Page 1

M9000-310 and M9000-320 Series Weather Shield

14- 1330-18, Rev. B

Enclosures

Installation Instructions

Applications

The M9000-310 and M9000-320 Weather Shield

Enclosures are cost-effective and durable weather

shields designed to provide a degree of protection for a

single Johnson Controls® M9000 Series Electric

Actuator used in either control damper or iron flanged

valve applications. These weather shield enclosures

are manufactured to National Electrical Manufacturers’

Association (NEMA) 3R specifications and protect the

electric actuator from corrosion, rain, freezing rain,

sleet, and snow. The enclosure can be mounted

indoors or outdoors; however, it may not prevent

externally formed ice from restricting the motion of the

rotary shaft.

Each enclosure is constructed of impact-grade ABS

plastic that provides excellent impact resistance. The

cover features ultraviolet inhibitors that extend service

life by preventing the cover from becoming brittle or

damaged by the sun or other environmental elements.

The transparent cover provides an unobstructed view

of the electric actuator without having to disassemble

the enclosure. An appliance cord enables installation of

control wiring, and a form-fitting seal prevents water or

moisture from entering the unit and damaging the

actuator.

IMPORTANT: The M9000-310 and M9000-320

Weather Shield Enclosures only provide protection

for the Johnson Controls M9000 Series Electric

Actuator used in control damper and iron flanged

valve applications. To ensure proper operation,

check that all associated equipment used in the

application is suitable for the surrounding

environment.

Part No. 14-1330-18, Rev. B

Issued

June 2016

Installation

Refer to the following documentation for more

information on the M9000 Series Electric Actuators and

Valve Linkages used with the M9000-310 and M9000320 Weather Shield Enclosures:

• M9106-xGx-2 Series Electric Non-Spring Return

Actuators Installation Instructions (Part No. 34636-1085)

• M9108, M91 1 6, M9124, and M9132 Series Electr

-Spring Return Actuators Installation

Non

Instructions (Part No. 34-636-399)

• M9109 Series Electric Non-spring Return

Actuators Installation Instructions (Part No. 34636-1190)

• M9220-AGx-3 Floating Electric Spring Return

Actuators Installation Instructions (Part No. 34636-1689)

• M9220-Bxx-3 On/Off Electric Spring Return

Actuators Installation Instructions (Part No. 34636-1239)

• M9220-GGx-3 Proportional Electric Spring Return

Actuators Installation Instructions (Part No. 34636-1697)

• M9000-53x Cast Iron Flanged V alve Linkage Kit for

Mounting a Single M9000 Series Electric Actuator

Installation Instructions (Part No. 14-1298-18)

• M9000-53x Series Cast Iron Flanged Va

kage Kit for Tandem Mounting of M9000 Series

Lin

Electric Actuators Installation Instruct

(

Part No. 14-1298-26)

