Johnson Controls YICS015B21S, HICS030B21S, HICS015B21S, HICS036B21S, YICS024B21S Installation And Maintenance Manual

...Page 1

Installation

and

Maintenance

Manual

INVERTER-DRIVEN

MULTI-SPLIT SYSTEM

HEAT PUMP

AIR CONDITIONERS

Type Model

(H,Y,C)ICS015B21S

Ceiling Suspended

(H,Y,C)ICS024B21S

(H,Y,C)ICS030B21S

(H,Y,C)ICS036B21S

IMPORTANT:

READ AND UNDERSTAND

THIS MANUAL BEFORE

INSTALLING THIS HEAT

PUMP AIR CONDITIONER.

KEEP THIS MANUAL FOR

FUTURE REFERENCE.

P5417058

Page 2

ATTENTION

Each model number and all matching model numbers within a system must have

the same version of software.

Follow these steps to verify that your product model numbers have the same

version of software.

• Access the main printed circuit board in each product.

• Locate a white sticker with a P-XXXX number or

• Connect a service checker and locate the ROM number.

For further assistance, please contact our Technical Support Center at 1 (844)

873-4445 and select Option 2.

Page 3

Important Notice

● Johnson Controls, Inc. pursues a policy of continuing improvement in design and performance in its

products. As such, Johnson Controls reserves the right to make changes at any time without prior

notice.

● Johnson Controls cannot anticipate every possible circumstance that might involve a potential hazard.

● This heat pump air conditioning unit is designed for standard air conditioning applications only. Do

not use this unit for anything other than the purposes for which it was intended.

● The installer and system specialist shall safeguard against leakage in accordance with local

pipetter and electrical codes. The following standards may be applicable, if local regulations are

not available. International Organization for Standardization: (ISO 5149 or European Standard, EN

378). No part of this manual may be reproduced in any way without the expressed written consent of

Johnson Controls.

● This heat pump air conditioning unit is operated and serviced in the United States of America and

comes with a full complement of the appropriate Safety, Dangers, Cautions, and Warnings.

● If you have questions, please contact your distributor or dealer.

● This manual provides common descriptions, basic and advanced information to maintain and service

this heat pump air conditioning unit which you operate as well for other models.

● This heat pump air conditioning unit has been designed for a specic temperature range. For optimum

performance and long life, operate this unit within the range limits according to the table below.

Temperature

Maximum Minimum

Cooling

Operation

Heating

Operation

DB: Dry Bulb, WB: Wet Bulb

* The temperature may change depending on the outdoor unit.

Indoor 89

Outdoor 118

Indoor 80

Outdoor 59

o

F DB/73oF WB (32oC DB/23oC WB) 69oF DB/59oF WB (21oC DB/15oC WB)

o

F DB (48oC DB) * 14oF DB (-10oC DB) *

o

F DB (27oC DB) 59oF DB ( 15oC DB)

o

F WB (15oC WB) * -4oF WB (-20oC WB) *

● This manual should be considered as a permanent part of the air conditioning equipment and should

remain with the air conditioning equipment.

Product Inspection upon Arrival

1. Upon receiving this product, inspect it for any damages incurred in transit. Claims for damage, either

apparent or concealed, should be led immediately with the shipping company.

2. Check the model number, electrical characteristics (power supply, voltage, and frequency rating),

and any accessories to determine if they agree with the purchase order.

3. The standard utilization for this unit is explained in these instructions. Use of this equipment for

purposes other than what it is designed for is not recommended.

4. Please contact your local agent or contractor as any issues involving installation, performance, or

maintenance arise. Liability does not cover defects originating from unauthorized modications

performed by a customer without the written consent of Johnson Controls, Inc. Performing any

mechanical alterations on this product without the consent of the manufacturer will render your

warranty null and void.

P5417058-rev.1

i

Page 4

TABLE OF CONTENTS

1. Introduction ........................................................................................................................................................... 1

2. Safety Instructions ................................................................................................................................................ 1

3. Before Installation ................................................................................................................................................. 8

3.1 Combinations of Outdoor Unit and Indoor Unit ............................................................................................ 8

3.2 Transportation and Handling ........................................................................................................................ 8

3.3 Factory-Supplied Accessories ...................................................................................................................... 9

4. Installation Work ................................................................................................................................................. 12

4.1 Position of Suspension Bolts ...................................................................................................................... 12

4.2 Installation of Suspension Bolts ................................................................................................................. 12

4.3 Mounting Indoor Unit .................................................................................................................................. 13

4.4 Installation of Wired Controller ................................................................................................................... 14

5. Refrigerant Piping Work ...................................................................................................................................... 15

5.1 Piping Materials .......................................................................................................................................... 15

5.2 Piping Connection ...................................................................................................................................... 15

5.3 Piping Connection Work ............................................................................................................................. 17

5.3.1 Position of Piping Connection ........................................................................................................... 17

5.3.2 Access of Piping Connection ............................................................................................................ 18

6. Condensate Piping .............................................................................................................................................. 19

7. Electrical Wiring .................................................................................................................................................. 22

7.1 General Check ........................................................................................................................................... 22

7.2 Electrical Wiring Capacity ........................................................................................................................... 22

7.2.1 Field Minimum Wire Sizes for Power Supply .................................................................................... 22

7.2.2 Details of Electrical Wiring Connection ............................................................................................. 23

7.3 Position of Electrical Wiring Connection ..................................................................................................... 24

7.4 Caution for Electrical Wiring ....................................................................................................................... 26

7.5 Wiring Connections .................................................................................................................................... 27

7.6 DIP Switch Settings .................................................................................................................................... 28

7.7 Function Selection by Wired Controller ...................................................................................................... 30

7.8 Setback Operation ...................................................................................................................................... 31

8. Test Run .............................................................................................................................................................. 32

8.1 Before Test Run .......................................................................................................................................... 32

8.2 Test Run ..................................................................................................................................................... 32

8.3 Alarm Codes ............................................................................................................................................... 36

ii

P5417058-rev.1

Page 5

1. Introduction

Read following sections carefully before installing this product.

Read over the "Installation and Maintenance Manual" for the outdoor unit as well.

Forward this information, and the warranty to all installers and users.

Ask end users to maintain copies for future reference.

(Refrigerant Piping Work) (Electrical Wiring Work) (Ref. Charge Work) (Test Run) (User)

● For details on wiring between the indoor unit and the outdoor unit, refer to the "Installation and Maintenance

Manual" for the outdoor unit.

● For details on the optional controller, refer to the "Installation and Maintenance Manual" for that optional

controller module.

● For details on each optional part, refer to the "Installation and Maintenance Manual" for each optional part.

● For central controller, refer to the "Installation and Maintenance Manual" for the central controller.

2. Safety Instructions

Signal Words

Indicates a hazardous situation that, if not avoided, could result in death

or serious injury.

Indicates a hazardous situation that, if not avoided, could result in minor or

moderate injury.

Indicates information considered important, but not hazard-related (for

example, messages relating to property damage).

General Precautions

To reduce the risk of serious injury or death, read these instructions

● This system should be installed by personnel certied by Johnson Controls, Inc. Personnel must be

qualied according to local, state and national building and safety codes and regulations. Incorrect

installation could cause leaks, electric shock, re or explosion. In areas where Seismic ‘’Performance

requirements are specied, the appropriate measures should be taken during installation to guard

against possible damage or injury that might occur in an earthquake if the unit is not installed

correctly, injuries may occur due to a falling unit. Suspend pipes at certain points and reinforce

against earthquakes so that they will not be damaged by an external force. Check local codes and

regulations.

● Use appropriate Personal Protective Equipment (PPE), such as gloves and protective goggles and,

where appropriate, have a gas mask nearby. Also use electrical protection equipment and tools suited

for electrical operation purposes. Keep a wet cloth and a re extinguisher nearby during brazing. Use

care in handling, rigging, and setting of bulky equipment.

● When transporting, be careful when picking up, moving and installing these units. Although the unit

may be packed using plastic straps, do not use them for transporting the unit from one location

to another. Do not stand on, or put any material on, the unit. Get a partner to help, and bend with

your knees when lifting to reduce strain on your back. Sharp edges or thin aluminum ns on the air

conditioner can cut ngers, so wear protective gloves.

thoroughly and follow all warnings or cautions included in all manuals

that accompanied the product and are attached to the unit. Refer back to

these safety instructions as needed.

