.9 742 2.3 799 2.7 856 3.0 910 3.3 967 4.2 1016 4.7 1064 5.1 1110 5.4 1154 5.5

6500 696 2.1 752 2.5 809 2.8 866 3.2 920 3.4 976 4.4 1025 4.9 1072 5.3 1118 5.6

6750 706 2.2 763 2.6 820 3.0 877 3.3 935 4.0 985 4.6 1034 5.1 1081 5.5 1127 5.8

7000 718 2.4 774 2.8 831 3.2 888 3.5 945 4.2 994 4.8 1043 5.3 1091 5.7 1137 6.0

7250 729 2.6 786 3.0 843 3.3 900 3.6 954 4.5 1004 5.0 1053 5.5 1100 5.9 1146 6.2

7500 741 2.8 798 3.1 855 3.5 912 3.8 965 4.7 1014 5.3 1063 5.8 1111 6.2

7750 700 2.6 754 2.9 810 3.3 868 3.7 925 4.3 975 4.9 1025 5.5 1074 6.0 1121 6.4

8000 712 2.8 767 3.1 823 3.5 881 3.9 936 4.6 986 5.2 1036 5.8 1085 6.3 1132 6.7

8250 726 3.0 780 3.3 837 3.7 894 4.1 948 4.9 998 5.5 1047 6.0 1096 6.5 1144 6.9

8500 740 3.2 794 3.6 850 3.9 908 4.3 959 5.1 1010 5.8 1059 6.3 1108 6.8

8750 754 3.4 808 3.8 865 4.2 922 4.8 972 5.4 1022 6.0 1071 6.6 1120 7.1

9000 768 3.6 823 4.0 879 4.4 934 5.1 984 5.7 1034 6.4 1084 6.9 1133 7.4

9250 783 3.9 838 4.3 894 4.6 947 5.4 997 6.1 1047 6.7 1097 7.2

9500 799 4.1 853 4.5 910 4.9 961 5.8 1011 6.4 1061 7.0 1110 7.6

9750 815 4.4 869 4.8 925 5.5 974 6.1 1024 6.7 1074 7.3 1124 7.9

10000 831 4.7 885 5.0 939 5.9 988 6.5 1038 7.1 1088 7.7 1138 8.3 High Static 7.5 HP & Field Supplied Drive

1. Airflow performance includes dry evaporator coil. See Static Resistance table for additional applications.

2. See RPM Selection table to determine desired motor sheave setting and to determine the maximum continuous BHP.

3. kW = BHP x 0.746 ÷ nameplate rated motor efficiency.

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0 2.2

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Std. 5 HP &

Field Supplied Drive

High Static 5 HP & Drive High Static 7.5 HP & Drive

Table 15: NH/NJ-20 Horizonta l

Available External Static Pressure - IWG

(CFM)

6000 708 2.0 754 2.3 801 2.6 849 2.8 898 2.9 976 4.0 1021 4.4 1066 4.8 1111 5.1 1155 5.3

6250 715 2.1 761 2.4 808 2.7 856 2.9 906 3.0 984 4.2 1029 4.6 1074 5.0 1118 5.3 1163 5.5

6500 723 2.3 769 2.6 816 2.8 864 3.0 947 3.9 991 4.4 1036 4.8 1081 5.2 1126 5.4

6750 731 2.4 777 2.7 824 3.0 872 3.2 955 4.1 999 4.6 1044 5,0 1089 5.3 1134 5.6

7000 740 2.5 786 2.8 833 3.1 881 3.3 963 4.3 1007 4.7 1052 5.2 1097 5.5 1142 5.8

7250 749 2.7 796 3.0 842 3.3 890 3.5 971 4.5 1015 4.9 1060 5.3 1105 5.7 1150 6.0

7500 712 2.6 759 2.9 806 3.2 852 3.4 900 3.6 979 4.7 1024 5.1 1069 5.5 1114 5.9 1158 6.2