lve

ions

ic

M9000-310 and M9000-320 Series Weather Shield Enclosures

Installation Instructions

1

Page 2

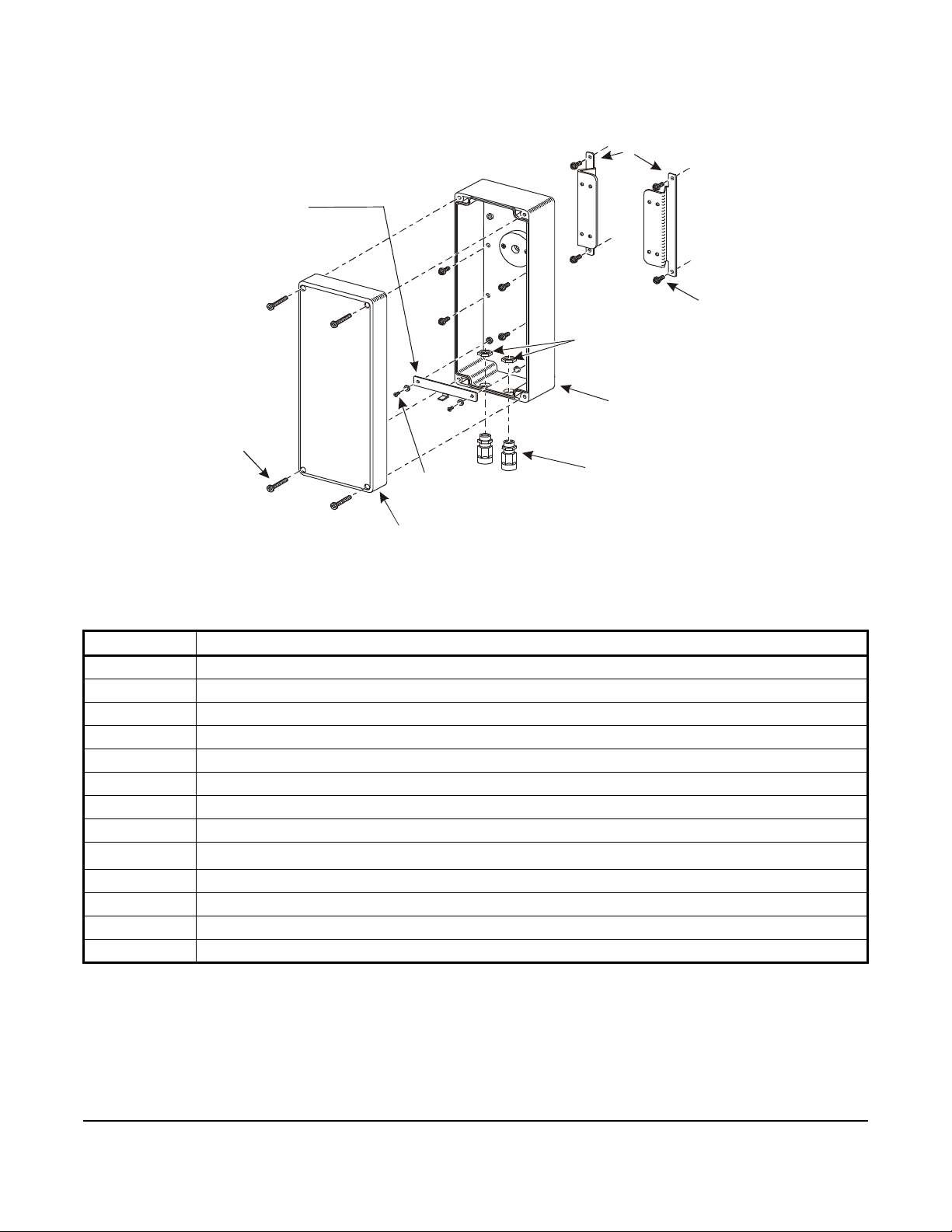

Parts Included

Hex-Head Screws

(Eight Lo cat ions)

Threaded

Hex Nuts

Enclos ure Base and

Seal Asse mbly

Cover Screws

(Four Locations)

Cover and

Strain Relief

Conduit Fittings

(Two Locat ions)

Anti-Rotation

Bracket

M3 x 8 mm

F

I

G

:

p

r

t

s

_

i

n

c

l

Figure 1: Parts Included in M9000-310 and M9000-320 Weather Shield Enclosure Kits (See Table 1)

Mounting

Brackets

No. 12-24 x 1/2 in.

Phillips Screws and

M4 Washers (Two Locations)

Gasket

Table 1: Parts Included in M9000-310 and M9000-320 Weather Shield Enclosure Kits

Quantity Description

1 Enclosure Base and Seal Assembly

1 Cover and Gasket

4 Cover Screws

2 Mounting Brackets

8 No. 12-24 x 1/2 in. Hex-Head Screws with Nitrile Patch

1 Anti-Rotation Bracket

2 M3 x 8 mm Phillips Screws

2 M4 Washers

2

1 Cap Plug

2 Threaded Hex Nuts

Strain Relief Conduit Fittings with 1/2 in. National Pipe Straight Mechanical (NPSM) Exit

1 Appliance Cord - 6 Conductor, 18 AWG Wire Gauge, 43 in. (109 cm)

1 Shaft Extender with Set Screw (M9000-320 Kit Only)

1. It is recommended that 1/2 in. liquid-tight conduit and 1/2 in. National Pipe Thread (NPT) liquid-tight fittings (purchased

locally) be used to terminate the control wiring to the weather shield enclosure strain relief conduit fittings.