P5417058-rev.1

1

Page 6

● Do not touch or adjust any safety devices inside the indoor or outdoor units. All safety features,

disengagement, and interlocks must be in place and functioning correctly before the equipment is put

into operation. If these devices are improperly adjusted or tampered with in any way, a serious accident

can occur. Never bypass or jump-out any safety device or switch.

● Before servicing, turn-OFF the power supply and use accepted lockout and tag out procedures at all

main switches.

● This unit is a pressurized system. Never loosen threaded joints while the system is under pressure and

never open pressurized system parts.

● Johnson Controls will not assume any liability for injuries or damage caused by not following steps

outlined or described in this manual. Unauthorized modications to Johnson Controls' products are

prohibited as they…

◦ May create hazards that could result in death, serious injury or equipment damage.

◦ Will void product warranties.

◦ May invalidate product regulatory certications.

◦ May violate OSHA standards.

Take the following precautions to reduce the risk of property damage.

● Be careful that moisture, dust, or variant refrigerant compounds not enter the refrigerant system

during installation work. Foreign matter could damage internal components or cause blockages.

● If air lters are required on this unit, do not operate the unit without the air lter set in place. If the air

lter is not installed, dust may accumulate and breakdown may result.

● Do not install this unit in any place where silicon gases can coalesce. If the silicon gas molecules

attach themselves to the surface of the heat exchanger, the nned surfaces repel water. As a result,

any amount of drainage moisture condensate can overow from the condensate pan and could run

inside of the electrical box, possibly causing electrical failures.

● When installing the unit in a hospital or other facility where electromagnetic waves are generated from

nearby medical and/or electronic devices, be prepared for noise and electromagnetic interference

(EMI). Do not install where the waves can directly radiate into the electrical box, controller cable,

or controller. Inverters, appliances, high-frequency medical equipment, and radio communications

equipment may cause the unit to malfunction. The operation of the unit may also adversely affect

these same devices. Install the unit at least 10 ft. (3m) away from such devices.

● When a wireless controller is used, locate at a distance of at least 3.3 ft. (1m) between the indoor unit

and electric lighting. Otherwise, the receiver part of the unit may have difculty receiving operation

commands.

● If the wired controller is installed in a location where electromagnetic radiation is generated, make

sure that the wired controller is shielded and cables are sleeved inside conduit tubing.

● If there is a source of electrical interference near the power source, install noise suppression

equipment (lter).

● Do not install the unit in any location where animals and plants can come into direct contact with the

outlet air stream. Exposure could adversely affect the animals and plants.

● Do not install the unit with any downward slope to the side of the drain adapter. If you do, you may

have condensate water owing back, which may cause leaks.

● Be sure the condensate hose discharges water properly. If connected incorrectly, it may cause leaks.

● Do not install the unit in any place where oil can seep onto the units, such as table or seating areas in

restaurants, and so forth. For these locations or social venues, use specialized units with oil-resistant

features built into them. In addition, use a specialized ceiling fan designed for restaurant use. These

specialized oil-resistant units can be ordered for such applications. However, in places where large

quantities of oil can splash onto the unit, such as a factory, even the specialized units cannot be used.

These products should not be installed in such locations.

2

P5417058-rev.1

Page 7

Installation Precautions

To reduce the risk of serious injury or death, the following installation

precautions must be followed.

● When installing the unit into…

▫ A wall: Make sure the wall is strong enough to hold the unit’s weight. It may be necessary to

construct a strong wood or metal frame to provide added support.

▫ A room: Properly insulate any refrigerant tubing run inside a room to prevent “sweating” that can

cause dripping and water damage to wall and oors.

▫ Damp or uneven areas: Use a raised concrete pad or concrete blocks to provide a solid, level

foundation for the unit to prevent water damage and abnormal vibration.

▫ An area with high winds: Securely anchor the outdoor unit down with bolts and a metal frame.

Provide a suitable wind bafe.

▫ A snowy area: Install the outdoor unit on a raised platform that is higher than drifting snow.

Provide snow protection hood.

● Do not install the unit in the following places. Doing so can result in an explosion, re, deformation,

corrosion, or product failure.

▫ Explosive or ammable atmosphere

▫ Where a re, oil, steam or powder can directly enter the unit, such as nearby or above a kitchen

stove.

▫ Where oil (including machinery oil) may be present.

▫ Where corrosive gases such as chlorine, bromine, or sulde can accumulate, such as near a hot

tub or a hot spring.

▫ Where dense, salt-laden airow is heavy, such as in coastal regions.

▫ Where the air quality is of high acidity.

▫ Where harmful gases can be generated from decomposition.

● Do not install the motion sensor kit in the following places. It may cause failure or deterioration of the

sensor.

▫ Ambient temperature changes drastically.

▫ Where excessive force or vibration is applied to the sensor.

▫ Where static electricity or electromagnetic waves may generate.

▫ Where interference of infrared light such as glasses or mist is in the detecting area.

▫ Where the lens for sensor is exposed in high temperature and humidity for a long time.

▫ Where uid and corrosive gas exist.

▫ Where light such as sunlight or direct light affects the sensor.

▫ Where hot air from a heater, or something similar directly affects the sensor.

▫ Where the airow bounces back to the sensor by hitting obstacles such as shelf or locker.

▫ Where blower devices such as a ceiling fan or ventilating fan affect the airow from the indoor

unit.

▫ Where weather directly affects the surface of the sensor.

▫ Where the lens surface may smudge or be damaged from something like a dusty environment.

Detecting function decreases, if the lens sensor has smudges.

In this case, wipe off smudges using a cotton swab soaked with alcohol or a soft cloth. Isopropyl

alcohol is recommended. (When wiping off smudges on the lens sensor, do not apply excessive

force. If excessive force is applied, the resin lens may be damaged and this may cause

malfunctions such as misdetection or undetectable motion.)

● Do not position the condensate pipe for the indoor unit near any sanitary sewers where corrosive

gases may be present. If you do, toxic gases can seep into breathable air spaces and can cause

respiratory injuries. If the condensate pipe is installed incorrectly, water leakage and damage to the

ceiling, oor, furniture, or other possessions may result. If the condensate pipe becomes clogged,

water may drip from the indoor unit. Do not install the indoor unit where such dripping can cause

moisture damage such as uneven locations. Use a raised concrete pad or concrete blocks to provide

a solid, level foundation for the unit to prevent water damage and abnormal vibration.

P5417058-rev.1

3

Page 8

● Before performing any brazing work, be sure that there are no ammable materials or open ames

nearby.

● Perform a test run to ensure normal operation. Safety guards, shields, barriers, covers, and protective

devices must be in place while the compressor/unit is operating. During the test run, keep ngers and

clothing away from any moving parts.

● Clean up the site when nished, remembering to check that no metal scraps or bits of wiring have

been left inside the unit being installed.

After installation work for the system has been completed, explain the “Safety Precautions,” the proper use

and maintenance of this unit to the customer according to the information in all manuals that came with the

system. All manuals and warranty information must be given to the user or left near the Indoor Unit.

Refrigerant Precautions

To reduce the risk of serious injury or death, the following refrigerant

precautions must be followed.

● As originally manufactured, this unit contains refrigerant installed by Johnson Controls. Johnson

Controls. uses only refrigerants that have been approved for use in the unit’s intended home country

or market. Johnson Controls' distributors similarly are only authorized to provide refrigerants that

have been approved for use in the countries or markets they serve. The refrigerant used in this unit

is identied on the unit’s faceplate and/or in the associated manuals. Any additions of refrigerant into

this unit must comply with the country’s requirements with regard to refrigerant use and should be

obtained from Johnson Controls' distributors. Use of any non-approved refrigerant substitutes will void

the warranty and will increase the potential risk of injury or death.

● If installed in a small room, take measures to prevent the refrigerant from exceeding the maximum

allowable concentration in the event that refrigerant gases should escape. The installation should

meet the requirements in ASHRAE Standards 15 and 34. If refrigerant gas has leaked during the

installation work, ventilate the room immediately.

● Check the design pressure for this product is 601 psi (4.15MPa). The pressure of the refrigerant

R410A is 1.4 times higher than that of the refrigerant R22. Therefore, the refrigerant piping for

R410A shall be thicker than that for R22. Make sure to use the specied refrigerant piping. If not, the

refrigerant piping may rupture due to an excessive refrigerant pressure. Besides, pay attention to

the piping thickness when using copper refrigerant piping. The thickness of copper refrigerant piping

differs depending on its material.