7750 722 2.8 770 3.0 816 3.3 863 3.6 945 4.4 988 4.9 1033 5.3 1078 5.8 1123 6.1

8000 733 2.9 781 3.2 827 3.5 874 3.8 954 4.6 998 5.1 1042 5.5 1087 6.0 1132 6.3

8250 745 3.1 793 3.4 839 3.7 886 4.0 964 4.8 1007 5.3 1052 5.8 1096 6.2 1141 6.5

8500 757 3.3 805 3.6 851 3.9 898 4.2 974 5.1 1017 5.6 1062 6.0 1107 6.4 1152 6.8

8750 770 3.6 818 3.8 864 4.1 942 4.8 984 5.3 1028 5.8 1072 6.3 1117 6.7

9000 784 3.8 831 4.1 878 4.4 953 5.1 995 5.6 1039 6.1 1083 6.5 1128 6.9

9250 798 4.0 845 4.3 923 4.9 964 5.4 1006 5.9 1050 6.3 1094 6.8 1139 7.2

9500 812 4.3 859 4.6 935 5.2 976 5.7 1018 6.2 1062 6.6 1106 7.1 1151 7.5

9750 827 4.5 908 5.1 947 5.5 988 6.0 1030 6.5 1074 6.9 1118 7.4

10000 842 4.8 921 5.4 960 5.8 1001 6.3 1043 6.8 1087 7.3 1131 7.7 High Static 7.5 HP & Field Supplied Drive

1. Airflow performance includes dry evaporator coil. See Static Resistance table for additional applications.

2. See RPM Selection table to determine desired motor sheave setting and to determine the maximum continuous BHP.

3. kW = BHP x 0.746 ÷ nameplate rated motor efficiency.

