Johnson Controls JXHX1252N, JXHX2452N, JXHX1852N, JXHX3652N, JXMHX1852N Engineering Manual

...Page 1

MINI 2-WAY

VARIABLE REFRIGERANT FLOW (VRF) SYSTEM

ENGINEERING GUIDE New Release Form 121.00-EG1 (512)

MINI 2-WAY

VARIABLE REFRIGERANT FLOW (VRF) SYSTEM

Issue Date:

May 25, 2012

Page 2

IMPORTANT!

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

JOHNSON CONTROLS

2

READ BEFORE PROCEEDING!

GENERAL SAFETY GUIDELINES

This equipment is a relatively complicated apparatus.

During installation, operation maintenance or service,

individuals may be exposed to certain components or

conditions including, but not limited to: refrigerants,

materials under pressure, rotating components, and

both high and low voltage. Each of these items has the

potential, if misused or handled improperly, to cause

bodily injury or death. It is the obligation and responsibility of operating/service personnel to identify and

recognize these inherent hazards, protect themselves,

and proceed safely in completing their tasks. Failure

to comply with any of these requirements could result

in serious damage to the equipment and the property in

which it is situated, as well as severe personal injury or

death to themselves and people at the site.

This document is intended for use by owner-authorized

operating/service personnel. It is expected that these

individuals possess independent training that will enable them to perform their assigned tasks properly and

safely. It is essential that, prior to performing any task

on this equipment, this individual shall have read and

understood this document and any referenced materials. This individual shall also be familiar with and

comply with all applicable governmental standards and

regulations pertaining to the task in question.

CHECK OF DENSITY LIMIT

The room in which the air conditioner is to be installed requires a design that in the event of refrigerant gas leaking out, its density will not exceed a

set limit.

The refrigerant (R410A), which is used in the airconditioner, is safe, without the toxicity or combustibil-

ity of ammonia, and is not restricted by laws imposed

to protect the ozone layer. However, since it contains

more than air, it poses the risk of suffocation if its density should rise excessively. Suffocation from leakage

of refrigerant is almost non-existent.

With the recent increase in the number of high density

buildings, however, the installation of multi air conditioner systems is on the increase because of the need

for effective use of floor space, individual control, energy conservation by curtailing heat and carrying power, etc. Most importantly, the multi air conditioner system is able to replenish a large amount of refrigerant

compared to conventional individual air conditioners.

If a single unit of the multi air conditioner system is

to be installed in a small room, select a suitable model

and installation procedure so that if the refrigerant accidentally leaks out, its density does not reach the limit

(and in the event of an emergency, measures can be

made before injury can occur).

ASHRAE and the International Mechanical Code of

the ICC as well as CSA provide guidance and define

safeguards related to the use of refrigerants, all of

which define a Refrigerant Concentration Level (RCL)

of 25 pounds per 1,000 cubic feet for R410A refrigerant. For additional guidance and precautions related to

refrigerant safety, please refer to the following documents:

International Mechanical Code 2009 (IMC-2009) (or

more recently revised)

ASHRAE 15

ASHRAE 34

Page 3

INDOOR UNIT NOMENCLATURE

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

3

JOHNSON CONTROLS

J UMHX 12 62N

SERIES

CAPACITY

SLIM CONCEALED DUCT TYPE

JOHNSON CONTROLS

OUTDOOR UNIT NOMENCLATURE

J CHX R 036 52N

CAPACITY

SALT-AIR DAMAGE RESISTANT

2-WAY FLOW MINI

JOHNSON CONTROLS

SERIES

OUTDOOR UNITS

KEY CLASS 36 52

JCHX Variable Refrigerant Flow

System

Refrigerant R410A is used in the outdoor units.

* Salt-Air Damage Resistant Specications.

JCHX03652N

JCHXR03652N*

JCHX05252N

JCHXR05252N*

INDOOR UNITS

KEY CLASS 7 9 12 15 18 24 36 48 54

JX 4-Way Air

Discharge

Semi-Concealed

JXM 4-Way Air

Discharge

Mini SemiConcealed

JA 1-Way Air Dis-

charge SemiConcealed

JU Concealed

Duct Type

JUM Slim Concealed

Duct Type

JD Concealed-

Duct High

Static Pressure

JT Ceiling-

Mounted

JK Wall-Mounted

Type

JF Floor-Standing

Type

JFM Concealed-

Floor Standing

Type

JAHX0752N JAHX0952N JAHX1252N

JUHX0762N JUHX0962N JUHX1262N JUHX1562N JUHX1862N JUHX2462N JUHX3662N JUHX4862N JUHX5462N

JUMHX0762N JUMHX0962N JUMHX1262N JUMHX1562N JUMHX1862N

JKHX0752N JKHX0952N JKHX1252N JKHX1862N JKHX2452N

JFHX0762N JFHX0962N JFHX1262N JFHX1562N JFHX1862N JFHX2462N

JFMHX0762N JFMHX0962N JFMHX1262N JFMHX1562N JFMHX1862N JFMHX2462N

JXHX1252N JXHX1852N JXHX2452N JXHX3652N

JXMHX1252N JXMHX1852N

JDHX3652N JDHX4852N

JTHX1252N JTHX1852N JTHX2452N

Page 4

TABLE OF CONTENTS

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

JOHNSON CONTROLS

4

INTRODUCTION .......................................................................................................................................................5

1. OFFERINGS ........................................................................................................................................................14

2. OUTDOOR UNIT DIMENSIONS AND SPECIFICATIONS .................................................................................17

3. INDOOR UNIT DIMENSIONS AND SPECIFICATIONS .....................................................................................27

4-Way Air Discharge Ceiling Semi-Concealed, Standard And Mini (JX, JXM Type) ......................................26

1-Way Air Discharge Ceiling Semi-Concealed (JA Type) ...............................................................................47

Slim Concealed Duct, Standard and Slim (JU, JUM Type) ............................................................................56

Concealed Duct High Static Pressure (JD Type)............................................................................................94

Ceiling Mounted Exposed Horizontal (JT T ype) ...........................................................................................101

Wall Mounted Exposed (JK Type) ................................................................................................................ 111

Floor Exposed (JF Type) ............................................................................................ ..................................124

Floor Concealed (JFM Type) ........................................................................................................................139

4. FRESH AIR INTAKE, SEMI-CONCEALED DUCT AND CONCEALED DUCT TYPES ...................................156

5. ELECTRICAL WIRING .....................................................................................................................................158

6. OUTDOOR UNIT WIRING DIAGRAMS ............................................................................................................168

7. INDOOR UNIT WIRING DIAGRAMS ................................................................................................................171

8. CAPACITY RATIO OF OUTDOOR UNITS .......................................................................................................196

9. COOLING CAPACITY OF INDOOR UNITS .....................................................................................................204

Note: 1. All data herein is subject to change without notice.

2. Drawings and performance data should not be used for submittal purposes

Page 5

INTRODUCTION

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

5

JOHNSON CONTROLS

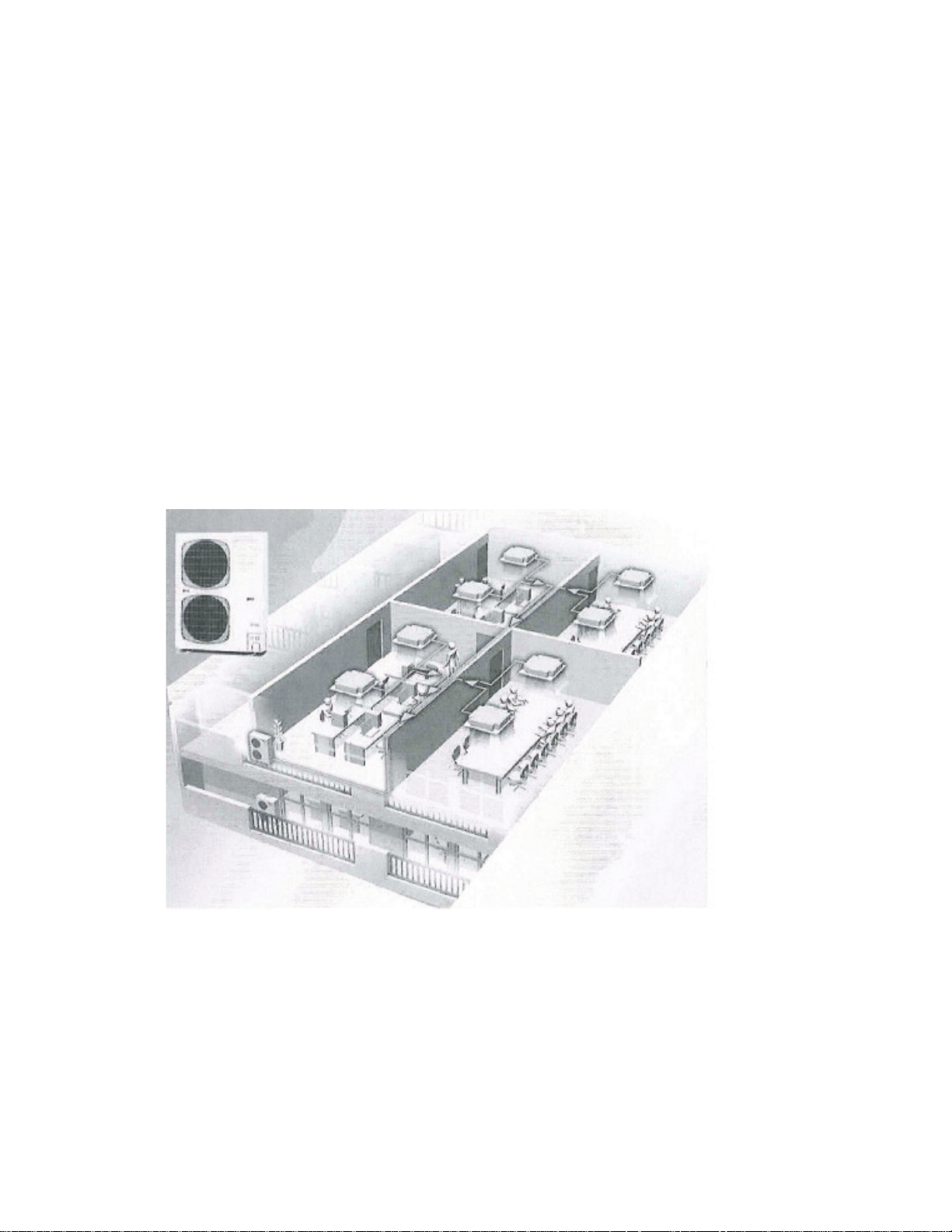

Suitability. Johnson Controls Mini 2-way Variable Refrigerant Flow (VRF) system is ideal for commercial office buildings subject to diverse loads and

varying occupant levels. Also, the 2-way VRF system

is ideal for schools, hotels, nursing homes and other

commercial living spaces where occupants will want

to control the temperature setting in their zone. In all

cases the system runs quietly, for a comfortable, productive environment.

Zone Control.

In buildings with multiple zones that

require separate comfort controls, you need options.

Johnson Controls Mini 2-way (VRF) systems give you

the heating and cooling flexibility you need, combined

with the reliability and energy efficiency you expect

from Johnson Controls. You get the freedom to create

comfortable, efficient buildings, without being limited

by ductwork runs.

Flexibility.

Johnson Controls Mini 2-way VRF systems offer multiple configurations for both new and

existing buildings. Multi-zone temperature control allows the system to handle diverse heating and cooling

loads, while giving occupants the ability to adjust temperature to satisfy their individual comfort needs. In

addition, variable refrigerant flow heating and cooling

uses energy efficiently, because VRF uses only refrigerant without air or water as a heat transfer medium.

Installation.

Johnson Controls Mini 2-way VRF

systems are modular which are easy to transport and

install. As remodeling occurs and building extensions

are planned, the VRF systems modularity allows to

simply add on to the system within the system parameters.

Control.

Johnson Controls Mini 2-way VRF systems are available with a variety of zone controls and

network controls that are responsive and provide immediate response to changes in zone loads. With wired

controls, wireless controls and a network portal that

supports BACnet®, LONWORKS® and Johnson Controls N2 protocols, the Mini 2-way VRF system will

have the solution to meet the needs of the owners and

tenants.

Page 6

JOHNSON CONTROLS Mini 2-WAY VARIABLE

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

JOHNSON CONTROLS

6

REFRIGERANT FLOW SYSTEM BENEFITS

Johnson Controls Mini 2-way Variable Refrigerant

Flow (VRF) systems are easy to select with flexibility

built in to the unit choices. With responsive controls

and advanced inverter controlled compressor technology, they offer immediate response to changes in zone

loads with the compressor precisely delivering the right

amount of refrigerant to each zone. VRF systems provide increased occupant comfort, with zone control, all

occupants enjoy consistent room temperature regardless of variations in load during the day. VRF systems

provide efficient operation resulting in high COP’s, in

excess of 4.0 at full load conditions.

Johnson Controls Mini 2-way VRF systems outdoor

units have a modular design and compact footprint,

choosing a Johnson Controls VRF system means easy

installation and commissioning. With multiple unit

connectivity, up to 9 indoor units can be connected to

one condensing unit and the system takes advantage

of building load diversity. Diversity ratios of 50% to

130% allow for a smaller outdoor unit. Johnson Controls Mini 2-way outdoor units come in 2 sizes, 3 ton

and 4.4 ton.

Page 7

OUTDOOR UNITS

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

7

JOHNSON CONTROLS

• Ultra-quiet operation as low as 22 dBA

• Range from 3-4.4 tons

• 208/230 volt — single-phase power supply

• Modular design for increased capacity from com-

pact footprint

• Ultra quiet operation as low as 51d (dBA)

• Maximum piping lengths up to 984 feet

• Up to 9 indoor units can be connected

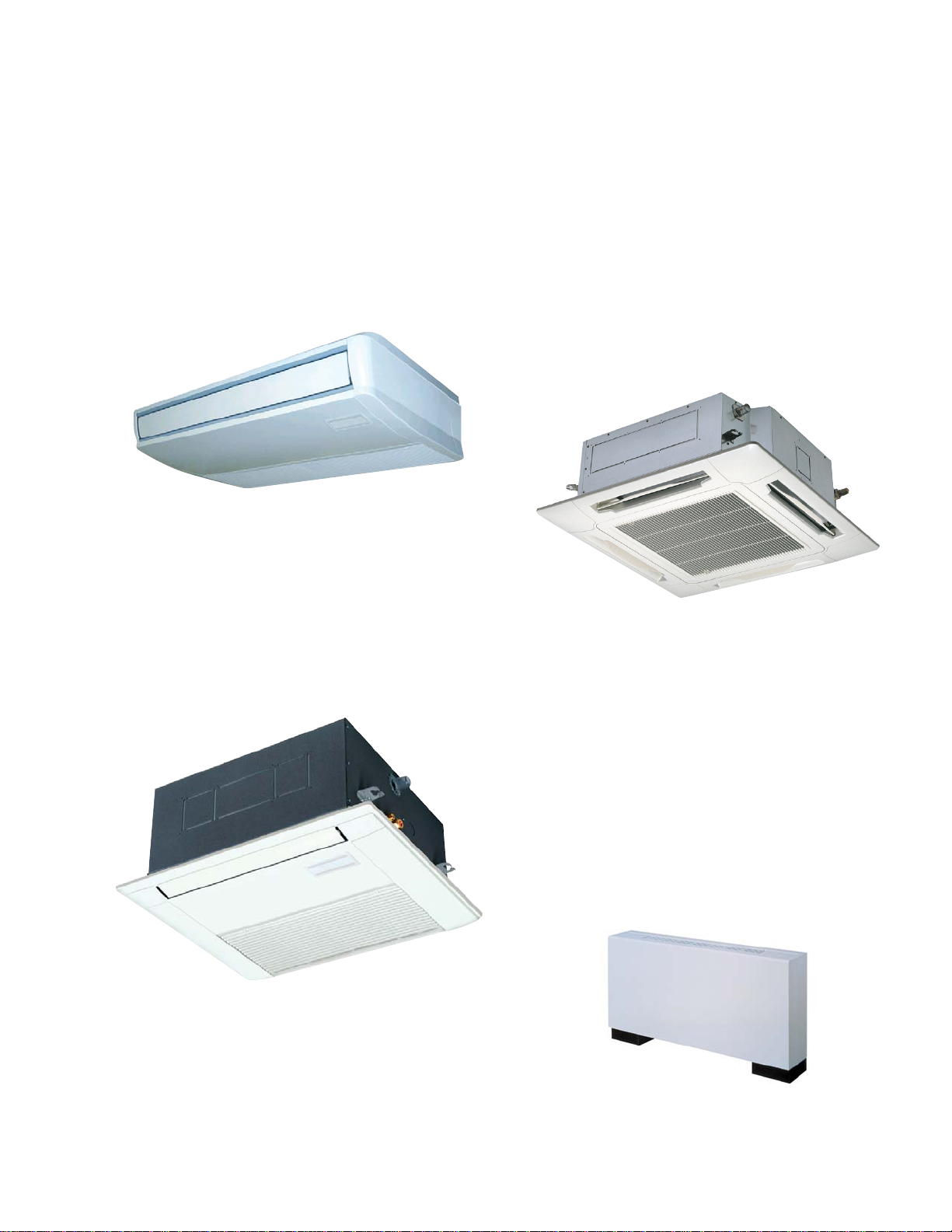

INDOOR UNITS

• Range from 7,500-48,000 btu

• 208/230 volt — single-phase power supply

•

Ceiling,wallandoormountedmodelsavailable

• Concealed, semi-concealed and exposed models

available

• All units can be controlled with any Johnson Controls VRF zone controller.

