Johnson Controls NexusPremier 25 Ton, NexusPremier 50 Ton, NexusPremier 30 Ton, NexusPremier 40 Ton Technical Manual

Page 1

TECHNICAL GUIDE

NexusPremier™ Rooftop Units

25–50 Tons

5513350-JTG-1018

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

LD26877

Page 2

5513350-JTG-1018

Table of Contents

Product Highlights and Options .............................................................................................................................................. 2

Component Location ..............................................................................................................................................................4

Features and Benets ............................................................................................................................................................5

Nomenclature .........................................................................................................................................................................9

Selection Procedure Examples ............................................................................................................................................12

Physical Data........................................................................................................................................................................15

Capacity Performance .......................................................................................................................................................... 19

Airow Performance .............................................................................................................................................................62

Electrical Data ......................................................................................................................................................................67

Controls ................................................................................................................................................................................72

Weights and Dimensions ......................................................................................................................................................84

Unit Placement ...................................................................................................................................................................109

Guide Specications ........................................................................................................................................................... 111

Product Highlights and Options

• Efciency

• 2023 DOE efficiency as standard

• Integral energy recovery wheel (ERW) option

• Optional variable speed drive compressors

• Standard direct drive plenum (DDP) supply fan

• Flexibility

• 208-230, 460, or 575 VAC, 3 phase, 60 Hz

• Cooling only units with heating options including

gas, electric, steam or hot water with modulation

• Exhaust or return fan options

• Various airflow path configurations for discharge

and return/exhaust air

• Optional humidifier, sound attenuator, or air blender

• Low ambient temperature option

• Variable frequency drive (VFD) options on all

fans (Figure 1)

2

Figure 1: VFD Displays

Johnson Controls

LD27639

Page 3

Product Highlights and Options (Continued)

5513350-JTG-1018

• Reliability and Serviceability

• Multiple refrigeration circuits

• Coil corrosion protection option

• Convenience outlet option

• Optional viewports

• Single point latching door option

• Internal air handler light option

• Replaceable core filter drier option

• Suction, liquid, and discharge line shutoff valve

options

• Pressure transducer options

• Start-up wizard

• Indoor Environmental Quality

• Double wall construction with foam insulation

• Modulating hot gas reheat (HGRH) option

• Final filtration options, including high efficiency

particulate air (HEPA) filters

• Ultraviolet (UV) lights option (Figure 2)

• Controls

• 5.5-inch, 5 row × 35 character (256 × 64 dot matrix) organic light-emitting diode (OLED) display

with full numeric keypad and navigation buttons

as standard

• Optional WiFi hotspot capability via a mobile ac-

cess portal (MAP) device provides additional unit

control when it is not always possible to physi-

cally access the unit

• Smart Equipment technology enabling self-discovery on Verasys™ Building Automation Sys-

tems (BAS)

• The controller supports the BACnet

®

cation protocol and is designed and certified by

BACnet Testing Laboratory (BTL) to meet the requirements of the advanced application control

profile

• Twinning algorithms to allow multiple units to

function as one on common supply and return

duct shafts

• Variable air volume (VAV) and single zone VAV

(SZVAV) control

• Building pressurization controls

communi-

• Stainless steel drain pan

• Condensate overflow switch option

• Airflow measurement options for outside air, sup-

ply fan, and return fan

LD27640

Figure 2: UV Lights

Johnson Controls

3

Page 4

5513350-JTG-1018

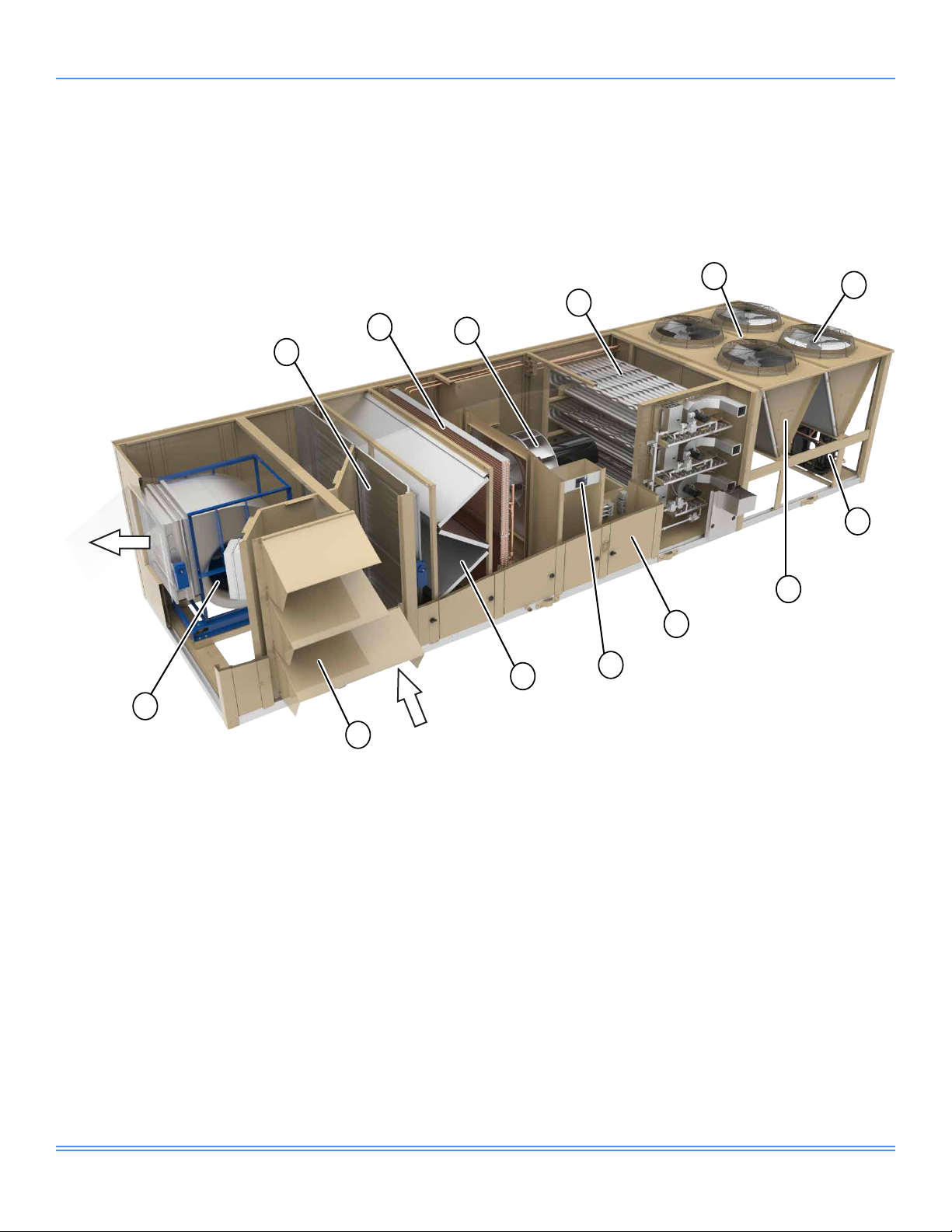

Component Location

Exhaust Air

13

5

4

2

1

3

8

9

11

10

6

7

12

1. Economizer

2. Evaporator coil

3. Direct drive plenum (DDP) supply fan

4. Modulating or staged gas heat

Figure 3: 25–50 Ton Packaged Rooftop Unit Cabinet Assembly

4

Outside Air

5. Condenser maintenance safety tie-off

6. Condenser fans

7. Scroll compressors

8. Condenser coil cleaning hatch

LD26878

9. Double wall construction

10. Unit controller

11. Filter section

12. Collapsible rain hoods

13. Exhaust/return fan

Johnson Controls

Page 5

5513350-JTG-1018

Features and Benefits

General

The 25–50 ton packaged rooftop platform is designed with

all the flexibility needed for today’s applications but with

tomorrow's requirements in mind. Realizing that efficiency

requirements are continuously pushing the envelope of

technology, the NexusPremier™ delivers today the energy

efficiency levels exceeding those mandated by the U.S.

Department of Energy for 2023. All cooling only and electric heat units have an integrated energy efficiency ratio

(IEER) in excess of 13.2. All units with gas or hydronic heat

have an IEER in excess of 13. For these particular rooftop

units, when equipped with a variable speed drive compressor, they deliver efficiency levels in excess of those suggested by the highest tier of the Consortium of Energy Ef-

ficiency (CEE) for 2019.

The NexusPremier is also designed for serviceability. With

small details—such as a maintenance safety tie-off (Item 5 in

Figure 3) on the roof of the condenser section that complies

with OSHA requirements, along with a single handle latching

mechanism for doors—the unit was designed for easy service. Options to make the unit serviceable include a convenience outlet to power lights and tools; internal lights in the air

handler section; viewports in doors of serviceable compartments to enable easier unit inspection; and extended grease

lines to simplify fan bearing lubrication for belt-driven fans.

Standard direct drive supply fan (Item 3 in Figure 3) do not

require lubricating fan bearings or changing belts. Numerous

refrigeration options are also available, including replaceable

core filter driers, liquid and suction isolation valves, as well as

high and low pressure transducers in each circuit that enable

easier sub-cooling and superheat measurements.

Besides options, there are also standard features to ensure

straightforward and safe servicing of the units, including

coil cleaning hatches (Item 8 in Figure 3) in the condenser

section to make cleaning condenser coils effortless, and

door safety latches to keep doors safe when opened in a

pressurized compartment. A discrete high and low voltage

compartment minimizes the amount of safety equipment re-

quired when only the low voltage compartment is accessed.

Selection Navigator is an online program available to assist in providing unit selections, performance reports, and

outputs to assist in design of the unit. Certain options may

require the assistance of the local sales office.

In order to facilitate its application, Selection Navigator

also provides building information modeling (BIM) files of

the specific unit selected. This aids in modeling placement

and integration of the rooftop unit into the overall building

design.

This packaged rooftop product is a sophisticated, highly

configurable rooftop unit. A controller is standard on each

unit with specific sequences of operation correlated to the

options selected. The Selection Navigator provides the

specific sequences of operation for the unit options select-

ed, eliminating confusion of the unit's capability.

Although the many options make customizing unlikely, it is

possible to have custom mechanical and sequences of operations designed into the unit from the factory for ultimate

convenience and reliability.

1. Economizer (Item 1 in Figure 3)

In order to deliver maximum efficiency, rooftop units

need an efficient economizer. The rooftop unit offers

various options for economizer control and fault de-

tection, as well as damper leakage rates and cycle

life to meet different regulatory requirements.

The amount of fresh air can also be optionally measured to ensure and record appropriate fresh air to

the conditioned space. An air blender option is also

available to deliver optimal comfort to the conditioned

space.

2. Refrigeration System (Items 2, 6, and 7 in Figure 3)

The refrigeration system is built to reliably deliver

cooling through a variety of loads. Two independent

refrigeration circuits ensure that in the unlikely event

of a compressor failure, the second circuit can still deliver cooling to the space. An interlaced tube and fin

evaporator provide maximum cooling performance

even at part loads. The microchannel condenser re-

duces the risk of refrigerant leaks and minimizes the

amount of refrigerant in the unit.

Standard fixed speed scroll compressors of different sizes deliver excellent part-load efficiency and

control, which eliminates the need for inefficient hot

gas bypass valves at low load conditions. Optional

variable speed drive scroll compressor configurations are available for stable and efficient discharge

air temperature (DAT) control regardless of the load.

For application flexibility, optional corrosion protection is available for the evaporator and condenser, as

well as intrusion protection options for the condenser.

Realizing that the refrigeration system is the heart

of the rooftop, when optionally equipped with transducers, the unit controller can display sub-cooling or

superheat. Additionally, low ambient operation is an

available option with a variable speed condenser fan.

Johnson Controls

5

Page 6

5513350-JTG-1018

Features and Benefits (Continued)

Maximized serviceability is also available with options such as replaceable core filter driers as well as

discharge, liquid, and suction line isolation valves.

The standard unit is equipped with accessible sight

glasses to verify proper refrigerant flow as well as

conveniently located condenser coil cleaning hatches to facilitate maintenance.

3. Direct Drive Plenum (DDP) Supply Fan (Item 3 in

Figure 3)

A direct drive plenum (DDP) supply fan (Figure 4)

provides outstanding reliability and efficiency, such

as eliminating the possibility of interrupting condi-

tioned air supply due to a broken belt or polluting

conditioned air with belt dust. The supply fan can

be optionally equipped with an airflow measurement

station to precisely measure the amount of air delivered to the conditioned space.

LD27636

Figure 4: DDP Supply Fan

The speed of the supply fan is controlled by a vari-

able frequency drive (VFD). A redundant VFD is

optionally available to ensure uptime in the unlikely

event of a VFD failure.

4. Heating Options (Item 4 in Figure 3)

Gas heat options are available either in staged or

modulating control. The flexibility of heater sizes

meets the specific application heating needs. Electric

heat is also available with size and staging/modulating options (Figure 5). Either hot water or steam heat

options are also available. All modulating heat options can be controlled precisely to temper the sup-

ply air, which is especially important when fresh air is

needed in cold climates.

5. Double Wall Construction (Item 9 in Figure 3)

The air handler section of the rooftop unit provides

foam injected double wall construction for maximum

unit rigidity and cleanability of the interior surfaces

for long term indoor air quality (IAQ). This construction of the walls, roof, and floor provides an insulating

value that minimizes unit sweating and contributes to

the overall unit efficiency.

LD27637

Figure 5: Electric Heat

6. Controls System (Item 10 in Figure 3)

The rooftop unit’s sophisticated options are intelligently controlled by a best-in-class controls platform

built exclusively for this application.

A 5.5-inch, 5 row × 35 character (256 × 64 dot matrix)

organic light-emitting diode (OLED) display (Figure

6) with full numerical and optimized navigational key-

pad, conveniently located in the low voltage compartment, is the nerve center. The control system can be

optionally augmented with a WiFi hotspot capability

for local or line-of-sight smart device control.

The control platform minimizes commissioning time

when connected to the Verasys™ Building Automation Systems (BAS), with self-discovery of the rooftop

unit and its points by the BAS.

6

Johnson Controls

Page 7

5513350-JTG-1018

Features and Benefits (Continued)

The unit controller has sequences of operation for

standalone applications. These sequences cover

simple applications such as single zone variable air

volume (SZVAV) control of the supply fan and compressors in accordance with ASHRAE 90.1-2016,

as well as demand control ventilation (DCV) that

ensures adequate fresh air to the building. Complex

applications are also supported, like the twinning of

multiple rooftops on a common supply and return

duct shaft for the ultimate in redundancy for critical

spaces, such as Medical Office Buildings (MOBs).

7. Blank Section (Figure 7)

Blank sections can be provided for field installed ac-

cessories or to accommodate the installation of specific factory components including an air blender, final filters, humidifier, or sound attenuator.

The rooftop unit can be equipped with a final filter

before the conditioned air is delivered from the rooftop into the supply duct. Various final filter options

are available to meet critical needs including high ef-

ficiency particulate air (HEPA) filtration. Differential

pressure measuring options can be supplied to meet

the requirements for ASHRAE 170-2017.

For cold northern climates where heat tends to dry

out the supply air, a humidifier option with a stainless

steel drain pan is also available.

In order to mitigate sound originating in the rooftop unit

from reaching the conditioned space, optional sound

attenuators in the rooftop unit can be factory-installed.

8. Exhaust/Return Fan (Item 13 in Figure 3)

The rooftop units enable installation flexibility with the

option of either exhaust or return fan to control the

building static pressure. Return ductwork with shorter runs and lower static requirements usually only

need an exhaust fan. The return fan is available to

overcome the static imposed by longer return ducts.