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0 2.2

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Std. 5 HP &

Field

Supplied

Drive

Standard 5 HP & Drive High Static 7.5 HP & Drive

24 Johnson Controls Unitary Products

Page 25

Table 16: RPM Selection

Unit Model HP Max BHP Motor Sheave Blower Sheave

NH-07

NH/NJ-10

NH/NJ-15

NH/NJ-20

Std. 1.5 1.73 1VL40 AK69 N/A 690 743 796 849 902 955

HS 2 2.30 1VL40 AK56 N/A 863 929 995 1062 1128 1194

Std. 2 2.30 1VL40 AK74 N/A 641 690 739 789 838 887

HS 3 3.45 1VP56 AK84 N/A 906 949 992 1035 1078 1121

Std. 3 3.45 1VP50 AK114 N/A 565 596 627 659 690 721

HS 5 5.75 2VP50 2B5V94 707 745 782 819 856 894 N/A

Std. 5 5.75 2VP50 2B5V94 686 722 758 794 830 866 N/A

HS 7.5 8.63 2VP65 2B5V94 925 960 996 1031 1067 1103 1138

6 Turns

Open

5 Turns

Open

4 Turns

Open

3 Turns

Open

520413-BIM-A-0209

2 Turns

Open

1 Turn

Open

Fully

Closed

Johnson Controls Unitary Products 25

Page 26

520413-BIM-A-0209

Table 17: Additional Static Resistance

Model CFM

NH-07

NH/NJ-10

NH/NJ-15

2250 0.03 0.10 0.01 0.02 0.03 0.04 ---

2500 0.03 0.11 0.01 0.02 0.03 0.05 ---

2750 0.02 0.11 0.01 0.03 0.04 0.07 ---

3000 0.02 0.12 0.01 0.03 0.05 0.08 ---

3250 0.01 0.13 0.02 0.04 0.06 0.09 ---

3500 0.00 0.14 0.02 0.04 0.07 0.10 ---

3750 0.00 0.15 0.02 0.05 0.08 0.12 ---

3000 0.08 0.12 0.01 0.03 0.05 0.08 ---

3250 0.07 0.13 0.02 0.04 0.06 0.09 ---

3500 0.07 0.14 0.02 0.04 0.07 0.10 ---

3750 0.06 0.15 0.02 0.05 0.08 0.12 ---

4000 0.05 0.16 0.03 0.06 0.09 0.14 ---

4250 0.04 0.18 0.03 0.06 0.10 0.15 ---

4500 0.03 0.19 0.03 0.07 0.11 0.17 ---

4750 0.02 0.21 0.04 0.08 0.13 0.19 ---

5000 0.00 0.23 0.04 0.09 0.14 0.21 ---

4500 0.07 0.11 0.03 0.07 0.11 0.17 0.21

4750 0.06 0.11 0.04 0.08 0.13 0.19 0.22

5000 0.06 0.11 0.04 0.09 0.14 0.21 0.24

5250 0.06 0.12 0.05 0.10 0.15 0.23 0.26

5500 0.05 0.12 0.05 0.11 0.17 0.25 0.29

5750 0.05 0.12 0.06 0.12 0.19 0.28 0.32

6000 0.05 0.13 0.06 0.13 0.20 0.30 0.35

6250 0.04 0.14 0.07 0.14 0.22 0.33 0.38

6500 0.03 0.14 0.07 0.15 0.24 0.35 0.42

6750 0.03 0.15 0.08 0.17 0.26 0.38 0.47

7000 0.02 0.16 0.08 0.18 0.28 0.41 0.50

7250 0.01 0.16 0.09 0.19 0.30 0.44 0.53

7500 0.00 0.17 0.10 0.20 0.32 0.47 0.56

Wet Indoor

Coil

1

2” Filters

10 16 26 36 50

Electric Heat kW

Model CFM

6000 0.08 0.12 0.01 0.03 0.05

6250 0.08 0.13 0.02 0.03 0.05

6500 0.08 0.13 0.02 0.04 0.06

6750 0.07 0.14 0.02 0.04 0.06

7000 0.07 0.14 0.02 0.04 0.07

7250 0.06 0.15 0.02 0.05 0.07

7500 0.06 0.16 0.02 0.05 0.08

7750 0.05 0.16 0.02 0.05 0.08

NH/NJ-20

1. Pressure drop added by condensate over a dry coil.

8000 0.05 0.17 0.03 0.06 0.09

8250 0.04 0.18 0.03 0.06 0.09

8500 0.04 0.19 0.03 0.06 0.10

8750 0.03 0.20 0.03 0.07 0.11

9000 0.02 0.21 0.03 0.07 0.11

9250 0.01 0.22 0.04 0.08 0.12

9500 0.00 0.23 0.04 0.08 0.13

9750 0.00 0.24 0.04 0.09 0.13

10000 0.00 0.25 0.04 0.09 0.14

Wet Indoor

Coil

2” Filters

Electric Heat kW

20 32 52

26 Johnson Controls Unitary Products

Page 27

520413-BIM-A-0209

Table 18: Blower Motor And Drive Data

Blower Motor Data Drive Data

Unit

Model

NH-07

NH/NJ-10

NH/NJ-15

NH/NJ-20

HP RPM SF

Std 1.5

HS 2 56HZ 1VL40 863 - 1194 2.4 - 3.4 0.875 AK56 5.2 1.000 1 40.3 A39

Std. 2

HS 3 56HZ 1VP56 906 - 1121 4.0 - 5.0 0.875 AK84 8.0 1.000 1 48.3 A47

Std. 3

HS 5 184T 2VP50 707 - 894 3.7 - 4.7 1.125 2B5V94 9.7 1.000 2 41.8 B40

Std. 5

HS 7.5 213T 2VP65 925 - 1138 5.2 - 6.2 1.375 2B5V94 9.7 1.188 2 46.8 B45

1725 1.15

1725 1.15

1725 1.15

1725 1.15

Frame

Model

Size

Number

56 1VL40 690 - 955 2.4 - 3.4 0.875 AK69 6.5 1.000 1 42.3 A41

56HZ 1VL40 641 - 887 2.4 - 3.4 0.875 AK74 7.0 1.000 1 45.3 A44

56HZ 1VP50 565 - 721 2.8 - 3.8 0.875 AK114 11.0 1.000 1 45.3 A44

184T 2VP50 686 - 866 3.7 - 4.7 1.125 2B5V94 9.7 1.188 2 41.8 B40

Blower

RPM

Range

Adjustable Motor Sheave

Diameter

To check the supply air CFM after the initial balancing has

been completed:

1. Drill two (2) 5/16-inch holes in the side panel as shown in

Figure 24.

2. Insert at least 8 inches of 1/4 inch tubing into each of these

holes for sufficient penetration into the airflow on both

sides of the evaporator coil.

3. Using an inclined manometer, determine the pressure drop

across a dry evaporator coil. Since the moisture on an

evaporator coil may vary greatly, measuring the pressure

drop across the wet coil under field conditions would be

inaccurate. To assure a dry coil, the refrigerant system

should be de-activated while the test is being run.

4. Knowing the pressure drop across a dry coil, the actual

CFM through the unit can be determined from the curves

shown in Figure 12.

If the CFM is above or below the specified value, the supply air

motor pulley may have to be readjusted. After one hour of

operation, check the belt and pulleys for tightness and

alignment.

