Page 1

FX-PCX3731 Input/Output Module Installation Instructions

Part No. 24-10144-181, Rev. CFX-PCX3731-0

Issued December 5, 2014

Refer to the QuickLIT website for the most up-to-date version of this document.

Application

The FX-PCX3731 controller is a part of the Facility

Explorer FX-PC Series Programmable Controller family.

FX-PCX controllers expand the number of points

connected to an FX-PCA, FX-PCG, or FX-PCV

programmable controller or to an FX Supervisory

Controller.

FX-PCX controllers operate on an RS-485 BACnet®

Master-Slave/Token-Passing (MS/TP) Bus as BACnet

Application Specific Controllers (B-ASCs) and integrate

into the web-based Facility Explorer system.

Note: At FX-PCT Release 10.1, a new capability was

introduced allowing FX-PCVs, FX-PCGs, and

FX-PCAs to communicate by using either the

BACnet or the N2 field bus networking protocol.

The operation of the FX-PCX Input/Output Module

is not affected by the selection of the BACnet or

the N2 protocol in the host controller.

North American Emissions Compliance

Installation

Observe these guidelines when installing a controller:

• Transport the controller in the original container to

minimize vibration and shock damage.

• Verify that all parts shipped with the controller.

• Do not drop the controller or subject it to physical

shock.

Parts Included

• one controller with removable terminal blocks (Power,

SA, and FC bus are removable)

• one installation instructions sheet

Materials and Special Tools Needed

• three fasteners appropriate for the mounting surface

(M4 screws or #8 screws)

• one 20 cm (8 in.) or longer piece of 35 mm DIN rail

and appropriate hardware for DIN rail mount (only)

• small straight-blade screwdriver for securing wires in

the terminal blocks

Canada

This Class (A) digital apparatus meets all the

requirements of the Canadian Interference-Causing

Equipment Regulations.

Cet appareil numérique de la Classe (A) respecte toutes

les exigences du Règlement sur le matériel brouilleur

du Canada.

United States

This equipment has been tested and found to comply with the

limits for a Class A digital device pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when this equipment

is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and,

if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential

area may cause harmful interference, in which case the users

will be required to correct the interference at their own expense.

Mounting

Observe these guidelines when mounting an FX-PCX

controller:

• Ensure the mounting surface can support the

controller, DIN rail, and any user-supplied enclosure.

• Mount the controller horizontally on 35 mm DIN rail

whenever possible.

• Mount the controller in the proper mounting position

(Figure 1).

• Mount the controller on a hard, even surface

whenever possible in wall-mount applications.

• Use shims or washers to mount the controller securely

and evenly on the mounting surface.

• Mount the controller in an area free of corrosive

vapors and observe the Ambient Conditions

requirements in Table 9.

• Provide for sufficient space around the controller for

cable and wire connections for easy cover removal

and good ventilation through the controller (50 mm

[2 in.] minimum on the top, bottom, and front of the

controller).

1FX-PCX3731 Input/Output Module Installation Instructions

Page 2

• Do not mount the controller on surfaces prone to

vibration, such as duct work.

• Do not mount the controller in areas where

electromagnetic emissions from other devices or

wiring can interfere with controller communication.

To remove the controller from the DIN rail, pull the

bottom mounting clip out to the extended position and

carefully lift the controller off the DIN rail.

Observe these additional guidelines when mounting a

controller in a panel or enclosure:

• Mount the controller so that the enclosure walls do

not obstruct cover removal or ventilation through the

controller.

• Mount the controller so that the power transformer

and other devices do not radiate excessive heat to

the controller.

• Do not install the controller in an airtight enclosure.

Figure 1: Controller Mounting Positions

Wall Mount Applications

To mount an FX-PCX controller directly on a wall or other

flat vertical surface:

1. Pull the two bottom mounting clips outward and

ensure they are locked in the extended position as

shown in Figure 2.

2. Mark the three mounting hole locations on the wall

using the dimensions in Figure 2 and one of the mount

positions shown in Figure 1. Or, hold the controller

up to the wall or surface in a proper mount position

and mark the hole locations through the mounting

clips.

3. Drill holes in the wall or surface and insert appropriate

wall anchors in all of the mounting holes (if

necessary).