Refer to the Variable Air Volume for Rooftop Units

Application Guide (Form 5515844-JAD).

Figure 6: OLED Display

Figure 7: Final Filter Section

Final Filters

Blank Section

LD27638

LD26881

Optional airflow measurement is available for units

equipped with a return fan. This makes it possible

to precisely understand and log the different airflows

through the rooftop unit.

9. Hot Gas Reheat (HGRH) (Figure 9)

Occupant comfort can be a challenge during shoul-

der months when low loads and high humidity occur.

In many cases, the combined efforts of refrigeration

system compressor multistep control, an interlaced

evaporator coil, and the supply fan modulation of SZVAV control are sufficient. The rooftop unit provides

an optional modulating hot gas reheat (HGRH) coil

to further reduce the humidity level within the space.

10. Indoor Air Quality (IAQ)

To meet the critical needs of IAQ, the rooftop unit

provides a stainless steel evaporator drain pan for

longevity and to facilitate cleanability. The drain pan

can be optionally equipped with an overflow switch to

warn of improper drainage and minimize the potential

for damage to the conditioned space. Ultraviolet (UV)

light banks are also an available option that minimize

mold and bacteria growth and assists in keeping the

evaporator coil clean.

Johnson Controls

7

Page 8

5513350-JTG-1018

Features and Benefits (Continued)

11. Energy Recovery Wheel (ERW) (Figure 8)

The rooftop unit provides an option for an energy re-

covery wheel (ERW) as an integral part of the unit.

This device uses exhaust air to condition the fresh

air brought into the unit and the conditioned space,

increasing the overall rooftop efficiency. As a factoryinstalled option, the ERW ensures reliability, minimizes field labor, and simplifies long-term maintenance

of the device.

12. Airow Flexibility

Whether a rooftop unit is mounted on a roof or on a

grade, the orientation of airflow from the rooftop to

the conditioned space and vice versa is important.

The NexusPremier was specifically designed to provide discharge airflow either at the bottom, top, left,

or right.

Similarly, the return airflow is designed for maximum

flexibility vertically in either direction as well as hori-

zontally in either direction. Depending on selected

options, an end return is also possible. This airflow

flexibility minimizes installation costs and maximizes

possible locations for this flexible rooftop unit.

Energy Recovery Wheel

LD26882

Figure 8: Energy Recovery Wheel (ERW)

8

Johnson Controls

Page 9

Nomenclature

5513350-JTG-1018

25–50 Ton Model Number

12345

6789101112131415161718192021222324252627282930313233343536373839404142434445464748

G V A 1 M – 1 B 1 A A – 1 A 6 0 A – A 2 4 1 B – F 2 B B H – 5 C 1 A 1 – B K A G 1 – 0 1 0 1 C – 0 1 0 B C – 0 0 0 1

Digits 1–2: Product Brand Name

GV: Johnson Controls

Digit 3: Capacity

A: 25 Ton

B: 30 Ton

C: 40 Ton

D: 50 Ton

Digit 4: Efficiency

1: Standard Capacity, Standard Efficiency

2: Std Capacity, High Efficiency

3: High Capacity, Std Efficiency

4: Std Capacity, Std Efficiency, Low Sound

5: Std Capacity, High Efficiency, Low Sound

6: High Capacity, Std Efficiency, Low Sound

Digit 5: Heat Source

A: Cooling Only

B: Staged Gas Aluminized Burner

C: Staged Gas Stainless Steel

G: Modulating Gas Stainless Steel

K: Steam Coil

L: Hot Water Coil

M: Electric Heat

Digit 6A: Electric Heat Capacity

0: None

1: Low Heat

3: High Heat

4: Low Heat with Silicon Controlled Rectifier

(SCR)

6: High Heat with SCR

Digit 6B: Natural Gas Heat Capacity

0: None

1: 250 MBH

2: 500 MBH

3: 750 MBH

5: 1,250 MBH

Digit 6C: Hot Water or Steam

Heating Coil Option

0: None

1: Low Heat without Valves

2: Low Heat with Valves

3: High Heat without Valves

4: High Heat with Valves

Digit 7: Unit Type

A: Single Zone VAV (SZVAV) (No Duct Pressure

Transducer)

B: Variable Air Volume (VAV) (Duct Pressure

Transducer)

Digit 8: Motor Control Options

1: Supply Fan Variable Frequency Drive (VFD)

2: Supply Fan VFD with Line Reactor

3: Supply Fan VFD with Bypass (Redundant

VFD)

4: Supply Fan VFD with Line Reactor and

Bypass (Redundant VFD)

5: Supply Fan VFD and Return/Exhaust Fan VFD

6: Supply Fan VFD with Line Reactor and

Return/Exhaust Fan VFD with Line Reactor

7: Supply Fan VFD and Return/Exhaust Fan

VFD with Bypass (Redundant VFD for Supply

Fan and Bypass for Return or Exhaust Fan)

8: Supply Fan VFD with Line Reactor and

Return/Exhaust Fan VFD with Line Reactor

with Bypass (Redundant VFD for Supply Fan

and Bypass for Return or Exhaust Fan

Digit 9: Voltage

A: 208-230 V 3Ph 60 Hz, Single Point Terminal

Block

B: 208-230 V 3Ph 60 Hz, Dual Point Terminal

Block

C: 208-230 V 3Ph 60 Hz, Single Point Non Fused DISC

D: 208-230 V 3Ph 60 Hz, Single Point Terminal

Block, 65KA Short-Circuit Current Rating (SCCR)

E: 208-230 V 3Ph 60 Hz, Dual Point Terminal

Block, 65KA SCCR

F: 208-230 V 3Ph 60 Hz, Single Point Non Fused DISC, 65KA SCCR

G: 460 V 3Ph 60 Hz, Single Point Terminal Block

H: 460 V 3Ph 60 Hz, Dual Point Terminal Block

J: 460 V 3Ph 60 Hz, Single Point Non-Fused

DISC

K: 460 V 3Ph 60 Hz, Single Point Terminal

65KA SCCR

L: 460 V 3Ph 60 Hz, Dual Point Terminal Block,

65KA SCCR

M: 460 V 3Ph 60 Hz, Single Point Non-Fused

DISC, 65KA SCCR

N: 575 V 3Ph 60 Hz, Single Point Terminal Block

P: 575 VA 3Ph 60 Hz, Dual Point Terminal Block

Q: 575 V 3Ph 60 Hz, Single Point Non-Fused

DISC

R: 575 V 3Ph 60 Hz, Single Point Terminal

65KA SCCR

S: 575 V 3Ph 60 Hz, Dual Point Terminal Block,

65KA SCCR

T: 575 V 3Ph 60 Hz, Single Point Non-Fused

DISC, 65KA SCCR

Block,

Block,

Digit 10: Return Configuration

A: Bottom Return, Right Outside Air (OA), Side

Exhaust

B: Bottom Return, Right OA, Front Exhaust

C: Bottom Return, Left OA, Side Exhaust

D: Bottom Return, Left OA, Front Exhaust

E: Top Return, Right OA, Side Exhaust

F: Top Return, Right OA, Front Exhaust

G: Top Return, Left OA, Side Exhaust

H: Top Return, Left OA, Front Exhaust

J: Left Return, Right OA, Front Exhaust

K: Right Return, Left OA, Front Exhaust

L: Front Return, Left OA, Right Exhaust

M: Front Return, Right OA, Left Exhaust

N: Bottom Return, No OA, No Exhaust Air (EA)

(No Return Fan Available)

P: Top Return, No OA, No EA (No Return Fan

Available)

Q: Left Return, No OA, No EA (No Return Fan

Available)

R: Right Return, No OA, No EA (No Return Fan

Available)

S: Front Return, No OA, No EA (No Return Fan

Available)

Digit 11: Discharge Locations

1: Bottom Discharge, from Discharge Plenum

2: Bottom Discharge, Discharge through Heat

Section

3: Top Discharge, from Discharge Plenum

4: Right Discharge, from Discharge Plenum

5: Left Discharge, from Discharge Plenum

6: Left Discharge, Discharge through Heat

Section

Digit 12: Supply Configuration

A: None

B: Small Blank

C, D: Large Blank

F:

Small Blank with Humidifier and Stainless Steel

(SST) Drain Pan

H, K: Large

L: Small Blank Sound Attenuator

M, N: Large Blank Sound Attenuator

P: Small Blank Final Filter

Q, T: Large Blank with Sound Attenuator and

S, V: Large Blank with Sound Attenuator and

Digit 13: Final Filter Options

1:

MERV 15 Bag Final Filters with 2-inch MERV 8

Filters

2: MERV 14 Rigid Final Filters with 2-inch MERV

8 Filters

3: MERV 17 High Efficiency Particulate Air

(HEPA) Final Filters with 2-inch MERV 8 Filters

4: MERV 14/15 Filter Rack (No Filters)

5: HEPA Filter Rack (No Filters)

6: None

Blank with Humidifier and SST Drain

Pan

Final Filter

Humidifier and SST Drain Pan

49

Johnson Controls

9

Page 10

5513350-JTG-1018

Nomenclature (Continued)

Digit 14: Final Filter Control Options

0: None

1: Combined Pre and Post Filter Transducer

2: Separate Pre and Post Filter Transducer

3: Combined Pre and Post Filter Transducer and

Combined Magnehelic Gauge

4: Separate Pre and Post Filter Transducer and

Magnehelic Gauge

5: Combined Pre and Post Filter Magnehelic

Gauge

6:

Separate Pre and Post Filter Magnehelic Gauge

7: Combined Pre and Post Filter Transducer,

Separate Pre and Post Filter Magnehelic Gauge

Digit 15: Supply Fan

A: Direct Drive Plenum (DDP) Supply Fan with

1-inch Spring Isolation

B: DDP Supply Fan with 2-inch Spring Isolation

C: DDP Supply Fan with 2-inch Spring Isolation

and Seismic Restraint

Digit 16: Supply Fan Motor

Horsepower

A: 5 HP

B: 7.5 HP

C: 10 HP

D: 15 HP

E: 20 HP

F: 25 HP

G: 30 HP

H: 40 HP

J: 50 HP

Digit 17: Supply Fan Motor Type

2: ODP Premium Efficiency 1,800 RPM

4: TEFC Premium Efficiency 1,800 RPM

Digit 18: Supply Fan Options

0: None

1: Inlet Guard

2: Airflow Measurement Station

3: Shaft Grounding Ring

4: Inlet Guard and Airflow Measurement Station

5: Inlet Guard and Shaft Grounding Ring

6: Airflow Measurement Station and Shaft

Grounding Ring

7: Shaft Grounding Ring, Inlet Guard and Airflow

Measurement Station

Digits 19: Building Pressure Control

0: None

1: Barometric Damper

2: Exhaust with VFD and Backdraft Damper

3: Modulating Damper (On/Off Exhaust Fan Only

without VFD)

4:

Modulating Damper (Return Fan Only with VFD)

Digit 20: Return/Exhaust Fan

A: None

B: Exhaust Fan with 1-inch Spring Isolation

C: Exhaust Fan with 2-inch Spring Isolation

D: Exhaust Fan with 2-inch Spring Isolation and

Seismic Restraint

E: Return Fan with 1-inch Spring Isolation

F: Return Fan with 2-inch Spring Isolation

G: Return Fan with 2-inch Spring Isolation and

Seismic Restraint

Digit 21: Return/Exhaust Fan Motor

Horsepower

A: None

E: 3 HP

F: 5 HP

G: 7.5 HP

H: 10 HP

J: 15 HP

K: 20 HP

Digit 22: Return/Exhaust Fan Motor

Type

0: None

2: ODP Premium Efficiency 1,800 RPM

4: TEFC Premium Efficiency 1,800 RPM

Digit 23: Return/Exhaust Fan

Options

A: None

B: Shaft Grounding Ring

C: Extended Grease Lines

D:

Extended Grease Lines and Shaft Grounding

Ring

E: Belt Guards

F: Belt Guards and Shaft Grounding Ring

G: Return Fan Airflow Measurement Station

H: Return Fan Airflow Measurement Station and

Shaft Grounding Ring

J: Extended Grease Lines and Belt Guards

K: Extended Grease Lines and Belt Guards

and Shaft Grounding Ring

L: Extended Grease Lines and Return Fan

Airflow Measurement Station

M: Extended Grease Lines and Return Fan

Airflow Measurement Station and Shaft

Grounding

N: Belt Guards and Return Fan Airflow

Measurement Station

P: Belt Guards and Return Fan Airflow Measure-

ment Station and Shaft Grounding Ring

Q: Extended Grease Lines and Belt Guards and

Return Fan Airflow Measurement Station

R: Extended Grease Lines and Belt Guards and

Return Fan Airflow Measurement Station and

Shaft Grounding Ring

Digits 24: Return/Exhaust Fan Drive

A: None

B–K: RPM

Digit 25: Evaporator Options

G: Aluminum Fin Evaporator with SST Drain Pan

H: Aluminum Fin Evaporator with SST Drain Pan

with Condensate Overflow Switch

J: E-Coat Aluminum Fin Evaporator with SST

Drain Pan

K: E-Coat Aluminum Fin Evaporator with SST

Drain Pan with Condensate Overflow Switch

L: Copper Fin Evaporator with SST Drain Pan

M: Copper Fin Evaporator with SST Drain Pan

with Condensate Overflow Switch

Digit 26: Condenser Coil Options

1: None

2: With Wire Guards

3: Full Louvered Panels

4: Partial Louvered Panels

5: E-Coat Condenser without Guards

6: E-Coat Condenser with Wire Guards

7: E-Coat Condenser, Full Louvered Panels

8: E-Coat Condenser, Partial Louvered Panels

Digit 27: Draw-Thru Filter Options

A: Angled Filter Rack, No Filters

B: Angled Filter Rack, 2-Inch Throwaway Filters

C: Angled Filter Rack, 2-Inch MERV 8 Filters

D: Rigid Filter Rack, No Filters

E: Rigid Filter Rack, MERV 15 Bag Filters with

2-Inch MERV 8 Pre-Filters

F: Rigid Filter Rack, MERV 14 Rigid Filters with

2-Inch MERV 8 Pre-Filters

G: Vertical Filter Rack, No Filters

H: Vertical Filter Rack, 4-Inch MERV 8 Filters

Digit 28: Draw-Thru Filter Control

Options

0: None

1: Combined Pre and Post Filter Transducer

2: Separate Pre and Post Filter Transducer

3: Combined Pre and Post Filter Transducer and

Combined Magnehelic Gauge

4: Separate Pre and Post Filter Transducer and

Magnehelic Gauge

5: Combined Pre and Post Filter Magnehelic

Gauge

6:

Separate Pre and Post Filter Magnehelic Gauge

7: Combined Pre and Post Filter Transducer,

Separate Pre and Post Filter Magnehelic Gauge

Digit 29: Economizer Options

A: None

C: Dry Bulb Economizer, Low Leak Dampers

D: Single Enthalpy Economizer, Low Leak

Dampers

E:

Dual Enthalpy Economizer, Low Leak Dampers

F: Dry Bulb Economizer, Low Leak Dampers

with Air Measurement Station

G: Single Enthalpy Economizer, Low Leak

Dampers with Air Measurement Station

H: Dual Enthalpy Economizer, Low Leak

Dampers with Air Measurement Station

K: Dry Bulb Economizer, Ultra Low Leak Dampers

L: Single Enthalpy Economizer, Ultra Low Leak

Dampers

S: Dual Enthalpy Economizer, Ultra Low Leak

Dampers

T: Dry Bulb Economizer, Ultra Low Leak

Dampers with Air Measurement Station

U: Single Enthalpy Economizer, Ultra Low Leak

Dampers with Air Measurement Station

V: Dual Enthalpy Economizer, Ultra Low Leak

Dampers with Air Measurement Station

10

Johnson Controls

Page 11

Nomenclature (Continued)

