24-7701-128, Rev. C

FANs 216, 1628.3

Installation Instructions HL-67x5

Issue Date 0316

TRUERH

Series

HL-67x5 Multi-function Humidity Dev ice with Temperature Sensor

nstallation

I

IMPORTANT: The HL-67x5 Series Multi-function

Humidity Device is intended to

provide an input to equipment

under normal operating conditions.

Where failure or malfunction of the

HL-67x5 Device could lead to

personal injury or property damage

to the controlled equipment or other

property, additional precautions

must be designed into the control

system. Incorporate and maintain

other devices, such as supervisory

or alarm systems or safety or limit

controls, intended to warn of or

protect against failure or

malfunction of the HL-67x5 Device.

IMPORTANT: Le HL-67x5 Series Multi-function

Humidity Device est destiné à

transmettre des données entrantes

à un équipement dans des

conditions normales de

fonctionnement. Lorsqu'une

défaillance ou un

dysfonctionnement du HL-67x5

Device risque de provoquer des

blessures ou d'endommager

l'équipement contrôlé ou un autre

équipement, la conception du

système de contrôle doit intégrer

des dispositifs de protection

supplémentaires. Veiller dans ce

cas à intégrer de façon permanente

d'autres dispositifs, tels que des

systèmes de supervision ou

d'alarme, ou des dispositifs de

sécurité ou de limitation, ayant une

fonction d'avertissement ou de

protection en cas de défaillance ou

de dysfonctionnement du HL-67x5

Device.

Parts Included

• HL-67N5-8N00P

• No. 8 x 1 in. Phillips-head sheet metal screw (2)

• washer for use with conduit fitting (conduit fitting

and nut not provided)

Tools Required

• hole saw with 1 in. (25 mm) diameter blade

• drill with 1/8 in. (3 mm) drill bit

• 1/8 in. (3 mm) flat-blade and No. 2 Phillips

screwdrivers

• pliers

• gasket, sealer, or other means to seal the area

between the unit and the duct

ocation Requirements

L

IMPORTANT: To avoid damage to the circuit

board and components, do not

mount the unit in a location where

high concentrations of corrosive

vapors are present.

When selecting a location for the HL-67N5-8N00P,

consider the following:

• Position: The HL-67N5-8N00P is designed for

duct mounting in any position, except with the

probe tip pointed up.

• Duct Diameter: Recommended minimum diameter

(round ducts) or width (square ducts) is 12 in.

(305 mm).

• Air Stratification (when the unit is mounted on the

discharge side of the fan): Recommended location

is at least 8 ft (2.4 m) downstream from

humidification equipment, where duct air and water

vapor are sufficiently mixed. Avoid areas where the

probe might be exposed to condensation.