4. Hold the controller in place, and insert the screws

through the mounting clips and into the holes (or

anchors). Carefully tighten all of the screws.

Important: Do not overtighten the mounting screws.

Overtightening the screws may damage

the mounting clips.

Figure 2: Back of Controller Showing Extended

Mounting Clips, DIN Rail Channel, and Mounting

Dimensions, mm (in.)

DIN Rail Mount Applications

Mounting the controller horizontal on 35 mm DIN rail is

the preferred mounting method.

To mount an FX-PCX controller on 35 mm DIN rail:

1. Securely mount a 20 cm (8 in.) or longer section of

35 mm DIN rail horizontal and centered in the desired

space so that the controller mounts in the horizontal

position shown in Figure 1.

2. Pull the bottom mounting clips outward from the

controller to the extended position as shown in Figure

2.

3. Hang the controller on the DIN rail by the hooks at

the top of the (DIN rail) channel on the back of the

controller (Figure 2), and position the controller snugly

against the DIN rail.

4. Push the bottom mounting clip inward (up) to secure

the controller on the DIN rail.

2FX-PCX3731 Input/Output Module Installation Instructions

Page 3

Figure 3: FX-PCX3731 Physical Features

Table 1: FX-PCX3731 Physical Features Callouts and Descriptions

Physical Feature: Description and ReferencesCallout

1

3

4

5

6

7

8

9

Binary Outputs (BOs) Terminal Block (See Table 3)

Mounting Clip (Three Total)2

Device Address DIP Switch Block (See Setting the Device Addresses)

24 VAC, Class 2 Supply Power Terminal Block (See Supply Power Terminal Block)

Cover Lift Tab (One of Two) (See Removing the Controller Cover)

Sensor Actuator (SA) Bus or Field Controller (FC) Bus Terminal Block (See SA/FC Bus Terminal Block)

Binary Inputs (BIs) Terminal Block (See Table 3)

LED Status Indicators (See Table 7)

Sensor Actuator (SA) Bus or Field Controller (FC) Bus Port (RJ-12 6-pin Modular Jack) (See SA/FC Bus Port)

3FX-PCX3731 Input/Output Module Installation Instructions

Page 4

Wiring

Risk of Electric Shock: Disconnect or isolate all power

supplies before making electrical connections. More than

one disconnect or isolation may be required to

completely de-energize equipment. Contact with

components carrying hazardous voltage can cause

electric shock and may result in severe personal injury

or death.

Avertissement: Risque de décharge électrique:

Débrancher ou isoler toute alimentation avant de réaliser

un branchement électrique. Plusieurs isolations et

débranchements sont peut-être nécessaires pour

-couper entièrement l'alimentation de l'équipement. Tout

contact avec des composants conducteurs de tensions

dangereuses risque d'entraîner une décharge électrique

et de provoquer des blessures graves, voire mortelles.

Risk of Property Damage: Do not apply power to the

system before checking all wiring connections. Short

circuited or improperly connected wires may result in

permanent damage to the equipment.

Terminal Blocks and Bus Ports

See Figure 3 for terminal block and bus port locations on

the FX-PCX controller. Observe the following guidelines

when wiring an FX-PCX controller.

Input and Output Terminal Blocks

All of the input terminal blocks are mounted on the bottom

of the controller and the output terminal blocks are

mounted on the top of the controller. See Table 3 for more

information about I/O terminal functions, requirements,

and ratings.

SA/FC Bus Terminal Block

An FX-PCX can be connected to a Sensor/Actuator (SA)

bus or a Field Controller (FC) bus, but not to both buses

simultaneously. The SA/FC bus terminal block is a

removable, 4-terminal plug that fits into a board-mounted

jack.

When connecting the FX-PCX to an FC bus, wire the bus

terminal block plugs on the controller, and the other

controllers in a daisy-chain configuration using 3-wire

twisted, shielded cable as shown in Figure 4. See Table

5 for more information.

Figure 4: FC Bus Terminal Block Wiring

Mise En Garde: Risque de dégâts matériels: Ne pas

mettre le système sous tension avant d'avoir vérifié tous

les raccords de câblage. Des fils formant un court-circuit

ou connectés de façon incorrecte risquent

d'endommager irrémédiablement l'équipement.

Important: Do not exceed the controller electrical

ratings. Exceeding controller electrical

ratings can result in permanent damage to

the controller and void any warranty.

