Page 1

M9106-xGx-2 Series

Electric Non-Spring-Return Actuator

Electric Damper Actuators

M9106-xGx-2 Series Electric Non-Spring-Return Actuators

Description

The M9106-xGx-2 Series direct-mount electric

actuators operate on AC 24 V power and are

available for use with on/off, floating, or

proportional controllers. These

non-spring-return actuators are easily installed

Electric Damper Actuators

Electric Damper ActuatorsElectric Damper Actuators

on a VAV box, a damper with a round shaft up

to 1/2 in. (13 mm) in diameter, or a square

shaft up to 3/8 in. (10 mm). The M9106 with an

M9000-520 linkage can also be used to

position VG1000 Series 1/2 in. (DN15) to

1-1/2 in. (DN40) ball valves.

The M9106 Series models have 53 lb·in

(6 N·m) running torque. These actuators have

a nominal 60-second travel time for 90° of

rotation at 60 Hz (72 seconds at 50 Hz) with a

load-independent rotation time.

The M9106-xGC-2 models are available with

integral auxiliary switches to perform switching

functions at any angle within the selected

rotation range. The -GGx models feature

DC 0(2) to 10 V position feedback, and the

-AGF models provide 10,000 ohm position

feedback.

Features

• simple direct coupling reduces installation

and commissioning time and improves

reliability by eliminating damper linkages;

single screw coupling provides three-point

shaft gripping

• designed for zone damper and ball valve

actuator applications

• small, compact design allows installation in

tight-fitting locations

• on/off, floating, and proportional control

inputs

• 60-second running time at 60 Hz

• long life brushless synchronous drive motor

technology provides constant running time

independent of load

• robust 53 lb·in (6 N·m) torque rating

Electric Damper Actuators

• whisper quiet 35 dBA noise rating

• magnetic clutch provides over torque

protection over the entire range of rotation

• -4 to 125°F (-20 to 52 °C) ambient

temperature rating

• 100,000 full stroke cycle, 2,500,000

reposition rating

• manual gear release simplifies setup and

field adjustments

• 1/2 in. NPT threaded conduit opening

meets electrical code requirements and

allows the use of flexible armored cable

• position feedback (-GGX models) provides

simple, closed-loop control with accurate

position sensing

• adjustable rotation stops allow application

versatility with 30 to 90° clockwise or

counterclockwise rotation

Applications

The M9106 actuators are used to position

balancing, control, round, and zone dampers

in typical HVAC applications. The M9106 can

also be used with an M9000-520 linkage to

control 1/2 in. (DN15) to 1-1/2 in. (DN40)

VG1000 Series ball valves. The M9106 Series

actuator mounts directly on the duct surface,

round damper, or small rectangular damper

with an anti-rotation bracket and two sheet

metal screws (included). Additional linkages or

couplers are not required.

Refer to the damper or VAV box

manufacturer’s information to select the

proper timing for the actuator. Refer to the

appropriate application note for specific wiring

diagrams and information.

Code No. LIT-1900118

Refer to the M9106-xGx-2 Electric

Non-Spring-Return Actuators Product Bulletin

(LIT-2681123) or the M9106-xGx-2 Electric

Non-Spring-Return Actuators Installation

Instructions (Part No. 34-636-1085) for

important product application information.

Repair Information

If the M9106-xGx-2 Series Electric Actuator

fails to operate within its specifications,

replace the unit. For a replacement actuator,

contact the nearest Johnson Controls®

representative.

Selection Chart

Code Number Control Type Torque / Timing / Voltage Auxiliary Switches Comments

1

M9106-AGA-2

M9106-AGC-2

M9106-AGF-2

M9106-GGA-2 DC 0(2) to 10 V

M9106-GGC-2 2-SPDT

M9106-IGA-2 On/off / floating with timeout None Adjustable timing 1, 1.5, 2, 5.5, or 11 minutes

M9106-IGC-2 2-SPDT

1. T o avoid excessive wear or dive time on t he motor for the -AGx models, use a cont roller and/or sof tware that provides a t ime-ou t functi on to remove the sign al at

the end of rotation (stall). The -GGx and -IGx models have an auto shutoff to avoid excessive wear or drive time on the motor.

The performance specifications are nomina l and con form to accep table ind ustry stand ards. For applicati ons at con ditions be yond these specification s, consult th

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2014 Johnson Controls, Inc.