Fixed Blower Sheave Belts

Pitch

Diameter

(in.)

Bore (in.) Qty.

Pitch

(in.)

Bore

(in.)

Model

Number

COIL SECTION

EVAPORATOR

COIL

FILTERS

7.00

7.00

DRILL Ø 5/16”

Figure 11: Hole Location For Pressure Drop Reading

Pitch

Length

(in.)

4.50

Designation

4.50

DRILL Ø 5/16”

Failure to properly adjust the total system air quantity

can result in extensive blower damage.

After readings have been obtained, remove the tubes and seal

up the drilled holes in the side panel. 5/16 inch dot plugs (P/N

029-12880) are available through normal York parts orderin g

procedures.

Johnson Controls Unitary Products 27

Page 28

520413-BIM-A-0209

0.60

0.50

0.40

0.30

0.20

PRESSURE DROP (IWG)

PRESSURE DROP ACROSS

A DRY INDOOR COIL VS. SUPPLY AIR CFM

NH/NJ-10

NH/NJ-15

NH-07

NH/NJ-20

0.10

0.00

012345678910

NOMINAL CFM SUPPLY AIR

Figure 12: Pressure Drop Across A Dry Indoor Coil vs. Supply Air CFM

Thousands

28 Johnson Controls Unitary Products

Page 29

Belt Tension

The tension on the belt should be adjusted as shown in Figure

13.

BELT TENSIONING BOLT

(A)

(A)

(B)

LOCK NUT

(C)

(A)

520413-BIM-A-0209

Procedure for adjusting belt tension:

1. Loosen four nuts (top and bottom) of the Belt Adjust/

Motor Mounting Bracket (A).

2. Loosen Lock Nut (C).

3. Adjust by turn Belt Tensioning Bolt (B).

4. Use belt tension checker to apply a perpendicular

force to one belt at the midpoint of the span as

shown. Deflection distance of 4mm (5/32”) is

obtained.

To determine the deflection distance from normal

position, use a straight edge from sheave to sheave

as reference line. The recommended deflection force

is as follows:

Tension new belts at the max. deflection force

recommended for the belt section. Check the belt

tension at least two times during the first 24 hours of

operation. Any retensioning should fall between the

min. and max. deflection force values.

5. After adjusting re-tighten nuts (A) and Lock Nut (C).

DEFL. FORCE

SPAN LENGTH

Figure 13: Belt Adjustment

Twin Belt Drive Adjustment

Check to see if both belts drive at the same speed. Do this by

making a mark across both belts. Turn the drive several

revolutions by hand. If the mark has not separated, the belts are

traveling at the same speed.

Twin groove blower motor pulleys should be installed with the

shaft set screw (A) towards the motor (see Figure 14).

B

A

C

Figure 14: Double Groove Pulley

B

E

D

C

STATIONARY WEB

If necessary to align pulleys, the housing of the twin groove

motor pulley may extend 25% of its length beyond end of motor

shaft.

Always align twin groove pulleys using the stationary web.

The blower motor pulleys are adjustable by half turns. Select

required RPM from table 5 and adjust pulley.

Johnson Controls Unitary Products 29

Page 30

520413-BIM-A-0209

Sequence of Operation

Continuous Blower

By setting the room thermostat to "ON," the low voltage control

circuit from the "R" to "G" is completed and the supply air

blower will operate continuously.

Intermittent Blower

With the room thermostat fan switch set to "AUTO" and the

system switch set to either the "AUTO" or "HEAT" settings, the

blower is energized whenever a cooling or heating operation is

requested. The blower is energized after any specified delay

associated with the operation.

Cooling Sequence of Operation

Single Stage Indoor Unit Matched with a Single Stage

Condensing Unit

When the thermostat calls for cooling, the low voltage control

circuit from "R" to "Y1" and "G" is completed. The Simplicity™

control board activates cooling by energizing the compressor

and condenser fans of the condensing unit. After completing

the specified fan on delay for cooling , th e Si mpl i ci ty™ co ntrol

board will energize the indoor blower motor.

Two Stage Indoor Units Matched with a Two Stage

Condensing Unit

When the thermostat calls for the first stage of cooling, the low

voltage control circuits from "R" to "Y1", "G1" and "S1" is

completed. The Simplicity™ control board activates the first

stage of cooling by energizing the System #1 liquid line

solenoid of the indoor unit and the System #1 compressor and

condenser fans of the condensing unit. After completing the

specified fan on delay for cooling, the Simplicity™ control board

will energize the indoor blower motor (Note: Both Terminals G1

and G2 need to be jumped together).

