Page 1

Code No. LIT-12012114

Installation Manual

Effective July 2015

JC-VSD Factory Packaged (FP) Series II

drive frames 4–8, Type 1 and 3R

Page 2

Page 3

Johnson Controls variable speed drives

Disclaimer of warranties and limitation of liability

The product discussed in this literature is subject to terms and conditions outlined in

Johnson Control Inc. selling policies. The sole source governing the rights and remedies

of any purchaser of this equipment is the relevant Johnson Control Inc. selling policy.

NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WARRANTIES OF FITNESS FOR

A PARTICULAR PURPOSE OR MERCHANTABILITY, OR WARRANTIES ARISING FROM

COURSE OF DEALING OR USAGE OF TRADE, ARE MADE REGARDING THE

INFORMATION, RECOMMENDATIONS AND DESCRIPTIONS CONTAINED HEREIN

In no event will Johnson Control Inc. be responsible to the purchaser or user in contract, in

tort (including negligence), strict liability or otherwise for any special, indirect, incidental or

consequential damage or loss whatsoever, including but not limited to damage or loss of use

of equipment, plant or power system, cost of capital, loss of power, additional expenses in

the use of existing power facilities, or claims against the purchaser or user by its customers

resulting from the use of the information, recommendations and descriptions contained

herein. The information contained in this manual is subject to change without notice.

Cover Photo: Johnson Controls variable speed drives

Safety

Read and follow all safety information shown in the JC-VSD Series II Installation Manual

LIT-12011775.

Johnson Controls variable speed drives LIT-12012114—July 2015 www.johnsoncontrols.com i

Page 4

Johnson Controls variable speed drives

Table of contents

SAFETY

Definitions and symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Hazardous high voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Warnings and cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

GENERAL INFORMATION

Catalog/style numbering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

COMPONENT DIAGRAMS

IntelliPass and IntelliDisconnect—typical component locations . . . . . . . . . . . . 3

STANDARD FACTORY WIRED COMPONENTS

Drive isolation fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Manual bypass switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Space heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Plug-in options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Auxiliary contacts (bypass only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

High temperature option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

DIMENSIONS AND MOUNTING

WIRING

Wiring schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Conduit plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Input power wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Motor wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Ground wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Control wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

INITIAL STARTUP

IntelliDisconnect operation

(starting/stopping of the motor) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

IntelliPass operation

(starting/stopping of the motor) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Switch operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

SA bus operation and setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

INTELLIPASS/INTELLIDISCONNECT TECHNICAL INFORMATION

Technical information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

ADDITIONAL HELP

Website address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Johnson Controls product sales operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

ii Johnson Controls variable speed drives LIT-12012114—July 2015 www.johnsoncontrols.com

Page 5

Johnson Controls variable speed drives

List of figures

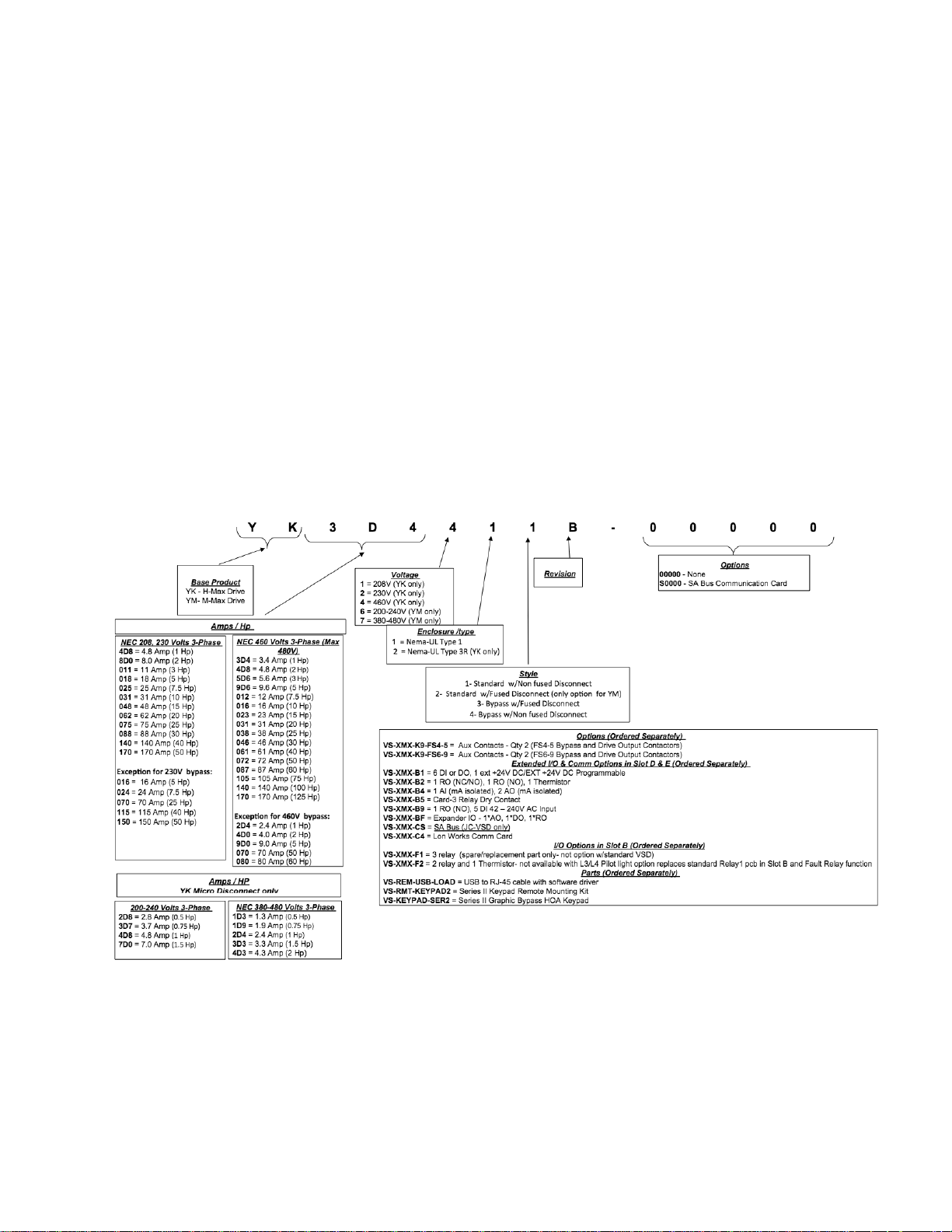

Figure 1. JC-VSD FP Series II master product part number matrix—

IntelliPass/IntelliDisconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. JC-VSD FP Series II IntelliPass/IntelliDisconnect carton label . . . . . . . . . . . . . 2

Figure 3. JC-VSD FP Series II IntelliPass/IntelliDisconnect nameplate . . . . . . . . . . . . . 2

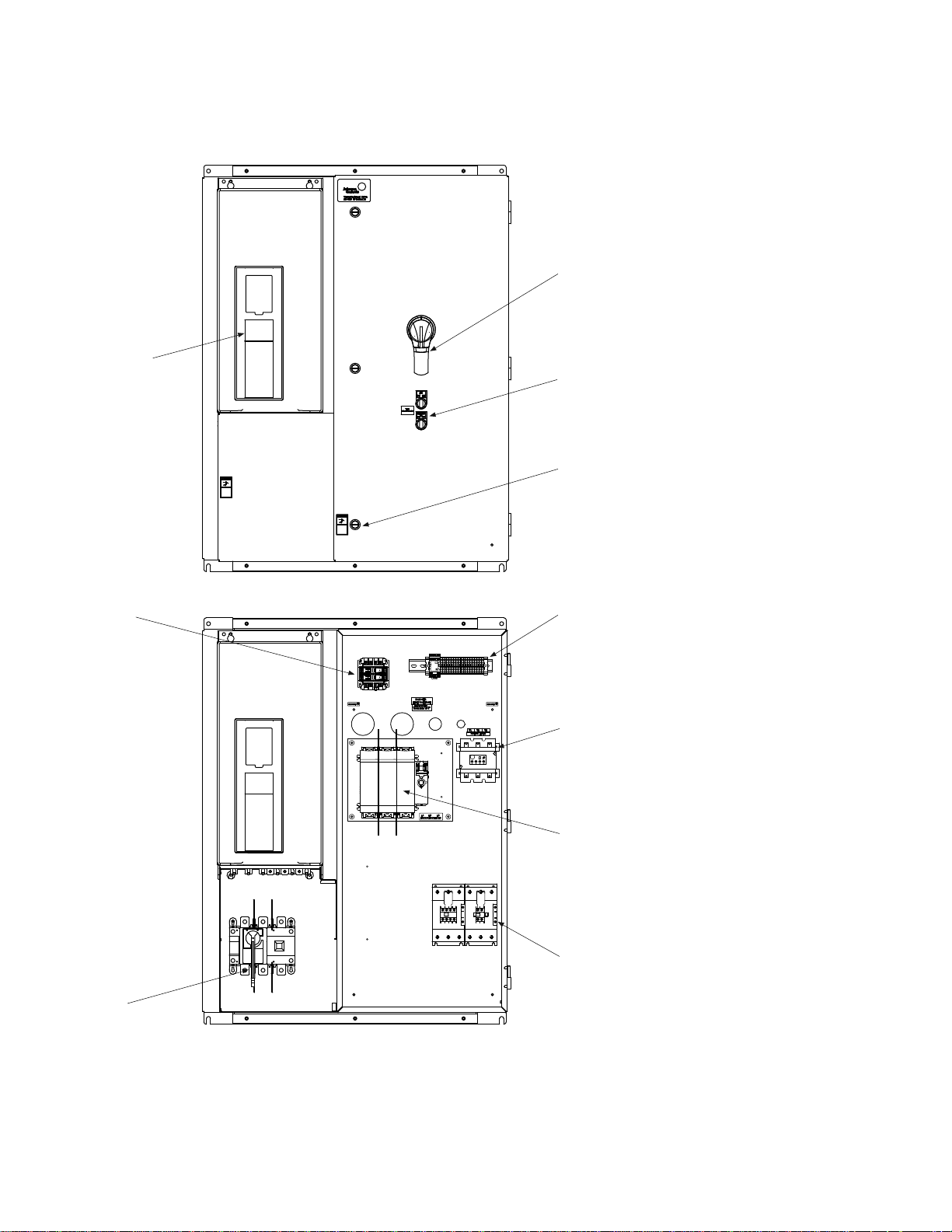

Figure 4. Type 1 IntelliDisconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Figure 5. Type 1 IntelliPass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

