Page 1

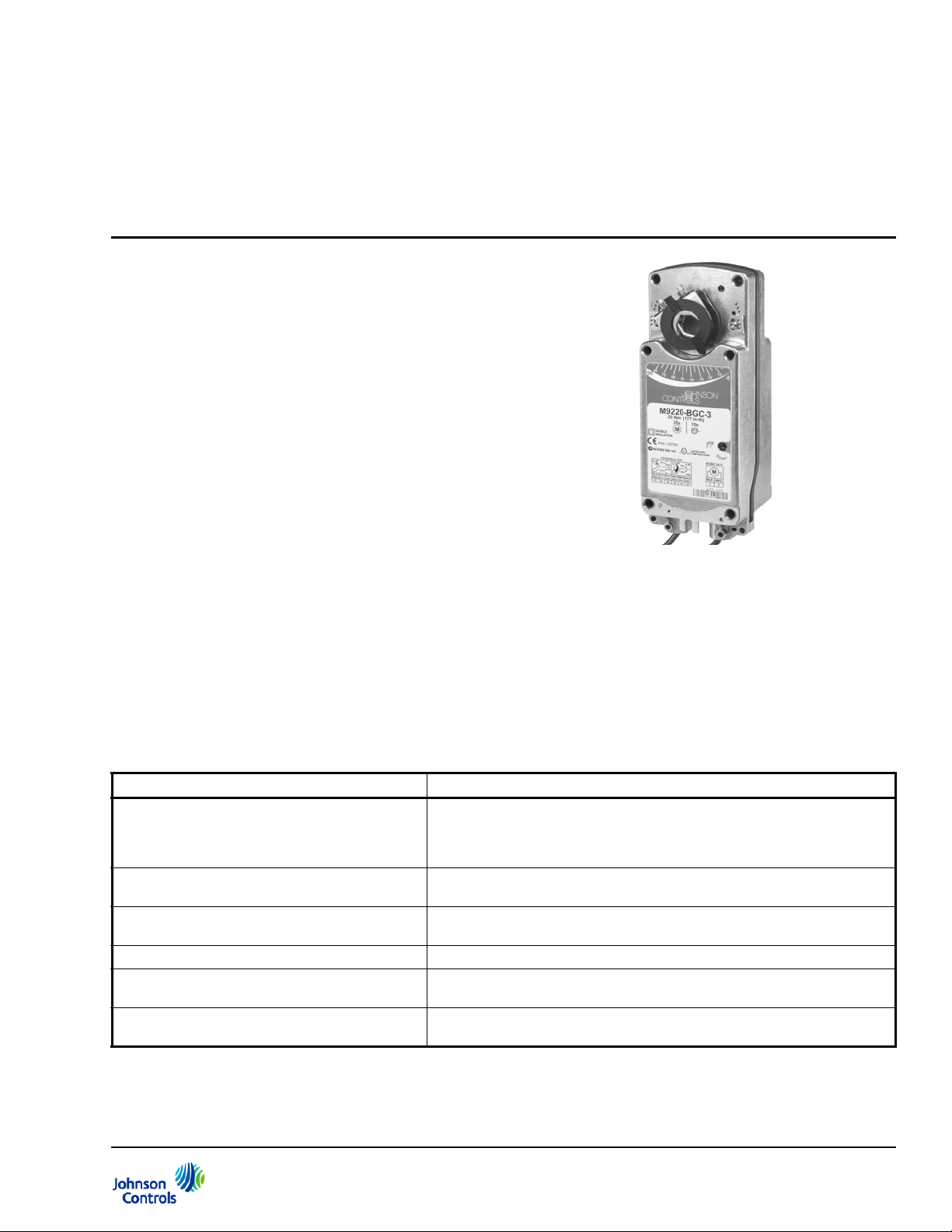

Figure 1: M9220-xxx-3 Electric Spring Return

Actuator

M9220-xxx-3 Electric Spring Return Actuators

Product Bulletin

Refer to the QuickLIT Web site for the most up-to-date version of this document.

The M9220-xxx-3 Actuators are direct mount, spring

return electric actuators that operate on these available

power options:

• AC 24 V at 50/60 Hz or DC 24 V (AGx, BGx, GGx,

HGx)

• AC 120 V at 60 Hz (BAx)

• AC 230 V at 50/60 Hz (BDx)

These bidirectional actuators do not require a damper

linkage and are easily installed on dampers with 1/2 to

3/4 in. or 12 to 19 mm round shafts, or on dampers with

3/8 and 1/2 in. or 10, 12, and 14 mm square shafts,

using the standard shaft clamp inclu ded with the

actuator. An optional M9220-600 Jackshaft Coupler Kit

is available for 3/4 to 1-1/16 in. or 19 to 27 mm round

shafts, or 5/8 and 3/4 in. or 16, 18, and 19 mm square

shafts.

