Page 1

Variable Speed Drives Series III

Quick Start Guide

Effective April 2018

New Information

CONTENTS

Step 1—Variable Speed Drives Series III Overview . . . . 1

Step 2—Keypad Operation Overview . . . . . . . . . . . . . . . 3

Step 3—Menu Navigation . . . . . . . . . . . . . . . . . . . . . . . . 6

Step 4—Startup Wizard . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Step 5—Standard Parameter List . . . . . . . . . . . . . . . . . . 10

Appendix A—Fault and Warning Codes . . . . . . . . . . . . . 40

Page 2

Page 3

Step 1—Variable Speed Drives Series III Overview

Step 1—Variable Speed Drives Series III Overview

This chapter describes the purpose and contents of this

manual, the receiving inspection recommendations and

the variable frequency drive catalog numbering system.

How to Use this Manual

The purpose of this manual is to provide you with information

necessary to install, set and customize parameters, start up,

troubleshoot and maintain the

variable frequency drive (VFD).

To provide for safe installation and operation of the

equipment, read the safety guidelines at the beginning of this

manual and follow the procedures outlined in the following

chapters before connecting power to the VFD. Keep this

operating manual handy and distribute to all users,

technicians and maintenance personnel for reference.

Receiving and Inspection

The Variable Speed Drives Series III has met a stringent

series of factory quality requirements before shipment. It is

possible that packaging or equipment damage may have

occurred during shipment. After receiving your VFD, please

check for the following:

Check to make sure that the package includes the Instruction

Leaflet, Quick Start Guide, and accessory packet. The

accessory packet includes:

●

Rubber grommets

●

Control cable grounding clamps

●

Additional grounding screw

Inspect the unit to ensure it was not damaged during

shipment.

Make sure that the part number indicated on the nameplate

corresponds with the catalog number on your order.

If shipping damage has occurred, please contact and file a

claim with the carrier involved immediately.

If the delivery does not correspond to your order, please

contact your sales representative.

Note: Do not destroy the packing. The template printed on

the protective cardboard can be used for marking the

mounting points of the VFD on the wall or in a cabinet.

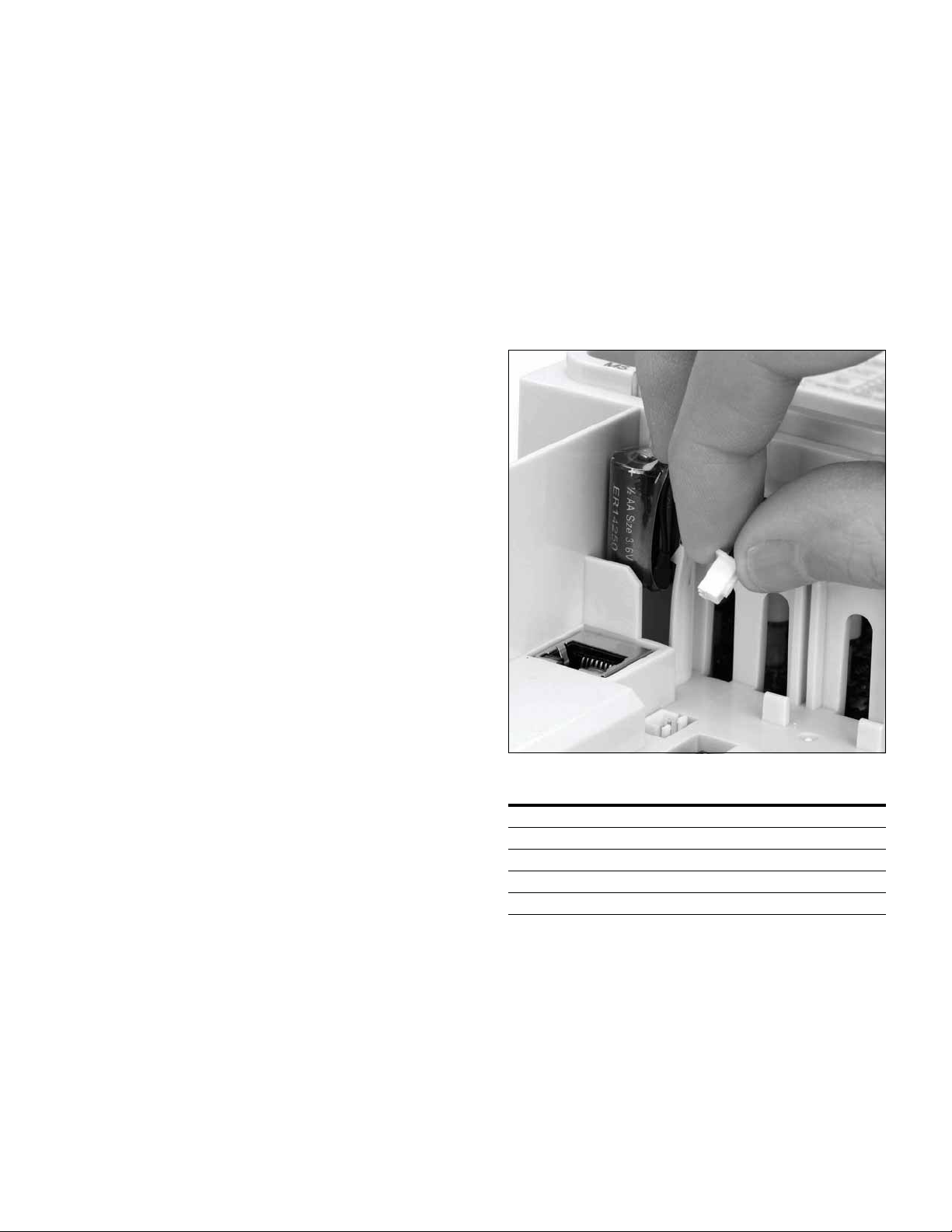

Real Time Clock Battery Activation

To activate the real time clock (RTC) functionality in the

VFD

, the RTC battery (already mounted in the drive) must

be connected to the control board.

Simply remove the primary drive cover, locate the RTC

battery directly below the keypad, and connect the white

2-wire connector to the receptacle on the control board.

Figure 1. RTC Battery Connection

Table 1. Common Abbreviations

Abbreviation Definition

CT Constant torque with high overload rating (150%)

VT Variable torque with low overload rating (110%)

I

H

I

L

VFD Variable Frequency Drive

High Overload (150%)

Low Overload (110%)

Variable Speed Drives Series III LIT-12012996—April 2018 www.johnsoncontrols.com 1

Page 4

Step 1—Variable Speed Drives Series III Overview

Programmable

Soft Key 2

Change Control

Place to Auto

Move Cursor

Right

Start/Hand Button

Stop/Off Button

Back/Reset

Button

Increase

Value Scroll

Menu Up

Programmable

Soft Key 1

Decrease Value

Scroll Menu Down

Move Cursor

Left

Enter Menu

Conrm Selection

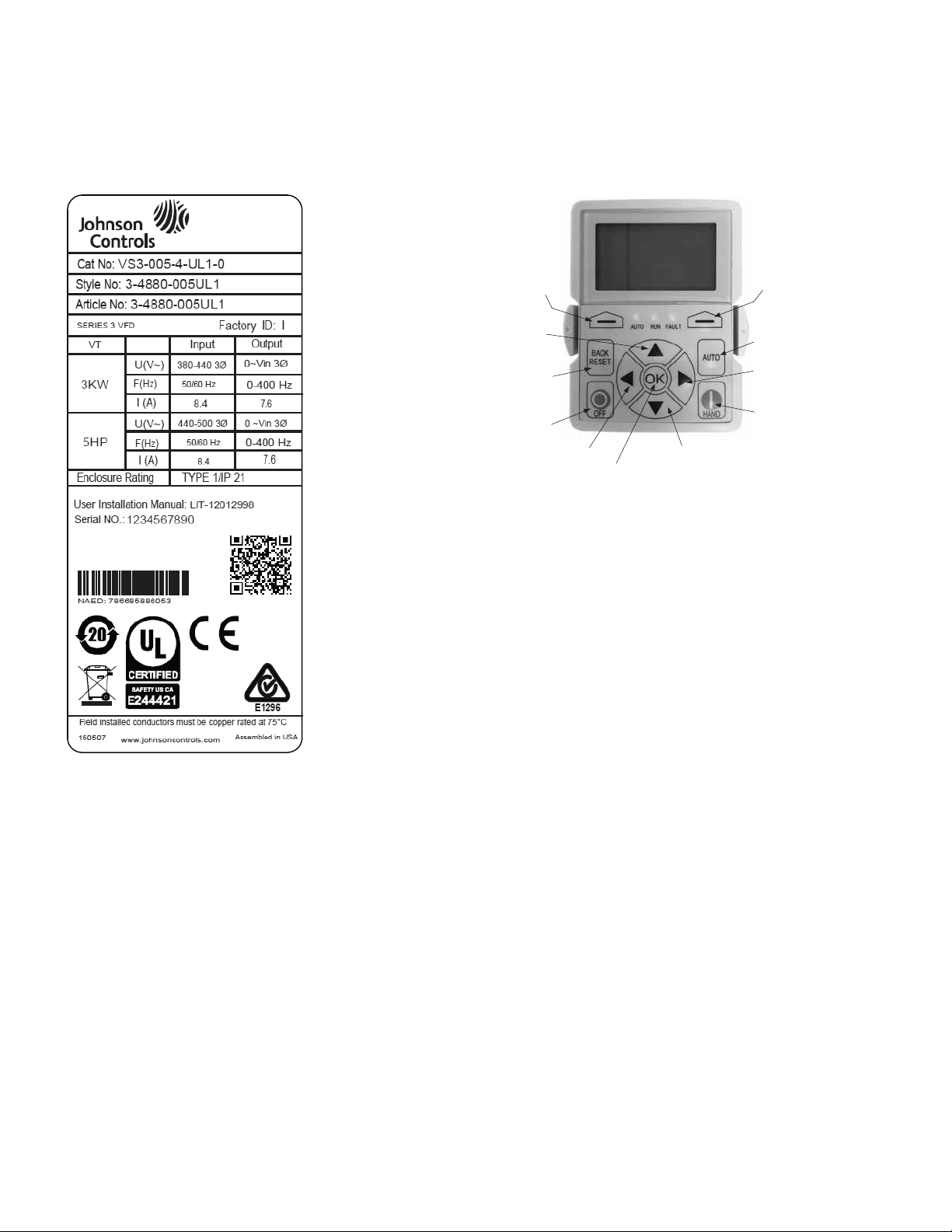

Rating Label

Figure 2. Rating Label

Keypad Overview

Figure 3. Keypad and Display

Carton Labels (U.S. and Europe)

Same as rating label shown above.

2 Variable Speed Drives Series III LIT-12012996—April 2018 www.johnsoncontrols.com

Page 5

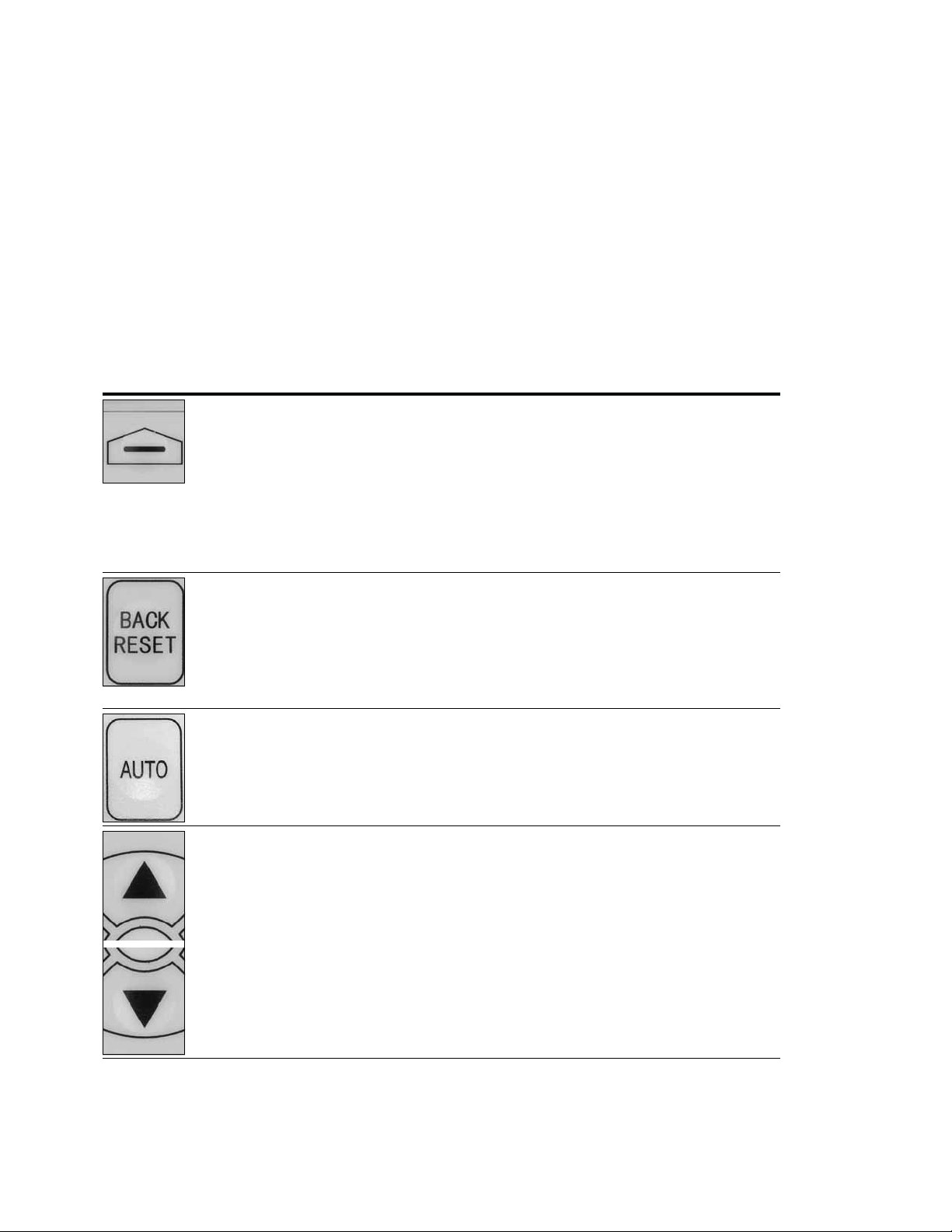

Step 2—Keypad Operation Overview

The keypad is the interface between the drive and the user.