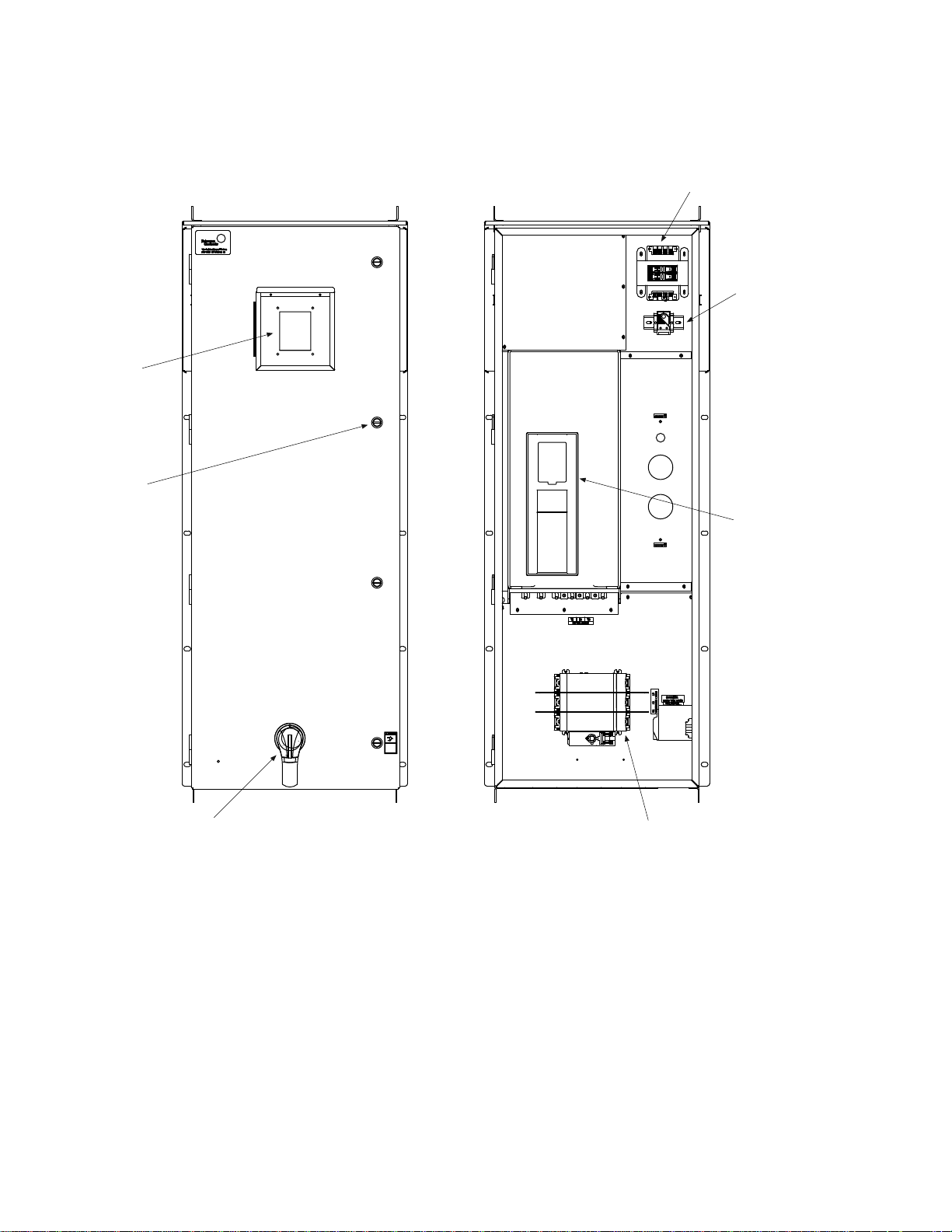

Figure 6. Type 3R IntelliDisconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 7. Type 3R IntelliPass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 8. Type 1 Micro Disconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 9. Fused disconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 10. Door 3-position switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 11. Larger framed bypass contactor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 12. Lower framed bypass contactor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 13. Option PCB cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 14. Type 1 IntelliDisconnect dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 15. Type 1 IntelliDisconnect knockout dimensions . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 16. Type 1 IntelliPass dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 17. Type 1 IntelliPass knockout dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 18. Type 3R IntelliDisconnect dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 19. Type 3R IntelliDisconnect knockout dimensions . . . . . . . . . . . . . . . . . . . . . . 20

Figure 20. Type 3R IntelliPass dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 21. Type 3R IntelliPass knockout dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 22. Type 1 Micro Disconnect dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 23. Type 1 Micro Disconnect knockout dimensions . . . . . . . . . . . . . . . . . . . . . . 24

Figure 24. Type 1 IntelliDisconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 25. Type 1 IntelliPass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 26. Type 3R IntelliDisconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 27. Type 3R IntelliPass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 28. Type 1 Micro Disconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 29. Lower frame incoming lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 30. Larger frame incoming lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 31. IntelliDisconnect motor wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 32. IntelliPass motor wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 33. Typical ground stud and label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 34. Terminal block access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 35. Startup Wizard prompt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 36. Enable bypass for IntelliPass models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 37. Disable bypass for IntelliPass models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 38. Keypad shown in drive mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 39. Keypad shown in bypass mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 40. Keypad with bypass and drive mode option . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 41. Keypad shown in run mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 42. Keypad already in bypass mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 43. Parameter menu for automatic reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 44. Menu selecting auto bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 45. Menu selecting reset/bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Johnson Controls variable speed drives LIT-12012114—July 2015 www.johnsoncontrols.com iii

Page 6

Johnson Controls variable speed drives

List of figures, continued

Figure 46. Displaying going into auto bypass after fault . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 47. Hand/Off/Auto parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 48. Off menu selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 49. Monitoring menu in STOP mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 50. JC-VSD Series II drive SA bus interface card VS-XMX-CS . . . . . . . . . . . . . . 39

List of tables

Table 1. hp rating and fuse rating (A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 2. Space heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 3. Auxiliary contacts (bypass only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 4. Option PCB cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 5. Enclosure size and frame size based on

voltage and horsepower (208/230 V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 6. Enclosure size and frame size based on

voltage and horsepower (480 V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 7. Type 1 Micro Disconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 8. Type 1 IntelliDisconnect dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 9. Type 1 IntelliDisconnect knockout dimensions . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 10. Type 1 IntelliPass dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 11. Type 1 IntelliPass knockout dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 12. Type 3R IntelliDisconnect dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 13. Type 3R IntelliDisconnect knockout dimensions . . . . . . . . . . . . . . . . . . . . . . . 20

Table 14. Type 3R IntelliPass dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 15. Type 3R IntelliPass knockout dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 16. Type 1 Micro Disconnect dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 17. Type 1 Micro Disconnect knockout dimensions . . . . . . . . . . . . . . . . . . . . . . . 24

Table 18. Input wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 19. Output wiring details—IntelliDisconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 20. Output wiring details—IntelliPass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 21. Terminal block designation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 22. SA bus setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 23. Object list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 24. Short-circuit rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

iv Johnson Controls variable speed drives LIT-12012114—July 2015 www.johnsoncontrols.com

Page 7

Safety

Johnson Controls variable speed drives

Definitions and symbols

WARNING

This symbol indicates high voltage. It calls your attention

to items or operations that could be dangerous to you

and other persons operating this equipment. Read the

message and follow the instructions carefully.

This symbol is the “Safety Alert Symbol.” It occurs with

either of two signal words: CAUTION or WARNING, as

described below.

WARNING

Indicates a potentially hazardous situation which, if not

avoided, can result in serious injury or death.

CAUTION

Indicates a potentially hazardous situation which, if not

avoided, can result in minor to moderate injury, or serious

damage to the product. The situation described in the

CAUTION may, if not avoided, lead to serious results.

Important safety measures are described in CAUTION (as

well as WARNING).

Warnings and cautions

This manual contains clearly marked cautions and warnings

which are intended for your personal safety and to avoid any

unintentional damage to the product or connected

appliances.

Please read the information included in cautions and

warnings carefully.

Hazardous high voltage

WARNING

Motor control equipment and electronic controllers are

connected to hazardous line voltages. When servicing

drives and electronic controllers, there may be exposed

components with housings or protrusions at or above

line potential. Extreme care should be taken to protect

against shock.

Stand on an insulating pad and make it a habit to use only

one hand when checking components. Always work with

another person in case an emergency occurs. Disconnect

power before checking controllers or performing

maintenance. Be sure equipment is properly grounded. Wear

safety glasses whenever working on electronic controllers or

rotating machinery.

Johnson Controls variable speed drives LIT-12012114—July 2015 www.johnsoncontrols.com v

Page 8

General information

This document provides supplement information to the

JC-VSD Series II Installation Manual LIT-12011772 specific

to the JC-VSD FP Series II IntelliPass® and IntelliDisconnect®

products. These products are offered with input/output

voltages of 208, 230, and 480 Vac with hp ranges from

1 to 125 hp. Both UL Type 1 and Type 3R enclosures

are available.

For drive setup and operation, i.e., application, keypad use,

drive and motor parameters setup, see the Quick Start Guide

LIT-12011775 included with the drive. The drive Startup

Wizard can be used to complete the process. For more

information on speed control and other JC-VSD Series II

drive features, see JC-VSD Series II Application Manual

LIT-12011771. The Application Manual and can be found

at http://www.johnsoncontrols.com

Catalog/style numbering

Figure 1. JC-VSD FP Series II master product part number matrix—IntelliPass/IntelliDisconnect

General information

Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com 1

Page 9

General information

Cat. No.

JC-VSD FP Series II

JCI OEM Part #:

Assembled in USA

Style No:

CRN4567456

3-4292-0104A

AOMS2345234

Qty

GO34656

Cust.Ref No:

-40°C to 70°C (-40°F to 158°F)

Max HP:

Storage Temp:

1

AOMS No:

www.johnsoncontrols.com

YK011111B-00000

Order No:

024-39261-003

152503

Disconnect Non-Fused

3 Hp @ 208VAC 11A

Rev B

Tag #:

9545151

40°C

Short Circuit Ratings:

Schematic:

Catalog No:

Max Ambient Temp:

Order No:

See manuals for more information:

Field installed conductors must be copper rated at 75°C.

For Assistace Call 1-800-524-1330 #611461

Max HP:

Enclosure:

Disconnect Non-Fused

Type 1

JCI OEM Part #:

AOMS No:

Assembled in USAW

Serial No:

www.johnsoncontrols.com

GO3463745

SN65461

AOMS24356457

153003

Style No:

YK011111B-00000

024 39261 004

3-4292-0104A

JC-VSD FP Series II Rev B

LIT12011773

and

3 Hp @ 208VAC 11A

65KA

LIT12011772

024 39261 002Outline DWG:

024 39261 003

Identification

Figure 2. JC-VSD FP Series II IntelliPass/IntelliDisconnect

carton label

Figure 3. JC-VSD FP Series II IntelliPass/IntelliDisconnect

nameplate

2 Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com

Page 10

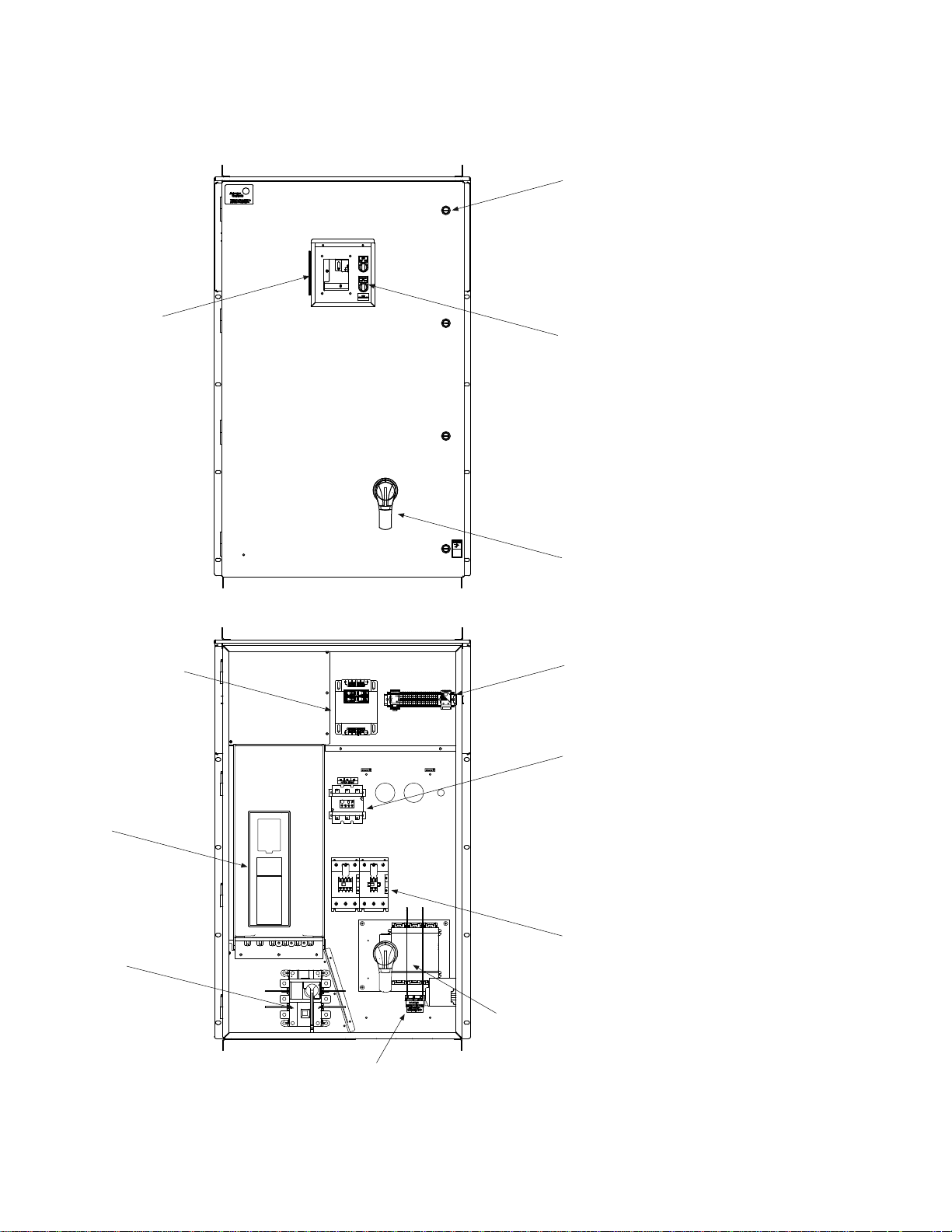

Component diagrams

JC-VSD Series II

Lockout

disconnect

handle

Quarter turn latches

Fused disconnect

with fuse holder

IntelliPass and IntelliDisconnect—typical component locations

Figure 4. Type 1 IntelliDisconnect

Component diagrams

Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com 3

Page 11

Component diagrams

JC-VSD Series II

Quarter turn latches

Cover controls

Lockout

disconnect

handle

Terminal

block access

Overload

protection relay

Fused disconnect

with fuse holder

Bypass and

drive contactor

Isolation

disconnect

Control power

transformer

Figure 5. Type 1 IntelliPass

4 Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com

Page 12

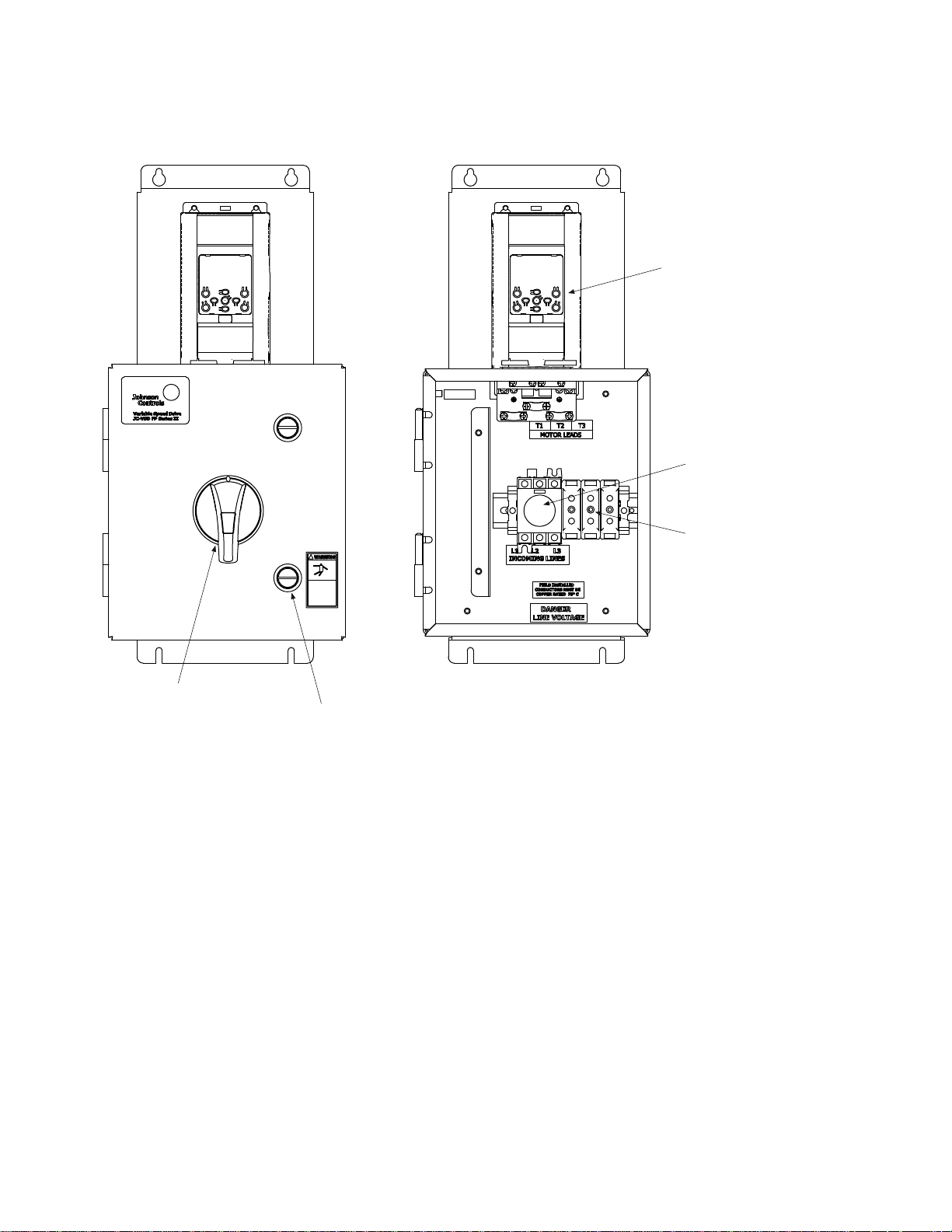

Figure 6. Type 3R IntelliDisconnect

Remote

mount

keypad

Quarter

turn

latches

Lockable

disconnect handle

Disconnect with

fuse holders

JC-VSD

Series II

Heater

Control

power transformer

Component diagrams

Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com 5

Page 13

Component diagrams

Cover controls

Quarter turn latches

Lockable

disconnect handle

Terminal

block access

Overload

protection relay

Bypass and

drive contactor

Disconnect with

fuse holder

Heater

Remote

mount keypad

Isolation

disconnect

JS-VSD

Series II

Control power

transformer

Figure 7. Type 3R IntelliPass

6 Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com

Page 14

Figure 8. Type 1 Micro Disconnect

Lockable

disconnect handle

Quarter turn

latches

Fuse holder

Disconnect

JS-VSD Series II

Micro

Component diagrams

Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com 7

Page 15

Standard factory wired components

Standard factory wired components

The IntelliPass and IntelliDisconnect have the following

factory installed options. Any additional option are sold

separately. See part numbering matrix for ordering

information.

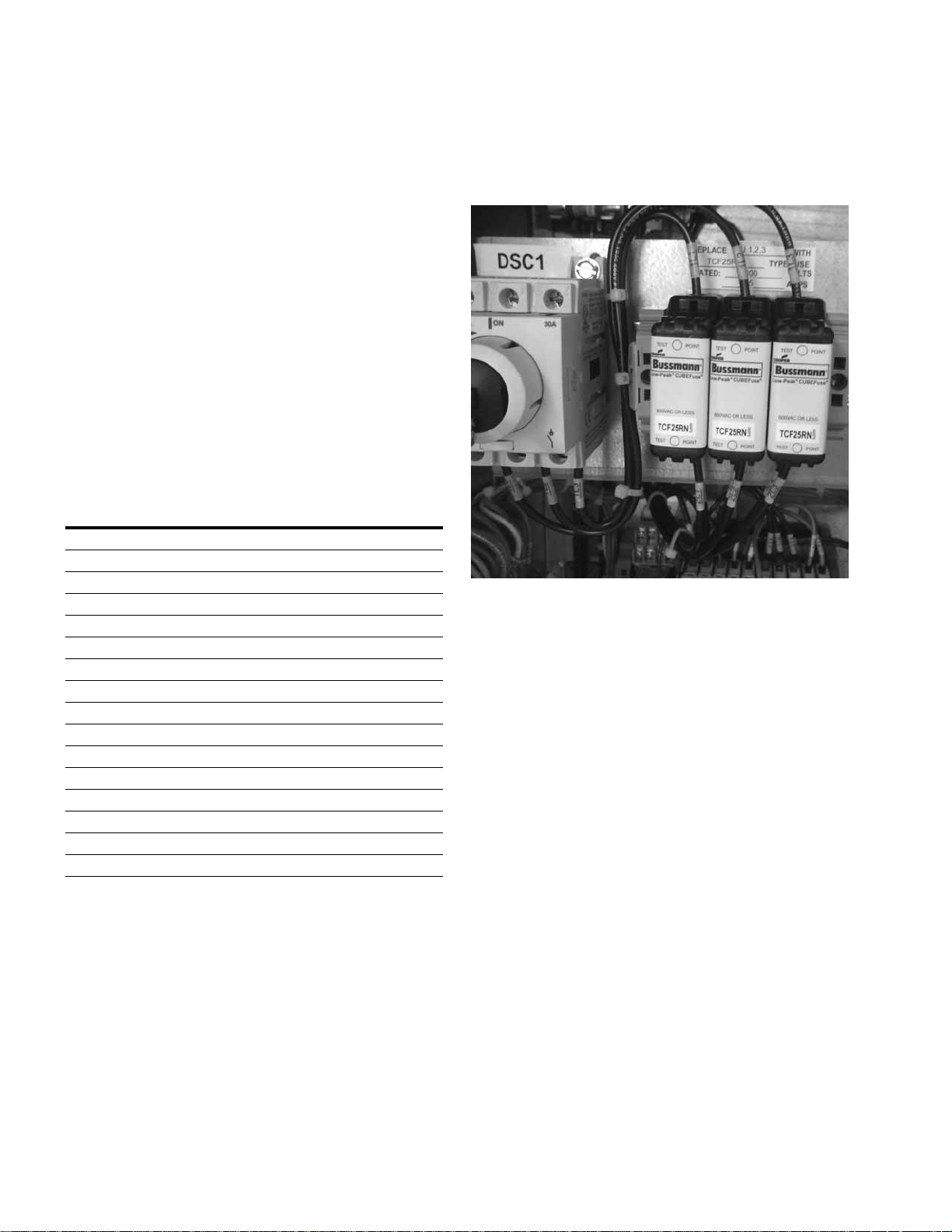

Drive isolation fuses

This option is available for both the IntelliPass and

IntelliDisconnect Fused Disconnect designs 208/230 V up

to 50 hp and 480 V models up to 125 hp.

