Page 1

HE-6800 Series Humidity Transmitters with

24-10409-28, Rev. E

Temperature Sensor

Installation Instructions

HE-68xx-xN00WS

Refer to the QuickLIT website for the most up-to-date version of this document.

Applications

The HE-6800 Series Humidity Transmitters with

Temperature Sensor provide both humidity and

temperature sensing in room wall-mount applications.

The transmitter offers local warmer/cooler temperature

setpoint adjustment and temporary oc cu pancy

override. The humidity sensor provides Relative

Humidity (RH) accuracy of ±2% or ±3% RH and

measures RH over the entire range of 0 to 100%.

A warmer/cooler dial is included on certain models for

minor temperature adjustments from the setpoint. All

models feature an occupancy override button that

allows the user to override time-of-day scheduling

when the space is occupied outside of the normal

occupied hours schedule. The transmitter also includes

DIP switches to enable or disable override and

Light-Emitting Diode (LED) functions. In addition, all

models feature a user-selectable 0 to 5 VDC or

0 to 10 VDC humidity output switch, and a power

supply selection switch.

The HE-6800 Series Humidity Transmitters include

screw terminal block terminations that provide flexibility

for field wiring. All models include a 6-pin modular jack

access port for connecting accessories to the

Zone Bus. This feature allows a technician to

commission or service the controller via the transmitter.

Part No. 24-10409-28, Rev. E

Issued February 2016

North American Emissions Compliance

United States

This equipment has been tested and found to

comply with the limits for a Class A digital device

pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection

against harmful interference when this equipment is

operated in a commercial environment. This

equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in

accordance with the instruction manual, may cause

harmful interference to radio communications.

Operation of this equipment in a residential area

may cause harmful interference, in which case users

will be required to correct the interference at their

own expense.

Canada

This Class (A) digital apparatus meets all the

requirements of the Canadian Interference-Cau sing

Equipment Regulations.

Cet appareil numérique de la Classe (A) respecte

toutes les exigences du Règlement sur le matériel

brouilleur du Canada.

IMPORTANT: Use the HE-6800 Series Humidity

Transmitter only to provide in put to equipment under

normal operating conditions. Where failure or

malfunction of the transmitter could lead to personal

injury or property damage to the controlled

equipment or other property, additional precautions

must be designed into the control system.

Incorporate and maintain other devices, such as

supervisory or alarm systems or safety or limit

controls, intended to warn of or protect against

failure or malfunction of the transmitter.

HE-6800 Series Humidity Transmitters with TemperatureSensor

Installation Instructions

1

Page 2

Installation

Special Tools Needed

A 1/16 in. (1.5 mm) Allen wrench or a

Johnson Controls® T-4000-1 19 Allen-Head Adjustment

Tool is required during installation.

Accessories

Installing the HE-6800 Series Humidity Transmitter on

a wallbox requires accessory NS-WALLPLATE-0,

ordered separately.

Mounting

Location Considerations

Locate the HE-6800 Series Humidity Transmitter:

• on a partitioning interior wall, and approximately

5 ft (1.5 m) above the floor in a location of average

temperature

• away from direct sunlight, radiant heat, outside

walls, behind doors, air discharge grills, stairwells,

or outside doors

• away from steam or water pipes, warm air stacks,

unconditioned areas (no heating and no cooling),

or sources of electrical interference

Note: The HE-6800 Series Humidity Transmitter is

shock and vibration resistant; however, be careful not

to drop the unit or mount it where it could be exposed

to excessive vibration.

The following ambient operating conditions apply:

• Temperature: 32 to 131°F (0 to 55°C)

• Humidity: 10 to 95% RH, noncondensing;

86°F (30°C) maximum dew point

To mount the transmitter to the wall:

2. Insert a blade screwdriver into the slot next to the

security screw location, and then carefully pry the

top edge of the transmitter assembly away from its

mounting base and remove.

IMPORTANT: Do not remove the Printed Circuit

Board (PCB). Removing the PCB voids the product

warranty.