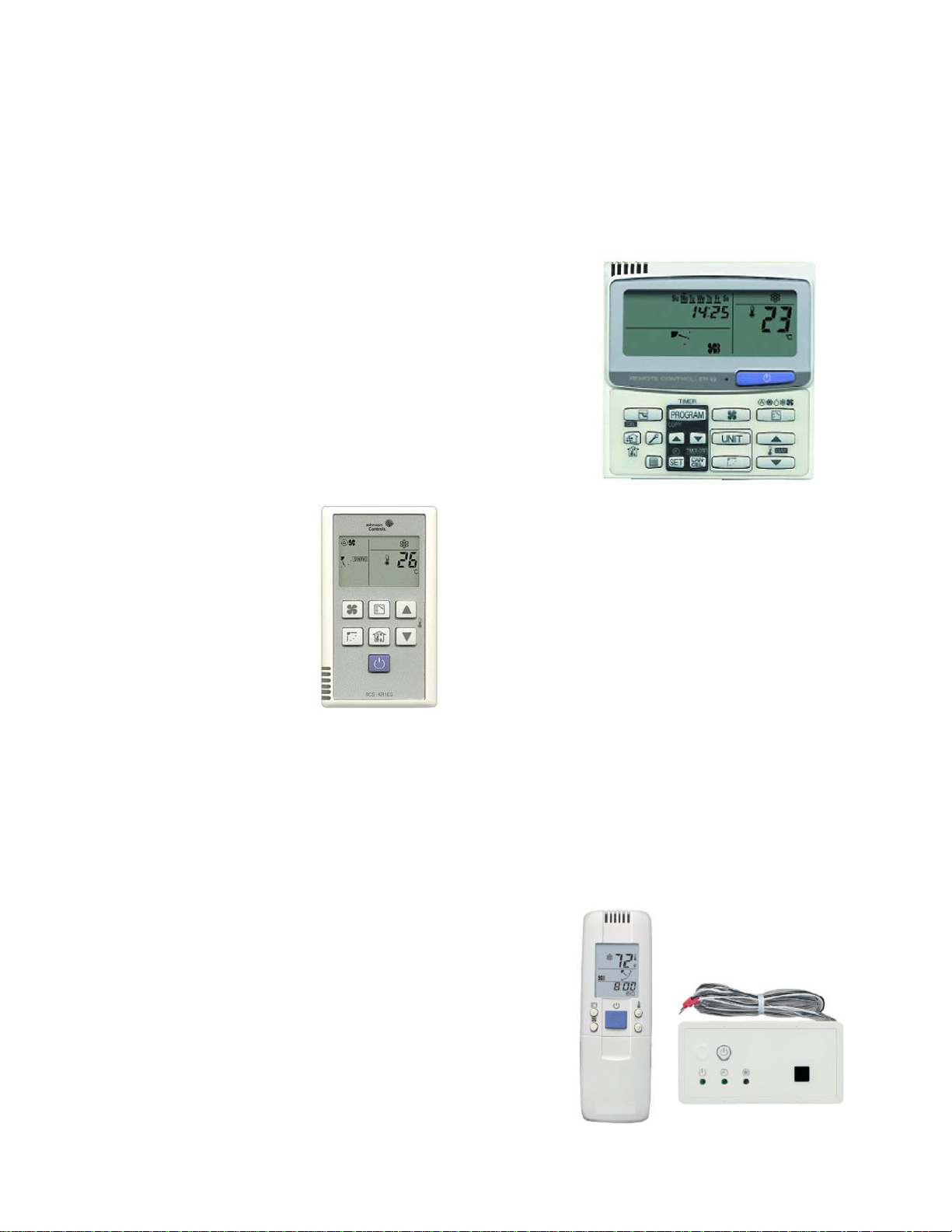

CONTROLS

• Variety of controls available, all provide control

of mode, temperature, on/off and fan speed

• Remote unit controls

• Optional wireless remote controls

• Optional system diagnostics capability

• Network controls available

• Network portal that supports BACnet

®

, LON-

WORKS® and Johnson Controls N2 protocols.

• Standard operation uses return air sensor, but can

beconguredtousethesensorinthecontroller.

Page 8

FEA TURES AND OPTIONS

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

JOHNSON CONTROLS

8

• Flexible Piping Design:

Outdoor Unit Features and Options:

• Range from 3-4.4 tons

• 208/230V, Single Phase, 60Hz

• Environmentally responsible R-410A refrigerant

• Ultra quiet operation as low as 51dBA

• Modular design for easy installation and compact

footprint

• Up to 9 indoor units can be connected

• Wide Operating Range (Outdoor Ambient)

• Cooling 14 °F to 109 °F

• Heating -4 °F to 59 °F

• 656 Feet - Maximum Total Liquid Line

• 492 Feet - Maximum Outdoor To Most Dis-

tant Indoor Unit

• 164 Feet - Maximum Vertical Between Indoor and Outdoor (Outdoor Above Indoor)

• 131 Feet - Maximum Vertical Between Indoor and Outdoor (Outdoor Below Indoor)

Indoor Unit Features and Options:

High Wall Mounted (JKHX Type)

• Lowest indoor unit cost per Btuh of cooling

• Surface mounts on walls

• Bottom discharge – should be mounted at least 5’

abovetheoorand12”fromceiling

• Wireless remote ready – comes with built-in wire-

less receiver

•

Anti-moldwashablelter(notMERVrated)

• 3-speed AC motor (not ECM)

• Condensate pump not included

JKHX Series - High Wall Mounted Indoor Unit

LD16391

Page 9

Ceiling Mounted Horizontal Exposed

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

9

JOHNSON CONTROLS

(JTHX Type)

Low prole (8.5” tall) – great for commercial

•

spaces

• Mounts against ceiling with horizontal discharge

4 Way Air Discharge Semi-Concealed

Cassette (JXHX and JXMHX Type)

• Great for large spaces

1and1.5tonunitstinthespaceofa2’X2’ceil-

•

ing(JXMHXType)

•

Bottomreturn–canbemountedushwithwall

• Anti-moldwashablelter(notMERVrated)

• 3-speed DC motor (ECM)

• Condensate pump not included

JTHX Ceiling Mounted - Horizontal Exposed

1 Way Air Discharge Semi-Concealed

Cassette (JAHX Type)

Only13”tall–tsintightceilingplenums

•

• Anti-moldwashablelter(notMERVrated)

• 3-speed DC motor (ECM)

• Condensate pump built in

LD16392

• 1, 1.5, 2 and 3 ton units available in 30" x 30" unit

size(JXHXType)

• Individual louvers can be disabled for use in cor-

ners

Anti-moldwashablelter(notMERVrated)

•

• 3-speed DC motor (ECM)

Condensatepumpwith25”liftbuiltin

•

LD16395

JXHX 4-Way Air Discharge - Semi-Concealed Cassette

Vertical Floor Mounted, Exposed (JFHX Type)

• Good choice for renovations where replacing

heating only radiators

Airdischargedirectioniseasilycongured

•

• Front panel removes without tools for easy servic-

ing

Anti-moldwashablelter(notMERVrated)

•

• Pipes can be connected to either side of the unit

from the bottom or rear

• Wired controller can be mounted in the unit.

• Condensate pump not included

JAHX 1 Way Air Discharge - Semi-Concealed Cassette

LD16393

LD16394

JFHX - Vertical Floor-Mounted

Exposed

Page 10

Vertical Floor Mounted, Concealed

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

JOHNSON CONTROLS

10

(JFMHX Type)

SameastheJFHXExposed,butwithoutcasing

•

• Low external static – discharge grille should be

attached to the unit discharge with very little or

no ducting

• Front panel removes without tools for easy servicing

Anti-moldwashablelter(notMERVrated)

•

• Pipes can be connected to either side of the unit

from the bottom or rear

• Condensate pump not included

Horizontal Concealed (JUHX Type)

High external static pressure up to 0.48” allows

•

enhancedltrationorlongerductruns

• Industry-leading low sound levels from 22 dBA

• Condensate pump built in

• Easy to install and maintain

• 3 speed AC motor (not ECM)

•

Standardround8”takeoffscaneasilyberemoved

if a rectangular plenum is desired

LD16399

JUHX - Horizontal Concealed

LD16397

JFMHX - Vertical Floor-Mounted

Concealed

Horizontal Concealed Slim (JUMHX Type)

Ultra-slimprole:7.9incheshighforallmodels

•

• DC fan motor greatly reduces power consumption

(ECM)

• Ideal for any application with short plenums

•

Anti-mold washable lters included, but use of

lterreturngrilleissuggested

• Easy maintenance and service by external electri-

cal box

• 0.16 in. w.g. static pressure enables ductwork to

betted

• Condensate pump built in

High Static Concealed Horizontal

(JDHX Type)

High external static pressure up to 0.70” allows

•

enhancedltrationorlongerductruns

• Can be used as 1:1 split system if required. Great

for large zones

• 3 speed AC motor (not ECM)

• Condensate pump not included

• This unit has a draw-through coil – a P-trap will

be required for the condensate

JUMHX - Horizontal Concealed Slim

LD16398

LD16400

JDHX - High-Static Horizontal Concealed

Page 11

Controller features and options:

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

11

JOHNSON CONTROLS

Simplied Wired Remote Control

• Cost effective individual zone control

• Thin and easy to read

• Simple to install – 2 low-voltage wires to the in-

door unit

• On / Off

• Mode Selection – choose heating, cooling, or auto

• Temperature set point

• Built in remote temperature sensor

•

Airowdirection(forindoorunitsthathavelou-

vers)

• Fan Speed Control

• 72 Hour Memory

Retention on Power Fail

• Mode Selection – choose heating, cooling, or auto

•

Airowdirection(forindoorunitsthathavelou-

vers)

• Fan speed control

• Controls up to 8 indoor units

LD16402

JRCS-TM80BGN - Standard Wired Remote Control

JRCS-KR1EGN - Simplified

Wired Remote Control

Standard Wired Remote Control

• Thin and Easy to Read

• Simple to install – 2 low-voltage wires to the in-

door unit

• Temperature set point

• 7 Day Timer, 6 time periods per day

• Temperature set-back

• Systems diagnostics capability (with connector

cable)

• Built in remote temperature sensor

LD16401

Wireless Remote Control

• Wireless unit for portable controls

• One remote can control many units

• On / Off

• Mode Selection – choose heating, cooling, or auto

• Temperature set point

•

Airowdirection(forindoorunitsthathavelou-

vers)

• Fan Speed Control

• Built in remote temperature sensor

•

Highwallmountedindoorunits(JKHX)havere-

ceivers built in, all other units require a receiver

thatmustbemountedintheeld

Wireless Remote Control

LD16497

Page 12

Wired Remote Sensor

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

JOHNSON CONTROLS

12

Schedule Timer

• Cost effective individual zone control

• Thin and easy to read

• Simple to install – 2 low-voltage wires to the in-

door unit

• Once installed and wired, the EEPROM automatically changes the control from the return sensor to

the remote sensor

LD16404

JART-K45AGBN - Wired Remote Sensor

System Controller

• Capable of handling up to 64 indoor units

• 4 zones – each with up To 16 indoor units

• Up to 30 outdoor units to a single control line

• Can operate system without individual zone con-

trollers

• All zone control functionality is available

• Can take power from the U1/U2 system

• Important notes:

• No clock included

• Cannot be used for setback – addition of the

schedule timer only allows on/off control

• Timer controls up to 64 Units into 1,4, or 8 groups

• 7 Day Timer ,6 Time Periods/Day (On/Of f only , no

setback)

• 100 hour backup battery

• Usually tied to a System Controller, but can be

used stand-alone

LD16406

JSHA-TM64AGBN - Schedule Timer

Intelligent Controller

• Controls up to 128 units in two groups

• Up to 256 units / 4 groups with Communica-

tions Adapter

• 6.5 inch touch screen panel

• Web accessible

• Individual zone override

• Provides tenant billing data

• Available alarm contact

• Real time diagnostics

• Diagnostic history of system past & present

JSHA-KC64AGN - System Controller

LD16405

• Maximum installation of two System Controls

• Requires separate power supply

LD16407

Page 13

OEM Portal

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

13

JOHNSON CONTROLS

• BAS to VRF interface

• LONworks

®

or BACnet

®

• Only way to control a VRF system with BAS

• This allows communication between the propri-

etary VRF controls network and the BMS

• Field labor is required to add this to the BMS

LD16496

Page 14

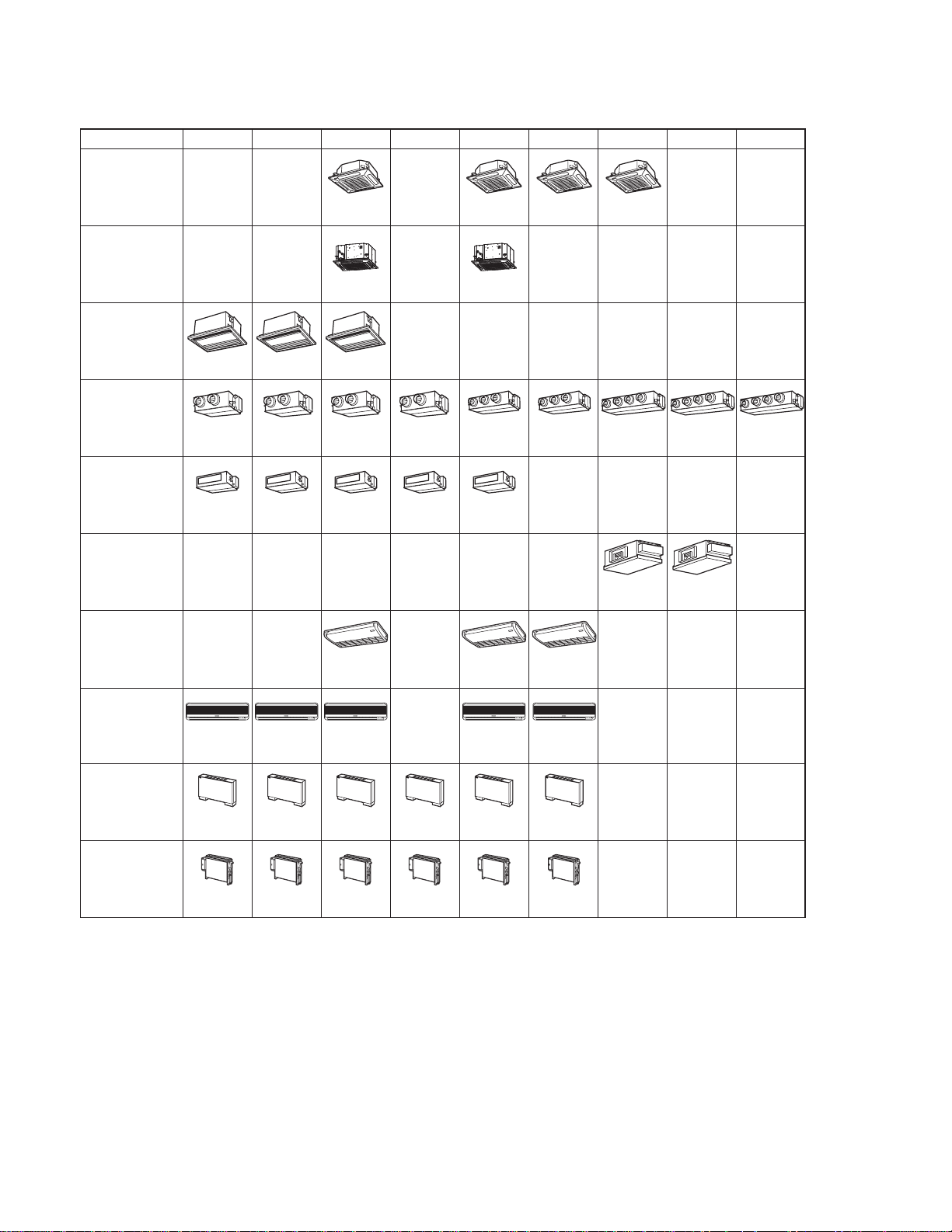

Indoor units

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

JOHNSON CONTROLS

14

1. Offerings

Type

4-Way Air

Discharge SemiConcealed Type

(JX Type)

4-Way Air

Discharge Mini

Semi-Concealed

Type (JXM T ype)

1-Way Air

Discharge SemiConcealed Type

(JA Type)

Concealed Duct

Type

(JU Type)

Slim Concealed

Duct Type

(JUM Type)

Concealed Duct

High-Static

Pressure Type

(JD Type)

97 12 15 18 24 36 48 54

JXHX1252N JXHX1852N

JXMHX1252N JXMHX1852N

JAHX0752N

JUHX0762N JUHX1262NJUHX0962N JUHX1562N JUHX1862N JUHX2462N

JUMHX0762N JUMHX1262NJUMHX0962N JUMHX1562N JUMHX1862N

JAHX0952N JAHX1252N

JXHX2452N JXHX3652N

JUHX3662N JUHX4862N JUHX5462N

JDHX3652N

JDHX4852N

Ceiling-Mounted

Type

(JT Type)

Wall-Mounted

Type

(JK Type)

Floor-Standing

Type

(JF Type)

Concealed-Floor

Standing Type

(JFM Type)