It features an LCD display, 3 LED lights and 11 buttons. With

the control keypad, it is possible to control the speed of a

motor, to supervise the state of the equipment and to set the

frequency converter’s parameters. See Figure 3.

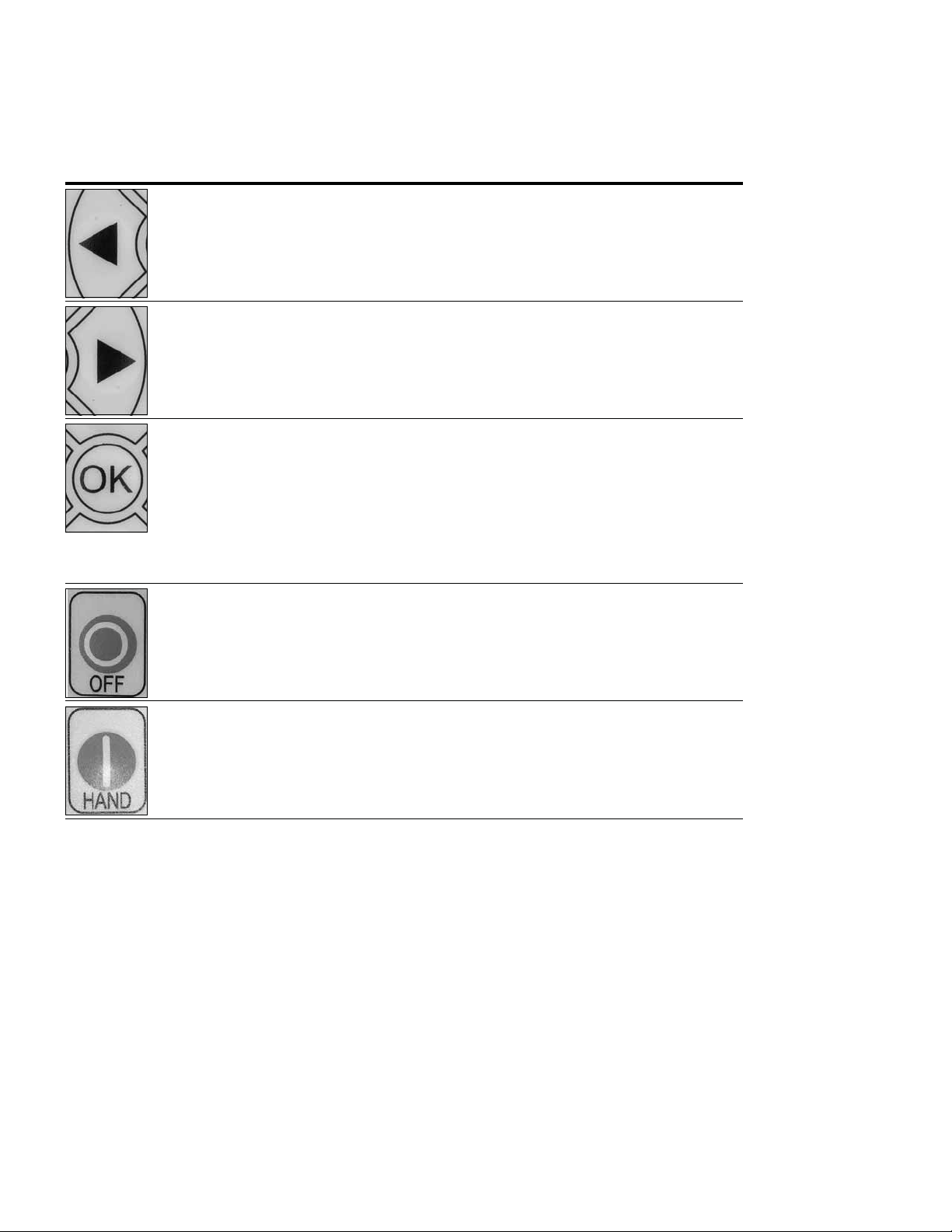

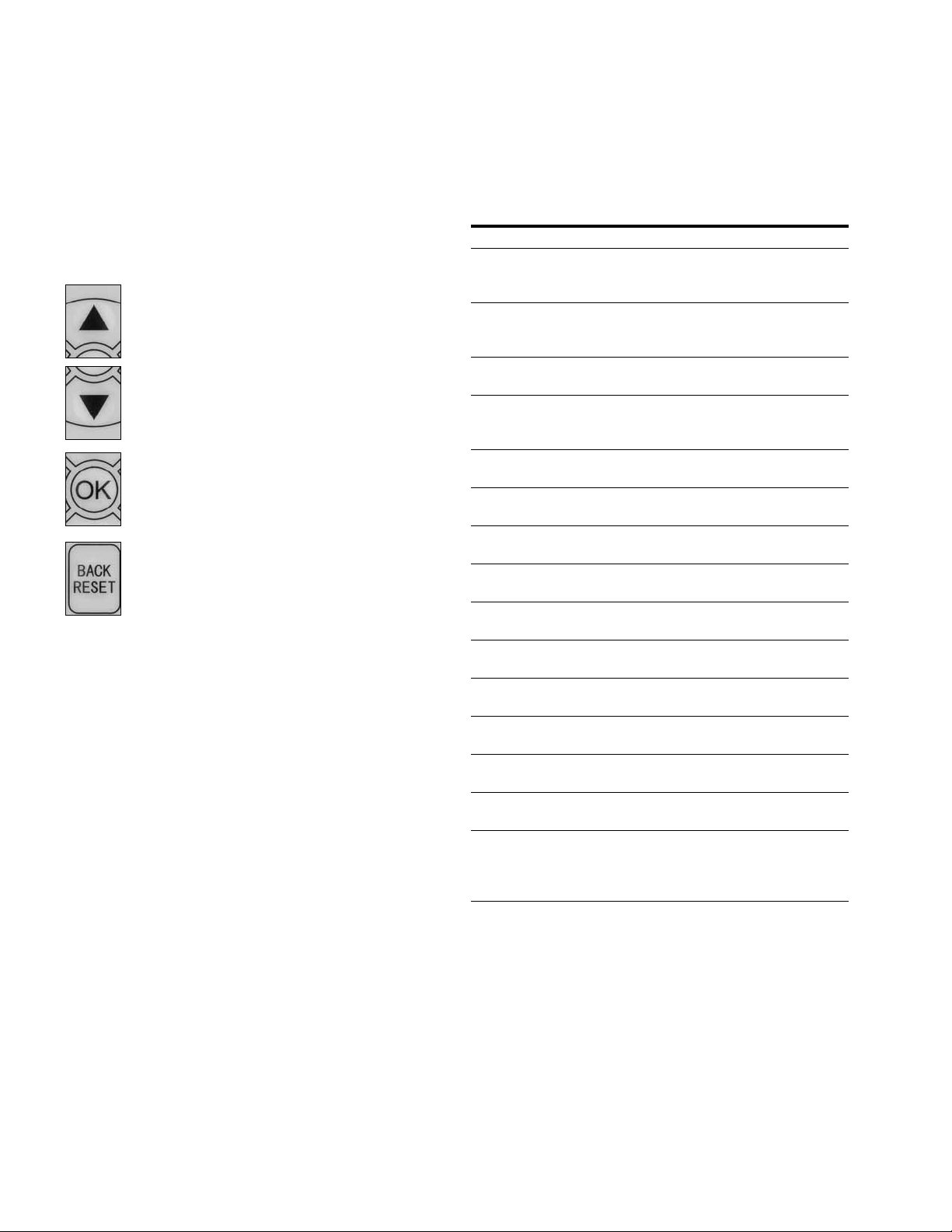

Keypad Buttons

Step 2—Keypad Operation Overview

Buttons Description

Table 2. Keypad Buttons

Icon Button Description

Soft Key 1,

Soft Key 2

Back/Reset Back/Reset:

Auto Auto:

Soft Key 1, Soft Key 2:

The functions of these two buttons shall be the following:

Forward/Reverse, this shall change motor’s run direction.

Reset, this shall ask MCU to reset after some parameters are modified.

• Menu, this shall return to main menu.

• Details, this shall display the details of the fault.

• Bypass, this shall make drive go into bypass.

• Jog, this shall activate jog.

• Favorite, this shall add this parameter to the Favorite menu.

• Delete, this shall delete this parameter from the Favorite menu.

This button has three integrated functions. The button operates as backward button during

normal mode.

In edit mode, it is used as cancel operate. It is also used to reset faults when faults occur.

• Backs up one step.

• Cancels Modify in edit mode.

• Resets the active faults (all the active faults shall be reset by pressing this button

more than 2s in any page).

This button switches the drive into the auto control place.

Up

Down

Up and Down Arrows:

• Move either up or down a menu list to select the desired menu item.

• Editing a parameter bit by bit, while the active digit is scrolled.

• Increase/decrease the reference value of the selected parameter.

• In parameter comparison mode, scroll through the parameters of which current value

is different from comparison parameter value.

• In parameter page when in read mode, move to the previous or next brother

parameter of this parameter.

Variable Speed Drives Series III LIT-12012996—April 2018 www.johnsoncontrols.com 3

Page 6

Step 2—Keypad Operation Over view

Table 2. Keypad Buttons, continued

Icon Button Description

Left Left Arrow:

• Navigation button, movement to left when editing a parameter digit by digit.

• Backs up one step.

Right Right Arrow:

• Enter parameter group mode.

• Enter parameter mode from group mode.

• Enter parameter whole edit mode when this parameter can be written.

• Enter parameter bit by bit edit mode from whole edit mode.

• Navigation button, movement to right when editing a parameter bit by bit.

OK OK:

• To clear all the Fault History if pressed for more than 5s (including 5s) in any page.

• This button is used in the parameter edit mode to save the parameter setting.

• To confirm the start-up list at the end of the Start-Up Wizard.

• To confirm the comparison item in parameters comparison mode.

The following is the same with Right key:

• Enter parameter whole edit mode when this parameter can be written.

• Enter parameter group mode.

• Enter parameter mode from group mode.

Stop/Off Stop/Off:

This button operates as the motor stop button for normal operation and places the drive in the

off control location. The Default is for this button to always be active. It can be changed in

Parameter P4.1.3 to only when “Keypad” is selected as the control source.

• Motor stop from the keypad.

• Transitions drive into an Off control location preventing start from any control source.

Start/Hand Start/Hand:

This button operates as motor start button for normal operation when the “Keypad” is

selected as the active control source, as well as selects the Hand control place location.

• When Keypad is the reference place after hitting the start button, it will jump directly

to the Keypad Ref Screen.

• Places drive into Hand Control place. Hitting start again if keypad is in the control

location will start the Drive.

4 Variable Speed Drives Series III LIT-12012996—April 2018 www.johnsoncontrols.com

Page 7

Step 2—Keypad Operation Overview

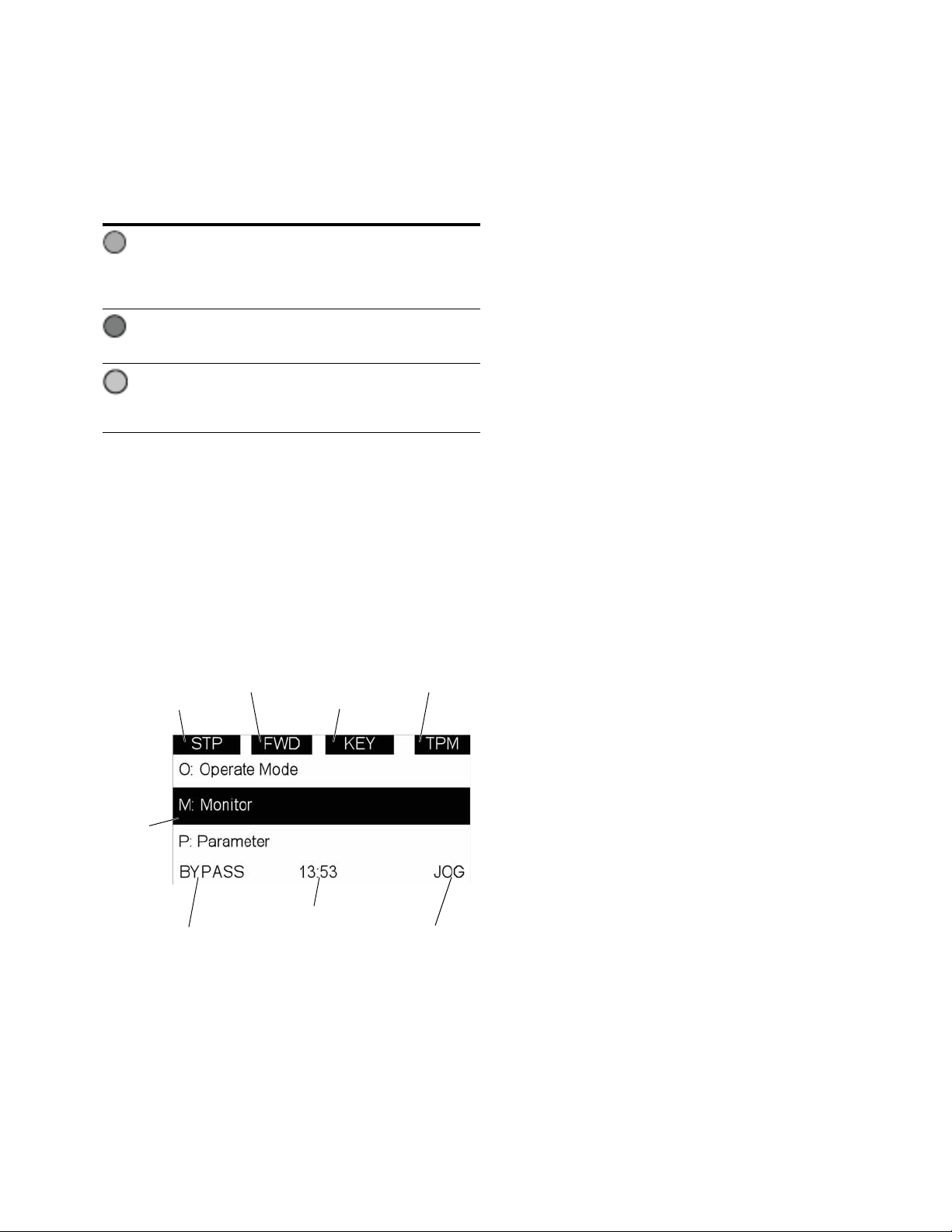

Drive Status

Direction Status

Control Place

Menu Location

Soft Key 2

Function Label

Soft Key 1

Function Label

Real Time Clock

(hh:mm)