3. Pull out approximately 6 in. (152 mm) of cable from

the wall, and insert the cable through the hole in

the mounting base.

4. Align the mounting base on the wall, and use the

base as a template to mark the location of the two

mounting holes on the surface.

Note: Make sure the mounting base is positioned

correctly with the security screw located on the top

edge of the base.

5. Secure the mounting base to the wall using the

appropriate mounting hardware (field furnished).

6. Set DIP switches for the desired operation. See the

Internal Wiring Diagrams

Adjustments sections for additional information.

7. Align the tabs on the bottom edge of the mounting

base with the slots on the bottom edge of the

transmitter assembly , and rot ate the assembly onto

its mounting base.

Note: Make sure the terminal block pins align with the

holes in the terminal block.

8. Use a 1/16 in. (1.5 mm) Allen wrench or

Johnson Controls T-4000-119 Allen-Head

Adjustment Tool to tighten the security screw and

fasten the network transmitter assembly to the

mounting base.

and Setup and

1. Use a 1/16 in. (1.5 mm) Allen wrench or

Johnson Controls T-4000-119 Allen-Head

Adjustment Tool to loosen the security screw on

the top of the unit.

HE-6800 Series Humidity Transmitters with Temperature Sensor Installation Instructions

2

Page 3

Wiring

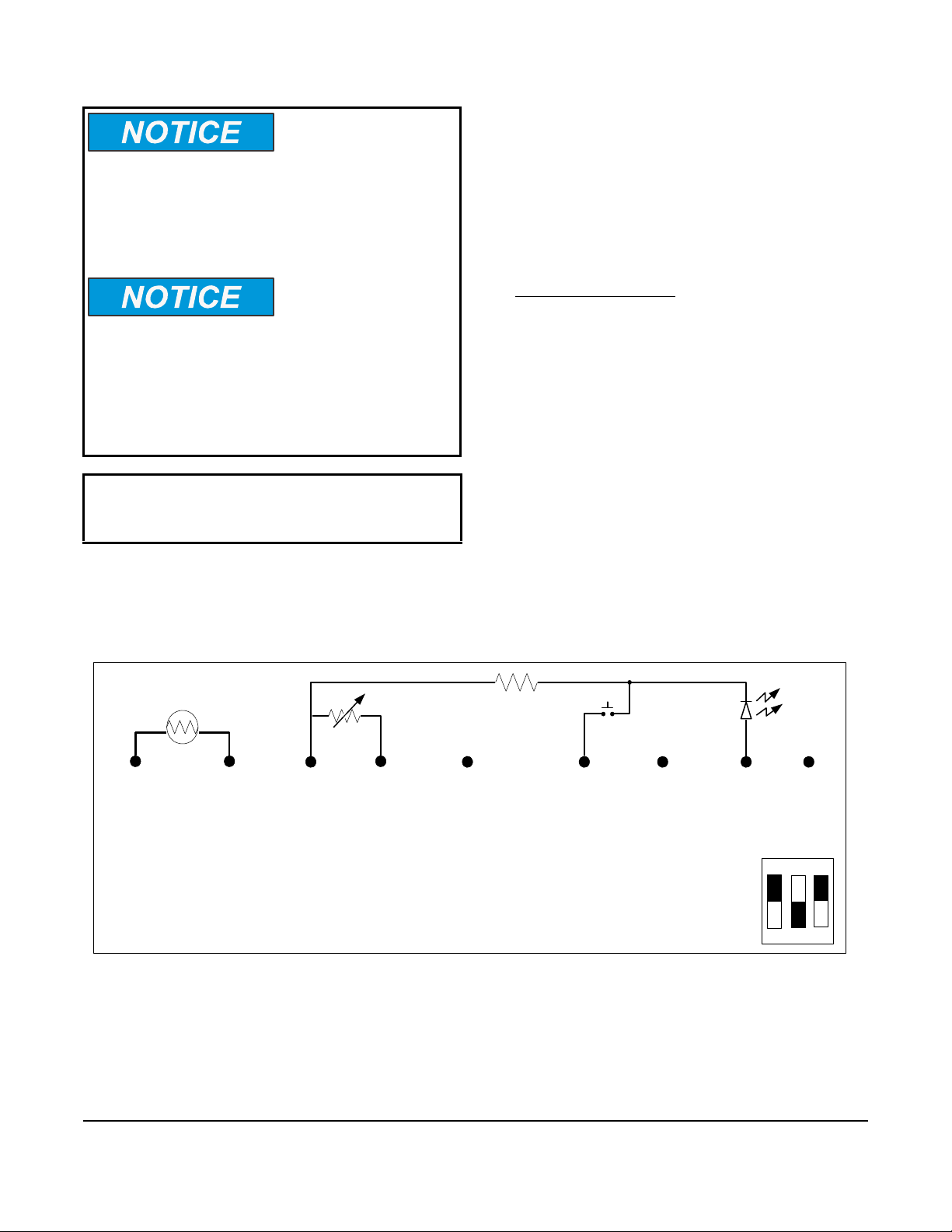

Figure 1: Terminal Block Wiring Designations

(LED ON Mode [Factory Default] and Manual Override PB Enabled)

RT

D

1

Temperature

Sensor

2

Temperature

Sensor

Common

3

Setpoint

Common

4

Setpoint

Setpoint

5

24 VAC/ +15 VDC

1k Ohms

6

Common

7

Zone Bus

Manual

Override

Button

8

LED

LED

Internal wiring diagram with DIP switches set as

shown on the right, LED Mode = ON and Manual

Override push button enabled.

FIG:term_blck_LED

NO

12

3

9

RH Output

0–10 VDC

Risk of Property Damage.

Do not apply power to the system before checking all

wiring connections. Short circuited or improperly