JTHX1852NJTHX1252N JTHX2452N

JKHX0752N

JFHX0762N JFHX1262NJFHX0962N JFHX1562N JFHX1862N JFHX2462N

JFMHX0762N JFMHX1262NJFMHX0962N JFMHX1562N JFMHX1862N JFMHX2462N

JKHX0952N JKHX1252N JKHX2452NJKHX1862N

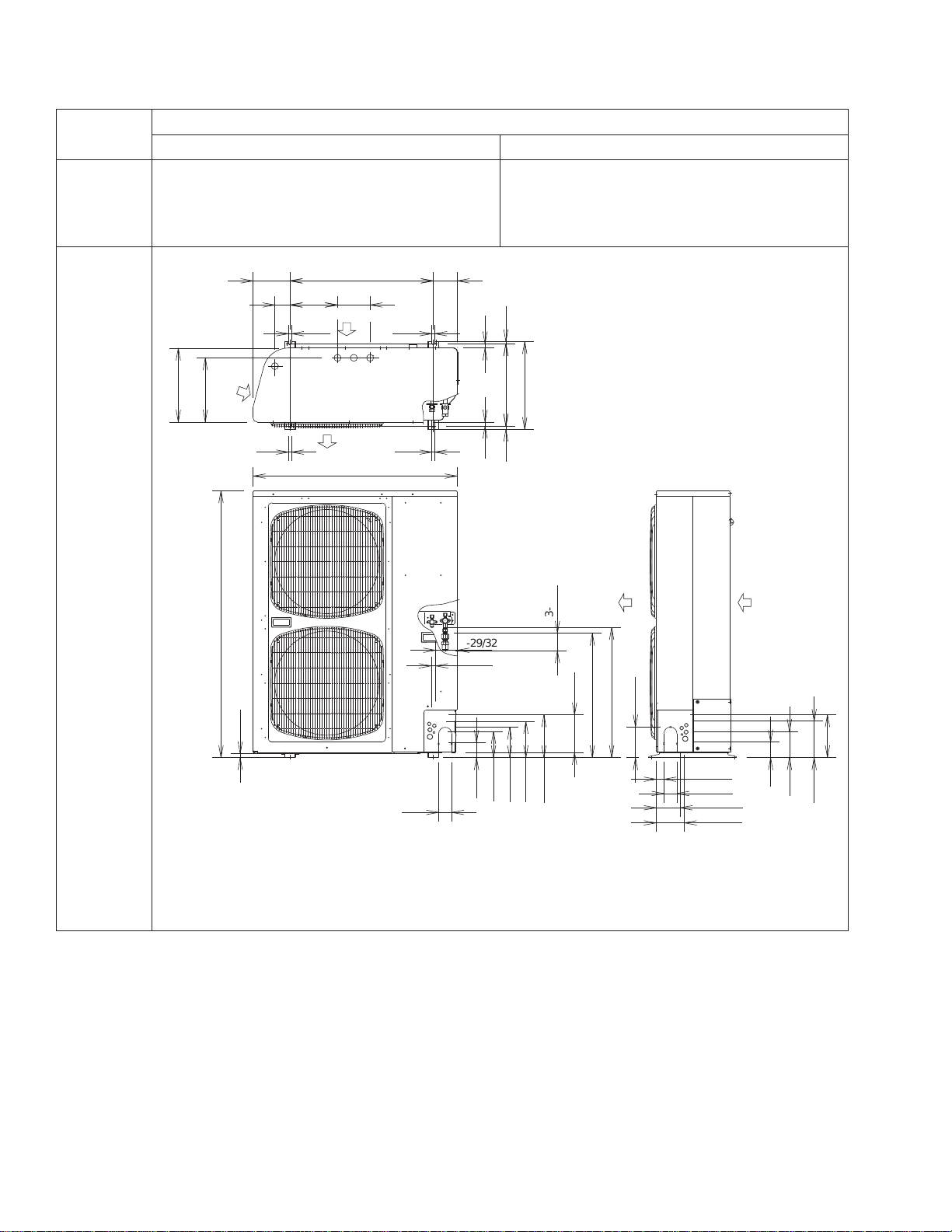

Page 15

Indoor units

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

15

JOHNSON CONTROLS

96

96,000 (28.1)96/

108,000 (31.6)

Type

Capacity:

BTU/h (kW)

DC inverter unit

36 52

38,200 (11.2)

52,900 (15.5)

Cooling /

Heating

Outdoor

Unit

13-3/8

11-21/32

48-7/16

/ 42,700 (12.5)

6-

11/16

2-

3/4

1/2 1/2

25-31/32

8-5/8

Air intake

1/2

5-29/32

Air

discharge

37

1/2

4-

5/16

25/32

13/32

3-29/32

25/32

13/32

15-15/16

14-31/32

19/32

3-3/16

Air

discharge

/ 60,000 (17.6)

Air

intake

23/32

2-3/8

* Outdoor unit model name beginning with letters “JCHXR”

Refer to the Section 1. Salt-Air Damage Resistant Specications”.

6-13/16

5-1/2

7-3/4

4-23/32

6-9/16

2-25/32

JCHX03652/05252

JCHXR03652/05252*

JCHX03652N/05252N

JCHXR03652N/05252N*

23-5/8

22-9/16

5-9/16

1-13/32

2-3/8

4-11/32

5-1/8

4-3/4

2-27/32

7-25/32

6-5/8

Page 16

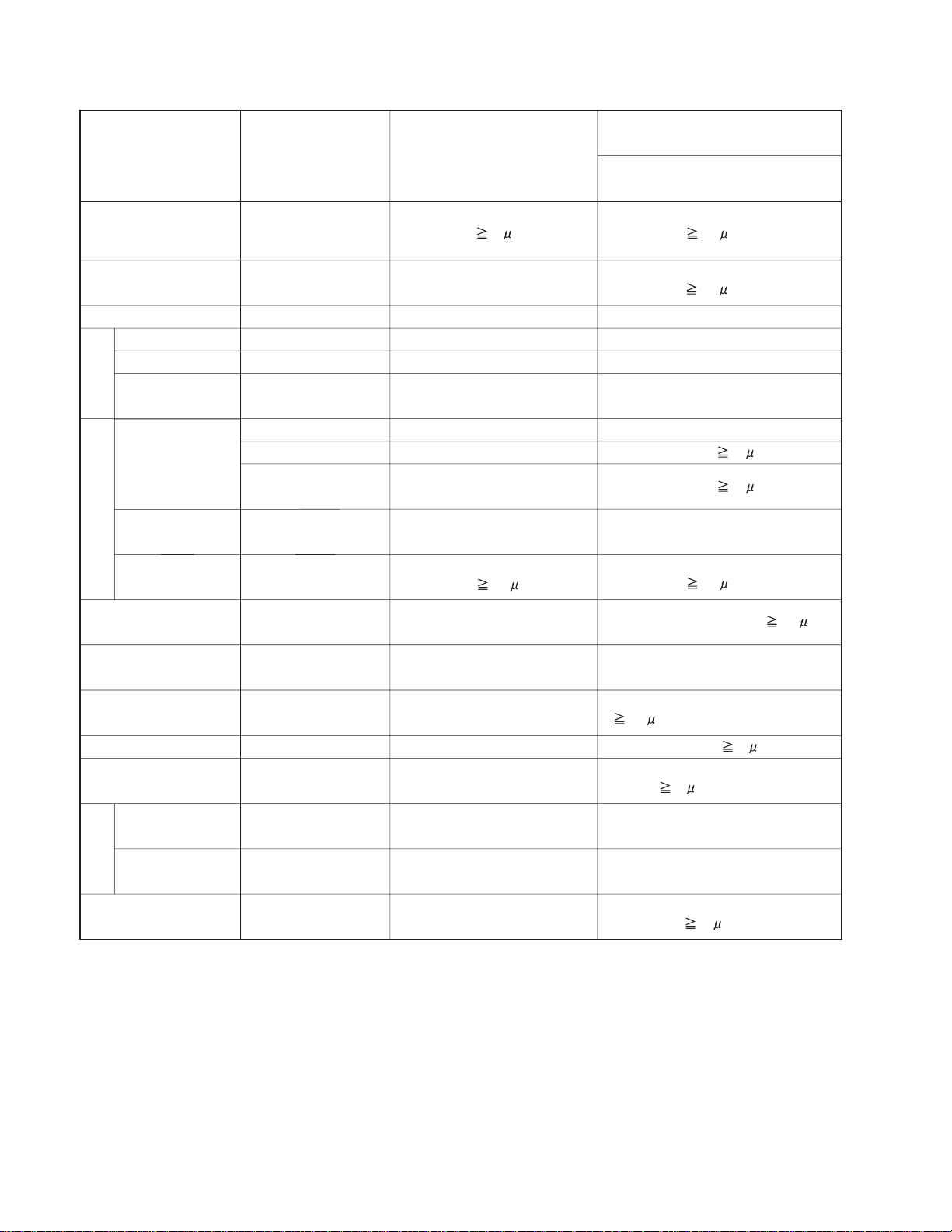

Salt-Air Damage Resistant Specifications (Anti-Corrosion)

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

JOHNSON CONTROLS

16

Relevant Parts Material Standard Specifications

Salt-Air Damage

Resistant Specifications

Outdoor unit model name

beginning with letters "CHXR"

Outer box/side plate/

drain pan

between the stud

Base frame

Fan guard

Fin Aluminum No treatment

Tube Copper No treatment Zinc rich treatment (whole)

Tube plate

Heat

Exchanger

Propeller fan

Fan

Motor Motor maker's standard spec.

Installation frame

Electrical component box

Tapping screws

Hot-dip zinc-coated

steel sheet

Hot-dip aluminum-zinc

coated steel sheet

Resin (Polypropylene) No treatment No treatment

Hot-dip zinc-coated

steel sheet

Resin

Aluminum

Hot-dip zinc-coated

steel sheet

--

Hot-dip zinc-coated

steel sheet

Hot-dip zinc-coated

steel sheet

SUS410

Polyester powder double coating

(both sides) ( 40 m)

No treatment

No treatment

No treatment

No treatment

No treatment

Polyester powder double coating

(both sides) ( 120 m)

No treatment

Hexavalent chromium-free

coating

Polyester powder double coating

(both sides) ( 120 m)

Polyester powder double coating

(both sides) ( 120 m)

Zinc rich treatment

Zinc rich treatment (whole)

No treatment

Urethane coating ( 30 m)

Urethane coating ( 30 m)

Motor maker's spec. for salt-air

damage resistant (urethane coating)

Polyester powder double coating

(both sides) ( 120 m)

Polyester powder coating ( 120 m)

Hexavalent chromium-free coating +

urethane coating

2

3

Stud supplementary

bracket

PC board No treatment Dessicant coating ( 30 m)--

Accumulator

Receiver tank

Welded portion Copper tube No treatment Urethane coating

Outer surface Copper tube No treatment Urethane coating

Refrigeration

cycle tube

Fixing bracket

Notes:

1 Consult us before introducing a salt-air damage resistant model as it requires a special treatment.

2 The specifications are subject to change without notice for development.

3 Contact us for the delivery schedule.

Hot-dip zinc-coated

steel sheet

Steel Epoxy coating + alkyd coating

Hot-dip zinc-coated

steel sheet

No treatment

No treatment

Polyester powder double coating

( 120 m)

Zinc rich double coating + urethane

coating ( 70 m)

Polyester powder double coating

(both sides) ( 80 m)

4

5

6

7

8

Page 17

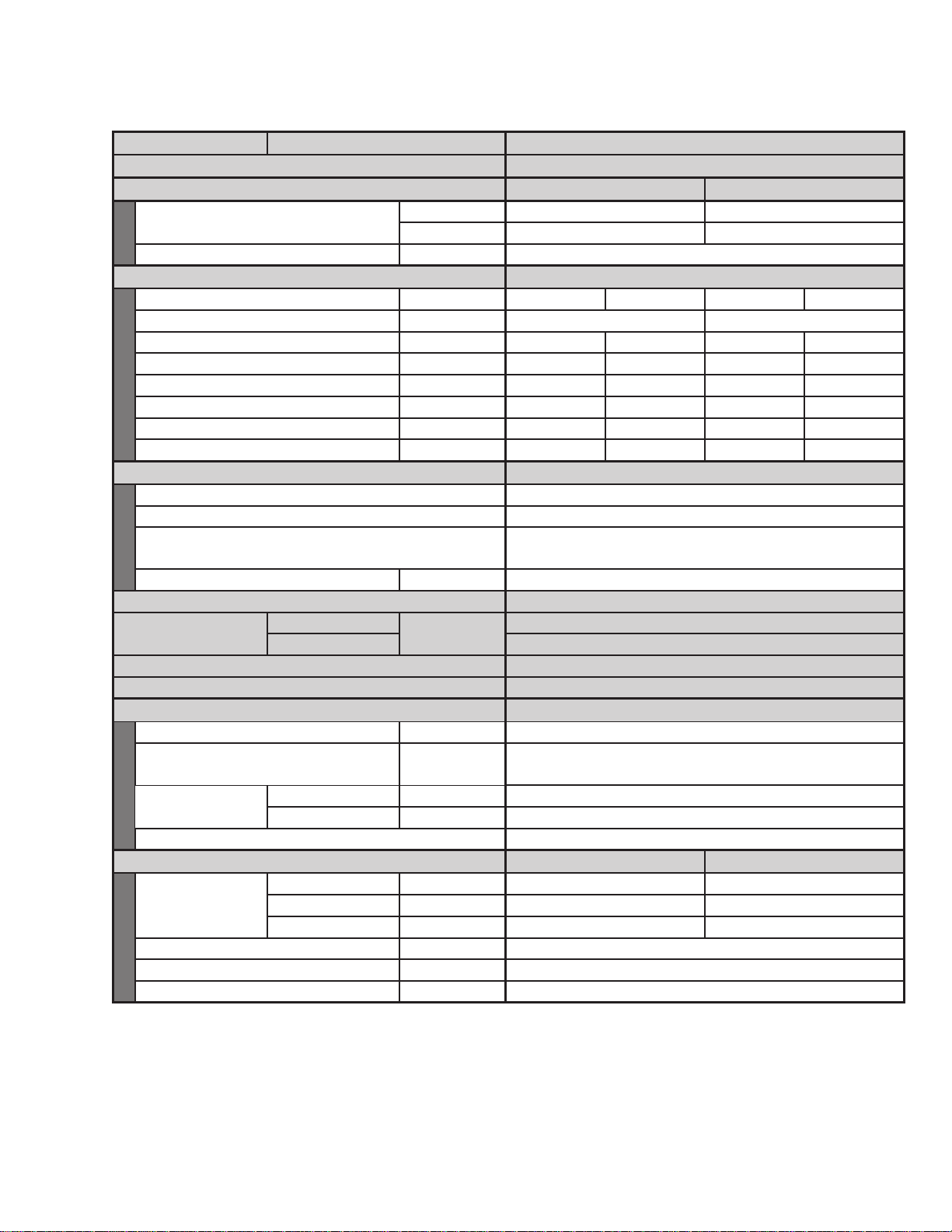

1-1. Specications

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

17

JOHNSON CONTROLS

2. Outdoor Unit Dimensions and Specifications

Unit specications (A)

MODEL No.

POWER SOURCE

PERFORMANCE

Capacity

Outdoor Unit JCHX03652N, JCHXR03652N*

208 - 230 V / 1ø / 60 Hz

Cooling Heating

BTU / h 38,200 42,700

kW 11.2 12.5

Air circulation (Hi) CFM 3,530

1

ELECTRICAL RATINGS

Voltage rating V 208 230 208 230

Available voltage range V 187 - 253 187 - 253

Running amperes A 14.6 13.6 14.6 13.6

Max. running amperes * A 23.6 23.6

– –

Power input kW 2.76 2.76 2.88 2.88

Max. power input kW 4.85 4.85

– –

Power factor % 91 88 95 92

Max. starting amperes A Approx. 1 Approx. 1 Approx. 1 Approx. 1

FEATURES

Controls Microprocessor

Defrost control Reverse cycle, microprocessor control

Service function

Sensor temp. recall function

Past service warnings recall function

Refrigerant amount at shipment lbs. (kg) R410A - 7.7 (3.5)

Refrigerant control Electronic expansion valve

Operation sound (Hi)

Power level

Pressure level 51

dB-A

67

External finish Galvanized steel plate with powder paint

Color (Approximate value) Munsell code 1Y 8.5 /0.5

Refrigerant tubing

Limit of tubing length ft. (m) 492 (150)

Limit of elevation difference

between the 2 units

Refrigerant tube

diameter

Liquid tube in. (mm) 3/8 (9.52)

Gas tube in. (mm) 5/8 (15.88)

ft. (m)

Refrigerant tubing kit / Joint kit Optional

DIMENSIONS & WEIGHT

Height in. (mm) 48-7/16 (1230)

Unit dimensions

Net weight lbs. (kg) 229 (104)

Shipping weight lbs. (kg) 247 (112)

Shipping volume ft

Rated conditions

Cooling : Indoor air temperature 80°F DB / 67°F WB ; Outdoor air temperature 95°F DB

Heating : Indoor air temperature 70°F DB ; Outdoor air temperature 47°F DB / 43°F WB

* Full-load conditions at Indoor / Outdoor capacity ratio 100%

Cooling : Indoor air temperature 89°F DB / 73°F WB ; Outdoor air temperature 109°F DB / 78°F WB

1

*

Outdoor unit model name beginning with letters "JCHXR"

Refer to the Section 1 "Salt-Ait Damage Resistant Specications".

Width in. (mm) 37 (940)

Depth in. (mm) 13-13/32 (340)

3 (m3

) 19.8 (0.56)

Outdoor unit is higher than indoor unit : 164 (50)

Outdoor unit is lower than indoor unit : 131 (40)

Unit dimensions

Package dimensions

52-13/32 (1331)

40 (1016)

16-11/32 (415)

DATA SUBJECT TO CHANGE WITHOUT NOTICE

Page 18

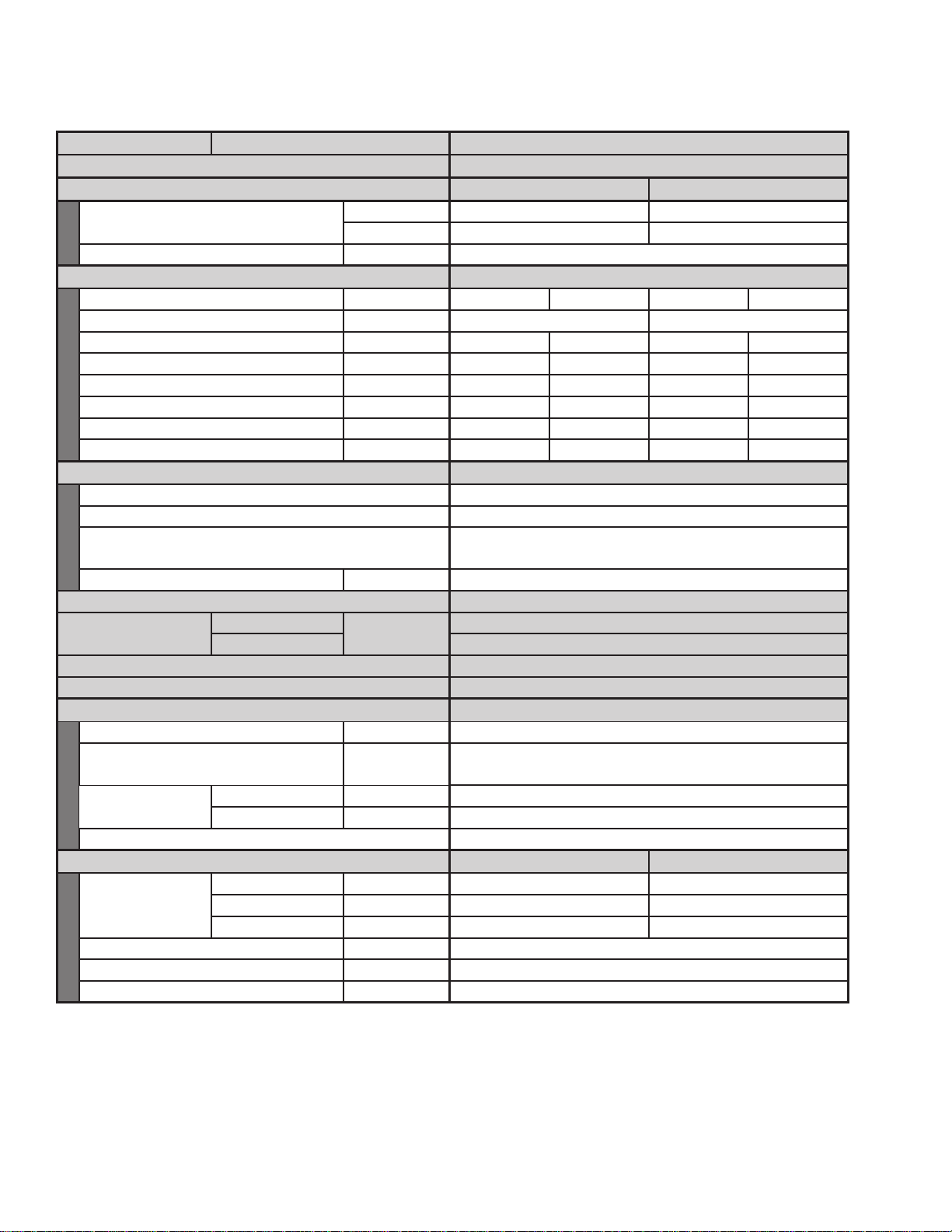

Unit specications (B)

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

JOHNSON CONTROLS

18

MODEL No.