Active

Selection

LED Lights

Table 3. LED State Indicators

Indicator Description

Run:

Indicates that the VFD is running and controlling the load in

Run

Drive or Bypass.

Blinks when a stop command has been given but the drive is

still ramping down.

Fault:

Turn on when there is one or more active drive fault(s).

Fault

Hand/OFF/Auto:

Hand: If the Hand or Off control place is selected,

Auto

turn off the light.

Auto: If the Auto control place is selected, turn on the light.

LCD Display

The keypad LCD indicates the status of the motor and the

drive and any faults in motor or drive functions. On the LCD,

the user sees information about the current location in the

menu structure and the item displayed.

Overview

Five lines shall be displayed in the screen. General view is as

following in Figure 4.

Figure 4. General View of LCD

The lines definition is as below:

The first line is State line, shows:

●

RUN / STP / NRD / FIM / TFM—If motor is running, the

run state shall display “RUN”, otherwise the state display

“STP”. “RUN” blinks when the stop command is sent but

the drive is decelerating. “NRD” is displayed if the drive is

not ready or does not have a signal. “FIM” is displayed to

indicate it is in Fire Mode and the drive is in a Run state.

“TFM” is displayed when in the Fire Mode Test Mode and

the drive is in a Run State.

●

FWD / REV / JOG—If the motor running the direction is

clockwise, it displays “FWD”, other wise displays “REV”

for counter clockwise. If “Jog” is displayed, it indicates

Jog mode is active.

●

KEY / I/O / BPS / RBP / BUS / OFF—If it is in bypass

currently, display “BPS”; when run command is given, it

will go to “RBP”; otherwise, if the current control source

is I/O terminal, display “I/O”. If it is keypad, then display

“KEY”; otherwise display “BUS.” When indicates “OFF”, it

indicates the drive will not accept a command from the

Hand or Auto Control place.

●

PAR / MON / FLT / OPE / QSW / FAV / TPM / BUx—

If the current page is parameter menu, display “PAR”;

If monitor menu, then display “MON”; If fault menu, then

display “FLT”; If operation menu, then display “OPE”;

If quick start wizard, then display “QSW”; If optional card

menu, then display “BOA”; If favorite menu, then display

“FAV”; If main menu, then display “TPM”. “BUx” indicates

the drive being a backup drive when in the redundant drive

system.

The second line is Code line, which shows the menu code.

The third line is Name line, which shows the menu name or

parameters name.

The fourth line is Value line, which shows the submenu

name or parameters value.

The fifth line is Soft key line, the functions of Soft key 1 and

Soft key 2 are changeable, and the real time is in the middle.

Variable Speed Drives Series III LIT-12012996—April 2018 www.johnsoncontrols.com 5

Page 8

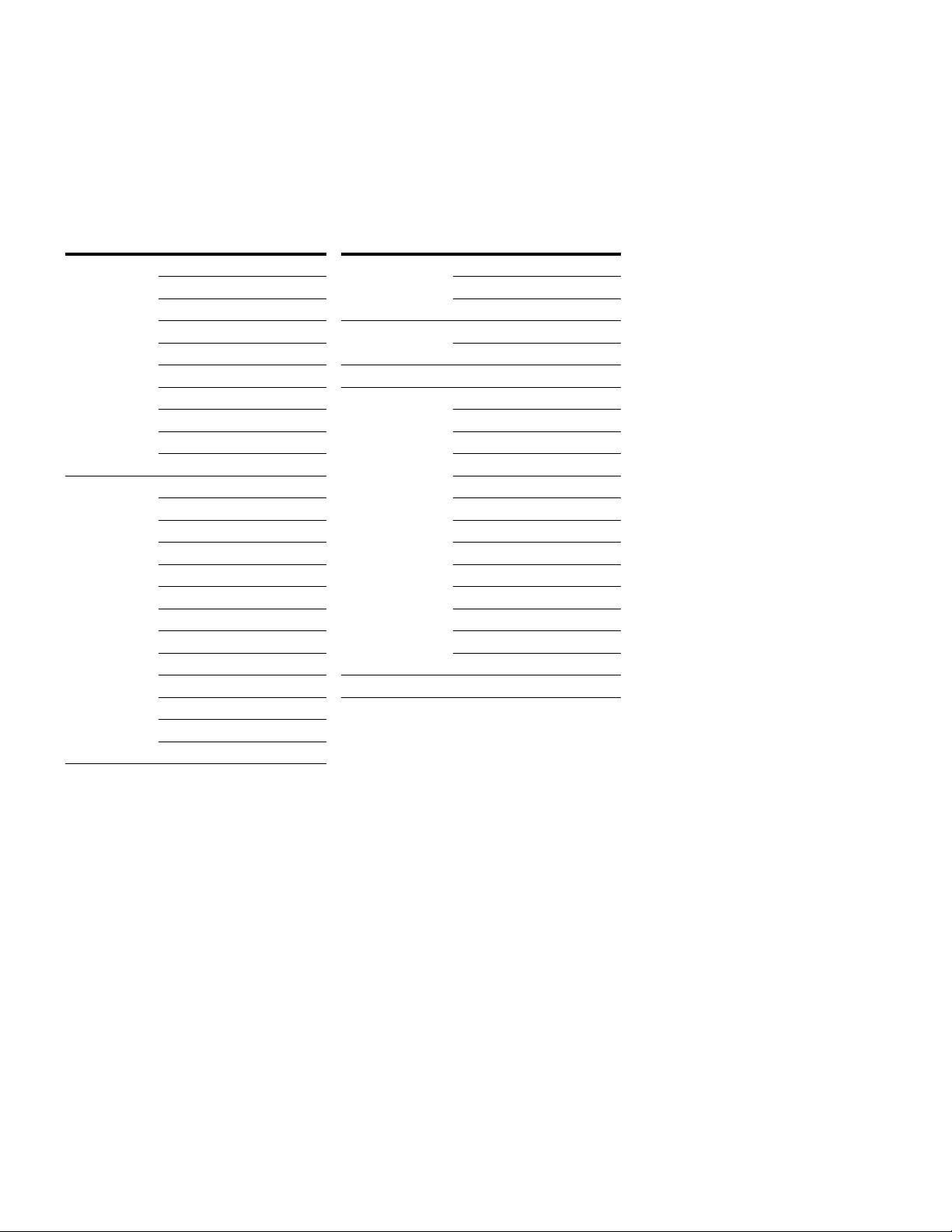

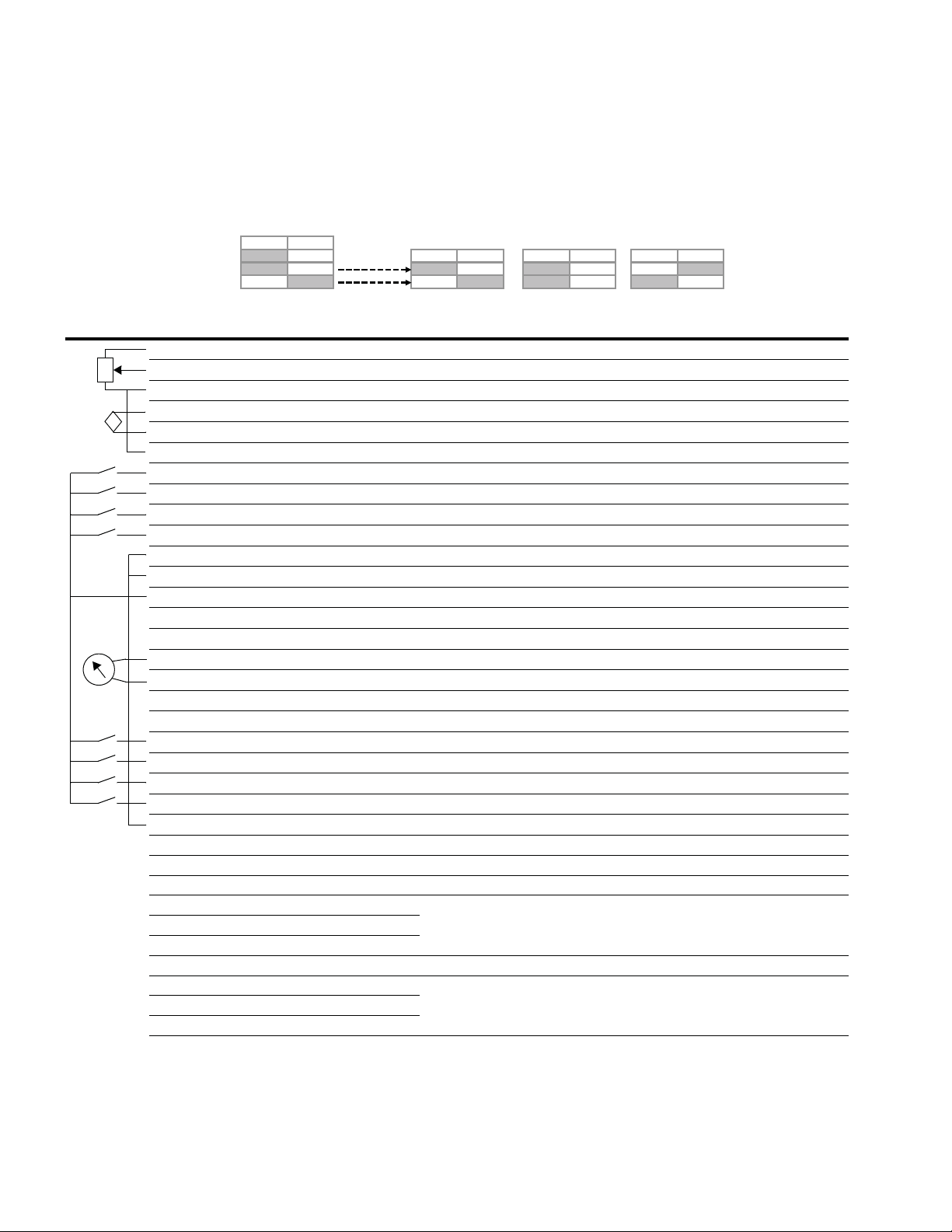

Step 3—Menu Navigation

Step 3—Menu Navigation

Menu Structure

Table 4. Keypad Menu

Item Description Item Description

Monitor M1—Basic Fault F1—Active Fault

M2—IO Status F2—History Fault

M3—Optional Boards F3—Fault Log

M4—Energy savings Option Boards B1—Slot A

M5—FB Monitor Menu B2—Slot B

M6—PID Monitor Favorite

M7—Timer/Interval Control Operate Mode O1—Output Frequency

M8—User Defined Output O2—Freq Reference

M9—MWH Monitor O3—Motor Speed

M10—Multi-Monitoring O4—Motor Current

Parameters P1—Basic Parameter O5—Motor Torque

P2—Inputs O6—Motor Power

P3—Outputs O7—Motor Voltage

P4—Drive Control O8—DC-link Voltage

P5—Motor Control O9—Unit Temperature

P6—Protections O10—Motor Temperature

P7—PID Controller 1 R11—Keypad Reference

P8—PID Controller 2 R12—PID1 Keypad Set Point 1

P9—Fire Mode R13—PID1 Keypad Set Point 2

P10—Bypass Startup Wizard S—Startup Wizard

P11—Real Time Clock

P12—Communication

P13—System

Note: Will vary depending on application selected.

6 Variable Speed Drives Series III LIT-12012996—April 2018 www.johnsoncontrols.com

Page 9

Menu Navigation

Back/left key Right/OK key

UP key

Down key

M – Monitor

P – Parameters

F – Fault

B – Optional Boards

T – Favorite

O – Operate Mode

…

…

…

M1 – Basic

M10 – Multi-Monitoring

P1 – Basic Parameters

P13 – System

F1 – Active Fault

F2 – History Fault

P1.1 – Min Frequency

P1.16 – Auto 2 Reference

M1.1

S – Startup Wizard

F3 – Fault Log

Output Frequency

0.00 Hz

P1.1

Min Frequency

0.00 Hz

This section provides basic instruction on navigating each

section in the menu structure.