Code No. LIT-12011057

Issued November 19, 2012

Supersedes November 8, 2012

A single M9220-xxx-3 Electric Spring Return Actuator

provides a running and spring return torque of 177 lb·in

(20 N·m). Two or three models mounted in tandem

deliver twice or triple the torque (354 lb·in [40 N·m] or

531 lb·in [60 N·m]). Integral line voltage auxiliary

switches are available on the xxC models to indicate

end-stop position or to perform switching functions

within the selected rotation range.

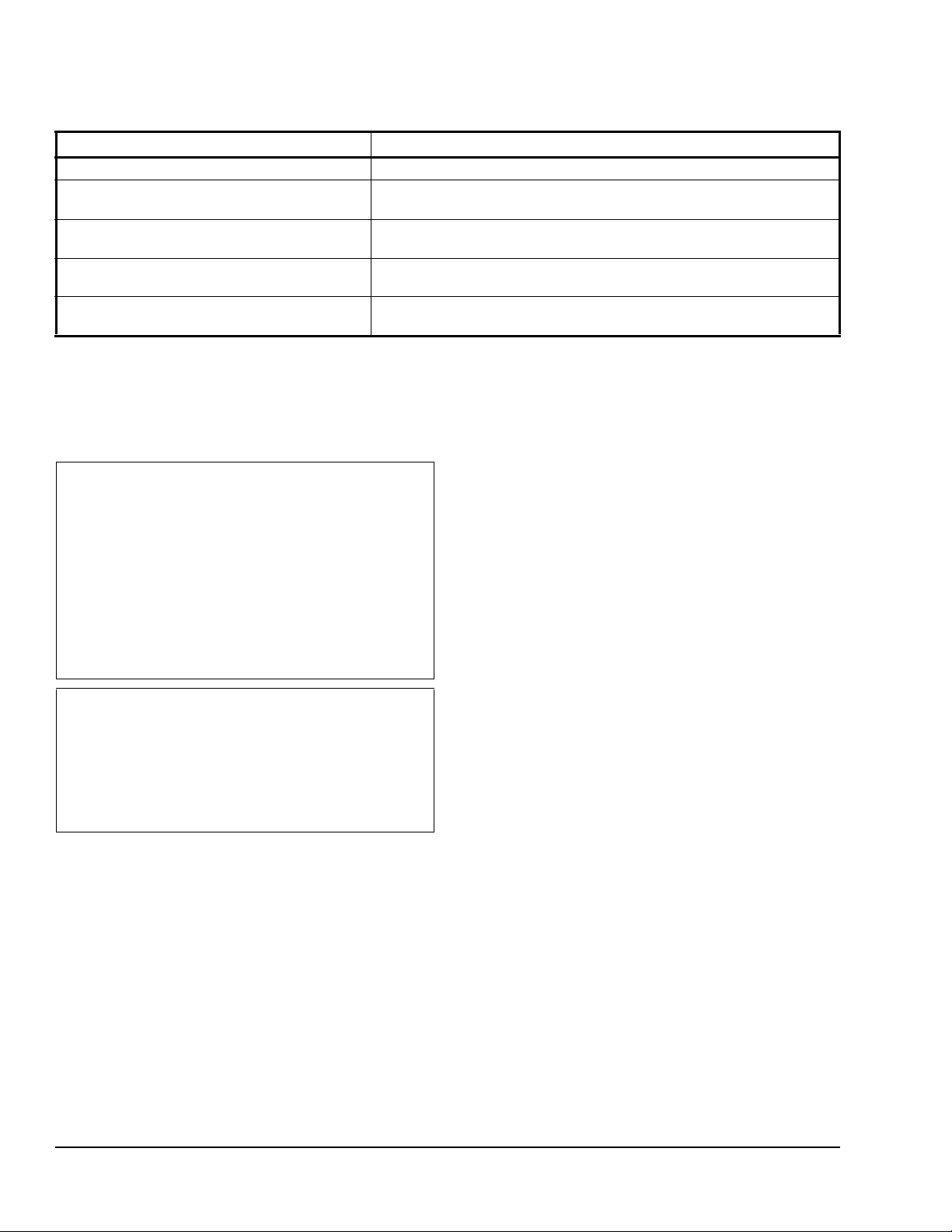

Table 1: Features and Benefits (Part 1 of 2)

Features Benefits

Available Torques of 177 lb·in (20 N·m) for

Single Actuators, 354 lb·in (40 N·m) for Two

Models, and 531 lb·in (60 N·m) for Three

Models Mounted in Tandem

Reversible Mounting Design Simplifies installation and enables the actuator to spring return in either

Electronic Stall Detection throughout Entire

Rotation Range

Removable Coupler Adapts to a shorter damper shaft.