Three power fuses are supplied wired to the drive input.

They are provided between the disconnect device and drive.

The fuses are not used in the bypass mode. The fuses are for

drive protection only. They are listed in the following table

and the Type J are sized according. See IntelliDisconnect or

Typical IntelliPass schematic.

Table 1. hp rating and fuse rating (A)

hp 208 V fuse 230 V fuse 460 V fuse

110106

2202010

3252510

5303020

7.5606025

10 60 60 30

15 60 100 30

20 100 100 60

25 100 100 60

30 200 200 60

40 200 200 125

50 200 200 150

60 N/A N/A 175

75 N/A N/A 200

100 N/A N/A 200

125 N/A N/A 200

Figure 9. Fused disconnect

8 Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com

Page 16

Standard factory wired components

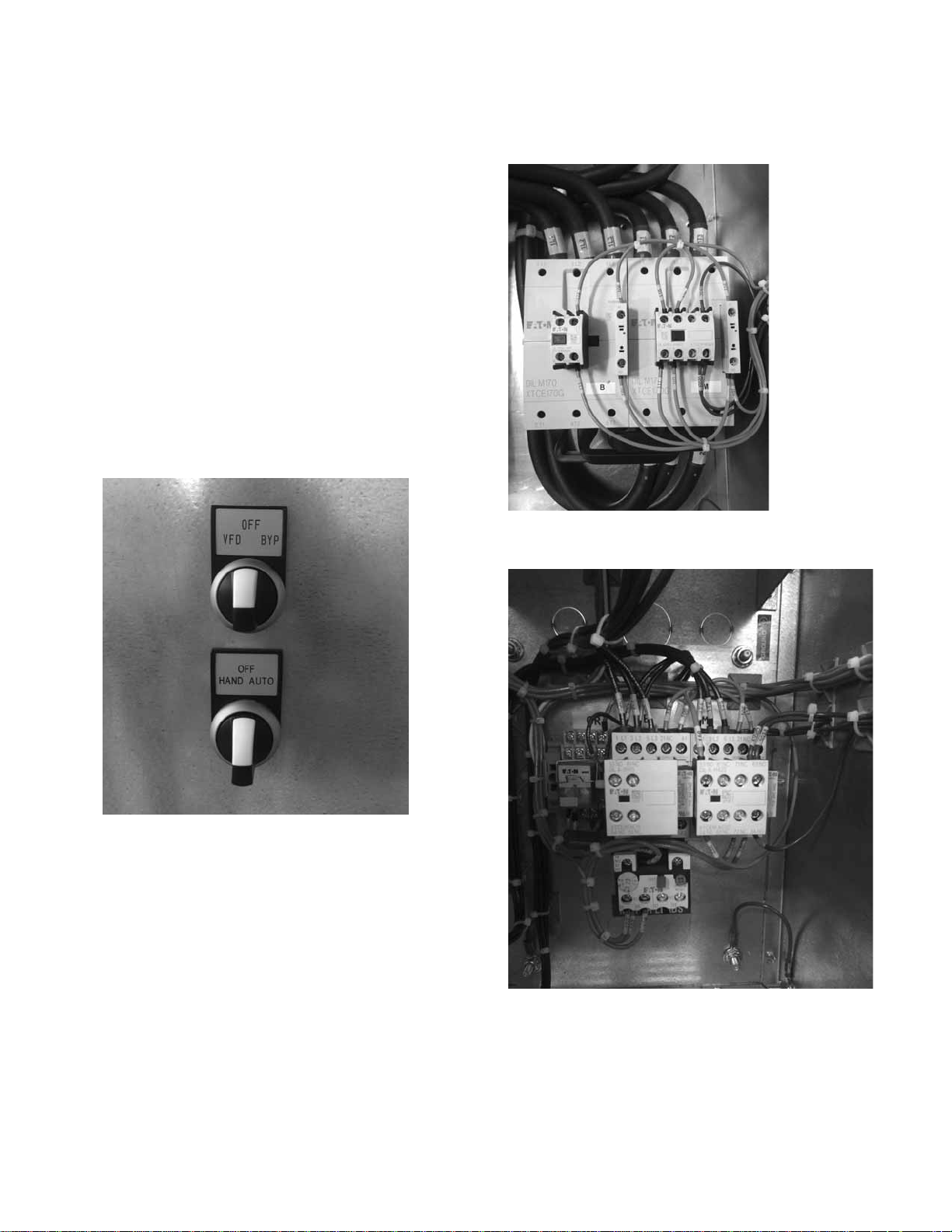

Manual bypass switch

This option is available on the IntelliPass models only. This

option includes a 3-position door mounted selector switch—

marked VFD / OFF / BYP. This switch manually overrides the

bypass control from the system (keypad) and puts unit in

bypass. See typical IntelliPass schematic.

When the door switch is in the drive position, the JC-VSD

Series II Drive logic controls the motor and the keypad

selects the operation (drive or bypass), the control source

and place (HOA, KEYPAD, or Terminal block).

When the door switch is moved to bypass, the drive output

contactor will be forced open and the bypass contactor will

be forced closed. The motor will immediately start and run

full speed across the line regardless of the state of the

system or drive. The keypad display will show “Bypass”.

When the switch is moved back to the drive position, drive

operation is restored after a system restart.

Figure 10. Door 3-position switches

Figure 11. Larger framed bypass contactor

Figure 12. Lower framed bypass contactor

Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com 9

Page 17

Standard factory wired components

Space heater

Type 3R enclosures only

This option aids in preventing or reducing condensation

from forming in the enclosure when the drive is inactive.

See selection table below for the size of heater that is

installed in each enclosure size. A control transformer

and fusing is also provided to power the heater. See

schematics for more information. The heater includes

a user adjustable thermostat for variable temperature

control and an internal fan.

Table 2. Space heater

Type 3R

IntelliDisconnect

enclosure size

C1 150 D1 150

C2 150 D2 150

C3 150 D3 150

C4 150 D4 250

C5 250 D5 250

C6 250 D6 250

Heater size

(W)

120 V rated

Type 3R

IntelliPass

enclosure size

Heater size

(W)

120 V rated

Setting the thermostat

The heater is controlled by an adjustable thermostat. Set the

thermostat to the desired temperature. It is recommended

not to exceed 75 °F for most applications. The heater is

active at all times when the main disconnect is closed

including when in the Drive, Off, or Bypass operation.

However, depending on the setting of the thermostat, the

internal heat generated by the system when in operation

should be enough to turn off the heater. Generally the heater

requires no maintenance because the fan bearings are

permanently lubricated and sealed.

10 Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com

Page 18

Standard factory wired components

Plug-in options

Auxiliary contacts (bypass only)

The bypass and drive contactor come installed with auxiliary

contacts. The configuration is used for bypass operation.

There are open NO and NC contacts on each the bypass and

drive contactor that can be used for customer use. See table

below for open contact configuration based on voltage and

horsepower.

Table 3. Auxiliary contacts (bypass only)

Bypass contactor (B) Drive contactor (M)

Voltage hp rating

208 / 203 V 1–4 B 1 1 N/A 1 NO is wired to terminal

5–10 C 1 1

15–20 D N/A 1

25–30 F N/A 1

40–50 G N/A 1

480 V 1–7.5 B 1 1

10–20 C 1 1

25–40 D N/A 1

50–60 F N/A 1

75–125 G N/A 1

Contactor

frame

Number of NC

available

Number of NO

available

Number of NC

available

Number of NO

available

block access 23 / 24

Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com 11

Page 19

Standard factory wired components

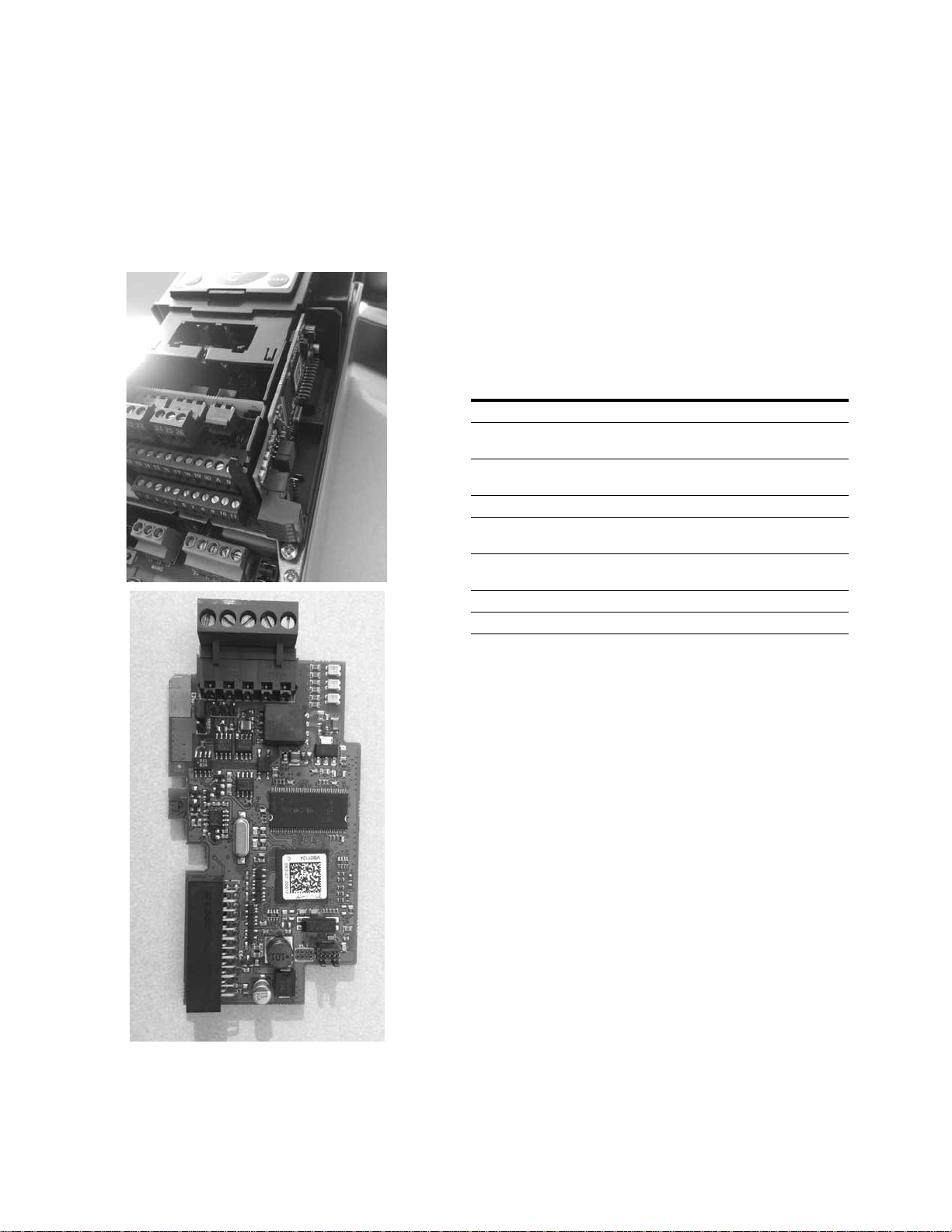

Option PCB cards

A number of plug-in cards are available to expand I/O and

communications. The SA Bus communication card is the only

factory installed option. Reference the catalog matrix for

ordering. All other cards are sold separately.

