Johnson Controls HVAHP036B21S, HVAHP048B21S, YVAHP036B21S, CVAHP036B21S, CVAHP048B21S Engineering Manual

...Page 1

ENGINEERING MANUAL

INVERTER-DRIVEN MULTI-SPLIT SYSTEM

HEAT PUMP AIR CONDITIONERS

Technical Catalog for Outdoor Unit

Engineering Manual

< Outdoor Units >

(H,Y,C)VAHP036B21S

(H,Y,C)VAHP048B21S

(H,Y,C)VAHP060B21S

TC-16001

Page 2

Page 3

IMPORTANT NOTICE AND SAFETY SUMMARY

1. Introduction

This Engineering Manual concentrates on heat pump air conditioning units. Read this manual carefully

before performing installations or operations.

This manual should be considered as a permanent part of the air conditioning equipment and should

remain with the air conditioning equipment.

(Transportation/Installation Work) > (Refrigerant Piping Work) > (Electrical Wiring Work) > (Ref. Charge Work) > (Test

Run) > (User)

2. Important Safety Instructions

Signal Words

Indicates a hazardous situation that, if not avoided, could result in death or

serious injury.

Indicates a hazardous situation that, if not avoided, could result in minor or

moderate injury.

Indicates information considered important, but not hazard-related

(for example, messages relating to property damage).

General Precautions

To reduce the risk of serious injury or death, read these instructions

thoroughly and follow all warnings or cautions included in all manuals that

accompanied the product and are attached to the unit. Refer back to these

instructions as needed.

● This system should be installed by personnel certied by Johnson Controls, Inc. Personnel must be

qualied according to local, state and national building and safety codes and regulations. Incorrect

installation could cause leaks, electric shock, re or explosion. In areas where Seismic ‘’Performance

requirements are specied, the appropriate measures should be taken during installation to guard

against possible damage or injury that might occur in an earthquake if the unit is not installed

correctly, injuries may occur due to a falling unit.

● Use appropriate Personal Protective Equipment (PPE), such as gloves and protective goggles and,

where appropriate, have a gas mask nearby. Also use electrical protection equipment and tools

suited for electrical operation purposes. Keep a quenching cloth and a re extinguisher nearby during

brazing. Use care in handling, rigging, and setting of bulky equipment.

● When transporting, be careful when picking up, moving and mounting these units. Although the

unit may be packed using plastic straps, do not use them for transporting the unit from one location

to another. Do not stand on or put any material on the unit. Get a partner to help, and bend with

your knees when lifting to reduce strain on your back. Sharp edges or thin aluminum ns on the air

conditioner can cut ngers, so wear protective gloves.

● Do not touch or adjust any safety devices inside the indoor or outdoor units. All safety features,

disengagement, and interlocks must be in place and functioning correctly before the equipment is

put into operation. If these devices are improperly adjusted or tampered with in any way, a serious

accident can occur. Never bypass or jump-out any safety device or switch.

● Johnson Controls will not assume any liability for injuries or damage caused by not following steps

outlined or described in this manual. Unauthorized modications to Johnson Controls products are

prohibited as they…

◦ May create hazards which could result in death, serious injury or equipment damage.

◦ Will void product warranties.

◦ May invalidate product regulatory certications.

◦ May violate OSHA standards.

TC-16001-rev.5

i

Page 4

Take the following precautions to reduce the risk of property damage.

● Be careful that moisture, dust, or variant refrigerant compounds not enter the refrigerant cycle during

installation work. Foreign matter could damage internal components or cause blockages.

● If air lters are required on this unit, do not operate the unit without the air lter set in place. If the air

lter is not installed, dust may accumulate and breakdown may result.

● Do not install this unit in any place where silicon gases can coalesce. If the silicon gas molecules

attach themselves to the surface of the heat exchanger, the nned surfaces will repel water. As a

result, any amount of drainage moisture condensate can overow from the drain condensate pan and

could run inside of the electrical box, possibly causing electrical failures.

● When installing the unit in a hospital or other facility where electromagnetic waves are generated

from nearby medical and/or electronic devices, be prepared for noise and electronic interference

Electromagnetic Interference (EMI). Do not install where the waves can directly radiate into the

electrical box, controller cable, or controller. Inverters, appliances, high-frequency medical equipment,

and radio communications equipment may cause the unit to malfunction. The operation of the unit

may also adversely affect these same devices. Install the unit at least 10 ft. (approximately 3m) away

from such devices.

● When a wireless controller is used, locate at a distance of at least 3.3 ft. (approximately 1m) between

the indoor unit and electric lighting. If not, the receiver part of the unit may have difculty receiving

operation commands.

● Do not install the unit in any location where animals and plants can come into direct contact with the

outlet air stream. Exposure could adversely affect the animals and plants.

● Do not install the unit with any downward slope to the side of the drain adaptor. If you do, you may

have drain water owing back which may cause leaks.

● Be sure the drain hose discharges water properly. If connected incorrectly, it may cause leaks.

● Do not install the unit in any place where oil can seep onto the units, such as table or seating areas in

restaurants, and so forth. For these locations or social venues, use specialized units with oil-resistant

features built into them. In addition, use a specialized ceiling fan designed for restaurant use. These

specialized oil-resistant units can be ordered for such applications. However, in places where large

quantities of oil can splash onto the unit, such as a factory, even the specialized units cannot be used.

These products should not be installed in such locations.

● If the wired controller is installed in a location where electromagnetic radiation is generated, make

sure that the wired controller is shielded and cables are sleeved inside conduit tubing.

● If there is a source of electrical interference near the power source, install noise suppression

equipment (lter).

● During the test run, check the unit’s operation temperature. If the unit is used in an environment

where the temperature exceeds the operation boundary, it may cause severe damage. Check the

operational temperature boundary in the manual. If there is no specied temperature, use the unit

within the operational temperature boundary of 35 to 104°F (0 to 40°C).

● Read installation and appropriate user manuals for connection with PC or peripheral devices. If a

warning window appears on the PC, the product stops, does not work properly or works intermittently,

immediately stop using the equipment.

ii

TC-16001-rev.5

Page 5

Installation Precautions

To reduce the risk of serious injury or death, the following installation

precautions must be followed.

● When installing the unit into…

◦ A wall: Make sure the wall is strong enough to hold the unit’s weight. It may be necessary to

construct a strong wood or metal frame to provide added support.

◦ A room: Properly insulate any refrigerant tubing run inside a room to prevent “sweating” that can

cause dripping and water damage to wall and oors.

◦ Damp or uneven areas: Use a raised concrete pad or concrete blocks to provide a solid, level

foundation for the unit to prevent water damage and abnormal vibration.

◦ An area with high winds: Securely anchor the outdoor unit down with bolts and a metal frame.

Provide a suitable wall for wind prevention (eld-supplied). Or install Wind Guard (optional).

◦ A snowy area: Install the outdoor unit on a raised platform that is higher than drifting snow.

Provide snow roof for snow prevention (eld-supplied). Or install Snow Protection Hood (optional).

● If the remote sensors are not used with this controller, then do not install this controller…

◦ in a room where there is no thermostat.

◦ where the unit is exposed to direct sunshine or direct light.

◦ where the unit will be in close proximity to a heat source.

◦ where hot/cold air from the outdoors, or a draft from elsewhere (such as air vents, diffusers or

grilles) can affect air circulation.

◦ in areas with poor air circulation and ventilation.

● Do not install the unit in the following places. Doing so can result in an explosion, re, deformation,

corrosion, or product failure.

◦ Explosive or ammable atmosphere.

◦ Where re, oil, steam, or powder can directly enter the unit, such as in close proximity or directly

above a kitchen stove.

◦ Where oil (including machinery oil) may be present.

◦ Where corrosive gases such as chlorine, bromine, or sulde can accumulate, such as near a hot

tub or hot spring.

◦ Where dense, salt-laden airow is heavy, such as in coastal regions.

◦ Where the air quality is of high acidity.

◦ Where harmful gases can be generated from decomposition.

● Do not install the indoor unit where such dripping can cause moisture damage or uneven locations:

Use a raised concrete pad or concrete blocks to provide a solid, level foundation for the unit to

prevent water damage and abnormal vibration. Do not position the drain pipe for the indoor unit near

any sanitary sewers where corrosive gases may be present.

● Before performing any brazing work, be sure that there are no ammable materials or open ames

nearby.

● Perform a test run to ensure normal operation. Safety guards, shields, barriers, covers, and protective

devices must be in place while the compressor/unit is operating. During the test run, keep ngers and

clothing away from any moving parts.

● Clean up the site when nished, remembering to check that no metal scraps or bits of wiring have

been left inside the unit being installed.

● During transportation, do not allow the backrest of the forklift make contact with the unit, otherwise,

it may cause damage to the heat exchanger and also may cause injury when stopped or started

suddenly.

● Remove gas inside the closing pipe when the brazing work is performed. If the brazing ller metal is

melted with remaining gas inside, the pipes will be blown off and it may cause injury.

● Be sure to use nitrogen gas for an airtight test. If other gases such as oxygen gas, acetylene gas or

uorocarbon gas are accidentally used, it may cause explosion or gas intoxication.

After installation work for the system has been completed, explain the “Safety Precautions,” the proper use

and maintenance of the unit to the customer according to the information in all manuals that came with the

system. All manuals and warranty information must be given to the user or left near the Indoor Unit.

TC-16001-rev.5

iii

Page 6

Refrigerant Precautions

To reduce the risk of serious injury or death, the following refrigerant

precautions must be followed.

● As originally manufactured, this unit contains refrigerant installed by Johnson Controls. Johnson

Controls uses only refrigerants that have been approved for use in the unit’s intended home country

or market. Johnson Controls distributors similarly are only authorized to provide refrigerants that

have been approved for use in the countries or markets they serve. The refrigerant used in this unit

is identied on the unit’s faceplate and/or in the associated manuals. Any additions of refrigerant into

this unit must comply with the country’s requirements with regard to refrigerant use and should be

obtained from Johnson Controls distributors. Use of any non-approved refrigerant substitutes will void

the warranty and will increase the potential risk of injury or death.

● If installed in a small room, take measures to prevent the refrigerant from exceeding the maximum

allowable concentration in the event that refrigerant gases should escape. Refrigerant gases can

cause asphyxiation (0.026 lbs/ft

3

(0.42 kg/m3) based on ISO 5149 for R410A). Consult with your

distributor for countermeasures (ventilation system and so on). If refrigerant gas has leaked during the

installation work, ventilate the room immediately.

● Check the design pressure for this product is 601 psi (4.15MPa). The pressure of the refrigerant

R410A is 1.4 times higher than that of the refrigerant R22. Therefore, the refrigerant piping for

R410A shall be thicker than that for R22. Make sure to use the specied refrigerant piping. If not, the

refrigerant piping may rupture due to an excessive refrigerant pressure. Besides, pay attention to

the piping thickness when using copper refrigerant piping. The thickness of copper refrigerant piping

differs depending on its material.

● The refrigerant R410A is adopted. The refrigerant oil tends to be affected by foreign matters such

as moisture, oxide lm, (or fat). Perform the installation work with care to prevent moisture, dust, or

different refrigerant from entering the refrigerant cycle. Foreign matter can be introduced into the cycle

from such parts as expansion valve and the operation may be unavailable.

● To avoid the possibility of different refrigerant or refrigerant oil being introduced into the cycle, the

sizes of the charging connections have been changed from R407C type and R22 type. It is necessary

to prepare the appropriate tools before performing installation work.

● Use refrigerant pipes and joints which are approved for use with R410A.