● The refrigerant R410A is adopted. The refrigerant oil tends to be affected by foreign matters such

as moisture, oxide lm, (or fat). Perform the installation work with care to prevent moisture, dust, or

different refrigerant from entering the refrigerant cycle. Foreign matter can be introduced into the cycle

from such parts as expansion valve and the operation may be unavailable.

● To avoid the possibility of different refrigerant or refrigerant oil being introduced into the cycle, the

sizes of the charging connections have been changed from R407C type and R22 type. It is necessary

to prepare the following tools listed in Section 3 before performing the installation work. Use

refrigerant pipes and joints that are approved for use with R410A.

● Before installation is complete, make sure that the refrigerant leak test has been performed. If

refrigerant gases escape into the air, turn OFF the main switch, extinguish any open ames and

contact your service contractor. Refrigerant (uorocarbon) for this unit is odorless. If the refrigerant

should leak and come into contact with open ames, toxic gas could be generated. Also, because the

uorocarbons are heavier than air, they settle to the oor, which could cause asphyxiation.

● When installing the unit, and connecting refrigerant piping, keep all piping runs as short as possible,

and make sure to securely connect the refrigerant piping before the compressor starts operating. If

the refrigerant piping is not connected, and the compressor activates with the stop valve opened, the

refrigerant system is subjected to extremely high pressure, which can cause an explosion or re.

● Tighten the are nut with a torque wrench in the specied manner. Do not apply excessive force to the

are nut when tightening. If you do, the are nut can crack and refrigerant leakage may occur.

4

P5417058-rev.1

Page 9

● A compressor/unit comprises a pressurized system. Never loosen threaded joints while the system is

under pressure and never open pressurized system parts.

● When maintaining, relocating, or disposing of the unit, dismantle the refrigerant piping after the

compressor stops.

● When pipes are removed from under the piping cover, after the insulation work is completed, cover

the gap between the piping cover and pipes using a packing (eld-supplied). If the gap is not covered,

the unit may be damaged if snow, rain water or small animals enter the unit.

● Do not apply an excessive force to the stop valve at the end of opening. Otherwise, the stop valve

ies out due to refrigerant pressure. At the test run, fully open the gas and liquid valves. Otherwise,

these devices become damaged. (It is closed before shipment.)

● If the arrangement for outdoor units is incorrect, it may cause owback of the refrigerant and result in

failure of the outdoor unit.

o

● The refrigerant system may be damaged if the slope of the piping connection kit exceeds +15

.

Electrical Precautions

Take the following precautions to reduce the risk of electric shock, re or

explosion resulting in serious injury or death.

● Highly dangerous electrical voltages are used in this system. Carefully refer to the wiring diagram and

these instructions when wiring. Improper connections and inadequate grounding can cause serious

injury or death.

● Perform all electrical work in strict accordance with this installation and maintenance manual and all

relevant regulatory standards.

● Do not open the service cover or access panel to indoor or outdoor units without turning OFF the

main power supply. Before servicing, open and tag all disconnect switches. Never assume electrical

power is disconnected. Check with a meter and equipment.

● Only use electrical protection equipment and tools suited for this installation.

● Use specied cables between units.

● Do not run the relay wiring for the motion sensor and power supply wiring in parallel. Electromagnetic

Interference (EMI) may cause malfunction of the sensor.

● Communication cable should be a minimum of AWG18 (0.82mm

2

), 2-Conductor, Stranded Copper.

Shielded cable must be considered for applications and routing in areas of high EMI and other

sources of potentially excessive electrical noise to reduce the potential for communication errors.

When shielded cable is applied, proper bonding and termination of the cable shield is required as per

Johnson Controls guidelines. Plenum and riser ratings for communication cables must be considered

per application and local code requirements.

● Use an exclusive power supply for the air conditioner at the unit’s rated voltage.

● Be sure to install circuit breakers (ground fault interrupter, isolating switch, molded case circuit

breaker and so on), with the specied capacity. Ensure that the wiring terminals are tightened

securely to recommended torque specications. If a circuit breaker or fuse is frequently activated,

shut down the system and contact your service contractor.

● The polarity of the input terminals is important, so be sure to match the polarity when using contacts

that have polarity.

● Before installing the controller or remote devices, ensure the indoor and outdoor unit operation has

been stopped. Further, be sure to wait at least ve minutes before turning OFF the main power switch

to the indoor or outdoor units. Otherwise, water leakage or electrical breakdown may result.

● Clamp electrical wires securely with a cable band after all wiring is connected to the terminal block. In

addition, run wires securely through the wiring access channel.

● When installing the power lines, do not apply tension to the cables. Secure the suspended cables at

regular intervals, but not too tightly.

● Make sure that the terminals do not come into contact with the surface of the electrical box. If the

terminals are too close to the surface, it may lead to failures at the terminal connection.

P5417058-rev.1

5

Page 10

● Turn OFF and disconnect the unit from the power supply when handling the service connector. Do not

open the service cover or access panel to the indoor or outdoor units without turning OFF the main

power supply.

● After stopping operation, be sure to wait at least ve minutes before turning off the main power

switch. Otherwise, water leakage or electrical breakdown may result. Disconnect the power supply

completely before attempting any maintenance for electrical parts. Conrm that no residual voltage is

present after disconnecting the power supply.

● Do not clean with, or pour water into, the controller as it could cause electric shock and/or damage the

unit. Do not use strong detergent such as a solvent. Clean with a soft cloth.

● Check that the ground wiring is securely connected. Do not connect ground wiring to gas piping,

water piping, lighting conductor, or telephone ground wiring.

● If a circuit breaker or fuse is frequently activated, shut down the system and contact your service

contractor.

● This equipment can be installed with a Ground Fault Circuit Breaker (GFCI), which is a recognized measure for

added protection to a properly grounded unit. Install appropriate sized breakers / fuses / overcurrent protection

switches, and wiring in accordance with local, state and NEC codes and requirements. The equipment installer

is responsible for understanding and abiding by applicable codes and requirements.

6

P5417058-rev.1

Page 11

● Proper handling of this unit requires two people. Safe handling and installation of the indoor unit requires

NOTICE

the strength of two people. Mounting the unit alone may cause injury due to a fall of the unit. Although the

unit may be girded with steel banding, do not use it for transportation. Avoid contact with nned surfaces

of the heat exchanger as sharp edges can cause severe injury to hands and ngers. Use appropriate

work gloves for the job.

● Check to ensure that the condensate hose discharges moisture properly. If connected incorrectly, it can

result in leakage and damage to property.

● Make sure to use the factory-supplied condensate hose and hose clamp. Other makes can cause

moisture leakage.

● Do not bend or twist the factory-supplied condensate hose. This could compromise the seal and result in

moisture leakage.

● Do not apply an excessive force to the condensate pipe connection. This can also compromise the seal

properties of the connection.

● Verify that the installed unit is level with oor and ceiling surfaces. Any variance or inclination can cause

moisture to back up into the condensate pan, overow, and seepage onto ceiling or wall surfaces, and

cause damage to carpeted surfaces or furniture below.

● Do not install this system in close proximity to septic sewer lines where ammable and toxic gases can coalesce.

● Inspect the condensate pan before the onset of winter to drain away all accumulated moisture in the pan.

● The heat exchanger of indoor units overheats whenever there is a slight amount of refrigerant circulating

during slowdown or stoppage. As a result, moisture in the condensate pan evaporates where it can affect

ceiling or wall surfaces.

● After the drain check is completed, insert the rubber plug again and seal the gap with a silicon sealant.

Electrical Installation

In some cases, the packaged air conditioner may not be operated normally under the following cases:

● When electrical power for the packaged air conditioner is supplied from the same power transformer

as the external equipment.

● When the power supply wiring for the external equipment and the packaged air conditioner are

located close to each other.

Regarding that mentioned above, surge voltage may be inducted into the power supply wiring for the crated

unit due to a spike in power consumption for this device and an activation of the switch. Check the eld

regulations and standards before performing any electrical work in order to safeguard the power supply for

the crated air conditioner unit.

P5417058-rev.1

7

Page 12

3. Before Installation

Air Inlet Grille

Side Cove

Louver

Side Cover

Securing Screw

(M4)

Position for Securing Screw

(three)

3.1 Combinations of Outdoor Unit and Indoor Unit

The combination capacity of the indoor unit against the outdoor unit is selected depending on the outdoor

unit capacity. Refer to the “Installation and Maintenance Manual” for the outdoor unit to decide the required

combination of indoor and outdoor units, and the combination unit capacity.