5513350-JTG-1018

Digit 30: Energy Recovery Options

0: None

1: Low CFM Energy Recovery Wheel (ERW)

without VFD

2: Low CFM ERW with VFD

3: High CFM ERW without VFD

4: High CFM ERW with VFD

Digit 31: Refrigeration System

Piping Options

A: None

B: Suction and Discharge Valves

C: Suction, Discharge, and Liquid Valves

D: Suction, Discharge, and Liquid Valves with

Replaceable Core Filter Driers

E: Hot Gas Reheat (HGRH)

F: Suction and Discharge Valves with HGRH

G: Suction, Discharge, and Liquid Valves with

HGRH

H: Suction, Discharge, and Liquid Valves with

Replaceable Core Filter Driers with HGRH

N: E-Coat HGRH

P: Suction and Discharge Valves with E-Coat

HGRH

Q: Suction, Discharge, and Liquid Valves with

E-Coat HGRH

R: Suction, Discharge, and Liquid Valves with

Replaceable Core Filter Driers with E-Coat

HGRH

Digit 32: Lights/Detectors/Conve-

nience Options

A: None

B: Convenience Outlet

C: Convenience Outlet and Internal Lights

D: Supply Smoke Detector

E: Return Smoke Detector

F: Supply and Return Smoke Detector

G: Convenience Outlet with Supply Smoke

Detector

H: Convenience Outlet with Return Smoke

Detector

J: Convenience Outlet with Supply and Return

Smoke Detectors

K: Convenience Outlet and Internal Lights with

Supply Smoke Detector

L: Convenience Outlet and Internal Lights with

Return Smoke Detector

M: Convenience Outlet and Internal Lights with

Supply and Return Smoke Detectors

Digit 33: Controls Options

A: None

B: Low Ambient

D: Subcool and Superheat Measurement

E: Low Ambient with Subcool and Superheat

Measurement

Digit 34: Interface Options

A: BACnet® MS/TP, Modbus™, N2

B: BACnet IP

G: BACnet® MS/TP, Modbus™, N2 with Mobile

Access Portal (MAP)

H: MAP with BACnet IP

N: BACnet® MS/TP, Modbus™, N2 with Building

Automation System (BAS) Interface Board

P: BACnet IP with BAS Interface Board

U: BACnet® MS/TP, Modbus™, N2 with MAP and

BAS Interface Board

V: MAP with BACnet IP and BAS Interface Board

Digit 35: Indoor Air Quality (IAQ)

Options

0: None

1: Ultraviolet (UV) Lights

2: Carbon Dioxide (CO2) Sensors, Demand

Controlled Ventilation

3: UV Lights and CO2 Sensors

Digit 36: Gas Heat Shipped Loose

Kits

0: None

1: Gas Heat, Side Penetration

2: Gas Heat, Bottom Penetration

3: Gas Heat, High Altitude Kit Natural Gas (NG),

Side Penetration

4: Gas Heat, High Altitude Kit NG, Bottom

Penetration

5: Gas Heat, High Altitude Kit Liquid Propane

(LP), Side Penetration

6: Gas Heat, High Altitude Kit LP, Bottom

Penetration

7: Gas Heat, LP Conversion Kit, Side Penetra-

tion

8: Gas Heat, LP Conversion Kit, Bottom

Penetration

Digit 37: Security Options

0: None

1: Supply and Return Opening Burglar Bars

Digit 38: Door Options

0: None

1: Viewport

2: Single Handle with Padlock

3: Single Handle with Padlock and Viewport

Digit 39: Cabinet Shipping Options

1: Single Piece Construction

Digit 40: Curb Options

A: No Roof Curb

C: Pedestal Curb

Digit 41: Pre-Evap Options

0: None

1, 2: Blank Pre-Evap Extension, No Air Blender

3, 4: Blank Pre-Evap Extension, with Air Blender

Digit 42: Shipped Loose Options

0: None

1: Spare Belts for Return/Exhaust

Digit 43: Construction Standard

0: None

Digit 44: Supply Fan VFD Frequency

A–Z: Internal Use Only

Digit 45: Supply Fan Brake

Horsepower

A–L: Internal Use Only

Digit 46: Future 3

0: None

Digit 47: Future 4

0: None

Digit 48: Testing and Special

Quotation (SQ)

0: None

T: Record Test Report

M: Mechanical Special

1: Mechanical Special and Record Test Report

S: Software Special

3: Software Special and Record Test Report

B: Mechanical and Software Special

5: Mechanical and Software Special and Record

Test Report

Digit 49: Generation/Revision Level

1: First Generation

Johnson Controls

11

Page 12

5513350-JTG-1018

Selection Procedure Examples

GIVEN:

Required Cooling Capacity 290,000 Btuh

Required Sensible Cooling 210,000 Btuh

Required Heating 180,000 Btuh

Entering Air on Evaporator 80.0°F dry bulb (DB)/

67.0°F wet bulb (WB)

Outside Design Temperature 95.0°F

Supply Fan CFM 12,000 CFM

External Static Pressure (ESP) 3.72 iwg

Electrical Supply Voltage 460-3-60

Economizer Required

2-inch Throwaway Filters

Variable Air Volume (VAV)

Calculating Cooling/Heating Capacity

1. Assume that the required cooling capacity and required sensible capacity include the space load requirements as well as the ventilation load requirements.

2. Calculate the supply fan motor heat Btuh addition.

d. Refer to Table 6 on page 28, and find the ca-

pacity of units that meet 331.0 total cooling ca-

pacity (TMBH) and 210 sensible cooling capacity

(SMBH) at 12,000 CFM, 95.0°F ambient, 80.0°F

entering dry bulb (EDB), and 67.0°F entering wet

bulb (EWB) onto the coil. A 30-ton unit can pro-

duce 362 TMBH and 287 SMBH.

e. Calculate the leaving air temperature.

1. Calculate sensible unit capacity with motor

heat included.

• Sensible Btuh = 287 MBH - 41.0 MBH

= 246.0 MBH

2. Calculate dry bulb supply air temperature

(SAT).

• Sensible Btuh = CFM x 1.085 x ∆T

• ∆T = 246,000 Btuh / (12,000 CFM x

1.085)

• ∆T = 18.9°F

• Dry bulb SAT = entering air tempera-

ture – ∆T

a. See Select Fan Speed and Horsepower Require-

ments for Supply Fan on page 13 to determine

the horsepower (HP) of the supply fan. The example is based on a 14.91 HP requirement.

b. Calculate sensible Btuh addition as a result of the

supply fan HP.

• Supply fan sensible Btuh addition = 14.91

HP x 2,750 (constant for motor heat calculation)

• Supply fan sensible Btuh addition = 41,003

Btuh

c. Calculate the total capacity requirement.

• Total capacity = required cooling capacity

(Btuh) + supply fan motor HP (Btuh)

• Total capacity = 290,000 Btuh + 41,003 Btuh

• Total capacity = 331,003 Btuh

• Dry bulb SAT = 80.0°F – 18.9°F = 61.1 °F

3. Calculate enthalpy delta.

• Total capacity Btuh = CFM x 4.5 x ∆h

• ∆h = 363,000 Btuh / (12,000 CFM x 4.5)

• ∆h = 6.7 Btu/lb

4. Calculate wet bulb SAT.

• Leaving enthalpy = enthalpy entering –

enthalpy delta (reference psychometric

chart to convert unit wet bulb temperature to Btu/lb)

• Leaving enthalpy = 31.6 Btu/lb – 6.7

Btu/lb

• Leaving enthalpy = 24.9 Btu/lb

• Wet bulb SAT = 57.7°F

5. Leaving air temperature = 61.1°F / 57.7°F

The 30 ton unit will meet the cooling requirements.

From the nomenclature, digit 3 will be B for 30 ton

capacity. Digit 4 will be 1 for standard capacity, stan-

dard efficiency as assumed.

12

Johnson Controls

Page 13

5513350-JTG-1018

Selection Procedure Examples (Continued)

3. For gas heating capacity, reference Table 16 on page

57.

a. If the unit being selected will use gas heat, refer

to Table 16. Trace down to the output column.

b. Find the output that exceeds the 180,000 Btuh

requirement.

The 250 MBH output exceeds this requirement.

c. This option is available on the 30 ton unit.

From the nomenclature, select digit 5, option B for

staged gas, option C for staged gas with stainless

steel burner, or option G for modulating gas with

stainless steel burner.

From digit 6B, select option 1 for 250 MBH. The re-

sulting model number will show C1 for digits 5 and 6,

assuming staged gas with stainless steel burner was

selected.

4. For electric heating capacity, reference Table 17 on

page 58.

a. If the unit being selected will use electric heat, re-

fer to Table 17. Trace down to the output column.

b. Find the output that exceeds the 180,000 Btuh

requirement at the given 460-3-60 voltage.

The 60 kW output exceeds this requirement.

c. This option is available on the 30 ton unit.

From the nomenclature, select digit 5, option M for

electric heat.

From digit 6A, select either option 1 with low staged

electric heat or option 4 with low silicon controlled

rectifier (SCR) electric heat. The resulting model

number will show M4 for digits 5 and 6, assuming

low SCR electric heat was selected.

5. For steam heating capacity for a 30 ton unit, reference

Table 22 on page 60 and Table 23 on page 61.

a. Assume the unit being selected will use a 10 psig

steam supply.

b. Find the output that exceeds the 180,000 Btuh

requirement with 12,000 CFM and 10 psig.

From the nomenclature, select digit 5, option K for

steam coil.

From digit 6C, select either option 1 for low heat without valves or option 2 for low heat with valves. The

resulting model number will show K2 for digits 5 and

6, assuming the unit is field provided with valves.

6. For hot water heating capacity for a 30 ton unit, refer-

ence Table 18 on page 58 and Table 19 on page

59.

a. Assume a hot water supply temperature of

140.0°F and 20 GPM.

b. Find the output that exceeds the 180,000 Btuh

requirement with 12,000 CFM at 140.0°F and 60

GPM.

The low heat option on Table 18 exceeds this re-

quirement.

c. This option is available on the 30 ton unit.

From the nomenclature, select digit 5, option L for hot

water coil heat.

From digit 6C, select either option 1 for low heat without valves or option 2 for low heat with valves. The

resulting model number will show L2 for digits 5 and 6,

assuming the unit is field provided with valves.

Select Fan Speed and Horsepower

Requirements for Supply Fan

1. Reference Table 27 on page 64 for the 30 ton unit.

a. Make any necessary additions to the static re-

sistance for the ductwork. Refer to Table 26 on

page 62:

Ductwork Static Resistance/ESP 3.72 iwg

+ return duct static pressure (assumed) 0.50 iwg

+ economizer static resistance addition 0.33 iwg

+ bottom supply air opening resistance

addition

+ wet evaporator coil standard capacity

static resistance addition

+ gas heat (250 MBH) 0.04 iwg

+ throwaway filters 0.13 iwg

Total Static Resistance (TSP) 5.50 iwg

0.09 iwg

0.69 iwg

The low heat option on Table 22 exceeds this re-

quirement.

c. This option is available on the 30 ton unit.

Johnson Controls

b. Enter Table 27 at 12,000 CFM and 5.50 iwg TSP:

RPM = 1768

BHP = 14.91

13

Page 14

5513350-JTG-1018

Selection Procedure Examples (Continued)

2. From the nomenclature, select digit 15, option A to

opt for direct drive plenum (DDP) supply fan with

1-inch spring isolation. Select digit 16, option E for

20 HP supply fan motor. Select digit 17, option 2 for

ODP premium efciency, 1,800 RPM.

Select Fan Speed and Horsepower

Requirements of Exhaust Fan

1. Reference Table 29 on page 65 for the 30 ton unit.

In the following example, a unit is designed for exhaust air capacity of 7,000 CFM.

a. Make any necessary additions to the static resis-

tance. To find the exhaust air damper pressure

drop, refer to Table 26 on page 62:

Return duct static pressure (assumed) 0.25 iwg

+ exhaust air damper pressure drop 0.33 iwg

TSP 0.58 iwg

b. Enter at 7,000 CFM and 0.58 iwg TSP:

RPM = 634 (interpolated)

BHP = 2.72 (interpolated)

2. From the nomenclature, select digit 19, option 2 for

exhaust with variable frequency drive (VFD) and

backdraft damper; digit 20, option B for the exhaust

fan with 1-inch spring isolation; and digit 21, option

E for 3 HP exhaust fan motor. The resulting model

number will show 2BE for digits 19, 20, and 21.

Select Energy Recovery Wheel (ERW)/

Hot Gas Reheat (HGRH)/Sound Attenuator/

Humidifier

Refer to Selection Navigator or contact the local sales office

for more information on available options and accessories.

Example Model Number

The following model number is an example based on the options selected in the previous sections.