Figure 5. Main Menu Navigation

Step 3—Menu Navigation

Variable Speed Drives Series III LIT-12012996—April 2018 www.johnsoncontrols.com 7

Page 10

Step 4—Startup Wizard

Step 4—Startup Wizard

Startup Wizard

In the Startup Wizard, you will be prompted for essential

information needed by the drive so that it can start

controlling your process. In the Wizard, you will need

the following keypad buttons:

Up/Down buttons.

Use these to change value.

OK button.

Confirm selection with this button, and enter into

next question.

Back/Reset button.

If this button was pressed at the first question,

the Startup Wizard will be cancelled.

Once you have connected power to your frequency

converter, and the Startup Wizard is enabled, follow

these instructions to easily set up your drive.

Table 5. Startup Wizard Instructions

Item Description

1 Startup Wizard Press OK?

2 Application 0 = Basic

1 = PID

2 = Advanced

3 Language 0 = English

1 = ѝ᮷

2 = Deutsch

4 Real Time Clock yy.mm.dd

hh:mm:ss

5 Daylight Saving 0 = Off

1 = EU

2 = US

6 Min Frequency Min: 0.00Hz

Max: Max Frequency

7 Max Frequency Min: Min Frequency

Max: 400.00Hz

8 Motor Nom Current Min: 0.1A

Max: 500.0A

9 Current Limit Min: Ih*1/10

Max: Ih*2

10 Motor Nom Speed Min: Ih*1/10

Max: Ih*2

11 Motor PF Min: 0.30

Max: 1.0

12 Motor Nom Voltage Min: 180V

Max: 690V

13 Motor Nom Frequency Min: 30.00 Hz

Max: 400.00 Hz

14 Accel Time 1 Min: 0.1 sec

Max:3000.0 sec

15 Decel Time 1 Min: 0.1 sec

Max:3000.0 sec

16 Hand Control Place 0 = Keypad

1 = I/O Terminal Start 1

2 = I/O Terminal Start 2

3 = Fieldbus

8 Variable Speed Drives Series III LIT-12012996—April 2018 www.johnsoncontrols.com

Page 11

Table 5. Startup Wizard Instructions, continued

Item Description

17 Hand Reference 0 = AI1

1 = AI2

2 = Slot A: AI1

3 = Slot B: AI1

4 = AI1 Joystick

5 = AI2 Joystick

6 = Keypad

7 = Fieldbus

9 = Max Frequency

10 = AI1 + AI2

11 = AI1 –AI2

12 = AI2 –AI1

13 = AI1 * AI2

14 = AI1 or AI2

15 = Min(AI1,AI2)

16 = Max(AI1,AI2)

17 = PID1 Control Output

18 = PID2 Control Output

18 Auto 1 Control Place 0 = I/O Terminal Start 1

1 = Fieldbus

2 = I/O Terminal Start 2

3 = Keypad

19 Auto 1 Control Reference 0 = AI1

1 = AI2

2 = Slot A: AI1

3 = Slot B: AI1

4 = AI1 Joystick

5 = AI2 Joystick

6 = Keypad

7 = Fieldbus

9 = Max Frequency

10 = AI1 + AI2

11 = AI1 –AI2

12 = AI2 –AI1

13 = AI1 * AI2

14 = AI1 or AI2

15 = Min(AI1,AI2)

16 = Max(AI1,AI2)

17 = PID1 Control Output

18 = PID2 Control Output

20 Bypass Enabled 0 = Disabled

1 = Enabled

21 Application Mini-Wizard Press OK?

Step 4—Startup Wizard

Now the Startup Wizard is done. It won’t show again when

next power up. If you want to reset it, please set the Startup

Wizard (P13.1.17) or select it from the main menu screen to

enable and cycle the power to the drive.

Variable Speed Drives Series III LIT-12012996—April 2018 www.johnsoncontrols.com 9

Page 12

Step 5—Standard Parameter List

Step 5—Standard Parameter List

Introduction

The Basic Application is designed for preloaded application

sets for use with HVAC specific terminology and functions.

It has the patent Active Energy Control algorithm that will

improve your efficiency as well as minimize losses in your

motor throughout the defined speed range. It provides the

ability for the user to define its Hand and Auto control and

reference signals with the standard Off condition as well.

In addition there is the ability to scale the analog input and

output signals to be read based off the desired motor

response. There are also 8 digital inputs, 3 relay outputs, and

1 digital output that can be programmed to allow for control

schemes that require the drive to have certain functions. It

provides full customization on the motor control sequence

with the ability to be in frequency or speed control mode, and

tuning of the V/Hz curve can be selected. Drive/Motor

protections can be customized to defined actions for added

user control. Below is a list of other features that are

available in the Basic Application.

Basic Application includes functions:

●

Bypass control

●

Fire mode

●

Pre heat/cold weather mode

●

Hand/Off/Auto in individual button for easy change of

control mode

●

Programmable protections

●

Programmable digital/analog input/output function

●

Programmable start/stop signal logic

●

Voltage and current limiters

●

Energy Savings Calculator

●

Two independent set of Acceleration/Deceleration ramps

●

Skip frequency

●

Start source (Local/Remote control function)

●

Reference source

●

Flying start

●

Volts per Hertz control programmable

●

Real time clock—RTC time display

●

Auto restart on fault to drive or bypass

●

Programmable switching frequency

●

Multi-preset speeds

●

Fan control

●

DC brake

I/O Controls

“Terminal To Function” (TTF) Programming

The design behind the programming of the digital inputs in

the DH1 drive is to use “Terminal To Function”

programming, which is composed of multiple functions that

get assigned a digital input to that function. The parameters

in the drive are set up with specific functions and by defining

the digital input and slot in some cases, depending on which

options are available. For use of the drives control board

inputs, they will be referred to as DigIN:1 through DigIN:8.

When additional option cards are used, they will be defined

as DigIN:X:IOY:Z. The X indicates the slot that the card is

being installed in, which will be either A or B. The IOY

determines the type of card it is, which would be IO1 or IO5.

The Z indicates which input is being used on that available

option card.

“Function To Terminal” (FTT) Programming

The design behind the programming of the relay outputs and

digital output in the DH1 drive is to use “Function To

Terminal” programming. It is composed of a terminal, be it a

relay output or a digital output, that is assigned a parameter.

Within that parameter, it has different functions that can be

set.

The parameters of the Standard Application are explained in

Appendix A of application manual.

The explanations are arranged according to the parameter

number. For the DI function, we use Terminal programming

method to function (TTF), where there is a fixed input that

gets programmed to a list of functions. This allows for

multiple inputs to be used for different functions. Connecting

a certain input with a certain parameter function is done by

give a parameter an appropriate value. The value is formed

by the location of the input, either being on the standard

control board or an external option board and the slot it is

located in.

10 Variable Speed Drives Series III LIT-12012996—April 2018 www.johnsoncontrols.com

Page 13

Step 5—Standard Parameter List

Force Open/Force Close Selection

The Force Open Selection would make the selected function

always off. Essentially this is a virtual switch that is always

open. The Force Close Selection would make the selected

function always on. Essentially this is a virtual switch that is

always closed. These options are assigned to a function if we

want to force a state without using a hardware input.

The standard options are DigIn: Force Open—indication that

the parameter function is always going to be open, that being

said depending on the logic of the function this could mean

the function is always not active or always active. When the

selection of a function is DigIN: Force Closed—indication that

the parameter function is always going to be closed, that

being said again depending on the location of the function

this could mean the function is always active or not active.

Examples of these options would be ID190 Start Signal 1,

when set to “Force Open” and the drive is

looking at I/O terminals for control, in this case the drive

would never start since this Function is always Open. If this

function is set to “Force closed” the drive would always be

in a start mode when in that control location.

Example:

If we set Run Enable to Force Closed the drive is always

enabled. If we set the same function to Force Open the drive

would never be Enabled. If a Digital input is to be used to

activate this Run Enable the function should be assigned to

a hardware input (See below for DIGIN Selections).

DIGIN Selection

This allows Assignment of a hardware digital input to a

function, this is set in a format of DigIN:X where X is one

of the 8 Digital inputs on the Main control board.

Example:

If we set Run Enable to DigIN:6 the drive will be enabled

when digital input 6 (Terminal 8) is closed, and would not

be enabled when digital input 6 (Terminal 8) is open.

Option Board digIN Selection

This allows Assignment of a hardware digital input on an

option card to a function, this is set in a format of DigIN:

Y:IO1:X where Y is the slot the option card is inserted on the

Main control board and X is the Input on the Board and IO1 is

the type of option board used.

Example:

If we set Run Enable to DigIN:A:IO5:6 the drive will be

enabled when digital input 6 is closed on the IO5 option card

which is inserted in Slot A, and would not be enabled when

digital input 6 on the option card is open.

Timer Channel Selection

A Time Channel is a virtual path to link the digital output of a

timer function to a digital input function. To utilize this feature

a timer or interval would need to be assigned to a time

channel 1 through 3, and the input function to be controlled

would need to be assigned to the same time channel.

Example:

If we set Run Enable to DigIN:TimeChannel1 the drive will be

enabled when the timer assigned to Time Channel 1 is active

or High, and would not be enabled when the Time Channel is

inactive or Low.

Table 6. Drive Communication Ports

Port Communication

RJ45 Keypad Port

Upload/Download Parameters USB to RJ45

Remote Mount Keypad Ethernet

Upgrade Drive Firmware USB to RJ45

RJ45 Ethernet Port

Upload/Download Parameters Ethernet

BACnet/IP Communications Ethernet

Modbus TCP Communications Ethernet

RS-485 Serial Port

Upload/Download Parameters

Upgrade Drive Firmware Two-Wire Twisted Pair

Modbus RTU Communications Two-Wire Twisted Pair

BACnet MS/TP Communications Two-Wire Twisted Pair

SA Bus Two-Wire Twisted Pair

Note

1

Shielded wire recommended.

1

Variable Speed Drives Series III LIT-12012996—April 2018 www.johnsoncontrols.com 11

Page 14

Step 5—Standard Parameter List

Control I/O Configuration

●

Run 240 Vac and 24 Vdc control wiring in separate conduit

●

Communication wire to be shielded

Table 7. Analog Signals/Galaxy I/O Interface

External

Wiring

1

Signal

Pin

Name Signal

1 +10V Ref. Output Voltage — 10 Vdc Supply Source

Res

2 AI1+

2

Analog Input 1 0–10V Voltage Speed Reference (Programmable to 4 mA to 20 mA)

3 AI1– Analog Input 1 Ground — Analog Input 1 Common (Ground)

4 AI2+

i

5 AI2– Analog Input 2 Ground — Analog Input 2 Common (Ground)

2

Analog Input 2 4 mA to 20 mA Current Speed Reference (Programmable to 0–10V)

6 GND I/O Signal Ground — I/O Ground for Reference and Control

7 DIN5 Digital Input 5 Preset Speed B0 Sets frequency output to Preset Speed 1

8 DIN6 Digital Input 6 Fire Mode Enables drive into Fire Mode

9 DIN7 Digital Input 7 Bypass Start (TI–) Enables drive into Bypass mode waiting for drive start

10 DIN8 Digital Input 8 Force Auto (TI+) Input forces drive into Auto Control place

11 CMB DI5 to DI8 Common Grounded Allows source input

12 GND I/O Signal Ground — I/O Ground for Reference and Control

13 24V +24 Vdc Output — Control voltage output (100 mA max.)

14 DO1 Digital Output 1 Ready Shows the drive is ready to run

15 24Vo +24 Vdc Output — Control voltage output (100 mA max.)

16 GND I/O Signal Ground — I/O Ground for Reference and Control

17 AO1+ Analog Output 1 Output Frequency Shows Output frequency to motor 0–60 Hz (4 mA to 20 mA)

18 AO2+ Analog Output 2 Motor Current Shows Motor current of motor 0–FLA (4 mA to 20 mA)

19 24Vi +24 Vdc Input — External control voltage input

20 DIN1 Digital Input 1 Run Forward Input starts drive in forward direction (start enable)

21 DIN2 Digital Input 2 Run Reverse Input starts drive in reverse direction (start enable)

22 DIN3 Digital Input 3 External Fault Input causes drive to fault

23 DIN4 Digital Input 4 Fault Reset Input resets active faults

24 CMA DI1 to DI4 Common Grounded Allows source input

25 A/+ RS-485 Signal A — Fieldbus Communication (Modbus, BACnet, SA Bus)

26 B/– RS-485 Signal B — Fieldbus Communication (Modbus, BACnet, SA Bus)

27 R3NO Relay 3 Normally Open Fault Relay output 3 shows VFD is Faulted

28 R1NC Relay 1 Normally Closed Bypass Run Relay output 1 shows VFD is in a bypass run state

29 R1CM Relay 1 Common

30 R1NO Relay 1 Normally Open

31 R3CM Relay 3 Common Fault Relay output 3 shows VFD is Faulted

32 R2NC Relay 2 Normally Closed Run Relay output 2 shows VFD is in a drive run state

33 R2CM Relay 2 Common

34 R2NO Relay 2 Normally Open

Notes

1

The above wiring demonstrates a SINK configuration. It is important that CMA and CMB are wired to ground (as shown by dashed line).

If a SOURCE configuration is desired, wire 24 V to CMA and CMB and close the inputs to ground. When using the +10 V for AI1, it is

important to wire AI1—ground (as shown by dashed line). If using +10 V for AI1 or AI2, terminals 3, 5, and 6 need to be jumpered together.