POWER SOURCE

PERFORMANCE

Capacity

Outdoor Unit JCHX05252N, JCHXR05252N*

208 - 230 V / 1ø / 60 Hz

Cooling Heating

BTU / h 52,900 60,000

kW 15.5 17.6

Air circulation (Hi) CFM 3,530

1

ELECTRICAL RATINGS

Voltage rating V 208 230 208 230

Available voltage range V 187 - 253 187 - 253

Running amperes A 23.5 21.9 23.5 21.9

Max. running amperes * A 28.0 28.0

– –

Power input kW 4.57 4.57 4.58 4.58

Max. power input kW 5.72 5.72

– –

Power factor % 93 91 94 91

Max. starting amperes A Approx. 1 Approx. 1 Approx. 1 Approx. 1

FEATURES

Controls Microprocessor

Defrost control Reverse cycle, microprocessor control

Service function

Sensor temp. recall function

Past service warnings recall function

Refrigerant amount at shipment lbs. (kg) R410A - 7.7 (3.5)

Refrigerant control Electronic expansion valve

Operation sound (Hi)

Power level

Pressure level 52

dB-A

68

External finish Galvanized steel plate with powder paint

Color (Approximate value) Munsell code 1Y 8.5 /0.5

Refrigerant tubing

Limit of tubing length ft. (m) 492 (150)

Limit of elevation difference

between the 2 units

Refrigerant tube

diameter

Liquid tube in. (mm) 3/8 (9.52)

Gas tube in. (mm) 3/4 (19.05)

ft. (m)

Refrigerant tubing kit / Joint kit Optional

DIMENSIONS & WEIGHT

Height in. (mm) 48-7/16 (1230)

Unit dimensions

Net weight lbs. (kg) 229 (104)

Shipping weight lbs. (kg) 247 (112)

Shipping volume ft

Width in. (mm) 37 (940)

Depth in. (mm) 13-13/32 (340)

3 (m3

) 19.8 (0.56)

Outdoor unit is higher than indoor unit : 164 (50)

Outdoor unit is lower than indoor unit : 131 (40)

Unit dimensions

Package dimensions

52-13/32 (1331)

40 (1016)

16-11/32 (415)

DATA SUBJECT TO CHANGE WITHOUT NOTICE

Rated conditions

Cooling : Indoor air temperature 80°F DB / 67°F WB ; Outdoor air temperature 95°F DB

Heating : Indoor air temperature 70°F DB ; Outdoor air temperature 47°F DB / 43°F WB

* Full-load conditions at Indoor / Outdoor capacity ratio 100%

Cooling : Indoor air temperature 89°F DB / 73°F WB ; Outdoor air temperature 109°F DB / 78°F WB

1

*

Outdoor unit model name beginning with letters "JCHXR"

Refer to the Section 1 "Salt-Ait Damage Resistant Specications".

Page 19

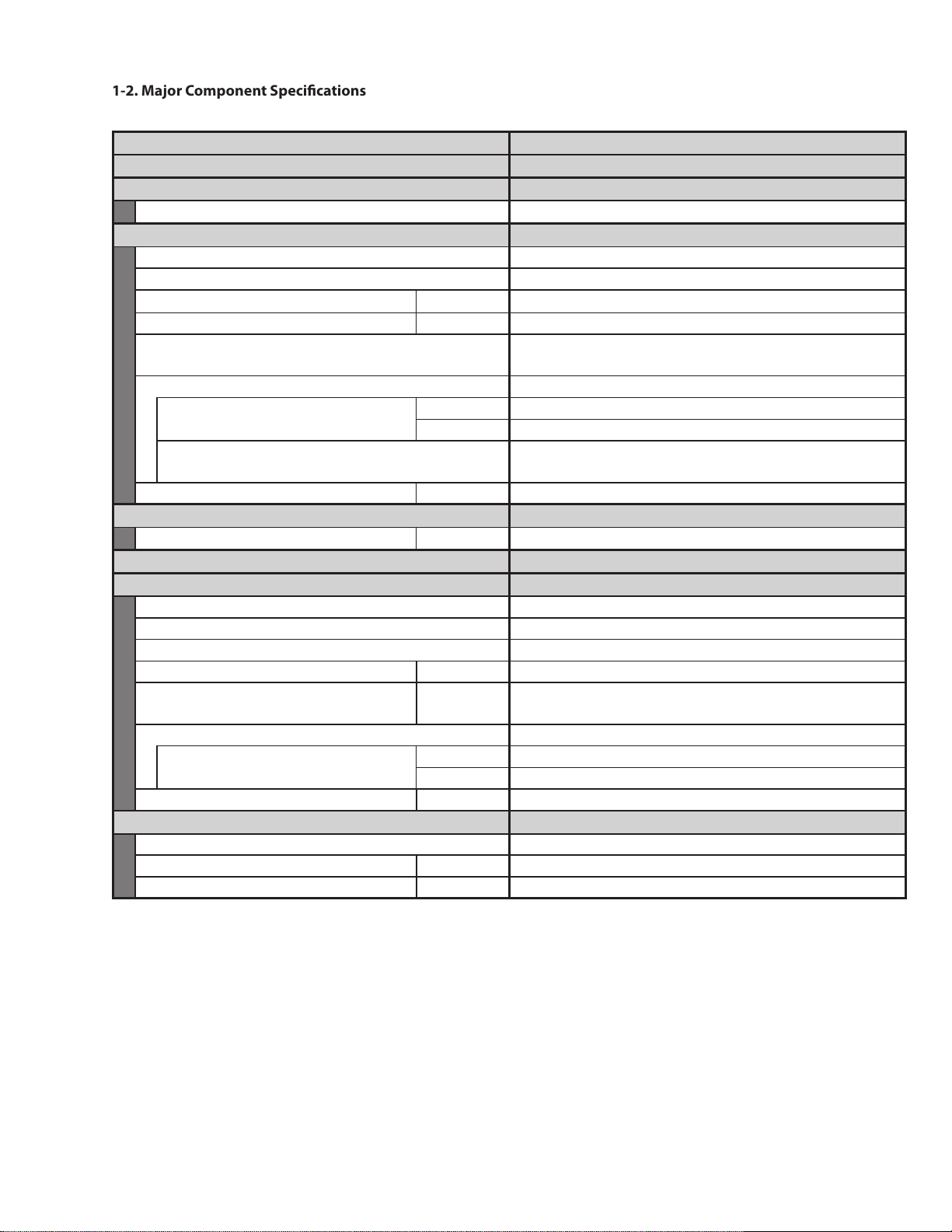

1-2. Major Component Specications

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

19

JOHNSON CONTROLS

Specifications

Unit Specifications (1)

Outdoor unit (A)

MODEL No.

POWER SOURCE

Controller P.C.B Assembly

Control circuit fuse 250V, 5A

Compresser

Type Rotary (Hermetic)

Model ... Code No. C-9RVN273H0W ... 80867080

Motor rated output kW 2.1

Compressor Oil (ETHER FV68S) gal (cc) 0.50 (1,900)

Coil resistance

(Ambient temperature 77°F)

Safety devices

Overload protector

(Operating temperature)

Microprocessor safety devices

Crank case heater V, W 230, 30

Open°F (°C) 230 (110)

Close°F (°C) 203 (95)

Compressor discharge gas temperature control

JCHX03652N, JCHXR03652N*

208 - 230 V / 1ø / 60 Hz

CR-CHX03652

INV (Inverter)

V - U: 0.169, U-W: 0.169,

W-V: 0.169

Compressor current detection circuit

High pressure switch

Set pressure ON / OFF in. WG 456 / 551

Fan...(Number diameter / length in. (mm))

Propeller (1 ... ø18-7/64 (ø460)) ×2

Fan motor

Model No. DAJ12-95B61A, B-CR

Source DC340V / 3 phase

No. of pole 8

Nominal output W 90

Coil resistance

(Ambient temperature 68°F)

Safety device

Operating temperature

Run capacitor VAC, μF

Ω

Open°F (°C) 284 (140)

Close°F (°C)

RED - WHT : 30.5 WHT - BLK : 30.5

BLK - RED : 30.5

–

–

Heat exchanger

Coil Aluminum plate fin / Copper tube

Rows...fin pitch in. (mm) 3 ... 7/128 (1.4)

Face area ft

* Outdoor unit model name beginning with letters “JCHXR”

Refer to the Section 1 “2. Salt-Air Damage Resistant Specications”.

2 (m2

) 11.7 (1.08)

DATA SUBJECT TO CHANGE WITHOUT NOTICE

Page 20

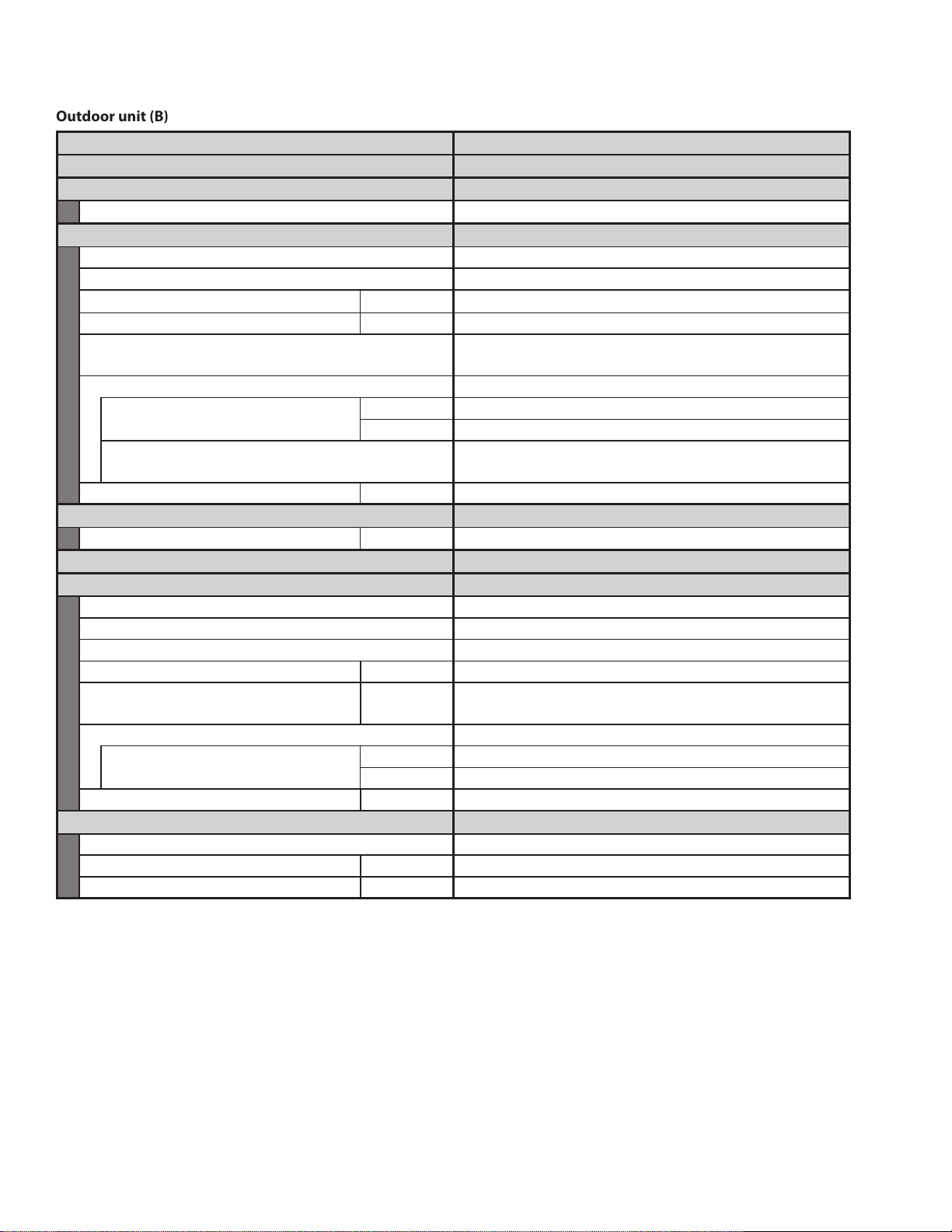

Outdoor unit (B)

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

JOHNSON CONTROLS

20

Unit Specifications (2)

MODEL No.

POWER SOURCE

Controller P.C.B Assembly

Control circuit fuse 250V, 5A

Compresser

Type Rotary (Hermetic)

Model ... Code No. C-9RVN273H0W ... 80867080

Motor rated output kW 4.0

Compressor Oil (ETHER FV68S) gal (cc) 0.50 (1,900)

Coil resistance

(Ambient temperature 77°F)

Safety devices

Overload protector

(Operating temperature)

Microprocessor safety devices

Crank case heater V, W 230, 30

Open°F (°C) 230 (110)

Close°F (°C) 203 (95)

Compressor discharge gas temperature control

JCHX05252N, JCHXR05252N*

208 - 230 V / 1ø / 60 Hz

CR-CHX06052

INV (Inverter)

V - U: 0.169, U-W: 0.169,

W-V: 0.169

Compressor current detection circuit

High pressure switch

Set pressure ON / OFF in. WG 456 / 551

Fan...(Number diameter / length in. (mm))

Propeller (1 ... ø18-7/64 (ø460)) ×2

Fan motor

Model No. DAJ12-95B61A, B-CR

Source DC340V / 3 phase

No. of pole 8

Nominal output W 90

Coil resistance

(Ambient temperature 68°F)

Ω

RED - WHT : 30.5 WHT - BLK : 30.5

BLK - RED : 30.5

Safety device

Operating temperature

Run capacitor VAC, μF

Open°F (°C) 284 (140)

Close°F (°C)

–

–

Heat exchanger

Coil Aluminum plate fin / Copper tube

Rows...fin pitch in. (mm) 3 ... 7/128 (1.4)

Face area ft

2 (m2

) 11.7 (1.08)

* Outdoor unit model name beginning with letters “JCHXR”

Refer to the Section 1 “2. Salt-Air Damage Resistant Specications”.