Figure 13. Option PCB cards

High temperature option

For NEMA Type 3R enclosures, vent covers are shipped

loose inside the enclosure. These vent covers would need to

be installed when the high temperature option is utilized. The

vent cover would be installed on the outside bottom of the

enclosure to cover the vents.

Also see JC-VSD Series II Installation Manual LIT-12011772

for more information on control wiring, control board layout

and option PCBs.

Table 4. Option PCB cards

Part number Description

VS-XMX-B1 I/O Expander Card, 6 DI/DO, Slot D/E VS-XMX-B1

VS-XMX-B2 I/O Expander Card 2 x RO + Thermistor, Slot D/E

VS-XMX-B4 I/O Expander Card 1 x AI, 2 x AO (isolated), Slot D/E

VS-XMX-B5 I/O Expander Card 3 x RO, Slot D/E VS-XMX-B5

VS-XMX-B9 I/O Expander Card 1 x RO, 5 x DI (42-240VAC), Slot D/E

VS-XMX-BF I/O expander Card, 1 x AO, 1 x DO, 1 x RO, Slot D/E

VS-XMX-C4 lonworks

VS-XMX-CS SA Bus, slot D/E

VS-XMX-B2

VS-XMX-B4

VS-XMX-B9

VS-XMX-BF

®

, Slot D/E VS-XMX-C4

12 Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com

Page 20

Dimensions and mounting

Dimensions and mounting

The IntelliPass / IntelliDisconnect physical dimensions are

based on the enclosure frame size. See following table to

determine the enclosure frame size based on horsepower

and voltage.

●

Weights and lifting provisions are on the dimension section

and with the drawing provided with the unit

●

Attach “load-rated” hooks or shackles to lifting eyes on

back panel

●

Always maintain a maximum of 45 degrees between the

The hardware to mount the Intellipass / IntelliDisconnect

units, all frame sizes, is as follows:

●

3/8-16 Grade 5 Hex Head Bolt, with 3/8 lock washer and

3/8 flat washer. QTY 4 of each required. Torque to 20 lb-ft

Use the tables below to determine enclosure size and

frame size based on voltage and horsepower. Enclosure

dimensions differ between Type 1 IntelliDisconnect, Type

1 IntelliPass, Type 3R IntelliDisconnect, Type 3R IntelliPass,

Type 1 Micro Disconnect.

lifting cables and the vertical plane

●

Do not pass ropes or cables through the lifting eyes as

sharp edges may cause excessive wear and possible

failure

●

Select or adjust rigging lengths to compensate for unequal

weight distribution of the load to keep unit in the upright

position

Table 5. Enclosure size and frame size based on voltage and horsepower (208/230 V)

hp Base drive Type 1 disconnect Type 1 bypass Type 3R disconnect Type 3R bypass

1 FS4 A1-4 B1-4 C1-4 D1-4

2 FS4 A1-4 B1-4 C1-4 D1-4

3 FS4 A1-4 B1-4 C1-4 D1-4

5 FS5 A1-5 B1-5 C1-5 D1-5

7.5 FS5 A2-5 B2-5 C2-5 D2-5

10 FS5 A2-5 B2-5 C2-5 D2-5

15 FS6 A3-6 B3-6 C3-6 D3-6

20 FS6 A3-6 B3-6 C3-6 D3-6

25 FS7 A4-7 B4-7 C4-7 D4-7

30 FS7 A4-7 B4-7 C4-7 D4-7

40 FS7 A4-8 B4-8 C4-8 D4-8

50 FS8 A6-8 B6-8 C6-8 D6-8

60FS8————

75FS8————

Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com 13

Page 21

Dimensions and mounting

Table 6. Enclosure size and frame size based on voltage and horsepower (480 V)

hp Base drive Type 1 disconnect Type 1 bypass Type 3R disconnect Type 3R bypass

1 FS4 A1-4 B1-4 C1-4 D1-4

2 FS4 A1-4 B1-4 C1-4 D1-4

3 FS4 A1-4 B1-4 C1-4 D1-4

5 FS4 A1-4 B1-4 C1-4 D1-4

7.5 FS4 A1-4 B1-4 C1-4 D1-4

10 FS5 A2-5 B2-5 C2-5 D2-5

15 FS5 A2-5 B2-5 C2-5 D2-5

20 FS5 A3-5 B3-5 C3-5 D3-5

25 FS6 A3-6 B3-6 C3-6 D3-6

30 FS6 A3-6 B3-6 C3-6 D3-6

40 FS6 A4-6 B4-6 C4-6 D4-6

50 FS7 A4-7 B4-7 C4-7 D4-7

60 FS7 A4-7 B4-7 C4-7 D4-7

75 FS7 A4-7 B4-7 C4-7 D4-7

100 FS8 A5-8 B5-8 C5-8 D5-8

125 FS8 A6-8 B6-8 C6-8 D6-8

Table 7. Type 1 Micro Disconnect

hp 208/230 V 480 V

0.5 M1-1 M1-1

0.75 M1-2 M1-1

1 M1-2 M1-1

1.5 M1-2 M1-2

2— M1-2

14 Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com

Page 22

Figure 14. Type 1 IntelliDisconnect dimensions

H

W

D

D1

H1

W1

Dimensions and mounting

Table 8. Type 1 IntelliDisconnect dimensions

Approximate dimensions in inches (mm)

Enclosure size—

drive frame size H H1 W W1 D D1

Weight in

lb (kg)

A1-4 20.61 (523.5) 19.75 (501.7) 8.65 (219.7) 6.75 (171.5) 10.40 (264.2) 8.96 (227.6) 34 (15)

A1-5 30.00 (762.0) 29.00 (736.6) 8.65 (219.7) 6.75 (171.5) 11.18 (284.0) 9.74 (247.4) 54 (25)

A2-5 30.00 (762.0) 29.00 (736.6) 8.65 (219.7) 6.75 (171.5) 11.18 (284.0) 9.74 (247.4) 54 (25)

A3-5 20.61 (523.5) 19.75 (501.7) 8.65 (219.7) 6.75 (171.5) 10.40 (264.2) 8.96 (227.6) 54 (25)

A3-6 32.50 (825.5) 31.50 (800.1) 10.40 (264.2) 7.50 (190.5) 11.41 (289.8) 9.97 (253.2) 101 (46)

A4-6 41.03 (1042.2) 39.50 (1003.3) 12.40 (315.0) 10.50 (266.7) 13.67 (347.2) 11.97 (304.0) 113 (51)

A4-7 41.55 (1055.4) 39.50 (1003.3) 12.40 (315.0) 10.50 (266.7) 13.94 (354.1) 12.25 (311.2) 200 (91)

A4-8 44.04 (1118.6) 39.50 (1003.3) 12.00 (304.8) 10.50 (266.7) 15.86 (402.8) 14.17 (359.9) 363 (165)

A5-8 44.05 (1118.9) 42.06 (1068.3) 12.00 (304.8) 10.50 (266.7) 15.86 (402.8) 14.17 (359.9) 363 (165)

A6-8 47.65 (1210.3) 46.50 (1181.1) 16.00 (406.4) 14.50 (368.3) 15.86 (402.8) 14.17 (359.9) 363 (165)

Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com 15

Page 23

Dimensions and mounting

F

A

5

4

3

21

E

D

B

C

C

A

B

F

E

D

G

3

2

1

4

5

Figure 15. Type 1 IntelliDisconnect knockout dimensions

Table 9. Type 1 IntelliDisconnect knockout dimensions

Approximate dimensions in inches (mm)

Enclosure

sizeABCDE FG

A1-4 1.12 (28.4) 3.74 (95.0) 4.24 (17.7) 4.77 (121.2) 6.27 (159.3) 7.77 (197.4) 0.875 1.109 & 0.875

A1-5 1.12 (28.4) 3.74 (95.0) 4.24 (17.7) 5.55 (141.0) 7.05 (179.1) 8.55 (217.2) 0.875 1.109 & 0.875

A2-5 1.12 (28.4) 3.74 (95.0) 4.24 (17.7) 5.55 (141.0) 7.05 (179.1) 8.55 (217.2) 0.875 1.109 & 0.875

A3-5 1.12 (28.4) 3.74 (95.0) 4.24 (17.7) 4.77 (121.2) 6.27 (159.3) 7.77 (197.4) 0.875 1.375 & 1.109

A3-6 1.00 (25.4) 3.63 (92.2) 5.03 (127.8) 5.79 (147.1) 7.29 (185.2) 8.79 (223.3) 0.875 1.375 & 1.109

A4-6 1.55 (39.4) 1.55 (39.4) 7.67 (194.8) 5.99 (152.1) 7.74 (196.6) 9.24 (234.7) 10.74 (272.8) 0.875 1.735 & 1.375

A4-7 1.55 (39.4) 1.55 (39.4) 7.67 (194.8) 6.27 (159.3) 8.02 (203.7) 9.52 (241.8) 11.02 (280.0) 0.875 1.735 & 1.375

A4-8 2.47 (62.7) 3.47 (88.1) 8.47 (215.1) 5.96 (151.4) 9.58 (243.3) 11.08 (281.4) 12.58 (319.5) 0.875 1.735 & 1.375

A5-8 2.53 (64.3) 3.53 (89.7) 8.53 (216.7) 5.96 (151.4) 9.58 (243.3) 11.08 (281.4) 12.58 (319.5) 0.875 1.984 & 1.734

A6-8 4.53 (115.1) 5.53 (140.5) 10.53 (267.5) 5.96 (151.4) 9.58 (243.3) 11.08 (281.4) 12.58 (319.5) 0.875 1.984 & 1.734

Conduit

1, 2 & 3

Conduit

4 & 5

16 Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com

Page 24

Figure 16. Type 1 IntelliPass dimensions

D1

W

W1

H1

H

D

Dimensions and mounting

Table 10. Type 1 IntelliPass dimensions

Approximate dimensions in inches (mm)

Enclosure size—

drive frame size H H1 W W1 D D1

Weight in

lb (kg)

B1-4 23.00 (584.2) 21.75 (552.5) 16.28 (413.5) 14.75 (374.7) 15.70 (398.8) 14.26 (362.2) 64 (29)

B1-5 23.00 (584.2) 21.75 (552.5) 16.28 (413.5) 14.75 (374.7) 15.70 (398.8) 14.26 (362.2) 88 (40)

B2-5 30.00 (762.0) 29.00 (736.6) 16.28 (413.5) 14.75 (374.7) 15.70 (398.8) 14.26 (362.2) 88 (40)

B3-5 31.50 (800.1) 30.50 (774.7) 19.13 (485.9) 17.75 (450.9) 15.70 (398.8) 14.26 (362.2) 88 (40)

B3-6 31.50 (800.1) 30.50 (774.7) 19.13 (485.9) 17.75 (450.9) 15.70 (398.8) 14.26 (362.2) 145 (66)

B4-6 39.50 (1003.3) 38.25 (971.6) 30.13 (765.3) 28.75 (730.3) 17.42 (442.5) 15.73 (399.5) 158 (72)

B4-7 42.75 (1085.9) 38.25 (971.6) 30.13 (765.3) 28.75 (730.3) 17.42 (442.5) 15.73 (399.5) 262 (119)

B4-8 42.90 (1089.7) 38.25 (971.6) 30.13 (765.3) 28.75 (730.3) 17.42 (442.5) 15.73 (399.5) 455 (207)

B5-8 44.00 (1117.6) 42.75 (1085.9) 33.13 (841.5) 31.75 (806.5) 17.42 (442.5) 15.73 (399.5) 455 (207)