2

AI1+ and AI2+ support 10K potentiometer.

Default

Setting Description

12 Variable Speed Drives Series III LIT-12012996—April 2018 www.johnsoncontrols.com

Page 15

Step 5—Standard Parameter List

Basic Application—Parameters List

On the next pages you will find the lists of parameters within the respective parameter

groups. The parameter descriptions are given in Appendix A of application manual. The

descriptions are arranged according to the parameter number.

Column explanations:

Code = Location indication on the keypad; shows the operator the present parameter number

Parameter = Name of parameter

Min = Minimum value of parameter

Max = Maximum value of parameter

Unit = Unit of parameter value; given if available

Default = Value preset by factory

ID = ID number of the parameter

Monitor

Table 8. Basic—M1

Code Parameter Min. Max. Unit Default ID Note

M1.1 Output Frequency Hz 1

M1.2 Freq Reference Hz 24

M1.3 Motor Speed rpm 2

M1.4 Motor Current A 3

M1.5 Motor Torque % 4

M1.6 Motor Power % 5

M1.7 Motor Voltage V 6

M1.8 DC-link Voltage V 7

M1.9 Unit Temperature °C 8

M1.10 Motor Temperature % 9

M1.11 Latest Fault Code 28

M1.12 Instant Motor Power kW 1686

M1.13 RTC Battery Status 583 0 = Not Installed

1 = Installed

2 = Change Battery

3 = OverVoltage

Notes

1

Parameter value can only be changed after the drive has stopped.

2

Parameter value will be set to be default when changing macros.

Variable Speed Drives Series III LIT-12012996—April 2018 www.johnsoncontrols.com 13

3

Input function is Level sensed.

4

Input function is Edge sensed.

5

Input function is Edge sensed when using StartP/StopP start logic.

Page 16

Step 5—Standard Parameter List

Table 9. IO Status—M2

Code Parameter Min. Max. Unit Default ID Note

M2.1 Analog Input 1 Varies 10

M2.2 Analog Input 2 Varies 11

M2.3 Analog Output 1 Varies 25

M2.4 Analog Output 2 Varies 575

M2.5 DI1, DI2, DI3 12

M2.6 DI4, DI5, DI6 13

M2.7 DI7, DI8 576

M2.8 DO1,Virtual RO1,Virtual RO2 14

M2.9 RO1, RO2, RO3 557

Table 10. Optional Boards—M3

Code Parameter Min. Max. Unit Default ID Note

M3.1 PT100 Temperature °C 1000.0 27

Table 11. Energy Savings—M4

Code Parameter Min. Max. Unit Default ID Note

2

M4.1

Energy Savings Varies 0.000 2120

Table 12. FB Monitor Menu—M5

Code Parameter Min. Max. Unit Default ID Note

M5.1 Control Board DIDO Status 2209 Bit 0 = DIN1 Status

Bit 1 = DIN2 Status

Bit 2 = DIN3 Status

Bit 3 = DIN4 Status

Bit 4 = DIN5 Status

Bit 5 = DIN6 Status

Bit 6 = DIN7 Status

Bit 7 = DIN8 Status

Bit 8 = DO1 Status

Bit 9 = RO1 Status

Bit 10 = RO2 Status

Bit 11 = RO3 Status

Bit 12 = Slot A with Board

Bit 13 = Slot B with Board

Bit 14–15 = Not used

3

Notes

1

Parameter value can only be changed after the drive has stopped.

2

Parameter value will be set to be default when changing macros.

14 Variable Speed Drives Series III LIT-12012996—April 2018 www.johnsoncontrols.com

Input function is Level sensed.

4

Input function is Edge sensed.

5

Input function is Edge sensed when using StartP/StopP start logic.

Page 17

Step 5—Standard Parameter List

Table 11. FB Monitor Menu—M5, continued

Code Parameter Min. Max. Unit Default ID Note

M5.2 SlotA DIDO Status 2210 Bit 0 = IO1_DIN1 Status

M5.3 SlotB DIDO Status 2211 Bit 0 = IO1_DIN1 Status

M5.4 Application Status Word 29 Bit 0 = MC Ready

Bit 1 = IO1_DIN2 Status

Bit 2 = IO1_DIN3 Status

Bit 3 = IO1_DO1 Status

Bit 4 = IO1_DO2 Status

Bit 5 = IO1_DO3 Status

Bite 6 = IO3_RO1 Status

Bit 7 = IO3_RO2 Status

Bit 8 = IO3_RO3 Status

Bit 9 = IO5_AC1 Status

Bit 10 = IO5_AC2 Status

Bit 11 = IO5_AC3 Status

Bit 12 = IO5_AC4 Status

Bit 13 = IO5_AC5 Status

Bit 14 = IO5_AC6 Status

Bit 15 = Not Used

Bit 1 = IO1_DIN2 Status

Bit 2 = IO1_DIN3 Status

Bit 3 = IO1_DO1 Status

Bit 4 = IO1_DO2 Status

Bit 5 = IO1_DO3 Status

Bite 6 = IO3_RO1 Status

Bit 7 = IO3_RO2 Status

Bit 8 = IO3_RO3 Status

Bit 9 = IO5_AC1 Status

Bit 10 = IO5_AC2 Status

Bit 11 = IO5_AC3 Status

Bit 12 = IO5_AC4 Status

Bit 13 = IO5_AC5 Status

Bit 14 = IO5_AC6 Status

Bit 15 = Not Used

Bit 1 = MC_Run

Bit 2 = MC_Fault

Bit 3 = FB_Ref_Active

Bit 4 = MC_Stopping

Bit 5 = MC_Reverse

Bit 6 = MC_Warning/AR-Fault

Bit 7 = MC_ZeroSpeed

Bit 8 = I/O Control Indicate

Bit 9 = Panel Control Indicator

Bit 10 = Panel Fieldbus Indicator

Bit 11 = MC_DC_Brake

Bit 12 = RunEnable

Bit 13 = Run Bypass

Bit 14 = Ext Brake Control

Bit 15 = Bypass Mode

Notes

1

Parameter value can only be changed after the drive has stopped.

2

Parameter value will be set to be default when changing macros.

Variable Speed Drives Series III LIT-12012996—April 2018 www.johnsoncontrols.com 15

3

Input function is Level sensed.

4

Input function is Edge sensed.

5

Input function is Edge sensed when using StartP/StopP start logic.

Page 18

Step 5—Standard Parameter List

Table 11. FB Monitor Menu—M5, continued

Code Parameter Min. Max. Unit Default ID Note

M5.5 Standard Status Word 2414 Bit 0 = See PAR ID 2415

Table 13. User Defined Output—M8

Code Parameter Min. Max. Unit Default ID Note

M8.1 Output Varies 2445

M8.2 Reference Varies 2447

(default = Ready)

Bit 1 = See PAR ID 2416

(default = Run)

Bit 2 = See PAR ID 2417

(default = Fault)

Bit 3 = See PAR ID 2418

(default = Fault Invert)

Bit 4 = See PAR ID 2419

(default = Warning)

Bit 5 = See PAR ID 2420

(default = Reversed)

Bit 6 = See PAR ID 2421

(default = At Speed)

Bit 7 = See PAR ID 2422

(default = Zero Frequency)

Bit 8–15 = Not Used

Table 14. MWH Monitor—M9

Code Parameter Min. Max. Unit Default ID Note

M9.1 Total MWh Count Mwh 601

M9.2 Total Power Day Count 603

M9.3 Total Power Hr Count 606

M9.4 Trip MWh Count Mwh 604

M9.5 Trip Power Day Count 636

M9.6 Trip Power Hr Count 637

Table 15. Multi-Monitoring—M10

Code Parameter Min. Max. Unit Default ID Note

M10.1 Multi-Monitoring 0, 1, 2 30

3

Notes

1

Parameter value can only be changed after the drive has stopped.

2

Parameter value will be set to be default when changing macros.

16 Variable Speed Drives Series III LIT-12012996—April 2018 www.johnsoncontrols.com

Input function is Level sensed.

4

Input function is Edge sensed.

5

Input function is Edge sensed when using StartP/StopP start logic.

Page 19

Step 5—Standard Parameter List

Table 16. Operate Mode—O

Code Parameter Min. Max. Unit Default ID Note

O1 Output Frequency Hz 0 1

O2 Freq Reference Hz 0 24

O3 Motor Speed rpm 0 2

O4 Motor Current A 0 3

O5 Motor Torque % 0 4

O6 Motor Power % 0 5

O7 Motor Voltage V 0 6

O8 DC-link Voltage V 0 7

O9 Unit Temperature °C 0 8

O10 Motor Temperature % 0 9

2

R11

Parameters

Keypad Reference PAR ID 101 PAR ID 102 Hz 0 141

Table 17. Basic Parameters—P1

Code Parameter Min. Max. Unit Default ID Note

12

P1.1

P1.2

P1.3

P1.4

P1.5

P1.6

P1.7

P1.8

P1.9

P1.10

12

2

2

1

1

1

1

1

Min Frequency 0.00 See Par ID 102 Hz 0.00 101

Max Frequency See Par ID 101 400.00 Hz Varies 102

Accel Time 1 0.1 3000.0 s 20.0 103

Decel Time 1 0.1 3000.0 s 20.0 104

Motor Nom Current DriveNomCurr

CT*1/10

DriveNomCurr

CT*2

A DriveNomCurrCT 486

Motor Nom Speed 300 20000 rpm Varies 489

Motor PF 0.30 1.00 0.85 490

Motor Nom Voltage 180 690 V Varies 487

Motor Nom Frequency 8.00 400.00 Hz Varies 488

12

HOA Source 0 2465 0 = I/O Terminal/Keypad/Fieldbus

1 = Keypad

2 = IO Terminal

3 = Fieldbus

2

P1.11

Hand Control Place 0 1695 0 = Keypad

1 = I/O Terminal Start 1

2 = I/O Terminal Start 2

3 = Fieldbus

Notes

1

Parameter value can only be changed after the drive has stopped.

2

Parameter value will be set to be default when changing macros.

Variable Speed Drives Series III LIT-12012996—April 2018 www.johnsoncontrols.com 17

3

Input function is Level sensed.

4

Input function is Edge sensed.

5

Input function is Edge sensed when using StartP/StopP start logic.

Page 20

Step 5—Standard Parameter List

Table 17. Basic Parameters—P1, continued

Code Parameter Min. Max. Unit Default ID Note

12

P1.12

P1.13

P1.14

P1.15

P1.16

Hand Reference 6 136 0 = AI1

1 = AI2

2 = Slot A: AI1

3 = Slot B: AI1

6 = Keypad

7 = Fieldbus Ref

9 = Max Frequency

10 = AI1 + AI2

11 = AI1 - AI2

12 = AI2 - AI1

13 = AI1 * AI2

14 = AI1 or AI2

15 = MIN(AI1,AI2)

16 = MAX(AI1,AI2)

2

Auto 1 Control Place 0 135 0 = I/O Terminal Start 1

1 = Fieldbus

2 = I/O Terminal Start 2

3 = Keypad

12

Auto 1 Reference 1 137 See Par ID 136

2

Auto 2 Control Place 1 138 See Par ID 135

12

Auto 2 Reference 7 139 See Par ID 136

Inputs

Table 18. Basic Setting—P2.1

Code Parameter Min. Max. Unit Default ID Note

2

P2.1.4

P2.1.5

AI Ref Scale Min Value 0.00 See Par ID 145 Hz 0.00 144

2

AI Ref Scale Max Value See Par ID 144 400.00 Hz 0.00 145

Table 19. Digital Input—P2.2

Code Parameter Min. Max. Unit Default ID Note

12

P2.2.1

IO Terminal 1 Start Stop

Logic

0 143 0 = Forward - Reverse

1 = Start - Reverse

2 = Start - Enable

3 = Start Pulse - Stop Pulse

3

Notes

1

Parameter value can only be changed after the drive has stopped.

2

Parameter value will be set to be default when changing macros.

18 Variable Speed Drives Series III LIT-12012996—April 2018 www.johnsoncontrols.com

Input function is Level sensed.

4

Input function is Edge sensed.

5

Input function is Edge sensed when using StartP/StopP start logic.

Page 21

Step 5—Standard Parameter List

Table 18. Digital Input—P2.2, continued

Code Parameter Min. Max. Unit Default ID Note

25

P2.2.2

P2.2.3

P2.2.4

P2.2.5

P2.2.6

P2.2.7

P2.2.8

P2.2.9

P2.2.10

P2.2.11

P2.2.12

IO Terminal 1 Start Signal 1 2 190 0 = DigIN:NormallyOpen

1 = DigIN:NormallyClose

2 = DigIN: 1

3 = DigIN: 2

4 = DigIN: 3

5 = DigIN: 4

6 = DigIN: 5

7 = DigIN: 6

8 = DigIN: 7

9 = DigIN: 8

10 = DigIN: A: IO1: 1

11 = DigIN: A: IO1: 2

12 = DigIN: A: IO1: 3

13 = DigIN: A: IO5: 1

14 = DigIN: A: IO5: 2

15 = DigIN: A: IO5: 3

16 = DigIN: A: IO5: 4

17 = DigIN: A: IO5: 5

18 = DigIN: A: IO5: 6

19 = DigIN: B: IO1: 1

20 = DigIN: B: IO1: 2

21 = DigIN: B: IO1: 3

22 = DigIN: B: IO5: 1

23 = DigIN: B: IO5: 2

24 = DigIN: B: IO5: 3

25 = DigIN: B: IO5: 4

26 = DigIN: B: IO5: 5

27 = DigIN: B: IO5: 6

31 = RO1 Function

32 = RO2 Function

33 = RO3 Function

34 = Virtual RO1 Function

35 = Virtual RO2 Function

25

IO Terminal 1 Start Signal 2 3 191 See Par ID 190

1 2

IO Terminal 2 Start Stop

0 2206 See Par ID 143

Logic

25

IO Terminal 2 Start Signal 1 2 2207 See Par ID 190

25

IO Terminal 2 Start Signal 2 3 2208 See Par ID 190

12

Thermistor Input Select 0 881 0 = Digital Input

1 = Thermistor Input

23

Reverse 0 198 See Par ID 190

23

Ext. Fault 1 NO 4 192 See Par ID 190

23

Ext. Fault 1 NC 1 193 See Par ID 190

2

Ext. Fault 1 Text 0 2297 0 = External Fault

1 = Vibration Cut out

2 = High Motor temp

3 = Low Pressure

4 = High Pressure

5 = Low Water

6 = Damper Interlock

7 = Run Enable

8 = Freeze Stat Trip

9 = Smoke Detect

10 = Seal Leakage

11 = Rod Breakage

23

Ext. Fault 2 NO 0 2293 See Par ID 190

Notes

1

Parameter value can only be changed after the drive has stopped.

