Page 1

M9102-AGA-1S and M9104-xGA-1S Series Electric

Non-Spring Return Actuators

Installation Instructions

Refer to the QuickLIT website for the most up-to-date version of this document.

Part No. 34-636-1506, Rev. F

Issued July 14, 2015

Applications

The M9102 and M9104 Series Actuators are directmount, non-spring return elec tric actuators that operate

on AC 24 V power. Employing a synchronous motor,

these actuators provide floating control (AGA), floating

control with automatic shut-off (IGA), and proportional

control with selectable 0-10 or 2-10 VDC (GGA).

All models are compact in size, and are easily installed

on Variable Air Volume (VAV) boxes, Variable Air

Volume and Temperature (VVT) two-position zone

applications, or small to medium-sized dampers with a

round shaft up to 13 mm in diameter, or a 10 mm

square shaft.

The M9102 Series Electric Non-Spring Return

Actuators provide a running torque of 2 N·m, and the

nominal travel time is 36 seconds at 50 Hz for 90° of

rotation.

The M9104 Series Electric Non-Spring Return

Actuators provide a running torque of 4 N·m, and the

nominal travel time is 72 seconds at 50 Hz for 90° of

rotation.

IMPORTANT: Use this M9102 or M9104 Series

Electric Non-Spring Return Actuator only to control

equipment under normal operating conditions.

Where failure or malfunction of the electric actuator

could lead to personal injury or property damage to

the controlled equipment or other property,

additional precautions must be designed into the

control system. Incorporate and maintain other

devices such as supervisory or alarm systems or

safety or limit controls intended to warn of, or protect

against, failure or malfunction of the electric

actuator.

IMPORTANT: Utiliser ce M9102 or M9104 Series

Electric Non-Spring Return Actuator uniquement

pour commander des équipements dans des

conditions normales de fonctionnement. Lorsqu'une

défaillance ou un dysfonctionnement du electric

actuator risque de provoquer des blessures ou

d'endommager l'équipement contrôlé ou un autre

équipement, la conception du système de contrôle

doit intégrer des dispositifs de protection

supplémentaires. Veiller dans ce cas à intégrer de

façon permanente d'autres dispositifs, tels que des

systèmes de supervision ou d'alarme, ou des

dispositifs de sécurité ou de limitation, ayant une

fonction d'avertissement ou de protection en cas de

défaillance ou de dysfonctionnement du electric

actuator.