Integral 48 in. (1.2 m) Halogen-Free Cables

with Colored and Numbered Conductors

Integral Auxiliary Switches (xxC Models) Provide one fixed and one adjustable switch point with line voltage

Offer a selection that is most suitable for the application.

direction.

Extends the life of the actuator by deactivating the actuator motor when an

overload condition is detected.

Simplify field wiring.

capability.

M9220-xxx-3 Electric Sp ring Return Actuators Product Bulletin 1

Page 2

Table 1: Features and Benefits (Part 2 of 2)

Features Benefits

NEMA 2 (IP54) Rated Aluminum Enclosure Protects the internal components of the actuator from dirt and moisture.

Easy-to-Use Locking Manual Override with

Auto Release and Crank Storage

Integral Connectors for 3/8 in. (10 mm)

Flexible Metal Conduit

Override Control

(Proportional Models Only)

Microprocessor-Controlled Brushless

DC Motor (-AGx, -GGx, and -HGx Types)

Allows for manual positioning of the actuator hub.

Simplify installation and field wiring.

Supports control system override applications through field wiring.

Provides constant run-time independent of torque.

Product Overview

The M9220-xxx-3 Electric Spring Return Actuators

provide reliable control of dampers and valves in

Heating, Ventilating, and Air Conditioning (HVAC)

systems.

IMPORTANT: Use this M9220-xxx-3 Electric Spring

Return Actuator only to control equipment under

normal operating conditions. Where failure or

malfunction of the electric actuator could lead to

personal injury or property damage to the controlled

equipment or other property, additional precautions

must be designed into the control system.

Incorporate and maintain other devices such as

supervisory or alarm systems or safety or limit

controls intended to warn of, or protect against,

failure or malfunction of the electric actuator.

IMPORTANT: Do not install or use this

M9220-xxx-3 Electric Spring Return Actuator in or

near environments where corrosive substances or

vapors could be present. Exposure of the electric

actuator to corrosive environments may damage the

internal components of the device, and will void the

warranty.

Operation

The M9220-xxx-3 Actuators are available for use with

on/off, floating, and proportional controllers.

On/Off Control (M9220-Bxx-3 Actuators)

When power is applied, the actuator drives open and

the output hub rotates against the spring from -5 to 90°.

The actuator is electronically overload protected should

the actuator stall before reaching 90°. It holds position

at the end of the stroke until power is removed. When

power is removed, the actuator spring returns to the

-5° position.

An M9220-603 adjustable stop kit is available to limit

the stroke of the actuator between 30 and 90° in 5°

increments. M9220-BxC-3 actuators include two

integral Single-Pole, Double-Throw (SPDT) auxiliary

switches. One switch is set to trip at 11° as the actuator

is spring return closed.

Floating Control (M9220-Axx-3 Actuators)

Note: The information in this section assumes that

Side A of the actuator (Counterclockwise [CCW] spring

return) is facing you and the Direct Acting/Reverse

Acting (DA/RA) selector switch is set in the DA

position.

The actuator receives power by applying AC/DC 24 V

between the black (common) and red (+AC/DC 24 V)

wires. A controller applies power between the black

and gray or black and orange wires to command the

actuator to drive Clockwise (CW) or CCW at a constant

speed, independent of load.

Applying AC/DC 24 V be twe e n the bl a ck and gr ay

wires causes the actuator to drive CW from -5 toward

90° at a constant speed, independent of load. The time

required to drive full stroke from 0 to 90° is nominally

150 seconds. When AC/DC 24 V power between the

black and gray wires is removed, the actuator stops

and holds its position. The longer power is applied

between the black and gray wires, the farther the

actuator rotates toward the 90° position.

Applying AC/DC 24 V power between the black and

orange wires causes the actuator to drive CCW toward

the -5° position. The longer AC/DC 24 V power is

applied between the black and orange wires, the

farther the actuator travels toward the -5° position.

When power between the black and orange wires is

removed, the actuator stops and holds its position.

M9220-xxx-3 Electric Spring Return Actuators Product Bulletin2

Page 3

Changing the DA/RA switch from DA to RA reverses

the direction the actuator drives when power is applied

between the black and gray or black and o range wir es.

The actuator is overload protected should it stall

anywhere within its stroke. If the actuator stalls, it

retries once after 2 minutes, assuming AC/DC 24 V is

still applied.

If power is lost between the black (common) and red

(+AC/DC 24 V) wires, the actuator spring returns to the

-5° position. If power between the black and red wires

is momentarily interrupted, the actuator drives to the

-5° position and waits for the controller to command it

in either the CW or CCW direction.