3.2 Transportation and Handling

1. Transport the product as close to the installation location as possible before unpacking.

r

Lower Cover

2. Do not put any objects on the indoor unit.

3. Remove the side cover (shown below) when the indoor unit is moved after unpacking. If it isn't

removed, the side cover may be damaged and may cause injury.

Removing Side Cover

a. Open the air inlet grille.

b. Remove the securing screw (M4).

c. Push the side cover forward to remove

the hooks and the hooking plate.

Hooking Plate

Hooks

d. Remove the side cover by lifting up.

4. When the indoor unit is unpacked, moved and installed, do not take out the air inlet grille, louver and

lower cover. Additionally, do not apply an excessive force to them. The air inlet grille, louver and lower

cover will become deformed or damaged.

5. The indoor unit covers are resin made. Do not apply an excessive force to the resin covers or allow

them to fall.

6. Do not move the louver by hand. If moved, the louver mechanism will be damaged.

8

P5417058-rev.1

Page 13

NOTICE

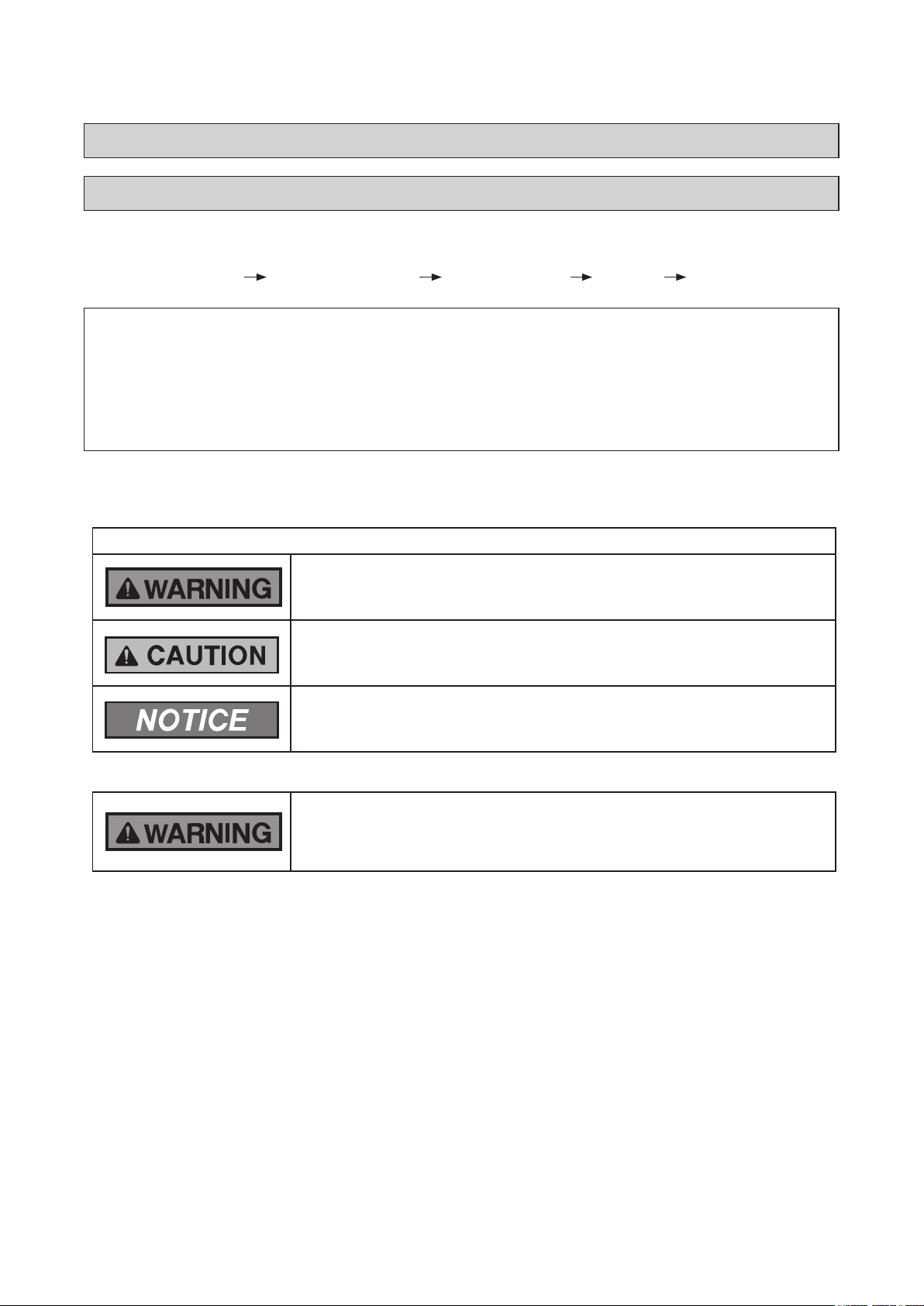

3.3 Factory-Supplied Accessories

1. Check to ensure that the following accessories are packed with the indoor unit.

The screws, washers, and are nuts are packed in the pipe insulation.

Accessory Qty. Purpose

Suspension Bracket

Washer

Pipe Insulation

(Large)

Pipe Insulation

(Small)

Cable Band

(Large)

Cable Band

(Small)

Condensate Hose

Hose Clamp

Insulation

2 For Installing Indoor Unit

8 For Suspension Bracket

1

For Refrigerant Piping Connection

1

6 For Securing Insulation

1 For Securing Plug

1 For Connecting Condensate Pipe

2 For Connecting Condensate Hose

2 For Condensate Hose Connection

PVC Tube

Cable Band

Logo Label

2

For Separating Communication Cables and Wired

Controller Cables from Power Supply Wirings;

7/16 ID (11 ID)

5

1 Logo Label for HITACHI Brand

1 Logo Label for YORK Brand

The controller and branch piping are optional accessories and are not included with the indoor unit.

If necessary, please contact your distributor or contractor.

P5417058-rev.1

9

Page 14

2. Do not insert or leave any foreign objects inside the indoor unit and verify that no foreign objects

inch (mm)

inch (mm)

remain inside the indoor unit before installation and the test run. Failure to do this can result in

equipment failure and damage to the unit.

3. Necessary Tools and Instrument List for Installation

No. Tool No. Tool

1 Handsaw 11 Wrench

2 Philips Screwdriver 12 Charging Cylinder

3 Vacuum Pump 13 Manifold Gauge

4 Refrigerant Gas Hose 14 Wire Cutter

5 Megohmmeter 15 Gas Leak Detector

6 Copper Pipe Bender 16 Level

7 Manual Water Pump 17 Clamp for Solderless Terminals

8 Copper Tube Cutter 18 Hoist (for Indoor Unit)

9 Brazing Kit 19 Ammeter

10 Hexagonal Wrench 20 Voltage Meter

NOTE:

Use tools and measuring

instruments (vacuum pump, gas

hose, charging cylinder, and

manifold gauge) exclusively for

the refrigerant R410A.

• Install the indoor unit with an appropriate clearance around it for operation and maintenance working

space, as shown in Fig. 3.1.

• Do not install ammable parts in the service space for the indoor unit.

• Install the indoor unit higher than 8 ft. (2.4m) from the oor level.

• Consider the air distribution from the indoor unit to the space of the room, and select a suitable

location so that uniform air temperature in the room can be obtained.

• Avoid obstacles such as electric lights or partitions that may hamper the air inlet or the air outlet ow.

• Check to ensure that the ceiling has sufcient strength to hang the indoor unit.

Do not install the indoor unit in a machinery shop or kitchen where vapor from oil ows to the indoor

•

unit. Oil will deposit on the heat exchanger, thereby reducing the indoor unit performance and the

plastic parts may deform, and in the worst case, break due to splashed oil during operation.

• Avoid an installation place where the indoor unit may be in contact with high humidity.

• Warm air may stay at the high ceiling space during the heating operation. Thus, the parallel installation

of a circulator is recommended.

Avoid installing the air conditioning where direct airow blows from the air outlet to temperature

•

detecting devices such an alarm device or a control device. It may cause a failure of an alarm device

or a control device.

Minimum service space to

tighten the suspension bolt

Min. 11-13/16 (300)Min. 1-9/16 (40)

Minimum service space

for auto louver motor

Min.