connected wires may result in permanent damage to

the equipment.

Risque de dégâts matériels.

Ne pas mettre le système sous tension avant d'avoir

vérifié tous les raccords de câblage. Des fils formant

un court-circuit ou connectés de façon incorrecte

risquent d'endommager irrémédiablement

l'équipement.

IMPORTANT: Use copper conductors only. Make

all wiring connections in accordance with local,

national, and regional regulations.

Keep wires as short as possible to minimize sensor

error. Each 2 50 ft (76 m) run of 18 AWG wire or

50 ft (15 m) of 24 AWG wire creates 1F° (0.56C°) error

for a nickel sensor or 1.5F° (0.83C°) error for a

platinum sensor due to wire resistance.

To maintain less than 1F° (0.56C°) error for nickel or

1.5F° (0.83C°) error for platinum, hold the total

resistance of all sensor wiring below 3 ohm. When

wiring the HE-6800, do not run low voltage wiring in the

same conduit as line voltage wiring or other conductors

supplying highly inductive loads.

Internal Wiring Diagrams

Internal wiring diagrams are shown in Figure 1 and

Figure 2. Terminal block designations are shown in

Figure 3. The terminals are identified in Table 1. See

the Setup and Adjustments

section and Figure 4 for an

explanation of the LED and Pushbutton (PB) modes.

Make connections pairing the following wires:

• sensor (Terminal 1 and Terminal 2)

• setpoint (Terminal 3 and Terminal 4)

• Zone Bus and Common (COM)

(Terminals 6 and 7)

Shielding is not required. If used, follow the system

controller’s recommenda tio ns for gr ou nd in g th e shie ld .

Note: The Manual Override PB does not respond

when the DIP switch positions are all down (LED mode

NO PB, as shown in Figure 2 and Figure 4).

Manual Override is selected for either Terminals 1 and

6 to short sensor (with DIP switch set for LED Off) or

Terminal 6 and Terminal 8 to short LED (with DIP

switch set for LED On).

HE-6800 Series Humidity Transmitters with Temperature Sensor Installation Instructions

3

Page 4

.