M9102-AGA-1S and M9104-xGA-1S Series Electric Non-Spring Return Actuators

Installation Instructions

1

Page 2

Installation

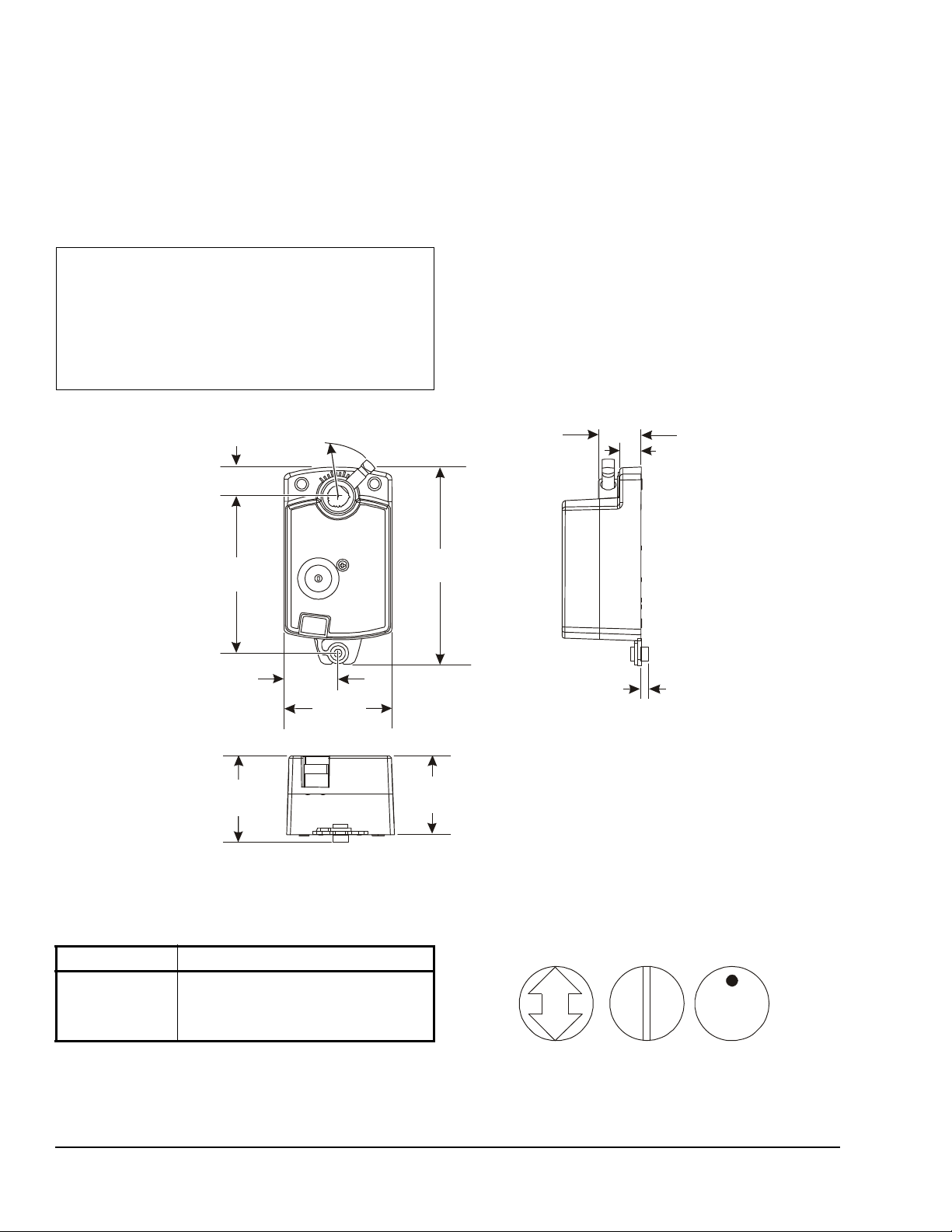

Figure 1: M9102 and M9104 Series Electric Non-Spring Return Actuator Dimensions, mm

36

71

104

131

57

32

20

Radius

Clearance

F

I

G

:

d

m

Figure 2: Damper Position Icons

The M9102 and M9104 Series Electric Non-Spring

Return Actuators mount directly to the surface in any

convenient orientation using a single No. 10 self-drilling

sheet metal screw (included with the actuator). No

additional linkages or couplers are required. Electrical

connections on the actuator are clearly labeled to

simplify installation.

IMPORTANT: Do not install or use this M9102 or

M9104 Series Electric Non-Spring Return Actuator

in or near environments where corrosive substances

or vapors could be present. Exposure of the electric

actuator to corrosive environments may damage the

internal components of the device, and will void the

warranty.

Set Screw

Parts Included

• one electric non-spring return actuator with an

integrated 1.2 m (48 in.) long cable

• one No.10 self-drilling sheet metal screw

Special Tools Needed

• 8 mm square socket

• #2 Phillips screwdriver

• 10 mm 12-point socket

• drill with a 8 mm hex nut driver

• digital voltmeter or M9000-200 Commissioning

Tool

28

14

Accessories

Table 1: Accessories (Order Separately)

Code Number Description

M9000-200 Commissioning Tool that Provides a

Mounting

To mount the actuator to a damper:

Control Signal to Drive 24 V On/Off,

Floating, Proportional, and/or Resistive

Electric Actuators

5

52

m

i

d

_

t

c

a

:

G

I

F

1. Check that the damper blade is visually accessible,

or its position is permanently marked on the end of

the damper shaft, as illustrated in Figure 2.