G V B 1 C – 1 B 5 G A – 1 A 6 0 A – E 2 0 2 B – E 2 A D G – 2 C 0 E 0 – D M A A 3 – 1 0 0 1 A – 0 0 0 C G – 0 0 0 1

7

5

3

4

3. Capacity 30 Ton 20. Forward Curved Exhaust Fan with 1-inch Spring Isolation

4. Standard Capacity, Standard Efciency 21. Exhaust Fan Motor, 3 HP

5. Staged Gas Stainless Steel 22. Exhaust Fan Motor Type, ODP Premium Efciency 1,800 RPM

6. 250 MBH 27. Pre-Evaporator Filter, Angled Filter Rack, 2-inch MERV 8 Filters

7. Variable Air Volume 29. Dual Enthalpy Economizer, Low Leak Dampers

8. Supply Fan with VFD and Return/Exhaust Fan with VFD

9. 460 V 3Ph 60 Hz, Single Point Terminal Block

15. Direct Drive Plenum Supply Fan with 1-inch Spring Isolation

16. Supply Fan Motor, 20 HP

17. Supply Fan Motor Type, ODP Premium Efciency 1,800 RPM 35. Ultraviolet (UV) Lights and Carbon Dioxide (CO

19. Exhaust fan with VFD and Backdraft Damper

9

6

8

15

16

17

19

20

21

22

27

31. Suction, Discharge, and Liquid Line Valves with Replaceable

Core Filter Driers

32. Convenience Outlet and Internal Lights with Supply and

Return Smoke Detectors

49. First Generation

31

29

32

35

) Sensors

2

49

14

Johnson Controls

Page 15

5513350-JTG-1018

Physical Data

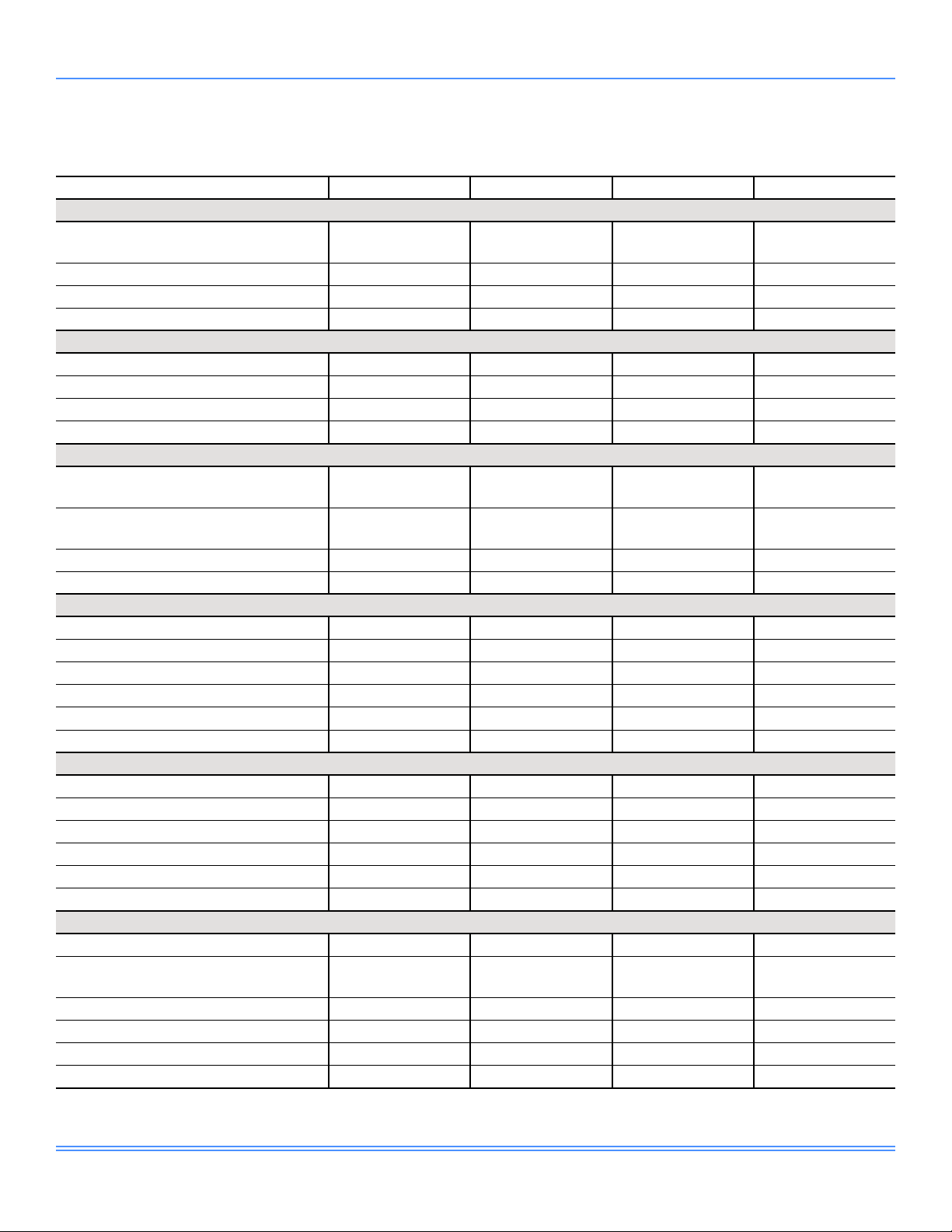

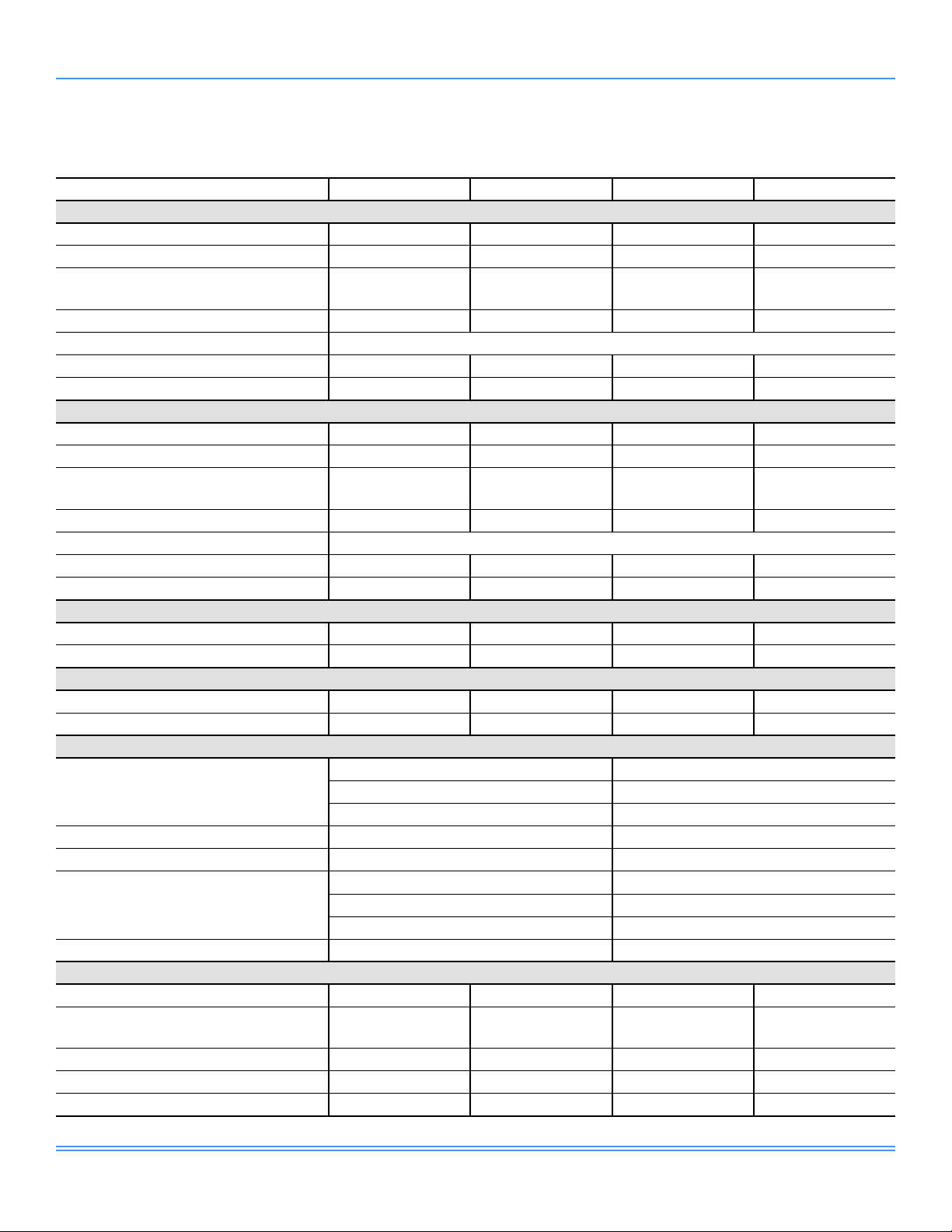

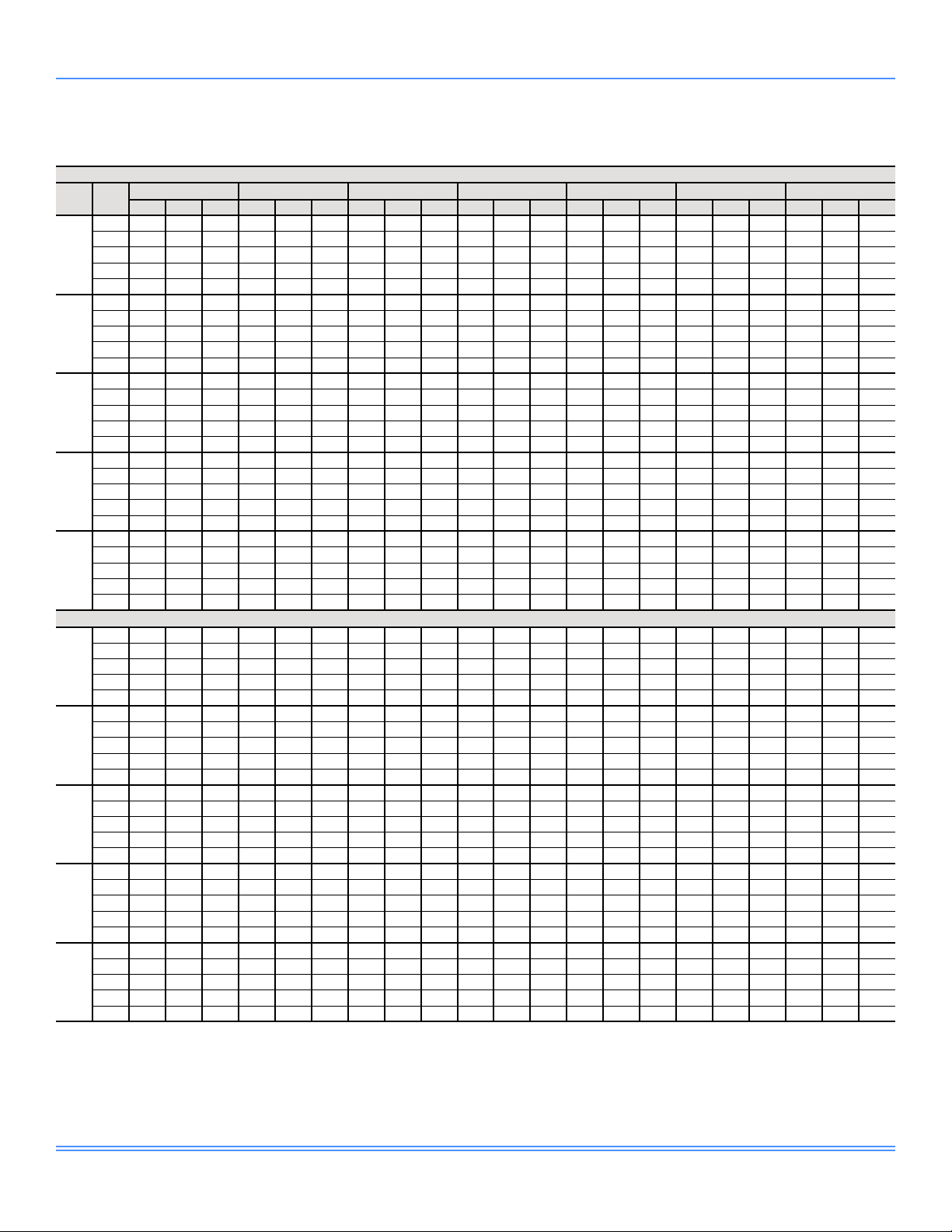

Table 1: Physical Data

Unit Size 25 Ton 30 Ton 40 Ton 50 Ton

Compressor Data - Standard Capacity, Standard Efciency

Quantity/Size (nominal HP) 1/4.5, 1/7, 1/10 1/5.5, 1/7, 1/7, 1/7.5

Type Scroll Scroll Scroll Scroll

Capacity Steps 7 11 15 15

Number of Circuits 2 2 2 2

Compressor Data - High Capacity, Standard Efciency

Quantity/Size (nominal HP) 1/5, 1/7.5, 1/10 1/5.5, 1/7, 1/7, 1/ 8.5 1/7, 1/13, 1/8.5, 1/10 1/8.5, 1/15, 1/7.5, 1/15

Type Scroll Scroll Scroll Scroll

Capacity Steps 7 11 15 13

Number of Circuits 2 2 2 2

Compressor Data - Standard Capacity, High Efciency

Quantity/Size (nominal HP) 1/5, 1/7.5, 1/13 1/7, 1/7, 1/18.5

Type

Capacity Steps 15–100% 15–100% 15–100% 15–100%

Number of Circuits 2 2 2 2

Supply Fan

Quantity of Fans/Motors 1/1 1/1 1/1 1/1

Type Direct Drive Plenum Direct Drive Plenum Direct Drive Plenum Direct Drive Plenum

Size (inches) 27 27 33 33

Motor Size Range (min to max HP) 5–25 5–25 10–50 10–50

Airow Range (min to max CFM) 5,000–12,000 5,000–12,000 8,000–20,000 8,000–20,000

Static Pressure Range (min to max iwg) 1.0–8.0 1.0–8.0 1.0–8.0 1.0–8.0

Return Fan

Quantity of Fans/Motors 1/1 1/1 1/1 1/1

Type Belt-Driven Plenum Belt-Driven Plenum Belt-Driven Plenum Belt-Driven Plenum

Size (inches) 27 27 30 30

Motor Size Range (min to max HP) 5–10 5–10 5–20 5–20

Airow Range (min to max CFM) 5,000–12,000 5,000–12,000 8,000–20,000 8,000–20,000

Static Pressure Range (min to max iwg)