Figure 2: Terminal Block Wiring Designations (LED OFF Mode and Manual Override PB Enabled)

RT

D

1

Temperature

Sensor

2

Temperature

Sensor

Common

3

Setpoint

Common

4

Setpoint

Setpoint

5

24 VAC/ +15 VDC

6

Common

7

Zone Bus

Manual

Override

Button

8

LED

LED

Internal wiring diagram with DIP switches set

as shown on the right, LED Mode = OFF and

Manual Override push button enabled.

FIG:term_blk_LED_OFF

Not Connected

NO

12

3

9

RH Output

0–10 VDC

Figure 3: Terminal Block Location and Wiring

FIG:term_b lk

Table 1: Terminal Block Wiring

Terminal Signal Designation

1 Temperature Sensor and Manual Override

2 Temperature Sensor Common

1. The +15 VDC power supply is used only when an

HE-6800 Series Humidity Transmitter is connected to

a VMA Controller.

Setup and Adjustments

3 Setpoint Common and LED Common

4 Setpoint

5

24 VAC (+15 VDC – VMA Only

1

)

6 Common (for Power, RH Output, Zone

Bus, or Manual Override)

7 Zone Bus

8 LED and Manual Override

9 RH Output (0 to 10 VDC)

HE-6800 Series Humidity Transmitters with Temperature Sensor Installation Instructions

Controller Configuration DIP Switch and LED Mode

A DIP switch configures the HE-6800 for use with the

desired controller by enabling or disabling the manual

override PB and the LED. To change the controller

mode, use the three position DIP switch located on the

PCB. See Figure 4 and consult Table 2 to determine

the controller compatibility.

4

Page 5

For all transmitter models, the factory default

Figure 4: Controller Configuration

DIP Switch Positions

DIP switch in the

default position.

KEY:

Switch is in up position (ON)

Switch is in down position (OFF)

Note: Read switch positions

from left to right.

LED MODE

OFF

ON

NO

PB

NO

12

3

REMOVING THE CIRCUIT

BOARD VOIDS WARRANTY

FIG:dip_switch

LED mode is LED Mode:ON. The DIP switch positions

enable/disable the functions listed in Table 3

Risk of Property Damage.

Do not use switch settings other than those shown in

Figure 4. Using other switch settings may cause

incorrect controller operation or damage to the

element, controller, [and/or] controlled equipment.

Risque de dégâts matériels.

Ne pas utiliser un paramétrage des commutateurs

différent de celui-ci illustré à la Figure 4. L'utilisation

d'autres paramètres de commutateurs risque de

provoquer un fonctionnement incorrect du contrôleur

ou d'endommager l'élément, le contrôleur [et/ou]

l'équipement contrôlé.

Table 2: Controller Compatibility with LED Mode and PB

Types of

HE-6800

All Models

LED Mode

(Figure 4)

Features

Enabled on

HE-6800

LED Off

2

LED On Sensor,

No PB Room Sensor

Sensor and

Manual

Override

Manual

Override, and

LED

Only

AHU UNT1100 VAV1xx or

No Yes Yes Yes Yes

No No No Yes Yes

Yes Yes Yes Yes Yes

Features Recognized by Controller

VMA12

UNT1xx

Series

1

VMA14

Series

1

1. For these controllers, the LED appears brig hter when pressing the manual override PB.

2. Holding the manual override PB for more than 2 seconds may affect the sensor reading.

Table 3: LED Mode and Functions

Humidity Output and Power Supply Selection Switch

A 0 to 10 VDC or 0 to 5 VDC selector DIP switch

enables you to change the output for % RH. The

LED Mode Functions Switch Positions

Enabled Disabled

OFF Sensor, PB LED Switch positions are down, up, and down. The LED remains off at all times.

ON LED, Sensor,

PB

--- Switch positions are factory set up, down, and up. The controller

determines the LED mode.

NO PB Sensor LED and PB Switch positions are all down. LED is off, and the PB does not function.

default factory setting is OFF (0 to 10 VDC output).

HE-6800 Series Humidity Transmitters with Temperature Sensor Installation Instructions

5

Page 6

The HE-6800 also features a power supply selection

Figure 5: Humidity Output and Power Supply

DIP Switch Positions

DIP switch in the

default position.