B6-8 44.00 (1117.6) 42.75 (1085.9) 33.13 (841.5) 31.75 (806.5) 17.42 (442.5) 15.73 (399.5) 455 (207)

Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com 17

Page 25

Dimensions and mounting

D

C

A

1

2

3

4

5

B

6

E

F

G

H

Figure 17. Type 1 IntelliPass knockout dimensions

Table 11. Type 1 IntelliPass knockout dimensions

Approximate dimensions in inches (mm)

Enclosure size—

drive frame size A B C D Conduit 1 Conduit 2 Conduit 3

B1-4 1.75 (44.5) 4.75 (120.7) 7.75 (196.9) 9.70 (246.4) 1.109 1.109 1.375 & 1.109

B1-5 1.75 (44.5) 4.75 (120.7) 7.75 (196.9) 9.70 (246.4) 1.109 1.109 1.375 & 1.109

B2-5 1.75 (44.5) 4.75 (120.7) 7.75 (196.9) 9.78 (248.4) 1.109 1.109 1.375 & 1.109

B3-5 2.13 (54.1) 5.13 (130.3) 8.13 (206.5) 9.78 (248.4) 1.109 1.109 1.984 & 1.109

B3-6 2.13 (54.1) 5.13 (130.3) 8.13 (206.5) 9.78 (248.4) 1.109 1.109 1.984 & 1.109

B4-6 6.15 (156.2) 10.15 (257.8) 14.00 (255.6) 10.26 (260.6) 1.109 1.109 1.964 & 1.109

B4-7 6.15 (156.2) 10.15 (257.8) 14.00 (255.6) 10.26 (260.6) 1.109 1.109 1.964 & 1.109

B4-8 6.15 (156.2) 10.15 (257.8) 14.00 (255.6) 10.26 (260.6) 1.109 1.109 1.964 & 1.109

B5-8 6.09 (154.7) 11.09 (281.7) 16.09 (408.7) 10.11 (256.8) 1.375 2.469 & 1.984 2.469 & 1.984

B6-8 6.09 (154.7) 11.09 (281.7) 16.09 (408.7) 10.11 (256.8) 1.375 2.469 & 1.984 2.469 & 1.984

Enclosure size—

drive frame size E F G H Conduit 4 Conduit 5 Conduit 6

B1-4 1.83 (46.5) 4.83 (122.7) 7.83 (198.9) 10.26 (260.6) 1.109 1.109 1.375 & 1.109

B1-5 1.83 (46.5) 4.83 (122.7) 7.83 (198.9) 10.26 (260.6) 1.109 1.109 1.375 & 1.109

B2-5 1.75 (44.5) 4.75 (120.7) 7.75 (196.9) 9.78 (248.4) 1.109 1.109 1.375 & 1.109

B3-5 2.13 (54.1) 5.13 (130.3) 8.13 (206.5) 9.78 (248.4) 1.109 1.109 1.984 & 1.109

B3-6 2.13 (54.1) 5.13 (130.3) 8.13 (206.5) 9.78 (248.4) 1.109 1.109 1.984 & 1.109

B4-6 6.09 (154.7) 10.08 (256.0) 14.00 (255.6) 10.11 (256.8) 1.109 1.109 1.964 & 1.109

B4-7 6.09 (154.7) 10.08 (256.0) 14.00 (255.6) 10.11 (256.8) 1.109 1.109 1.964 & 1.109

B4-8 6.09 (154.7) 10.08 (256.0) 14.00 (255.6) 10.11 (256.8) 1.109 1.109 1.964 & 1.109

B5-8 6.09 (154.7) 11.09 (281.7) 16.09 (408.7) 10.11 (256.8) 1.375 2.469 & 1.984 2.469 & 1.984

B6-8 6.09 (154.7) 11.09 (281.7) 16.09 (408.7) 10.11 (256.8) 1.375 2.469 & 1.984 2.469 & 1.984

18 Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com

Page 26

Figure 18. Type 3R IntelliDisconnect dimensions

H5

W

H

D1

D

H4

H2

H3

W1

H1

Dimensions and mounting

Table 12. Type 3R IntelliDisconnect dimensions

Approximate dimensions in inches (mm)

Enclosure size—

drive frame size H H1 H2 H3 H4 H5 W W1 D D1

C1-4 22.79

(578.9)

C1-5 22.79

(578.9)

C2-5 29.79

(756.7)

C3-5 31.72

(805.7)

C3-6 31.72

(805.7)

C4-6 53.67

(1363.2)

C4-7 53.67

(1363.2)

C4-8 53.67

(1363.2)

C5-8 53.67

(1363.2)

C6-8 53.67

(1363.2)

3.75

(95.25)

3.75

(95.25)

4.10

(104.1)

0.70

(17.78)

0.70

(17.78)

3.37

(85.6)

3.37

(85.6)

3.37

(85.6)

1.87

(47.5)

2.20

(55.9)

11.25

(285.8)

11.25

(285.8)

14.10

(358.1)

9.87

(250.7)

9.87

(250.7)

12.87

(326.9)

12.87

(326.9)

12.87

(326.9)

11.87

(301.5)

13.95

(354.3)

18.75

(476.25)

18.75

(476.25)

24.10

(612.1)

19.03

(483.4)

19.03

(483.4)

22.37

(568.2)

22.37

(568.2)

22.37

(568.2)

21.87

(555.5)

25.70

(652.8)

— — 15.13

(384.3)

— — 15.13

(384.3)

-— — 15.13

(384.3)

28.20

(716.3)

28.20

(716.3)

31.87

(809.5

31.87

(809.5)

31.87

(809.5)

31.87

(809.5)

37.45

(951.2)

— 18.13

-— 18.13

41.37

)

(1050.8)

41.37

(1050.8)

41.37

(1050.8)

41.37

(1050.8)

49.20

(1249.7)

(460.5)

(460.5)

17.63

(447.8

17.63

(447.8)

17.63

(447.8)

21.38

(543.1)

22.88

(581.2)

14.19

(360.4)

14.19

(360.4)

14.19

(360.4)

17.19

(436.6)

17.19

(436.6)

16.61

)

(421.9)

16.61

(421.9)

16.61

(421.9)

20.36

(517.1)

21.86

(555.2)

14.24

(361.7)

14.24

(361.7)

14.24

(361.7)

14.24

(361.7)

14.24

(361.7)

16.11

(409.2)

16.11

(409.2)

18.11

(460.0)

18.11

(460.0)

21.11

(539.2)

11.48

(291.6)

11.48

(291.6)

11.48

(291.6)

11.48

(291.6)

11.48

(291.6)

13.36

(339.3)

13.36

(339.3)

15.36

(390.1)

15.36

(390.1)

18.36

(466.3)

Weight in

lb (kg)

46 (21)

63 (29)

66 (30)

66 (30)

113 (51)

128 (58)

226 (103)

378 (172)

405 (184)

405 (184)

Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com 19

Page 27

Dimensions and mounting

D

B

1

2

3

C

A

Figure 19. Type 3R IntelliDisconnect knockout dimensions

Table 13. Type 3R IntelliDisconnect knockout dimensions

Approximate dimensions in inches (mm)

Enclosure size—

drive frame size A B C D Conduit 1 Conduit 2 Conduit 3

C1-4 4.99 (126.7) 7.99 (202.9) 10.99 (279.1) 6.07 (154.2) 1.375 & 1.109 1.109 1.109

C1-5 4.99 (126.7) 7.99 (202.9) 10.99 (279.1) 6.07 (154.2) 1.375 & 1.109 1.109 1.109

C2-5 4.99 (126.7) 7.99 (202.9) 10.99 (279.1) 6.57 (166.9) 1.375 & 1.109 1.109 1.109

C3-5 7.99 (202.9) 10.99 (279.1) 13.99 (355.3) 6.57 (166.9) 1.109 1.109 1.734 & 1.109

C3-6 7.99 (202.9) 10.99 (279.1) 13.99 (355.3) 6.57 (166.9) 1.109 1.109 1.734 & 1.109

C4-6 6.49 (164.8) 9.49 (241.0) 12.49 (317.2) 7.58 (192.5) 1.984 & 1.109 1.109 1.109

C4-7 6.49 (164.8) 9.49 (241.0) 12.49 (317.2) 7.58 (192.5) 1.984 & 1.109 1.109 1.109

C4-8 6.49 (164.8) 9.49 (241.0) 12.49 (317.2) 7.58 (192.5) 1.984 & 1.109 1.109 1.109

C5-8 6.24 (158.5) 10.74 (272.8) 15.24 (387.1) 8.08 (205.2) 2.469 & 1.948 2.469 & 1.948 1.375

C6-8 7.74 (196.6) 12.24 (310.9) 16.74 (425.2) 11.08 (281.4) 2.469 & 1.984 2.469 & 1.984 1.375

20 Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com

Page 28

Figure 20. Type 3R IntelliPass dimensions

H5

W

H

D1

D

H4

H2

H3

W1

H1

Dimensions and mounting

Table 14. Type 3R IntelliPass dimensions

Approximate dimensions in inches (mm)

Enclosure size—

drive frame size H H1 H2 H3 H4 H5 W W1 D D1

D1-4 22.87

(580.9)

D1-5 22.87

(580.9)

D2-5 22.87

(580.9)

D3-5 30.74

(780.8)

D3-6 30.74

(780.8)

D4-6 48.67

(1236.2)

D4-7 48.67

(1236.2)

D4-8 48.67

(1236.2)

D5-8 48.67

(1236.2)

D6-8 50.17

(1274.3)

1.25

(31.8)

1.25

(31.8)

1.00

(25.4)

3.25

(82.6)

3.25

(82.6)

1.75

(44.5)

1.75

(44.5)

1.75

(44.5)

2.00

(50.8)

2.00

(50.8)

8.75

(222.3)

8.75

(222.3)

8.50

(215.9)

13.25

(336.6)

13.25

(336.6)

10.25

(260.4)

10.25

(260.4)

10.25

(260.4)

11.50

(292.1)

13.00

(330.2)

16.25

(412.8)

16.25

(412.8)

16.00

(406.4)

23.25

(590.6)

23.25

(590.6)

18.75

(476.3)

18.75

(476.3)

18.75

(476.3)

21.00

(533.4)

24.00

(609.6)

— — 18.13

(460.5)

— — 18.13

(460.5)

— — 18.13

(460.5)

— — 21.13

(536.7)

— — 21.13

(536.7)

27.25

(692.2)

27.25

(692.2)

27.25

(692.2)

30.50

(774.7)

35.00

(889.0)

35.75

(908.1)

35.75

(908.1)

35.75

(908.1)

40.00

(1016.0)

46.00

(1168.4)

28.13

(714.5

28.13

(714.5)

28.13

(714.5)

32.13

(816.1)

32.13

(816.1)

17.19

(436.6)

17.19

(436.6)

17.19

(436.6)

20.19

(512.8)

20.19

(512.8)

27.11

)

(688.6)

27.11

(688.6)

27.11

(688.6)

31.19

(792.2)

31.19

(792.2)

17.23

(437.6)

17.23

(437.6)

17.23

(437.6)

17.23

(437.6)

17.23

(437.6)

18.11

(460.0)

18.11

(460.0)

18.11

(460.0)

22.11

(561.6)

22.11

(561.6)

14.48

(367.8)

14.48

(367.8)

14.48

(367.8)

14.48

(367.8)

14.48

(367.8)

15.36

(3

90.1)

15.36

(390.1)

15.36

(390.1)

19.36

(491.7)