Important: Use copper conductors only. Make all wiring

in accordance with local, national, and

regional regulations.

Important: Electrostatic discharge can damage

controller components. Use proper

electrostatic discharge precautions during

installation, setup, and servicing to avoid

damaging the controller.

For detailed information on configuring and wiring an

MS/TP Bus, FC bus, and SA bus, refer to the FX-PC

Series Controllers MS/TP Communications Bus Technical

Bulletin (LIT-12011670).

When connecting the FX-PCX to an SA bus, wire the bus

terminal block plugs on the controller and other SA bus

devices in a daisy-chain configuration using 4-wire

twisted, shielded cable as shown in Figure 5. See Table

3 for more information.

4FX-PCX3731 Input/Output Module Installation Instructions

Page 5

Figure 5: SA Bus Terminal Block Wiring

Note: The SA PWR/SHLD terminal does not supply 15

VDC. The SA PWR/SHLD terminal is isolated and

can be used to connect (daisy chain) the 15 VDC

power leads on the SA bus (Figure 5) or the cable

shields on the FC bus (Figure 4). The SA bus

supervisor supplies 15 VDC to devices on the SA

bus requiring power.

SA/FC Bus Port

The SA/FC bus port on the front of the controller is an

RJ-12, 6-position modular jack that provides a connection

for devices on the SA bus, a Bluetooth® Commissioning

Converter, ZigBee™wireless dongle, or an FX-ZFR1811

Wireless Router (depending on which bus the controller

is operating on).

Figure 6: Pin Number Assignments for Sensor, SA

Bus and FC Bus Ports on Controllers

Supply Power Terminal Block

The 24 VAC supply power terminal block is a gray,

removable, 3-terminal plug that fits into a board-mounted

jack on the top right of the controller.

Wire the 24 VAC supply power wires from the transformer

to the HOT and COM terminals on the terminal plug as

shown in Figure 7. The middle terminal on the supply

power terminal block is not used. See Table 5 for more

information about the supply terminal block.

Figure 7: 24 VAC Supply Power Terminal Block Wiring

The SA/FC bus port is connected internally to the SA/FC

bus terminal block. See Table 5 for more information.

The SA/FC bus port pin assignment is shown in Figure

6.

Note: The supply power wire colors may be different on

transformers from other manufacturers. Refer to

the transformer manufacturer’s instructions and

the project installation drawings for wiring details.

5FX-PCX3731 Input/Output Module Installation Instructions

Page 6

To configure a controller for use with the FX-ZFR Series

Important: Connect 24 VAC supply power to the

controller and all other network devices so

that transformer phasing is uniform across

the network devices. Powering network

devices with uniform 24 VAC supply power

phasing reduces noise, interference, and

ground loop problems. The controller does

not require an earth ground connection.

Wireless Network Applications

The controller can also be installed in a wireless

application using an FX-ZFR1811 Wireless Field Bus

Router.

Wireless Field Bus system:

Note: FX-PCXs can talk wirelessly on the FC bus only.

1. Connect the FX-ZFR1811 Wireless Field Bus Router

to the FC bus port (RJ-12 modular jack) on the front

of the controller.

2. Ensure that the controller's device address DIP

switches are set to the correct device address. See

Setting the Device Addresses.

3. Set DIP switch 128 to ON, which enables wireless

operation on the controller.

For more information on installing a controller in a

wireless configuration, refer to the FX-ZFR Wireless

Field Bus Router Installation Instructions (Part No.

24-10325-29).

Termination Details

A set of Johnson Controls® termination diagrams provides details for wiring inputs and outputs to the controllers.

See the figures in this section for the applicable termination diagrams.