Exhaust Fan

Quantity of Fans/Motors 1/1 1/1 1/1 1/1

Type

Size (inches) 18–18 18–18 25–25 25–25

Motor Size Range (min to max HP) 3–15 3–15 5–20 5–20

Airow Range (min to max CFM) 5,000–12,000 5,000–12,000 8,000–20,000 8,000–20,000

Static Pressure Range (min to max iwg) 0.5–3.0 0.5–3.0 0.5–3.0 0.5–3.0

Variable Speed

Drive Scroll

0.5–3.0 0.5–3.0 0.5–3.0 0.5–3.0

Belt-Driven Forward

Curved

Variable Speed

Drive Scroll

Belt-Driven Forward

Curved

1/5.5, 1/8.5, 1/10,

1/11.5

1/7.5, 1/7.5, 1/10,

1/13

Variable Speed

Drive Scroll

Belt-Driven Forward

Curved

1/7.5, 1/10, 1/11.5,

1/15

1/10, 1/10, 1/12,

1/17.5

Variable Speed

Drive Scroll

Belt-Driven Forward

Curved

Johnson Controls

15

Page 16

5513350-JTG-1018

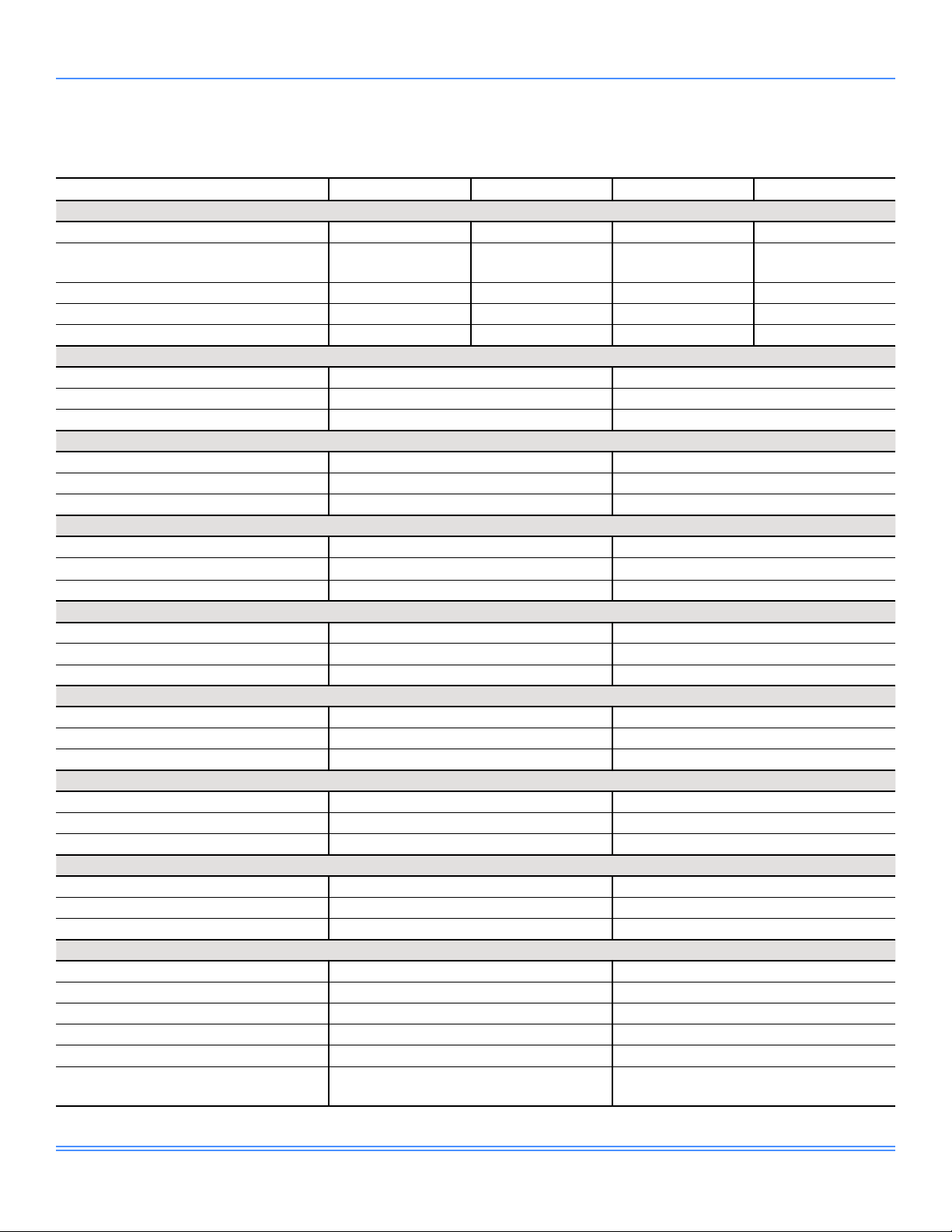

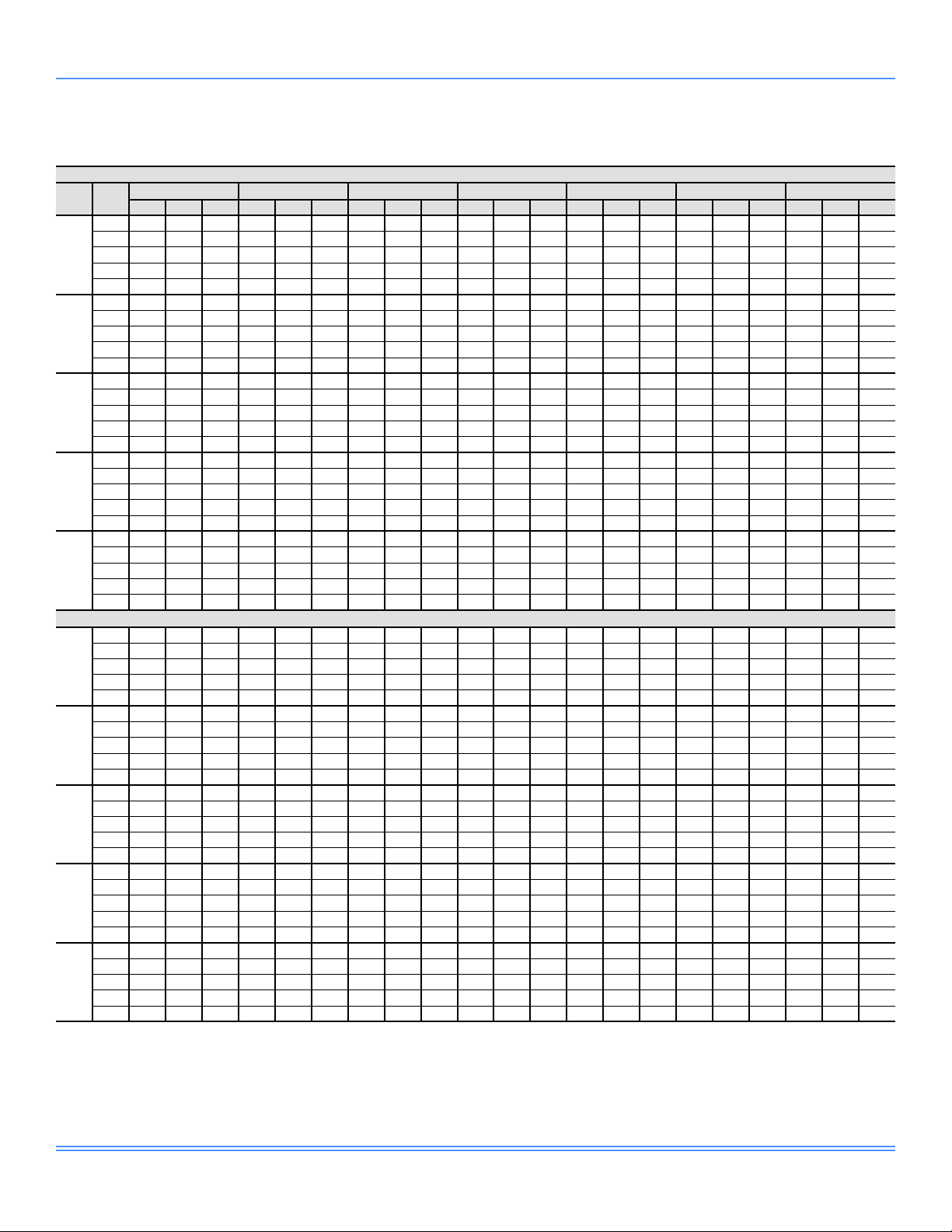

Physical Data (Continued)

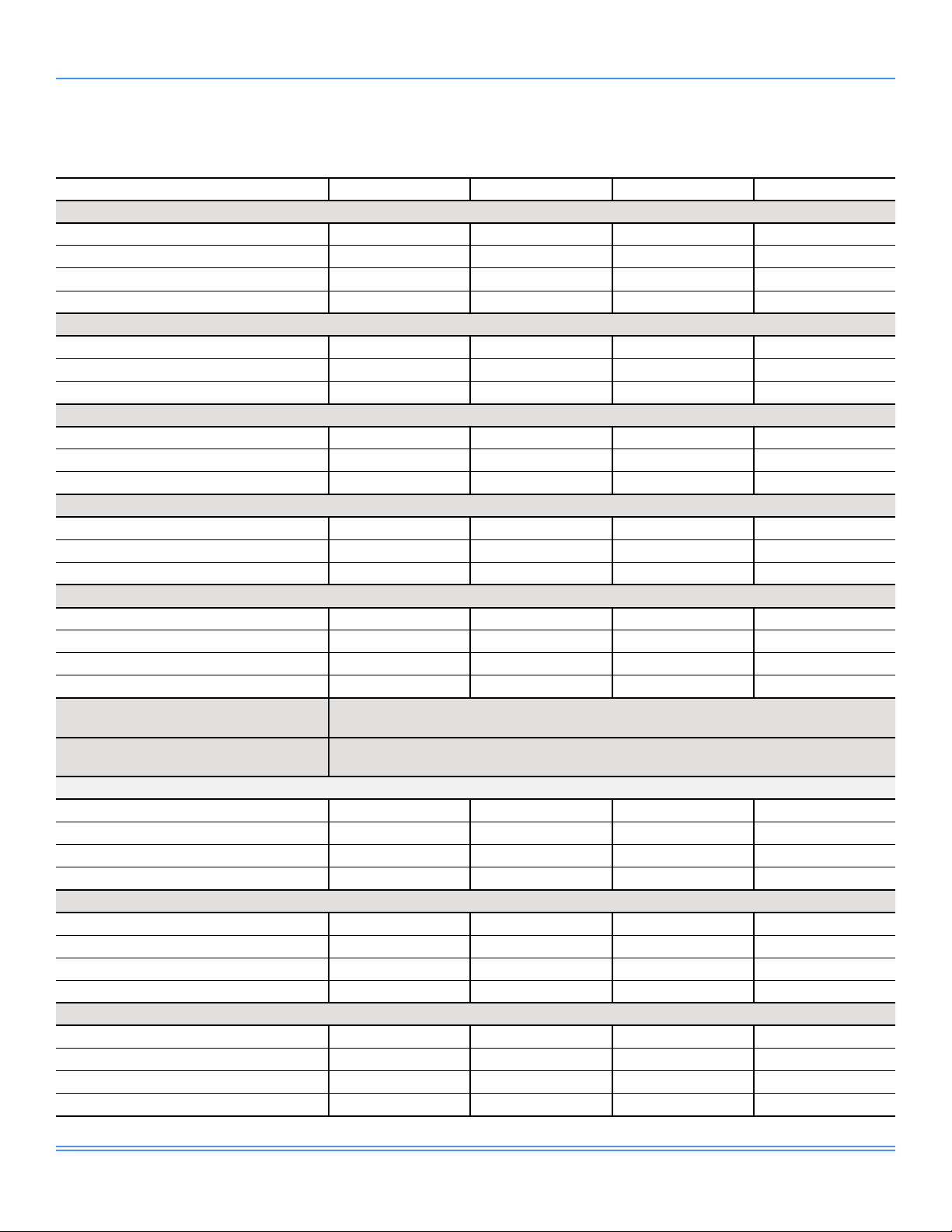

Table 1: Physical Data (Continued)

Unit Size 25 Ton 30 Ton 40 Ton 50 Ton

Condenser Fan

Quantity 2 2 4 4

Type Propeller Propeller Propeller Propeller

Size (diameter in inches) 30 30 30 30

Power (HP) 2 2 2 2

Evaporator Coil - Standard Capacity, Standard Efciency

Size (sq. ft.) 24 24 36 36

Number of Rows/Fins Per Inch 3/17 5/17 4/17 4/17

Size (tube diameter in inches) 3/8 3/8 3/8 3/8

Evaporator Coil - High Capacity, Standard Efciency

Size (sq. ft.) 24 24 36 36

Number of Rows/Fins Per Inch 4/17 6/17 4/17 6/17

Size (tube diameter in inches) 3/8 3/8 3/8 3/8

Evaporator Coil - Standard Capacity, High Efciency

Size (sq. ft.) 24 24 36 36

Number of Rows/Fins Per Inch 4/17 6/17 4/17 6/17

Size (tube diameter in inches) 3/8 3/8 3/8 3/8

Hot Gas Reheat (HGRH) Coil

Coil Type Microchannel Microchannel Microchannel Microchannel

Control Type Modulating Modulating Modulating Modulating

Size (area in sq. ft./thickness in inches) 19.5/0.8 19.5/0.8 19.5/1 19.5/1

Number of Rows/Fins Per Inch 1 / 23 1 / 23 1 / 23 1 / 23

Minimum Outside Air (OA)

Temperature for Mechanical Cooling

Low Ambient Option Minimum OA

Temperature for Mechanical Cooling

Condenser Coil - Standard Capacity, Standard Efciency

Size (sq. ft.) 61 61 98 98

Number of Rows/Fins Per Inch 1/23 1/23 1/23 1/23

Size (thickness in inches) 0.8 0.8 0.8 1

Type Microchannel Microchannel Microchannel Microchannel

Condenser Coil - High Capacity, Standard Efciency

Size (sq. ft.) 61 61 98 98

Number of Rows/Fins Per Inch 1/23 1/23 1/23 1/23

Size (thickness in inches)

Type Microchannel Microchannel Microchannel Microchannel

Condenser Coil - Standard Capacity, High Efciency

Size (sq. ft.) 61 61 98 98

Number of Rows/Fins Per Inch 1/23 1/23 1/23 1/23

Size (thickness in inches) 1 1 0.8 1

Type Microchannel Microchannel Microchannel Microchannel

0.8 0.8 0.8 1

45.0°F

-10.0°F

16

Johnson Controls

Page 17

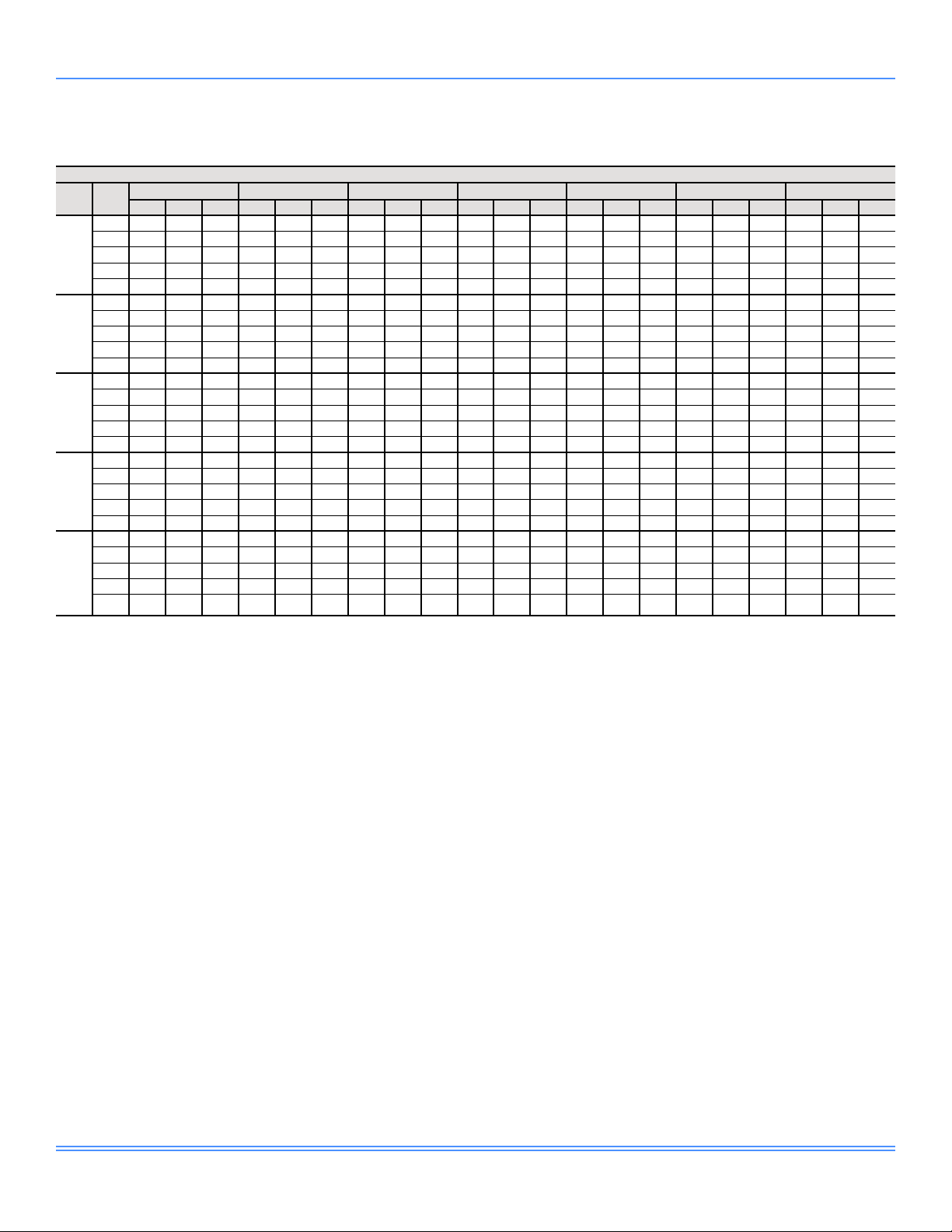

5513350-JTG-1018

Physical Data (Continued)

Table 1: Physical Data (Continued)

Unit Size 25 Ton 30 Ton 40 Ton 50 Ton

Energy Recovery Wheel (ERW) - High CFM

Cassette Dimensions (L x W x H in inches)

Wheel Segments 6 6 8 8

Motor (V, ph, Hz)

Horsepower (HP) 1/6 1/6 1/4 1/4

Filter Type 2-inch MERV 8 Pleated

RA Filters - Size (Number) 25 x 25 (2) 25 x 25 (2) 15 x 20 (6) 15 x 20 (6)

OA Filters - Size (Number) 25 x 25 (2) 25 x 25 (2) 15 x 20 (6) 15 x 20 (6)

Energy Recovery Wheel (ERW) - Low CFM

Cassette Dimensions (L x W x H in inches)

Wheel Segments 6 6 6 6

Motor (V/ph/Hz)

Horsepower (HP) 1/6 1/6 1/6 1/6

Filter Type 2-inch MERV 8 Pleated

RA Filters - Size (Number) 25 x 25 (2) 25 x 25 (2) 15 x 20 (6) 15 x 20 (6)

OA Filters - Size (Number) 25 x 25 (2) 25 x 25 (2) 15 x 20 (6) 15 x 20 (6)