Proportional Control (M9220-GGx-3 Actuators)

Note: The information in this section assumes that

Side A of the actuator (CCW spring return) is facing

you and the control selector switch is set to the

0 …10 V CW position.

The actuator is powered with AC/DC 24 V power

between the black (common) and red (+AC/DC 24 V)

wires. A proportional controller provides a DC 0 to 10 V

signal between the black (common) and gray (control

signal input) wires.

As the control signal increases from DC 0 to 10 V, the

actuator drives CW from the -5 to 90° position. The

position at which the actuator stops is proportional to

the control signal. The actuator provides about

120 steps of control.

As the signal decreases, the actuator reverses

direction and drives CCW toward the -5° position. A

DC 0 to 10 V feedback signal is provided between the

black (common) and orange (DC 0 to 10 V feedback

signal output) to indicate the position of the actuator.

The direction in which the actuator drives with an

increasing control signal can be reversed by

positioning the selector switch to the DC 0... 10 V CCW

position. When the actuator is placed in this position,

and it is at the 90° position with a DC 0 V control signal,

the actuator proportionally drives to the -5° position as

the control signal increases.

The actuator spring returns when power is interrupted

between the black and red wires. When power returns,

the actuator drives to the fully spring-return position to

establish an end-of-stroke position, then drives to the

position commanded by the DC 0 to 10 V controller.

This model has a selector switch that provides

operation for DC 2 to 10 V controllers. This switch

allows a CW or CCW rotation as the control signal

increases from DC 2 to 10 V. The feedback signal

between the black and orange wires changes to

DC 2 to 10 V when the input signal selector is set to the

DC 2...10 V CW or CCW position.

The M9220-GGx-3 actuators can be controlled by a

DC0to20mA or DC4to20mA controller by placing

a field furnished 1/4 watt 500 ohm resistor between the

black (common) and orange (+DC 0([4] to 20 mA

control signal input) wires.

Proportional Control/Adjustable (M9220-HGx-3 Actuators)

The M9220-HGx-3 actuators operate in a similar

manner to the M9220-GGx-2 actuators, except the

M9220-HGx-3 actuators have an adjustable start

voltage, which can be programmed between

DC 0 to 10 V. The span adjustment can be

programmed between a DC 2 to 10 V range, allowing

the actuator to operate between DC 0 to 20 V. The

M9220-HGx-3 actuator is programmed in the factory

for DC0to10V.

For this actuator, the feedback signal between the

black and orange wires always provides a DC 0 to 10 V

output, regardless of the start voltage or span selected.

Repair Information

A number of replacement parts are available; see

Table 2 for more details. If the M9220-xxx-3 Electric

Spring Return Actuator fails to operate within its

specifications, replace the unit. For a replacement

electric actuator, contact the nearest

Johnson Controls® representative.

