Page 1

IOM1710 Input/Output Module

Installation Instructions

MS-IOM1710-0

Part No. 24-10144-9, Rev. G

Release 5.0

Issued January 4, 2010

Supersedes October 6, 2008

Applications

The Input/Output Module (IOM) 1710 is a member of

the Metasys® system Field Equipment Controller

(FEC) family. The IOM controller provides increased

capacity to larger FEC applications when used on the

Sensor Actuator (SA) Bus. The IOM controller can also

be used on the Field Controller (FC) Bus to connect

additional physical points to the system.

IMPORTANT: In Metasys system smoke control

applications, use only the IOM1710 models that are

UL Listed, UUKL 864 Listed, Smoke Control

Equipment. See Repair Information

UUKL 864 Listed IOM1710 models. For Metasys

system smoke control applications, you must refer to

the Metasys System UL 864 UUKL Ninth Edition

Smoke Control System Technical Bulletin

(LIT-12011252) for detailed requirements and

procedures for installing and operating UUKL 864

Listed Metasys system devices. Failure to meet the

requirements or follow the procedures in the

Metasys System UL 864 UUKL Ninth Edition Smoke

Control System Technical Bulletin (LIT-12011252)

can void the UUKL 864 listing for Smoke Control

Equipment.

on page 6 for

North American Emissions Compliance

United States

This equipment has been tested and found to

comply with the limits for a Class A digital device

pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection

against harmful interference when this equipment is

operated in a commercial environment. This

equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in

accordance with the instruction manual, may cause

harmful interference to radio communications.

Operation of this equipment in a residential area is

likely to cause harmful interference, in which case

the user will be required to correct the interference

at his/her own expense.

Canada

This Class (A) digital apparatus meets all the

requirements of the Canadian Interference-Causing

Equipment Regulations.

Cet appareil numérique de la Classe (A) respecte

toutes les exigences du Règlement sur le matériel

brouilleur du Canada.

Installation

Observe the following guidelines when installing the

IOM controller:

• Transport the IOM controller in the original

container to minimize vibration and shock damage

to the IOM.

• Do not drop the IOM controller or subject it to

physical shock.

Materials and Special Tools Needed

Y ou need either of the following items to install the IOM

controller:

• three fasteners appropriate for the mounting

surface (#8 screws or M4 screws)

• one 20.3 cm (8 in.) or longer piece of DIN rail and

appropriate hardware for mounting the DIN rail

Mounting

Follow these guidelines when mounting an IOM

controller:

• Ensure that the mounting surface can support the

IOM controller and any user-supplied enclosure.

• Mount the IOM controller in the proper orientation.

See the Wall Mount Applications

Mount Applications section.

• Mount the IOM controller on an even surface

whenever possible.

• Use shims or washers to mount the unit securely

on the mounting surface.

• Mount the IOM controller in areas free of corrosive

vapors and observe the environmental limitations

listed in the Technical Specifications

and DIN Rail

section.