DATA SUBJECT TO CHANGE WITHOUT NOTICE

Page 21

6-11/16

13-3/8

11-21/32

25/32

13/32

14-31/32

15-15/16

13/32

19/32

25-31/32

37

Air

discharge

8-5/8 5-29/32

1/2 1/2

1/21/2

2-

3/4

4-5/16

1

2

3

4

5

6

7

8

9

2-7/32

4-19/32

11-11/32

10-25/32

5/16

2-3/8

2-7/16

R1-3/16

R3/4

7

8

7

6

5

4

7

8

3-7/16

2-1/4

1-13/16

7

6

5

4

1-13/32

2-3/8

4-11/32

5-1/8

7-25/32

5-9/16

23-5/8

22-9/16

6-13/16

3-3/16

2-25/32

48-7/16

23/32

4-23/32

5-1/2

6-9/16

7-3/4

6-5/8

8-15/16

8-9/32

7-8/32

6-11/16

5-29/32

4-3/4

2-27/32

Air

intake

Air

discharge

7

8

2

3

9

3-29/32

25/32

6

5

2-3/8

7

4

Air intake

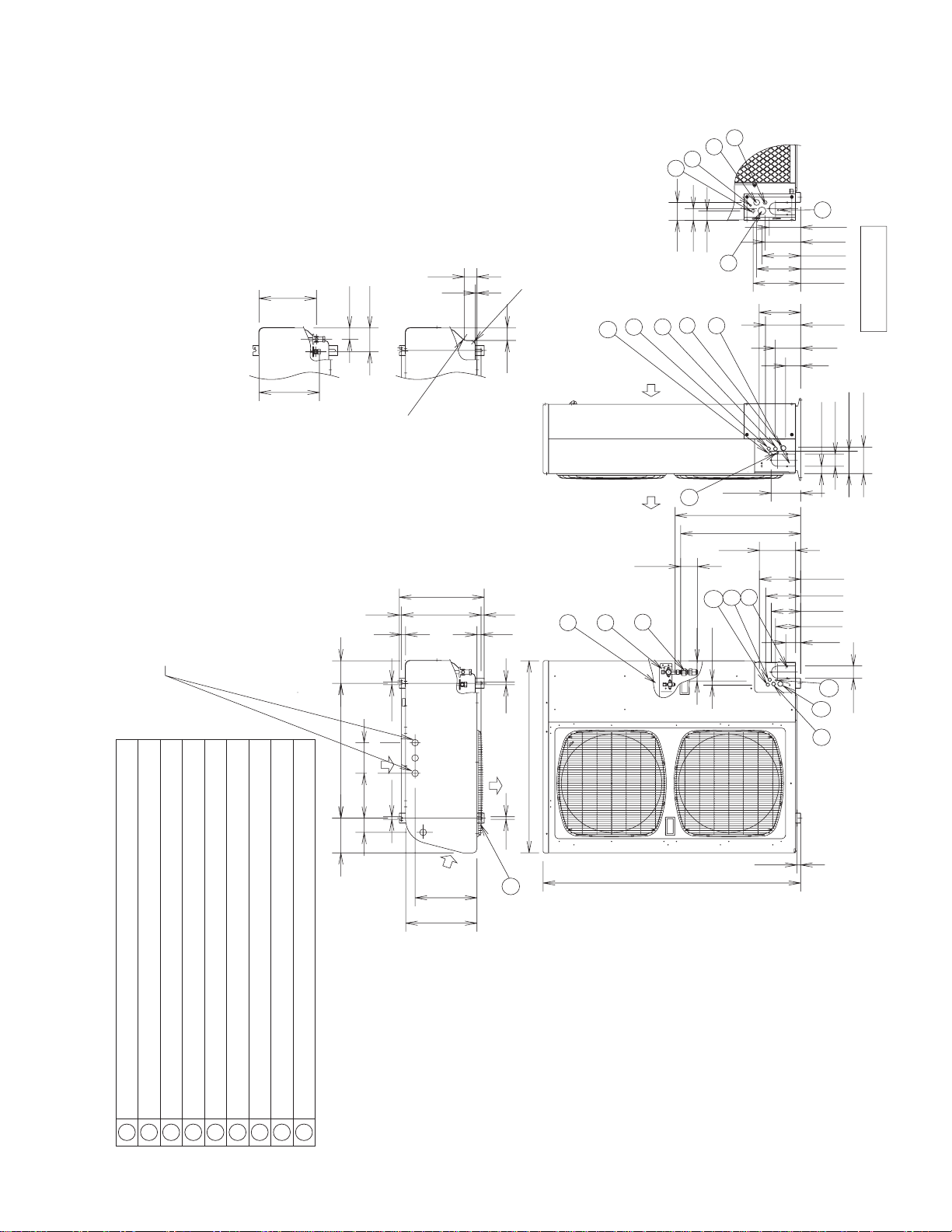

Installation anchoring hole (4-R6.5 or R1/4"), anchor bolt: M10 or 13/32''

Refrigerant tubing (liquid tube), flared connection ø3/8'' (ø9.52)

Refrigerant tubing (gas tube), flared connection ø5/8'' (ø15.88)

Refrigerant tubing port

Electrical wiring port ø1-3/8'' (ø35)

Electrical wiring port ø1-7/64'' (ø28)

Electrical wiring port ø55/64'' (ø22)

Electrical wiring port ø33/64'' (ø13)

Auxiliary connection tube ø5/8'' to ø3/4'' (ø15.88 to ø19.05) 6 hp only

2 x ø32 or ø1/4'' holes (holes for drain)

Of the 4 ø32 or ø1/4'' holes, use 1 of the 2 holes specified

for drain use to install the drain port.

Use rubber plugs to seal the remaining 3 holes.

1

For R410A only

Unit: inch

1-3. Dimensional Data

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

21

JOHNSON CONTROLS

JCHX03652N, JCHXR03652N

JCHX05252N, JCHXR05252N

Page 22

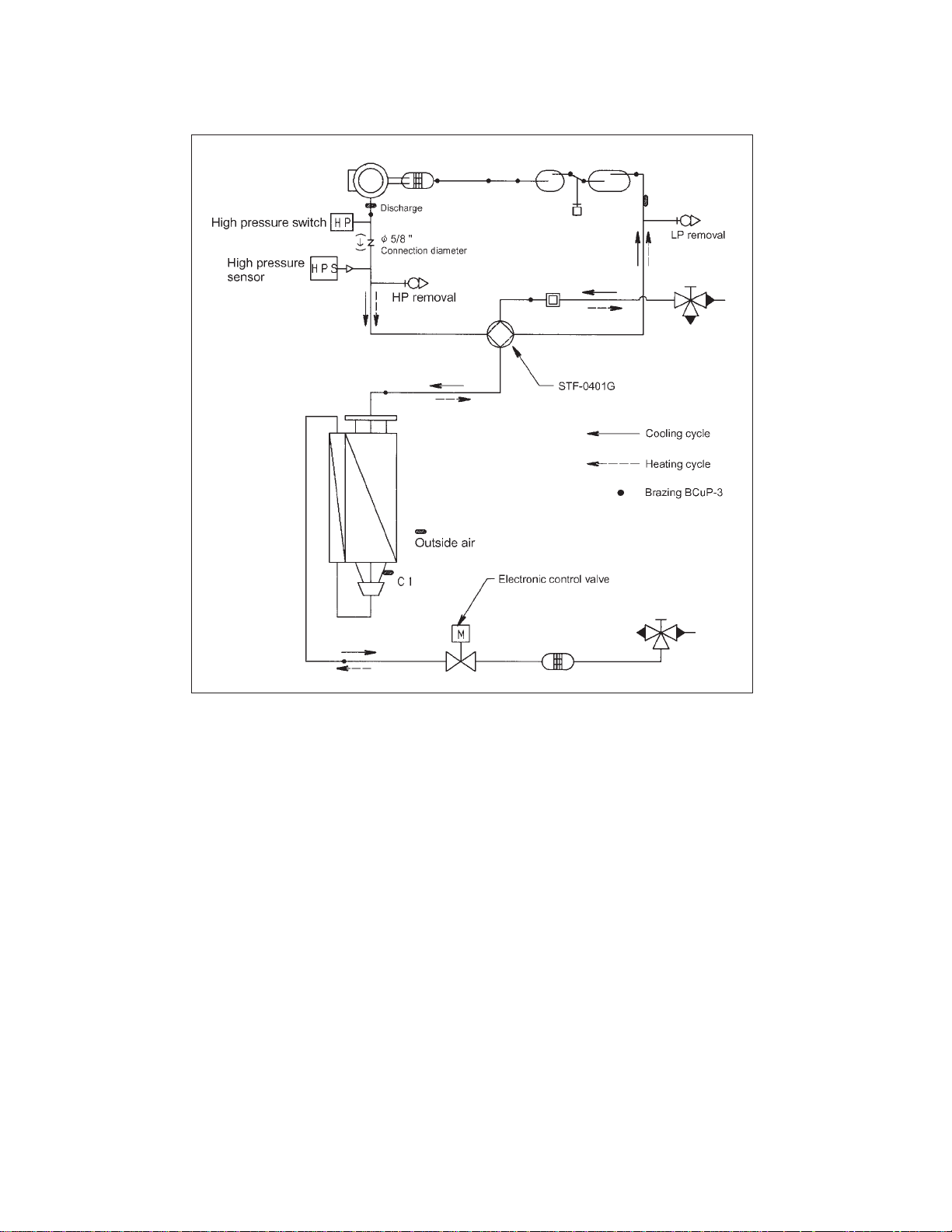

1-4. Refrigerant Flow Diagram

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

JOHNSON CONTROLS

22

JCHX03652N

JCHXR03652N

JCHX05252N

JCHXR05252N

Suction

Page 23

1-5. Sound Data

NOTE

Model

Sound Power

Level

Condition

Sound Power Level (dB)

Frequency at center of sound pressure band (Hz)

JCHX03652N, JCHXR03652N

67 dB (A)

Cooling

10

20

30

40

50

60

70

80

NC – 70

NC – 60

NC – 50

NC – 40

NC – 30

NC – 20

63 125 250 500 1000 2000 4000 8000

90

1. dBA = A – weighted sound power level (A – scale according to IEC)

2. Reference acoustic intensity 0 dB = 10

–13

W/ft

2

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

23

JOHNSON CONTROLS

JCHDZ07263N

JCHDZR07263N

JCHDZ09663N

JCHDZR09663N

(1) Sound Power Level

JCHX03652N, JCHXR03652N

Page 24

NOTE

Model

SoundPower

Level

Condition

SoundPowerLevel(dB)

JCHX05252N,JCHXR05252N

68dB(A)

Cooling

10

20

30

40

50

60

70

80

NC‒70

NC‒60

NC‒50

NC‒40

NC‒30

NC‒20

63 125 250 500 1000 2000 4000 8000

90

Frequencyatcenterofsoundpressureband(Hz)

1.dBA=A‒weightedsoundpowerlevel(A‒scaleaccordingtoIEC)

2.Referenceacousticintensity0dB=10

‒13

W/ft

2

JCHX05252N, JCHXR05252N

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

JOHNSON CONTROLS

24

Page 25

Octave Band Level (dB)*

* 0 dB = 0.0002 µbar

Frequency at center of sound pressure band (Hz)

Front

Quiet Mode

10

20

30

40

50

60

70

80

NC – 70

NC – 60

NC – 50

NC – 40

NC – 30

NC – 20

63

Overall

125 250 500 1000 2000 4000 8000

90

Approximate

minimum audible

limit for continuous

noise

(2) Sound Pressure Level

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

25

JOHNSON CONTROLS

JCHDZ07263N, JCHDZR07263N

JCHDZ09663N, JCHDZR09663N

JCHX0352N, JCHXR03652N

Model

Sound Pressure Level

Cooling

Condition

JCHX03652N, JCHXR03652N

Front 51 dB (A)

Quiet Mode 48 dB (A)

3.3 ft. in front at height of 4.9 ft.

Page 26

Model

Sound Pressure Level

Cooling

Condition

Octave Band Level (dB)*

* 0 dB = 0.0002 µbar

Frequency at center of sound pressure band (Hz)

JCHX05252N, JCHXR05252N

Front 52 dB (A)

Quiet Mode 49 dB (A)

Front

Quiet Mode

3.3 ft. in front at height of 4.9 ft.

10

20

30

40

50

60

70

80

NC – 70

NC – 60

NC – 50

NC – 40

NC – 30

NC – 20

63 125 250 500 1000 2000 4000 8000

90

Approximate

minimum audible

limit for continuous

noise

Overall

JCHX05252N, JCHXR05252N

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

JOHNSON CONTROLS

26

Page 27

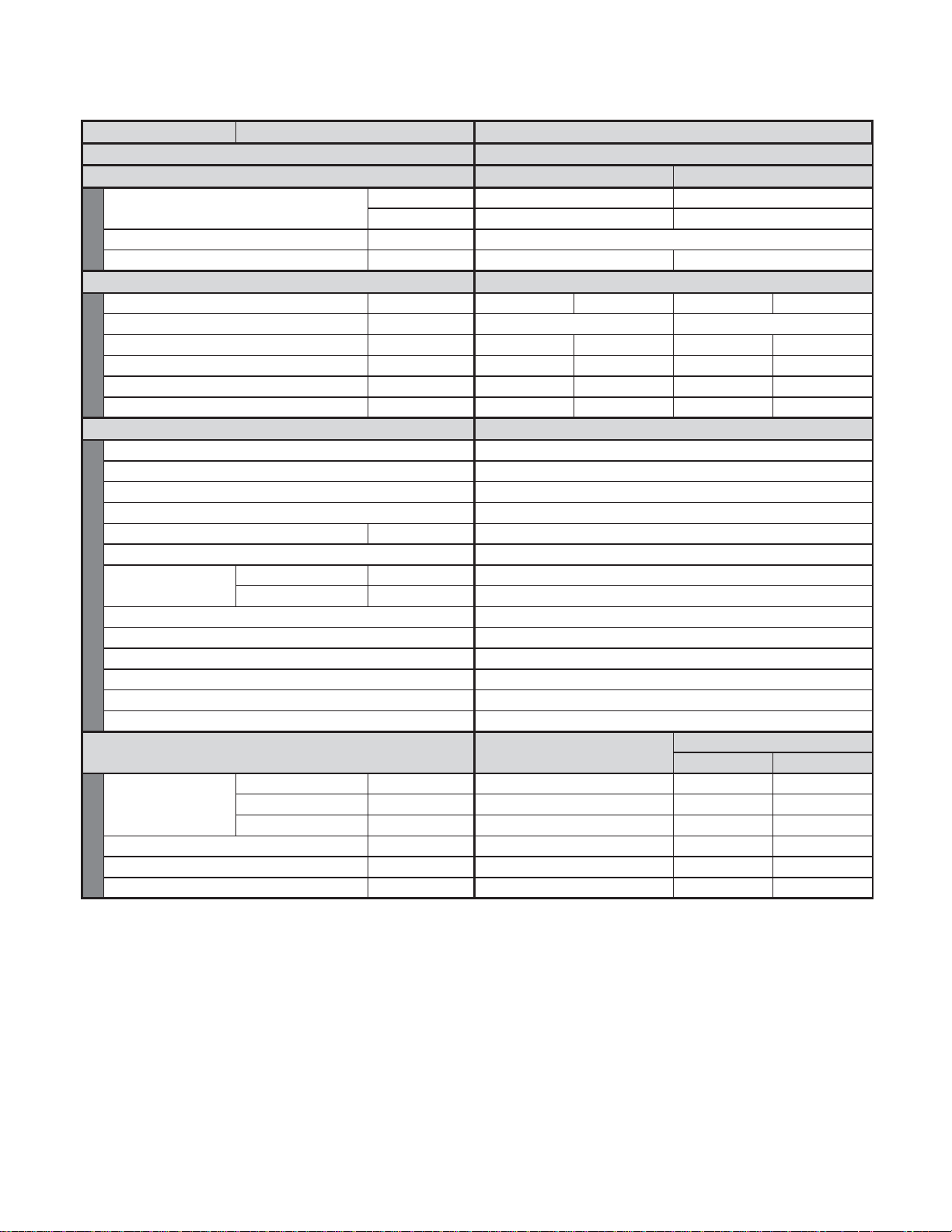

MODEL No.

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

27

JOHNSON CONTROLS

3. Indoor Unit Dimensions and Specifications

4-Way Air Discharge Ceiling Semi-Concealed, Standard and Mini (JX, JXM Types)

Unit specifications (A)

POWER SOURCE

PERFORMANCE

Capacity

Air circulation (Hi / Me / Lo) CFM 550 / 495 / 450

Moisture removal (High) Pints / h 4.65 –

ELECTRICAL RATINGS

Voltage rating V 208 230 208 230

Available voltage range V 187 - 253 187 - 253

Running amperes A 0.19 0.22 0.21 0.21

Power input W 26 29 19 20

Power factor % 66 57 43 41

Max. starting amperes A 1111

FEATURES

Controls Microprocessor

Fan speeds 3 and Automatic control

Air filter Washable, easy access, long life (2,500 hr)

Refrigerant control Electronic expansion valve

Operation sound (

Refrigerant tubing connections Flare type

Refrigerant tube

diameter

Drain connection 25 A, OD 1-1/4"

Drain pump Max. head 2.1 ft. above drain connection

Panel Optional (JPNR-XH3652N)

Remote controller Optional (JRCS-TM80BGN, JRCS-SH80AABWLN)

Refrigerant tubing kit / Accessories Optional / –

Color (Approximate value) Munsell 2.5GY 9.0 / 0.5, RAL 9001-GL (resemblant color)

DIMENSIONS & WEIGHT

Unit dimensions

Net weight lbs. (kg) 56 (25.5) – –

Shipping weight lbs. (kg) – 53 (24) 16 (7)

Shipping volume ft

Hi / Me / Lo

Liquid tube in. (mm) 1 / 4 (6.35)

Gas tube in. (mm) 1 / 2 (12.7)

Height in. (mm) 11-15 / 32 (291)

Width in. (mm) 37-13 / 32 (950)

Depth in. (mm) 37-13 / 32 (950)

Indoor Unit JXHX1252N

208 - 230 V / 1ø / 60 Hz

Cooling Heating

BTU / h 12,000 14,000

kW 3.6 4.2

) dB-A 31 / 29 / 27

Indoor unit (including panel)

11-5 / 32 (283)

35-1 / 8 (892)

35-5 / 8 (905) 38-31 / 32 (990)

3 (m3

) – 8.1 (0.228) 3.8 (0.104)

Package

Body Panel

4-3 / 32 (104)

39-11 / 16 (1008)

1

2

3

4

5

6

Rated conditions

Cooling : Indoor air temperature 80°F DB / 67°F WB ; Outdoor air temperature 95°F DB

Heating : Indoor air temperature 70°F DB ; Outdoor air temperature 47°F DB / 43°F WB

7

8

Page 28

2

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

JOHNSON CONTROLS

28

4-Way Air Discharge Ceiling Semi-Concealed, Standard and Mini (JX, JXM Types)

Unit specifications (B)

3

4

5

MODEL No.

POWER SOURCE

PERFORMANCE

Capacity

Air circulation (Hi / Me / Lo) CFM 565 / 495 / 450

Moisture removal (High) Pints / h 4.65 –

ELECTRICAL RATINGS

Voltage rating V 208 230 208 230

Available voltage range V 187 - 253 187 - 253

Running amperes A 0.23 0.26 0.23 0.22

Power input W 30 33 25 25

Power factor % 63 55 52 49

Max. starting amperes A 1111

FEATURES

Controls Microprocessor

Fan speeds 3 and Automatic control

Air filter Washable, easy access, long life (2,500 hr)

Refrigerant control Electronic expansion valve

Operation sound (

Refrigerant tubing connections Flare type

Refrigerant tube diameter

Drain connection 25 A, OD 1-1/4"

Drain pump Max. head 2.1 ft. above drain connection

Panel Optional (JPNR-XH3652N)

Remote controller Optional (JRCS-TM80BGN, JRCS-SH80AABWLN)

Refrigerant tubing kit / Accessories Optional / –

Color (Approximate value) Munsell 2.5GY 9.0 / 0.5, RAL 9001-GL (resemblant color)

DIMENSIONS & WEIGHT

Unit dimensions

Net weight lbs. (kg) 56 (25.5) – –

Shipping weight lbs. (kg) – 53 (24) 16 (7)

Shipping volume ft

Hi / Me / Lo

Liquid tube in. (mm) 1 / 4 (6.35)

Gas tube in. (mm) 1 / 2 (12.7)

Height in. (mm) 11-15 / 32 (291)

Width in. (mm) 37-13 / 32 (950)

Depth in. (mm) 37-13 / 32 (950)

Indoor Unit JXHX1852N

208 - 230 V / 1ø / 60 Hz

Cooling Heating

BTU / h 19,000 21,000

kW 5.6 6.3

) dB-A 31 / 29 / 27

Indoor unit (including panel)

11-5 / 32 (283)

35-1 / 8 (892)

35-5 / 8 (905) 38-31 / 32 (990)

3 (m3

) – 8.1 (0.228) 3.8 (0.104)

Package

Body Panel

4-3 / 32 (104)

39-11 / 16 (1008)

6

7

8

Rated conditions

Cooling : Indoor air temperature 80°F DB / 67°F WB ; Outdoor air temperature 95°F DB

Heating : Indoor air temperature 70°F DB ; Outdoor air temperature 47°F DB / 43°F WB

Page 29

MODEL No.