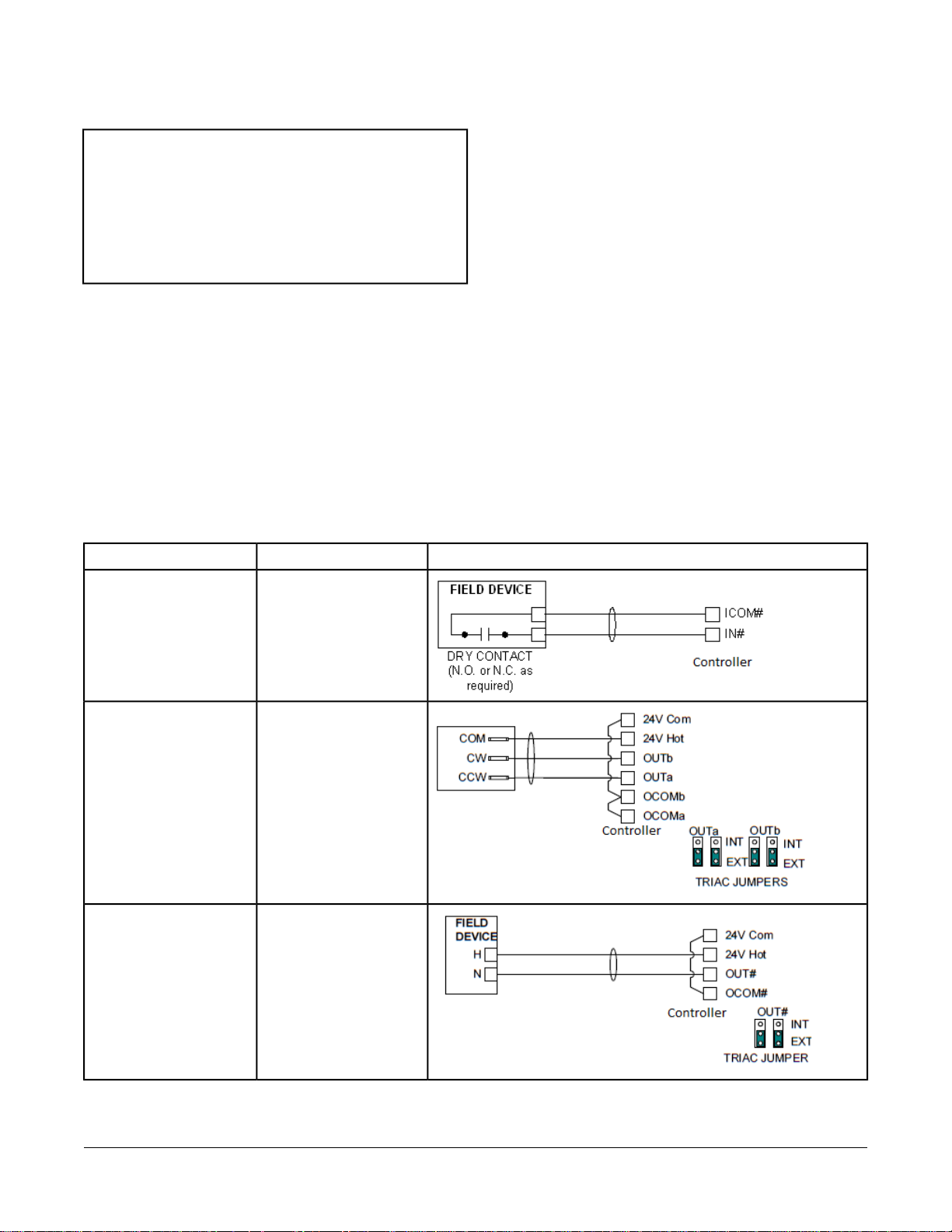

Table 2: Termination Details

Termination DiagramsType of Input/OutputType of Field Device

BIDry Contact (Binary

Input)

Actuator (Switch Low,

Externally Sourced)

(Switch Low, Externally

Sourced)