© 2016 Johnson Controls, Inc. 1

Part No. 24-7701-128, Rev. C www.johnsoncontrols.com

Code No. LIT-216024

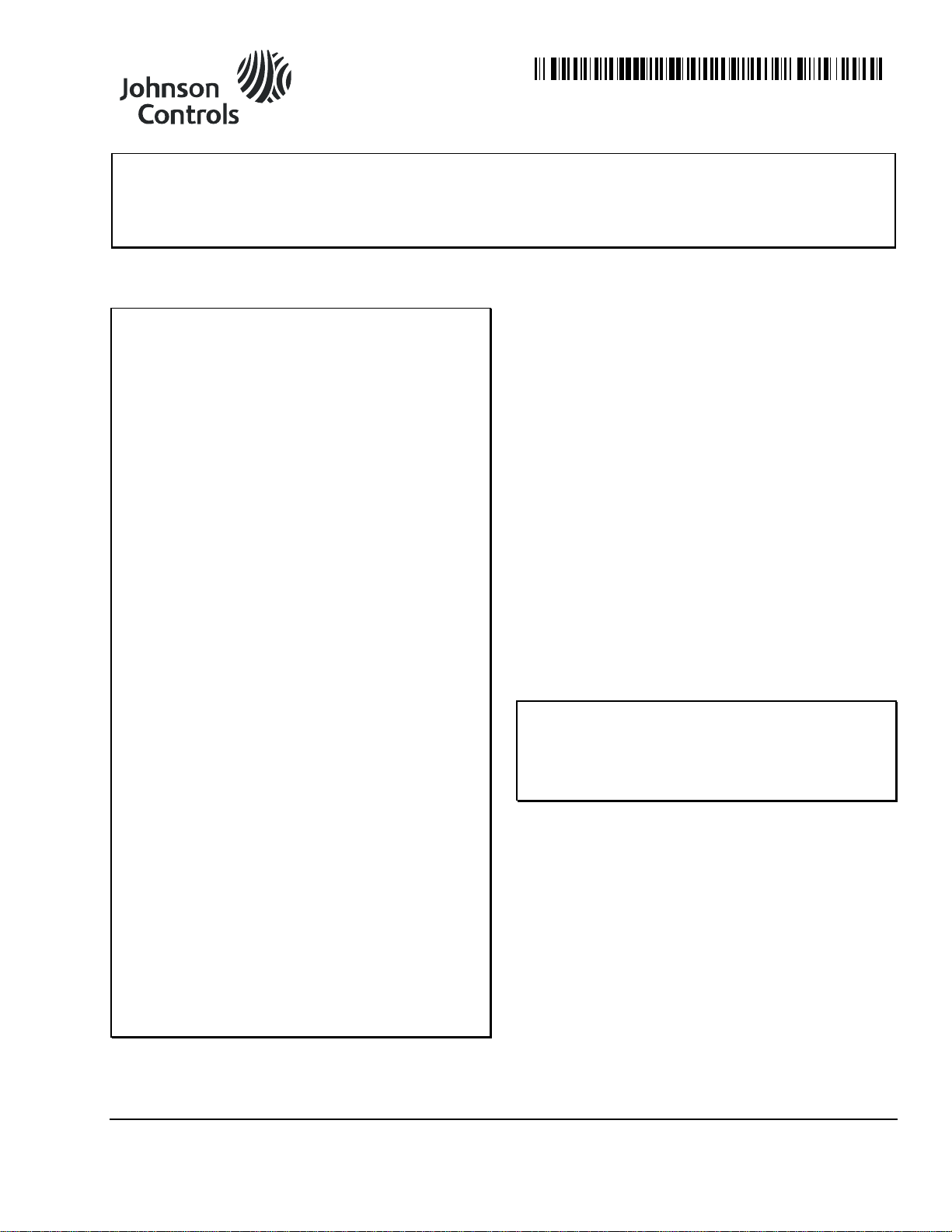

pplication Setup

Output

Jumper

Input

Jumper

Setpoint

Potentiometer

5 30

60 95

5

678

Probe

14 3 2

Label

Input:

Output:

0 to 10 VDC or Relay

(Factory Set)

0 to 20 mA

0 to 10 VDC

(Factory Set)

0 to 20 mA

No Input

VDC

VDC

MA

MA

NONE

27-4523-9

RY10048

RELAY TEMP

8 7 6

5

4

2

1

OUTPUT

INPUT

OUT IN COM PWR

Holes for

Mounting Screw (2)

Terminal

Block

Proportiona l Band

Potentiometer

24 VAC

Transformer

Humidification

Equipment

8

7 6

5

4

3

2

1

HL-67N5

Common

Power

Common

Output

Controller

Position

Position

AS-LCPx00-0

FM-OAE

24 VAC

Transformer

System

Controller

Humidification

Equipment

876

5

4

3 2 1

HL-67N5

Input

Common

Power

Common

Output

A

The multi-function humidity device must be configured

prior to installation for the following: input and output

signals and setpoint and proportional band.

The HL-67N5-8N00P has a setpoint potentiometer

(adjustable from 60 to 95% Relative Humidity [RH]) and

a proportional band potentiometer (adjustable from 5 to

30% RH). Refer to Figure 1 to change the setpoint or

proportional band for the application desired.

Figure 2: HL-67N5-8N00P as a Standalone Device

b. If the HL-67x5 is used as a proportional

override device, refer to Table 1 for jumper

positions.