● A compressor/unit comprises a pressurized system. Never loosen threaded joints while the system is

under pressure and never open pressurized system parts.

● Before installation is complete, make sure that the refrigerant leak test has been performed. If

refrigerant gases escape into the air, turn OFF the main switch, extinguish any open ames and

contact your service contractor. Refrigerant (Fluorocarbon) for this unit is odorless. If the refrigerant

should leak and come into contact with open ames, toxic gas could be generated. Also, because the

uorocarbons are heavier than air, they settle to the oor, which could cause asphyxiation.

● When installing the unit, and connecting refrigerant piping, keep all piping runs as short as

possible, and make sure to securely connect the refrigerant piping before the compressor starts

operating. If the refrigerant piping is not connected and the compressor activates with the stop

valve opened, the refrigerant cycle will become subjected to extremely high pressure, which can

cause an explosion or re.

● Tighten the are nut with a torque wrench in the specied manner. Do not apply excessive force to the

are nut when tightening. If you do, the are nut can crack and refrigerant leakage may occur.

● When maintaining, relocating, and disposing of the unit, dismantle the refrigerant piping after the

compressor stops.

● When pipes are removed out from under the piping cover, after the insulation work is completed,

cover the gap between the piping cover and pipes by a packing (eld-supplied). If the gap is not

covered, the unit may be damaged if snow, rain water or small animals enter the unit.

● Do not apply an excessive force to the spindle valve at the end of opening. Otherwise, the spindle

valve ies out due to refrigerant pressure. At the test run, fully open the gas and liquid valves,

otherwise, these devices will be damaged. (It is closed before shipment.)

● If the arrangement for outdoor units is incorrect, it may cause owback of the refrigerant and result in

failure of the outdoor unit.

● The refrigerant system may be damaged if the slope of the piping connection kit exceeds +15

o

.

iv

TC-16001-rev.5

Page 7

Electrical Precautions

Take the following precautions to reduce the risk of electric shock, re or

explosion resulting in serious injury or death.

● Highly dangerous electrical voltages are used in this system. Carefully refer to the wiring diagram

and these instructions when wiring. Improper connections and inadequate grounding can cause

serious injury or death.

● Perform all electrical work in strict accordance with this installation and maintenance manual and all

the relevant regulatory standards.

● Before servicing, open and tag all disconnect switches. Never assume electrical power is

disconnected. Check with meter and equipment.

● Only use electrical protection equipment and tools suited for this installation.

● Insulate a wired controller against moisture and temperature extremes.

● Use specied cables between units.

● The new air conditioner may not function normally in the following instances:

◦ If electrical power for the new air conditioner is supplied from the same transformer as the device*

referred to below.

◦ If the power source cables for this device* and the new air conditioner unit are located in close

proximity to each other.

Device*: (Example): A lift, container crane, rectier for electric railway, inverter power device,

arc furnace, electric furnace, large-sized induction motor and large-sized switch.

Regarding the cases mentioned above, surge voltage may be inducted into the power supply

cables for the packaged air conditioner due to a rapid change in power consumption of the device

and an activation of a switch.

Check eld regulations and standards before performing electrical work in order to protect the

power supply for the new air conditioner unit.

● Communication cabling shall be a minimum of AWG18 (0.82mm

2

), 2-Conductor, Stranded Copper.

Shielded cable must be considered for applications and routing in areas of high EMI and other

sources of potentially excessive electrical noise to reduce the potential for communication errors.

When shielded cabling is applied, proper bonding and termination of the cable shield is required

as per Johnson Controls guidelines. Plenum and riser ratings for communication cables must be

considered per application and local code requirements.

● The polarity of the input terminals is important, so be sure to match the polarity when using contacts

that have polarity.

● Use an exclusive power supply for the air conditioner at the unit’s rated voltage.

● Highly dangerous electrical voltages may be used in this system. Carefully refer to the wiring diagram

and these instructions when wiring. Improper connections and inadequate grounding can cause

serious injury or death.

● Before installing the controller or remote devices, ensure that the indoor and outdoor unit operation

has been stopped. Further, be sure to wait at least ve minutes before turning off the main power

switch to the indoor or outdoor units. Otherwise, water leakage or electrical breakdown may result.

● Do not open the service cover or access panel to the indoor or outdoor units without turning OFF the

main power supply. Before connecting or servicing the controller or cables to indoor or outdoor units,

open and tag all disconnect switches. Never assume electrical power is disconnected. Check with a

meter and equipment.

● This equipment can be installed with a Ground Fault Circuit Breaker (GFCI), which is a recognized

measure for added protection to a properly grounded unit. Install appropriate sized breakers / fuses

/ overcurrent protection switches, and wiring in accordance with local, state and NEC codes and

requirements. The equipment installer is responsible for understanding and abiding by applicable

codes and requirements.

TC-16001-rev.5

v

Page 8

- TABLE OF CONTENTS -

IMPORTANT NOTICE AND SAFETY SUMMARY ......................................................................................... i

1. Introduction ................................................................................................................................................ i

2. Important Safety Instructions ..................................................................................................................... i

1. General Information (Features) .................................................................................................................. 1-1

2. Outdoor Units ............................................................................................................................................. 2-1

2.1 Unit Nomenclature ............................................................................................................................. 2-1

2.2 Line-up .............................................................................................................................................. 2-1

2.3 General Data ..................................................................................................................................... 2-2

2.4 Dimensional Data and Weights ......................................................................................................... 2-3

2.4.1 Overall Dimensional and Weight Data ..................................................................................... 2-3

2.4.2 Outdoor Units ........................................................................................................................... 2-4

2.5 Structure ............................................................................................................................................ 2-5

2.6 Component Data ............................................................................................................................... 2-6

2.7 Service Space ................................................................................................................................... 2-7

2.8 Center of Gravity ............................................................................................................................... 2-10

2.9 Electrical Data ................................................................................................................................... 2-11

2.10 Sound Data ....................................................................................................................................... 2-12

2.11 Control System .................................................................................................................................. 2-13

2.11.1 Refrigerant Cycle ..................................................................................................................... 2-13

2.11.2 Control System ........................................................................................................................ 2-14

2.11.3 Standard Operation Sequence ................................................................................................ 2-15

2.11.4 Safety and Control Device Setting ........................................................................................... 2-29

2.11.5 Electrical Wiring Diagram ........................................................................................................ 2-31

2.12 Operation Range ............................................................................................................................... 2-33

2.13 Combination of Indoor Unit and Outdoor Unit ................................................................................... 2-34

2.14 Piping Work ....................................................................................................................................... 2-35

2.14.1 Piping Work Conditions ........................................................................................................... 2-35

2.14.2 Piping Size and Multi-Kit Selection .......................................................................................... 2-37

2.14.3 Piping Connection Method ....................................................................................................... 2-39

2.15 Electrical Wiring ................................................................................................................................. 2-41

2.15.1 Electrical Wiring Connection .................................................................................................... 2-41

2.15.2 Electrical Wiring Method .......................................................................................................... 2-43

2.16 Additional Refrigerant Charge Calculation ........................................................................................ 2-46

3. Optional Parts ............................................................................................................................................ 3-1

3.1 Line-Up .............................................................................................................................................. 3-1

3.2 Drain Adaptor: DBS-26 ...................................................................................................................... 3-2

3.3 Airow Guide: AG-335A ..................................................................................................................... 3-3

3.4 Wind Guard: WSP-160A .................................................................................................................... 3-5

3.5 Wind Prevention Tool: THS-335A ...................................................................................................... 3-7

3.6 Snow Protection Hood ....................................................................................................................... 3-9

3.7 Protection Net: PN-SP10C1 .............................................................................................................. 3-12

3.8 Multi-Kit (Line Branch): MW-NP282A2 and MW-NP282A3 ............................................................... 3-13

3.9 Multi-Kit (Header Branch): MH-NP224A and MH-NP288A ................................................................ 3-14

vi

TC-16001-rev.5

Page 9

- TABLE OF CONTENTS -

4. Selection Data ............................................................................................................................................ 4-1

4.1 Selection Guide ................................................................................................................................. 4-1

4.2 Outdoor Unit Capacity According to Temperature Condition and Connected IDU Capacity Ratio .... 4-5

4.3 Correction Factor According to Piping Length ................................................................................... 4-11

4.4 Correction Factor According to Defrost Operation ............................................................................ 4-13

4.5 Correction Factor According to Altitude ............................................................................................. 4-13

TC-16001-rev.5

vii

Page 10

Page 11

FEATURES

1. General Informations (Features)

Johnson Controls presents the inverter-driven Mini VRF series product, which is characterized by energy-

saving, high efciency, comfort, environmental protection, stability and reliability. In order to meet the

requirement of increasing the control intelligence of equipment and of comfort, the intelligent control, energysaving operation and comfort are particularly important. Specically the business buildings, building ofces,

apartments and residential areas, need an intelligent and comfortable environment throughout the year.

Better air conditioning solutions can be provided for these buildings using an improved inverter-driven and

scroll compressor.

VRF System

l

Johnson Controls has developed the VRF system with its customers in mind.

This system provides the consumer with greater exibility for installation, which means that the airconditioning systems will integrate better with complex facility structures.

Wide Variety of Indoor Unit Line-Up

l

Various indoor units can be selected depending on the installation location, shape of air outlet and interior.

Table 1.1 Indoor Unit Models

Ducted

Non-

Ducted

Indoor Unit Type

Ducted (High Static)

Ducted (Medium Static)

Ducted (Slim) (H,Y,C)IDS_B21S

Ducted (EconoFresh) (H,Y,C)IDM_B21E

Air Handler with DX-Kit (H,Y,C)MAHP_(B,C,D)21S

Ceiling-Mounted 4-Way Cassette (H,Y,C)IC4_B21S

Ceiling-Mounted 4-Way Cassette Mini (H,Y,C)ICM_B21S

Ceiling-Mounted 2-Way Cassette (H,Y,C)IC2_B21S

Ceiling-Mounted 1-Way Cassette (H,Y,C)IC1_B21S

Wall-Mounted TIWM_B21S

Ceiling Suspended (H,Y,C)ICS_B21S

Floor Exposed (H,Y,C)IFE_B21S

Floor Concealed (H,Y,C)IFC_B21S

(H,Y)IDH_B21S

(H,Y,C)IDH_B22S

(H,Y,C)IDM_B21S

(H,Y,C)IDM_B22S

6 8 12 15 18 24 27 30 36 48 54 60

: Available

NOTE:

Please refer to Section 2.13 “Combination of Indoor Unit and Outdoor Unit”.

Capacity (MBH)

TC-16001-rev.5

1-1

Page 12

FEATURES

High Efciency and Energy Saving

l

By improving the performance of the compressor and optimizing the refrigerant system, considerable

energy savings for buildings are achieved with the Mini VRF.

Seasonal energy efciency based on the AHRI 210/240 performance standard satises DOE minimum

levels as follows.

< Cooling >

Combination with Ducted Medium Static Type

SEER

26

24

22

20

18

16

14

12

10

23.50

18.70

(H,Y,C)VAHP036B21S(H,Y,C)VAHP048B21S(H,Y,C)VAHP060B21S

18.40

Combination with 4-Way Cassette Type

24.10

15.90

16.80

Minimum Level=14.0

(DOE10 CFR430.32)

< Heating >

HSPF

14

13

12

11

10

Combination with Ducted Medium Static Type

Combination with 4-Way Cassette Type

12.80

11.80

11.70

11.00

9

8

7

6

5

(H,Y,C)VAHP036B21S(H,Y,C)VAHP048B21S(H,Y,C)VAHP060B21S

12.10

10.60

Minimum Level=8.2

(DOE10 CFR430.32)

1-2

TC-16001-rev.5

Page 13

Flexibility of Facility Design

l

The piping can be designed and constructed up to a maximum piping length of 492ft. (150m).