M9220-xxx-3 Electric Spring Return Actuators Product Bulletin 3

Page 4

Ordering Information

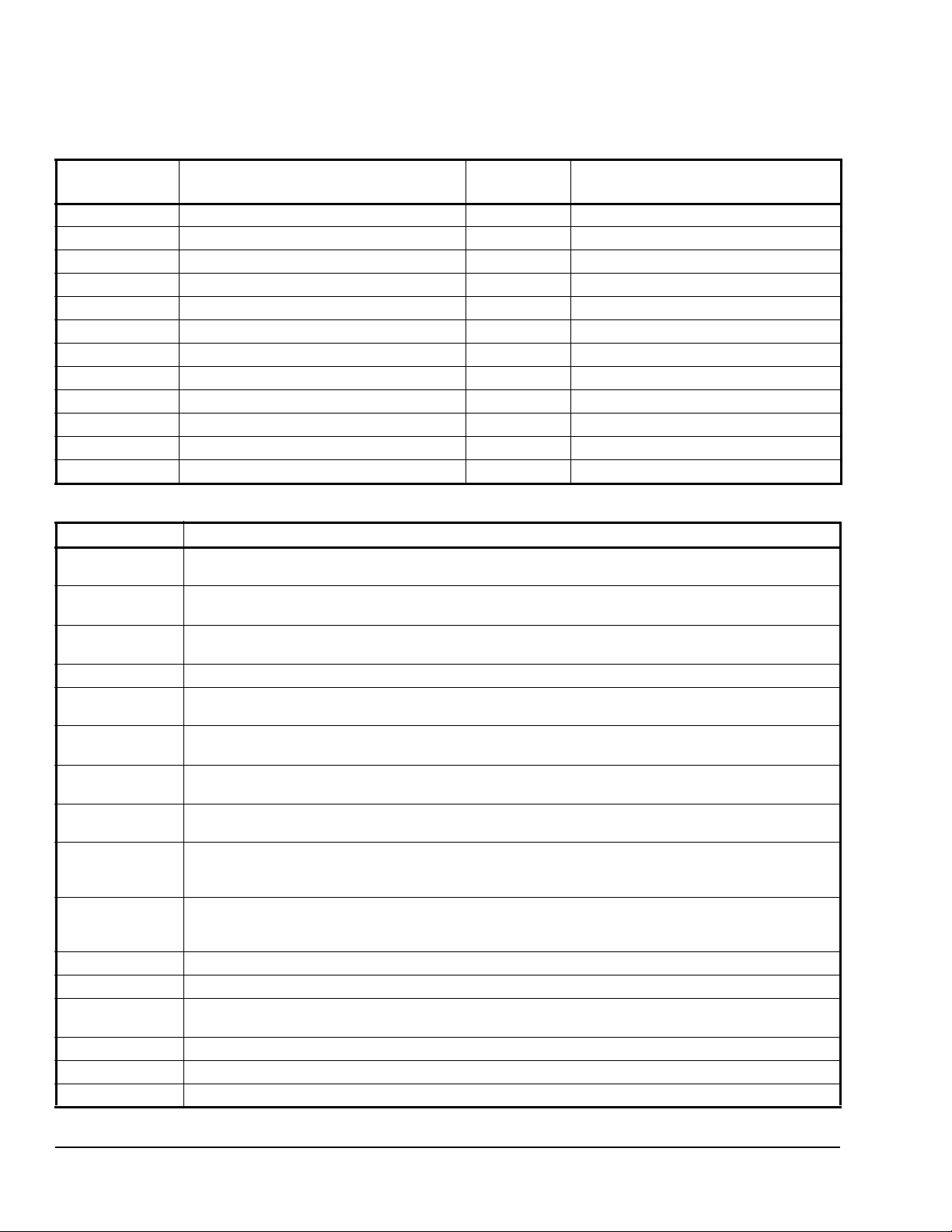

Table 2: Electric Spring Return Actuator Models

Code Number Control Type Auxiliary

Switches

M9220-AGA-3 Floating None AC 24 V at 50/60 Hz or DC 24 V

M9220-AGC-3 Floating Two AC 24 V at 50/60 Hz or DC 24 V

M9220-BAA-3 On/Off None AC 120 V at 60 Hz

M9220-BAC-3 On/Off Two AC 120 V at 60 Hz

M9220-BDA-3 On/Off None AC 230 V at 50/60 Hz

M9220-BDC-3 On/Off Two AC 230 V at 50/60 Hz

M9220-BGA-3 On/Off None AC 24 V at 50/60 Hz or DC 24 V

M9220-BGC-3 On/Off Two AC 24 V at 50/60 Hz or DC 24 V

M9220-GGA-3 Proportional None AC 24 V at 50/60 Hz or DC 24 V

M9220-GGC-3 Proportional Two AC 24 V at 50/60 Hz or DC 24 V

M9220-HGA-3 Proportional w/Adjustable Zero and Span None AC 24 V at 50/60 Hz or DC 24 V

M9220-HGC-3 Proportional w/Adjustable Zero and Span Two AC 24 V at 50/60 Hz or DC 24 V

Table 3: Accessories and Replacement Parts (Order Separately)

Code Number Description

1

DMPR-KC003

M9000-158 Tandem Mounting Kit used to Mount Two Models of M9220-xxx-3 Series Proportional Electric Spring

M9000-200 Commissioning Tool that Provides a Control Signal to Drive 24 V On/Off, Floating, Proportional,

M9000-153 Crank arm

M9000-170 Remote Mounting Kit, Horizontal. Kit includes Mounting Bracket, M9000-153 Crank Arm, Ball Joint, and

M9000-171 Remote Mounting Kit, Vertical. Kit includes Mounting Bracket, M9000-153 Crank Arm, Ball Joint, and

M9000-320 Weather Shield Enclosure - NEMA 3R Enclosure for Protecting a Single M9210/20 Actuator from Rain,

M9000-604 Replacement Anti-rotation Bracket Kit (with Screws) for

M9220-600 1 in. (25 mm) Jackshaft Coupler Kit (with Locking Clip) for Mounting M9220-xxx-3 Proportional Electric

M9220-601 Replacement Coupler Kit (with Locking Clip) for Mounting M9220-xxx-3 Proportional Electric Spring

M9220-602 Replacement Locking Clips for M9220-xxx-3 Proportional Electric Spring Return Actuators (Five per Bag)

M9220-603 Adjustable Stop Kit for M9220-xxx-3 Proportional Electric Spring Return Actuators

M9220-604 Replacement Manual Override Cranks for M9220-xxx-3 Proportional Electric Spring Return Actuators