IOM1710 Input/Output Module Installation Instructions 1

Page 2

• Do not mount the IOM controller on surfaces that

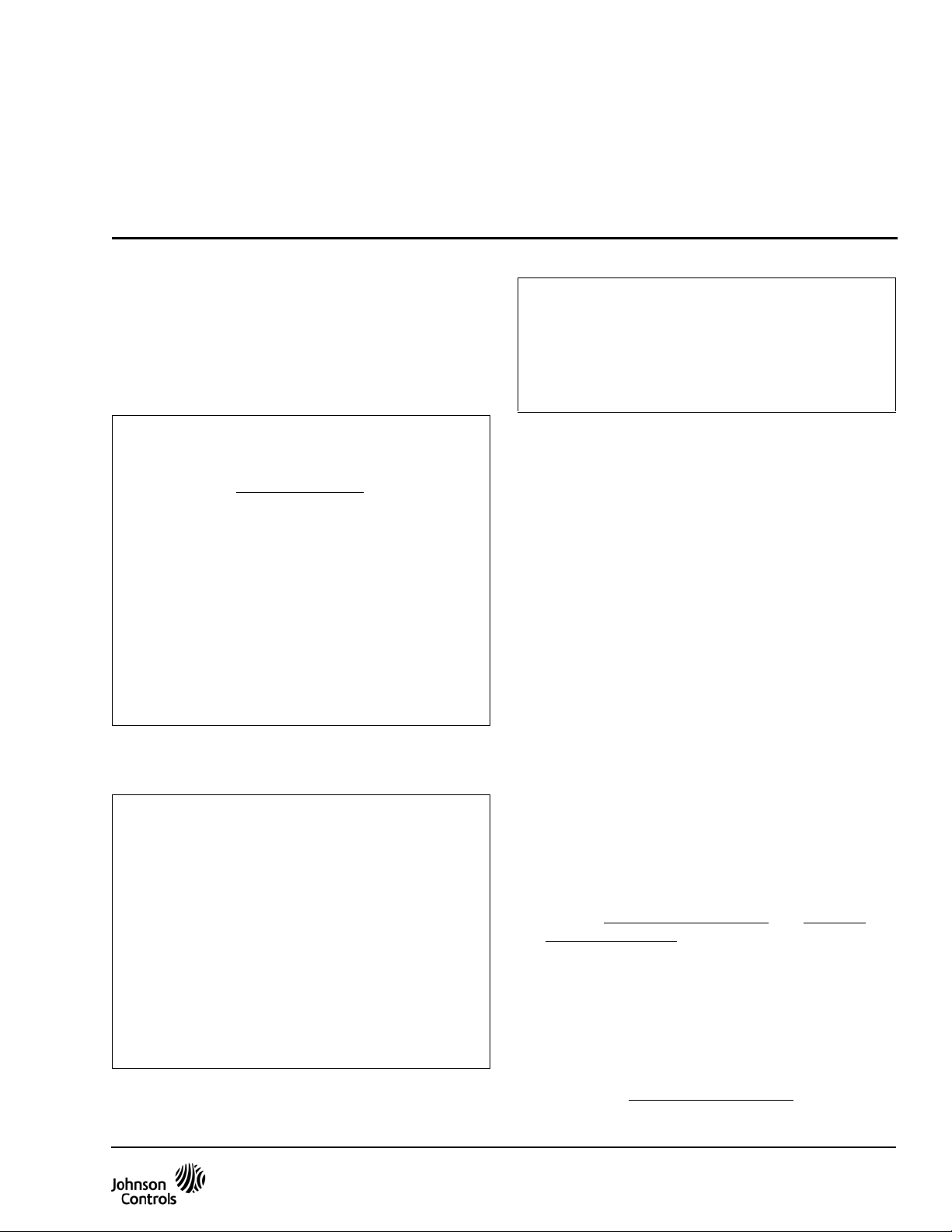

Figure 1: IOM1710 Controller Physical Features

and Wiring Terminal Blocks

FAULT

POWER

A

ON

IN 1

ICOM 1

IN 2

ICOM 2

IN 3

ICOM 3

IN 4

ICOM 4

BINARY INPUTS

COM

+

–

SHLD

+

–

COM

PWR

A

O

N

Binary

Inputs

Clip

EOL

Switch

DIP Switches

SA BUS

FC BUS

Mounting

Clip

Status

LEDs

Port

FIG:IOM17 10_frnt

54

(2.13 )

54

(2.13)

108

(4-1/4 )

F

I

G

:

I

O

M

1

7

1

0

_

b

c

k

Hooks

Mounting Clip

(Shown Extended )

143

(5 - 5/8)