19-11/16

(500)

Min. 15-3/4

For Single Installation

Min. 1-9/16 (40) Min. 11-13/16 (300)

Min. 11-13/16 (300)

For Parallel Installation

NOTE:

If there is a cornice on the ceiling, measure the dimension from the front or undersurface.

Fig. 3.1 Space around Indoor Unit

10

Min. 5/16 (8)

(400)

P5417058-rev.1

Page 15

• For the indoor unit with a motion sensor, the detecting area for the motion sensor is shown in the gure

Detecting Area

29.5 ft (9m)

Floor-to-Ceiling Height

below.

Depth 23 ft (7m)

Detecting Area

Detecting Area

8.9 ft (2.7m)

2.6 ft (0.8m) from Floor Level

5.9 ft

(1.8m)

To avoid any corrosive action to the heat exchangers, do not install the indoor unit in an acidic or alkaline

•

23.6 ft (7.2m)

environment.

• The temperature and humidity inside the ceiling have the potential to exceed 86

o

F/RH (30oC/RH) (Relative

Humidity 80%). Thus, apply additional insulation materials to the indoor unit's external surface to avoid

condensation.

Pay attention to the following points when the indoor unit is installed in a hospital or other facility where

•

there may be electromagnetic waves from medical equipment.

a. Do not install the indoor unit where the electromagnetic wave is directly radiated to the electrical box,

wired controller cable or wired controller.

b. Install the indoor unit and components as far as practical or at least 9.8 ft. (3m) from the electromagnetic

wave radiator.

c. Prepare a steel box and install the wired controller inside it. Prepare a steel conduit tube and wire the

wired controller cable in it. Then, connect the ground wire with the box and the tube.

d. Install a noise lter when the power supply emits electromagnetic interference (EMI).

P5417058-rev.1

11

Page 16

4. Installation Work

7/8 (22)

* Dimension for Suspension Bolt

Steel

5-7/8 to 6-5/16 inches

(100 to 150kg)

(W3/8 or M10)

I Beam

Suspension Bolt

(W3/8 or M10)

4.1 Position of Suspension Bolts

1. Determine the nal location and installation direction of an indoor unit with care to spacing for piping

and wiring.

2. After the position of the indoor unit is determined, make holes in the ceiling to install the suspension

bolts.

3. The positions of suspension bolts are shown below.

Upper Surface

4-3/4

(120)

inch (mm)

Model A B

(B)

A

11*

(280)*

7/8 (22)

(H,Y,C)ICS015B21S

(H,Y,C)ICS024B21S

(H,Y,C)ICS030B21S

(H,Y,C)ICS036B21S

37-13/16

(960)

50

(1270)

62-3/16

(1580)

36-1/16

(916)

48-1/4

(1226)

60-1/2

(1536)

4. Ceiling Work: It is different depending on the building structure. Consult with an architect or an interior

nish worker for more information.

• Do not install electric light units and the indoor unit to the same ceiling furring. Otherwise, electric

lights may icker or vibrate during the indoor unit operation. When installing the indoor unit and

electric lights, a separate ceiling furring must be used for each.

4.2 Installation of Suspension Bolts

The structure for suspension should be strong enough.

For Steel Beam

For Concrete Slab

(150 to 160mm)

12

NOTES:

To hang the indoor unit, a strong wooden beam shall

be utilized.

Span < 35-7/16 inches (90cm):

2 x 4 wood support

Span < 70-7/8 inches (180cm):

2 x 4 wood support

Insert

220 to 330 lb

Concrete

Suspension Bolt

P5417058-rev.1

Page 17

4.3 Mounting Indoor Unit

attached in the upper cap.

Suspension

Max. 1-15/16 inches (50mm)

of Indoor Unit

Suspension Bolt

1. Pattern Board for Installation

The pattern board for the installation is printed on the packing.

When making holes in the wall and ceiling, use the pattern board that has printed hole positions for

suspension, refrigerant pipe and condensate pipe.

Upper Cap

The pattern board is

2. Hanging Indoor Unit

A. Hanging Indoor Unit with Suspension Bracket

a. Make holes in the ceiling for the suspension bolts.

b. Remove the suspension brackets attached to the indoor unit.

c. Afx the suspension brackets to the suspension bolts (four places).

d. Mount the indoor unit to the suspension brackets.

e. Tighten the four nuts and the securing screw for the suspension bracket.

Bolt

Tighten four

accessory nuts.

Nut

(Accessory)

Washer

Nut

Suspension Bolt

Suspension

Bracket

Ceiling

Rear Side

1/4 inch

(6mm)

P5417058-rev.1

13

Page 18

B. Hanging Indoor Unit without Suspension Bracket

Suspension Bolt (Field-Supplied)

Max. 1-15/16 inches

1/16 ~ 3/8 inch

(1 ~ 10mm)

from horizontal

View from Right

1/16 ~3/8 inc

(1 ~ 10mm

from horizontal

Hook the supporting string into the rectangular holes.

Side Cover

Supporting String

(If there is not enough service space between the ceiling and the indoor unit, hang the indoor unit

using procedures of A above.)

a. Determine the position to install the

suspension bolt.

b. Afx the washer and nut to the suspension

bolt.

c. Mount the indoor unit to the suspension bolts.

Nut (Field-Supplied)

Washer (Field-Supplied)

Washer (Field-Supplied)

Nut (Field-Supplied)

Suspension Bolt

(50mm)

Ceiling

3. When the indoor unit is installed, create a down-slope toward the condensate pipe connection for

drainage. The gure at the right shows the right condensate pipe connection (before shipment). For the

left condensate pipe connection, create a down-slope toward the left.

(Condensate Pipe Connection)

View from Front

Lower the indoor unit

3/8 inch (10mm) when

the optional drain-up

mechanism is installed.

NOTE:

The ceiling surface may not be level. When the indoor unit is installed, using a level, check the

alignment as it pertains to the condensate pipe connection down-slope. If the indoor unit is mounted

with incorrect suspending position, it may deform and the abnormal vibration may occur.

4. Attach the side cover and the supporting string.

h

)

5. Remove the protection lm attached to the louver surface.

6. Remove the protection tape attached to the air inlet lter.

4.4 Installation of Wired Controller

The installation of the wired controller should be performed according to the installation manual for the

wired controller.

14

P5417058-rev.1

Page 19

5. Refrigerant Piping Work

0.016 ~ 0.031R

Use the specied non-ammable refrigerant (HFC R410A) for the outdoor unit refrigerant system. Do

not charge the unit with anything other than HFC R410A, such as hydrocarbon refrigerants (propane

and isobutene), oxygen, and other ammable gases (acetylene, ammonia, and so forth), or any

poisonous gases when installing, maintaining or moving the unit. These substances are volatile and

dangerous and can result in re, explosion, and serious or fatal injuries.

For details of refrigerant piping work, vacuum pump and refrigerant charging, refer to the "Installation and

Maintenance Manual" for the outdoor unit.

5.1 Piping Materials

1. Tolerances of refrigerant piping lengths depend on the combination with the outdoor unit.

Refer to the "Installation and Maintenance Manual" for the outdoor unit.

2. Select the piping size from the following table.

Table 5.1 Piping Size

inch (mm)

Model Gas Piping Liquid Piping

(H,Y,C)ICS015B21S 1/2 (12.7) 1/4 (6.35)

(H,Y,C)ICS024B21S

(H,Y,C)ICS030B21S

5/8 (15.88) 3/8 (9.52)

(H,Y,C)ICS036B21S

3. Prepare eld-supplied copper pipes.

4. Select clean copper pipes. Make sure there is no dust or moisture inside.

5. The refrigerant lubricating oil used in these units is Polyvinylether (PVE), a chemically stable, resilient,

synthetic lubricant that, when combined with refrigerant R410A, maintains its compatibility, lubricity,

and viscosity over extended periods of time and is impervious to heat, oxidation, moisture absorption

and breakdown as long as it remains in a sealed system. Its chemical properties will remain intact only

so long as moisture is not introduced into the system.

The gaseous element, PVE, is a moisture magnet that, once exposed to open air can quickly

become saturated with moisture, lose its lubricity, and become useless. Minimize exposure to

the open air, over the summer months, and in southern or tropical climates.

6. When cutting piping, do not use conventional tools such as saws or grinding wheel cutting disks that

produce harmful metallic lings and burrs that can damage a refrigerant system. Use a pipe cutter to

eliminate metal lings produced by the cutting operation. After the cut is made, blow out each pipe

with dry compressed air or nitrogen to remove any residue before making pipe connections.