M9220-610 Replacement Shaft Gripper, 10 mm Square Shaft with Locking Clip

M9220-612 Replacement Shaft Gripper, 12 mm Square Shaft with Locking Clip

M9220-614 Replacement Shaft Gripper, 14 mm Square Shaft with Locking Clip

7 in. (178 mm) Blade Pin Extension (without Bracket) for Johnson Controls Direct-Mount Damper

Applications

Return Actuators

and/or Resistive Electric Actuators

Mounting Bolts

Mounting Bolts

Sleet, or Snow

M9220-xxx-3 Series Proportional Electric Spring Return Actuators

Spring Return Actuators on Dampers with 3/4 to 1-1/16 in. or 19 to 27 mm Round Shafts, or

5/8 and 3/4 in. or 16, 18, and 19 mm Square Shafts

Return Actuators on Dampers with 1/2 to 3/4 in. or 12 to 19 mm Round Shafts, or 3/8 and 1/2 in. or 10,

12, and 14 mm Square Shafts

(Five per Bag)

Power Requirements

1. Furnished with the damper and orderable separately.

M9220-xxx-3 Electric Spring Return Actuators Product Bulletin4

Page 5

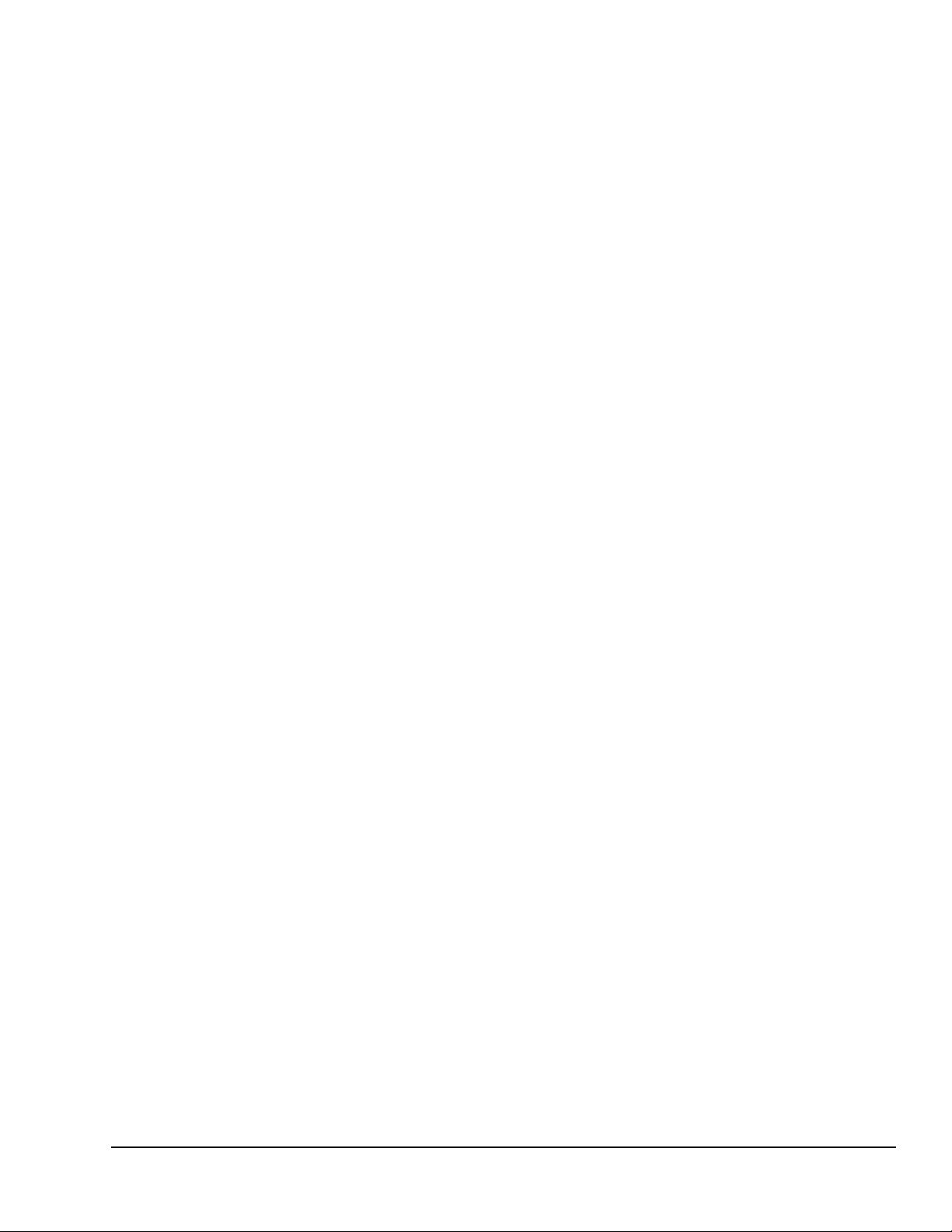

Figure 2: M9220-xxx-3 Electric Spring Return Actuator Dimensions, in. (mm)