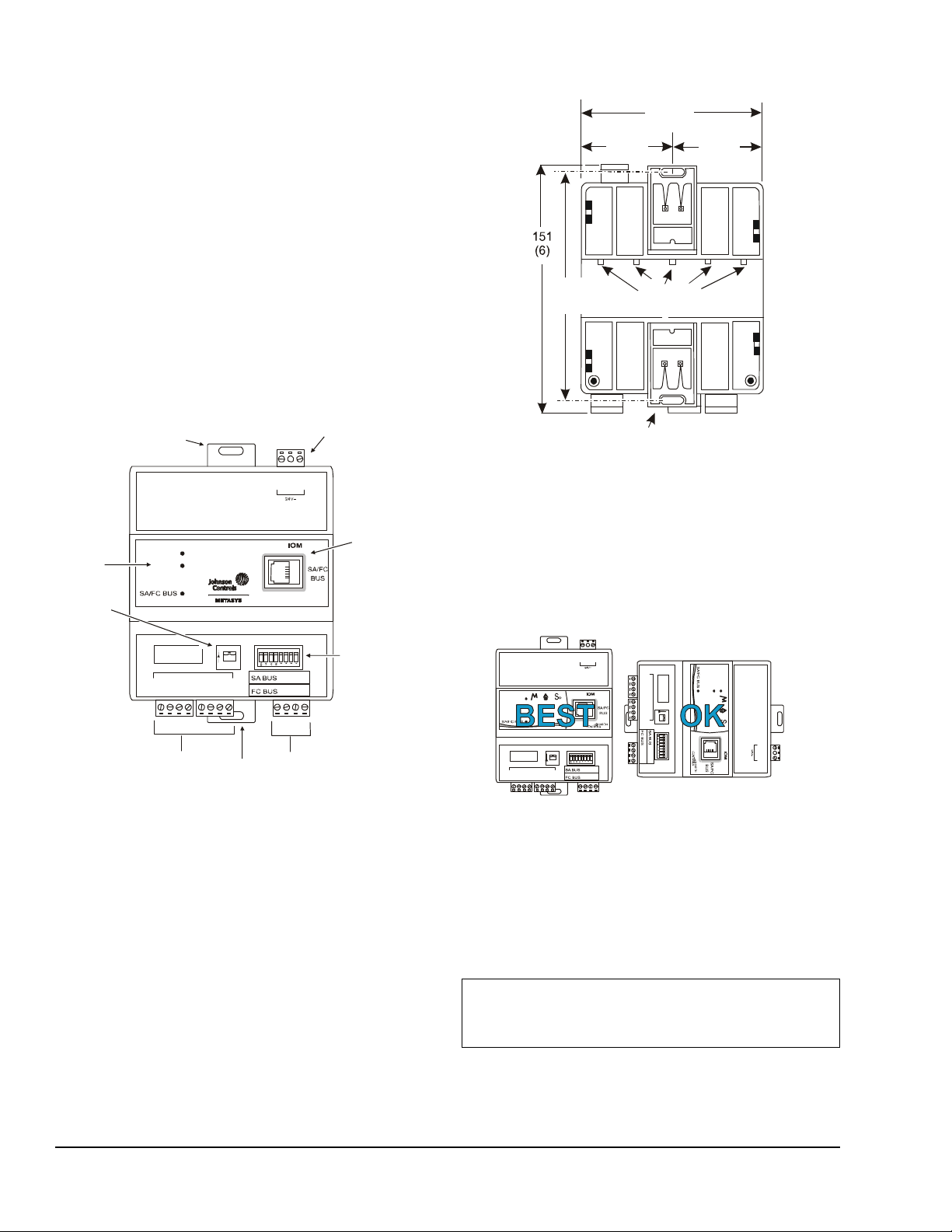

Figure 2: IOM1710 Controller Mounting Features,

mm (in.)

IN 1

ICOM 1

IN 2

ICOM 2

IN 3

ICOM 3

IN 4

ICOM 4

B

I

N

A

R

Y

I

N

P

U

T

S

COM

+

–

SHLD

–

R

ET SY

FAULT

POWER

ADDRESS

ON

I

N

1

I

C

O

M

1

I

N

2

I

C

O

M

2

I

N

3

I

C

O

M

3

I

N

4

I

C

O

M

4

BINARY INPUTS

C

O

M

+

–

S

H

L

D

+

–

C

O

M

P

W

R

ADDRESS Ø = ALL OFF

EOL

O

N

Figure 3: Required Orientation for Wall Mount

Applications

are prone to vibration, such as duct work, or in

areas where electromagnetic emissions from other

devices or wiring can interfere with IOM controller

communication.

• Allow sufficient space for cable and wire

connections (minimum of 51 mm [2 in.] in each

direction).

On panel or enclosure mount applications, observe

these guidelines:

• Do not install the IOM controller in an airtight

enclosure.

• Mount the IOM controller so that the enclosure wall

or the transformer does not obstruct ventilation of

or radiate heat into the IOM controller housing.

24 VAC

Power Terminal

HOT

COM

DIN Rail

DDRESS

DDRESS Ø = ALL OFF

EOL

Mounting

Wall Mount Applications

Use the holes in the mounting clips for wall mount

applications.

To mount the IOM controller on a wall or other vertical

surface:

1. Ensure that the bottom mounting clip(s) are pulled

outward and snapped firmly into the extended

position and that the top clip is securely installed

(Figure 2).