When the thermostat calls for the second stage of cooling, the

low-voltage control circuit from "R" to "Y2" and "S2" is

completed. The Simplicity™ control board activates the second

stage of cooling by energizing System #2 liquid line solenoid of

the indoor unit and the System #2 compressor and condenser

fans of the condensing unit.

If there is an initial call for both stages of cooling, the

Simplicity™ control board will delay energizing compressor #2

by 30 seconds in order to avoid an excessive power rush.

The jumper between G1 and G2 must be removed on the T2

terminal block. Both G1 and G2 will provide 24V signals to

operate their respective indoor fan motors.

When a thermostat calls for cooling, the Simplicity™ control

board energizes the appropriate compressor and condenser

fans. Fan #1 will start immediately upon the call for cooling.

However, the control circuit for fan #2 is equipped with a fan

cycling switch that operates the fan in the 180-280 psig head

pressure range.

When the second thermostat calls for cooling, the Simplicity™

control board energizes the appropriate compressor and

condenser fans. Fan #3 will start immediately upon the call for

cooling. However, the control circuit for fan #4 is equipped with

a fan cycling switch that operates the fan in the 180-280 psig

head pressure range.

Once a call for cooling has been satisfied, the Simplicity™

control board will de-energize the respective Y1 or Y2 signal. If

the associated compressor has satisfied its minimum run time,

it is de-energized along the system's condenser fans. If both

calls for cooling have been satisfied, the Simplicity™ control

board will de-energize the other signal. If the associated

compressor has satisfied its minimum run time, it and its

associated condenser fans are de-energized. Otherwise, the

unit operates each compressor and condenser fans until the

ASCD has elapsed.

The appropriate blower is stopped following the completion of

the fan off-delay cycle.

Maintenance

Filters must be cleaned or replaced as often as necessary to

assure good airflow and filtering action.

To remove filters through the side of the unit, remove the solid

side panel on the piping end.

To remove the filters from the front of the unit, open access

panel. The filters can be lifted out through the access panel.

The drain pan should be inspected regularly to assure proper

drainage.

Blower bearings and motor bearings are permanently

lubricated.

Two Single Stage Indoor Units Matche d with a Two Stage

Condensing Unit

Two appropriately sized indoor units can operate with a single,

4-pipe condensing unit. Each indoor unit must be controlled by

a single-stage thermostat. One thermostat will connect to Y1 on

the condensing unit Simplicity™ control board and the other

thermostat will connect to Y2.