1

M9000-310 and M9000-320 Series Weather Shield Enclosures Installation Instructions

2

Page 3

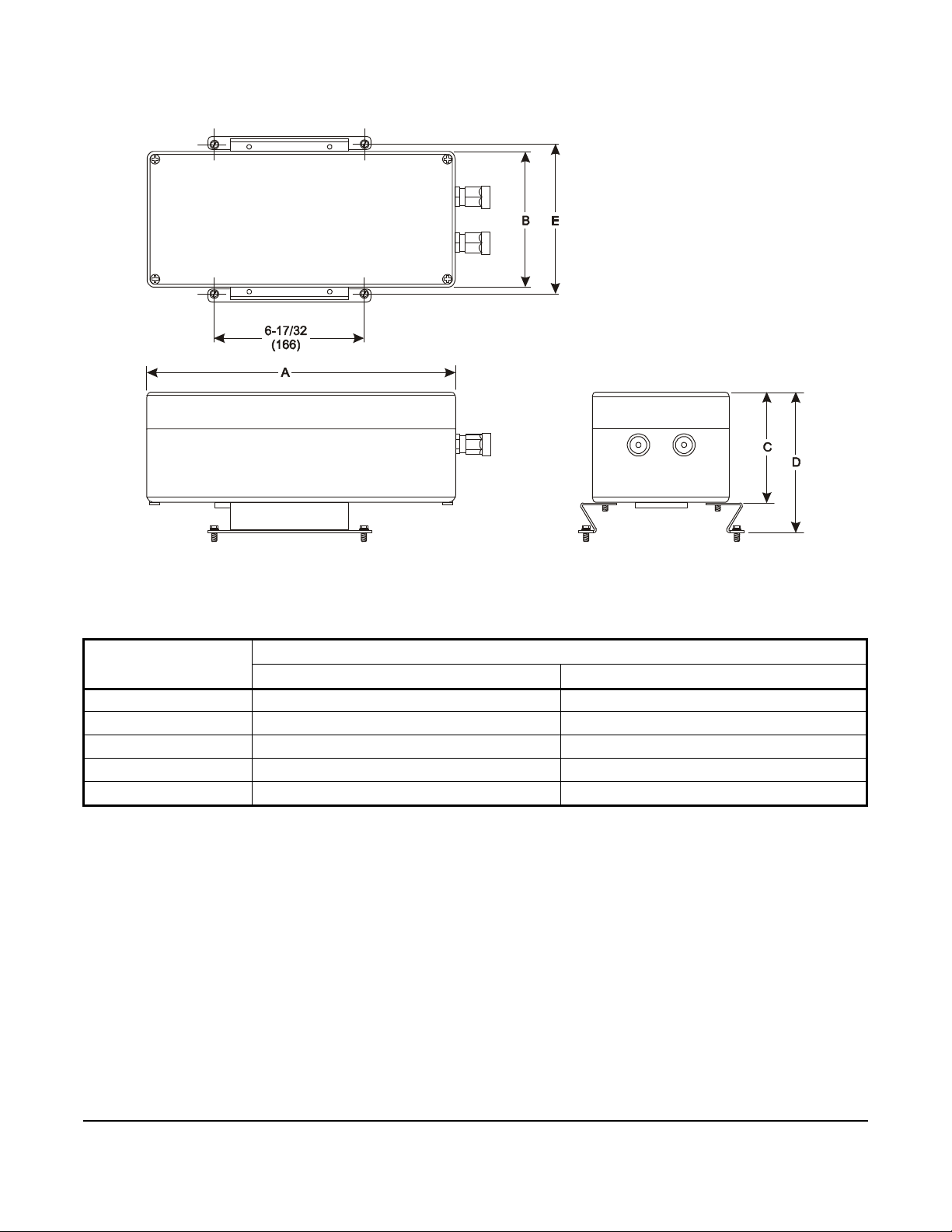

Dimensions

Figure 2: Weather Shield Enclosure Dimensions, in. (mm)