IOM1710 Input/Output Module Installation Instructions2

SA/FC Bus

Device Address

2. Mark the location of the wall mount holes using the

dimensions in Figure 2, or hold the IOM controller

up to the wall as a template and mark the locations.

Note: Mount the IOM controller horizontally for

proper airflow.

T

M

O

O

H

C

A

D

D

R

E

S

S

Ø

=

A

L

L

O

F

F

O

N

E

O

L

A

D

O

N

D

R

E

S

S

+

COM

PWR

P

F

O

A

W

U

L

E

T

R

E

T

S

Y

R

COM

HOT

l

l

w

_

t

n

r

o

:

G

I

F

3. Drill holes in the wall at the locations marked in

Step 2 and insert wall anchors (if necessary).

4. Position the IOM controller and insert the screws

through the holes in the mounting clips, and

carefully tighten all the screws.

IMPORTANT: Do not overtighten the mounting

screws. Overtightening the screws may damage the

mounting clips or IOM housing.

Page 3

DIN Rail Mount Applications

Figure 4: Required Orientation for DIN Rail

Mount Applications

R

ET SY

FAULT

POWER

A

ON

I

N

1

I

C

O

M

1

I

N

2

I

C

O

M

2

I

N

3

I

C

O

M

3

I

N

4

I

C

O

M

4

BINARY INPUTS

C

O

M

+

–

S

H

L

D

+

–

C

O

M

P

W

R

A

O

N

F

I

G

:

I

O

M

1

7

1

0

_

o

r

n

t

_

D

I

N

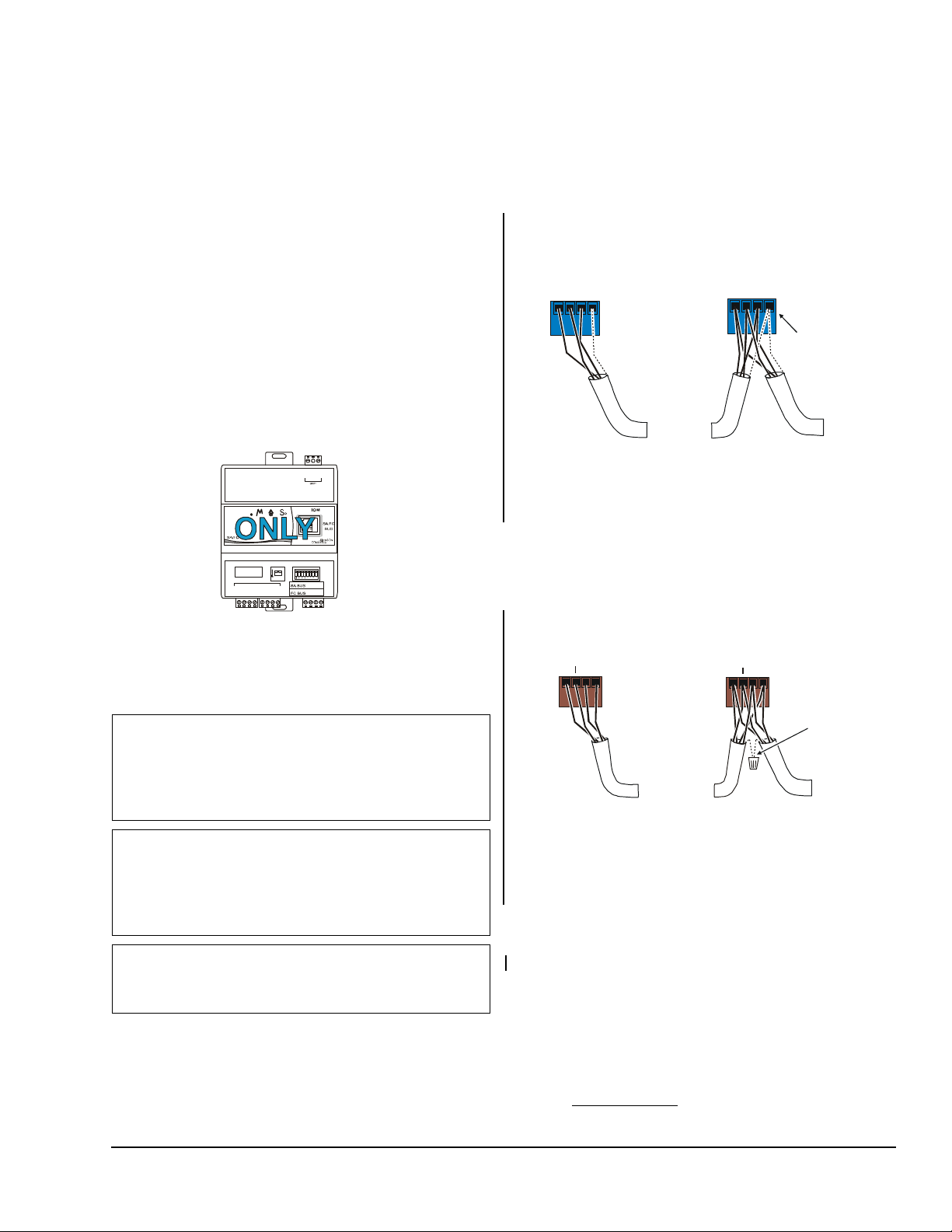

Figure 5: FC Bus Terminal Block Wiring

Isolated Shield

Connection

Terminal

the FC Bus

Segment

FC Bus

Terminal

FIG: fc_bus_term

+

_

COM

SHLD

Terminating Device

on FC Bus Segment

To Next

Device on

the FC Bus

Segment

Daisy Chained Device

on FC Bus Segment

(One twist ed pair is the and leads.

The second pair is COM and SA PWR.)

+ -

Cable Shield

Connection

To Next

Device on

the SA Bus

FIG:sa_bus_terms

SA Bus

Terminal

Block Plugs

Terminating Device

on SA Bus

on SA Bus

To Next

Device on

the SA Bus

+

CO

SA

Figure 6: SA Bus Terminal Block Wiring

To mount the IOM controller on a DIN rail:

1. Securely mount the section of DIN rail horizontally

and centered in the required space.

2. Carefully pull down (outward) the bottom mounting

clip(s) until they lock in place (Figure 2).

Note: The top mounting clip is not used on DIN

rail applications. You may remove the clip.

To wire the IOM controller:

1. Terminate wiring per engineering drawings.

2. If the IOM is connected to the FC Bus of a Network

Automation Engine (NAE) or Network Control

Engine (NCE), wire the FC Bus in a daisy chain

(Figure 5).

s

3. Hang the IOM controller on the DIN rails using the

DIN rail hooks on the back of the IOM controller.

4. Secure the IOM controller on the DIN rail by

pressing the bottom mounting clips up until they

snap into place.

To remove the IOM controller from the DIN rail, snap

the bottom DIN clips to the outboard position and

carefully lift the IOM controller off the DIN rail.

EOL

DDRESS Ø = ALL OFF

Wiring

IMPORTANT: Do not connect 24 VAC supply

power to the IOM controller before finishing wiring

and checking all wiring connections. Short circuits or

improperly connected wires may result in permanent

damage to the equipment.

IMPORTANT: User copper conductors only. Make

all wiring in accordance with local, national, and

regional regulations. The IOM controller is a

low-voltage (<30 VAC) device. Do not exceed the

IOM controller electrical ratings.

to the IOM controller. Static elec tric discharge can

damage the IOM controller and void any warranties.

Refer to the MS/TP Communications Bus Technical

Bulletin (LIT-12011034) for more information on

Master-Slave/Token-Passing (MS/TP) devices.

IMPORTANT: Prevent any static electric discharge

T

M

O

O

H

C

DDRESS

_

+

COM

SHLD

Block Plugs

To Next

Device on

Stranded 3-Wire Tw isted Shiel ded Cable

3. If the IOM is connected to the SA Bus of an NCE or

FEC, wire the SA Bus in a daisy chain (Figure 6).

Daisy Chained Device

M

PWR

+

COM

SA PWR

Stranded, 4- Wire (2 Twisted Pair) Shielded Cable

Note: The SA/FC Bus Port (RJ-12, 6-pin, modular

connector) provides 15 VDC on two of its pins,

which is used to power the MS-BTCVT (Figure 7).

Note: If the IOM controller is at one end of the SA

Bus daisy chain, set the End-of-Line (EOL) switch

to ON.

4. Connect power to the IOM controller.

5. Download and commission the IOM controller . See

the Commissioning

section.