Electric Heat (208V/230V)

Size Range - Low/High (kW) 50/100 50/100 60/120 60/120

Heating Steps - Low/High 3/6 3/6 4/8 4/8

Electric Heat (460V/575V)

Size Range - Low/High (kW) 60/120 60/120 80/160 80/160

Heating Steps - Low/High 3/6 3/6 4/8 4/8

Gas Furnace

Staged Furnace Sizes

(input/output/stages)

Airow Range (min to max CFM) 5,000–12,000 8,000–20,000

Gas Heat Steady State Efciency (SSE) 81% 81%

Modulating Furnace Sizes

(input/output/turndown)

Airow Range (min to max CFM) 5,000–12,000 8,000–20,000

Hot Water Coil

Coil Tube Diameter (inches)

Material

Fins Per Inch - Low/High 13/10 13/10 13/10 13/10

Size (H x L in inches) / Rows Low 25 x 70 / 1 25 x 70 / 1 42.5 x 70 / 1 42.5 x 70 / 1

Size (H x L in inches) / Rows High 25 x 70 / 2 25 x 70 / 2 42.5 x 70 / 2 42.5 x 70 / 2

50 x 4.36 x 50 50 x 4.36 x 50 62.42 x 6.07 x 62.42 62.42 x 6.07 x 62.42

208-230/3/60,

460/3/60, 575/3/60

44 x 4.36 x 44 44 x 4.36 x 44 56.19 x 4.36 x 56.19 56.19 x 4.36 x 56.19

208-230/3/60,

460/3/60, 575/3/60

250 / 202.5 / 2 500 / 405 / 2

500 / 405 / 2 750 / 607.5 / 4

750 / 607.5 / 4 1,250 / 1012.5 / 6

250 / 202.5 / 10:1 500 / 405 / 20:1

500 / 405 / 20:1 750 / 607.5 / 30:1

750 / 607.5 / 30:1 1,250 / 1012.5 / 50:1

1/2 1/2 1/2 1/2

Copper Tube/

Aluminum Fin

208-230/3/60,

460/3/60, 575/3/60

208-230/3/60,

460/3/60, 575/3/60

Copper Tube/

Aluminum Fin

208-230/3/60,

460/3/60, 575/3/60

208-230/3/60,

460/3/60, 575/3/60

Copper Tube/

Aluminum Fin

208-230/3/60,

460/3/60, 575/3/60

208-230/3/60,

460/3/60, 575/3/60

Copper Tube/

Aluminum Fin

Johnson Controls

17

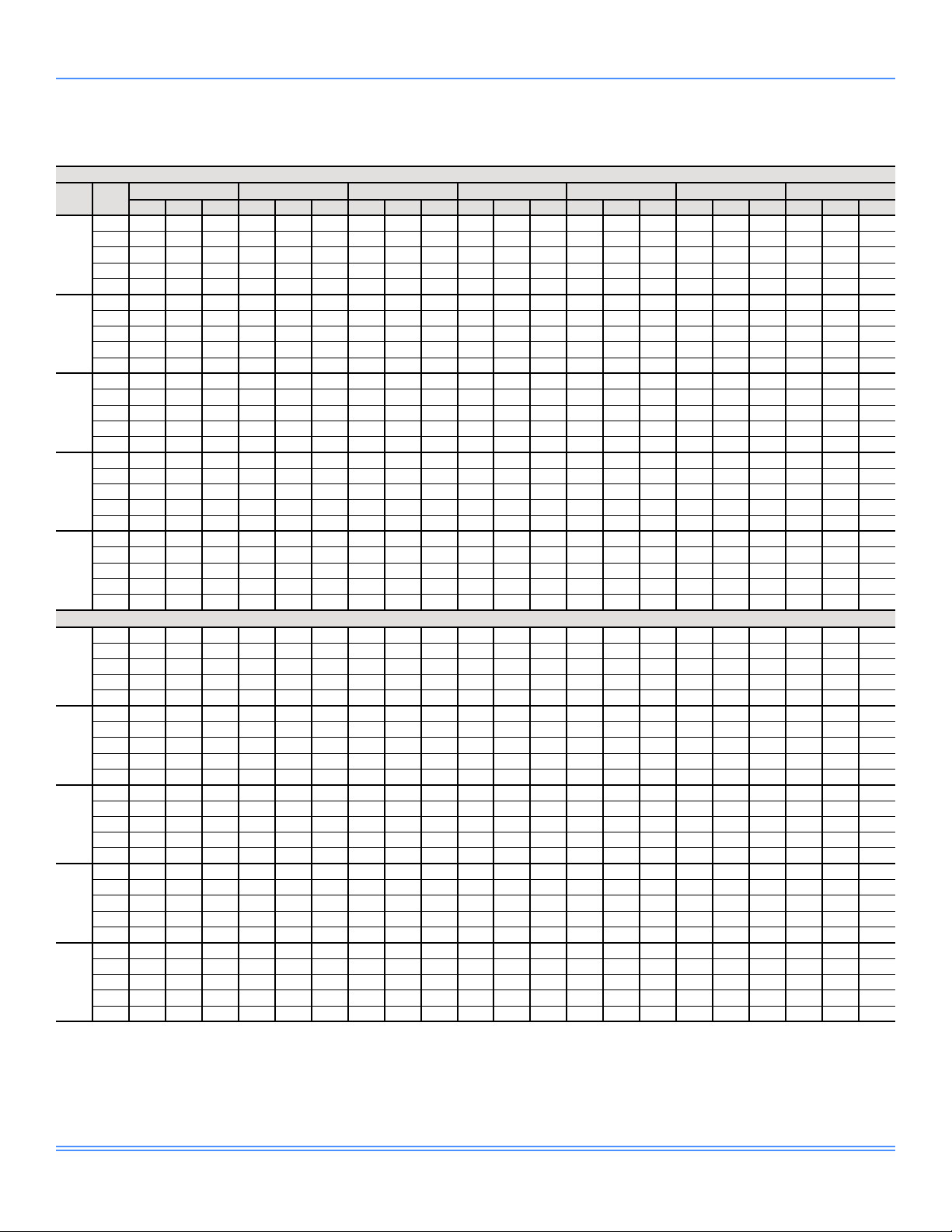

Page 18

5513350-JTG-1018

Physical Data (Continued)

Table 1: Physical Data (Continued)

Unit Size 25 Ton 30 Ton 40 Ton 50 Ton

Steam Coil

Coil Tube Diameter (inches)

Material

Fins Per Inch - Low/High 8/14 8/14 8/14 8/14

Size (H x L in inches) / Rows Low 24 x 68 / 1 24 x 68 / 1 42 x 68 / 1 42 x 68 / 1

Size (H x L in inches) / Rows High 24 x 68 / 1 24 x 68 / 1 42 x 68 / 1 42 x 68 / 1

Draw-Thru - 2-inch Throwaway Filters

Quantity

Size (L x W in inches) 24 x 24 / 16 x 20 24 x 24 / 12 x 24

Total Filter Face Area (sq. ft.) 29.33 40

Draw-Thru - 2-inch MERV 8 Filters

Quantity

Size (L x W in inches) 24 x 24 / 16 x 20 24 x 24 / 12 x 24

Total Filter Face Area (sq. ft.) 29.33 40

Draw-Thru - MERV 15 Bag Filters with 2-inch MERV 8 Pre-Filters

Quantity*

Size (L x W in inches)* 24 x 24 / 24 x 20 24 x 24 / 12 x 24

Total Filter Face Area (sq. ft.) 29.33 40

Draw-Thru - MERV 14 Rigid Filters with 2-inch MERV 8 Pre-Filters

Quantity*

Size (L x W in inches)* 24 x 24 / 24 x 20 24 x 24 / 12 x 24

Total Filter Face Area (sq. ft.) 29.33 40

Draw-Thru - Vertical 4-inch MERV 8 Filters

Quantity

Size (L x W in inches) 16 x 25 / 16 x 20 16 x 20

Total Filter Face Area (sq. ft.) 30 40

Final Filters - MERV 15 Bag Filters with 2-inch Pre-Filters

Quantity*

Size (L x W in inches)* 24 x 24 / 24 x 20 24 x 24 / 12 x 24

Total Filter Face Area (sq. ft.) 29.33 40

Final Filters - MERV 14 Rigid Filters with 2-inch Pre-Filters

Quantity*

Size (L x W in inches)* 24 x 24 / 24 x 20 24 x 24 / 12 x 24

Total Filter Face Area (sq. ft.) 29.33 40

Final Filters - MERV 17 HEPA Filters with 2-inch Pre-Filters

Quantity - Prelter

Size (L x W in inches) - Prelter 24 x 24 / 24 x 20 24 x 24 / 12 x 24

Total Filter Face Area (sq. ft.) - Prelter 29.33 40

Quantity - HEPA Filter

Size (L x W in inches) - HEPA Filter 24 x 24 12 x 24 / 12 x 17

Total Filter Face Area (sq. ft.) - HEPA

Filter

1 1 1 1

Copper Tube/

Aluminum Fin

Copper Tube/

Aluminum Fin

4 / 6 8 / 4

4 / 6 8 / 4

4 / 4 8 / 4

4 / 4 8 / 4

6 / 6 18

4 / 4 8 / 4

4 / 4 8 / 4

4 / 4 8 / 4

6 15 / 3

23.5 34.26

Copper Tube/

Aluminum Fin

Copper Tube/

Aluminum Fin

*NOTE: The quantities/sizes are the same for both the pre and post lters where noted.

18

Johnson Controls

Page 19

5513350-JTG-1018

Capacity Performance

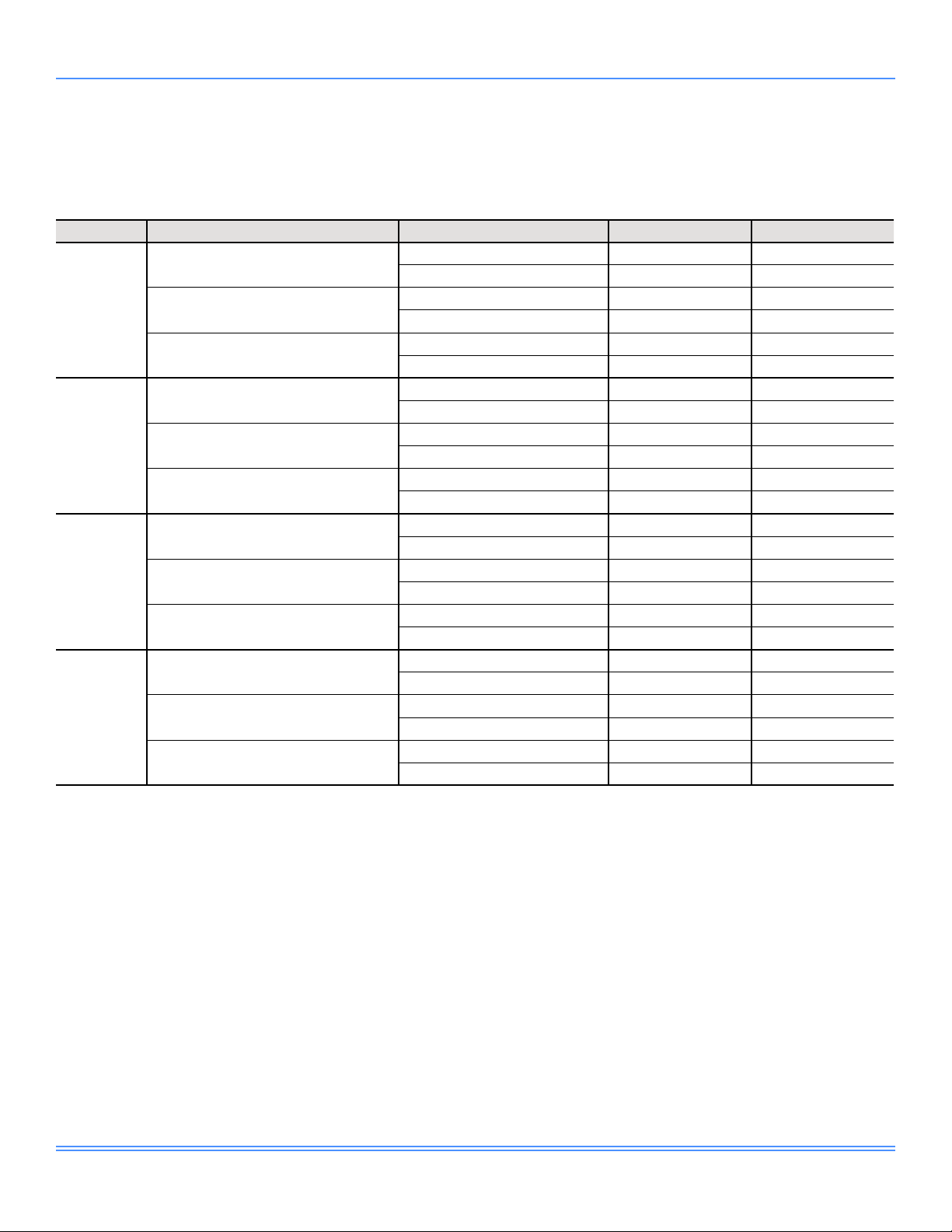

Energy Efficiency Ratio/Integrated Energy Efficiency Ratio (EER/IEER) Ratings

Table 2: EER/IEER Ratings

Capacity Efciency Heat Source EER IEER

Cooling Only/Electric Heat 10.8 14.9

Gas/Steam/Hot Water 10.6 14.8

Cooling Only/Electric Heat 11.4 16.7

Gas/Steam/Hot Water 11.2 16.6

Cooling Only/Electric Heat 10.8 14.9

Gas/Steam/Hot Water 10.6 14.8

Cooling Only/Electric Heat 10.5 14.3

Gas/Steam/Hot Water 10.3 14.2

Cooling Only/Electric Heat 10.9 15.2

Gas/Steam/Hot Water 10.7 15.1

Cooling Only/Electric Heat 10.5 14.3

Gas/Steam/Hot Water 10.3 14.2

Cooling Only/Electric Heat 10.9 14.6

Gas/Steam/Hot Water 10.7 14.5

Cooling Only/Electric Heat 11.1 16.1

Gas/Steam/Hot Water 10.9 16.0

Cooling Only/Electric Heat 10.7 14.6

Gas/Steam/Hot Water 10.5 14.5

Cooling Only/Electric Heat 10.8 15.0

Gas/Steam/Hot Water 10.6 14.9

Cooling Only/Electric Heat 10.9 15.9

Gas/Steam/Hot Water 10.7 15.8

Cooling Only/Electric Heat 10.5 14.8

Gas/Steam/Hot Water 10.3 14.7

25 Tons

30 Tons

40 Tons

50 Tons

Standard Capacity/Standard Efciency

Standard Capacity/High Efciency

High Capacity/Standard Efciency

Standard Capacity/Standard Efciency

Standard Capacity/High Efciency

High Capacity/Standard Efciency

Standard Capacity/Standard Efciency

Standard Capacity/High Efciency

High Capacity/Standard Efciency

Standard Capacity/Standard Efciency

Standard Capacity/High Efciency

High Capacity/Standard Efciency

Johnson Controls

19

Page 20

5513350-JTG-1018

Capacity Performance (Continued)