2

Parameter value will be set to be default when changing macros.

Variable Speed Drives Series III LIT-12012996—April 2018 www.johnsoncontrols.com 19

3

Input function is Level sensed.

4

Input function is Edge sensed.

5

Input function is Edge sensed when using StartP/StopP start logic.

Page 22

Step 5—Standard Parameter List

Table 18. Digital Input—P2.2, continued

Code Parameter Min. Max. Unit Default ID Note

23

P2.2.13

P2.2.14

P2.2.15

P2.2.16

P2.2.17

P2.2.18

P2.2.19

P2.2.20

P2.2.21

P2.2.22

P2.2.23

P2.2.24

P2.2.25

P2.2.26

P2.2.27

P2.2.28

P2.2.29

P2.2.30

P2.2.32

P2.2.33

P2.2.34

P2.2.35

P2.2.40

P2.2.42

P2.2.43

P2.2.44

Ext. Fault 2 NC 1 2294 See Par ID 190

2

Ext. Fault 2 Text 1 2298 See Par ID 2297

23

Ext. Fault 3 NO 0 2295 See Par ID 190

23

Ext. Fault 3 NC 1 2296 See Par ID 190

2

Ext. Fault 3 Text 2 2299 See Par ID 2297

24

Fault Reset 5 200 See Par ID 190

23

Run Enable 1 194 See Par ID 190

23

Preset Speed B0 6 205 See Par ID 190

23

Preset Speed B1 0 206 See Par ID 190

23

Preset Speed B2 0 207 See Par ID 190

23

Jog Enable 0 199 See Par ID 190

23

Accel/Decel Time Set 0 195 See Par ID 190

23

Accel/Decel Prohibit 0 201 See Par ID 190

24

No Access To Param 0 215 See Par ID 190

23

Auto Control 9 196 See Par ID 190

23

Hand Control 0 197 See Par ID 190

23

Auto 1/2 Select 0 209 See Par ID 190

23

HOA On/Off 1 2395 See Par ID 190

24

Parameter Set1/2 Sel 0 2312 See Par ID 190

23

AI Ref Source Select 0 208 See Par ID 190

24

Bypass Start 8 218 See Par ID 190

23

Bypass Overload 0 1246 See Par ID 190

23

DC Brake Active 0 202 See Par ID 190

23

Fire Mode 7 220 See Par ID 190

23

Fire Mode Ref 1/2 Select 0 221 See Par ID 190

23

Fire Mode Reverse 0 2119 See Par ID 190

Table 19. Preset Speed—P2.3

Code Parameter Min. Max. Unit Default ID Note

2

P2.3.1

P2.3.2

P2.3.3

P2.3.4

P2.3.5

P2.3.6

P2.3.7

P2.3.8

Notes

1

Parameter value can only be changed after the drive has stopped.

2

Parameter value will be set to be default when changing macros.

20 Variable Speed Drives Series III LIT-12012996—April 2018 www.johnsoncontrols.com

Preset Speed 1 0.00 See Par ID 102 Hz 5.00 105

2

Preset Speed 2 0.00 See Par ID 102 Hz 10.00 106

2

Preset Speed 3 0.00 See Par ID 102 Hz 15.00 118

2

Preset Speed 4 0.00 See Par ID 102 Hz 20.00 119

2

Preset Speed 5 0.00 See Par ID 102 Hz 25.00 120

2

Preset Speed 6 0.00 See Par ID 102 Hz 30.00 121

2

Preset Speed 7 0.00 See Par ID 102 Hz 35.00 122

2

Jog Reference See Par ID 101 See Par ID 102 Hz 0.00 117

3

Input function is Level sensed.

4

Input function is Edge sensed.

5

Input function is Edge sensed when using StartP/StopP start logic.

Page 23

Step 5—Standard Parameter List

Table 20. AI1 Settings—P2.4

Code Parameter Min. Max. Unit Default ID Note

P2.4.1 AI1 Mode 1 222 0 = 0–20 mA

2

P2.4.2

P2.4.3

P2.4.4

P2.4.5

P2.4.6

AI1 Signal Range 0 175 0 = 0–100%/0–20 mA/0–10 V

2

AI1 Custom Min 0.00 See Par ID 177 % 0.00 176

2

AI1 Custom Max See Par ID 176 100.00 % 100.00 177

2

AI1 Filter Time 0.00 10.00 s 0.10 174

2

AI1 Signal Invert 0 181 0 = Not Inverted

Table 21. AI2 Settings—P2.5

Code Parameter Min. Max. Unit Default ID Note

P2.5.1 AI2 Mode 0 223 0 = 0–20 mA

2

P2.5.2

P2.5.3

P2.5.4

P2.5.5

P2.5.6

AI2 Signal Range 1 183 0 = 0–100%/0–20 mA/

2

AI2 Custom Min 0.00 See Par ID 185 % 0.00 184

2

AI2 Custom Max See Par ID 184 100.00 % 100.00 185

2

AI2 Filter Time 0.00 10.00 s 0.10 182

2

AI2 Signal Invert 0 189 See Par ID 181

1 = 0–10 V

1 = 20–100%/4–20 mA/2–10 V

2 = Customized

1 = Inverted

1 = 0–10 V

2 = -10– +10 V

0 = 0–10 V/-10–10 V

1 = 20–100%/4–20 mA/

1 = 2–10 V/-6–10 V

2 = Customized

Table 22. Digital Output—P3.1

Code Parameter Min. Max. Unit Default ID Note

2

P3.1.1

DO1 Function 1 151 0 = Not Used

1 = Ready

2 = Run

3 = Fault

4 = Fault Invert

5 = Warning

6 = Reversed

7 = At Speed

8 = Zero Frequency

9 = Freq Limit 1 Superv

10 = Freq Limit 2 Superv

13 = OverHeat Fault

14 = OverCurrent Regular

15 = OverVoltage Regular

16 = UnderVoltage Regular

17 = 4mA Ref Fault/Warning

20 = Torq Limit Superv

21 = Ref Limit Superv

22 = Control from I/O

23 = Un-Requested Rotation

23 = Direction

24 = Thermistor Fault Output

3

Notes

1

Parameter value can only be changed after the drive has stopped.

2

Parameter value will be set to be default when changing macros.

Input function is Level sensed.

4

Input function is Edge sensed.

5

Input function is Edge sensed when using StartP/StopP start logic.

Variable Speed Drives Series III LIT-12012996—April 2018 www.johnsoncontrols.com 21

Page 24

Step 5—Standard Parameter List

Table 22. Digital Output—P3.1, continued

Code Parameter Min. Max. Unit Default ID Note

2

P3.1.1

,

continued

P3.1.2

P3.1.3

P3.1.4

P3.1.5

P3.1.6

P3.1.7

P3.1.8

P3.1.9

P3.1.10

P3.1.11

P3.1.12

P3.1.13

DO1 Function 1 151 25 = Fire Mode

2

RO1 Function 62 152 See Par ID 151

2

RO1 On Delay 0.0 320.0 s 0.0 2112

2

RO1 Off Delay 0.0 320.0 s 0.0 2113

2

RO2 Function 2 153 See Par ID 151

2

RO2 On Delay 0.0 320.0 s 0.0 2114

2

RO2 Off Delay 0.0 320.0 s 0.0 2115

2

RO3 Function 3 538 See Par ID 151

2

RO3 On Delay 0.0 320.0 s 0.0 2116

2

RO3 Off Delay 0.0 320.0 s 0.0 2117

2

RO3 Reverse 0 2118 0 = No

2

Virtual RO1 Function 0 2463 See Par ID 151

2

Virtual RO2 Function 0 2464 See Par ID 151

26 = In Bypass Mode

27 = Ext Fault/Warning

28 = Auto Control

29 = Jog Speed Select

30 = Motor Therm Protection

31 = FB Digital Input 1

32 = FB Digital Input 2

33 = FB Digital Input 3

34 = FB Digital Input 4

40 = Power Limit Superv

41 = Temp Limit Superv

42 = Analog Input Superv

51 = Motor Current 1 Supv

52 = Motor Current 2 Supv

53 = Second AI Limit Supv

54 = DC Charge Switch Close

55 = Preheat Active

56 = Cold Weather Active

58 = 2th Stage Ramp Frequency

58 = Active

59 = STO Fault Output

60 = Run Bypass/Drive

61 = Bypass Overload

62 = Bypass Run

1 = Yes

Table 23. Supervisions—P3.2

Code Parameter Min. Max. Unit Default ID Note

2

P3.2.1

Freq Limit 1 Supv 0 154 0 = No Limit

1 = Low Limit Superv

2 = High Limit Superv

2

P3.2.2

P3.2.3

P3.2.4

P3.2.5

P3.2.6

P3.2.7

Notes

1

Parameter value can only be changed after the drive has stopped.

2

Parameter value will be set to be default when changing macros.

22 Variable Speed Drives Series III LIT-12012996—April 2018 www.johnsoncontrols.com

Freq Limit 1 Supv Val 0.00 See Par ID 102 Hz 0.00 155

2

Freq Limit 1 Supv Hyst 0.10 1.00 Hz 0.10 2200

2

Freq Limit 2 Supv 0 157 See Par ID 154

2

Freq Limit 2 Supv Val 0.00 See Par ID 102 Hz 0.00 158

2

Freq Limit 2 Supv Hyst 0.10 1.00 Hz 0.10 2201

2

Torque Limit Supv 0 159 See Par ID 154

3

Input function is Level sensed.

4

Input function is Edge sensed.

5

Input function is Edge sensed when using StartP/StopP start logic.

Page 25

Step 5—Standard Parameter List

Table 23. Supervisions—P3.2, continued

Code Parameter Min. Max. Unit Default ID Note

2

P3.2.8

P3.2.9

P3.2.10

P3.2.11

P3.2.12

P3.2.13

P3.2.14

P3.2.15

P3.2.16

P3.2.17

P3.2.18

P3.2.19

P3.2.20

P3.2.21

P3.2.22

P3.2.23

P3.2.24

P3.2.25

P3.2.26

P3.2.27

P3.2.28

P3.2.29

P3.2.30

P3.2.31

P3.2.32

Torque Limit Supv Val -1000.0 1000.0 % 100.0 160

2

Torque Limit Supv Hyst 1.0 5.0 % 1.0 2202

2

Ref Limit Supv 0 161 See Par ID 154

2

Ref Limit Supv Val 0.00 See Par ID 102 Hz 0.00 162

2

Ref Limit Supv Hyst 0.10 1.00 Hz 0.10 2203

2

Temp Limit Supv 0 165 See Par ID 154

2

Temp Limit Supv Val -10.0 75.0 °C 40.0 166

2

Temp Limit Supv Hyst 1.0 10.0 °C 1.0 2204

2

Power Limit Supv 0 167 See Par ID 154

2

Power Limit Supv Val -200.0 200.0 % 0.0 168

2

Power Limit Supv Hyst 0.1 10.0 % 0.1 2205

2

AI Supv Select 0 170 0 = AI1

2

AI Limit Supv 0 171 See Par ID 154

2

AI Limit Supv Val 0.00 100.00 % 0.00 172

2

AI Supv Hyst 1.00 10.00 % 1.00 2198

2

Motor Current 1 Supv 0 2189 See Par ID 154

2

Motor Current 1 Supv Value 0.0 DriveNomCurr

A DriveNomCurrCT 2190

CT*2

2

Motor Current 1 Supv Hyst 0.1 1.0 A 0.1 2196

2

Motor Current 2 Supv 0 2191 See Par ID 154

2

Motor Current 2 Supv Value 0.0 DriveNomCurr

A DriveNomCurrCT 2192

CT*2

2

Motor Current 2 Supv Hyst 0.1 1.0 A 0.1 2197

2

Second AI Supv Select 0 2193 See Par ID 170

2

Second AI Limit Supv 0 2194 See Par ID 154

2

Second AI Limit Supv Val 0.00 100.00 % 0.00 2195

2

Second AI Supv Hyst 1.00 10.00 % 1.00 2199

1 = AI2

Notes

1

Parameter value can only be changed after the drive has stopped.

2

Parameter value will be set to be default when changing macros.

Variable Speed Drives Series III LIT-12012996—April 2018 www.johnsoncontrols.com 23

3

Input function is Level sensed.

4

Input function is Edge sensed.

5

Input function is Edge sensed when using StartP/StopP start logic.