1

Piping length: 492ft. (150m) *1

(Equivalent Length: 623ft. (190m))

2

Height difference between Outdoor Unit and Indoor Unit

Outdoor Unit is higher: 164ft. (50m)

Outdoor Unit is lower: 131ft. (40m)

3

Height difference between Indoor Units: 49ft. (15m)

4

Maximum length after branch

1

2

between 1st branch and each Indoor Unit: 131ft. (40m)

5

Maximum length after branch

between each branch and each Indoor Unit: 131ft. (40m)

3

5

Total Piping Length: 984ft. (300m) *1, *2

4

NOTE:

For details of piping restriction, refer to Section 2.14.1 “Piping Work Conditions”.

FEATURES

o

*1: When operating the outdoor unit in cold areas with temperatures of 14

F (-10oC), or under high heating

load conditions,the total piping length should be less than 310ft (95m) and the maximum piping length

(actual length) should be less than 246ft (75m).

*2: Total piping length may be restricted by the maximum additional refrigerant charge.

Field additional charge should not exceed the maximum additional refrigerant charge (table below).

< Max. Additional Refrigerant Charge Quantity Allowed >

Outdoor Unit Capacity (MBH) 36 - 60

Max. Additional Refrigerant Charge: lbs (kg) 18.5 (8.4)

Regarding additional refrigerant charge, refer to Section 2.16 “Additional Refrigerant Charge

Calculation”.

TC-16001-rev.5

1-3

Page 14

FEATURES

(H,Y)VAHP096B31S (H,Y,C)VAHP048B21S

54-5/16 in.

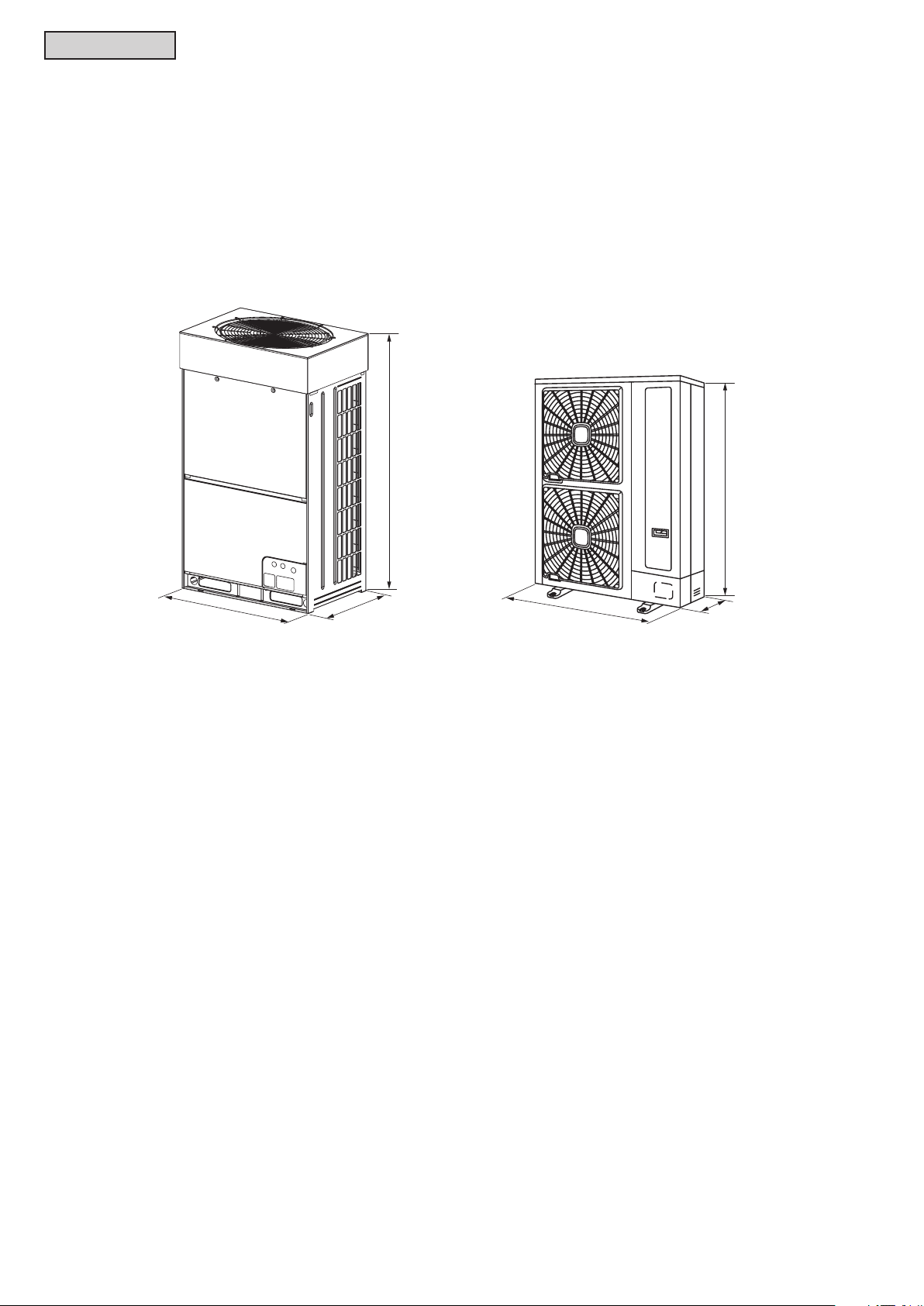

Compact and Lightweight Design

l

Facilitation and exibility at installation are further advanced by adopting a lightweight and compact design

of the outdoor unit compared to a top-ow model.

< For Example: Comparing (H,Y,C)VAHP048B21S and (H,Y,C)VAHP096B21S >

* Floor Area per Nominal Capacity:

* Net Weight per Nominal Capacity:

48-1/8 in.

32% Decrease

27% Decrease

68-1/8 in.

31-1/4 in.

37-3/8 in.

14-9/16 in.

Net Weight =

Nominal Capacity = 96,000 Btu/h Nominal Capacity = 48,000 Btu/h

730 lbs

(331kg) (113kg)

Net Weight =

249 lbs

● With a width of only 14-9/16 in. (370mm), a Mini VRF can be installed on a staircase landing or balcony

on each oor. (Regarding service space, refer to Section 2.7 “Service Space”.)

● Side-ow type Mini VRF can be installed under the eaves.

● With its light and compact body, Mini VRF can be easily carried in the elevator site.

(No cranes required for delivery.)

● The Mini VRF can be transported by as few as two people.

1-4

TC-16001-rev.5

Page 15

FEATURES

< System Example >

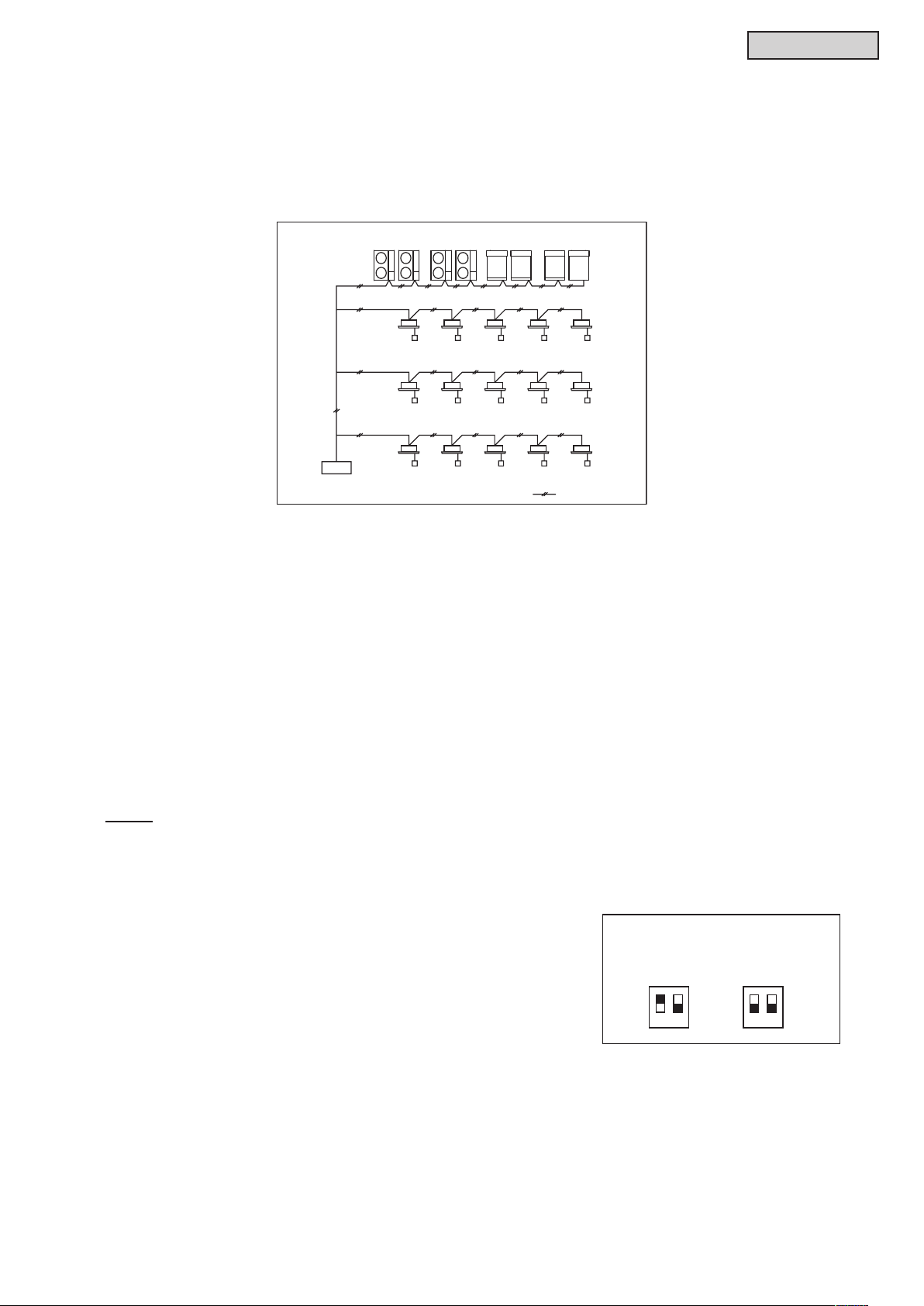

Corresponds to H-LINK II System

l

The outdoor units in the VRF Series correspond to the H-LINK II communication system. A maximum

of 64 refrigerant groups and a maximum of 160 indoor units can be controlled by only one central

control device when the equipment (central control device, indoor units, wired controller) in the same

communication system all correspond to H-LINK II.

Outdoor Units (Max. 64 Refrigerant Group)

Indoor Units (

Max. Connectable Q'ty: 160)

H-LINK II System

l

The H-LINK II wiring system requires only two communication cables to connect each indoor unit and

<Specications>

* Communication Cable: 2-Wire

* Polarity of Communication Cable: Non-Polar Cable

* Maximum Outdoor Units to be Connected: 64 Units per System

* Maximum Indoor Units to be Connected: 160 Units per H-LINK II System

* Maximum Cable Length: Total 3,280 ft. (1,000m) (including central controller)

* Recommended Cable: Communication Cable with Shield, over AWG18 (Equivalent to KPEV-S)

* Voltage: DC5V

NOTE:

When using an H-LINK II system, the setting of DIP switches for an outdoor unit and indoor unit is required.