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

29

JOHNSON CONTROLS

4-Way Air Discharge Ceiling Semi-Concealed, Standard and Mini (JX, JXM Types)

Unit specifications (C)

POWER SOURCE

PERFORMANCE

Capacity

Air circulation (Hi / Me / Lo) CFM 705 / 565 / 495

Moisture removal (High) Pints / h 5.92 –

ELECTRICAL RATINGS

Voltage rating V 208 230 208 230

Available voltage range V 187 - 253 187 - 253

Running amperes A 0.29 0.26 0.30 0.31

Power input W 38 40 33 33

Power factor % 63 67 39 46

Max. starting amperes A 1111

FEATURES

Controls Microprocessor

Fan speeds 3 and Automatic control

Air filter Washable, easy access, long life (2,500 hr)

Refrigerant control Electronic expansion valve

Operation sound (

Refrigerant tubing connections Flare type

Refrigerant tube diameter

Drain connection 25 A, OD 1-1/4"

Drain pump Max. head 2.1 ft. above drain connection

Panel Optional (JPNR-XH3652N)

Remote controller Optional (JRCS-TM80BGN, JRCS-SH80AABWLN)

Refrigerant tubing kit / Accessories Optional / –

Color (Approximate value) Munsell 2.5GY 9.0 / 0.5, RAL 9001-GL (resemblant color)

DIMENSIONS & WEIGHT

Unit dimensions

Net weight lbs. (kg) 58 (26.5) – –

Shipping weight lbs. (kg) – 53 (24) 16 (7)

Shipping volume ft

Hi / Me / Lo

Liquid tube in. (mm) 3 / 8 (9.52)

Gas tube in. (mm) 5 / 8 (15.88)

Height in. (mm) 11-15 / 32 (291)

Width in. (mm) 37-13 / 32 (950)

Depth in. (mm) 37-13 / 32 (950)

Indoor Unit JXHX2452N

208 - 230 V / 1ø / 60 Hz

Cooling Heating

BTU / h 25,000 27,000

kW 7.3 8.0

) dB-A 34 / 31 / 28

Indoor unit (including panel)

11-5 / 32 (283)

35-1 / 8 (892)

35-5 / 8 (905) 38-31 / 32 (990)

3 (m3

) – 8.1 (0.228) 3.8 (0.104)

Package

Body Panel

4-3 / 32 (104)

39-11 / 16 (1008)

1

2

3

5

Rated conditions

Cooling : Indoor air temperature 80°F DB / 67°F WB ; Outdoor air temperature 95°F DB

Heating : Indoor air temperature 70°F DB ; Outdoor air temperature 47°F DB / 43°F WB

6

7

8

Page 30

2

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

JOHNSON CONTROLS

30

4-Way Air Discharge Ceiling Semi-Concealed, Standard and Mini (JX, JXM Types)

Unit specifications (D)

3

4

5

MODEL No.

POWER SOURCE

PERFORMANCE

Capacity

Air circulation (Hi / Me / Lo) CFM 990 / 810 / 740

Moisture removal (High) Pints / h 8.24 –

ELECTRICAL RATINGS

Voltage rating V 208 230 208 230

Available voltage range V 187 - 253 187 - 253

Running amperes A 0.51 0.46 0.54 0.49

Power input W 74 79 76 76

Power factor % 70 75 68 67

Max. starting amperes A 1111

FEATURES

Controls Microprocessor

Fan speeds 3 and Automatic control

Air filter Washable, easy access, long life (2,500 hr)

Refrigerant control Electronic expansion valve

Operation sound (

Refrigerant tubing connections Flare type

Refrigerant tube diameter

Drain connection 25 A, OD 1-1/4"

Drain pump Max. head 2.1 ft. above drain connection

Panel Optional (JPNR-XH3652N)

Remote controller Optional (JRCS-TM80BGN, JRCS-SH80AABWLN)

Refrigerant tubing kit / Accessories Optional / –

Color (Approximate value) Munsell 2.5GY 9.0 / 0.5, RAL 9001-GL (resemblant color)

DIMENSIONS & WEIGHT

Unit dimensions

Net weight lbs. (kg) 58 (26.5) – –

Shipping weight lbs. (kg) – 66 (30) 16 (7)

Shipping volume ft

Hi / Me / Lo

Liquid tube in. (mm) 3 / 8 (9.52)

Gas tube in. (mm) 5 / 8 (15.88)

Height in. (mm) 13-15 / 16 (354) 13-5 / 8 (346) 4-3 / 32 (104)

Width in. (mm) 37-13 / 32 (950) 35-1 / 8 (892)

Depth in. (mm) 37-13 / 32 (950) 35-5 / 8 (905)

Indoor Unit JXHX3652N

208 - 230 V / 1ø / 60 Hz

Cooling Heating

BTU / h 36,000 39,000

kW 10.6 11.4

) dB-A 39 / 36 / 33

Indoor unit (including panel)

3 (m3

) – 9.9 (0.279) 3.8 (0.104)

Package

Body Panel

39-11 / 16 (1008)

38-31 / 32 (990)

6

7

8

Rated conditions

Cooling : Indoor air temperature 80°F DB / 67°F WB ; Outdoor air temperature 95°F DB

Heating : Indoor air temperature 70°F DB ; Outdoor air temperature 47°F DB / 43°F WB

Page 31

MODEL No.

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

31

JOHNSON CONTROLS

4-Way Air Discharge Ceiling Semi-Concealed, Standard and Mini (JX, JXM Types)

Unit specifications (E)

SOURCE

PERFORMANCE

Capacity

Air circulation (Hi / Me / Lo) CFM 320 / 280 / 250

Moisture removal (High) Pints / h 2.3 –

ELECTRICAL RATINGS

Voltage rating V 208 230 208 230

Available voltage range V 187 - 253 187 - 253

Running amperes A 0.22 0.20 0.19 0.17

Power input W 38 43 30 35

Power factor % 83 93 76 90

Max. starting amperes A 1111

FEATURES

Controls Microprocessor

Timer ON / OFF Timer (Max. 72 hr)

Fan speeds 3 and Automatic control

Air filter Washable, easy access, long life (2,500 hr)

Refrigerant control Electronic expansion valve

Operation sound (

Refrigerant tubing connections Flare type

Refrigerant tube diameter

Drain connection OD 1-1/4"

Drain pump Max. head 2.1 ft. above drain connection

Panel Optional (JPNR-XMH1852N)

Remote controller Optional (JRCS-TM80BGN, JRCS-XM18AABWLN)

Refrigerant tubing kit / Accessories Optional / –

Color (Approximate value) Munsell 2.5GY 9.0 / 0.5, RAL 9001-GL (resemblant color)

DIMENSIONS & WEIGHT

Unit dimensions

Net weight lbs. (kg) 40.6 (18.4) – –

Shipping weight lbs. (kg) – 41.9 (19) 7.7 (3.5)

Shipping volume ft

Hi / Me / Lo

Liquid tube in. (mm) 1 / 4 (6.35)

Gas tube in. (mm) 1 / 2 (12.7)

Height in. (mm) 12-3 / 8 (313) 11-3 / 8 (290) 4-1 / 8 (105)

Width in. (mm) 24-5 / 8 (625) 28-1 / 8 (714) 26-1 / 4 (665)

Depth in. (mm) 24-5 / 8 (625) 24-3 / 4 (630) 26-5 / 8 (678)

Indoor Unit JXMHX1252N

208 - 230 V / 1ø / 60 Hz

Cooling Heating

BTU / h 12,000 14,000

kW 3.6 4.2

) dB-A 31 / 29 / 27

Indoor unit (including panel)

3 (m3

) – 4.6 (0.13) 1.7 (0.047)

Package

Body Panel

1

2

3

4

5

6

Rated conditions

Cooling : Indoor air temperature 80°F DB / 67°F WB ; Outdoor air temperature 95°F DB

Heating : Indoor air temperature 70°F DB ; Outdoor air temperature 47°F DB / 43°F WB

7

8

Page 32

2

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

JOHNSON CONTROLS

32

4-Way Air Discharge Ceiling Semi-Concealed, Standard and Mini (JX, JXM Types)

Unit specifications (F)

3

4

5

6

MODEL No.

SOURCE

PERFORMANCE

Capacity

Air circulation (Hi / Me / Lo) CFM 440 / 370 / 320

Moisture removal (High) Pints / h 4.0 –

ELECTRICAL RATINGS

Voltage rating V 208 230 208 230

Available voltage range V 187 - 253 187 - 253

Running amperes A 0.32 0.30 0.30 0.27

Power input W 52 56 48 47

Power factor % 78 81 77 76

Max. starting amperes A 1111

FEATURES

Controls Microprocessor

Timer ON / OFF Timer (Max. 72 hr)

Fan speeds 3 and Automatic control

Air filter Washable, easy access, long life (2,500 hr)

Refrigerant control Electronic expansion valve

Operation sound (

Refrigerant tubing connections Flare type

Refrigerant tube diameter

Drain connection OD 1-1/4"

Drain pump Max. head 2.1 ft. above drain connection

Panel Optional (JPNR-XMH1852N)

Remote controller Optional (JRCS-TM80BGN, JRCS-XM18AABWLN)

Refrigerant tubing kit / Accessories Optional / –

Color (Approximate value) Munsell 2.5GY 9.0 / 0.5, RAL 9001-GL (resemblant color)

DIMENSIONS & WEIGHT

Unit dimensions

Net weight lbs. (kg) 40.6 (18.4) – –

Shipping weight lbs. (kg) – 41.9 (19) 7.7 (3.5)

Shipping volume ft

Hi / Me / Lo

Liquid tube in. (mm) 1 / 4 (6.35)

Gas tube in. (mm) 1 / 2 (12.7)

Height in. (mm) 12-3 / 8 (313) 11-3 / 8 (290) 4-1 / 8 (105)

Width in. (mm) 24-5 / 8 (625) 28-1 / 8 (714) 26-1 / 4 (665)

Depth in. (mm) 24-5 / 8 (625) 24-3 / 4 (630) 26-5 / 8 (678)

Indoor Unit JXMHX1852N

208 - 230 V / 1ø / 60 Hz

Cooling Heating

BTU / h 19,000 21,000

kW 5.6 6.3

) dB-A 41 / 37 / 33

Indoor unit (including panel)

3 (m3

) – 4.6 (0.13) 1.7 (0.047)

Package

Body Panel

7

8

Rated conditions

Cooling : Indoor air temperature 80°F DB / 67°F WB ; Outdoor air temperature 95°F DB

Heating : Indoor air temperature 70°F DB ; Outdoor air temperature 47°F DB / 43°F WB

Page 33

MODEL No.

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

33

JOHNSON CONTROLS

4-Way Air Discharge Ceiling Semi-Concealed, Standard and Mini (JX, JXM Types)

Major Component Specifications

Indoor unit (A)

Power source

Controller P.C.B. Ass'y

Fan...(Number diameter / length in. (mm))

Fan motor

Model...Nominal output W DK8-53B280HB...50W

Power source 280 VDC

No. of pole...r.p.m. (230V, High) rpm 8P...360

Coil resistance

(Ambient temperature 68°F)

Run capacitor VAC, μF –

Safety device

Operating temperature Open °F (°C)

Electronic expansion valve

Coil UKV-U030E

Coil resistance (at 68°F)

Valve body UKV-18D31

Heat exchanger

Coil Aluminum plate fin / Copper tube

Rows...fin pitch in. (mm) 2...3/64 (1.25)

Face area ft

Panel

Model No. JPNR-XH3652N

Auto louver motor MP24ZN

Coil resistance (at 77°F)

Drain pump

Rated

Total head & capacity

(above drain connection)

2 (m2

) 3.88 (0.360)

V, Hz, W

ft. (mm), gal/

min (cc/min)

ORG – GRY : 46 YEL – GRY : 46

RED – GRY : 46 BLK – GRY : 46

CR-UMHX0762 (Microprocessor)

JXHX1252N

208 - 230 V / 1ø / 60 Hz

Turbo (1...ø18-7/64 (ø460))

RED – WHT : 87.0

WHT – BLU : 87.0

BLU – RED : 87.0

fuse

+4

+2

(141

285

–5

380 ± 7% / phase

PLD-12230ST

AC230V, 60Hz, 10.8W

2.1 (640), 0.11 (400)

)

–3

1

2

3

4

5

6

7

8

Page 34

2

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

JOHNSON CONTROLS

34

4-Way Air Discharge Ceiling Semi-Concealed, Standard and Mini (JX, JXM Types)

Indoor unit (B)

3

4

5

MODEL No.

Power source

Controller P.C.B. Ass'y

Fan...(Number diameter / length in. (mm))

CR-UMHX0762 (Microprocessor)

Turbo (1...ø18-7/64 (ø460))

JXHX1852N

208 - 230 V / 1ø / 60 Hz

Fan motor

Model...Nominal output W DK8-53B280HB...50W

Power source 280 VDC

No. of pole...r.p.m. (230V, High) rpm 8P...390

Coil resistance

(Ambient temperature 68°F)

Run capacitor VAC, μF –

Safety device

Operating temperature Open °F (°C)

RED – WHT : 87.0

WHT – BLU : 87.0

BLU – RED : 87.0

fuse

+4

–5

(141

+2

)

–3

285

Electronic expansion valve

Coil UKV-U030E

Coil resistance (at 68°F)

Valve body UKV-25D32

ORG – GRY : 46 YEL – GRY : 46

RED – GRY : 46 BLK – GRY : 46

Heat exchanger

Coil Aluminum plate fin / Copper tube

Rows...fin pitch in. (mm) 2...3/64 (1.25)

2 (m2

Face area ft

) 3.88 (0.360)

Panel

Model No. JPNR-XH3652N

Auto louver motor MP24ZN

Coil resistance (at 77°F)

Drain pump

Rated

Total head & capacity

(above drain connection)

V, Hz, W

ft. (mm), gal/

min (cc/min)

380 ± 7% / phase

PLD-12230ST

AC230V, 60Hz, 10.8W

2.1 (640), 0.11 (400)

6

7

8

Page 35

MODEL No.

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

35

JOHNSON CONTROLS

4-Way Air Discharge Ceiling Semi-Concealed, Standard and Mini (JX, JXM Types)

Indoor unit (C)

Power source

Controller P.C.B. Ass'y

Fan...(Number diameter / length in. (mm))

Fan motor

Model...Nominal output W DK8-53B280HB...50W

Power source 280 VDC

No. of pole...r.p.m. (230V, High) rpm 8P...440

Coil resistance

(Ambient temperature 68°F)

Run capacitor VAC, μF –

Safety device

Operating temperature Open °F (°C)

Electronic expansion valve

Coil UKV-U030E

Coil resistance (at 68°F)

Valve body UKV-25D32

Heat exchanger

Coil Aluminum plate fin / Copper tube

Rows...fin pitch in. (mm) 2...3/64 (1.25)

Face area ft

Panel

Model No. JPNR-XH3652N

Auto louver motor MP24ZN

Coil resistance (at 77°F)

Drain pump

Rated

Total head & capacity

(above drain connection)

2 (m2

) 4.36 (0.405)

V, Hz, W

ft. (mm), gal/

min (cc/min)

ORG – GRY : 46 YEL – GRY : 46

RED – GRY : 46 BLK – GRY : 46

CR-UMHX0762 (Microprocessor)

Turbo (1...ø18-7/64 (ø460))

RED – WHT : 87.0

WHT – BLU : 87.0

BLU – RED : 87.0

JXHX2452N

208 - 230 V / 1ø / 60 Hz

fuse

+4

–5

(141

+2

)

–3

285

380 ± 7% / phase

PLD-12230ST

AC230V, 60Hz, 10.8W

2.1 (640), 0.11 (400)

1

2

3

4

5

6

7

8

Page 36

2

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

JOHNSON CONTROLS

36

4-Way Air Discharge Ceiling Semi-Concealed, Standard and Mini (JX, JXM Types)

Indoor unit (D)

3

4

5

MODEL No.

Power source

Controller P.C.B. Ass'y

Fan...(Number diameter / length in. (mm))

CR-UMHX0762 (Microprocessor)

Turbo (1...ø18-7/64 (ø460))

JXHX3652N

208 - 230 V / 1ø / 60 Hz

Fan motor

Model...Nominal output W DK8-93C280HB...90W

Power source 280 VDC

No. of pole...r.p.m. (230V, High) rpm 8P...540

Coil resistance

(Ambient temperature 68°F)

Run capacitor VAC, μF –

Safety device

Operating temperature Open °F (°C)

RED – WHT : 43.0

WHT – BLU : 43.0

BLU – RED : 43.0

fuse

+4

–5

(141

+2

)

–3

285

Electronic expansion valve

Coil UKV-U030E

Coil resistance (at 68°F)

Valve body UKV-30D33

ORG – GRY : 46 YEL – GRY : 46

RED – GRY : 46 BLK – GRY : 46

Heat exchanger

Coil Aluminum plate fin / Copper tube

Rows...fin pitch in. (mm) 2...3/64 (1.25)

2 (m2

Face area ft

) 6.29 (0.584)

Panel

Model No. JPNR-XH3652N

Auto louver motor MP24ZN

Coil resistance (at 77°F)

Drain pump

Rated

Total head & capacity

(above drain connection)

V, Hz, W

ft. (mm), gal/

min (cc/min)

380 ± 7% / phase

PLD-12230ST

AC230V, 60Hz, 10.8W

2.1 (640), 0.11 (400)

6

7

8

Page 37

MODEL No.