19.36

(491.7)

Weight in

lb (kg)

80 (36)

104 (47)

104 (47)

104 (47)

164 (74)

183 (83)

291 (132)

485 (220)

526 (239)

532 (242)

Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com 21

Page 29

Dimensions and mounting

D

B

1

2

3

C

A

Figure 21. Type 3R IntelliPass knockout dimensions

Table 15. Type 3R IntelliPass knockout dimensions

Approximate dimensions in inches (mm)

Enclosure size—

drive frame size A B C D Conduit 1 Conduit 2 Conduit 3

D1-4 4.06 (103.1) 7.06 (179.3) 10.06 (255.5) 9.62 (244.3) 1.109 1.109 1.375 & 1.109

D1-5 4.06 (103.1) 7.06 (179.3) 10.06 (255.5) 9.62 (244.3) 1.109 1.109 1.375 & 1.109

D2-5 4.06 (103.1) 7.06 (179.3) 10.06 (255.5) 9.62 (244.3) 1.109 1.109 1.375 & 1.109

D3-5 4.06 (103.1) 7.06 (179.3) 10.06 (255.5) 9.62 (244.3) 1.109 1.109 1.375 & 1.109

D3-6 4.06 (103.1) 7.06 (179.3) 10.06 (255.5) 9.62 (244.3) 1.109 1.109 1.375 & 1.109

D4-6 6.06 (153.9) 10.56 (268.2) 15.06 (382.5) 11.13 (282.7) 1.109 1.109 1.984 & 1.109

D4-7 6.06 (153.9) 10.56 (268.2) 15.06 (382.5) 11.13 (282.7) 1.109 1.109 1.984 & 1.109

D4-8 6.06 (153.9) 10.56 (268.2) 15.06 (382.5) 11.13 (282.7) 1.109 1.109 1.984 & 1.109

D5-8 6.06 (153.9) 10.56 (268.2) 15.06 (382.5) 11.13 (282.7) 1.375 2.469 & 1.984 2.469 & 1.984

D6-8 6.06 (153.9) 10.56 (268.2) 15.06 (382.5) 11.13 (282.7) 1.375 2.469 & 1.984 2.469 & 1.984

22 Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com

Page 30

Figure 22. Type 1 Micro Disconnect dimensions

H1

D1

D

W

W1

H

Dimensions and mounting

Table 16. Type 1 Micro Disconnect dimensions

Approximate dimensions in inches (mm)

Enclosure size—

drive frame size H H1 W W1 D D1

Weight in

lb (kg)

M1-1 19.78 (502.4) 19.03 (483.4) 9.59 (243.6) 5.25 (133.4) 8.61 (218.7) 7.19 (182.6) 13.9 (6.3)

M1-2 19.78 (502.4) 19.03 (483.4) 9.59 (243.6) 5.25 (133.4) 8.61 (218.7) 7.19 (182.6) 15.4 (7.0)

Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com 23

Page 31

Dimensions and mounting

A

C

1

23

4

B

D

E

F

Figure 23. Type 1 Micro Disconnect knockout dimensions

Table 17. Type 1 Micro Disconnect knockout dimensions

Approximate dimensions in inches (mm)

Enclosure size—

drive frame size A B C D E F Conduit 1, 2, 3 & 4

M1-1 4.28 (108.7) 5.78 (146.8) 3.28 (83.3) 3.78 (96.0) 4.78 (121.4) 7.90 (200.7) 1.125 & 0.875

M1-2 4.28 (108.7) 5.78 (146.8) 3.28 (83.3) 3.78 (96.0) 4.78 (121.4) 7.90 (200.7) 1.125 & 0.875

24 Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com

Page 32

Wiring

Wiring schematic

A schematic is included with each product. The schematic

number can be found on the product nameplate.

Typical schematics are shown on the next few pages.

Notes

●

Power and motor leads must be in separate conduit

●

Do not run control wires in same conduit as input power

or motor wires

●

Two grounding points are provided, input ground and

output ground

●

Ground unit properly – improper grounding could

damage the unit

Wiring

Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com 25

Page 33

Wiring

Figure 24. Type 1 IntelliDisconnect

26 Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com

Page 34

Figure 25. Type 1 IntelliPass

Wiring

Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com 27

Page 35

Wiring

Figure 26. Type 3R IntelliDisconnect

28 Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com

Page 36

Figure 27. Type 3R IntelliPass

Wiring

Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com 29

Page 37

Wiring

Figure 28. Type 1 Micro Disconnect

30 Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com

Page 38

Wiring

Conduit plates

There are removable top and bottom conduit plates on drives

frames size 8 on designations A4, A5, and A6 (Type 1

IntelliDisconnect) configurations to allow for easier wiring

and conduit connections.

Input power wiring

Input power connection are made to the disconnect device.

Input power connection points are identified by Label (L1, L2,

and L3).

Both the IntelliDisconnect and IntelliPass systems provide an

input disconnect by using a UL Listed, R9 rotary disconnect

fusible or non-fusible as indicated below. These devices

provide a disconnect function and branch protection. In

non-fusible systems, the disconnect is paired with fused

for short circuit protections.

Figure 29. Lower frame incoming lines

Figure 30. Larger frame incoming lines

Input wiring details

Table 18. Input wiring

Voltage hp Wire range Torque (lb-in)

Non-fused disconnect type

208/230 V 1–5 #14–#10 25

7.5–10 #14–#10 28

15–20 #12–2/0 35

25 #6–300 kcmil 160

30–40 #6–300 kcmil 160

480 V 1–15 #14–#10 25

20–30 #14–#10 28

40–125 #6–300 kcmil 160

Fused disconnect type

208/230 V 1–5 #14–#10 25

7.5–10 #14–#10 28

15–20 #12–2/0 35

25 #12–#1 35

30–40 #6–3/0 200

480 V 1–15 #14–#10 25

20–30 #14–#10 28

40–125 #6–3/0 200

Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com 31

Page 39

Wiring

Motor wiring

Motor connection points are identified by a label (T1, T2,

and T3). See output wiring table in technical section for

wiring and torque information. For IntelliDisconnect models,

the motor wiring is direct to the drive output terminals. For

IntelliPass models, the motor wiring is directly to the output

of the overload protection relay on the bypass contactor.

Figure 31. IntelliDisconnect motor wiring

Figure 32. IntelliPass motor wiring

Table 19. Output wiring details—IntelliDisconnect

Voltage hp Drive frame size Torque (lb-in)

208/230 V 1–3 4 4.5

5–10 5 11

15–20 6 35

25–30 7 88

40–50 8 170

480 V 1–7.5 4 4.5

10–20 5 11

25–40 6 35

50–75 7 88

100–125 8 170

Micro

208/230/480 V 0.5–2 FS1 / FS2 4.5

Table 20. Output wiring details—IntelliPass

Voltage hp Torque (lb-in)

208/230 V 1–3 15

5–10 15

15–20 28

25–50 90

480 V 1–7.5 15

10–20 15

25–40 28

50–125 90

32 Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com

Page 40

Wiring

Ground wiring

Ground studs are provided and marked with label. Hardware

is also supplied.

Figure 33. Typical ground stud and label

Frames 1 through 5 have ground lugs supplied for wire size

14 to 2/0.

Frame 6 with drive frame size 8 has ground lugs supplied for

wire size 3/0.

Control wiring

All customer wiring points are supplied on a terminal block

strip. This terminal strip allows easy access to the drives

control terminals and auxiliary contacts. The control I/O

terminals must be tightened to 4.5 lb (0.5 Nm). Please see

table below for terminal block designation.

Figure 34. Terminal block access

Table 21. Terminal block designation

Terminal block Description

AI1 Analog Input Voltage (Range 0–10 Vdc)–2

COM Analog Input Common–3

AO1 Output Frequency–18

COM (AGND) Analog Output–19

SHD GND–7

15 Safety 3

16 Safety 3–Run Permissive IP Interlock–10

25 RO3 Drive Fault Output–32

27 RO3 Drive Fault Output–33

2 Run/Time Clock Start/Stop Command

3 Run/Time Clock Start/Stop Command

4 Electronic Bypass connection points

5 Electronic Bypass connection points

6 Electronic Bypass connection points

7 Safety 1 and 2 connection points

8 Safety 1 and 2 connection points

9 Safety 1 and 2 connection points

22 Drive Contactor (Run Output)–53

24 Drive Contactor (Run Output)–54

Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com 33

Page 41

Initial startup

Initial startup

When the IntelliPass or IntelliDisconnect is first powered up,

the Startup Wizard command should be displayed.

Figure 35. Startup Wizard prompt

Follow the Quick Setup guide LIT-12011773 to set up drive

for your specific application with the following exceptions:

When the Bypass screen appears, set it to “Enabled” for

IntelliPass models and “Disabled” for IntelliDisconnect

models.

Figure 36. Enable bypass for IntelliPass models

IntelliDisconnect operation

(starting/stopping of the motor)

IntelliDisconnect operation is the identical to a standard

JCI-VSD Series II open drive. The only difference is that an

input disconnect is provided. For more information on speed

control and other drive features, see Application Manual

LIT-12011771. See option sections for more information on

operation of IntelliDisconnect options, i.e., drive output

contactor.

IntelliPass operation

(starting/stopping of the motor)

The IntelliPass operation is similar to the IntelliDisconnect

but has the added feature of a built-in drive bypass. This

section gives basic information on operations for controlling

the starting and stopping of the motor in both the drive and

bypass modes. For more information on speed control and

other drive features, see Application Manual LIT-12011771.

The IntelliPass has 2 modes:

●

Drive mode (normal VFD operation)

●

Bypass mode (across the line)

The mode is selected via the keypad. The actual starting and

stopping of the motor is determined by the HOA selection

and the control place selections. The control place is defined

as the location from where the drive is started and stopped.

The control place can be: keypad start button, I/O contacts

wired to the logic terminal blocks, Fieldbus control or PC.

See Quick Start Guide LIT-12011775 or Application Manual

LIT-12011771 for more information.

The only exception is the use of the drive—bypass 3-position

switch for manual operation. This will override the drive logic

and can start the motor in Bypass immediately.

Switch operation

Figure 37. Disable bypass for IntelliPass models

34 Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com

HOA switch

Auto position = the drive will follow a run command from the

runtime clock wired to terminal block 2 and 3.

Hand position = this will force a run command to the drive.

This is true in both bypass and drive mode.

VFD- OFF-BYP

VFD position = the drive will run in normal drive operation.

BYP position = the drive will go into bypass mode. The

bypass contactor will close and the drive contactor will open.

When in the VFD position, the bypass can be selected

electronically from the keypad or from external

communications such as SA Bus.

Page 42

Initial startup

Drive mode

When the IntelliPass is in the drive mode, the text

“E-Energy” is shown on status bar. (If E-Energy function is

not active, the text “Ready” will be shown.)

Figure 38. Keypad shown in drive mode

When the system is first commanded to run, the output

contactor M is energized and the motor is connected to the

drive. The “M” contactor is controlled by the IntelliPass logic

via Relay 2 output. The “M” contactor will always be

energized while the VFD-OFF-BYP switch is in the VFD

position unless the bypass command is electronic. The

speed of the motor is determined by the speed set point of

the JCI-VSD Series II Drive. When the JCI-VSD Series II is

commanded to stop, the drive will reduce the speed of the

motor and when the motor speed reaches zero, the output

contactor “M” is de-energized and the motor is

disconnected from the IntelliPass. The output contactor also

opens immediately if there is a drive fault.