KEY:

Switch is in up position (ON)

Switch is in down position (OFF)

NO

12

FIG:pwr_bst_ds

Switch 2

OFF = Low supply voltage operation

ON = High supply voltage operation

Switch 1

OFF = 0–10 VDC output, corresponding to 0–100%RH

ON = 0–5 VDC output, corre spo nding to 0–100%RH

DIP switch. If you are using the transmitter where

supply voltage is 24 VAC or higher, set this switch to

ON.

3. Check all supply voltage connections. See

Figure 1, Figure 2, or Figure 3, if necessary.

4. Check the settings:

• Verify that any scaling modifications, setpoint

adjustments, and overrides have been saved

and downloaded to the controller.

• Check the override status (Temporary

Occupancy mode vs. Unoccupied mode) at the

controller.

• Check the setpoint settings.

5. Confirm DIP switch positions if:

• the LED remains on or is dim

• the room sensor reading is outside of the

normal range for the space being sensed

Note: Make sure the DIP switch setting is correct for

the controller used with the HE-6800.

Temperature Setpoint

Adjust the setpoint using the setpoint adjustment dial.

Rotate clockwise to raise the temperature; rotate

counterclockwise to lower the temperature.

Troubleshooting

HE-6800 Series Humidity Transmitters are

recommended for use only with Johnson Controls

6. Replace the HE-6800 if the troubleshooting

suggestions fail to remedy the problem.

Accessories

Contact the nearest Johnson Controls representative

to order any of the parts listed in Table 4.

Note: Review the technical specifications of the

accessories prior to their use in an application.

digital controllers. If the HE-6800 is not functioning

properly, use the following procedure to identify the

problem and determine a solution:

1. Check that the HE-6800 is mounted in a location

indicative of the space temperature (for example,

away from drafts or sunlight).

2. Verify that the wiring is correct.

Repair Information

Do not field repair the HE-6800 Series Humidity

Transmitters. As with any electrica l device, keep the air

vents clean and free from dust or obstruction. If an

HE-6800 Series Humidity Transmitter fails to operate

within its specifications, replace the unit. For a

replacement transmitter, contact the nearest

Johnson Controls representative.

Table 4: Optional Accessories

Product Code Number Description

ACC-INSL-0

ACC-INSL-1

NS-WALLPLATE-0 Adapts an HE-6800 Series Humidity Transmitter (3-3/16 x 3-3/16 in. [80 x 80 mm]) to a

T-4000-119 Allen-Head Adjustment Tool (30 per Bag)

1

1

Wallbox Mounting Pad (10 per Bag)

Surface Mounting Pad (10 per Bag)

Standard 3-3/16 x 4-3/4 in. (80 x 120 mm) Wallbox

1. These foam pads help prevent drafts from entering the unit through the wall, and make installation easier when mounting on

an uneven surface.

HE-6800 Series Humidity Transmitters with Temperature Sensor Installation Instructions

6

Page 7

Technical Specifications

HE-6800 Series Humidity Transmitters with Temperature Sensor (Part 1 of 2)

Power Requirements 4.5 to 7.5 mA at 14 to 30 VDC and 5K ohm Load, or 18 to 25 mA at 20 to 30 VAC

and 5K ohm Load

Terminations 9-Position Screw Clamp Terminal Block

Wire Size 16 to 24 AWG (1.3 to 0.6 mm Diameter); 18 AWG (1.0 mm Diameter)

Temperature Measurement Range 32 to 131°F (0 to 55°C)

Humidity

Measurement

Range

Temperature

Sensor

Humidity Sensor Type Capacitive Polymer Sensor

Humidity

Element

Accuracy

Setpoint Range Warmer/Cooler

Temperature Sensor Time Constant 10 Minutes at 10 ft per Minute

Manual Override Integral Momentary Pushbutton (DIP Switch Selectable)

LED Green LED Indicates Three Modes of Operation (VMA12 and VMA14 Series

Ambient Operating Conditions 32 to 131°F (0 to 55°C), 10 to 95% RH Noncondensing;