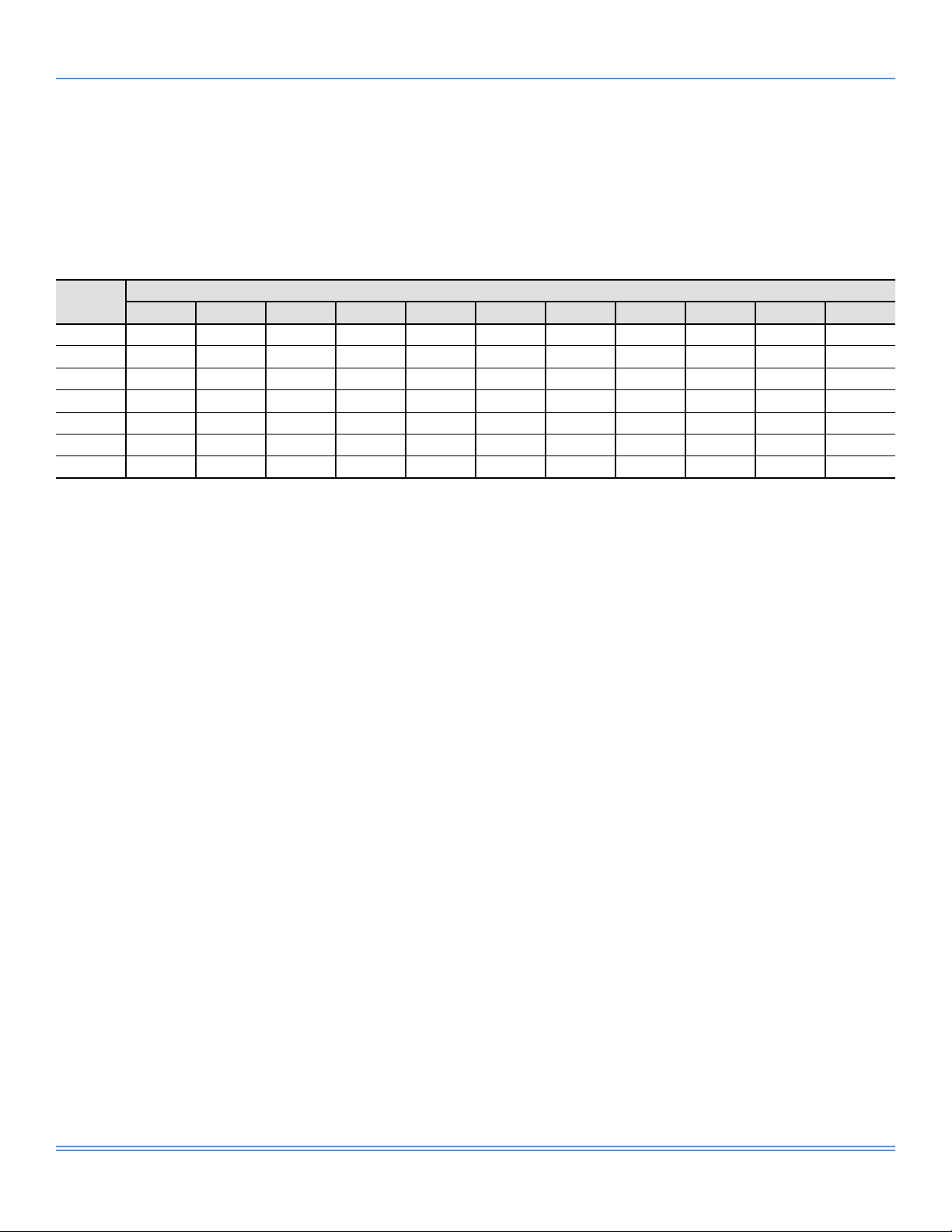

Altitude/Temperature Correction Factors

The information below should be used to assist in application of product when applied at altitudes equal to or above

1000 feet above sea level.

Table 3: Altitude/Temperature Correction Factors

Air Temp

(°F)

40 1.060 1.022 0.986 0.95 0.916 0.822 0.849 0.818 0.788 0.758 0.729

50 1.039 1.002 0.966 0.931 0.898 0.864 0.832 0.802 0.772 0.743 0.715

60 1.039 1.002 0.966 0.931 0.880 0.848 0.816 0.787 0.757 0.729 0.701

70 1.000 0.964 0.930 0.896 0.864 0.832 0.801 0.772 0.743 0.715 0.688

80 0.982 0.947 0.913 0.88 0.848 0.817 0.787 0.758 0.73 0.702 0.676

90 0.964 0.929 0.897 0.864 0.833 0.802 0.772 0.744 0.716 0.689 0.663

100 0.946 0.912 0.880 0.848 0.817 0.787 0.758 0.730 0.703 0.676 0.651

0* 1,000 2,000 3,000 4,000 5,000 6,000 7,000 8,000 9,000 10,000

Altitude (feet)

*NOTE: Correction factors at sea level to calculate for actual tempera-

ture conditions.

The examples below will assist in determining the airflow

performance of NexusPremier™ at specific altitudes.

Example 1: What are the corrected cubic feet per minute

(CFM), static pressure, and brake horse power (BHP) at

an elevation of 5,000 feet if the airflow performance data is

6,000 CFM, 1.4 inches of water gauge (iwg), and 2.0 BHP?

Solution: At an elevation of 5,000 feet, the supply fan still

delivers 6,000 CFM if the revolutions per minute (RPM) is

unchanged. However, the altitude correction must be used

to determine the static pressure and BHP. Since no tem-

perature data is given, we assume an air temperature of

70.0°F. Table 3 shows the correction factor to be 0.832.

Corrected static pressure = 1.4 x 0.832 = 1.16 iwg

Corrected BHP = 2.0 x 0.832 = 1.66

Example 2: A system, located at 5,000 feet of elevation is

to deliver 6,000 CFM at a static pressure of 1.4 iwg. Use

the unit blower tables to select the RPM, blower speed, and

the BHP requirement.

Solution: As in the example above, no temperature information is given, so 70.0°F is assumed.

Enter Table 27 on page 64 at 6,000 CFM and static pres-

sure of 1.68 iwg. The RPM listed is the same RPM needed

at 5,000 feet.

Using interpolation, the corresponding BHP listed in the

table is 2.25. This value must be corrected for elevation.

BHP at 5,000 feet = 2.25 x 0.832 = 1.87

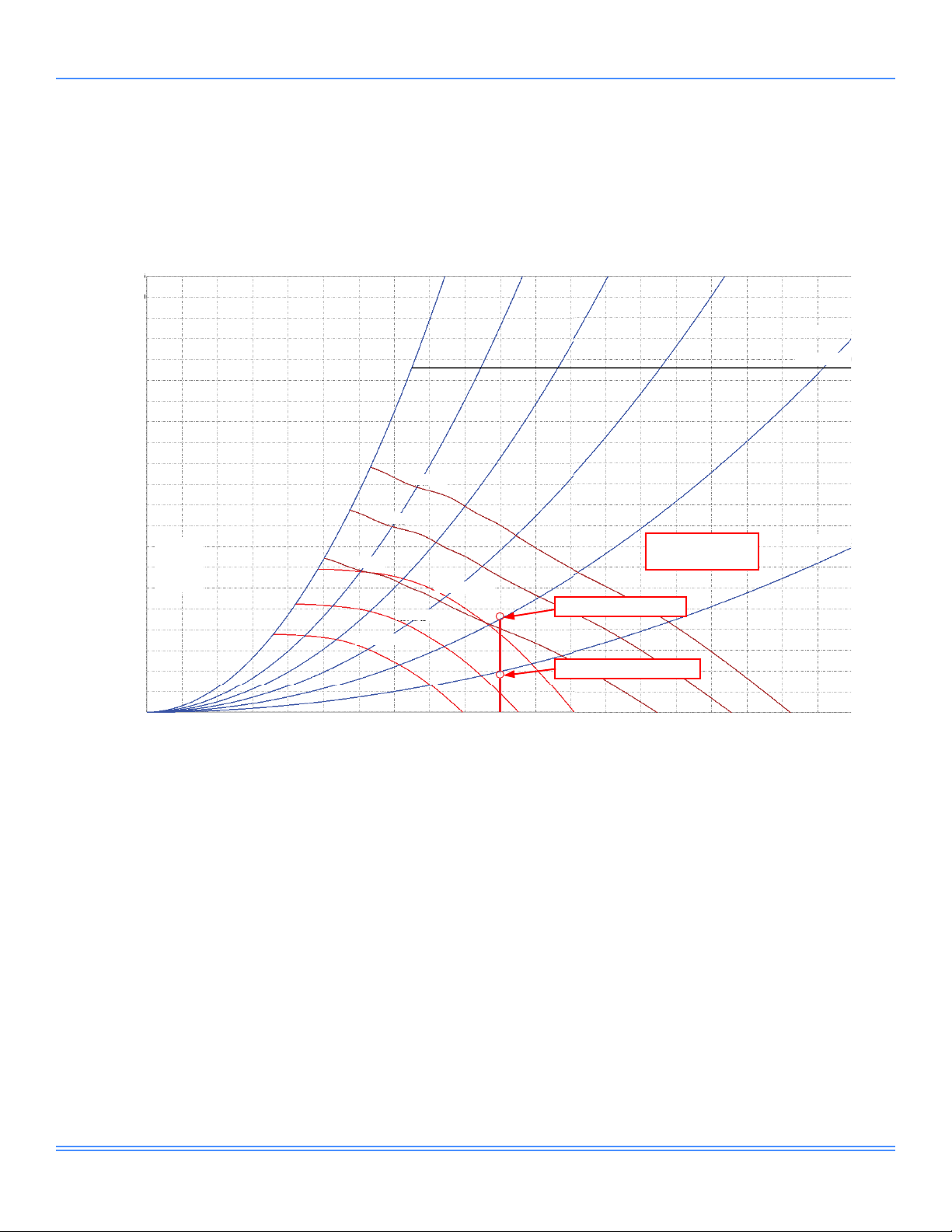

Example 3: Plot fan performance using Table 26 on page

62.

Plot the fan performance at cooling sea level (0 feet) elevation. Design conditions are a 25-ton unit producing 10,000

CFM at 1.5 external static pressure (ESP) with additional

static losses for a wet evaporator coil, bottom return air,

bottom supply air, outside air, and angled filter rack with

2-inch MERV 8 filters.

Wet evaporator coil standard capacity

additional static loss = 0.41 iwg

Bottom return air additional static loss = 0.05 iwg

Bottom supply air additional static loss = 0.06 iwg

Outside air additional static loss = 0.30 iwg

Air filter additional static loss = 0.11 iwg

The 1.4 iwg static pressure given is at an elevation of 5,000

feet. The first step is to convert this static pressure to equivalent sea level conditions.

Sea level static pressure = 1.4 iwg / 0.832 = 1.68 iwg

20

Add the ESP and all additional losses (internal static loss):

ESP loss = 1.5 iwg

Total internal static loss = 0.93 iwg

Total system static = 2.43 iwg

Johnson Controls

Page 21

Capacity Performance (Continued)

5513350-JTG-1018

10.5

10.0

9.5

9.0

8.5

8.0

7.5

7.0

6.5

6.0

5.5

5.0

4.5

Do Not

4.0

Select in

3.5

Static Pressure (iwg)

3.0

2.5

2.0

1.5

1.0

0.5

0.0

This

Region

1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 10.09.0

0.0

10 HP

7.5 HP

5 HP

1266 RPM

1101 RPM

936 RPM

Flow Rate (CFM x 1,000)

70% W.O.60% W.O.50% W.O.40% W.O.

Total System Static

= 2.43 inches

1.5-inch external static

0.93-inch internal static

12.0 13.0 14.0 15.0 16.0 17.0 18.0 19.0 20.0

11.0

80% W.O.

Max TSP

90% W.O.

LD26887

Figure 9: 25-Ton Unit Fan Performance

Johnson Controls

21

Page 22

5513350-JTG-1018

Capacity Performance (Continued)

Cooling Performance Data

Table 4: Cooling Performance Data - 25 Ton Standard Efficiency

75°F Ambient Air Temperature

EWB

CFM

(°F)

77 342 206 20 342 179 20 341 152 20 341 125 20 - - - - - - - - 72 313 234 20 314 207 20 313 181 20 313 154 20 313 127 20 - - - - - 67 288 261 19 287 235 19 287 208 19 286 181 19 285 153 19 284 126 19 - - -

5,000

62 275 275 19 262 258 19 259 231 19 259 204 19 258 177 19 257 150 19 256 122 19

57 274 274 19 260 260 19 - - - - - 77 365 242 20 363 205 20 363 169 20 362 132 20 - - - - - - - - 72 336 279 20 336 243 20 334 207 20 334 171 20 333 134 20 - - - - - 67 315 314 20 310 280 19 308 244 19 307 208 19 305 171 19 304 134 19 - - -

6,750

62 314 314 20 298 298 19 283 277 19 279 241 19 278 205 19 276 168 19 275 131 19

57 314 314 20 297 297 19 280 280 19 264 264 19 253 238 19 251 201 19 249 165 19

77 379 276 20 377 230 20 377 185 20 375 138 20 - - - - - - - - 72 353 322 20 350 278 20 348 232 20 347 187 20 346 141 20 - - - - - 67 343 343 20 328 322 20 322 278 20 319 232 20 318 187 20 316 140 20 - - -

8,500

62 343 343 20 326 326 20 307 307 19 294 276 19 290 230 19 289 184 19 287 138 19

57 342 342 20 325 325 20 306 306 19 288 288 19 270 269 19 263 227 19 261 182 19

77 390 309 21 387 254 21 386 200 21 384 144 20 - - - - - - - - 72 368 362 20 361 311 20 357 257 20 356 202 20 354

67 366 366 20 347 347 20 333 312 20 328 257 20 327 202 20 324 146 20 - - 62 365 365 20 347 347 20 327 327 20 307 306 20 299 255 19 297 200 19 295 145 19

10,250

57 365 365 20 346 346 20 326 326 20 306 306 20 287 287 19 272 252 19 269 198 19

77 398 342 21 394 279 21 392 215 21 390 150 21 - - - - - - - - 72 385 385 21 370 343 20 364 281 20 363 217 20 361 153 20 - - - - - 67 384 384 20 364 364 20 344 340 20 335 281 20 333 217

62 383 383 20 363 363 20 343 343 20 321 321 20 307 278 20 303 215 19 301 150 19

12,000

57 383 383 20 363 363 20 342 342 20 320 320 20 299 299 19 281 274 19 275 213 19

77 330 201 22 329 174 22 329 147 22 329 120 22 - - - - - - - - 72 301 227 21 300 200 21 299 173 21 298 145 21 298 118 21 - - - - - 67 274 252 21 272 225 21 272 198 21 271 171 21 270 144 21 269 11 6 21 - - -

5,000

62 262 262 21 249 247 21 245 221 21 244 194 21 243 167

57 261 261 21 247 247 21 - - - - - - - - - - - - - - 77 351 237 22 350 200 22 349 164 22 347 127 22 - - - - - - - - 72 322 272 22 320 236 22 318 199 22 318 162 22 316 125 22 - - - - - 67 302 302 21 294 270 21 291 234 21 290 197 21 289 161 21 287 124 21 - - -

6,750

62 300 300 21 283 283 21 268 265 21 263 230 21 262 194 21 260 157 21 259 121 21

57 299 299 21 282 282 21 266 266 21 250 250 21 237 226 21

77 364 271 22 363 225 22 362 179 22 359 132 22 - - - - - - - - 72 338 315 22 333 270 22 331 223 22 330 178 22 327 131 22 - - - - - 67 330 330 22 312 310 22 305 268 22 302 222 21 301 177 21 298 130 21 - - -

8,500

62 329 329 22 310 310 22 292 292 21 277 265 21 273 219 21 271 174 21 269 127 21

57 328 328 22 309 309 22 291 291 21 272 272 21 255 255 21 246 215 21 244 170 21

77 373 304 22 371 249 22 369 194 22 367 138 22 - - - - - - - - 72 353 352 22 343 303 22 339 248 22 338 193 22 335 137 22 - - - - - 67 352 352 22 332 332 22 316 301 22 310 247 22 309 192 22 306 137 22 - - 62 351 351 22 331 331 22 3 11 311 22 291 291 21 281 244 21 279 189 21 277 134 21

10,250

57 351 351 22 330 330 22 310 310 22 290 290 21 270 270 21 255 240 21 252 186 21

77 382 336 23 378 273 22 375 208 22 372 143 22 - - - - - - - - 72 370 370 22 352 333 22 346 272 22 343 207 22 340 142 22 67 370 370 22 348 348 22 326 326 22 317 271 22 314 207 22 3 11 142 22 - - 62 369 369 22 347 347 22 325 325 22 304 304 22 289 267 21 285 204 21 282 140 21

12,000

57 369 369 22 346 346 22 324 324 22 303 303 22 283 283 21 263 261 21 257 201 21

NOTES:

Rated performance is at sea level. Cooling capacities are gross cooling capacities.