A

4

(102)

10-5/16

(262)

2-3/16

(56)

FIG:dmns

1-3/4

(44)

3-3/16

(81)

3/4

(19)

(56)

2

(51)

1-19/32

(40)

1-1/16

(27)

1/4 (6.5)

Mounti ng Hole

(6 Locations)

1-19/32

(40)

1-19/32

(40)

6-15/16

(176)

Dimensions

10

(254)

1/8

(3)

1

(25)

2-3/16

M9220-xxx-3 Electric Spring Return Actuators Product Bulletin 5

Page 6

Technical Specifications

M9220-xxx Series Electric Spring Return Actuators (Part 1 of 3)

Product Codes M9220-AGx-3 Models: Floating

M9220-Bxx-3 Models: On/Off

M9220-GGx-3 Models: Proportional

M9220-HGx-3 Models: Proportional Adjustable

Power Requirements AGx, HGx, GGx

Models

BAx Models AC 120 V (AC 102 to 132 V) at 60 Hz: 0.25 A Running, 0.13 A Holding

BDx Models AC 230 V (AC 198 to 264 V) at 50/60 Hz: 0.15 A Running, 0.09 A Holding

BGx Models AC 24 V (19.2 to 30 V) at 50/60 Hz: Class 2, 24.6 VA Running,

Transformer Sizing

Requirements

Input Signal/Adjustments AGx Models AC 19.2 to 30 V at 50/60 Hz or DC 24 V ±10%, Class 2;

Control Input Impedance GGx, HGx

Feedback Signal GGx Models 0 (2) to 10 VDC for Desired Rotation Range up to 90°;

Auxiliary Switch Rating xxC Models Two Single-Pole, Double-Throw (SPDT), Double-Insulated Switches with

Spring Return Direction is Selectable with Mounting Position of Actuator:

Running and Spring Return Torque 177 lb·in (20 N·m) for a Single Actuator;

AGx, HGx, GGx

Models

Bxx Models 25 VA Minimum per Actuator

GGx Models Factory Set DC 0 to 10 V, CW Rotation with Signal In crease;

HGx Models Factory Set DC 0 to 10 V, CW Rotation with Signal Increase;

Models

HGx Models 0 to 10 VDC for Desired Rotation Range up to 90°;

AC 24 V (19.2 to 30 V) at 50/60 Hz: Class 2, 15.5 VA Running,

7.7 VA Holding Position;

DC 24 V (21.6 to 26.4 V): Class 2, 6.7 W Running, 2.9 W Holding Position

Position

Position

7.7 VA Holding Position;

DC 24 V (21.6 to 26.4 V): Class 2, 17.6 W Running,

2.8 W Holding Position

20 VA Minimum per Actuator

Switch Selectable Direct or Reverse Action with Signal Increase

Selectable DC 0 (2) to 10 V or 0 (4) to 20 mA with Field Furnished 500

Ohm, 0.25 W Minimum Resistor; Switch Selectable Direct or Reverse

Action with Signal Increase

Selectable DC 0 to 10 V or 0 to 20 mA with Field Furnished 500 Ohm,

0.25 W Minimum Resistor;

Start Point Programmable DC 0 to 10 V;

Span Programmable DC2to10V;

Switch Selectable Direct or Reverse Action with Signal Increase

Voltage Input: 100,000 Ohms;

Current Input: 500 Ohms with Field Furnished 500 ohm Resistor

Corresponds to Rotation Limits, 1 mA maximum

Corresponds to Rotation Limits, 1 mA maximum

Gold Flash Contacts:

AC 24 V, 50 VA Pilot Duty;

AC 120 V, 5.8 A Resistive, 1/4 hp, 275 VA Pilot Duty;

AC 240 V, 5.0 A Resistive, 1/4 hp, 275 VA Pilot Duty

Side A, Actuator Face Away from Damper for CCW Spring Return;

Side B, Actuator Face Away from Damper for CW Spring Return

354 lb·in (40 N·m) for Two Models Mounted in Tandem

531 lb·in (60 N·m) for Three Models Mounted in Tandem

M9220-xxx-3 Electric Spring Return Actuators Product Bulletin6

Page 7

M9220-xxx Series Electric Spring Return Actuators (Part 2 of 3)