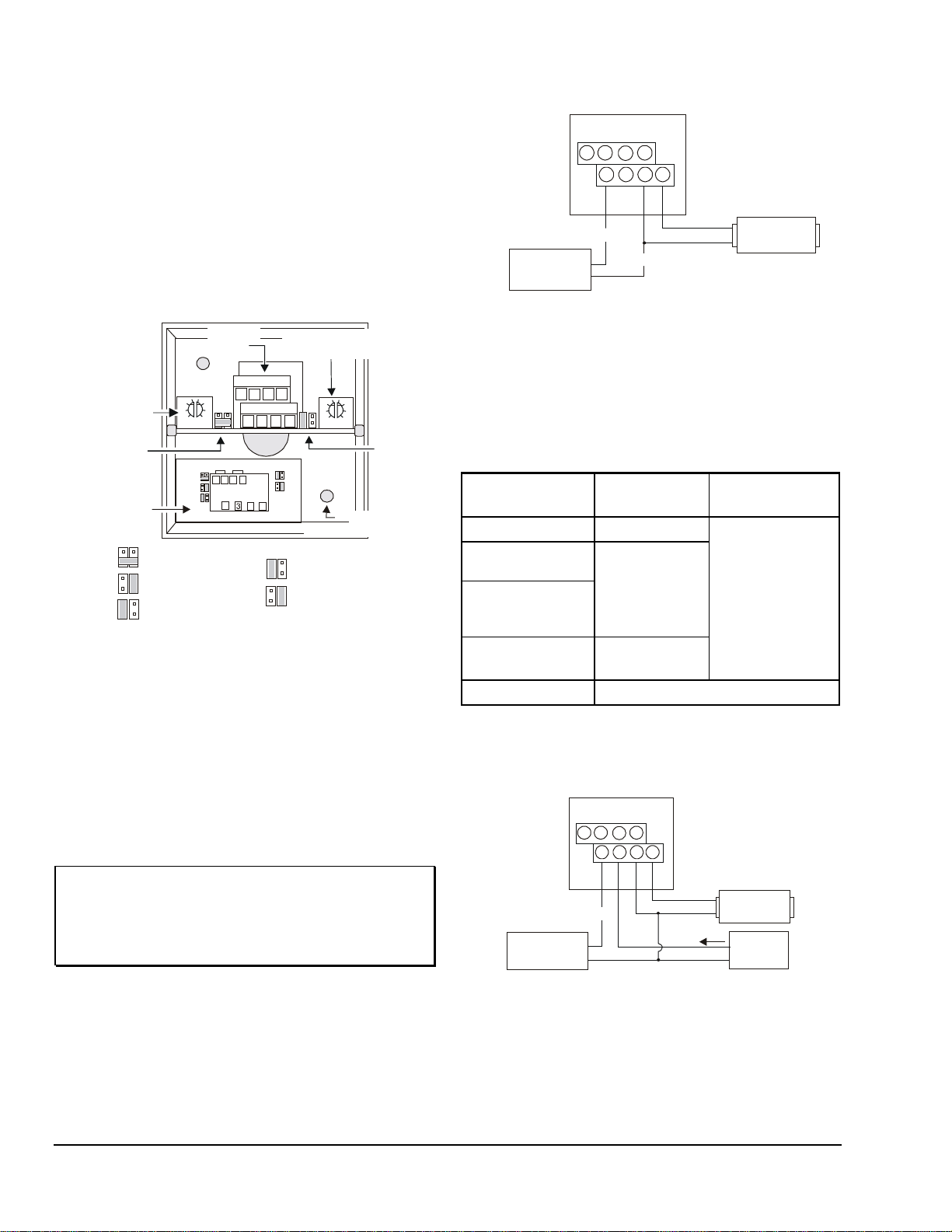

Table 1: Jumper Positions with

HL-67N5-8N00P Used as a

Proportional Override Device

1. Use a 1/8 in. (3 mm) flat-blade screwdriver to

2. Adjust the proportional band potentiometer to the

Note: Setpoint minus proportional band is the highest

IMPORTANT: Set the proportional band to the

3. Select the appropriate input and output jumpers for

2 TRUERH Series HL-67x5 Multi-function Humidity Device with Temperature Sensor Installation Instructions

Figure 1: Internal View of the HL-67N5-8N00P

adjust the setpoint potentiometer to the humidity

level where the humidification equipment is

completely off.

desired range of humidity below the setpoint.

duct humidity reading at which the HL-67x5 will

allow the humidity equipment to be fully on.

highest number to reduce excessive

cycling of the humidification

equipment for optimum system

the application.

a. If the HL-67N5 is used as a standalone device

as shown in Figure 2, set the input jumper for

no input. Set the output jumper for the type of

signal the humidifier receives. (See Figure 1.)

performance without oscillation.

System

Air Handling Unit

DX-9xxx or

Input Jumper

Output Jumper

0 to 20 mA User selectable

0 to 10 VDC

(See Figure 1.)