CFM = airow EWB = entering wet bulb air EDB = entering dry bulb air TMBH = total cooling capacity (MBH)

SMBH = sensible cooling capacity (MBH) kW = total input

95°F EDB 90°F EDB 85°F EDB 80°F EDB 75°F EDB 70°F EDB 65°F EDB

TMBH SMBH kW TMBH SMBH kW TMBH SMBH kW TMBH SMBH kW TMBH SMBH kW TMBH SMBH kW TMBH SMBH kW

- - - - - - - - -

147 20 - - - - - -

20 330 152 20 - - -

85°F Ambient Air Temperature

21 242 139 21 241 112 21

235 190 21 233 153 21

- - - - -

22

Johnson Controls

Page 23

Capacity Performance (Continued)

Table 4: Cooling Performance Data - 25 Ton Standard Efciency (Continued)

95°F Ambient Air Temperature

EWB

CFM

(°F)

77 312 192 24 311 164 24 310 137 24 309 109 24 - - - - - - - - 72 284 217 24 283 190 24 282 163 24 281 136 24 281 108 24 - - - - - 67 260 244 23 258 217 23 258 190 23 257 163 23 256 136 23 256 109 23 - - -

5,000

62 250 250 23 237 237 23 231 212 23 230 185 23 229 158 23 228 131 23 228 104 23

57 247 247 23 233 233 23 219 219 23 - - 77 331 226 24 329 190 24 328 153 24 326 115 24 - - - - - - - - 72 304 262 24 302 226 24 300 189 24 299 152 24 297 115 24 - - - - - 67 289 289 24 279 262 24 276 226 24 274 189 23 274 153 23 272 11 6 23 - - -

6,750

62 286 286 24 270 270 23 254 254 23 248 221 23 246 184 23 245 148 23 243 111 23

57 284 284 24 267 267 23 251 251 23 235 235 23 221 214 23 218 178 23 216 142 23

77 342 260 24 341 214 24 339 168 24 337 121 24 - - - - - - - - 72 319 304 24 314 259 24 3 11 213 24 310 168 24 308 121 24 - - - - - 67 316 316 24 298 298 24 289 260 24 285 214 24 284 169 24 282 122 24 - - -

8,500

62 313 313 24 295 295 24 277 277 24 262 255 23 256 210 23 255 164 23 253 118 23

57 311 311 24 292 292 24 274 274 24 256 256 23 239 239 23 228 204 23 227 158 23

77 351 292 25 349 238 25 346 182 24 343 126 24 - - - - - - - - 72 336 336 24 323 292 24 319 238 24 317 182 24 315

67 336 336 24 317 317 24 299 291 24 293 239 24 291 184 24 289 128 24 - - 62 334 334 24 314 314 24 295 295 24 275 275 24 265 234 23 262 180 23 260 124 23

10,250

57 332 332 24 312 312 24 292 292 24 272 272 24 253 253 23 237 227 23 233 174 23

77 359 324 25 354 262 25 351 196 25 348 131 25 - - - - - - - - 72 351 351 25 332 322 24 325 261 24 322 197 24 319 132 24 - - - - - 67 352 352 25 331 331 24 3 11 311 24 300 262 24 296 198

62 350 350 25 329 329 24 308 308 24 288 288 24 272 257 24 267 194 23 264 130 23

12,000

57 348 348 25 327 327 24 306 306 24 285 285 24 265 265 23 246 246 23 238 189 23

77 292 180 26 290 153 26 290 125 26 288 98 26 - - - - - - - - 72 264 205 26 263 178 26 262 151 26 261 123 26 260 96 26 - - - - - 67 242 231 26 239 204 26 238 177 26 237 150 26 237 123 26 236 95 26 - - -

5,000

62 234 234 26 220 220 26 212 198 26 211 172 26 210 144

57 233 233 26 219 219 26 205 205 25 191 191 25 186 166 25 185 139 25 - - 77 308 214 27 307 178 27 306 141 27 304 104 27 - - - - - - - - 72 282 249 26 280 213 26 278 176 26 277 139 26 275 102 26 - - - - - 67 271 271 26 259 248 26 255 213 26 253 176 26 252 140 26 250 103 26 - - -

6,750

62 269 269 26 252 252 26 236 236 26 228 207 26 225 171 26 224 134 26 222 97 26

57 267 267 26 251 251 26 235 235 26 219 219 26 204 202 25

77 319 248 27 317 202 27 315 155 27 313 109 27 - - - - - - - - 72 298 290 27 291 246 27 289 201 27 287 154 26 284 108 26 - - - - - 67 297 297 27 279 279 26 267 246 26 263 201 26 262 155 26 260 109 26 - - -

8,500

62 294 294 27 276 276 26 258 258 26 241 239 26 235 196 26 233 150 26 231 104 26

57 293 293 27 275 275 26 257 257 26 239 239 26 221 221 26 210 191 26 207 146 26

77 328 280 27 324 226 27 322 170 27 319 114 27 - - - - - - - - 72 315 315 27 300 278 27 296 225 27 293 169 27 290 113 27 - - - - - 67 316 316 27 296 296 27 278 275 26 271 225 26 268 170 26 265 11 4 26 - - 62 314 314 27 294 294 27 274 274 26 255 255 26 243 220 26 239 165 26 237 110 26

10,250

57 313 313 27 292 292 27 273 273 26 254 254 26 235 235 26 218 214 26 213 161 26

77 336 312 27 330 250 27 326 185 27 323 119 27 - - - - - - - - 72 330 330 27 310 306 27 301 248 27 298 184 27 295 119 27 67 331 331 27 311 311 27 290 290 27 277 248 26 272 185 26 270 120 26 - - 62 329 329 27 308 308 27 288 288 27 268 268 26 250 242 26 244 180 26 241 115 26

12,000

57 328 328 27 307 307 27 286 286 27 266 266 26 247 247 26 228 228 26 218 176 26

95°F EDB 90°F EDB 85°F EDB 80°F EDB 75°F EDB 70°F EDB 65°F EDB

TMBH SMBH kW TMBH SMBH kW TMBH SMBH kW TMBH SMBH kW TMBH SMBH kW TMBH SMBH kW TMBH SMBH kW

- - - - - - - - -

105°F Ambient Air Temperature

5513350-JTG-1018

127 24 - - - - - -

24 294 134 24 - - -

26 209 117 25 208 90 25

199 166 25 198 130 25

- - - - -

NOTES:

Rated performance is at sea level. Cooling capacities are gross cooling capacities.

CFM = airow EWB = entering wet bulb air EDB = entering dry bulb air TMBH = total cooling capacity (MBH)

SMBH = sensible cooling capacity (MBH) kW = total input

Johnson Controls

23

Page 24

5513350-JTG-1018

Capacity Performance (Continued)

Table 4: Cooling Performance Data - 25 Ton Standard Efciency (Continued)

115°F Ambient Air Temperature

EWB

CFM

(°F)

77 269 168 29 268 141 29 267 11 3 29 266 85 29 - - - - - - - - 72 243 192 29 242 165 29 240 138 29 239 110 29 238 82 29 - - - - - 67 220 215 29 217 189 29 215 162 29 214 134 29 213 107 29 212 79 29 - - -

5,000

62 217 217 29 204 204 29 193 185 28 191 158 28 190 131 28 189 103 28 187 76 28

57 217 217 29 203 203 29 189 189 28 176 176 28

77 284 202 30 283 165 30 281 128 30 279 91 30 - - - - - - - - 72 260 236 29 256 199 29 255 163 29 253 126 29 251 89 29 - - - - - 67 251 251 29 236 232 29 230 197 29 228 160 29 227 123 29 225 86 29 - - -

6,750

62 250 250 29 234 234 29 218 218 29 207 193 29 203 157 29 202 120 29 200 83 29

57 249 249 29 233 233 29 217 217 29 202 202 29 186 186 28 180 153 28 179 117 28

77 294 235 30 292 190 30 290 143 30 287 96 30 - - - - - - - - 72 275 274 30 267 233 29 264 187 29 262 141 29 259 94 29 - - - - - 67 275 275 30 256 256 29 242 229 29 238 185 29 235 138 29 233 92 29 - - -

8,500

62 274 274 30 256 256 29 238 238 29 220 220 29 213 182 29 210 136 29 208 90 29

57 273 273 30 255 255 29 237 237 29 220 220 29 203 203 29 190 178 28 187 133 28

77 303 268 30 299 213 30 296 158 30 293 102 30 - - - - - - - - 72 293 293 30 276 264 30 271 2 11 30 268 156 29 265

67 292 292 30 273 273 30 254 254 29 244 209 29 241 153 29 238 98 29 - - 62 292 292 30 272 272 30 253 253 29 235 235 29 220 205 29 216 151 29 213 95 29

10,250

57 291 291 30 272 272 30 253 253 29 234 234 29 216 216 29 199 198 29 192 148 29

77 311 298 30 304 237 30 300 172 30 296 107 30 - - - - - - - - 72 307 307 30 287 287 30 276 235 30 272 170 30 268 105 29 - - - - - 67 307 307 30 286 286 30 266 266 29 250 231 29 245 168

62 306 306 30 286 286 30 266 266 29 246 246 29 227 225 29 220 166 29 217 101 29

12,000

57 306 306 30 285 285 30 265 265 29 246 246 29 227 227 29 208 208 29 196 163 29

95°F EDB 90°F EDB 85°F EDB 80°F EDB 75°F EDB 70°F EDB 65°F EDB

TMBH SMBH kW TMBH SMBH kW TMBH SMBH kW TMBH SMBH kW TMBH SMBH kW TMBH SMBH kW TMBH SMBH kW

168 154 28 167 127 28 166 99 28

100 29 - - - - - -

29 242 103 29 - - -

NOTES:

Rated performance is at sea level. Cooling capacities are gross cooling capacities.

CFM = airow EWB = entering wet bulb air EDB = entering dry bulb air TMBH = total cooling capacity (MBH)

SMBH = sensible cooling capacity (MBH) kW = total input

24

Johnson Controls

Page 25

Capacity Performance (Continued)

Table 5: Cooling Performance Data - 25 Ton High Efficiency

75°F Ambient Air Temperature

EWB

CFM

(°F)

77 351 211 18 351 184 18 350 157 18 350 129 18 - - - - - - - - 72 321 239 18 321 212 18 321 185 18 320 158 18 320 131 18 - - - - - 67 294 266 18 293 239 18 292 212 18 292 184 18 290 156 18 290 129 18 - - -

5,000

62 279 279 18 266 262 18 263 235 18 262 208 18 262 180 18 261 153 18 260 125 18

57 279 279 18 264 264 18 - - - - - 77 375 248 19 374 211 19 374 174 19 373 137 19 - - - - - - - - 72 345 286 18 344 249 18 343 213 18 343 176 18 342 139 18 - - - - - 67 322 321 18 317 286 18 315 249 18 314 212 18 312 175 18 3 11 138 18 - - -

6,750

62 321 321 18 304 304 18 288 282 18 284 246 18 283 209 18 282 172 18 281 134 18

57 321 321 18 303 303 18 285 285 18 268 268 18 257 242 18 255 205 18 253 168 18

77 391 284 19 389 237 19 389 191 19 387 144 19 - - - - - - - - 72 363 331 18 360 285 18 358 239 18 358 193 18 356 146 18 - - - - - 67 352 352 18 336 330 18 330 285 18 327 238 18 326 192 18 324 145 18 - - -

8,500

62 352 352 18 333 333 18 314 314 18 300 282 18 296 235 18 295 189 18 293 142 18

57 351 351 18 333 333 18 313 313 18 294 294 18 275 275 18 268 232 18 266 185 18

77 402 319 19 400 263 19 398 206 19 396 150 19 - - - - - - - - 72 379 373 19 371 320 19 368 264 19 367 208 19 365

67 376 376 19 357 357 18 342 320 18 337 264 18 335 208 18 333 151 18 - - 62 376 376 19 356 356 18 335 335 18 314 313 18 306 261 18 304 205 18 302 148 18

10,250

57 375 375 19 356 356 18 335 335 18 314 314 18 293 293 18 277 258 18 275 202 18

77 411 353 19 408 288 19 405 222 19 402 156 19 - - - - - - - - 72 397 397 19 381 354 19 376 289 19 374 224 19 371 158 19 - - - - - 67 396 396 19 375 375 19 353 350 18 345 289 18 342 223

62 395 395 19 374 374 19 352 352 18 329 329 18 314 286 18 310 221 18 308 155 18

12,000

57 395 395 19 374 374 19 352 352 18 329 329 18 307 307 18 287 282 18 281 218 18

77 337 206 20 337 179 20 337 151 20 336 124 20 - - - - - - - - 72 307 232 20 306 204 20 305 177 20 304 149 20 304 121 20 - - - - - 67 277 255 20 276 228 20 275 200 20 274 173 20 273 145 20 273 11 7 20 - - -

5,000

62 266 266 20 252 250 20 248 224 20 247 196 20 246 169

57 265 265 20 250 250 20 236 236 20 - - - - - - - - - - - 77 360 243 20 359 206 20 359 169 20 357 131 20 - - - - - - - - 72 329 278 20 327 241 20 326 203 20 325 166 20 323 129 20 - - - - - 67 307 307 20 298 275 20 296 238 20 294 200 20 293 163 20 292 125 20 - - -

6,750

62 306 306 20 289 289 20 272 270 20 267 234 20 265 197 20 264 160 20 263 122 20

57 305 305 20 288 288 20 271 271 20 254 254 20 241 231 20

77 374 278 21 373 231 21 371 185 21 369 137 21 - - - - - - - - 72 345 323 20 341 276 20 339 229 20 338 182 20 335 135 20 - - - - - 67 337 337 20 318 316 20 310 273 20 307 226 20 306 180 20 304 132 20 - - -

8,500

62 336 336 20 317 317 20 297 297 20 282 270 20 277 223 20 276 177 20 274 130 20

57 336 336 20 316 316 20 297 297 20 278 278 20 259 259 20 250 220 20 248 174 20

77 384 312 21 382 256 21 379 200 21 376 142 21 - - - - - - - - 72 362 361 20 352 311 20 348 254 20 346 198 20 343 141 20 - - - - - 67 361 361 20 339 339 20 321 308 20 316 252 20 314 195 20 3 11 138 20 - - 62 360 360 20 339 339 20 317 317 20 297 297 20 286 249 20 284 193 20 282 136 20

10,250

57 359 359 20 338 338 20 317 317 20 296 296 20 276 276 20 260 246 20 256 190 20

77 393 347 21 388 281 21 385 215 21 382 148 21 - - - - - - - - 72 380 380 21 361 344 20 355 279 20 351 213 20 348 146 20 67 380 380 21 356 356 20 333 333 20 323 277 20 319 211 20 316 144 20 - - 62 379 379 21 356 356 20 333 333 20 311 311 20 294 274 20 290 208 20 287 142 20

12,000