s

o

p

_

p

M9102-AGA-1S and M9104-xGA-1S Series Electric Non-Spring Return Actuators Installation Instructions2

Page 3

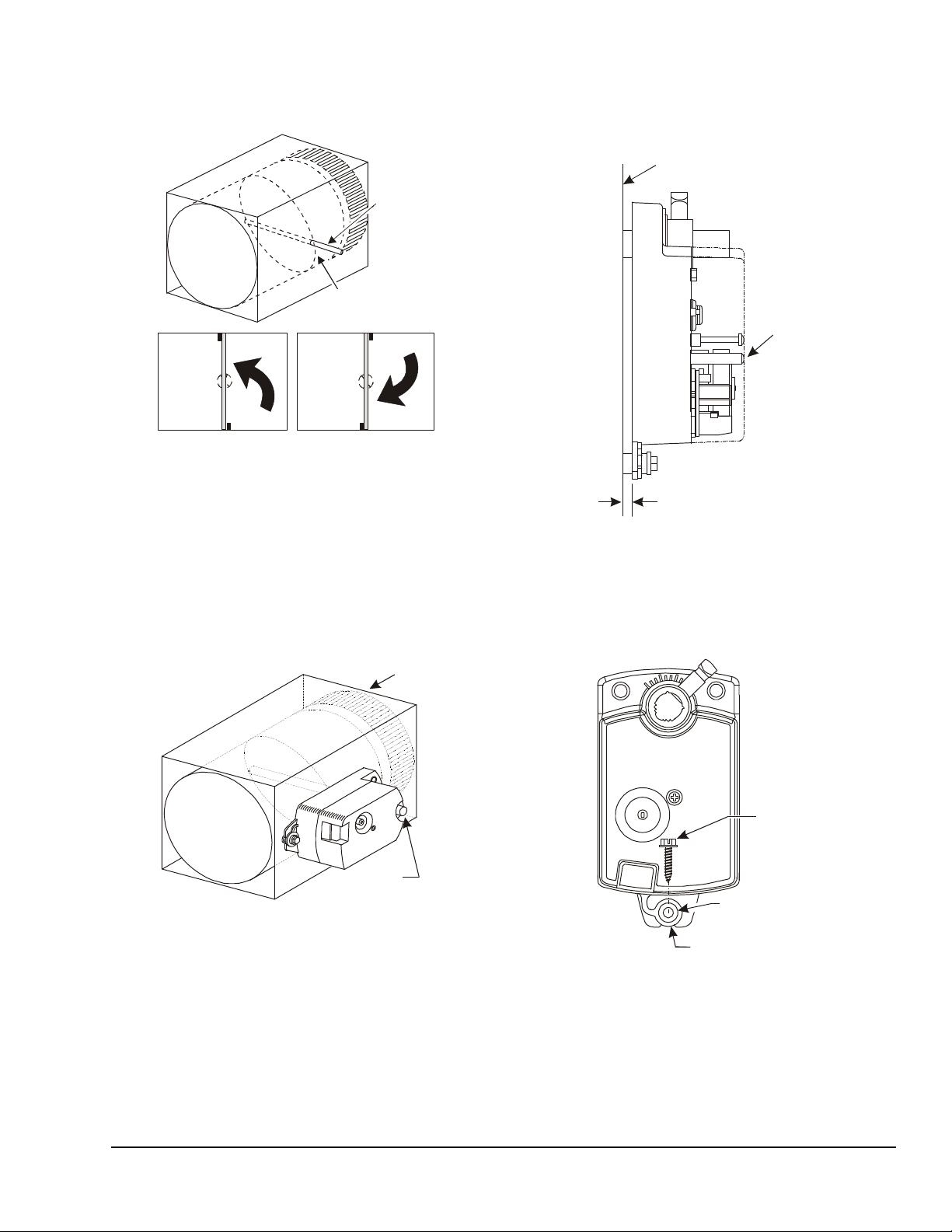

2. Grasp the damper shaft firmly with pliers and rotate

Shaft

CCW to

Close

CW to

Close

Blade

Damper

Figure 3: Damper Rotation

F

I

G

:

a

c

t

_

m

o

u

n

t

Damper

Shaft

Figure 4: Mounting the Actuator onto the

Damper Shaft

Figure 5: Positioning the Actuator

F

I

G

:

a

c

t

_

p

o

s

Button

Approximately a

5 mm Gap

Surface

Figure 6: Inserting the Screw into the Shoulder

Washer

No. 10

Sheet Metal

Screw

F

I

G

:

s

c

r

_

w

a

s

h

Plastic

Washer

Washer

the damper fully closed, as illustrated in Figure 3.