IOM1710 Input/Output Module Installation Instructions 3

Page 4

SA/FC Bus Port

Figure 7: Pin Number Assignments for

Sensor, SA Bus, and FC Bus Ports on

FEC, IOM, and VMA16

(15 VDC)

SA or FC Bus +

SA or FC Bus

-

Power

(15 VDC)

(RJ-12 Mod u l ar Jack)

FIG:RJ_pinout

2

3

4

5

6

1

The SA/FC Bus port on the front of the IOM is an

RJ-12, 6-position modular jack that provide s a

connection for the Wireless Commissioning Converter

(MS-BTCVT).

SA/FC

Bus Port pin assignment is shown in (Figure 7).

See Table 1 for more information. The

Table 1: IOM1710 Controller W iring List

Terminal

Block

Binary IN IN n Dry Contact Maintained Mode

SA/FC Bus

1,2

Port

SA Bus

FC Bus

24~ Power Hot AC Supply Input

Terminal

Function and Electrical Ratings/Requirements Wiring Requirements

Labels

0.01 s minimum pulse width (50 Hz at 50% duty cycle)

Internal 8 V, 1.1k ohm Pullup

Pulse Counter Mode

0.01 s minimum pulse width (50 Hz at 50% duty cycle)

Internal 8 V, 1.1k ohm Pullup

ICOM n The signal common for all Binary IN terminals; isolated from

SA/FC

Bus

1,2

+

COM

1

+

COM

SHLD Provides an optional shield connection.

COM The 24~ Power common; isolated from all other terminal

all other terminal commons

Provides SA Bus communication network.

RJ-12 6-position modular connector

Provides SA Bus communication network. Daisy-chained

Provides FC Bus communication network. Daisy-chained

Supply 20-30 VAC (Nominal 24 VAC)

commons.

Sensor, SA Bus, or FC Bus Port

Bus and Power Com m on

Bus and Power Com m on

Power

(See Table 2 for A, B, or C.)

A

30.5 m (100 ft) maximum length

phone cord

366 m (1,200 ft) maximum

length

0.6 mm to 1.5 mm

24 AWG)

[22 AWG Recommended]

1,524 m (5,000 ft) maximum

length

0.6 mm to 1.5 mm

AWG)

[22 AWG Recommended]

16 AWG

2

(18 to

2

(18 to 24

1. The SA Bus and the SA/FC Bus Port are daisy-chained internally.

2. The SA Bus and FC Bus specifications in this table are for MS/TP bus communications at 38.4k baud. For more

information, refer to the MS/TP Communications Bus Technical Bulletin (LIT-12011034).

IOM1710 Input/Output Module Installation Instructions4

Page 5

Wiring Requirements

137 m 450 f t()

122 m 400 f t()

107 m 350 f t()

91 m 300 ft()

h

t

g

n

76 m 250 ft()

e

L

e

l

61 m 200 ft()

b

a

C

46 m (150 ft )

31 m 100 ft()

15 m 50 ft()

0 m 0 ft()

0.8 mm (20 AWG)

0.6 mm(22 AWG)

N/A (24 AWG )

2

1.5 mm (18 AWG)

Load Current (mA)

Figure 8: Maximum Wire Length by Current and Wire Size

T

able 2: Wire Gauge and Length Guidelines

Guideline Cable Size Maximum Length Assumptions

A

1.5 mm

0.8 mm

0.6 mm

(18 AWG)

(20 AWG)

(22 AWG)

N/A (24 AWG) 106.7 m (350 ft)

B

1.5 mm (18 AWG)

0.8 mm

0.6 mm

N/A

(20 AWG)

(22 AWG)

(24 AWG)

C See Figure 8. See Figure 8. N/A

457.2 m (1,500 ft) 100 mV maximum voltage drop

297.2 m (975 ft)

182.9 m (600 ft)

228.6 m (750 ft) 100 mV maximum voltage drop

137.1 m (450 ft)

91.4 m (300 ft)

61 m (200 ft)

H

T

G

N

L

_

R

I

W

_

G

I

F

450 500400350300250200150100500

Setup and Adjustments

The IOM controller can reside on either the FC Bus or

the SA Bus. When you set the device address, you are

setting the address for the specified bus. The IOM

controller can be connected to only one bus.