The IntelliPass system is also interlocked. When the output

contact “M” is energized, the bypass contactor “B” is

prevented from being energized by electrical interlocks in

each contactor coil control circuit and a logic interlock built in

to the IntelliPass software.

Bypass mode

When the IntelliPass is in the bypass mode, the text

“Bypass” is shown on status bar. When bypass is selected

electronically, if selected via the VFD-OFF-BYP switch, the

drive will not be ready. “E-Energy” will be flashing.

Figure 39. Keypad shown in bypass mode

When the system is commanded to run in the bypass mode,

the motor is connected to the line through the bypass

contactor (B). The “B” contactor is controlled by the drive

logic via a Relay 1 output.

The bypass mode can be selected in 3 ways:

●

Manually via the drive logic controls (i.e., keypad, fieldbus,

or I/O)

●

Automatically after a drive fault; if the auto bypass feature

is active

●

Manually by a door switch; manually using the manual

bypass switch

Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com 35

Page 43

Initial startup

Manual bypass

Manual bypass can be activated either by using the bypass

button on the keypad, by using a digital input on the control

terminal block or from the fieldbus. The user can toggle

between bypass and drive modes by pressing the keypad

bypass button or the terminal block inputs. Once in the

bypass mode, the start command can be given through any

control place (I/O, keypad, and fieldbus) in the same manner

as starting in the drive mode.

Using the keypad to select bypass mode

When the bypass button is pressed, the following options

are shown to the user. Select the desired mode by using the

arrow keys and pressing the OK key.

Figure 40. Keypad with bypass and drive mode option

Figure 41. Keypad shown in run mode

Figure 42. Keypad already in bypass mode

The user can toggle between modes by pressing the bypass

button again. If bypass button is pressed while the drive is

running, the keypad will display “Bypass is not allowed”. The

system must be stopped to allow a change from drive to

bypass mode. Likewise if the system is running in bypass

and the bypass key is pressed, the display will indicate

“Motor Running in Bypass.” To change state back to drive,

the system must be stopped. The keypad will display bypass

in the status display when in the bypass mode and ready or

E-Energy when in the drive mode.

Using the digital input to select bypass

If the digital input (Force Bypass) is used to enable the

bypass mode, the drive will ramp to zero speed. Once the

drive stops, the bypass mode is active and the keypad will

display the bypass mode. The bypass and motor will start

when a valid start command is received. Note that the Force

Bypass function is the factory default for Digital Input #6

P2.3.6.2 located at TB16 on the control module and is also

factory wired to the M1 Manual Bypass option if supplied.

mode

Using the fieldbus to select bypass mode

The fieldbus command works the same as the digital input.

36 Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com

Page 44

Initial startup

Auto bypass operation

The drive can also be bypassed automatically if certain faults

occur. When the selected fault occurs, the drive is first

stopped. Then, depending on the automatic reset parameter,

the drive is either bypassed instantly or the fault is first tried

to reset. If the reset fails, the motor is automatically started

in bypass.

Figure 43. Parameter menu for automatic reset

Figure 44. Menu selecting auto bypass

Figure 45. Menu selecting reset/bypass

When the drive goes to auto bypass, the keypad displays

“Going into Auto Bypass” for 10 seconds. After the delay,

the drive goes to the bypass mode and starts the motor (the

run command must still be present). When the fault

condition is not active, the drive is set back to drive mode

automatically and the bypass running signal is reset. The

drive returns to the normal operation.

Figure 46. Displaying going into auto bypass after fault

Automatic reset selections

0 = Not used

1 = Auto Bypass (Visible only if Bypass is enabled)

2 = Reset faults

3 = Reset/Bypass (Visible only if Bypass is enabled)

Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com 37

Page 45

Initial startup

Activate the automatic reset functions with

this parameter

For option 1, if the drive faults, the drive switches

automatically to bypass and leaves the fault active on the

drive. For option 3, the drive will first try to auto reset the

faults but if not successful, it will then switch to bypass.

Option 2 just tries to reset the fault without going into

bypass. See the application manual for more information on

auto reset operation.

Manual bypass (forced)

The IntelliPass also has a forced manual bypass option. This

is controlled by a door mounted Drive / Off / Bypass switch.

The door switch will start the motor in bypass following the

HOA switch run commands. Switch to the Hand position to

start bypass immediately. This switch manually overrides the

system (keypad) and forces the unit into bypass mode even

if the drive is in operative or removed from the system.

HOA control

The keypad HOA button is used for fast and easy changing

between Hand, Off and Auto control places to change the

speed set point source. HOA control works in both the drive

and bypass modes of operation. However, speed set point

has no functions when in bypass because the motor runs full

speed across the line. The drive should remain in Auto mode

during normal operation.

There are four parameters for selecting a control source and

reference source for them: P2.1.3 HOA Control Source,

P2.1.4 Start Source Hand, P2.1.5 Speed Set point Hand,

P2.1.6 Start Source Auto & P2.1.7 Speed Set point Auto. The

Start Source selections are: Keypad, I/O Terminal, I/O 3-wire

& Fieldbus Ctrl. For the drive mode, the Speed set point the

selections are: Keypad Ref, Fieldbus, AI1, AI2, AI1+AI2, &

PID1 (if PID is activated). See Quick Start Guide

LIT-12011773 or Application Manual LIT-12011771 for more

information.

When control place Off is selected, the drive cannot be

started anywhere. It prohibits the start command for both

drive and bypass. Bypass may force started in the HOA off

mode by using the door switch.

Figure 48. Off menu selection

Figure 47. Hand/Off/Auto parameter

Control place is defined as the location from where the drive

or bypass is started and stopped. Hand and auto are two

different control places.

Figure 49. Monitoring menu in STOP mode

38 Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com

Page 46

Key parameters related to proper IntelliPass bypass

operation

The following parameters are related to Bypass functionality

and are factory default set. Changing them will affect proper

IntelliPass operation.

●

P2.1.2 Bypass: This parameter is for activating the bypass

functionality. It is factory enabled. If disabled, the Bypass

keypad button is inactive and some parameters may be

hidden. This is part of the Startup Wizard.

●

P2.3.2.2.1 (RO1 Function) set to Bypass Run. This signal is

active if the bypass mode has been selected and the run

command is active—this relay output controls the bypass

contactor it should not be changed.

●

P2.3.2.2.5 (RO2 Function) set to Run. This signal is active if

the drive mode has been selected and the run command is

active—this relay output controls the output contactor and

should not be changed.

SA bus operation and setup

Initial startup

Wiring SA bus

Wire the SA bus as shown below.

If this is the last device on the line, set the X4 termination

resistor to ON.

Table 22. SA bus setup

SA bus terminal Wire Color

3SA– Black

4SA+ Blue

5 Common White

N/C SA Power Red

Figure 50. JC-VSD Series II drive SA bus interface card VS-XMX-CS

Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com 39

Page 47

Initial startup

Programming

1. Ensure the correct fieldbus protocol is selected.

a. Navigate: P4.4.3.1

b. Main Menu R I/O Hardware R OPTCS R Parameters R Comm. Protocol

2. Set the slave address.

a. Navigate: P4.4.3.2

b. Main Menu R I/O Hardware R OPTCS R Parameters R Slave Address

3. Set the Start Source Auto to “Fieldbus.”

a. Navigate: P2.1.6

b. Main Menu R Parameters R Basic Parameters R StartSourceAuto

4. Set the Speed Set Point Auto to “Fieldbus.”

a. Navigate: P2.1.7

b. Main Menu R Parameters R Basic Parameters R SpeedSetptAuto

40 Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com

Page 48

Control

1. To run the VSD in drive mode, write a 1 to VSD-C and

a speed reference in percent to VSD-O.

2. To run in bypass mode, write a 1 to VSD-BYPASS and a

1to VSD-C.

Table 23. Object list

Object

name

VSD-C

VSD-O

VSD-S

VSD-BYPASS

VSD-RESET

VSD-KWH

VSD-SPEED

VSD-FREQ

VSD-%

VSD-HOA

VSD-FAULT

Object

description Port function NetDeviceRefAttrID I/O Units States text Set members

VSD Command

VSD Output

VSD Status

VSD Bypass Drive

VSD Reset Drive Fault

VSD Kilowatt Hours

VSD Motor Speed

VSD Output Frequency

VSD Speed Feedback

VSD Control Mode

VSD Fault Code

Run/Stop

Output

Status

Bypass Enable

Reset Drive Fault

Kilowatt Hours

Motor Speed

Frequency

Speed Setpoint

Control Mode

Fault Code

Drive Command

Reference Command

Drive Running

Bypass Enable

Reset Drive Fault

Kilowatt Hours

Motor Speed

Output Frequency

Speed Setpoint

Control Mode

Fault Code

Output

Output

Input

Output

Output

Input

Input

Input

Input

Input

Input

%

kWh

rpm

Hz

%

Off/On

Off/On

Inactive/Active

Off/Reset

Hand Off Auto

Drive Fault

Initial startup

0=Off, 1=On

0=Off, 1=On

0=Inactive, 1=Active

0=Off, 1=Reset

0=Hand, 1=Off, 2=Auto

0=No Fault

1=Over Current

2=Over Voltage

3=Ground Fault

4=Bypass Overload

5=Charging Switch

6=Emergency Stop

7=Saturation Trip

8=System Fault

9=Under Voltage

10=Input Line Supervision

11=Output Phase Supervision

12=System Fault

13=Drive Heatsink Under Temp

14=Drive Heatsink Over Temp

15=Motor Stalled

16=Motor Overload Temp

17=Motor Underload

18=External Fault

19=Comm Bus Fault

20=Drive Fault

Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com 41

Page 49

IntelliPass/IntelliDisconnect technical information

IntelliPass/IntelliDisconnect technical information

See JCI-VSD Series II Installation Manual LIT-12011775 for

additional data.

●

Enclosure: Type 1 or Type 3R as ordered

●

Max. Ambient Temp: 40 °C

●

Wire temperature rating of field installed conductors: use

75 °C copper conductors only

Table 24. Short-circuit rating

Frame Voltage Available current

4–8 208 Vac, 280 Vac,

480/277 Vac

100,000 A

42 Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com

Page 50

Additional help

Website address

www.johnsoncontrols.com R HVAC Controls R Variable Speed Drives

Johnson Controls product sales operation

Call the Johnson Controls PSO Team if you need assistance with placing an order, stock

availability or proof of shipment, expediting an existing order, emergency shipments, product

price information and returns (including warranty returns).

Voice: 1-800-ASK-JNSN [275-5676] (US); 1-800-321-4023 (CA)

FAX: 1-800-356-1191 (US); 1-800-321-4024 (CA)

Support Hours of Operation: Monday–Friday, 6:30 a.m.–5:30 p.m. CST

(No evening or weekend Customer Service hours)

If you are in the U.S. or Canada, you can take advantage of our toll-free line for technical

assistance. Technical support engineers are available for calls during regular business hours.

Johnson Controls Field Support Center

1-888-281-3792 Monday–Friday, 7:30 a.m.–5:30 p.m. CST

email:CGFieldSupportCenter@jci.com

Additional help

Johnson Controls Variable Speed Drives LIT-12012114—July 2015 www.johnsoncontrols.com 43

Page 51

Powered by

Controls Group

507 E Michigan Street

PO Box 423

Milwaukee, WI 53201

© 2015 Johnson Controls

All Rights Reserved

Publication No. LIT-12012114 / Z16866

July 2015

Eaton Technology

All trademarks are property of their

respective owners.

Loading...

Loading...