If the DIP switches are not set, or set incorrectly, an alarm may occur because of a communication failure.

Setting of End Terminal Resistance

l

Factory setting of the No.1 pin of DSW5 is in the "ON" position.

Central Control Device

: Control Line

outdoor unit for up to 64 refrigerant systems, and to connect wires for all indoor units and outdoor units.

Setting of End Terminal Resistance

When the number of outdoor units in the same H-LINK system is

two or more, set the No.1 pin of DSW5 at "OFF" at the second unit.

If only one outdoor unit is used, no setting is required.

Factory Setting Cancellation

DSW5

ON

OFF

12 12

ON

OFF

TC-16001-rev.5

1-5

Page 16

FEATURES

Indoor Air Inlet Temperature oF DB/WB (oC DB/WB)

Outdoor Air Temperature

Indoor Air Inlet Temperature oF DB (oC DB)

Outdoor Air Temperature

Wide Operation Range

l

This unit has been designed for cooling operations under low ambient temperatures down to

23°F (-5°C) DB.

This wide operation range enables cooling even in winter in buildings with high internal heat gains

resulting from lighting, people and machines, particularly in areas such as shops, lecture rooms, and data

processing areas Heating operations under low ambient temperature down to -4°F (-20°C) WB can also

be accomplished.

Cooling Operation

118(48)

C DB)

o

F DB (

o

50(10)

23(-5)

Continuous Operation

Working Range

70/59

(21/15)

90/74

(32/23)

NOTE:

For details, please refer to Section 2.12 “Operation Range”.

C WB)

o

F WB (

o

59(15)

5(-15)

-4(-20)

Heating Operation

Continuous Operation

Working Range

Operation

Working Range

-9.5

(15)

80

(27)

1-6

TC-16001-rev.5

Page 17

FEATURES

Operating Hours

Power Consumption

the reference power consumption

Power Setting

8 A.M. 12 P.M. 3 P.M. 6 P. M.

Time

Group A Group B

The specific outdoor unit and the period of time can be set from

computerized controller.

Computerized Controller

(

Energy-Saving through Schedule Setting of “Self-Demand Function”

l

“Self-Demand Function”* can be set for each outdoor unit from a Computerized Central Controller (CCCS01

and CCCA01) or Wired Controller (CIW01).

For small and medium buildings, it facilitates power saving. The energy-saving operation can be adjusted

conforming to an operating environment and individual needs.

* Self-Demand Function: It saves capacity so as not to exceed demand current control based on

the electric power data detected.

< Self-Demand Function >

Excessive power usage exceeding

the setting range is restricted.

Power Setting

Selectable from 100%,

Maximum efficiency is secured

within the power setting range.

Morning Daytime Night

80%, 70%, 60% and 40% of

for cooling operation.

Outdoor Unit Capacity

[MBH]

Reference Power Consumption

[kW]

036 3.9

048 4.5

060 4.5

< Setting Example: Schedule Setting for Each Group by Computerized Controller >

Group A

Group B

Power Setting: 60%

Power Setting: 80%

Various operating methods

are available depending on

purpose and needs.

CCCS01 and CCCA01)

NOTES:

1. The demand current control (%) is indicated by approximate values. The value in this control which is

calculated by the current is different from the value in the wattmeter.

If it is required that the maximum power consumption is managed precisely, a eld-supplied demand

controller should be used.

2. The range may temporarily be higher than the power-setting range (%) depending on the operating

control condition such as protection control.

3. When the above self-demand control is set, performance is restricted because the rotation frequency of

the compressor is automatically lowered.

TC-16001-rev.5

1-7

Page 18

FEATURES

Operation Sound Reduction Function

l

(1) Night Shift Mode (Optional Function)

With the Night Shift Mode setting by optional function, when ambient temperature is 86

less in a cooling operation, rotation speed of the compressor and the outdoor fan is automatically

lowered.

o

F (30oC) or

Outdoor Unit Capacity

[MBH]

036 51 44

048 52 46

060 53 46

Sound Pressure Level [dB]

Rated Operation Night Shift

NOTES:

1. Night shift mode is recommended when cooling capacity has sufcient margin compared to cooling

load and operation sound should be reduced at night time.

2. Cooling capacity may be decreased about 60%.

3. Regarding setting methods, refer to the Service Manual.

(2) Low Noise Setting Mode (Optional Function)

With Low Noise Setting Mode by optional function, rotation speed of the compressor is forcibly

decreased regardless of ambient temperature.

Low Noise Setting Mode can be selected from three levels and time can be scheduled and set by the

Wired Controller (CIW01).

Outdoor Unit Capacity

[MBH]

036 -1 -2 -3

048 -1 -2 -3

060 -2 -3 -4

Low Noise Setting 1 Low Noise Setting 2 Low Noise Setting 3

Sound Pressure Level [dB]

NOTES:

1. Cooling and heating capacity may drop to 80%, 70% and 60% in each setting mode.

2. Regarding setting method, refer to the Service Manual.

3. Regarding time schedule setting, refer to the Installation Manual for the Wired Controller.

1-8

TC-16001-rev.5

Page 19

2. Outdoor Units

2.1 Unit Nomenclature

● Outdoor Units

Model Descriptions

Example

Nomenclature Description

H = Hitachi Brand

Y = York Brand

C = Coleman Brand

VRF V

A = Air Source A

HP = Heat Pump HP

036 = 36 MBH

048 = 48 MBH

060 = 60 MBH

B = R410A B

2 = 208/230Volts - 1Phase - 60Hz 2

1 = 1st Generation 1

S = Standard (Factory Options) S

OUTDOOR UNITS

H V A HP 036 B 2 1 S

H

036

2.2 Line-up

Voltage Capacity (MBH) Model Name

208/230V

TC-16001-rev.5

2-1

36 (H,Y,C)VAHP036B21S

48 (H,Y,C)VAHP048B21S

60 (H,Y,C)VAHP060B21S

Page 20

OUTDOOR UNITS

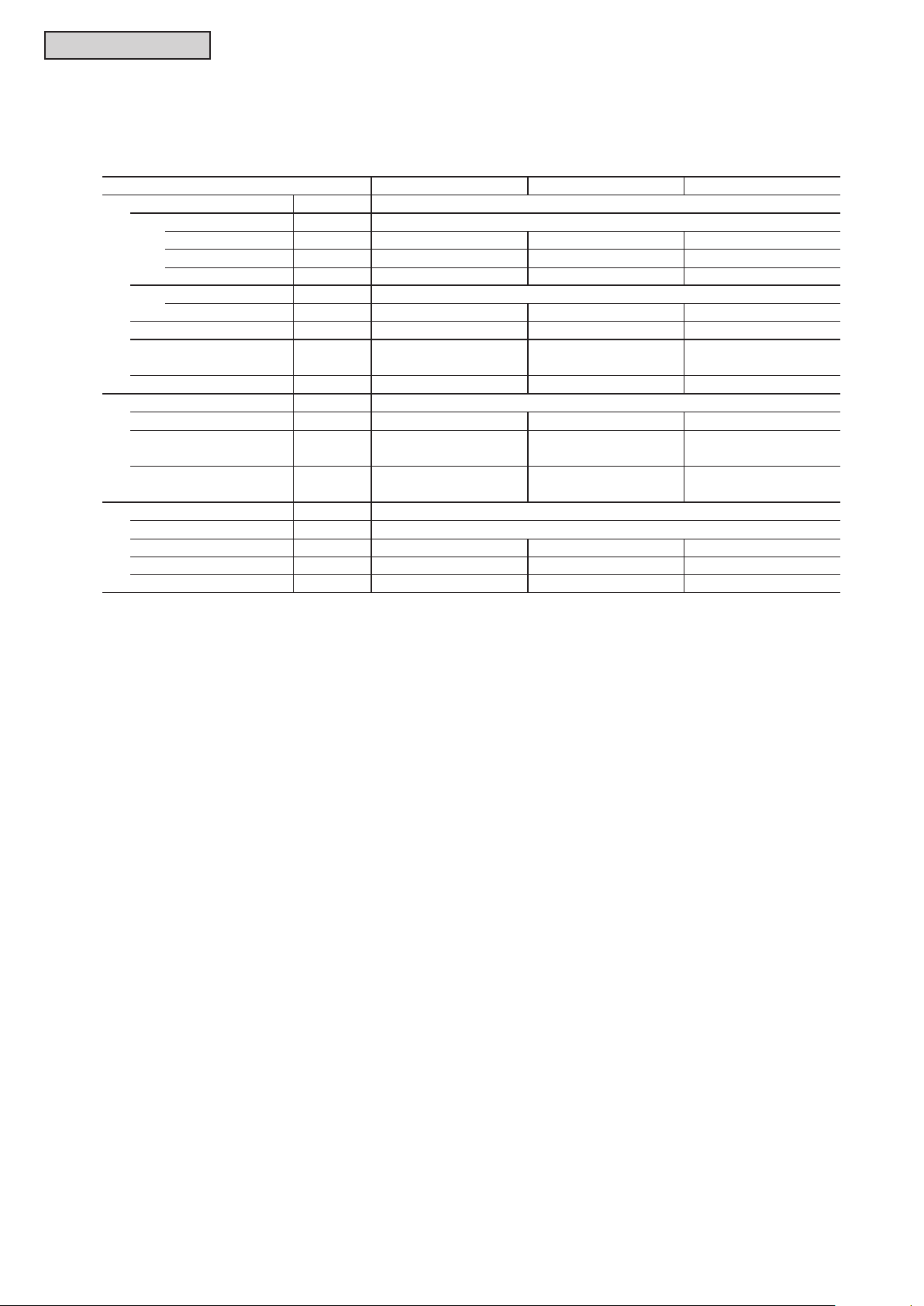

2.3 General Data

Category Mini VRF Outdoor Unit

Model (H,Y,C)VAHP036B21S (H,Y,C)VAHP048B21S (H,Y,C)VAHP060B21S

Power Supply 208/230V/ 1PH 60Hz 208/230V/ 1PH 60Hz 208/230V/ 1PH 60Hz

Capacity (Nominal) *1

Efficiency Ratings *2

(Non-Ducted / Ducted)

Cooling Operating

Range

Heating Operating

Range

Cabinet Color (Munsell Code) - 1.0Y8.5/0.5 1.0Y8.5/0.5 1.0Y8.5/0.5

Outer Dimensions

Package Dimensions

Weight

Connection Ratio

Heat Exchanger

Compressor

Crank Case Heater W × Qty 52W(208V) ×1 52W(208V) ×1 52W(208V) ×1

Fan

Electrical

Sound Pressure Level

*5

Protection Devices

Refrigerant

Refrigeration Oil Charge Amount gal/Unit (L/Unit) 0.34 (1.3) 0.34 (1.3) 0.34 (1.3)

Defrost Method - Reversed Refrigerant Cycle Reversed Refrigerant Cycle Reversed Refrigerant Cycle

Main Refrigerant

Piping

Cooling Capacity (Nominal) Btu/h (kW) 36,000 (10.6) 48,000 (14.1) 60,000 (17.6)

Heating Capacity (Nominal) Btu/h (kW) 40,000 (11.7) 54,000 (15.8) 64,000 (18.8)

Cooling

Heating

Indoor

Outdoor

Indoor

Outdoor

Height in. (mm) 54-5/16 (1380) 54-5/16 (1380) 54-5/16 (1380)

Width in. (mm) 37-3/8 (950) 37-3/8 (950) 37-3/8 (950)

Depth in. (mm) 14-9/16 (370) 14-9/16 (370) 14-9/16 (370)