Damper

Damper

t

a

t

o

r

_

p

m

d

:

G

I

F

3. Press and hold the gear release lever, and rotate

the actuator coupler to the fully closed position.

4. Make a note of the rotation range and direction,

either Clockwise (CW) or Counterclockwise

(CCW), required to close the damper.

5. Position the actuator onto the damper shaf t so that

the damper shaft protrudes through the actu at or

coupler, as illustrated in Figure 4.

6. Be certain that the actuator is in the desired

mounting position parallel to the mounting surface,

as illustrated in Figure 5.

Mounting

Gear

Release

7. Hold the actuator in place on the damper shaf t, and

insert the No. 10 self-drilling sheet metal screw

through the shoulder washer as illustrated in

Figure 6.

Damper

Self-Drilling

Shoulder

Retainer

M9102-AGA-1S and M9104-xGA-1S Series Electric Non-Spring Return Actuators Installation Instructions 3

Page 4

8. Place a 8 mm socket on the screw and use a drill

Figure 7: M9102-AGA-1S and M9104-AGA-1S

Control Wiring Diagram

DA

1

3

F

I

G

:

M

9

1

0

x

-

A

G

A

-

1

S

d

i

DA

2

BLK

Figure 8: M9104-IGA-1S Control Wiring

Diagram - Floating

3

~

12

RED

BLK ORN

DA

DA

Figure 9: M9104-IGA-1S Control Wiring

Diagram - On/Off

312

BLK

DADA

and extension to drill the screw into the mounting

surface. Drive the screw until it is tight against the

washer.

IMPORTANT: Do not overtighten the mounting

screw. Overtightening may strip the threads.

9. Tighten the square cou pler bolt to the shaft using

an 8 mm (5/16 in.) wrench or 10 mm (3/8 in.) 12point socket. Tighten to 11 to 15 N·m (100 to 130

lb·in).

Wiring

M9102-AGA-1S, M9104-AGA-1S

The M9102 and M9104 Series Electric Non-Spring

Return Actuators require an AC 24 V input signal and

are compatible with a variety of VAV and VVT

controllers. These electric actuators include an

integrated 1.2 m (48 in.) long cable. See Figure 7 for

proper wiring.

g

a

RED ORN

M9104-IGA-1S

The M9104-IGA Series Electric Non-Spring Return

valve actuators require an AC 24 V input signal and

work with a variety of controllers. These electric

actuators include an integrated 1.2 m (48 in.) long

cable and have an auto-shutoff feature to preven t

excessive wear or drive time on the motor. See

Figure 8 and Figure 9 for proper wiring options.

AC 24 V 50/60 Hz

AC 24 V 50/60 Hz

~

Note: When using an AGA model, you must use a

VAV or VVT controller and/or software that provides a

timeout function at the end of rotation (stall) to avoid

excessive wear or drive time on the actuator motor.

ORN

RED

AC 24 V 50/60 Hz

~

Note: When using the VA9104-AGA-1S or

VA9104-IGA-1S Series actuator with a controller

featuring triac output, add a 4.7k ohm resistor one half

watt between the Common (COM) and CCW terminals.

M9102-AGA-1S and M9104-xGA-1S Series Electric Non-Spring Return Actuators Installation Instructions4

Page 5

M9104-GGA-1S

Figure 10: M9104-GGA-1S Control Wiring

Diagram

External Resistor

Y

DC 0(2)...10 V Control

DC 0(2)...10 V

~

2

AC 24 V

0(2)...10 V

1

DC 0(4)...20 mA

AC

24 V

Y

~

+

2

AC 24 V

1

!