30 Johnson Controls Unitary Products

Page 31

Top View

520413-BIM-A-0209

Ø 1.38 KNOCKOUT

ELECTRIC HEAT CONNECTION

4.68

18.44

15.63

TOP VIEW - BLOWER OUTLET

NH-07 INDOOR

20.19

5.10

13.44

4.68

Front and Side View

Ø 1.38 KNOCKOUT

ELECTRIC HEAT

CONNECTION

18.44

2.59

5.09

Ø 1.09 KNOCKOUT

POWER ACCESS

Ø 0.88 KNOCKOUT

CONTROLS ACCESS

18.60

TOP VIEW - BLOWER OUTLET

NH/NJ-10 INDOOR

9.06

30.00

17.62

5.08

15.90

56.16

FRONT VIEW - RETURN AIR

NH-07 / -10 & NJ-10 INDOOR

Figure 15: Unit Dimensions NH-07 Thru -10 & NJ-10

66.09

65.00

7.43

35.00

SYSTEM 2

20.34

SYSTEM 1*

2.00

2.0053.44

DRAIN CONNECTION

3/4 PVC PIPE CONNECTIONS

RIGHT SIDE VIEW - DRAIN PIPING/CONTROLS

*SYSTEM 1 USED FOR 2-PIPE DIMENSIONS

6.44

5.54

6.54

4.16

FIELD PIPING

CONNECTIONS

10.14

9.84

1.42

11.87

12.23

Johnson Controls Unitary Products 31

Page 32

520413-BIM-A-0209

Top View

10.23

Ø 1.38 KNOCKOUT

ELECTRIC HEAT CONNECTION

24.71

21.58

TOP VIEW - BLOWER OUTLET

NH/NJ-15 INDOOR

Front and Side View

5.09

2.59

9.06

26.46

3.44

18.91

33.00

71.94

74.66

FRONT VIEW - RETURN AIR

NH/NJ-15 INDOOR

Figure 16: Unit Dimensions NH/NJ-15

27.34

2.00

2.00

76.09

75.00

42.00

Ø 1.09 KNOCKOUT

POWER ACCESS

Ø 0.88 KNOCKOUT

CONTROLS ACCESS

SYSTEM 2

SYSTEM 1*

DRAIN CONNECTION

3/4 PVC PIPE CONNECTIONS

RIGHT SIDE VIEW - DRAIN PIPING/CONTROLS

*SYSTEM 1 USED FOR 2-PIPE DIMENSIONS

7.43

6.54

6.44

5.54

4.16

FIELD PIPING

CONNECTIONS

10.14

9.84

1.42

11.87

12.23

32 Johnson Controls Unitary Products

Page 33

Top View

520413-BIM-A-0209

5.56

Ø 1.38 KNOCKOUT

ELECTRIC HEAT CONNECTION

23.47

18.63

TOP VIEW - BLOWER OUTLET

NH/NJ-20 INDOOR

Front and Side View

18.63

5.09

2.59

54.65

Ø 1.38 KNOCKOUT

ELECTRIC HEAT CONNECTION

9.06

30.00

25.37

23.62

4.94

5.11

15.90

2.00

95.94

98.66

FRONT VIEW - RETURN AIR

NH/NJ-20 INDOOR

Figure 17: Unit Dimensions NH/NJ-20

45.97

65.00

35.00

20.34

2.00

2.00

Ø 1.09 KNOCKOUT

POWER ACCESS

Ø 0.88 KNOCKOUT

CONTROLS ACCESS

66.10

SYSTEM 2

SYSTEM 1*

DRAIN CONNECTION

3/4 PVC PIPE CONNECTIONS

RIGHT SIDE VIEW - DRAIN PIPING/CONTROLS

*SYSTEM 1 USED FOR 2-PIPE DIMENSIONS

7.43

6.44

5.54

6.54

4.16

FIELD PIPING

CONNECTIONS

10.14

9.84

1.42

11.87

12.23

Johnson Controls Unitary Products 33

Page 34

520413-BIM-A-0209

35.00

HORIZONTAL VIEW

30.00

42.00

60.00

61.09

TYPICAL NH-07, -10, -20 and NJ-10, -20 HORIZONTAL CONFIGURATION

33.00

33.00

66.00

[

TYPICAL NH/NJ-15 HORIZONTAL CONFIGURATION

Figure 18: Typical Horizontal Configuration

34 Johnson Controls Unitary Products

Page 35

520413-BIM-A-0209

Table 19: Unit Connections

MODEL NH-07 NH-10 NJ-10 NH-15 NJ-15 NH-20 NJ-20

SYSTEM DATA

No. Refrigeration Circuits 1 1 2 1 2 1 2

Suction Line OD (in.) 1 1/8 1 3/8 1 1/8 1 5/8 1 1/8 1 5/8 1 3/8

Liquid Line OD (in.) 5/8 7/8 5/8 7/8 5/8 7/8 7/8

Power Wiring Knockout 1 1 1 1 1 1 1

Control Wiring Knockout 7/8 7/8 7/8 7/8 7/8 7/8 7/8

Electric Heat Wiring Knockout 1 3/8 1 3/8 1 3/8 1 3/8 1 3/8 1 3/8 1 3/8

Drain Line Fitting PVC Stub 3/4 3/4 3/4 3/4 3/4 3/4 3/4

BLOWER OUTLET

Number 1111122

Width 13.4 15.9 15.9 18.9 18.9 15.9 15.9

Length 15.6 18.6 18.6 21.6 21.6 18.6 18.6

RETURN AIR INLET

Width 20.3 20.3 20.3 27.3 27.3 20.3 20.3

Length 53.4 53.4 53.4 71.9 71.9 95.9 95.9

1

1. 1 in. blower duct flange shipped with air handler.

Johnson Controls Unitary Products 35

Page 36

520413-BIM-A-0209

Typical Wiring Diagrams

Air Handling Units

Typical NH-07 Wiring Diagram

36 Johnson Controls Unitary Products