Page 26

Step 5—Standard Parameter List

Table 24. Analog Output 1—P3.3

Code Parameter Min. Max. Unit Default ID Note

2

P3.3.1

P3.3.2

P3.3.3

P3.3.4

P3.3.5

P3.3.6

P3.3.7

AO1 Mode 0 227 See Par ID 222

2

AO1 Function 1 146 0 = Not Used

2

AO1 Minimum 1 149 0 = 0 V / 0 mA

2

AO1 Filter Time 0.00 10.00 s 1.00 147

2

AO1 Scale 10 1000 % 100 150

2

AO1 Inversion 0 148 See Par ID 181

2

AO1 Offset -100.00 100.00 % 0.00 173

1 = Output Frequency

2 = Freq Reference

3 = Motor Speed (0–Nom)

4 = Motor Current (0–Nom)

5 = Motor Torque (0–Nom)

6 = Motor Power (0–Nom)

7 = Motor Voltage (0–Nom)

8 = DC-Bus Voltage

19 = AI1

20 = AI2

21 = Output Freq (-2-+2N)

22 = Motor Torque (-2-+2N)

23 = Motor Power (-2-+2N)

24 = PT100 Temperature

33 = SlotA PT100 Temp Channel 1

34 = SlotA PT100 Temp Channel 2

35 = SlotA PT100 Temp Channel 3

36 = SlotB PT100 Temp Channel 1

37 = SlotB PT100 Temp Channel 2

38 = SlotB PT100 Temp Channel 3

39 = User Defined Output

40 = Motor Current (-2-+2N)

1 = 2 V / 4 mA

Table 25. Analog Output 2—P3.4

Code Parameter Min. Max. Unit Default ID Note

2

P3.4.1

P3.4.2

P3.4.3

P3.4.4

P3.4.5

P3.4.6

P3.4.7

Notes

1

Parameter value can only be changed after the drive has stopped.

2

Parameter value will be set to be default when changing macros.

AO2 Mode 0 228 See Par ID 222

2

AO2 Function 4 229 See Par ID 146

2

AO2 Minimum 1 232 See Par ID 149

2

AO2 Filter Time 0.00 10.00 s 1.00 230

2

AO2 Scale 10 1000 % 100 233

2

AO2 Inversion 0 231 See Par ID 181

2

AO2 Offset -100.00 100.00 % 0.00 234

3

Input function is Level sensed.

4

Input function is Edge sensed.

5

Input function is Edge sensed when using StartP/StopP start logic.

24 Variable Speed Drives Series III LIT-12012996—April 2018 www.johnsoncontrols.com

Page 27

Step 5—Standard Parameter List

Drive Control

Table 26. Basic Setting—P4.1

Code Parameter Min. Max. Unit Default ID Note

2

P4.1.1

P4.1.2

P4.1.3

P4.1.4

P4.1.5

P4.1.6 Change PhaseSequence

P4.1.7

P4.1.9

P4.1.10

P4.1.11

P4.1.12

P4.1.13

P4.1.14

P4.1.15

P4.1.16

P4.1.17

P4.1.18

Keypad Reference See Par ID 101 See Par ID 102 Hz 0.00 141

2

Keypad Direction 0 116 0 = Forward

1 = Reverse

2

Keypad Stop 1 114 0 = Enabled-Keypad Operation

1 = Always Enabled

2

Hand Key Enable 0 1724 0 = Enabled

1 = Disabled

1

Reverse Enable 0 1679 0 = Disabled

1 = Enabled

0 2515 0 = Change Disable

Motor

2

Power Up HOA Select 0 1685 0 = Hold Last

1 = Change Enable

1 = Hand Control

2 = Auto control

3 = Off

2

Run Delay Time 0 32500 s 0 2423

2

Start Mode 0 252 0 = Ramp

1 = Flying Start

2

Stop Mode 0 253 0 = Coasting

1 = Ramp

2

Ramp 1 Shape 0.0 10.0 s 0.0 247

2

Ramp 2 Shape 0.0 10.0 s 0.0 248

2

Accel Time 2 0.1 3000.0 s 10.0 249

2

Decel Time 2 0.1 3000.0 s 10.0 250

2

Power Loss Function 0 267 See Par ID 1679

2

Power Loss Time 0.3 5.0 s 2.0 268

1 2

2nd Stage Ramp Frequency See Par ID 101 See Par ID 102 Hz 30.00 2444

Table 27. Brake—P4.2

Code Parameter Min. Max. Unit Default ID Note

1 2

P4.2.1

P4.2.2

P4.2.3

P4.2.4

P4.2.5

DC-Brake Current DriveNomCurr

CT*15/100

1 2

Start DC-Brake Time 0.00 600.00 s 0.00 263

1 2

Stop DC-Brake Frequency 0.10 10.00 Hz 1.50 262

1 2

Stop DC-Brake Time 0.00 600.00 s 0.00 255

1 2

Brake Chopper Define 0 251 0 = Disabled

DriveNomCurr

CT*15/10

A DriveNomCurr

CT*1/2

254

1 = B(Run) T(Rdy)

2 = External

3 = B(Rdy) T(Rdy)

4 = B(Run) T(No)

1 2

P4.2.6

Flux Brake 0 266 0 = Off

1 = On

1 2

P4.2.7

Flux Brake Current ActiveMotor

NomCurr*1/10

Notes

1

Parameter value can only be changed after the drive has stopped.

2

Parameter value will be set to be default when changing macros.

See Par ID 107 A ActiveMotorNom

265

Curr*1/2

3

Input function is Level sensed.

4

Input function is Edge sensed.

5

Input function is Edge sensed when using StartP/StopP start logic.

Variable Speed Drives Series III LIT-12012996—April 2018 www.johnsoncontrols.com 25

Page 28

Step 5—Standard Parameter List

Table 28. Skip Frequency—P4.3

Code Parameter Min. Max. Unit Default ID Note

2

P4.3.1

P4.3.2

P4.3.3

P4.3.4

P4.3.5

P4.3.6

P4.3.7

Table 29. Energy Savings Calc—P4.4

Code Parameter Min. Max. Unit Default ID Note

P4.4.1

P4.4.2

P4.4.3

P4.4.4 Energy Savings Reset 2125 0 = Not Reset

Skip Range Ramp Factor 0.1 10.0 1.0 264

2

Skip F1 Low Limit 0.00 See Par ID 257 Hz 0.00 256

2

Skip F1 High Limit See Par ID 256 400.00 Hz 0.00 257

2

Skip F2 Low Limit 0.00 See Par ID 259 Hz 0.00 258

2

Skip F2 High Limit See Par ID 258 400.00 Hz 0.00 259

2

Skip F3 Low Limit 0.00 See Par ID 261 Hz 0.00 260

2

Skip F3 High Limit See Par ID 260 400.00 Hz 0.00 261

2

Currency 0 2122 0 = $

2

Energy Cost Varies 0.00 2123

2

Data Type 0 2124 0 = Cumulative

1 = £

2 = €

3 = ¥

4 = Rs

5 = R$

6 = Fr

7 = kr

1 = Daily Avg

2 = Weekly Avg

3 = Monthly Avg

4 = Yearly Avg

1 = Reset

Motor Control

Table 30. Basic Setting—P5.1

Code Parameter Min. Max. Unit Default ID Note

1 2

P5.1.1

P5.1.2

P5.1.3

P5.1.4

P5.1.5

P5.1.6

P5.1.7

P5.1.8

P5.1.9

Notes

1

Parameter value can only be changed after the drive has stopped.

2

Parameter value will be set to be default when changing macros.

Motor Control Mode 0 287 0 = Freq Control

1

Current Limit DriveNomCurr

CT*1/10

1 2

V/Hz Optimization 0 109 See Par ID 1679

1 2

V/Hz Ratio 3 108 0 = Linear

1 2

Field Weakening Point 8.00 400.00 Hz Varies 289

1 2

Voltage at FWP 10.00 200.00 % 100.00 290

1 2

V/Hz Mid Frequency 0.00 See Par ID 289 Hz Varies 291

1 2

V/Hz Mid Voltage 0.00 100.00 % 100.00 292

1 2

Zero Frequency Voltage 0.00 40.00 % 0.00 293

DriveNomCurr

CT*2

A DriveNomCurrCT*2 107

3

Input function is Level sensed.

4

Input function is Edge sensed.

5

Input function is Edge sensed when using StartP/StopP start logic.

1 = Speed Control

1 = Squared

2 = Programmable

3 = Linear + Flux Optimization

26 Variable Speed Drives Series III LIT-12012996—April 2018 www.johnsoncontrols.com

Page 29

Step 5—Standard Parameter List

Table 30. Basic Setting—P5.1, continued

Code Parameter Min. Max. Unit Default ID Note

2

P5.1.10

P5.1.11

P5.1.12

Protections

Table 31. Motor—P6.1

Code Parameter Min. Max. Unit Default ID Note

P6.1.1

P6.1.2

P6.1.3

P6.1.4

P6.1.5

P6.1.6

P6.1.7

P6.1.8

P6.1.9

P6.1.10

P6.1.11

P6.1.12

P6.1.13

P6.1.14

P6.1.15

P6.1.16

P6.1.17

Switching Frequency MinSwitchFreq MaxSwitchFreq kHz DefaultSwitch

2522

FreqCT

2

Sine Filter Enable 0 1665 See Par ID 1679

1 2

OverVoltage Control 1 294 See Par ID 1679

1 2

Output Phase Fault 2 308 0 = No Action

1 2

Ground Fault 2 309 See Par ID 308

2

Ground Fault Limit 0 30 % 15 2158

1 2

Motor Thermal Protection 2 310 See Par ID 308

2

Motor Thermal F0 Current 0.0 150.0 % 40.0 311

2

Motor Thermal Time 1 200 min 12 312

1 2

Stall Protection 0 313 See Par ID 308

2

Stall Current Limit 0.1 ActiveMotor

NomCurr*2

2

Stall Time Limit 1.0 120.0 s 15.0 315

2

Stall Frequency Limit 1.00 See Par ID 102 Hz 25.00 316

1 2

Underload Protection 0 317 See Par ID 308

2

Underload Fnom Torque 10.0 150.0 % 50.0 318

2

Underload F0 Torque 5.0 150.0 % 10.0 319

2

Underload Time Limit 2.00 600.00 s 20.00 320

1 2

Thermistor Fault Response 2 333 See Par ID 308

1 2

PT100 Fault Response 2 337 See Par ID 308

2

Preheat Mode 0 2159 See Par ID 1679

A ActiveMotorNom

Curr*13/10

314

1 = Warning

2 = Fault

3 = Fault, Coast

Notes

1

Parameter value can only be changed after the drive has stopped.

2

Parameter value will be set to be default when changing macros.

Variable Speed Drives Series III LIT-12012996—April 2018 www.johnsoncontrols.com 27

3

Input function is Level sensed.

4

Input function is Edge sensed.

5

Input function is Edge sensed when using StartP/StopP start logic.

Page 30

Step 5—Standard Parameter List

Table 31. Motor—P6.1, continued

Code Parameter Min. Max. Unit Default ID Note

2

P6.1.18

P6.1.19

P6.1.20

P6.1.21

Preheat Control Source 31 2160 0 = DigIN:NormallyOpen

1 = DigIN:NormallyClose

2 = DigIN: 1

3 = DigIN: 2

4 = DigIN: 3

5 = DigIN: 4

6 = DigIN: 5

7 = DigIN: 6

8 = DigIN: 7

9 = DigIN: 8

10 = DigIN: A: IO1: 1

11 = DigIN: A: IO1: 2

12 = DigIN: A: IO1: 3

13 = DigIN: A: IO5: 1

14 = DigIN: A: IO5: 2

15 = DigIN: A: IO5: 3

16 = DigIN: A: IO5: 4

17 = DigIN: A: IO5: 5

18 = DigIN: A: IO5: 6

19 = DigIN: B: IO1: 1

20 = DigIN: B: IO1: 2

21 = DigIN: B: IO1: 3

22 = DigIN: B: IO5: 1

23 = DigIN: B: IO5: 2

24 = DigIN: B: IO5: 3

25 = DigIN: B: IO5: 4

26 = DigIN: B: IO5: 5

27 = DigIN: B: IO5: 6

28 = Time Channel 1

29 = Time Channel 2

30 = Time Channel 3

31 = Drive Temperature

32 = SlotA PT100 Temp Channel 1

33 = SlotA PT100 Temp Channel 2

34 = SlotA PT100 Temp Channel 3

35 = SlotA Max PT100 Temp

36 = SlotB PT100 Temp Channel 1

37 = SlotB PT100 Temp Channel 2

38 = SlotB PT100 Temp Channel 3

39 = SlotB Max PT100 Temp

40 = SlotA and SlotB Max PT100

40 = Temp

2

Preheat Enter Temp 0.0 19.9 °C 10.0 2161

2

Preheat Quit Temp 20.0 40.0 °C 20.0 2162

2

Preheat Output Volt 0.0 20.0 % 2.0 2163

3

Notes

1

Parameter value can only be changed after the drive has stopped.

2

Parameter value will be set to be default when changing macros.

28 Variable Speed Drives Series III LIT-12012996—April 2018 www.johnsoncontrols.com

Input function is Level sensed.

4

Input function is Edge sensed.

5

Input function is Edge sensed when using StartP/StopP start logic.