Height in. (mm) 59-9/16 (1513) 59-9/16 (1513) 59-9/16 (1513)

Width in. (mm) 40-3/8 (1025) 40-3/8 (1025) 40-3/8 (1025)

Depth in. (mm) 18-1/8 (460) 18-1/8 (460) 18-1/8 (460)

Net lbs (kg) 249 (113) 249 (113) 249 (113)

Gross lbs (kg) 267 (121) 267 (121) 267 (121)

Total Indoor Unit Capacity % 130-60 130-60 105-60

Max. Indoor Units/System - 6 8 8

Type -

Material - Cu-Al (Anti-corrosion) Cu-Al (Anti-corrosion) Cu-Al (Anti-corrosion)

Type - HA36PHD-A1S2 HA36PHD-A1S2 HA36PHD-A1S2

Motor Phase / Pole - / - 3PH / 6 3PH / 6 3PH / 6

Start Method - Inverter Inverter Inverter

Operation Range % 10 ~ 100 10 ~ 100 10 ~ 100

Refrigeration Oil Type - FVC68D FVC68D FVC68D

Type - Propeller Fan Propeller Fan Propeller Fan

Quantity Qty 2 2 2

Motor Output (Pole) W (Pole) 58(10) + 58(10) 58(10) + 58(10) 58(10) + 58(10)

Airflow Rate cfm

Drive - Direct-drive Direct-drive Direct-drive

Min. Circuit Amps A 31 31 31

Max. Overcurrent Protective Device A 40 40 40

Cooling (Night-Shift) dB (A) 51 (44) 52 (46) 53 (46)

Heating dB (A) 52 54 56

Cycle -

Compressor -

Fan Motor -

PCB (Control Circuit) Type - R410A R410A R410A

Charge Amount lbs (kg) 7.9 (3.6) 7.9 (3.6) 7.9 (3.6)

Gas Line in. (mm) 5/8 (15.88) 5/8 (15.88) 5/8 (15.88)

Liquid Line in. (mm) 3/8 (9.52) 3/8 (9.52) 3/8 (9.52)

Power Input kW 2.53 3.78 5.05

Current Input A (208V/230V) 12.3 / 11.1 18.6 / 16.9 24.8 / 22.4

Power Input kW 2.36 3.95 4.42

Current Input A (208V/230V) 11.8 / 10.6 19.6 / 17.7 21.7 / 19.6

Rated Capacity Btu/h 36,000 / 36,000 48,000 / 48,000 60,000 / 55,000

EER Btu/Wh 16.70 / 13.80 16.70 / 13.10 12.20 / 9.70

SEER Btu/Wh 23.50 / 18.70 24.10 / 18.40 16.80 / 15.90

Rated Capacity Btu/h 40,000 / 40,000 54,000 / 54,000 64,000 / 64,000

COP W/W 5.12 / 3.90 4.56 / 3.86 3.90 / 3.30

HSPF Btu/Wh 12.80 / 11.00 11.70 / 11.80 12.10 / 10.60

o

F WB (oC WB)

o

F DB (oC DB)

o

F DB (oC DB)

o

F WB (oC WB)

(m

23 (-5) ~ 118 (48) *3 23 (-5) ~ 118 (48) *3 23 (-5) ~ 118 (48) *3

-4 (-20) ~ 59 (15) *4 -4 (-20) ~ 59 (15) *4 -4 (-20) ~ 59 (15) *4

3

3177 (90) 3530 (100) 3530 (100)

/min)

High pressure switch

at 601psi (4.15MPa)

Over-current protection

Over-heat protection

Circuit Breaker (30A)

Over-current protection

Over-heat protection

Self-contained fuse (5A)

59 (15) ~ 73 (23) 59 (15) ~ 73 (23) 59 (15) ~ 73 (23)

59 (15) ~ 80 (27) 59 (15) ~ 80 (27) 59 (15) ~ 80 (27)

Multi-Pass Cross-

Finned Tube

Fuse on PCB(5A)

Multi-Pass Cross-

Finned Tube

High pressure switch

at 601psi (4.15MPa)

Over-current protection

Over-heat protection

Circuit Breaker (30A)

Over-current protection

Over-heat protection

Self-contained fuse (5A)

Fuse on PCB(5A)

Multi-Pass Cross-

High pressure switch

at 601psi (4.15MPa)

Over-current protection

Over-heat protection

Circuit Breaker (30A)

Over-current protection

Over-heat protection

Self-contained fuse (5A)

Fuse on PCB(5A)

Finned Tube

NOTES:

*1 Rating Conditions:

Cooling Heating

Indoor Air Inlet Temperature: 80

67

Outdoor Air Inlet Temperature: 95

o

F (26.7oC) DB Indoor Air Inlet Temperature: 70oF (21.1oC) DB

o

F (19.4oC) WB Outdoor Air Inlet Temperature: 47oF (8.3oC) DB

o

F (35.0oC) DB 43oF (6.1oC) WB

Piping Length: 24.6ft. (7.5m), Piping Lift: 0ft. (0m)

*2 Efciency ratings are based on the AHRI 210/240 test standard.

*3 There are some exceptions and notes for cooling operation ranges. For details, refer to Section 2.12 “Operation Range”.

*4 There are some exceptions and notes for heating operation ranges. For details, refer to Section 2.12 “Operation Range”.

*5 Measurement Point: 3.3ft. (1m) from the air outlet side, 4.9ft. (1.5m) from oor level.

The operation sound is measured in an anechoic chamber. However, the actual operation sound may appear louder or with an echo

because of surrounding environmental noise. Be sure to check environmental conditions before installation.

The sound of the air inlet side may be 3dB higher than that of the air outlet side.

2-2

TC-16001-rev.5

Page 21

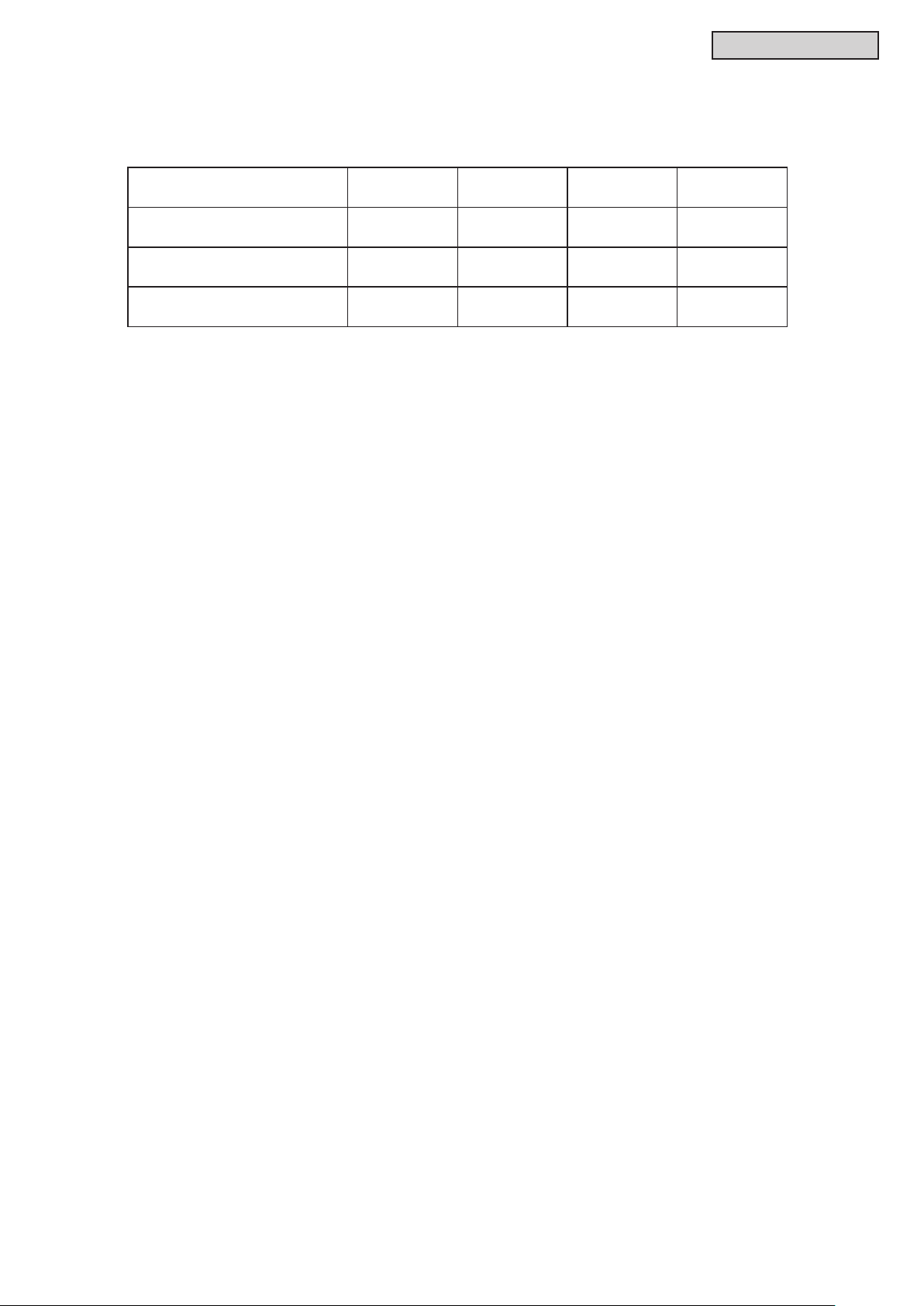

2.4 Dimensional Data and Weights

2.4.1 Overall Dimensional and Weight Data

OUTDOOR UNITS

Model

(H,Y,C)VAHP036B21S

(H,Y,C)VAHP048B21S

(H,Y,C)VAHP060B21S

Height

[in. (mm)]

54-5/16

(1380)

54-5/16

(1380)

54-5/16

(1380)

Width

[in. (mm)]

37-3/8

(950)

37-3/8

(950)

37-3/8

(950)

Depth

[in. (mm)]

14-9/16

(370)

14-9/16

(370)

14-9/16

(370)

Net Weight

[lbs (kg)]

249

(113)

249

(113)

249

(113)

TC-16001-rev.5

2-3

Page 22

OUTDOOR UNITS

2.4.2 Outdoor Units

Model: (H,Y,C)VAHP036B21S to (H,Y,C)VAHP060B21S

inch [mm]

A side view

•

Drain Water

Drain water is caused during heating operation or defrost operation.

1

Choose a place where well drainage is available.

Or provide a groove for drain.

2

Do not provide an upward slope from the unit

to avoid reverse ow of the drain.

3

When dripping drain water is not permissible,

provide a second drain pan under the outdoor unit to

ensure collection of drain water.

2-4

TC-16001-rev.5

Page 23

2.5 Structure

Model: (H,Y,C)VAHP036B21S to (H,Y,C)VAHP060B21S

OUTDOOR UNITS

inch [mm]

No. Part Name

1 Compressor (Inverter)

2 Heat Exchanger

3 Propeller Fan (2 pcs.)

4 Fan Motor (2 pcs.)

5 Strainer (2 pcs.)

6 Distributor

7 Reversing Valve

8 Electronic Expansion Valve

9 Solenoid Valve

10 Stop Valve (Gas)

11 Stop Valve (Liquid)

TC-16001-rev.5

2-5

No. Part Name

12 Check Valve

13 Accumulator

14 Access Port

15 Oil Separator

16 Capillary Tube

17 Electrical Control Box

18 High Pressure Switch for Protection

19 High Pressure Sensor

20 Low Pressure Sensor

21 Crankcase Heater

22 Vibration Absorber (4 pce.)

Page 24

OUTDOOR UNITS

222

222

EEE

222

2.6 Component Data

Outdoor Heat Exchanger and Fan

Model

Heat Exchanger Type

Tube Material Copper Tube

Outer Diameter

Rows

Number of Tube/Coil

Fin Material Aluminum

Pitch in. (mm) 0.055 (1.4) 0.055 (1.4) 0.055 (1.4)

Maximum Operating Pressure

Total Face Area 14.42 14.42 14.42

Number of Coil/Unit 1 1 1

Outdoor Fan

Number/Unit

Outer Diameter

Nominal Airflow cfm

Outdoor Fan Motor

Starting Method DC Motor

Nominal Output W

Quantity

Insulation Class

in. (mm)

psi (MPa) 601 (4.15) 601 (4.15) 601 (4.15)

2

ft

(m2)

in.