Ambient Storage Conditions -40 to 140°F (-40 to 60°C), 5 to 95% RH Noncondensing;

Materials White Thermopla stic

Dimensions

(H x W x D)

Shipping Weight 0.44 lb (0.20 kg)

Full Range 0 to 100% RH

Calibrated Range 10 to 90% RH

Nickel

(HE-68Nx Models)

Platinum

(HE-68Px Models)

Nonlinear NTC,

Thermistor,

Type II

(HE-686x Models)

HE-68x2 Models ±2% RH for 20 to 80% RH at 50 to 95°F (10 to 35°C);

HE-68x3 Models ±3% RH for 20 to 80% RH at 77°F (25°C);

HE-68xx-0 Models 3-3/16 x 3-3/16 x 1-5/16 in. (80 x 80 x 32 mm)

HE-68xx-1 Models 3-3/16 x 3-3/16 x 1-7/16 in. (80 x 80 x 35 mm)

Recommended

Sensor Type 1,000 ohm Thin Film Nickel

Coefficient Approximately 3 ohm per F° (5.4 ohm per C°)

Reference

Resistance

Accuracy ±0.3 4F° at 70°F (±0.18C° at 21°C)

Sensor Type 1,000 ohm Thin Film Platinum

Coefficient Approximately 2 ohm per F° (3.9 ohm per C°)

Reference

Resistance

Accuracy ±0.3 5F° at 70°F (±0.19C° at 21°C)

Sensor Type 10,000 ohm NTC Thermistor

Coefficient Nonlinear NTC, Johnson Controls Type II

Reference

Resistance

Accuracy ±0.9 F° (±0.5C°) at 32 to 15 8°F (0 to 70°C)

±4% RH for 10 to 20% RH and 80 to 90% RH at 50 to 95°F (10 to 35°C)

±6% RH for 10 to 20% RH and 80 to 90% at 77°F (25°C)

Controllers Only)

86°F (30°C) Maximum Dew Point

86°F (30°C) Maximum Dew Point

Protection: IP30 (EN 60529)

1,000 ohm at 70°F (0°C)

1,000 ohm at 32°F (0°C)

10,000 ohm at 77°F (25°C)

HE-6800 Series Humidity Transmitters with Temperature Sensor Installation Instructions

7

Page 8

Metasys® and Johnson Controls® are registered trademarks of Johnson Controls, Inc.

All other marks herein are the marks of their respective owners. © 2016 Johnson Controls, Inc.

Building Efficiency

507 E. Michigan Street, Milwaukee, WI 53202

HE-6800 Series Humidity Transmitters with Temperature Sensor (Part 2 of 2)

Compliance United States UL Listed, File E107041,

CCN PAZX, Under UL 916, Energy Management Equipment

Canada UL Listed, File E107041,

Europe CE Mark – Johnson Controls, Inc., declares that this product is in compliance

Australia and New

Zealand

The performance specifications are nominal and conform to acceptable industry standards. For application at conditions beyond these

specifications, consult the local Johnson Controls office. Johnson Controls, Inc. shall not be liable for damage resulting from misapplication or

misuse of its products.

European Single Point of Contact: NA/SA Single Point of Contact: APAC Single Point of Contact:

JOHNSON CONTROLS

WESTENDHOF 3

45143 ESSEN

GERMANY

CCN PAZX7, Under CAN/CSA C22.2 No. 205, Signal Equipment

with the essential requirements and other relevant provisions of the

EMC Directive, WEEE Directive, and RoHS Directive.

RCM, Australia/NZ Emissions Compliant

JOHNSON CONTROLS

507 E MICHIGAN ST

MILWAUKEE WI 53202

USA

JOHNSON CONTROLS

C/O CONTROLS PRODUCT

MANAGEMENT

NO. 22 BLOCK D NEW DISTRICT

WUXI JIANGSU PROVINCE 214142

CHINA

HE-6800 Series Humidity Transmitters with Temperature Sensor Installation Instructions

Published in U.S.A. www.johnsoncontrols.com

8

Loading...

Loading...