Floating 53 lb·in (6 N·m)

1

1

Floating with resistive feedback None 10,000 ohm feedback pot

DC 0(4) to mA proportional

60 seconds at 60 Hz

AC 24 V 50/60 Hz

None

2-SPDT

None DC 0(2) to 10 V feedback

V–24

Page 2

Electric Damper Actuators

M9106-xGx-2 Series Electric Non-Spring-Return Actuators (Continued)

Accessories

Code Number Description

CBL-2000-1 20 in. (0.5 m) wiring harness, UL accepted for plenum use, connects the M9106 and DPT-2015 to the VAV controll er

CBL-2000-2 20 in. (0.5 m) plenum rated wiring harness

CBL-2000-3 72 in. (1.8 m) plenum rated wiring harness

DPT-2015-0 0 to 1.5 in. W.C. (0 to 374 Pa) differential pressure transmitter

DMPR-KC003 Square head blade pin extension without bracket supplied with Johnson Controls CD-1300 dampers and may be ordered separately for all

DMPR-KC010 Adjustable blade position indicator switch kit with total switching load limited to 2,000 VA for the foll owing applications:

DMPR-KC011 Hex head blade pin extension without bracket

DMPR-KC012 Hex head blade pin extension with bracket

DMPR-KC213 Damper jackshaft 1/2 in. diameter, 1 panel

DMPR-KC214 Damper jackshaft 1/2 in. diameter, 2 panel

M9000-105 Pluggable 3-terminal block

M9000-106 Pluggable 4-terminal block

M9000-160 Replacement anti-rotation bracket for M9106 Series actuators

M9000-200 Commissioning tool provides a control signal to drive on/off, floating, proportional, or resistive actuators

M9000-520 Valve linkage kit for field mounting an M9106 Series actuator to a 1/2 in. (DN15) to 1-1/2 in. (DN40) VG1000 Series ball valve

direct-mount applications

Pilot duty: AC 24 V, 50 VA; AC 125/ 250/277 V, 125 VA

Motor load: AC 125/250/277 V, 1/3 hp

Resistive load: AC 125 V , 11 A; AC 250 V, 8 A; AC 277 V, 7 A (all maximum values)

Electric Damper ActuatorsElectric Damper ActuatorsElectric Damper ActuatorsElectric Damper Actuators

The performance specifications are no minal and co nform t o acceptab le ind ustry standar ds. For appl ications at condition s beyond these specifica tions, consult th

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2014 Johnson Controls, Inc.

V–25

Page 3

Electric Damper Actuators

M9106-xGx-2 Series Electric Non-Spring-Return Actuators (Continued)

Technical Specifications

Power Requirement AGx: AC 20-30 V at 50/60 Hz, 2.5 VA supply, Class 2

Control Type AGx: floating

Electric Damper Actuators

Electric Damper ActuatorsElectric Damper Actuators

Input Signal AGx and IGx: AC 20 to 30 V at 50/60 Hz

Input Signal Adjustments: AGx and IGx: CW and COM Terminals, CW rotation; CCW and COM terminals, CCW rotation

Input Impedance AGx: 200 ohms, nominal

Feedback Signal AGF: 10,000 ohm potentiometer, 1 W

Auxiliary Switch Rating xGC: two single-pole, double-throw (SPDT) switches rated at AC 24 V, 1.5 A inductive, 3.0 A resistive, 35 VA

Torque Rating 1, 1.5, and 2 minute settings: 53 lb·in (6 N·m)

Cycle Life 100,000 full cycles; 2,500,000 repositions rated at 53 lb·in (6 N·m)

Audible Noise Rating 35 dBA maximum at 39.4 in. (1 m)

Rotation Range Adjustable from 30 to 90°, CW or CCW

Rotation Time IGx: adjustable with switch settings (factory set for 1 minute) 60, 90, 120, 330, or 660 seconds (1, 1.5, 2, 5.5 or

Electrical Connection 1/4 in. spade terminals (to order optional pluggable terminal blocks, see Accessories