(mm)

3

/min)

(m

(H,Y,C)VAHP036B21S (H,Y,C)VAHP048B21S (H,Y,C)VAHP060B21S

Multi-Pass Cross Finned Tube

0.28 (7.0) 0.28 (7.0) 0.28 (7.0)

132 132 132

(1.34) (1.34) (1.34)

Large Diameter Fan (Propeller Fan)

21-7/16 21-7/16 21-7/16

(544) (544) (544)

3496 3885 3885

(99) (110) (110)

Drip-Proof Type Enclosure

58+58 58+58 58+58

2-6

TC-16001-rev.5

Page 25

OUTDOOR UNITS

inch (mm)

inch (mm)

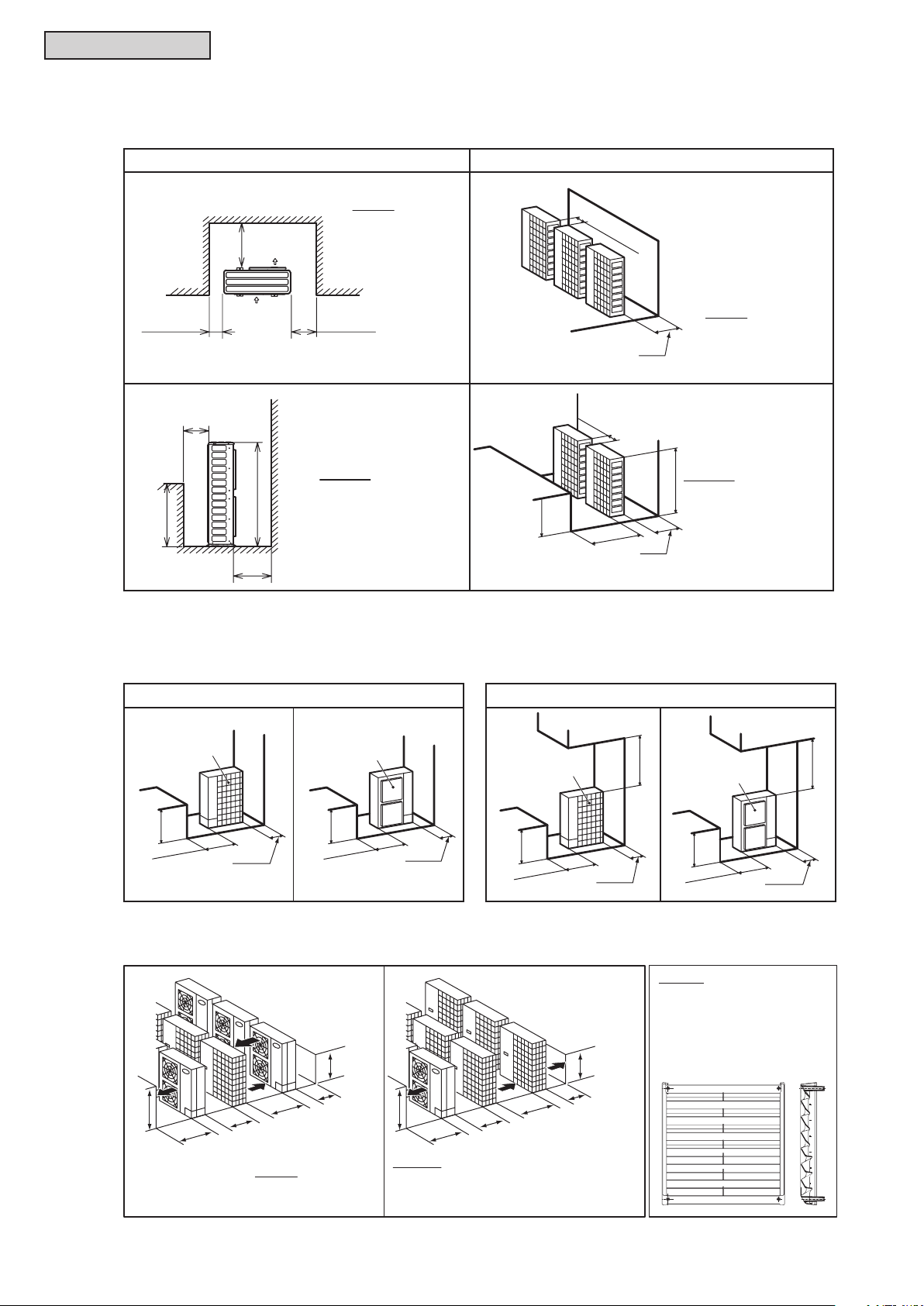

2.7 Service Space

When an outdoor unit is installed, allow sufcient clearance as follows:

•If there is insufcient clearance for air inlets and outlets, it may result in a performance drop-off and

mechanical issues due to insufcient air intake.

•Additionally, adequate clearance is required for service maintenance access.

(1) Obstacles on Inlet Side

(a) Upper Side is Open.

Single Installation Multiple Installation

* Around sides

are open.

Min. 8 (200)

Front Side

* Around sides

are closed.

Min. 2

(50)

Fit positions " " with unit front side.

NOTES:

A

● Install Airflow Guide

(optional)

● Open both

right and left sides.

H

L

B

(b) Obstacles on Upper Side

Min. 12 (300)

Front

Side

Min. 4

(100)

Min. 12 (300)

Front Side

Min. 4

(100)

NOTE:

Open both right and left sides.

Min. 4

(100)

L

A

B

Front Side

NOTES:

● Install Airflow Guide

(optional)

● Open both

right and left sides.

Max. 12 (300)

Max. 12 (300)

A

L

B

Single Installation Multiple Installation

Min. B

Min. 40

(1000)

H

Min. 40

(1000)

H

NOTES:

● Install Airflow Guide

(optional)

● Open both

right and left sides.

Min. 4 (100)

Min. 4 (100)

L

Max. 12 (300)

B

Max. 12 (300)

A

B

(1000)

Min. 40

NOTE:

Open both

H

right and left sides.

(1000)

Min. 40

NOTES:

● Install Airflow Guide

(optional)

H

● Open both

right and left sides.

● No more than 2 units

for multiple installation

TC-16001-rev.5

2-7

Page 26

OUTDOOR UNITS

inch (mm)

inch(mm)

inch (mm)

inch (mm)

(2) Obstacles on Outlet Side

(a) Upper Side is Open.

Single Installation Multiple Installation

Front

A

Side

Min. 2 (50)Min. 4 (100)

B

NOTES:

H

L

● Install Airflow Guide

(optional)

● Open both

right and left sides.

A

(3) Obstacles on Right and Left Side

NOTE:

Open eather

right or left side.

Min. 4 (100)

NOTE:

Open both

A

Min. 6 (150)

L

B

A

right and left sides.

NOTES:

H

● Install Airflow Guide

(optional)

● Open both

right and left sides.

● No more than 2 units

for multiple installation

(a) Upper Side is Open. (b) Obstacles on Upper Side

L

Min. 20

(500)

Rear Side

Single Installation

L

Min. 2

(50)

Min. 20

(500)

Front Side

Min. 4

(100)

L

Min. 20

(500)

Rear Side

Single Installation

Min. 2

(50)

(4) Multi-Row and Multiple Installations

L

A

(4000)

(3000)

L

B

L

Min. 24

A

Min. 158

(600)

NOTES:

● Open both right and left sides.

● Install each outdoor unit not to inlet

the outlet air from the other outdoor units.

L

A

Min. 119

Min. 24

(600)

NOTE:

Open both

right and left sides.

(1000)

Min. 40

Front Side

L

Min. 20

(500)

Min. 4

NOTE:

Ensure that the outlet

ow is not short-circuited

to the air inlet side when

using the Airow Guide

(optional).

(100)

(1000)

Min. 40

2-8

TC-16001-rev.5

Page 27

OUTDOOR UNITS

NOTE

inch (mm)

• If L is larger than H, mount the units on a base so that H

is greater or equal to L.

Be sure to seal up every surface of the base. If the base

allows the airow to go, it may cause a short-circuit.

• The Airow Guide (optional) is required when there are interferences in both the front and rear side of the

outdoor unit.

• The installation of multi-row and multiple outdoor units should be up to three outdoor units on a roof. Use

the Airow Guide (optional) in order to prevent short-circuiting if more than three outdoor units are installed.

L A B

0 < L < 1/2H

1/2H < L < H

24 (600)

or more

56 (1400)

or more

12 (300)

or more

14 (350)

or more

TC-16001-rev.5

2-9

Page 28

OUTDOOR UNITS

2.8 Center of Gravity

Model

(H,Y,C)VAHP036B21S

(H,Y,C)VAHP048B21S

(H,Y,C)VAHP060B21S

Model

(H,Y,C)VAHP036B21S 44

(H,Y,C)VAHP048B21S 54

(H,Y,C)VAHP060B21S 74

Net Weight

[lbs (kg)]

249

(113)

249

(113)

249

(113)

Frequency

of Vibration

[Hz]

Center of Gravity

[inch (mm)]

a b c

23-5/8

(600)

23-5/8

(600)

23-5/8

(600)

Amplitude Value [×10

1 2 3 4 1 2 3 4

0.04

(1)

0.04

(1)

0.04

(1)

7-1/16

7-1/16

7-1/16

0.04

(1)

0.04

(1)

0.04

(1)

(180)

(180)

(180)

24-7/16

(620)

24-7/16

(620)

24-7/16

(620)

-3

inch (μm)] Acceleration of Vibration [dB]

0.08

(2)

0.08

(2)

0.08

(2)

0.04

(1)

0.04

(1)

0.04

(1)

72 72 78 72

75 75 81 75

81 81 87 81

< Vibration Characteristics Measurement Conditions >

Above values are measured under the following conditions:

1. Outdoor unit is placed on a concrete oor 5 in (120mm) thick (concrete oor is directly cast on ground).

2. Outdoor unit is operated under our standard operating conditions.

2-10

TC-16001-rev.5

Page 29

OUTDOOR UNITS

2.9 Electrical Data

Outdoor Unit INV Comp.