Determining the FC Bus or SA Bus Address

The ADDRESS DIP switch sets a unique address for

the controller (or module) on the FC Bus or SA Bus.

Set the address to 4-127 for an IOM. For best

performance, all devices on the same Bus (FC Bus or

SA Bus) should have consecutive addresses. Do not

use Addresses 128 and above when connecting the

IOM to the FC Bus or SA Bus. For more information,

refer to the MS/TP Communications Bus Technical

Bulletin (LIT-12011034).

Table 3 sh

ows the valid FC Bus and SA Bus device

addresses for FECs and IOMs on Johnson Controls®

MS/TP communications bus applications.

Table 3: FC Bus Device Address Descriptions

Device

Description

Address

0 Reserved for FC Bus supervisory controller.

1-3 Reserved for peripheral devices.

4-127 Available for FECs on the FC bus and IOMs

on the SA or FC Bus.

128 Disables (Off) or Enables (ON) a controller for

wireless operation.

129-255 Are not valid addresses for FEC or IOM

controllers on the SA or FC Bus.

IOM1710 Input/Output Module Installation Instructions 5

Page 6

Setting the FC Bus or SA Bus Address

Figure 9: Device Address Switches Set to 21

ON

Note:

Switch 12 8 i s

used to enable or

disable an FEC for

wireless oper ation.

Figure 10: EOL Switch Positions

FIG:E

O

N

For most devices on an FC Bus or SA Bus, the

(non-supervisory) device address is set using the DIP

switches on the device’s ADDRESS DIP switch block.

The DIP switch blocks are binary switch blocks and

each switch represents a binary numerical value when

the switch is set to the ON position. For example,

positioning switches 16, 4, and 1 to ON, as shown in

Figure 9, sets the device address to 21.

FC Bus or SA Bus EOL Switch

The EOL switch applies power termination to the

device’s FC Bus or SA Bus. If the IOM is at the

End-of-Line (EOL) position on the Bus, set the EOL

switch to the ON position. Otherwise, set the EOL

switch to the OFF position (Figure 10). The controller

ships with the EOL switch set in the OFF position.

O

N

OL_Swtch

EOL ON Position EOL Off Position

128

64

32

16

8

1

2

4

FIG:fec_dip_swtch

Commissioning

Commission the IOM controller through the Wireless

Commissioning Converter with Bluetooth® Technology

(MS-BTCVT) and the Controller Configuration Tool

(CCT) software. Refer to the CCT Help.

T roubleshooting

Use Table 4 to troubleshoot the IOM controller.

Table 4: Status Light-Emitting Diodes (LEDs)

Name Color Normal Descriptions

Power Green On Steady Off S teady = No Power

On Steady = Power is supplied by primary voltage.

Fault Red Off Steady Blink - 2 Hz = Download or startup in progress, not ready for normal operation

Off Steady = No faults

On Steady = Device fault or no application loaded

SA/FC Bus Green Blink - 2 Hz Blink - 2 Hz = Data transmission (normal communication)

Off Steady = No data transmission (auto baud in progress)

On Steady = Communication lost, waiting to join communication ring

Repair Information

If the IOM controller fails to operate within its

specifications, replace the unit. For a replacement IOM

controller, contact the nearest Johnson Controls®

representative.

Accessories

Use T able 5 to order accessories fo r the IOM controller .

Table 5: FEC and IOM Accessories (Order Separately) (Part 1 of 2)

Product Code

Description

Number

Y64T15-0 Transformer, 120/208/240 VAC Primary to 24 VAC Secondary, 92 VA, Foot Mount, 30 in. Primary

Leads and 30 in. Secondary Leads, Class 2

Y65A13-0 Transformer, 120 VAC Primary to 24 VAC Secondary, 40 VA, Foot Mount (Y65AS), 8 in. Primary

Leads and 30 in. Secondary Leads, Class 2

Y65T42-0 Transformer , 120/208/240 VAC Primary to 24 VAC Secondary, 40 VA, Hub Mount (Y65SP+), 8 in.

Y65T31-0 Transformer , 120/208/240 VAC Primary to 24 VAC Secondary , 40 VA, Foot Mount (Y65AR+), 8 in.