In Case of Getting the Pipe

Through a Hole in the Wall

Correct

HoleHole

Attach a cap or put a plastic bag

over the pipe end.

Do not lay the pipe

directly on the ground.

CorrectIncorrect Incorrect

Attach a cap or put a plastic

bag over the pipe end.

In Case of Rain

Correct Incorrect

Rain water

can come in.

Attach a cap or put a plastic

bag over the pipe end.

Rubber Band

5.2 Piping Connection

1. Perform the aring work as shown below.

o

+

90

φA

φd

P5417058-rev.1

o

2

45

o

+

o

2

Diameter

(d)

inch (mm)

+0

A

-0.02 (-0.4)

1/4 (6.35) 0.36 (9.1)

3/8 (9.52) 0.52 (13.2)

1/2 (12.7) 0.65 (16.6)

5/8 (15.88) 0.78 (19.7)

15

Page 20

Fasten with cable bands

at three locations along the pipe

(Accessory).

2. Use the specic are nut attached with the unit.

A

pply a small amount

of oil to the flare face.

3. Verify that there are no scratches or burrs stuck to internal surfaces, or surface distortion at the ared opening.

4. Before tightening the are nut, apply a small amount of oil (eld-supplied) to the are face. (Do not

apply any oil to the backside of the are or the threads.) Tighten the liquid pipe are nut to the specied

torque while using a backup wrench to prevent damage to the unit. Next, tighten the gas pipe are nut

following the same procedures. Ensure that the are connections are leak free upon completion of the

work.

NOTE:

1. Refrigerant oil is eld-supplied. [Ethereal Oil FVC50K, FVC68D (Idemitsu Kousan Co. Ltd.)]

2. If refrigerant comes into contact with decorative panel surfaces, damage in the form of cracks can

occur on panel surfaces. Use with caution.

Required Tightening Torque (JIS B 8607)

Pipe Size Tightening Torque

1/4 inch (6.35 mm) 10.3 - 13.3 ft·lbs (14 - 18 N·m)

Do not apply

oil here.

3/8 inch (9.52 mm) 25.1 - 31.0 ft·lbs (34 - 42 N·m)

1/2 inch (12.7 mm) 36.1 - 45.0 ft·lbs (49 - 61 N·m)

5/8 inch (15.88 mm) 50.2 - 60.5 ft·lbs (68 - 82 N·m)

5. Wherever buried piping exists onsite, make sure there is a service doorway to provide adequate access

to inspect piping sockets and elbows, and for interconnecting parts.

6. Suspend pipes at certain points and reinforce against earthquakes so that they are not damaged by

an external force. Appropriate measures should be taken during installation to guard against possible

damage or injury that might occur in an earthquake. Check local codes and refer to the Safety Section

in this manual for additional information.

7. Do not tightly secure refrigerant piping to accommodate expansion and contraction.

8. Prevent the pipes from contacting weak portions such as a wall or ceiling. Otherwise, abnormal sound

may be heard due to vibration of the piping.

9. Leak test all piping and connections. The procedures should be performed in accordance with the

"Installation and Maintenance Manual" for the outdoor unit.

10. If temperature and humidity inside the ceiling exceed 80.6°F (27°C)/RH80%, condensation occurs

on the surface of the accessory insulation. Wrap additional insulation (approximately 3/16 to 3/8 inch

(5~10mm) thickness) around the accessory insulation of the refrigerant pipe as a preventive measure.

11. Insulate each are connection ensuring no gap with accessory insulations to prevent condensation.

Then insulate each refrigerant pipe as well.

● Do not apply excessive force to the are nut when tightening. If applied, the are nut may crack due

to stress fracture and refrigerant leakage may occur. Use the correct torque specications.

● Make sure that a refrigerant leak test has been performed. Refrigerant (uorocarbon) for this unit is

non-ammable, non-toxic, and odorless. If the refrigerant should somehow escape and come into

contact with ame, toxic gas will form. This gas is heavier than air and will settle near oor areas

and spread where it can cause asphyxiation to those nearby.

16

Securely fasten cable bands and vinyl tape in

order to prevent the accumulation of moisture.

Affix the vinyl tape position at the vertical part

(Insulation for Refrigerant Pipe (Accessory)).

Refrigerant Pipe

(Field-Supplied)

Unit

Side

Insulation Material

(Factory-Supplied)

Check for any gap between

the indoor unit and the insulation.

Insulation for

Refrigerant Pipe

(Field-Supplied)

P5417058-rev.1

Page 21

5.3 Piping Connection Work

to prevent dangling.

Upper Side

Right Side

View from Front

View from Bottom

Front

5-1/2 (140)

of Indoor Unit

7-15/16 (201)1-9/16 (40)

17) (Liquid Pipe)

4-3/16 (107) (Gas Pipe)

1-9/16 (40) (Condensate Pipe

5.3.1 Position of Piping Connection

The piping connection is performed inside the indoor unit. The pipe connection can be performed from

three directions - rear, right and upper. For rear and upper pipe connection, the plastic cap is attached at

the knockout hole for the refrigerant pipe and the condensate pipe. Cut out the knockout hole of the cap

for piping and attach the cap again after running the refrigerant pipe through the cap.

Hole Position and Size

Ceiling

φ5-1/8

(φ130)

4-3/4 (120)

6-9/16 (166)

1/4 (6)

Right End

of Indoor Unit

φ3-15/16

(φ100)

Wall

4-7/16 (113)

inch (mm)

Right End

5/16 (8)

NOTE:

When the optional drain-up mechanism is attached, refer to the installation manual for the drain-up

mechanism.

Position of Pipe Connection

Cap (Rear Side)

Gas Pipe

Suspension Band

Liquid Pipe

Rear Side

Condensate Pipe

1/4 (6)

3 (76)

P5417058-rev.1

If the liquid pipe contacts strongly to the plate,

noise caused by refrigerant flowing may increase.

Suspend the local liquid pipe using a suspension band

Cap (Rear Side)

5-3/4 (146) (Liquid Pipe)

3-11/16 (94) (Gas Pipe)

5-13/16 (147) (Condensate Pipe)

Condensate Pipe Connection

(VP20, Left Side)

Condensate Pipe Connection

(VP20, Right Side)

8-1/16 (205) (Gas Pipe)

7-1/2 (190) (Liquid Pipe)

5-7/16 (138) (Condensate Pipe)

View from Front View from Right

1/4 (6)

inch (mm)

4-7/8 (124)

5-1/4 (134)

4-5/8 (1

7-15/16 (201)

)

17

Page 22

● Piping from Rear Side

View from Front

1-9/16 (40)

9/16 (14)

View from Right

View from Bottom

Rear Side

of Indoor Uni

)

Air Inlet Grille

Supporting String

r

inch (mm)

Upper Surface

Cap (Rear Side)

3 (76)

Condensate Pipe Connection

(VP20, Left Side)

4-3/4 (121) 2-7/16 (62)

9/16 (15) 5-9/16 (142)

● Piping from Right Side ● Piping from Upper Side

Cap (Upper Side)

Hole for

Condensate Pipe Conncetion

(Knockout hole)

4-3/4 (120)

6-1/16 (154)

t

4-5/8 (118) 2 (51)

6-7/16 (163)

3/4 (19)

5.3.2 Access of Piping Connection

Open the air inlet grille and perform the connecting work from the lower side.

1. Press and slide the cover of the air inlet grille in the direction of the arrow with ngers in the holes

on the cover.

2. Remove the supporting string from the side plate.

3. While the air inlet grille is being opened,

depress the knobs of the hinge (

),

1

push the air inlet grille toward the arrow

direction (2) and remove the air inlet

grille.

Holes

(Two or three places

Push

2

Hinge

Depress

1

Side Plate

Depress the knob of

hinge and push the ai

inlet grille forward.

18

P5417058-rev.1

Page 23

6. Condensate Piping

NOTICE

Left Side

(Condensate Pipe Connection)

Silicon Sealant

Do not run condensate piping into underground areas near sanitary or sewage lines where toxic and

corrosive gases can seep into the system. This creates a pathway for the ow of poisonous gas to

penetrate inhabited areas.

● Check to ensure that the condensate pipe discharges moisture properly. If connected incorrectly, it can

cause structural damage to the indoor wall and ceiling surfaces and damage to property.