Model

(H,Y,C)VAHP036B21S 60 208/230 228/253 188/207 31 40 40 24 30

(H,Y,C)VAHP048B21S 60 208/230 228/253 188/207 31 40 40 24 30

(H,Y,C)VAHP060B21S 60 208/230 228/253 188/207 31 40 40 24 30

Model

(H,Y,C)VAHP036B21S 0.058+0.058 0.5+0.5 8 8 18 3/4 (19.05)

(H,Y,C)VAHP048B21S 0.058+0.058 0.5+0.5 8 8 18 3/4 (19.05)

(H,Y,C)VAHP060B21S 0.058+0.058 0.5+0.5 8 8 18 3/4 (19.05)

MCA: Minimum Circuit Ampacity (A)

MOP: Maximum Overcurrent Protective Device (A)

RLA: Rated Load Ampacity (A)

LRA: Locked Rotor Ampacity (A)

FLA: Full Load Ampacity (A)

Hz Voltage Max. Min. MCA MOP Max. Fuse RLA LRA

[Hz] [V] [V] [V] [A] [A] [A] [A] [A]

Fan Motor Wiring Size Conduit Tube

Output FLA

[kW] [A] [AWG] [AWG] [AWG] [in. (mm)]

Power Supply

Wiring

Ground Wiring

Communication

Cable

for Power

Supply Wiring

TC-16001-rev.5

2-11

Page 30

OUTDOOR UNITS

2.10 Sound Data

Model: (H,Y,C)VAHP036B21S

Octave Band Central Frequency [Hz]

63 125 250 500 1k 2k 4k 8k

Cooling 32.4 33.5 40.8 47.0 46.1 41.5 36.6 23.1 51

Cooling (Night Shift) 29.9 27.4 34.6 41.8 33.4 31.2 32.7 22.8 44

Heating 53.7 52.9 49.9 50.6 47.0 42.5 37.0 31.9 52

Overall

[dB(A)]

Model: (H,Y,C)VAHP048B21S

Octave Band Central Frequency [Hz]

63 125 250 500 1k 2k 4k 8k

Cooling 32.1 33.1 40.9 47.3 47.6 43.6 38.9 26.9 52

Cooling (Night Shift) 29.9 29.3 36.3 44.1 34.6 32.9 34.6 24.8 46

Heating 32.1 36.9 42.9 48.8 49.3 45.8 44.0 29.9 54

Overall

[dB(A)]

Model: (H,Y,C)VAHP060B21S

Octave Band Central Frequency [Hz]

63 125 250 500 1k 2k 4k 8k

Cooling 33.1 34.1 42.0 48.3 48.6 44.6 39.9 27.9 53

Cooling (Night Shift) 29.9 29.3 36.3 44.1 34.6 32.9 34.6 24.8 46

Heating 30.0 37.9 45.3 51.8 49.8 47.9 46.7 33.1 56

Overall

[dB(A)]

NOTE:

The operation sound is measured in an anechoic chamber. However, the actual operation sound may appear louder because

of ambient noise or echoing. Be sure to check ambient conditions before installation.

The sound of the air inlet side may be 3dB higher than that of the air outlet side.

2-12

TC-16001-rev.5

Page 31

2.11 Control System

2.11.1 Refrigerant Cycle

Model: (H,Y,C)VAHP036B21S to (H,Y,C)VAHP060B21S

OUTDOOR UNITS

TC-16001-rev.5

Access Port

2-13

Page 32

OUTDOOR UNITS

2.11.2 Control System

Cycle Control

No. Item Details

Comp. Frequency Control

I.U. Electronic Exp. Valve Control

Cooling

1

Operation

Heating

2

Operation

Defrost

3

Operation

4 Comp. Preheating Control Crankcase Heater Control

O.U. Electronic Exp. Valve Control EVO: 480pls (Fully Opened)

Outdoor Fan Control

Reversing Valve Control Reversing Valve: OFF

Control of Solenoid Valve for

High/Low Pressure Bypass (SVA)

High/Low Pressure Control SVA: ON (during Operation Stop)

Comp. Frequency Control

I.U. Electronic Exp. Valve Control

O.U. Electronic Exp. Valve Control

Outdoor Fan Control

Reversing Valve Control Reversing Valve: ON

Control of Solenoid Valve for

High/Low Pressure Bypass (SVA)

High/Low Pressure Control SVA: ON (during operation stop)

Comp. Frequency Control Fixed Compressor Frequency

I.U. Electronic Exp. Valve Control

O.U. Electronic Exp. Valve Control EVO: 480pls (Fully Opened)

Outdoor Fan Control To stop the outdoor fan.

Reversing Valve Control Reversing Valve: OFF

Control of Solenoid Valve for

High/Low Pressure Bypass (SVA)

To determine the compressor frequency depending on (a),

(b) and (c).

● Quasi PI Control:

To determine the I.U. electronic expansion valve opening

so as to keep (d) at an optimum value.

● To change the I.U. electronic expansion valve opening

when the number of operating indoor units is changed.

To control the fan steps so that High Pressure is within a

stable temperature range.

At Start-up and when High Pressure Increase Protection

activated: ON

● PI Control:

To determine the compressor frequency so as to keep

High Pressure.

● To determine the compressor frequency from (a) and

(c) when heating operation is started or the number of

operating indoor units is changed.

● To determine the I.U. electronic expansion valve opening

so that the indoor liquid pipe temperature (trl) is at an

optimum level.

● To change the I.U. electronic expansion valve opening

when the number of operating indoor units is changed.

● Quasi PI Control:

To determine the O.U. electronic expansion valve

opening so as to keep the temperature at the top of the

compressor at an optimum level.

● When Operating Indoor Unit Number Changed:

To determine the O.U. electronic expansion valve

opening from the compressor frequency ratio before/after

the change and Quasi PI Control.

The fan steps are dependent on Ta in the beginning. After

that to control the fan steps so that Pd is within a stable

pressure range.

At Start-up and when High Pressure Increase Protection

activated: ON

To determine the I.U. electronic expansion valve opening

depending on the temperature at the top of the compressor

(Td).

at Start-up: ON

(a): Difference between Indoor Inlet Air Temperature and Setting Temperature

(b): Amount of Temperature Difference Change

(c): Capacity Ratio between Operating Indoor Unit and Outdoor Unit

(d): Temperature Difference between Indoor Gas Pipe and Indoor Liquid Pipe

(= Indoor Gas Pipe Temperature - Indoor Liquid Pipe Temperature)

2-14

TC-16001-rev.5

Page 33

only for Decorative Panel

I.U. : Indoor Unit

2.11.3 Standard Operation Sequence

Cooling Operation

n

Power to

O.U.: ON

Power to

I.U.: ON

Set

Operation Mode

to “COOL”

Power to

O.U. PCB: ON

Power to

I.U. PCB: ON

Power to YH2

in I.U.: OFF

FS

ON

(Lower than

Activation Level)

Temp. at Top

of Compressor

o

F (30oC)

< 86

or

< Outdoor Temperature +45

o

> 86

F (30oC)

and

> Outdoor Temperature +45

Auto-Louver

0 Reset

OFF

(Higher than

Activation Level)

only for indoor unit

with auto-louver

Power to YH2 in

I.U.: ON

o

F (+25oC)

o

F (+25oC)

OUTDOOR UNITS

O.U. : Outdoor Unit

: Actuator (refer to Ta ble 2.1)

Power to CH : ON

Power to CH : OFF

Start of Communication between

O.U. and I.U.

Start of Communication between

I.U. and Wired Controller

MD Operation: ON

for unit with drain pump

“COOL” Indication

Press

Fan Speed

Switch

Press

Temp. Setting

Switch

Press

RUN/STOP

Switch

Cooling

Operation

HIGH

(HIGH 2)

Fan Speed

Switch

LOW

Power to YH2 for 20 sec.

I.U. Air

Inlet

Temp.

< Set Temp.

MED

> Set Temp.

< 23

Outdoor

Temp.

o

F (-5oC)

Switch: To increase Set Te mp.

Switch: To Decrease Set Te mp.

o

> 23

F

(-5oC)

Power to

Y52C :

ON

Power to

CMC :

ON

Elapsed Time:

1sec.

No

“HIGH (HIGH 2)”

“LOW” Indication

Run Indicator: ON

MIF Operation at

Set Fan Speed

Yes

Power to

YH2 : ON

for unit with drain pump

Indication

“MEDIUM”

Indication

Indication

of Set Temp.

MC Operation: ON

MOF Operation: ON

MD Operation: ON

Press

AUTO-LOUVER

Switch

to 1

TC-16001-rev.5

Start of

Auto-Louver

< Alternately >

Stop of

Auto-Louver

or Indoor Unit

with Auto-Louver

2-15

Page 34

OUTDOOR UNITS

I.U. : Indoor Unit

able 2.1)

Cooling Operation

n

1

Press

RUN/STOP

Switch

STOP

Temp. at Top

of Compressor

MOF Operation: OFF

No

Elapsed Time:

1 min. 20 sec.

< 77oF (25oC)

or

< Outdoor Temperature +36

o

> 86

and

> Outdoor Temperature +45

Power to Y52C : OFF

Yes

O.U. : Outdoor Unit

: Actuator (refer to T

Inverter: OFF

MC Operation: OFF

o

F (+20oC)

F (30oC)

o

F (+25oC)

RUN Indicator: OFF,

COOL, Set Fan Speed & Set Temp. Indications: Continuously ON

Power to CH : ON

Power to CH : OFF

Power to CMC : OFF

MD Operation: OFFPower to YH2 : OFF

for unit with drain pump

MIF Operation: OFF

Power to

I.U.: OFF

Power to

O.U.: OFF

Power to I.U. PCB: OFF

Power to O.U. PCB: OFF

LCD Indication: OFF

Power to CH : OFF

2-16

TC-16001-rev.5

Page 35

Dry Operation

only for Decorative Panel

I.U. : Indoor Unit

n

Power to

O.U.: ON

Power to

I.U.: ON

Set

Operation Mode

to “DRY”

Power to

O.U. PCB: ON

Power to

I.U. PCB: ON

Power to YH2

in I.U.: OFF

Temp. at Top

of Compressor

FS

ON

(Lower than

Activation Level)

Auto-Louver

0 Reset

OFF

(Higher than

Activation Level)

< 86oF (30oC)

or

< Outdoor Temperature +45

o

> 86

F (30oC)

and

> Outdoor Temperature +45

only for indoor unit

with auto-louver

Power to YH2

in I.U.: ON

o

F (+25oC)

o

F (+25oC)

OUTDOOR UNITS

O.U. : Outdoor Unit

: Actuator (refer to Table 2.1)

Power to CH : ON

Power to CH : OFF

Start of Communication between

I.U. and O.U.

Start of Communication between

I.U. and Wired Controller

MD Operation: ON

for unit with drain pump

“DRY” Indication

Press

TEMP. Setting

Switch

Press

RUN/STOP

Switch

Dry Operation

Power to YH2 : ON

I.U. Air

Inlet

Temp.

< Set Temp.

> Set Temp.

< 23

Outdoor

Temp.

o

F (-5oC)

Switch: To increase Set Te mp.

Switch: To decrease Set Te mp.

MIF Operation at Low Fan Speed

> 23oF

(-5oC)

Power to

Y52C :

ON

Indication of Set Temp.

RUN Indicator: ON

Elapsed Time:

1sec.

No

Power to MC : OFF

Power to MIF : OFF

MIF Operation at Low Fan Speed

Yes

Elapsed Time:

6 min.

Yes

Power to MC :ON

MOF Operation

: ON

No

Elapsed Time:

6 min.

Yes

No

Press

AUTO-LOUVER

Switch

To 2

TC-16001-rev.5

Start of

Auto-Louver

< Alternately >

Stop of

Auto-Louver

or Indoor Unit

with Auto-Louver

2-17

Page 36

OUTDOOR UNITS

I.U. : Indoor Unit

able 2.1)

Dry Operation

n

2

O.U. : Outdoor Unit

: Actuator (refer to T

Inverter: OFF

Press

RUN/STOP

Switch

STOP

Power to

I.U.: OFF

of Compressor

No

Elapsed Time:

3min. 20sec.