AP-TBK1002-0 2-position Screw Terminal that Plugs onto VMA output point Spade Lugs

AP-TBK1003-0 3-position Screw Terminal that Plugs onto VMA output point Spade Lugs

IOM1710 Input/Output Module Installation Instructions6

Primary Leads and Secondary Screw Terminals, Class 2

Primary Leads and Secondary Screw Terminals, Class 2

Page 7

Table 5: FEC and IOM Accessories (Order Separately) (Part 2 of 2)

Product Code

Description

Number

AP-TBK4SA-0 Replacement MS/TP SA Bus Terminal, 4 Position Connector, Brown, Bulk Pack

AP-TBK4FC-0 Replacement MS/TP FC Bus Terminal, 4 Position Connector, Blue, Bulk Pack

AP-TBK3PW-0 Replacement Power Terminal, 3 Position Connector, Gray, Bulk Pack

MS-BTCVT-1 Wireless Commissioning Converter, with Bluetooth technology

MS-BTCVTCBL-700 Cable replacement Set for the MS-BTCVT-1 or the NS-ATV7 003-0; includes one 5-foot

retractable cable.

MS-DIS1710-0 Local Controller Display for FEC1610 and FEC2610 models

Technical Specifications

IOM1710 Input/Output Module

Product Code Number MS-IOM1710-0

Supply Voltage 20-30 VAC at 50 or 60 Hz, Class 2 or Safety Extra-Low Voltage (SELV)

Power Consumption 10 VA typical, 14 VA maximum plus all BO and Configurable Output loads

Ambient Conditions Operating: 0 to 50°C (32 to 122°F); 10 to 90% RH noncondensing

Storage: -40 to 70°C (-40 to 158°F); 10 to 90% RH noncondensing

Terminations Screw terminals, 3-Position Screw Terminal Pluggable Blocks, 4-Position Screw Terminal

Pluggable Blocks

Controller Addressing DIP switch set (4-127). Addresses 1-3, 128-255 are reserved.

Communications Bus BACnet® MS/TP; 3-wire FC Bus between the NAE/NCE and other devices. 4-wire SA Bus

when used as expansion to FEC.

Analog Input/Analog Output

Resolution and Accuracy

Mounting On flat surface with screws on three mounting clips or a single 35 mm DIN rail

Dimensions

(Height x Width x Depth)

Housing Plastic housing

Weight 0.31 kg (0.7 lb)

Compliance United States: UL Listed, File E107041, CCN PAZX, UL 916, Energy Management

Analog Input: 16-bit resolution

Analog Output: 16-bit resolution and ±200 mV in 0-10 VDC applications

108 x 127 x 58 mm (4-1/4 x 5 x 2-1/4 in.)

Plastic material: ABS + polycarbonate UL94 5VB

Protection: IP20 (IEC529)

Equipment; UL Listed, File S4977, UUKL 864 - 9th Edition, Smok e Control Equipment (MSIOMx710-0U and MS-IOU4710-0U models only)

FCC Compliant to CFR47, Part 15, Subpart B, Class A

Canada: UL Listed, File E107041, CCN PAZX7, CAN/CSA C22.2 No. 205, Signal

Equipment; Industry Canada Compliant, ICES-003

Europe: CE Mark, EMC Directive 89/336/EEC, in accordance with EN 61000-6-3 (2001)

Generic Emission Standard for Residential and Light Industry and EN 61000-6-2 (2001)

Generic Immunity Standard for Heavy Industrial Environment and the Low Voltage Directive

73/23/EEC in accordance with EN 60730-1 (1999) Automatic electrical controls for

household and similar use.

Australia and New Zealand: C-Tick Mark, Australia/NZ Emissions Compliant

BACnet International: BACnet Testing Laboratories™ (BTL) 135-2004 Listed BACnet

Application Specific Controller (B-ASC)

1

1. For more information, refer to the MS/TP Communications Bus Technical Bulletin (LIT-12011034).

The performance specifications are nominal and conform to acceptable industry standard. For application at conditions beyond these

specifications, consult the local Johnson Controls office. Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or

misuse of its products.

IOM1710 Input/Output Module Installation Instructions 7

Page 8

IOM1710 Input/Output Module Installation Instructions8

Metasys® and Johnson Controls® are registered trademarks of Johnson Controls, Inc.

All other marks herein are the marks of their respective owners. © 2010 Johnson Controls, Inc.

Building Efficiency

507 E. Michigan Street, Milwaukee, WI 53202

Published in U.S.A. www.johnsoncontrols.com

Loading...

Loading...