● Avoid sloping the condensate pipe upward as this impede drainage. Moisture can settle back into the unit

and it cause water leakage when the unit operation stops.

● Do not connect drainage with sanitary or sewer lines or any other condensate pipe.

● When the main condensate pipe is connected with other indoor units, the connected position of each

indoor unit must be higher than the main pipe. The pipe size of the main condensate pipe must be large

enough according to the unit size and number of units.

● After performing condensate piping work and electrical wiring, check to ensure that water outow is

smooth as in the following procedures.

1. Connecting Direction of Condensate Pipe

The standard direction of the condensate piping connection is the right side as viewed from the front.

However, it can be performed from the left side when it is required due to building construction.

For Left Side Condensate Piping

Left Side Right Side

Cable Band

Condensate

Pan

Insulation

Condensate Plug

Remove the condensate plug.

Right Side

Insert the Condensate plug into

the drain adaptor by using a screwdriver.

Screwdriver

Condensate Plug

Wrap the insulation around

the condensate pipe connection.

Condensate Plug

Drain Adaptor

P5417058-rev.1

19

Page 24

2. Connecting Condensate Hose

Hose Clamp

Hose Clamp

Condensate

Pan

Condensate Hose

a. Insert the hose into the hose clamp.

b. Push the condensate hose onto the drain adaptor until the hose reaches the end of the condensate

pan. (If the condensate hose is not inserted completely, it causes water leakage.)

c. Tighten the screw for the hose clamp to face the screw part downward as shown in the gure below

to prevent dripping of condensate.

d. Wrap the insulation (accessory) around the hose clamp to cover the condensate hose, condensate

pan, and hose clamp without any gaps. (If there is a gap, dripping of condensate may occur.)

3. Connecting Condensate Piping

a. Prepare a PVC piping with a 1 inch (26mm) outer diameter.

b. When the condensate hose is used, do not create a raised part or twist.

c. Insulate the PVC piping securely after connecting.

d. Tighten the hose clamp after inserting the PVC piping.

e. The condensate pipe must be performed with a down-slope pitch of 1/25 to 1/100.

f. Wrap the insulation (accessory) around the hose clamp to cover the condensate hose, condensate

pan, and hose clamp without any gaps.

NOTE:

* Do not connect the condensate pipe with sanitary or sewage piping or any other drainage piping.

* Do not tighten the condensate pipe and the refrigerant pipe together with the hose clamp.

(Accessory)

Drain Adaptor

Gluing is

not required.

(Attach to indoor unit.)

Insulation

(Attached to condensate hose)

Insulation

(Accessory)

Connect tightly.

(Accessory)

Insulate without gap

and wrap the tape

around the connection.

Insulation (Field-Supplied)

Create down-slope

for proper drainage.

PVC Piping

(VP20, Field-Supplied)

Gluing is

not required.

Insulation

(Accessory)

NOTE:

Connect the eld-supplied condensate pipe to the condensate hose using PVC adhesive.

•

Perform rmly cleaning the connection surface, applying the adhesive, inserting the pipe, and retaining

and curing according to the adhesive manufacturer information.

Insert the condensate hose completely. If not, or twisted, it will cause water leakage.

•

Attach the hose clamp to the screw part upward but not allowing the screw part to touch the air lter.

•

If the PVC adhesive is used on the drain adaptor that is ABS resin, a crack and water leakage may

•

occur.

The tightening torque for the hose clamp should be 2.2 to 2.6 ft∙lbs (3.0 to 3.5N-m).

•

20

P5417058-rev.1

Page 25

4. After the condensate piping work is completed, check that water ows smoothly by pouring water into

Hose Clamp

Insulation

Rear Side Piping Right Side Piping

the condensate pan using a hose.

NOTE:

The optional drain-up mechanism is required when the condensate piping is connected from the upper

surface of the indoor unit. For details, refer to the installation and maintenance manual for the drain-up

mechanism.

(Accessory)

Pay attention not to splash water on the electrical parts such as the fan motor, the oat switch or

thermistors.

P5417058-rev.1

21

Page 26

7. Electrical Wiring

● All electrical work must be done as outlined in this manual and in accordance with this manual.

Substandard work can result in re and damage to the unit.

● Use specied cables between units and choose the cables correctly. If not, an electrical shock or

re may occur.

● Do not open the service cover or access panel for the indoor or outdoor units without turning OFF

the main power supply. It can result in an electrical shock.

● Turn OFF the main power switch of the indoor unit and the outdoor unit before attempting any electrical

wiring work or a periodical check is performed. Otherwise, the result will be an electric shock or a re.

● Check to ensure that the indoor fan and the outdoor fan have stopped before attempting any

electrical wiring work or for any scheduled electrical work that is being performed.

● Tighten screws according to the following torque.

M3.5: 0.9 ft·lbs (1.2 N·m)

M4: 0.7 to 1.0 ft·lbs (1.0 to 1.3 N·m)

● Secure all cables together with cable bands and seal the connecting hole against moisture and

insects.

● Run the electrical wiring through the connecting hole in the side cover when using conduit.

● Secure the wired controller cable using the cable band inside the electrical box.

7.1 General Check

1. Make sure that the eld-selected electrical components: (main power switches, circuit breakers,

wires, conduit connectors, and wire terminals) are properly labeled in accordance with electrical data

as specied in the Engineering Manual. Make sure that the components comply with the National

Electrical Code (NEC).

2. Conrm that the power supply voltage is within ±10% of the rated voltage.

3. Verify the capacity of the electrical wires.

If the power supply capacity is too low, the system cannot be started due to a voltage drop.

4. Verify that the ground wiring is securely connected.

7.2 Electrical Wiring Capacity

7.2.1 Field Minimum Wire Sizes for Power Supply

This equipment can be installed with a Ground Fault Circuit Breaker (GFCI), which is a recognized

•

measure for added protection to a properly grounded unit. Install appropriate sized breakers / fuses

/ overcurrent protection switches, and wiring in accordance with local, state and NEC codes and

requirements. The equipment installer is responsible for understanding and abiding by applicable

codes and requirements. Failure to use a GFCI can result in electric shock or re.

Do not operate the system until all check points have been cleared.

•

▫ Conrm that the electrical resistance is more than one megaohm, by measuring the resistance

between the ground and the terminal of the electrical parts. If it is less than one megaohm, do not

operate the system until the source of the electrical drain is found and repaired.

▫ Conrm that the stop valves of the outdoor unit are fully opened, and then start the system.

▫ Apply power to the outdoor unit(s) at least 12 hours prior to operation of the system for preheating

of the compressor oil.

Do not touch any of the parts with hands at the discharge gas side since the compressor chamber and

•

the pipes at the discharge side are heated to temperatures higher than 194

o

F (90oC).

22

P5417058-rev.1

Page 27

7.2.2 Details of Electrical Wiring Connection

NOTICE

Outdoor Unit

Power Supply

Indoor Unit

Power Supply

GFCI and main switch for outdoor unit.

Outdoor Unit

Power Supply

Indoor Unit

Power Supply

GFCI and main switch for outdoor unit.

Details for electrical wiring capacity of the outdoor unit should be referenced according to the installation

and maintenance manual for the outdoor unit. Adjusting the DIP switches may be required depending on

the arrangement with the outdoor unit.

Select wiring capacity according to Table 7.1. Install a Ground Fault Circuit Interrupter (GFCI) and main

switch as shown in each of the system diagrams below.

Heat Pump System Heat Recovery System

Outdoor

Unit

Main

GFCI

Switch

Indoor

Unit

GFCI

Main

Switchbox

Switch

Refer to the “Installation and Maintenance Manual”

for the connected outdoor unit for details of wire,

Indoor

Unit

Indoor

Unit

GFCI

GFCI

Main

Switch

Main

Switch

Refer to the “Installation and Maintenance Manual”

for the connected outdoor unit for details of wire,

Change-Over

Switchbox

Outdoor

Unit

Box

Indoor

Unit

Indoor

Unit

Indoor

Unit

Table 7.1 Recommended Wiring Capacity and Sizes

Follow local electrical codes when selecting a GFCI device.