< 77oF (25oC)

or

Temp. at Top

Yes

Power to I.U. PCB: OFF

< Outdoor Temperature +36

> 86

and

> Outdoor Temperature +45

Power to Y52C : OFF

MC Operation: OFF

o

F (+20oC)

o

F (30oC)

o

F (+25oC)

RUN Indicator: OFF,

DRY, Set Fan Speed & Set Temp. Indications: Continuously ON

Power to CH : ON

Power to CH : OFF

Power to CMC : OFFMOF Operation: OFF

MD Operation: OFFPower to YH2 : OFF

for unit with drain pump

MIF Operation: OFF

LCD Indication: OFF

Power to

O.U.: OFF

Power to O.U. PCB: OFF

Power to CH : OFF

2-18

TC-16001-rev.5

Page 37

Heating Operation

(*) Refer to Service Manual for the timing diagram of the reversing valve.

I.U. : Indoor Unit

ble 2.1)

n

Power to

O.U.: ON

Power to

O.U. PCB: ON

Temp. at Top

of Compressor

< 86oF (30oC)

or

< Outdoor Temperature +45

o

> 86

F (30oC)

and

> Outdoor Temperature +45

o

F (+25oC)

o

F (+25oC)

OUTDOOR UNITS

O.U. : Outdoor Unit

: Actuator (refer to Ta

Power to CH : ON

Power to CH : OFF

Power to

I.U.: ON

Set

Operation

Mode to

"HEAT"

Press

Fan Speed

Switch

Press

Temp. Setting

Switch

Press

RUN/STOP

Switch

Power to

I.U. PCB: ON

HIGH

(HIGH 2)

Fan Speed

Switch

LOW

Power to YH2 for 20 sec.

MED

Auto-Louver

0 Reset

Switch: To increase Set Te mp.

Switch: To decrease Set Te mp.

only for indoor unit

with auto-louver

Start of Communication between

O.U. and I.U.

Start of Communication between

I.U. and Remote Control Switch

“HEAT” Indication

“HIGH (HIGH 2)”

Indication

“MEDIUM”

Indication

“LOW” Indication

Indication

of Set Temp.

MD Operation: ON

for unit with drain pump

RUN Indicator Lights.

Heating

Operation

To 3

I.U. Air

Inlet

Temp.

> Set Temp.

MIF Operation

at Slo Fan Speed

< Set Temp.

Pd < 261 psi

(1.8MPa)

After 30 sec.

Yes

No

Power to

Y52C : ON

MIF Operation

at Slo Fan Speed

(with Thermo-OFF:

Low Fan Speed)

MIF Operation at

Low Fan Speed

Power to

CMC : ON

Power to

RVR : ON

< 77

(25

(*)

o

F

o

C)

> 77

< 86oF (30oC)

Elapsed Time:

Elapsed Time

>3min.

Yes

I.U. Air

Outlet

Temp.

o

F (25oC) and

No

1 sec.

No

> 86

(30oC)

Yes

MC Operation: ON

MOF Operation: ON

MIF Operation

o

F

at Set Fan Speed

Downward Angle of

Auto-Louver: Available

only for indoor unit

with auto-louver

TC-16001-rev.5

2-19

Page 38

OUTDOOR UNITS

I.U. : Indoor Unit

able 2.1)

Heating Operation

n

3

Press

RUN/STOP

Switch

STOP

MIF Operation: OFF

I.U. Air

Outlet

Temp.

Heat

Rejection

Operation

MIF Operation

at Slo Fan Speed

of Compressor

o

> 122

Temp. at Top

o

< 122

F (50oC)

< 77oF (25oC)

or

< Outdoor Temperature +36

o

> 86

F (30oC)

and

> Outdoor Temperature +45

Power to Y52C

F (50oC)

I.U Air

Outlet

Temp.

RUN Indicator: OFF,

HEAT, Set Airflow Volume & Set Te mp. Indications: Continuously ON

< 104

: OFF

> 104oF (40oC)

o

F (40oC)

o

F (+20oC)

o

F (+25oC)

O.U. : Outdoor Unit

: Actuator (refer to T

MC Operation: OFF

Power to CH : ON

Power to CH : OFF

Power to CMC : OFF

MIF Operation: OFF

Elapsed Time

< 2 min.

Operation

at Slo Fan

Speed

Elapsed Time

> 2 min.

Inverter: OFF

Power to

I.U.: OFF

Power to

O.U.: OFF

Power to I.U. PCB: OFF

Power to O.U. PCB: OFF

LCD Indication: OFF

Reset of Timer for Defrost Operation

Power to CH : OFF

2-20

TC-16001-rev.5

Page 39

Defrost Operation

ble 2.1)

(*) Refer to Service Manual for the timing diagram of the reversing valve.

n

OUTDOOR UNITS

Heating

Operation

Defrosting

Start Condition

is approved.

Yes

Power to

RVR : OFF

Defrost

Operation

Defrosting

Stop Condition

is approved.

Yes

I.U. : Indoor Unit

: Actuator (refer to Ta

No

(*)

“DEFROST” Indication

MIF Operation: OFF

MOF Operation: OFF

No

Power to

RVR : ON

Heating

Operation

Pd < 261 psi

(1.8MPa)

(*)

Yes

No Yes

< 77

o

C)

MIF Operation

at Slo Fan Speed

MIF Operation at

Low Fan Speed

(25

Elapsed Time

o

F

o

F (25oC) and

> 77

< 86oF (30oC)

>3min.

I.U. Air

Outlet

Temp.

“DEFROST” Indication: OFF

MOF Operation: ON

No

> 86oF

(30oC)

MIF Operation at Set Fan Speed

TC-16001-rev.5

2-21

Page 40

OUTDOOR UNITS

Table 2.1

CH

FS

YH2

MD

MIF

Y52C

CMC

MC

MOF

RVR

Crankcase Heater in O.U.

Float Switch in I.U.

Relay for Drain Pump Motor in I.U.

Drain Pump Motor in I.U.

Indoor Fan Motor in I.U.

Relay for Magnet Switch in O.U.

Magnet Switch in O.U.

Compressor Motor in O.U.

Outdoor Fan Motor in O.U.

Reversing Valve in O.U.

< Defrost Operation >

The following defrost operations, “Standard Defrost”, “Forced Defrost” and “Manual Defrost” are available.

(1) Standard Defrost

This operation starts according to the outdoor temperature, the outdoor evaporating temperature and

the operating time.

(2) Forced Defrost

This operation starts when the indoor unit repeats Thermo-ON/OFF* operation and therefore cannot

start the “Standard Defrost.”

(3) Manual Defrost

This operation starts when the push switch “PSW1” on the outdoor unit PCB is pressed for more than

3 seconds during maintenance, etc. (This function cannot be used when the pressure and the outdoor

evaporating temperature is high or at the beginning of the operation.)

NOTE:

Do not repeatedly use “Manual Defrost” frequently.

* Thermo-ON: The outdoor unit and some indoor units are running.

Thermo-OFF: The outdoor unit and some indoor units stay on, but don’t run.

2-22

TC-16001-rev.5

Page 41

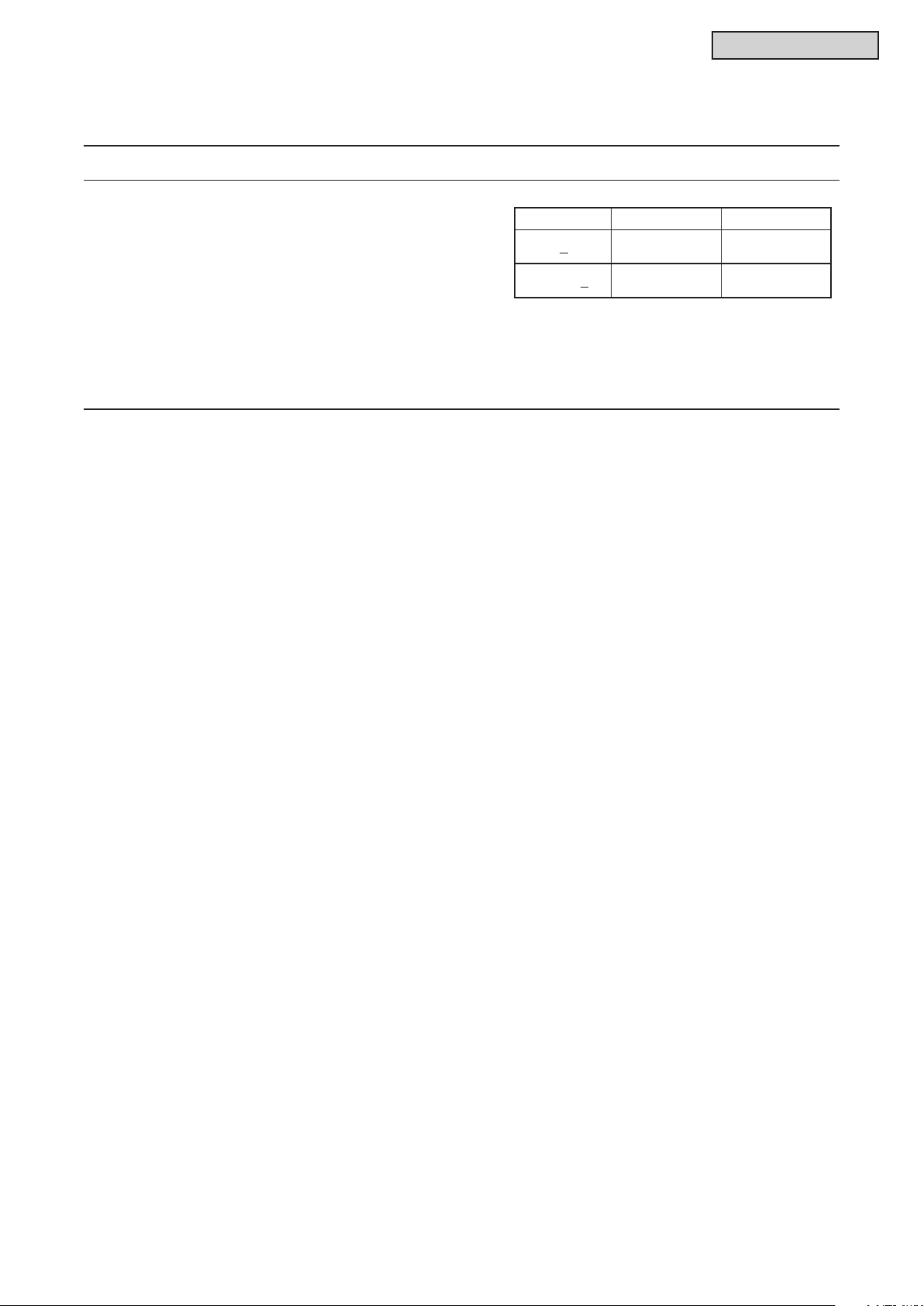

< Condition for Starting Defrost Operation >

Outdoor Evaporating

(1) Standard Defrost

(a) Temperature Condition

Defrost Operation

59

(15)

41

(5)

Stop Area

Temperature

Conditions

under

Defrost

Operation

28

(-2)

Temperature (Te) [°F (°C)]

14

(-10)

-6

(-21)

5

(-15)

23

(-5)

Outdoor Temperature [°F (°C)]

Defrost Operation

Start Area

42

(6)

(b) Condition of Operating Time for Defrost Operation Start

The defrost operation starts when the temperature condition shown in “(a) Temperature Condition”

is met after a heating operation of 40 to 120 minutes. The heating operation time is determined by

estimating the amount of frost on the heat exchanger.

50

(10)

OUTDOOR UNITS

(2) Forced Defrost

The “Forced Defrost” starts when all the following conditions are met.

(a) The reversing valve is “ON” for more than 120 minutes.

o

(b) The outdoor temperature is 50

F (10oC) or lower.