Valid Tandem Combinations Two M9220-Bxx-3

Three M9220-AGx-3

One M9220-HGx-3 Master with One or Two M9220-GGX-3 Slaves

One M9220-GGx-3 Master with One or Two M9220-GGX-3 Slaves

Rotation Range Adjustable from 30 to 90° CW or CCW with Optional

M9220-603 Adjustable Stop Kit; Mechanically Limited to 90°

Rotation Time

Power On (Running)

Rotation Time

Power Off

(Spring Returning)

Cycles 60,000 Full Stroke Cycles; 1,500,000 repositions

Audible Noise Rating

(AGx, HGx, GGx Models)

Audible Noise Rating

(BGx Models)

Electrical Connections Actuator

Conduit Connections Integral Connectors for 3/8 in. (10 mm) Flexible Metal Conduit

Mechanical Connections Standard

Aluminum Enclosure NEMA 2 (IP54) for All Mounting Orientations

Ambient Conditions Operating -40 to 131°F (-40 to 55°C); 90% RH Maximum, Noncondensing

Dimensions See Figure 2.

AGx Models 150 Seconds for 0 to 177 lb·in (0 to 20 N·m) at All Operating Conditions;

Independent of Load

HGx, GGx

Models

BGx Models 24 to 57 Seconds for 0 to 177 lb·in (0 to 20 N·m) at All Operating

AGx, HGx, GGx

Models

BGx Models 11 to 15 Seconds for 0 to 177 lb·in (0 to 20 N·m) at Room Temperature;

Power On

(Running)

Power On

(Holding)

Power Off

(Spring

Returning)

Power On

(Running)

Power On

(Holding)

Power Off

(Spring

Returning)

(All Models)

Auxiliary

Switches

(xxC Models)

Shaft Clamp

Included with

Actuator

Optional

M9220-600

Jackshaft

Coupler Kit

Storage -85 to 185°F (-65 to 85°C); 95% RH Maximum, Noncondensing

150 Seconds for 0 to 177 lb·in (0 to 20 N·m) at All Operating Conditions;

Independent of Load

90 Seconds for 0 to 177 lb·in (0 to 20 N·m) in Calibration or Override Mode

Conditions; 35 Seconds Nominal at Full Rated Load

20 Seconds for 0 to 177 lb·in (0 to 20 N·m) at Room Temperature

35 Seconds Maximum for 0 to 177 lb·in (0 to 20 N·m) at -22°F (-30°C)

130 Seconds Maximum for 0 to 177 lb·in (0 to 20 N·m) at -40°F (-40°C)

<40 dBA at 39-13/32 in. (1 m)

<20 dBA at 39-13/32 in. (1 m)

<55 dBA at 39-13/32 in. (1 m)

<66 dBA at 39-13/32 in. (1 m)

<18 dBA at 39-13/32 in. (1 m)

<66 dBA at 39-13/32 in. (1 m)

48 in. (1.2 m) Halogen-Free Cable with 18 AWG (0.75 mm

48 in. (1.2 m) Halogen-Free Cable with 18 AWG (0.75 mm2) Wire Leads

1/2 to 3/4 in. or 12 to 19 mm Diameter Round Shafts, or

3/8 and 1/2 in. or 10, 12, and 14 mm Square Shafts

3/4 to 1-1/16 in. or 19 to 27 mm Diameter Round Shafts, or

5/8 and 3/4 in. or 16, 18, and 19 mm Square Shafts

2

) Wire Leads

M9220-xxx-3 Electric Spring Return Actuators Product Bulletin 7

Page 8

Metasys® and Johnson Controls® are registered trademarks of Johnson Controls, Inc.

All other marks herein are the marks of their respective owners. © 2012 Johnson Controls, Inc.

Building Efficiency

507 E. Michigan Street, Milwaukee, WI 53202

M9220-xxx Series Electric Spring Return Actuators (Part 3 of 3)

Compliance North America UL Listed, File E27734, CCN XAPX (United States) and XAPX7 (Canada)

Europe CE Mark, EMC Directive 89/336/EEC (M9220-xGA-3 Models)

CE Mark, Low Voltage Directive 73/23/EEC

(M9220-BDA-3 and M9220-xxC-3 Models)

Australia and

New Zealand

Shipping Weight xGx Models 6.4 lb (2.9 kg)

BAx and BDx

Models

The performance specifications are nominal and conform to acceptable industry standards. For application at conditions beyond these

specifications, consult the local Johnson Controls office. Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or

misuse of its products.

C-Tick Mark, Australia/NZ Emissions Compliant

(Models: All M9220-xGx and M9220-xDx)

7.6 lb (3.5 kg)

M9220-xxx-3 Electric Spring Return Actuators Product Bulletin 8

Published in U.S.A. www.johnsoncontrols.com

Loading...

Loading...