Page 31

Step 5—Standard Parameter List

Table 32. Drive—P6.2

Code Parameter Min. Max. Unit Default ID Note

2

P6.2.1

P6.2.2

P6.2.3

P6.2.4

P6.2.5

P6.2.6

P6.2.7

P6.2.8

P6.2.9

P6.2.10

P6.2.11

P6.2.12

P6.2.13

P6.2.14

P6.2.15 Cold Weather Password 2129

P6.2.16 Under Temp Fault Override 2130 See Par ID 2118

P6.2.17

Line Start Lockout 2 750 0 = Disabled, No Change

1 = Enable, No Change

2 = Disabled, Changed

3 = Enable, Changed

2

Fault Reset Start 0 2483 0 = Start/Stop After Fault Reset

1 = Restart After Fault Reset

1 2

4mA Input Fault 0 306 0 = No Action

1 = Warning

2 = Warning: Previous Freq

3 = Warning: Preset Freq

4 = Fault

5 = Fault, Coast

1 2

4mA Fault Frequency 0.00 See Par ID 102 Hz 0.00 331

1 2

External Fault 2 307 See Par ID 308

1 2

Input Phase Fault 2 332 See Par ID 308

1 2

Uvolt Fault Response 2 330 See Par ID 308

1 2

Unit Under Temp Prot 2 1564 See Par ID 308

1 2

RTC Fault 1 955 See Par ID 308

1 2

Replace Battery Fault

1 1256 See Par ID 308

Response

1 2

Replace Fan Fault Response 1 1257 See Par ID 308

2

Cold Weather Mode 0 2126 See Par ID 1679

2

Cold Weather Volt. Level 0.0 20.0 % 2.0 2127

2

Cold Weather Time Out 0 10 min 3 2128

2

STO Fault Response 2 2427 0 = No Action

1 = Warning

2 = Fault

Table 33. Communication—P6.3

Code Parameter Min. Max. Unit Default ID Note

1 2

P6.3.1

Fieldbus Fault Response 2 334 0 = No Action

1 = Warning

2 = Fault

3 = Fault, Coast

4 = Warning, Coast

1 2

P6.3.2

P6.3.3

P6.3.4

OPTCard Fault Response 2 335 See Par ID 308

1 2

IP Address Confliction Resp 1 1678 See Par ID 308

1 2

Keypad Comm Fault

2 2157 See Par ID 308

Response

3

Notes

1

Parameter value can only be changed after the drive has stopped.

2

Parameter value will be set to be default when changing macros.

Variable Speed Drives Series III LIT-12012996—April 2018 www.johnsoncontrols.com 29

Input function is Level sensed.

4

Input function is Edge sensed.

5

Input function is Edge sensed when using StartP/StopP start logic.

Page 32

Step 5—Standard Parameter List

Table 34. Auto Restart—P6.4

Code Parameter Min. Max. Unit Default ID Note

2

P6.4.1

P6.4.2

P6.4.3

P6.4.4

P6.4.5

P6.4.6

P6.4.7

P6.4.8

P6.4.9

P6.4.10

Table 35. Fire Mode—P9

Code Parameter Min. Max. Unit Default ID Note

1 2

P9.1

1 2

P9.2

2

P9.3

2

P9.4

2

P9.5

P9.6 Fire Mode Test Enable 2443 See Par ID 1679

AR Wait Time 1.00 300.00 s 1.00 321

2

AR Trail Time 0.00 600.00 s 30.00 322

2

AR Start Function 0 323 0 = Flying Start

2

Undervoltage Attempts 0 10 1 324

2

OverVoltage Attempts 0 10 1 325

2

OverCurrent Attempts 0 3 0 326

2

4mA Fault Attempts 0 10 0 327

2

Motor Temp Fault Attempts 0 10 0 329

2

External Fault Attempts 0 10 0 328

2

Underload Attempts 0 10 0 336

Fire Mode Function 0 535 0 = Closing Contact

Fire Mode Ref Select

0 536 0 = Fire Mode Min Frequency

Function

Fire Mode Min Frequency See Par ID 101 See Par ID 102 Hz 15.00 537

Fire Mode Freq Ref 1 0.0 100.0 % 75.0 565

Fire Mode Freq Ref 2 0.0 100.0 % 100.0 564

1 = Ramp

1 = Opening Contact

1 = Fire Mode Ref

2 = Fieldbus Ref

3 = AI1

4 = AI2

5 = AI1 + AI2

3

Notes

1

Parameter value can only be changed after the drive has stopped.

2

Parameter value will be set to be default when changing macros.

30 Variable Speed Drives Series III LIT-12012996—April 2018 www.johnsoncontrols.com

Input function is Level sensed.

4

Input function is Edge sensed.

5

Input function is Edge sensed when using StartP/StopP start logic.

Page 33

Step 5—Standard Parameter List

Bypass

Table 36. Basic Setting—P10.1

Code Parameter Min. Max. Unit Default ID Note

12

P10.1.1

P10.1.2

P10.1.3

P10.1.4

P10.1.5

P10.1.6

P10.1.7

P10.1.8

P10.1.9

P10.1.10

P10.1.11

P10.1.12

P10.1.13

P10.1.14

P10.1.15

P10.1.16

P10.1.17

P10.1.18

P10.1.19

P10.1.20

P10.1.21

P10.1.22

P10.1.23

P10.1.24

P10.1.25

Bypass Enable 1 1418 See Par ID 1679

12

Bypass Start Delay 1 32765 s 1 544

12

Auto Bypass 1 542 See Par ID 1679

12

Auto Bypass Delay 0 32765 s 10 543

12

OverCurrent Bypass Enable 0 547 See Par ID 1679

12

IGBT Fault Bypass Enable 0 546 See Par ID 1679

12

4mA Fault Bypass Enable 0 548 See Par ID 1679

12

UnderVoltage Bypass

0 545 See Par ID 1679

Enable

12

OverVoltage Bypass Enable 0 549 See Par ID 1679

12

Motor OverTemp Bypass

0 1698 See Par ID 1679

Enable

12

UnderLoad Bypass Enable 0 1699 See Par ID 1679

12

External Bypass Enable 0 1700 See Par ID 1679

12

Charge Switch Fault Bypass

0 1701 See Par ID 1679

Enable

12

Saturation Trip Fault Bypass

0 1702 See Par ID 1679

Enable

12

Under Temp Fault Bypass

0 1703 See Par ID 1679

Enable

12

EEPROM Fault Bypass

0 1704 See Par ID 1679

Enable

12

FRAM Fault Bypass Enable 0 1705 See Par ID 1679

12

Watchdog Fault Bypass

0 1706 See Par ID 1679

Enable

12

Fan Cooling Fault Bypass

0 1707 See Par ID 1679

Enable

12

Keypad Com Fault Bypass

0 1708 0 = Disabled

Enable

12

Option Card Fault Bypass

0 1709 See Par ID 1679

Enable

12

RTC Clock Fault Bypass

0 1710 See Par ID 1679

Enable

12

Ctrl Board OverTemp Fault

0 1711 See Par ID 1679

Bypass Enable

12

Speed Search Start Fault

0 1712 See Par ID 1679

Bypass Enable

12

Fieldbus Fault Bypass

0 1713 See Par ID 1679

Enable

2 = Enabled

Notes

1

Parameter value can only be changed after the drive has stopped.

2

Parameter value will be set to be default when changing macros.

Variable Speed Drives Series III LIT-12012996—April 2018 www.johnsoncontrols.com 31

3

Input function is Level sensed.

4

Input function is Edge sensed.

5

Input function is Edge sensed when using StartP/StopP start logic.

Page 34

Step 5—Standard Parameter List

Communication

Table 37. FB Process Data Input Sel—P12.1

Code Parameter Min. Max. Unit Default ID Note

2

P12.1.1

P12.1.2

P12.1.3

P12.1.4

P12.1.5

P12.1.6

P12.1.7

P12.1.8

Table 38. FB Process Data Output Sel—P12.2

Code Parameter Min. Max. Unit Default ID Note

P12.2.1

P12.2.2

P12.2.3

P12.2.4

P12.2.5

P12.2.6

P12.2.7

P12.2.8

FB Process Data Input 1 Sel 0 2560 0 2533

2

FB Process Data Input 2 Sel 0 2560 2542 2534

2

FB Process Data Input 3 Sel 0 2560 2550 2535

2

FB Process Data Input 4 Sel 0 2560 103 2536

2

FB Process Data Input 5 Sel 0 2560 104 2537

2

FB Process Data Input 6 Sel 0 2560 107 2538

2

FB Process Data Input 7 Sel 0 2560 0 2539

2

FB Process Data Input 8 Sel 0 2560 0 2540

2

FB Process Data Output 1

1 1556

Sel

2

FB Process Data Output 2

2 1557

Sel

2

FB Process Data Output 3

3 1558

Sel

2

FB Process Data Output 4

4 1559

Sel

2

FB Process Data Output 5

5 1560

Sel

2

FB Process Data Output 6

6 1561

Sel

2

FB Process Data Output 7

7 1562

Sel

2

FB Process Data Output 8

28 1563

Sel

3

Notes

1

Parameter value can only be changed after the drive has stopped.

2

Parameter value will be set to be default when changing macros.

32 Variable Speed Drives Series III LIT-12012996—April 2018 www.johnsoncontrols.com

Input function is Level sensed.

4

Input function is Edge sensed.

5

Input function is Edge sensed when using StartP/StopP start logic.

Page 35

Step 5—Standard Parameter List

Table 38. FB Process Data Output Sel—P12.2, continued

Code Parameter Min. Max. Unit Default ID Note

2

P12.2.9

P12.2.10

P12.2.11

P12.2.12

P12.2.13

Standard Status Word Bit0

Function Select

2

Standard Status Word Bit1

Function Select

2

Standard Status Word Bit2

Function Select

2

Standard Status Word Bit3

Function Select

2

Standard Status Word Bit4

Function Select

1 2415 0 = Not Used

1 = Ready

2 = Run

3 = Fault

4 = Fault Invert

5 = Warning

6 = Reversed

7 = At Speed

8 = Zero Frequency

9 = Freq Limit 1 Superv

10 = Freq Limit 2 Superv

13 = OverHeat Fault

14 = OverCurrent Regular

15 = OverVoltage Regular

16 = UnderVoltage Regular

17 = 4mA Ref Fault/Warning

20 = Torq Limit Superv

21 = Ref Limit Superv

22 = Control from I/O

23 = Un-Requested Rotation

23 = Direction

24 = Thermistor Fault Output

25 = Fire Mode

26 = In Bypass Mode

27 = Ext Fault/Warning

28 = Auto Control

29 = Jog Speed Select

30 = Motor Therm Protection

31 = FB Digital Input 1

32 = FB Digital Input 2

33 = FB Digital Input 3

34 = FB Digital Input 4

40 = Power Limit Superv

41 = Temp Limit Superv

42 = Analog Input Superv

51 = Motor Current 1 Supv

52 = Motor Current 2 Supv

53 = Second AI Limit Supv

54 = DC Charge Switch Close

55 = Preheat Active

56 = Cold Weather Active

58 = 2th Stage Ramp Frequency

58 = Active

59 = STO Fault Output

60 = Run Bypass/Drive

61 = Bypass Overload

62 = Bypass Run

2 2416 See Par ID 2415

3 2417 See Par ID 2415

4 2418 See Par ID 2415

5 2419 See Par ID 2415

Notes

1

Parameter value can only be changed after the drive has stopped.

2

Parameter value will be set to be default when changing macros.

Variable Speed Drives Series III LIT-12012996—April 2018 www.johnsoncontrols.com 33

3

Input function is Level sensed.

4

Input function is Edge sensed.

5

Input function is Edge sensed when using StartP/StopP start logic.

Page 36

Step 5—Standard Parameter List

Table 38. FB Process Data Output Sel—P12.2, continued

Code Parameter Min. Max. Unit Default ID Note

P12.2.14 2Standard Status Word Bit5

Function Select

2

P12.2.15

Standard Status Word Bit6

Function Select

2

P12.2.16

Standard Status Word Bit7

Function Select

RS-485 Bus

Table 39. Basic Setting—P12.3.1

Code Parameter Min. Max. Unit Default ID Note

1

P12.3.1.1

Table 40. Modbus RTU—P12.3.2

Code Parameter Min. Max. Unit Default ID Note

P12.3.2.1

P12.3.2.2

P12.3.2.3

P12.3.2.4 Modbus RTU Protocol

P12.3.2.5 Comm Timeout Modbus RTU 0 60000 ms 10000 593

P12.3.2.6 Modbus RTU Fault

RS485 Comm Set 0 586 0 = Modbus RTU

1

Slave Address 1 247 1 587

1

Baud Rate 1 584 0 = 9600

1

Parity Type 2 585 0 = None

Status

Response

6 2420 See Par ID 2415

7 2421 See Par ID 2415

8 2422 See Par ID 2415

1 = BACnet MS/TP

2 = SA Bus

1 = 19200

2 = 38400

3 = 57600

4 = 115200

1 = Odd

2 = Even

588 0 = Initial

1 = Stopped

2 = Operational

3 = Faulted

0 2516 0 = in Fieldbus Control

1 = in all Control

Table 41. BACnet MS/TP—P12.3.3

Code Parameter Min. Max. Unit Default ID Note

1

P12.3.3.1

MSTP Baud Rate 2 594 0 = 9600

1 = 19200

2 = 38400

3 = 76800

4 = 115200

1

P12.3.3.2

P12.3.3.3

MSTP Device Address 0 127 1 595

1

MSTP Instance Number 0 4194302 0 596

P12.3.3.4 MSTP Comm Timeout 0 60000 ms 10000 598

P12.3.3.5 MSTP Protocol Status 599 0 = Stopped

1 = Operational

2 = Faulted

3

Notes

1

Parameter value can only be changed after the drive has stopped.

2

Parameter value will be set to be default when changing macros.

34 Variable Speed Drives Series III LIT-12012996—April 2018 www.johnsoncontrols.com