!

Figure 11: Feedback Signal Relative to the

Rotation Range

10.0V

8.7V

7.3V

6.0V

4.7V

3.3V

10.0V

8.3V

6.7V

5.0V

3.3V

1.7V

75°

75°

60°

60°45°

45°

30°

30°

15°

15°

0°

0°

Rotation Range

2-10V

Feedback

0-10V

Feedback

Direct

Acting

2-10V

Feedback

Reverse

Acting

0-10V

Feedback

0.0V

1.7V

3.3V 5.0V

6.7V

8.3V

10.0V

10.0V

8.7V7.3V6.0V4.7V

3.3V2.0V

Figure 12: M9104-GGA Factory Switch Setting

The M9104-GGA Series Electric Non-Spring Return

valve actuators require AC 24 V power and a

DC 0(2) to 10 V or DC 0(4) to 20 mA controller input

signal. These electric actuators include an integrated

1.2 m (48 in.) long cable. See Figure 10 for proper

wiring.

BLK

RED

GRY ORN

4

3

90°

90°

0.0V

2.0V

k

b

d

f

:

G

I

F

AC

24 V

DC 0(2)...10 V

DC 0(4)...20 mA Control with

0(2)...10 V

BLK

RED

GRY

34

DC 0(2)...10 V

M9104-GGA actuators are factory set for Direct Acting

(DA) mode and for a DC 0 to 10 V input control signal.

In DA mode, a minimum control signal drives the

actuator to the full CCW position, and a maximum

control signal drives the actuator to the full CW

position.

For Reverse Acting (RA) operation, a minimum control

signal drives the actuator to the full CW position and a

maximum signal drives the actuator to the full CCW

position.

To change the factory settings (DA, 0-10 V), remove

the actuator cover and adjust the switches on the

circuit board as shown in Figure 12.

M9102-AGA-1S and M9104-xGA-1S Series Electric Non-Spring Return Actuators Installation Instructions 5

+

U

ORN

U

+

CAUTION: Risk of Electric Shock.

Disconnect the power supply before

making electrical connections to avoid

electric shock.

+

MISE EN GARDE : Risque de décharge

électrique.

Débrancher l'alimentation avant de

réaliser tout raccordement électrique afin

d'éviter tout risque de décharge

électrique.

CAUTION: Risk of Property Damage.

Do not apply power to the system before

checking all wiring connections. Short

circuited or improperly connected wires

may result in permanent damage to the

equipment.

MISE EN GARDE : Risque de dégâts

matériels.

Ne pas mettre le système sous tension

avant d'avoir vérifié tous les raccords de

câblage. Des fils formant un court-circuit

ou connectés de façon incorrecte

risquent d'endommager

irrémédiablement l'équipement.

Page 6

IMPORTANT: Make all wiring connections in

accordance with local, national, and regional

regulations. Do not exceed the electrical ratings of

the M9102 or M9104 Series Electric Non-Spring

Return Valve Actuator.

Setup and Adjustments

Commissioning

After wiring is completed, apply power to the VAV or

VVT controller and provide input signals to the actuator

to drive it at least one complete cycle open and closed.

Troubleshooting

If the M9102 or M9104 Series Electric Non-Spring

Return Actuator is not responding or working properly:

• verify that the actuator assembly is properly

secured to the duct

• check that all electrical connections are complete

and that power is applied

• verify that the damper fully opens and closes, using

the gear release button on the actuator

• check that the actuator stroke is set for the desired

application

Repairs and Replacement

If the M9102 or M9104 Series Electric Non-Spring

Return Actuator fails to operate within its specifications,

replace the unit. For a replacement electric actuator,

contact the nearest Johnson Controls® representative.