Model

Power

Supply

Minimum Wire Thickness

[AWG (mm

Power

Supply

Wiring Size

(Main)

Ground

Wiring

Size

2

)]

Communication

Cable Size

(H,Y,C)ICS015B21S

(H,Y,C)ICS024B21S 0.9

(H,Y,C)ICS030B21S 1.2

1~,

208/230V

60Hz

18

(0.82)

18

(0.82)

18

(0.82)

(H,Y,C)ICS036B21S 2.0

GFCI Main Switch

Nominal

Current

Nominal

Sensitive

Current

Nominal

Current

Fuse

[A] [mA] [A] [A] [A]

15 30 15 15

MCA

(Minimum

Circuit

Ampacity)

0.6

NOTE:

1. Follow local codes and regulations when selecting eld wires.

2. Select the GFCI with an activation speed of 0.1 sec. or less.

3. Total operating current is less than 12A.

● Conrm the recommended size GFCI as shown in Table 7.1.

● Communication cabling should be a minimum of AWG18 (0.82mm

2

), 2-Conductor, Stranded Copper.

Shielded cable must be considered for applications and routing in areas of high EMI and other sources

of potentially excessive electrical noise to reduce the potential for communication errors. When shielded

cabling is applied, proper bonding and termination of the cable shield is required as per Johnson

Controls guidelines. Plenum and riser ratings for communication cables must be considered per

application and local code requirements. Total cable length must not exceed 3281 ft (1000m).

● Select the wiring size, Ground Fault Circuit Interrupter (GFCI) in accordance with the regulations for

each region, the "Installation and Maintenance Manual", and the dedicated electrical circuit that must be

used.

● Outside of the indoor unit, installation of the power supply wiring, communication cable, and wired

controller cable should be spaced as far apart as possible.

P5417058-rev.1

23

Page 28

7.3 Position of Electrical Wiring Connection

(C)

12

NOTICE

Stranded Wire Single Wire

Connect it with

Connect it Direct

.

● The electrical wiring connection for the indoor unit is shown in Section 7.2.2. For details relating to the

intermediate connections between the indoor unit and the decorative panel, refer to installation of the

decorative panel.

● The connection at the terminal block for the indoor unit is shown in the gure below. Check the

arrangement for the outdoor unit before performing any wiring. Tighten screws in the terminal block as

indicated in the torque specication table shown below.

Tightening Torque for Terminals

Screw Size Tightening Torque

TB1 M4

TB2 M3.5

0.7 - 1.0

(1.0 - 1.3

0.9

(1.2

ft·lbs

N·m)

ft·lbs

N·m)

Terminal Block for

Power Supply Wiring

TB1 (black)

S/L2R/L1

Mp/N

Terminal Block for

Communication Cable

TB2 (white)

AB

● Do not connect the main power supply wiring to the communication

line (Terminals A, B, 1, and 2 of TB2). If connected, the printed circuit

board (PCB) is destroyed.

● Be aware of the following when wires are connected at the terminal block:

Screw

▫ Attach a piece of insulation tape or a sleeve at each terminal.

▫ Maintain the recommended distance between the electrical box

and the terminals to prevent a short circuit.

(B)

(A)

▫ Maintain the recommended distance between terminals.

1. Connect the cable for the optional controller or the optional extension cable to the terminals inside the

electrical box through the connecting hole of the cabinet.

2. Connect the power supply and the ground wiring to the terminals in the electrical box.

3. Connect the cables between the indoor unit and the outdoor unit to the terminals inside the electrical box.

4. Connect cables to their corresponding terminal number and the similarly marked band.

5. Connect the communication cable between those indoor units connected to the same outdoor unit.

6. Do not connect the main power supply wiring to the communication line (Terminals A, B, 1 and 2 of

TB2). If connected, the printed circuit board (PCB) is destroyed.

7. Tightly clamp the power supply wiring and communication cables using the cable band inside the

electrical box.

NOTE:

When stranded wire is used for the eld-wiring

connection, use the M4 crimping terminal. When the

single wire is used, fashion it into the shape as shown

at the right and connect it in order to tighten the washer

uniformly. Tighten the screws at the terminal block

according to the torque specication as shown in the

table above.

24

Crimping Terminal.

As Shown Below

P5417058-rev.1

Page 29

8. All electrical work should be performed in strict accordance with electrical schematics in the

NOTE:

Thermo-ON:

Thermo-OFF:

Controller

Controller

A

Incorrect Wiring Reconnect wirings correctly.

PCB

"Installation and Maintenance Manual".

9. If Power Supply Voltage (208V/230V) is introduced into the Communication Line:

If 208V/230V are applied to the communication line at (Terminals 1 and 2 of TB2) by mistake, the fuse

on the PCB for the communication line will blow. In this case, perform the recovery work as shown in

the diagrams below.

a. Reconnect the wirings correctly.

b. Set the No.1 pin at DSW7 (on the PCB) to ON.

After the fuse is replaced and the PCB recovers, do not reintroduce 208V/230V into the communication

line. This voltage causes serious damage to the PCB, and it will not recover.

S

L1RL2

C 208V/230V

5V

AB12

AC 208V/230V

5V

10. Wired Controller Connections

a. Wired Controllers at each unit for an individual operation setting

Indoor Unit Indoor Unit

Outdoor Unit

Wired

A B

Wired

A B

b. Single Wired Controller for an individual operation setting

Indoor Unit

A B

Outdoor Unit

Indoor Unit

A B

S

L1RL2

AB12

DSW7

ON

OFF

12

Set No.1 Pin

at ON side.

Wired

Controller

Communication cables

for the wired controller

are necessary.

c. Wired Controller connections between different refrigerant systems

Outdoor Unit

A B

Wired

Controller

Individual

The outdoor unit and some indoor units are running.

The outdoor unit and some indoor units stay on, but don’t run.

Wired

Controller

Simultaneous

(Thermo ON / OFF individually)

P5417058-rev.1

A BA B

Indoor UnitIndoor UnitIndoor Unit Indoor Unit

A B

Outdoor Unit

Wired

Controller

Individual

25

Page 30

1. The DIP switch settings for the outdoor unit should be performed in accordance with the "Installation and

NOTICE

Indoor Unit

Switchbox

Indoor UnitIndoor Unit

Maintenance Manual" for the outdoor unit.

2. Be aware that communication cable for the wired controller is required in these instances:

a. The following functions are set to the sub unit, which is not installed with the wired controller.

● Remote ON/OFF function settings, (No.1, 2, and 3), (External Input / Output Function)

● Power supply ON/OFF functions, (No.1 and 2), (Function Selection)

● Prohibiting the wired controller after manual stoppage (External Input / Output Function)

● Group setting by the centralized controller

b. The combination of twin, triple, or quad is controlled by a single wired controller.

c The address for the indoor unit is changed from the wired controller.

d. The multiple panels with the motion sensor are controlled by a single wired controller.

7.4 Caution for Electrical Wiring

Do not connect the power supply wiring and the communication cable into one terminal.

The manual switchbox is required when communication cable is required.

RL1SL2Mp

N

G

F

S

C

I

RL1SL2Mp

N

RL1SL2Mp

N

Indoor Unit Indoor Unit Indoor Unit

RL1SL2Mp

N

G

F

S

C

I

RL1SL2Mp

N

RL1SL2Mp

N

26

P5417058-rev.1

Page 31

7.5 Wiring Connections

Communication Cable

(Accessory)

TB2

Upper Side

ɸ7/8 inch (22.2mm) Conduit Opening

Electrical Box

and Communication Cable

Terminal Block (White)

Wire for Fan Motor

Wiring connections for the indoor unit are shown below.

1. The wiring connection for the indoor unit is shown in the gure below.

Cap

Communication Cable and

Wired Controller Cable

ɸ1/2 inch (13mm) Opening

Rear Side

Cap

Power Supply Wiring

2. The wiring connection for the electrical box is as follows.

a. Open the air inlet grille.

b. Remove the electrical box cover.

c. Connect the communication cable, power supply wiring and wired controller cable.

PCB1

Terminal Block (Black)

Ground Screw (M5)

Power Supply Wiring

Wired Controller Cable

d. After the wiring is completed, attach the electrical box cover again with care in order not to pinch

wires.

NOTE

Insert the communication cable and wired

•

AB

12

TB1

S/L2

R/L1

Power Supply Wiring

Mp/N

controller cable into the PVC tube “VW-1 600V”

(accessory) to separate from the power supply

wiring for the indoor unit.

Afx both ends of the PVC tube with cable band

•

(accessory).

If shielded cable is used, terminate at the ground

•

terminal.

Install and secure all electrical wiring correctly through the opening, to the terminal blocks using

Secure the PVC Tube by

Cable Band (Accessory)