(See Table 2.)

s

n

m

d

:

G

I

F

Table 2: Weather Shield Enclosure Dimensions, in. (mm)

Dimension Weather Shield Enclosure

M9000-310 M9000-320

A 7-7/8 (200) 13-3/8 (340)

B 4-23/32 (120) 5-29/32 (150)

C 3-17/32 (90) 4-23/32 (120)

D 4-27/32 (123) 6-1/32 (153)

E 5-13/32 (137) 6-9/16 (167)

M9000-310 and M9000-320 Series Weather Shield Enclosures Installation Instructions

3

Page 4

Mounting

M9000-310

Bracket

Anti-Rotation

Bracket

Figure 3: Proper Orientation of the Anti- Rotation

Bracket

M9000-310

Figure 4: Proper Orientation of the

Mounting Brackets onto the Enclosure Base

The M9000-310 and M9000-320 Weather Shield

Enclosure Kits are shipped from the factory partially

assembled, with the cover held in place using the four

cover screws included with the kit. The remainder of

the parts required for moun ting can be foun d inside the

enclosure.

Control Damper Applications

Mount the weather shield enclosure onto a control

damper as follows:

1. Loosen the four cover screws using a No.1 Phillips

screwdriver and remove the cover and gasket

assembly from the enclosure base.

2. Orient the anti-rotation bracket onto the enclosure

as illustrated in Figure 3.

Note: The anti-rotation bracket must be oriented

properly for the anti-rotation tab to align with the slo t on

the electric actuator.

4. Orient the two mounting brackets onto the

enclosure base as illustrated in Figure 4.

M9000-320

5. Secure the mounting brackets to the enclosure

base using four No. 12-24 x 1/2 in. hex-head

screws (included with the kit).

Note: Each hex-head screw should be inserted from

the inside of the enclosure so that the nitrile patch

seals the mounting hole in the base.

t

k

r

b

t

n

m

:

G

I

F

Anti-Rotation

M9000-320

3. Secure the anti-rotation bracket to the threaded

brass inserts of the enclosure base using two

M3 x 8 mm Phillips screws and M4 washers

included with the kit. Tighten the Phillips screws to

a torque of 15 to 20 lb·in (1.7 to 2.3 N·m).

IMPORTANT: Do not overtighten the Phillips

screws. Overtightening may cause the threaded

inserts located in the enclosure base to become

dislodged, resulting in damage to the enclosure.

6. Install the enclosure and mounting bracket

assembly onto the damper shaft extension. Orient

the assembly so that the flanges of the mounting

brackets are flush with the mounting surface.

7. Using the mounting brackets as a template, mark

the mounting hole locations with a ball-peen

t

k

r

b

t

r

:

G

I

F

hammer and punch.

8. Remove the enclosure and mounting bracket

assembly from the damper shaft extension.

9. Drill pilot holes at each of the marked spots using a

drill and a No. 10 drill bit.

10. Reinstall the enclosure and mounting bracket

assembly onto the damper shaft extension. Orient

the assembly so that the flanges of the mounting

brackets are flush with the mounting surface and

the holes in the mounting brackets align with the

pilot holes drilled in Step 9.

11. Secure the enclosure and mounting bracket

assembly to the mounting surface using four

No. 12-24 x 1/2 in. hex-head screws included with

the kit. Tighten the hex-head screws to a torque of

20 to 25 lb·in (2.3 to 2.8 N·m).

M9000-310 and M9000-320 Series Weather Shield Enclosures Installation Instructions

4

Page 5

12. Install the two conduit fittings included with the kit

M9000-53x Series

Valve Lin kage

Primary Side of

M9000-53x Series

Valve Link age

Figure 5: Proper Orientation of the

Mounting Brackets onto the M9000-

53x Series Valve Linkage

into the enclosure base and secure them in place

using the threaded hex nuts.