Digital Control

Module via an

System 350 with a

W351P

Generic

0 to 20 mA or

0 to 10 VDC

User selectable

Figure 3 shows a typical proportional override

application for the HL-67x5. The relay output cannot be

used in this application.

Figure 3: HL-67N5-8N00P Using a System Controller

ounting

Housing

Conduit Hole

Snap-on Cover

Conduit Knockout

(Top and Bott om

of Cover)

Duct

Washer (Cup ped Side

Toward Housing)

Conduit Fitting

(Not Provided)

Nut for Conduit Fitting

(Not Provided)

No. 8

Screw

(2)

!

5

7

8

M

To mount the humidity device, refer to Figure 4, and

proceed as follows:

Figure 4: Mounting and Assembly

1. Remove any excess insulation from the duct that

prevents the probe from extending a minimum of

3 in. (76 mm) into the air stream.

2. Use the hole saw to make a 1 in. (25.4 mm)

diameter hole in the duct for inserting the probe.

3. Pull the plastic cover off the housing.

4. Insert the probe into the duct, and mark the

location of the holes for the mounting screws.

5. Remove the unit, and drill a 1/8 in. (3 mm) hole for

each mounting screw.

iring

W

CAUTION: CAUTION: Risk of Electric

Shock.

Disconnect the power supply

before making electrical

connections to avoid electric

shock.

MISE EN GARDE: Risque de décharge électrique.

Débrancher l'alimentation avant

de réaliser tout raccordement

électrique afin d'éviter tout

risque de décharge électrique.

Observe the following when wiring the unit:

• Do not run low voltage wiring in the same conduit

as line voltage wiring or other conductors that

supply highly inductive loads.

• Use 18 or 24 AWG wire.

• Make all wiring connections in accordance with the

National Electrical Code and local regulations.

To wire the device:

1. Route the wires from the controller to the

HL-67N5-8N00P through the conduit hole in the

housing. (Refer to Table 2 for wiring terminal

details.)

Table 2: Wiring Information

IMPORTANT: Remove the unit before drilling to

prevent any metal remnants from

falling onto the circuit board.

Seal any holes created during

installation to help reduce drafts and

ensure accurate sensor readings.

6. Use a gasket, sealer, or other means to seal the

area around the 1 in. (2.54 mm) hole between the

unit and the duct.

7. Reinsert the probe, and secure the housing to the

duct using the two No. 8 screws provided.

TRUERH Series HL-67x5 Multi-function Humidity Device with Temperature Sensor Installation Instructions 3

Terminal Terminal

Designation

1

2

3

4

6

Power + From the system

Common - For power, input,

Input + 0 to 20 mA or

Output + To humidification

Temperature N/A 1,000 ohm nickel

Relay N/A For on/off

Polarity Source/

Destination

controller or a

separate 24 VAC

transformer

and output

0 to 10 VDC from

the system

controller

equipment

temperature sensor

humidity equipment

2. Break out the plastic knockout on the cover

Note: X is either 10 VDC or 20 mA, depending on the application.

Setpoint - Measured RH

Proportiona l Band

HL-67N5’s Output Signal = X

(shown in Figure 4) with pliers to accommodate

the wiring or conduit.

Gradually raise the setpoint and monitor the

results. (Make sure the setpoint is not too high, or

excess moisture could collect in the duct.)

IMPORTANT: If using a conduit fitting

(not provided), use the washer

provided to support the fitting in the

housing. If the washer is not used,

the fitting could stress the plastic

housing.

3. Make wire connections to the appropriate screw

terminals. (See Table 2.)

4. Press the cover onto the base.

IMPORTANT: Check all connections before

applying power to the system.

Short-circuited or misconnected

wires could permanently damage

the unit.

roubleshooting

T

If the humidity device is not functioning properly:

1. Make sure the power supply is functioning and

wired properly to the HL-67N5-8N00P. Check the

output wiring connections.

5. Verify that the system controller operates properly.

Refer to the appropriate controller documentation.

6. If the HL-67N5-8N00P’s output is still inaccurate

after performing Steps 4 and 5, record the

proportional band setting and proceed as follows:

a. Measure duct humidity with a humidity

measuring device, such as an optical dew

point hygrometer, and record the result.

b. Measure the output of the HL-67N5-8N00P

using a Digital Volt Meter (DVM) or a

Milliampere (mA) meter, and record the result.

c. Measure the system controller’s output

(input to the HL-67N5-8N00P), using the DVM

or the mA meter, and record the result.