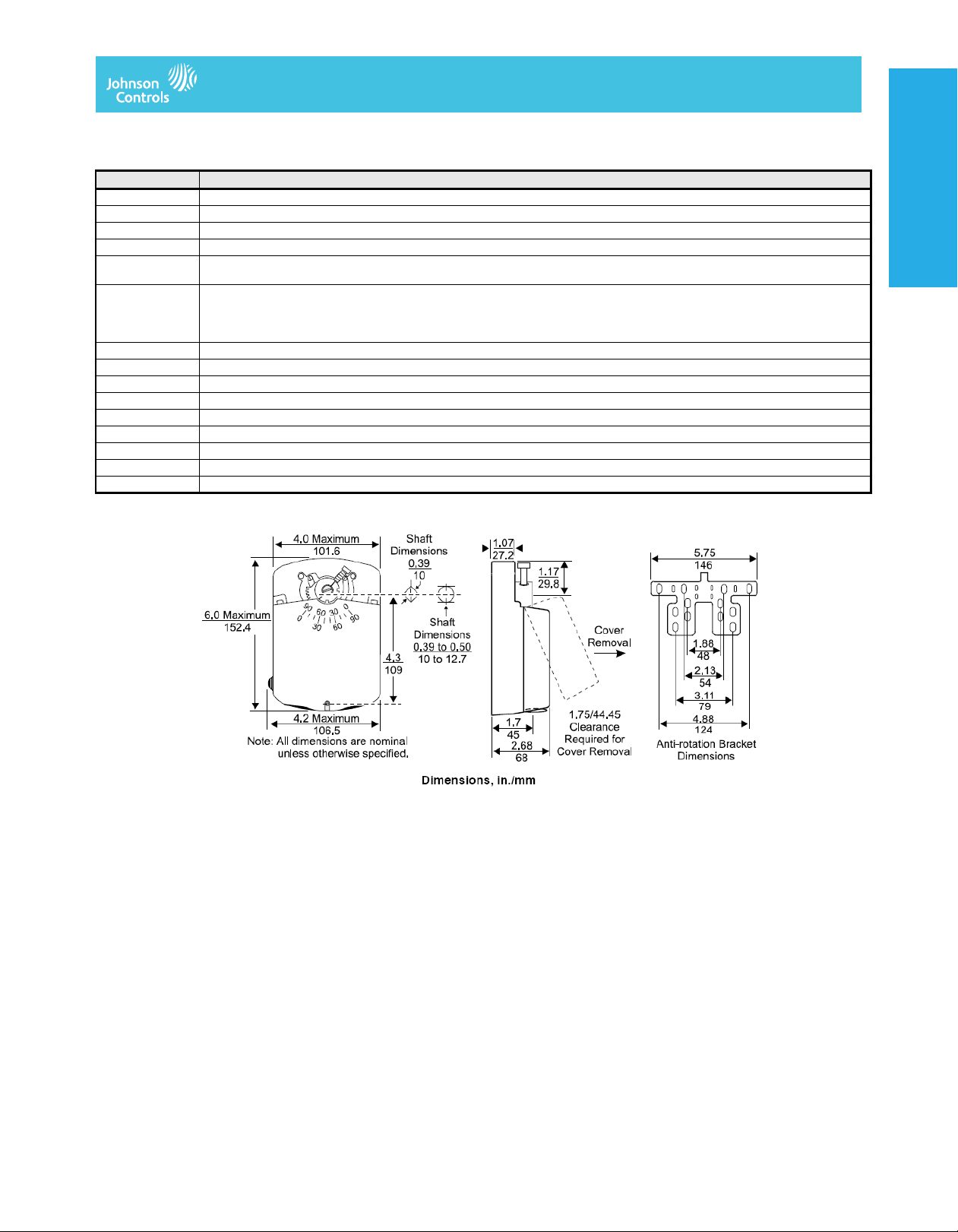

Mechanical Connection 3/8 to 1/2 in. (10 to 12.7 mm) round shaft or 3/8 in. (10 mm) square shaft

Enclosure Rating NEMA 2, IP32

Ambient Operating Rating -4 to 125°F (-20 to 52°C); 90% RH maximum, noncondensing

Ambient Storage Rating IGx: -40 to 186°F (-40 to 86°C); 90% RH maximum, noncondensing

Shipping Weight 2.4 lb (1.08 kg)

Compliance United States UL 873 Listed, File E27734, CCN XAPX

Electric Damper Actuators

M9106-xGx-2 Series Electric Non-Spring-Return Actuators

IGx: AC 20-30 V at 50/60 Hz, 2.8 VA supply, Class 2

GGx: AC 20-30 V at 50/60 Hz, 3.2 VA supply, Cl ass 2

IGx: on/off, floating

GGx: DC 0(2) to 10 V or DC 0(4) to 20 mA proportional

GGx: DC 0 to 10 V or DC 0(4) to 20 mA

GGx (voltage input or current input):

Jumper selectable: DC 0(2) to 10 V or DC 0(4) to 20 mA

Factory setting: DC 0 to 10 V, CW rotation with signal increase

Action is jumper selectable direct (CW) or reverse (CCW) with signal increase.

IGx: 160 ohms, nominal

GGx: voltage input, 150,000 ohms; current input , 500 ohms

GGx: DC 0 to 10 V or DC 2 to 10 V for 90° (1 mA);

Corresponds to input signal span selection

maximum per switch, Class 2

5.5 and 11 minute se ttings: 35 lb·in (4 N·m)

11minutes) at 60 Hz and 72, 108, 144, 396, or 792 seconds at 50 Hz

All other models: nominal 60 seconds at 60 Hz and 72 seconds at 50 Hz for 90°

)

All other models: -40 to 176°F (-40 to 80°C); 90% RH maximum, noncondensing

Canada CSA C22.2 No. 139 Certified, File LR85083, Class 3221 02

Europe CE Mark - Johnson Controls, Inc. declares that this product is in compliance wit h the essential requirement s and othe r

relevant provisions of the EMC Directive 2004/108/EC.

The performance specifications are no minal and co nform t o acceptab le ind ustry standar ds. For appl ications at condition s beyond these specifica tions, consult th

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2014 Johnson Controls, Inc.

V–26

Loading...

Loading...