IMPORTANT: The conduit fittings must be installed

properly to ensure a tight seal. Water or moisture

may damage or affect the operation of the electric

actuator within the enclosure.

13. Insert the appliance cord into one of the conduit

fittings so that the cable wrapping is visible inside

the enclosure. Tighten the conduit fitting to a

torque of 10 to 15 lb·in (1.1 to 1.7 N·m) to secure

the appliance cord in place.

14. Install the electric actuator onto the damper shaft

extension and the enclosure anti-rotation bracket.

Note: Refer to the documentation included with the

electric actuator for complete installation instructions.

15. Reinstall the cover and gasket assembly and

secure it in place using the four cover screws

included with the kit. Tighten the cover screws to a

torque of 5 to 8 lb·in (0.6 to 0.9 N·m) maximum.

IMPORTANT: The cover and gasket assembly

must be installed properly to ensure a tight seal.

Water or moisture may damage or affect the

operation of the electric actuator within the

enclosure.

3. Secure the anti-rotation bracket to the threaded

brass inserts of the enclosure base using two

M3 x 8 mm Phillips screws and M4 washers

included with the kit. Tighten the Phillips screws to

a torque of 15 to 20 lb·in (1.7 to 2.3 N·m).

IMPORTANT: Do not overtighten the Phillips

screws. Overtightening may cause the threaded

inserts located in the enclosure base to become

dislodged, resulting in damage to the enclosure.

4. Orient the two mounting brackets onto the primary

side of the M9000-53x Series Valve Linkage (for

single-mount applications) as illustrated in

Figure 5.

x

3

5

t

k

r

b

t

n

m

:

G

I

F

Secondary Side of

16. If one of the conduit fittings remains unused, seal

the fitting using the cap plug included with the

enclosure kit.

Iron Flanged Valve Applications

Mount the weather shield enclosure onto the M900053x Series Valve Linkage as follows:

1. Loosen the four cover screws using a No. 1 Phillips

screwdriver and remove the cover and gasket

assembly from the enclosure base.

2. Orient the anti-rotation bracket onto the enclosure

as illustrated in Figure 3.

Note: The anti-rotation bracket must be oriented

properly in order for the anti-rotation tab to align with

the slot on the electric actuator.

5. Secure the mounting brackets to the M900053x Series Valve Linkage using four No. 12-24 x 1/

2 in. hex-head screws (included with the kit).

6. Install the enclosure onto the input shaft of the

M9000-53x Series Valve Linkage. Orient the

enclosure so that the flanges of the mounting

brackets are flush with the surface of the enclosure

base.

7. Secure the enclosure to the mounting brackets

using four No. 12-24 x 1/2 in. hex-head screws

included with the kit. Tighten the hex-head screws

to a torque of 20 to 25 lb·in (2.3 to 2.8 N·m).

Note: Each hex-head screw should be inserted from

the inside of the enclosure so that the nitrile patch

seals the mounting hole in the base.

M9000-310 and M9000-320 Series Weather Shield Enclosures Installation Instructions

5

Page 6

8. Install the two conduit fittings included with the kit

Figure 6: Proper Mounting Position for Shaft

Extension

F

I

G

:

m

n

t

g

_

p

o

s

into the enclosure base and secure them in place

using the threaded hex nuts.

IMPORTANT: The conduit fittings must be installed

properly to ensure a tight seal. Water or moisture

may damage or affect the operation of the electric

actuator within the enclosure.

Steps 9 and 11 apply only to the M9000-320 kit when

used with the M9220 Series actuators. For the M90 00310 kit, proceed to Step 12.

9. For the M9000-320 kit used with the M9220 Series

actuators, install the shaft extension onto the input

shaft of the valve linkage. Ensure that the set

screws located on the shaft extension are oriented

perpendicular to the flat surfaces on the input shaft.

(See Figure 6.) To reduce friction, ensure that the

shaft extension and the seal assembly are not in

contact. A gap of no more than 1/8 in. is

recommended between these two components.

11. Using a flat blade screwdriver, remove and save

the spring clip from the M9220 actuator hub and

gripper assembly. Remove the actuator gripper

assembly from the actuator and retain.