Notes: If the duct humidity is below the proportional

band, the HL-67N5-8N00P’s output should be

equal to the system controller’s output. If the

duct humidity is above the proportional band,

the HL-67x5’s output should be 0 VDC (0 mA).

If the duct humidity is inside the proportional

band, calculate the HL-67x5’s output as

follows:

2. If the HL-67N5-8N00P is not delivering an output,

check the jumper positions and make sure they

are appropriately selected for the application.

(Refer to Figure 1.)

3. If the humidification equipment is cycling

excessively, the proportional band setting may be

too low. Set the proportional band potentiometer to

a higher value. (See Figure 1.)

4. If room humidity never reaches the desired level,

the HL-67N5-8N00P’s setpoint may be set too low.

dditional Information

A

There are no accessories for the HL-67N5-8N00P.

See Table 3 for product specifications.

4 TRUERH Series HL-67x5 Multi-function Humidity Device with Temperature Sensor Installation Instructions

Table 3: Specifications

Output Load

Voltage: ≥ 1,000 ohm Current: ≤ 500 ohms

Conditions

Ambient Storage Conditions

-40 to 150°F (-40 to 66°C); 0 to 100% RH; 90°F (32°C) maximum dew point

European Single Point of Contact:

NA/SA Single Point of Contact:

APAC Single Point of Contact:

JOHNSON CONTROLS

JOHNSON CONTROLS

JOHNSON CONTROLS

Building Efficiency

All other marks herein are the marks of their respective owners. © 2016 Johnson Controls, Inc.

Product

Power Requirements

Wire Gauge

Humidity

Temperature Sensor

Controller Signal

Input Impedance

Relay Contact

Relay Contact Rating

Ambient Operating

Materials

Dimensions (H x W x D)

Shipping Weight

Agency Compliance

The performance specificati ons are nominal and conform to acceptable industry standards. For application at condi tions beyond these

specifications, consult the local Johnson Controls office. Johnson Control s, Inc. shall not be liable f or damages resulting from misapplication

or misuse of its products .

HL-67N5-8N00P Multi-function Humidity Device with Temperature Sensor

Proportional Output: 20 to 30 VAC, 1.1 VA at 50/60 Hz or 14 to 30 VDC at 22 mA

Relay Output: 20 to 30 VAC, 1.1 VA at 50/60 Hz or 20 to 30 VDC at 22 mA

16 to 24 AWG (18 AWG is recommended)

Element: All-Polymer

Setpoint: Adjustable from 60 to 95% RH

Proportional Band: Adjustable from 5 to 30% RH

Type: Thin-film nickel

Resistance: 1,000 ohm at 70°F (21°C)

Accuracy: ±0.34°F (0.18°C) at 70°F (21°C)

Coefficient: Approximately +3 ohms/°F; 5 ohms/°C

Input and Output: 0 to 10 VDC or 0 to 20 mA

Voltage: 20,000 ohms Current: 500 ohms

Single-Pole, Single-Throw (SPST), Normally Open — Open at setpoint and closed at

setpoint minus proportional band, standalone operation only

Maximum: 4A, 24 VAC, Class 2; Pilot Duty, 42.4 VA at 24 VAC;

Minimum: 100 mA at 5 VDC

32 to 150°F (0 to 66°C); 0 to 100% RH non-condensing; 90°F (32°C) maximum dew point

Light gray plastic cover with dark gray housing and probe

3.28 x 3.25 x 8.27 in. (83 x 83 x 210 mm) Probe (L x D): 6.25 x 0.98 in. (159 x 25 mm)

0.7 lb (0.03 kg)

UL Listed, File E107041, CCN PAZX, UL916

cUL Listed, File E107041, CCN PAZX7, CSA C22.2 No. 205-M1983

Duct Probe Material: 94-5V flammability rated per UL 94

WESTENDHOF 3

45143 ESSEN

GERMANY

507 E MICHIGAN ST

MILWAUKEE WI 53202

USA

Metasys® and Johnson Controls® are registered trademarks of Johnson Controls, Inc.

TRUERH Series HL-67x5 Multi-function Humidity Device with Temperature Sensor Installation Instructions 5

C/O CONTROLS PRODUCT

MANAGEMENT

NO. 22 BLOCK D NEW DISTRICT

WUXI JIANGSU PROVINCE 2 14142

CHINA

507 E. Michigan Street, Milwaukee, WI 53202

Loading...

Loading...