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

37

JOHNSON CONTROLS

4-Way Air Discharge Ceiling Semi-Concealed, Standard and Mini (JX, JXM Types)

Indoor unit (E)

Source

Controller P.C.B. Ass'y

Fan...(Number diameter)

Fan motor

Model...Nominal output W SIC-72FV-D866-1B...20W

Source 340 V (DC)

No. of pole...r.p.m. (230V, High) rpm 8P...750

in. (mm) Turbo (1...ø12-5/8 (ø322), L5-3/4 (L147))

CR-XMHX1252 (Microprocessor), POW-XM075XH

JXMHX1252N

208 - 230 V / 1ø / 60 Hz

Coil resistance

(Ambient temperature 68°F)

Run capacitor VAC, μF –

Safety device

Operating temperature Open °F (°C)

Electronic expansion valve

Coil UKV-A054

Coil resistance (at 68°F)

Valve body UKV-18D31

Heat exchanger

Coil Aluminum plate fin / Copper tube

Rows...fin pitch in. (mm) 2...1/16 (1.4)

Face area ft

Panel

Model No. JPNR-XMH1852N

Auto louver motor MP24ZN-12V

Coil resistance (at 77°F)

Drain pump

Rated

Total head & capacity

(above drain connection)

2 (m2

) 2.91 (0.27)

V, Hz, W

ft. (mm), gal/

min (cc/min)

–

fuse

+4

–5

(141

+2

)

–3

285

ORG – GRY : 46 YEL – GRY : 46

RED – GRY : 46 BLK – GRY : 46

380 ± 7% / phase

PLD-12230ST-2

AC230V, 60Hz, 10.8W

2.1 (640), 0.11 (400)

1

2

3

4

5

6

7

8

Page 38

MODEL No.

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

JOHNSON CONTROLS

38

4-Way Air Discharge Ceiling Semi-Concealed, Standard and Mini (JX, JXM Types)

Indoor unit (F)

Source

Controller P.C.B. Ass'y

Fan...(Number diameter)

CR-XMHX1252 (Microprocessor), POW-XM075XH

in. (mm) Turbo (1...ø12-5/8 (ø322), L5-3/4 (L147))

JXMHX1852N

208 - 230 V / 1ø / 60 Hz

Fan motor

Model...Nominal output W SIC-72FV-D866-1B...20W

Source 340 V (DC)

No. of pole...r.p.m. (230V, High) rpm 8P...750

2

3

4

5

Coil resistance

(Ambient temperature 68°F)

Run capacitor VAC, μF –

Safety device

Operating temperature Open °F (°C)

285

fuse

+4

–5

–

(141

+2

)

–3

Electronic expansion valve

Coil UKV-A054

Coil resistance (at 68°F)

Valve body UKV-25D32

ORG – GRY : 46 YEL – GRY : 46

RED – GRY : 46 BLK – GRY : 46

Heat exchanger

Coil Aluminum plate fin / Copper tube

Rows...fin pitch in. (mm) 2...1/16 (1.4)

2 (m2

Face area ft

) 2.91 (0.27)

Panel

Model No. JPNR-XMH1852N

Auto louver motor MP24ZN-12V

Coil resistance (at 77°F)

Drain pump

Rated

Total head & capacity

(above drain connection)

V, Hz, W

ft. (mm), gal/

min (cc/min)

380 ± 7% / phase

PLD-12230ST-2

AC230V, 60Hz, 10.8W

2.1 (640), 0.11 (400)

6

7

8

Page 39

Dimensional Data

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

39

JOHNSON CONTROLS

4-Way Air Discharge Ceiling Semi-Concealed, Standard and Mini (JX, JXM Types)

Dimensional Data

Indoor unit: JXHX1252N/JXHX1852N/JXHX2452N

1-3/16

3-13/16

3-15/32

3-15/32

33-55/64 – 35-53/64

Ceiling opening dimensions

28-15/32

Suspension bolt pitch

Ceiling opening

dimensions

X

31-7/64 Suspension bolt pitch

33-55/64 – 35-53/64

Center of

4-23/32

panel

18-57/64

8

15-3/4

6-19/64

19/32

2-15/16

X View

3-5/32 6-19/64

10-5/64

2-23/64

2-3/4

1-3/8

4-29/64

1-49/64

7

bolts should be selected so that

there is a gap of 1-3/16" or

more below the lower surface of

* The length of the suspension

2

611

the ceiling (19/32" or more

below the lower surface of the

main unit), as shown in the

figure at right. If the suspension

bolt is too long, it will contact

the ceiling panel and the unit

cannot be installed.

37-13/32

20-15/64

1

4

33-5/64

13-21/32

9-27/32

1-3/16

7

37-13/32

20-15/64

2

15-3/64

9

9.52) (flared)

15.88) (flared)

ø3/8" (ø

ø5/8" (ø

)

) (flared), 24 type

) (flared), 24 type

ø6.35

ø12.7

1/4" (

ø

1/2" (

ø

)

ø1 - 1/4"

ø5 - 29/32"

53

4-23/32

8-17/64

33-5/64

18-57/64

3 - 15/16")

ø

10

6-19/64

3-13/16

Less than 1-3/8

8

Less than 1-3/8

7-13/32

2

3

2

1

2

4

5

6

7

Power supply outlet

Air intake

Discharge outlet

Refrigerant tubing (liquid tube) 12-18 type

Refrigerant tubing (gas tube) 12-18 type

1

2

3

4

Discharge duct connection port (

Drain tube connection port VP25 (outer dia.

5

Vaporizing-type humidifier (optional) installation point

6

7

8

Inter-unit control wiring

Suspension bolt hole (4 - 15/32" × 1 - 29/64" hole)

Fresh air intake duct connection port (

9

10

11

8

Page 40

5.

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

JOHNSON CONTROLS

40

4-Way Air Discharge Ceiling Semi-Concealed, Standard and Mini (JX, JXM Types)

4-Way Air Discharge (Mini) Semi-concealed Type (JX, JXM Types)

Indoor unit: JXHX3652N

1-3/16

3-13/16

3-15/32

7-13/64

18-57/64

8

X view

3-5/32 6-19/64

6-19/64

19/32

2-15/16

7

1

2

3

4

5

Ceiling opening

dimensions

X

Suspension bolt pitch

35-53/64

~

31-7/64

33-55/64

Center

of panel

9

3-15/32

33-55/64 ~ 35-53/64

Suspension bolt pitch

28-15/32

(15-3/4)

15-3/64

Ceiling opening dimensions

2-23/64

2-3/4

9-27/32

33-5/64

1-3/16

13-21/32

5 3 4

7-13/64

8-17/64

33-5/64

18-57/64

12-9/16

1-3/8

4-29/64

1-49/64

611

37-13/32

20-15/64

7

6-19/64

3-13/16

1-3/8 less than

8

* The length of the suspension

bolts should be selected so that

there is a gap of 1-3/16" or

2

2

2

more below the lower surface of

the ceiling (19/32" or more

below the lower surface of the

main unit), as shown in the

figure at right. If the suspension

bolt is too long, it will contact

the ceiling panel and the unit

cannot be installed.

37-13/32

20-15/64

1

2

6

7

Air intake

Discharge outlet

Refrigerant tubing (liquid tube) ø3/8" (ø9.52) (flared)

Refrigerant tubing (gas tube) ø5/8" (ø15.88) (flared)

Drain tube connection port VP25 (outer dia. ø1-1/4")

Power supply port

Discharge duct connection port (ø5-29/32")

Vaporizing-type humidifier (optional) installation point

Suspension bolt hole (4-15/32" × 1-29/64" hole)

Fresh air intake duct connection port (ø3-15/16")

1

234

5

6

7

8

9

10

10

Inter-unit control wiring

11

1-3/8 less than

7-13/32

8

Page 41

7-5/8

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

41

JOHNSON CONTROLS

4-Way Air Discharge Ceiling Semi-Concealed, Standard and Mini (JX, JXM Types)

Indoor unit: JXMHX1252N/JXMHX1852N

1-1/8

8

5/8

3-1/8

4-7/8

A View

AA

21

23-5/8

Suspension bolt pitch

Ceiling opening dimensions

21

Center of

panel

7

(flared)

1/4" (flared)

ø

ø1/2"

23-5/8

Ceiling opening dimensions

Suspension bolt pitch

12-1/2

12-7/8

5

22-5/8

6-1/4 6-3/4

2-1/8

1-3/4

11-1/8

8-1/2

1-3/4

4-5/8

1-1/8

2

3

24-5/8

14-1/8

6

Less than 1 Less than 1

The length of the suspension

bolts should be selected so that

there is a gap of 1-1/8" or

the ceiling (5/8" or more

below the lower surface of the

main unit), as shown in the

figure at right. If the suspension

bolts is too long, it will contact

the ceiling panel and the unit

cannot be installed.

24-5/8

13-1/8

2

2

1

1

2

3

2

4

5

(liquid tube)

(gas tube)

Air intake

Discharge outlet

Refrigerant tubing

Refrigerant tubing

Drain tube connection port VP20 (outer dia. ø1")

Power supply port

Suspension bolt hole (4 - 1/2" x 1-1/8" hole)

1

234

5

6

7

22-5/8

Fresh air intake duct connection port (ø3-7/8")

8

3-5/8

6

7

8

Page 42

MODEL :

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

JOHNSON CONTROLS

42

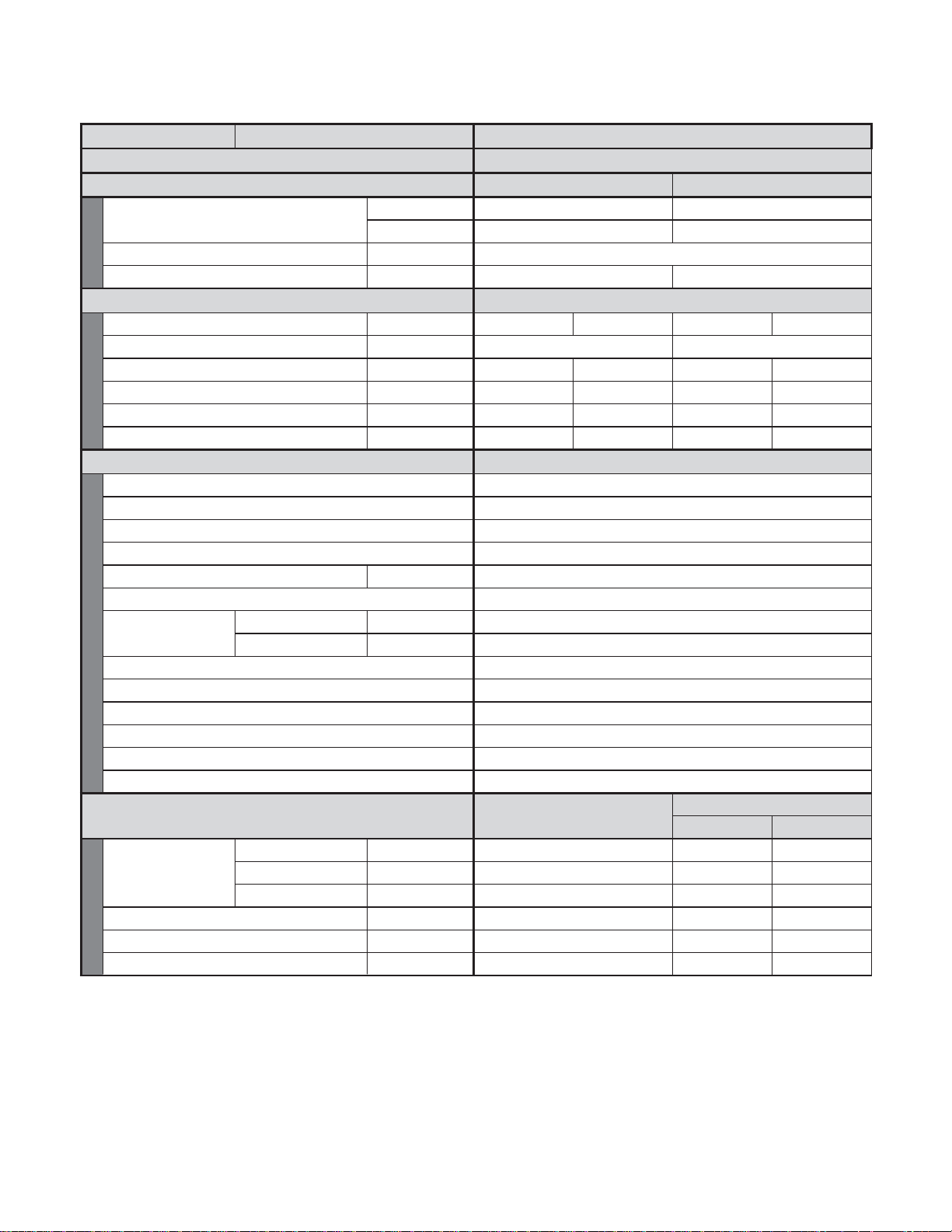

Noise Criterion Curves

4-Way Air Discharge Ceiling Semi-Concealed, Standard and Mini (JX, JXM Types)

SOUND LEVEL : 31 dB(A)

CONDITION :

60

JXHX1252N, JXHX1852N

STRONG

HIGH

LOW

4.9 ft directly below unit

29 dB(A)

27 dB(A)

60Hz

MODEL :

SOUND LEVEL : 34 dB(A)

CONDITION :

60

JXHX2452N

STRONG

HIGH

LOW

4.9 ft directly below unit

31 dB(A)

28 dB(A)

o

Strong

Weak

2

3

4

5

50

40

30

Approximate

20

minimum audible

(0dB = 0.0002μbar)

limit for

Sound pressure level (dB)

continuous noise

10

Overall

Frequency at center of sound pressure band (Hz)

MODEL :

SOUND LEVEL : 39 dB(A)

CONDITION :

60

50

40

30

Approximate

minimum audible

20

(0dB = 0.0002μbar)

limit for

Sound pressure level (dB)

continuous noise

10

Overall

Frequency at center of sound pressure band (Hz)

JXHX3652N

STRONG

HIGH

LOW

4.9 ft directly below unit

36 dB(A)

33 dB(A)

o

400063 125 250 800020001000500

400063 125 250 800020001000500

NC-50

NC-40

NC-30

NC-20

NC-50

NC-40

NC-30

NC-20

50

40

30

Approximate

minimum audible

20

(0dB = 0.0002μbar)

limit for

Sound pressure level (dB)

continuous noise

10

Overall

Frequency at center of sound pressure band (Hz)

MODEL :

SOUND LEVEL 32 dB(A)

CONDITION

60

50

40

30

Approximate

20

minimum audible

(0dB = 0.0002μbar)

limit for

Sound pressure level (dB)

continuous noise

10

Overall

Frequency at center of sound pressure band (Hz)

JXMHX1252N

STRONG

:

WEAK 26 dB(A)

4.9 ft directly below unit

:

NC-50

NC-40

NC-30

NC-20

400063 125 250 800020001000500

NC-50

NC-40

NC-30

NC-20

400063 125 250 800020001000500

MODEL :

SOUND LEVEL 41 dB(A)

6

7

8

CONDITION

60

50

40

30

Approximate

minimum audible

20

(0dB = 0.0002μbar)

limit for

Sound pressure level (dB)

continuous noise

10

Overall

Frequency at center of sound pressure band (Hz)

JXMHX1852N

:

STRONG

WEAK 33 dB(A)

4.9 ft directly below unit

:

NC-50

NC-40

NC-30

NC-20

400063 125 250 800020001000500

Page 43

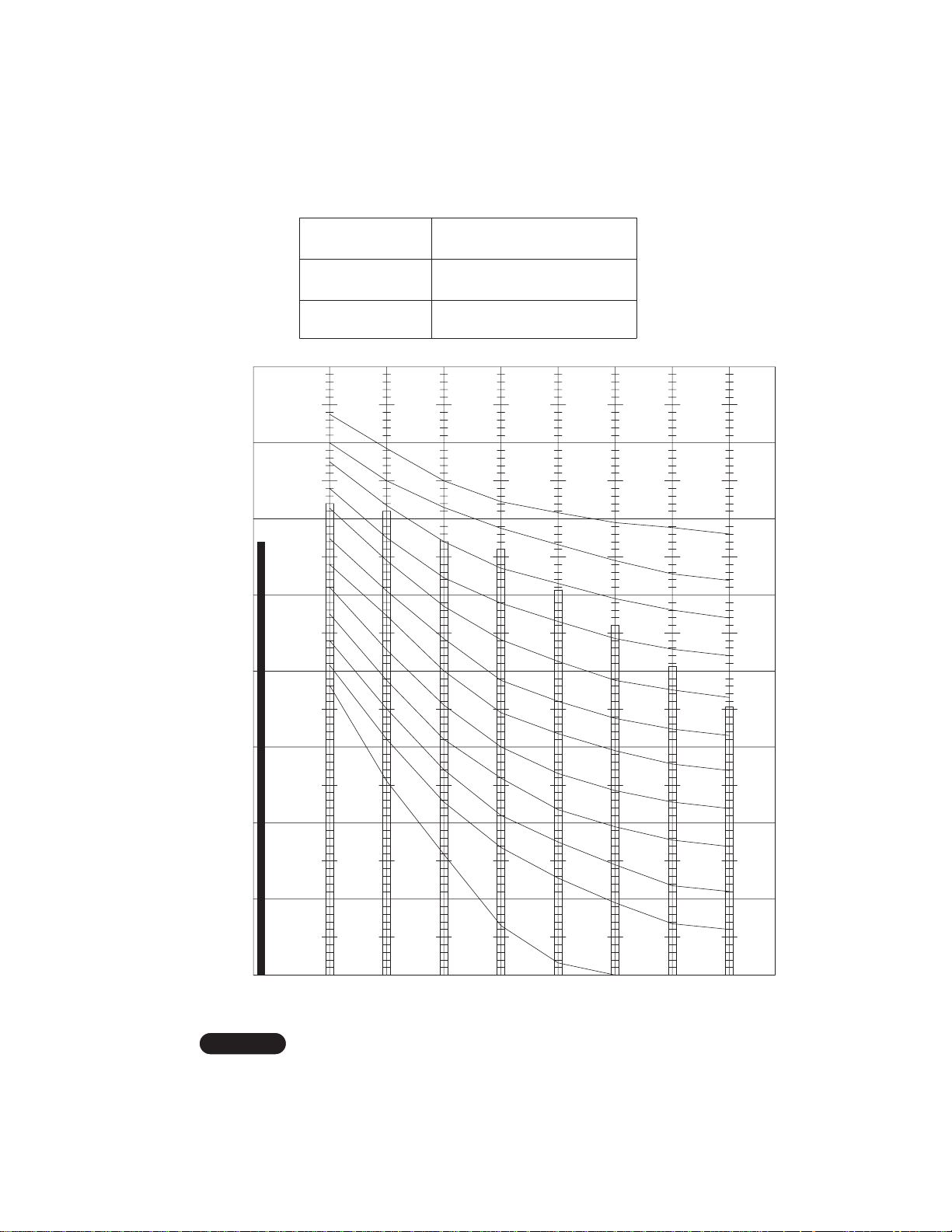

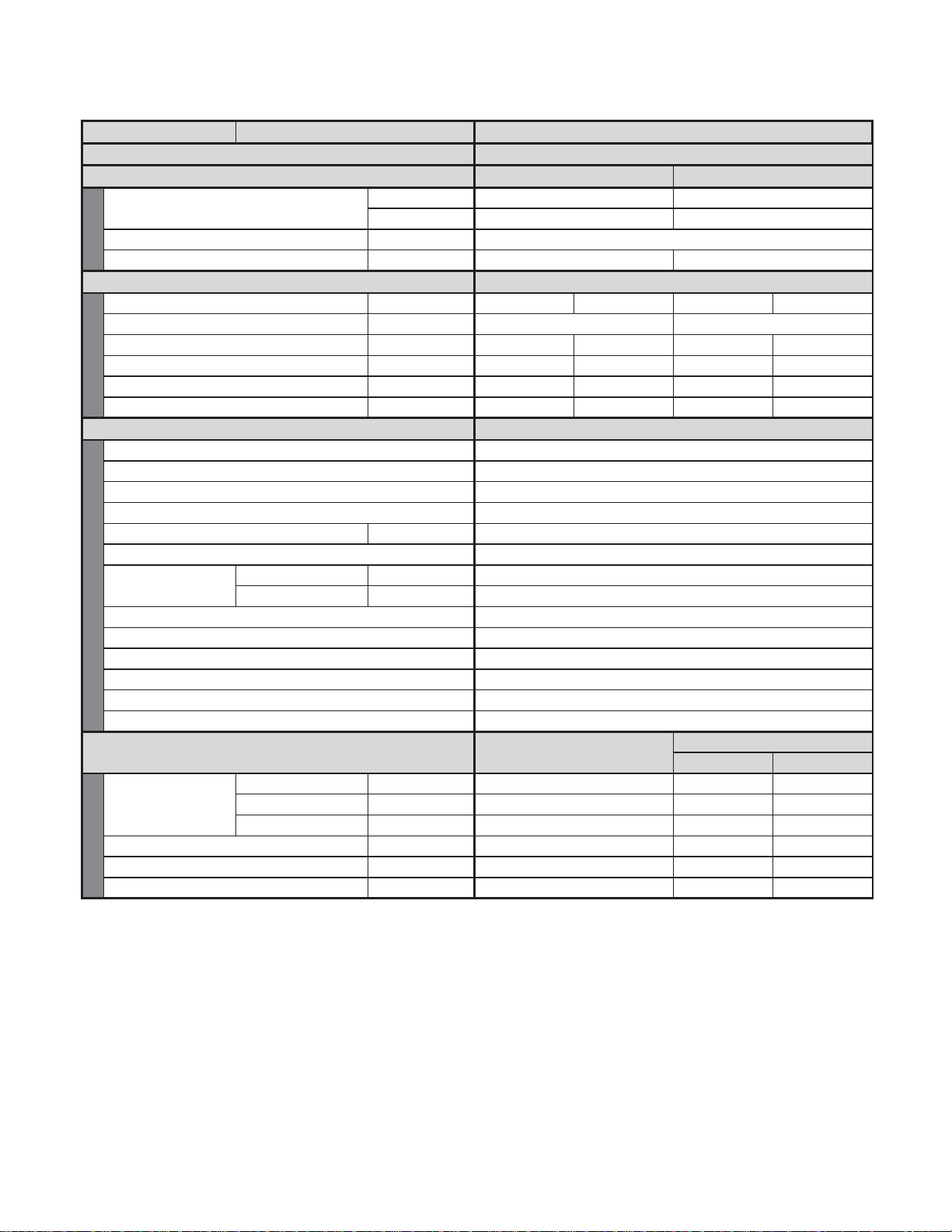

If an ultra long-life fi lter or high performance fi lter (65% by colorimetric method) is installed, the vertical air throw dis-

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

43

JOHNSON CONTROLS

4-Way Air Discharge Ceiling Semi-Concealed, Standard and Mini (JX, JXM Types)

Air Flow Distance/Temperature Chart

tance for heating and cooling will be approximately 0.7 ft less than the values shown in the graph below.

If a high performance fi lter (90% by colorimetric method) or electronic fi lter is installed, the vertical air throw distance

for heating and cooling will be approximately 1.6 ft less than the values shown in the graph below.

JXHX1252N/JXHX1852N

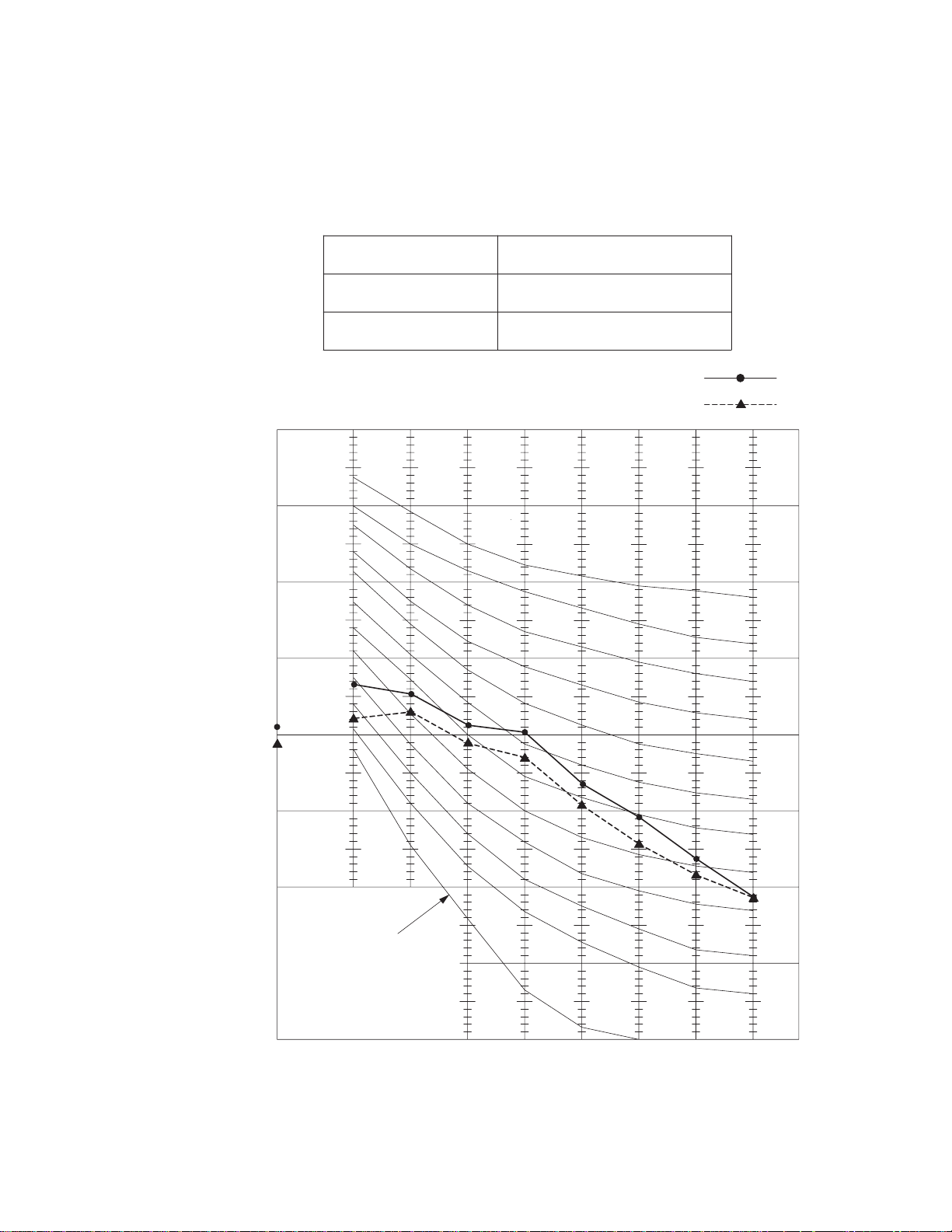

Heating : Distribution of wind velocity

(Strong wind : Discharge angle approx.65 ) (Room temperature approx.68°F)

9.8

6.6

4.9 ft/s

3.3 ft/s

1.6 ft/s

0.98 ft/s

9.8

6.6

3.3

0

Vertical air flow distance (ft.)

16.4 16.413.19.8 6.66.6 3.33.3 013.1 9.8

Heating : Distribution of temperature

(Strong wind : Discharge angle approx.65 )

9.8

6.6

3.3

0

Vertical air flow distance (ft.)

16.4 16.413.19.8 6.66.6 3.33.3 013.1 9.8

Cooling : Distribution of wind velocity

(Strong wind : Discharge angle approx.30 )

9.8

6.6

3.3

Horizontal air flow distance (ft.)

(Room temperature approx.68°F)

91°F

86°F

Horizontal air flow distance (ft.)

(Room temperature approx.80°F)

80°F

4.9 ft/s

75°F

3.3 ft/s

1.6 ft/s

0.98 ft/s

3.3

0

9.8

6.6

3.3

0

9.8

6.6

3.3

1

2

3

4

5

0

Vertical air flow distance (ft.)

16.4 16.413.19.8 6.66.6 3.33.3 013.1 9.8

Cooling : Distribution of temperature

(Strong wind : Discharge angle approx.30 )

9.8

6.6

3.3

0

Vertical air flow distance (ft.)

16.4 16.413.19.8 6.66.6 3.33.3 013.1 9.8

Horizontal air flow distance (ft.)

(Room temperature approx.80°F)

Horizontal air flow distance (ft.)

68°F

71°F

75°F

78°F

0

6

9.8

7

6.6

3.3

8

0

Page 44

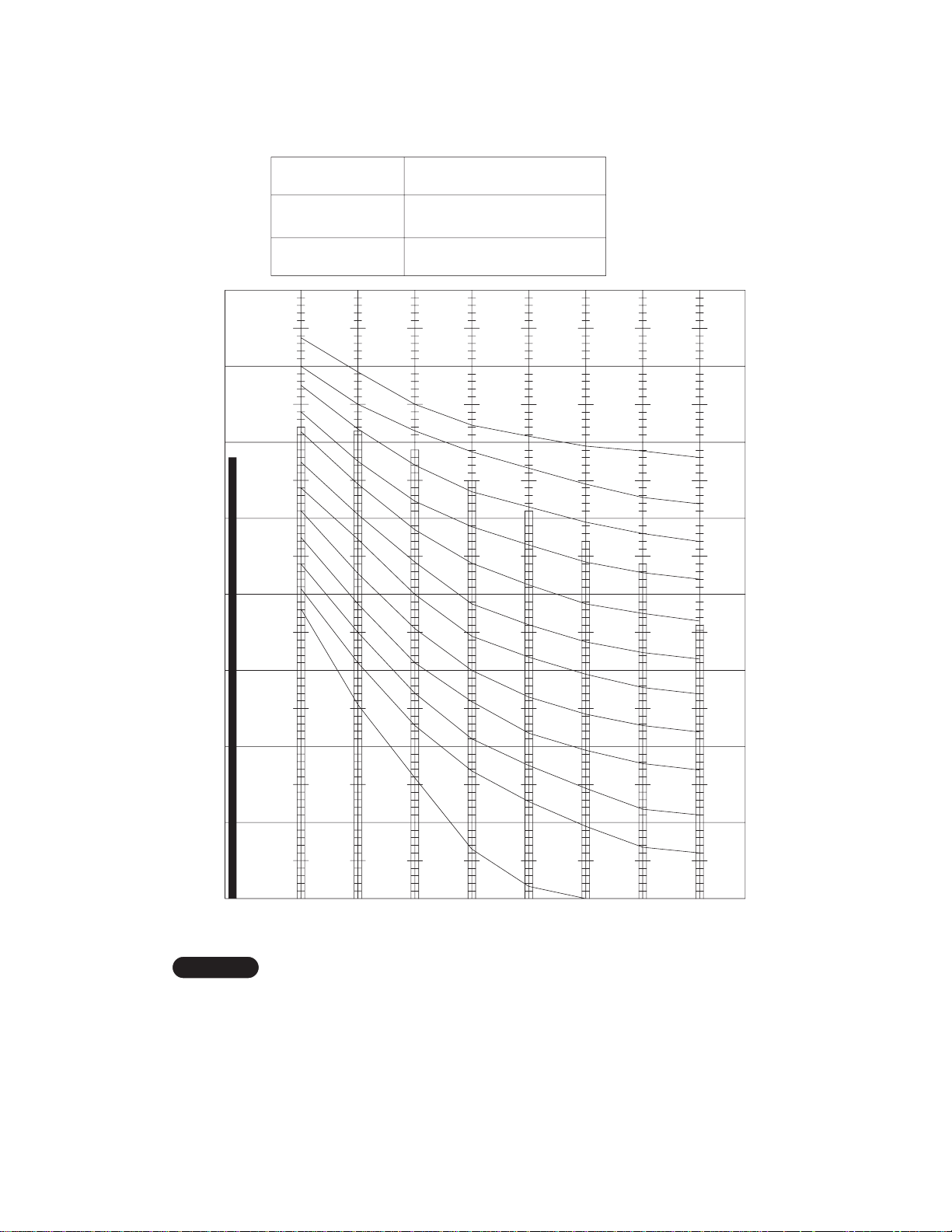

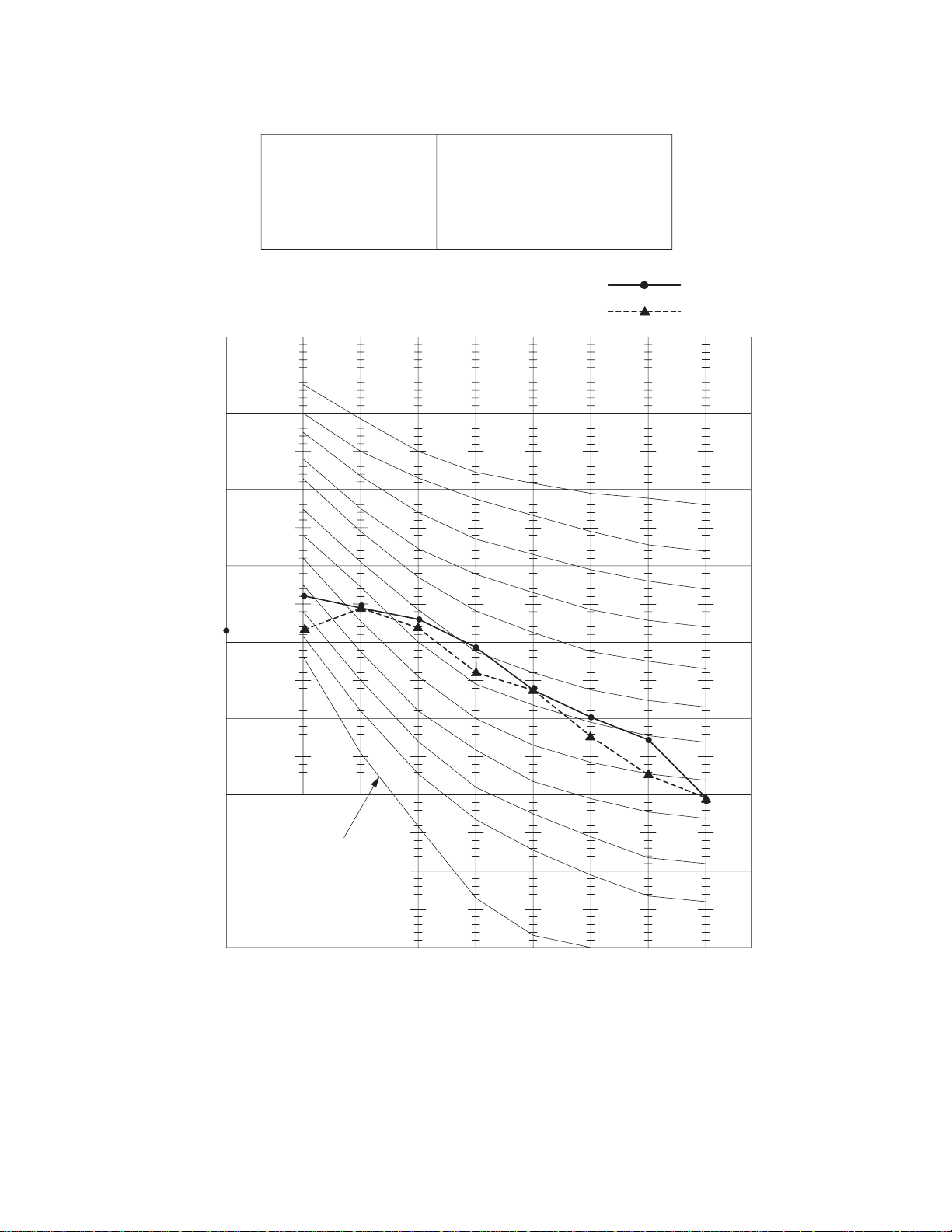

JXHX2452N

FORM 121.00-EG1

ISSUE DATE: 5/31/2012

JOHNSON CONTROLS

44

4-Way Air Discharge Ceiling Semi-Concealed, Standard and Mini (JX, JXM Types)

Heating : Distribution of wind velocity