Technical Specifications

M9102-AGA-1S and M9104-xGA-1S Series Electric Non-Spring Return Actuators (Part 1 of 2)

Power Requirements M910x-AGA-1S AC 24 V +25%/-20% at 50/60 Hz, 2.1 VA, Class 2, Safety Extra-Low

M9104-IGA-1S AC 24 V +25%/-20% at 50/60 Hz, 3.0 VA, Class 2, SELV

M9104-GGA-1S AC 24 V +25%/-20% at 50/60 Hz, 2.9 VA, Class 2, SELV (Class III)

Control Ty pe M910x-AGA-1S Floating Control without Timeout

M9104-IGA-1S Floating or On/Off Control with Timeout

M9104-GGA-1S Proportional Control

Input Signal M9102-AGA-1S AC 24 V +25%/-20% at 50/60 Hz, Class 2, SELV

M9104-AGA-1S AC 24 V +25%/-20% at 50/60 Hz, Class 2, SELV

M9104-IGA-1S AC 24 V +25%/-20% at 50/60 Hz, Class 2, SELV

M9104-GGA-1S DC 0 (2) to 10 V or 0 (4) to 20 mA with field furnished 500 ohm resistor

Feedback Signal M9104-GGA-1S 0 to 10 VDC or 2 to 10 VDC for 90° (10 VDC at 1 mA)

Motor Input Impedance 200 ohms Nominal

Running Torque M9102 Series 2 N·m

M9104 Series 4 N·m

Travel Time M9102 Series 36 seconds at 50 Hz for 90° of rotation

M9104 Series 72 seconds at 50 Hz for 90° of rotation

Rotation Range 93° ±3°, CW or CCW

Cycles 100,000 Full Stroke Cycles;

Audible Noise Rating 35 dBA Nominal at 1 m

Electrical Connections M9104-AGA-1S

M9104-IGA-1S

M9104-GGA-1S

Mechanical Connections Up to 13 mm Diameter Round Damper Shaft or 10 mm Square Damper

Enclosure IP42, NEMA 2

Voltage (SELV)

Corresponds to input signal span selection

2,500,000 Repositions at Rated Running Torque

1.2 m (48 in.) Polyvinyl Chloride (PVC) cable with 0.75 mm

(19 AWG) and 6 mm (.25 in.) ferrule ends

2

1.2 m (48 in.) PVC cable with 0.75 mm

6 mm (.25 in.) ferrule ends

Shaft

conductors (19 AWG) and

2

conductors

M9102-AGA-1S and M9104-xGA-1S Series Electric Non-Spring Return Actuators Installation Instructions6

Page 7

Metasys® and Johnson Controls® are registered trademarks of Johnson Controls, Inc.

All other marks herein are the marks of their respective owners. © 2015 Johnson Controls, Inc.

Building Efficiency

507 E. Michigan Street, Milwaukee, WI 53202

M9102-AGA-1S and M9104-xGA-1S Series Electric Non-Spring Return Actuators (Part 2 of 2)

Ambient Conditions Operating -20 to 60°C; 90% RH Maximum, Noncondensing

Storage -29 to 66°C; 90 RH Maximum, Noncondensing

Compliance United States UL Listed, CCN XAPX, File 27734

Plenum rated, UL2043, suitable for use in other environmental spaces

(plenums) in accordance with section 300.22.(c) of the National Electrical

Code

Canada cUL Listed, CCN XAPX7, File 27734

Plenum Rated Per CSA 22.2 No. 236/UL 1995, Heating and Cooling

Equipment

Europe Johnson Controls, Inc. declares that this product is in compliance with the

essential requirements and other relevant provisions of the EMC Directive

2004/108/EC and the Low Voltage Directive 2006/95/EC.

Australia and

New Zealand

Shipping Weight 0.5 kg

The performance specifications are nominal and conform to acceptable industry standards. For application at conditions beyond these

specifications, consult the local Johnson Controls office. Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or

misuse of its products.

C-Tick Mark, Australia/NZ Emissions Compliant

M9102-AGA-1S and M9104-xGA-1S Series Electric Non-Spring Return Actuators Installation Instructions 7

Published in U.S.A. www.johnsoncontrols.com

Loading...

Loading...