12. Insert the appliance cord(s) for the actuator

through the conduit fittings.

13. Install the actuator into the enclosure/linkage

assembly. Insert the actuator anti-rotation slots

over the anti-rotation tab of th e bracket from

Step 3.

14. Center the shaft or shaft extension in the actuator

hub. For the M9220, reinstall the actuator gripper

assembly and secure in place using th e spring clip.

Secure the actuator coupler assembly to the shaft

following the actuator mounting instructions.

Note: Refer to the documentation included with the

electric actuator and valve linkage for complete

installation instructions.

15. Tighten the conduit fitting to a torque of 10 to

15 lb·in (1.1 to 1.7 N·m) to secure the appliance

cord in place.

16. Reinstall the cover and gasket assembly and

secure it in place using the four cover screws

included with the kit. Tighten the co ver scr ews to a

torque of 5 lb·in (0.6 N·m) maximum.

17. If the valve application is a tandem configuration,

repeat Steps 11 through 16 on the secondary side

of the M9000-53x Series Valve Linkage.

10. Secure the shaft extension to the input shaft of the

valve linkage using the supplied set screws and 5/

16 in. (8 mm) wrench. The recommended torque

applied to the set screws is 100 in·lb (11 N·m).

Tighten the screws evenly.

IMPORTANT: The cover and gasket assembly

must be installed properly to ensure a tight seal.

Water or moisture may damage or affect the

operation of the electric actuator within the

enclosure.

18. If one of the conduit fittings remains unused, seal

the fitting using the cap plug included with the

enclosure kit.

Repair Information

If the M9000-310 or M9000-320 Ser ies Weathe r Shield

Enclosure fails to operate within its specifications,

replace the unit. For a replacement weather shield,

contact the nearest Johnson Controls representative .

M9000-310 and M9000-320 Series Weather Shield Enclosures Installation Instructions

6

Page 7

Metasys® and Johnson Controls® are registered trademarks of Johnson Controls, Inc.

All other marks herein are the marks of their respective owners. © 2016 Johnson Controls, Inc.

Building Efficiency

507 E. Michigan Street, Milwaukee, WI 53202

Technical Specifications

M9000-310 and M9000-320 Weather Shield Enclosures

Materials Enclosure Impact-Grade ABS Plastic

Enclosure Seal Nitrile

Cover Transparent Impact-Grade ABS Plastic with Ultraviolet Inhibitors

Cover Gasket Neoprene

Weather Shield Rating NEMA 3R, IP32

Actuator Ambient

Operating

Temperature Limits

Weather Shield Enclosure Ambient Storage

Temperature Limits

Electrical Connections Strain Relief Conduit Fittings with 1/2 in. National Pipe Straight Mechanical

Shipping Weight M9000-310 2.0 lb (0.9 kg)

The performance specifications are nominal and conform to acceptable industry standards. For application at conditions beyond these

specifications, consult the local Johnson Controls office. Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or

misuse of its products.

M9106 and M9109

(M9000-310 Only)

M9108, M9116,

M9124, and M9132

M9220 -40 to 131°F (-40 to 55°C)

M9000-320 3.3 lb (1.5 kg)

-4 to 122°F (-20 to 50°C)

-4 to 122°F (-20 to 50°C)

-40 to 176°F (-40 to 80°C)

(NPSM) Exit

European Single Point of Contact: NA/SA Single Point of Contact: AP AC Single Point of Contact:

JOHNSON CONTROLS

WESTENDHOF 3

45143 ESSEN

GERMANY

JOHNSON CONTROLS

507 E MICHIGAN ST

MIL WAUKEE WI 53202

USA

JOHNSON CONTROLS

C/O CONTROLS PRODUCT MANAGEMENT

NO. 22 BLOCK D NEW DISTRICT

WUXI JIANGSU PROVINCE 214142

CHINA

M9000-310 and M9000-320 Series Weather Shield Enclosures Installation Instructions

Published in U.S.A. www.johnsoncontrols.com

7

Loading...

Loading...