BOIncremental Control to

BO24 VAC Binary Output

6FX-PCX3731 Input/Output Module Installation Instructions

Page 7

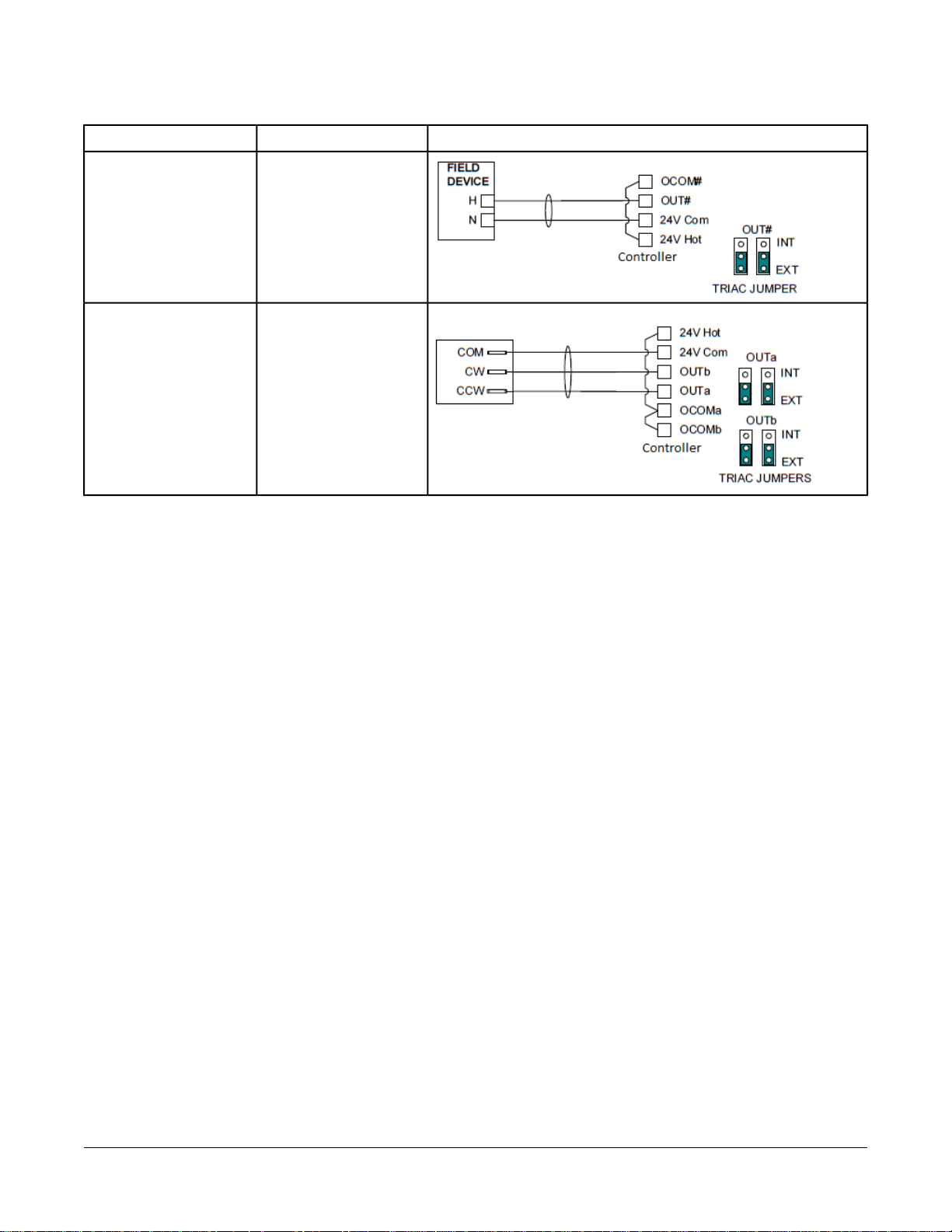

Table 2: Termination Details

BO24 VAC Binary Output

(Switch High, Externally

Sourced)

BOIncremental Control to

Actuator (Switch High,

Externally Sourced)

Termination DiagramsType of Input/OutputType of Field Device

Terminal Wiring Guidelines, Functions, Ratings, and Requirements

Input and Output Wiring Guidelines

Table 3 provides information and guidelines about the

functions, ratings, and requirements for the controller

input and output terminals; and references guidelines for

determining proper wire sizes and cable lengths.

In addition to the wiring guidelines in Table 3, observe

these guidelines when wiring controller inputs and

outputs:

• Run all low-voltage wiring and cables separate from

high-voltage wiring.

• All input and output cables, regardless of wire size or

number of wires, should consist of stranded, insulated,

and twisted copper wires.

• Shielded cable is not required for input or output

cables.

• Shielded cable is recommended for input and output

cables that are exposed to high electromagnetic or

radio frequency noise.

• Inputs/outputs with cables less than 30 m (100 ft)

typically do not require an offset in the software setup.

Cable runs over 30 m (100 ft) may require an offset

in the input/output software setup.

7FX-PCX3731 Input/Output Module Installation Instructions

Page 8

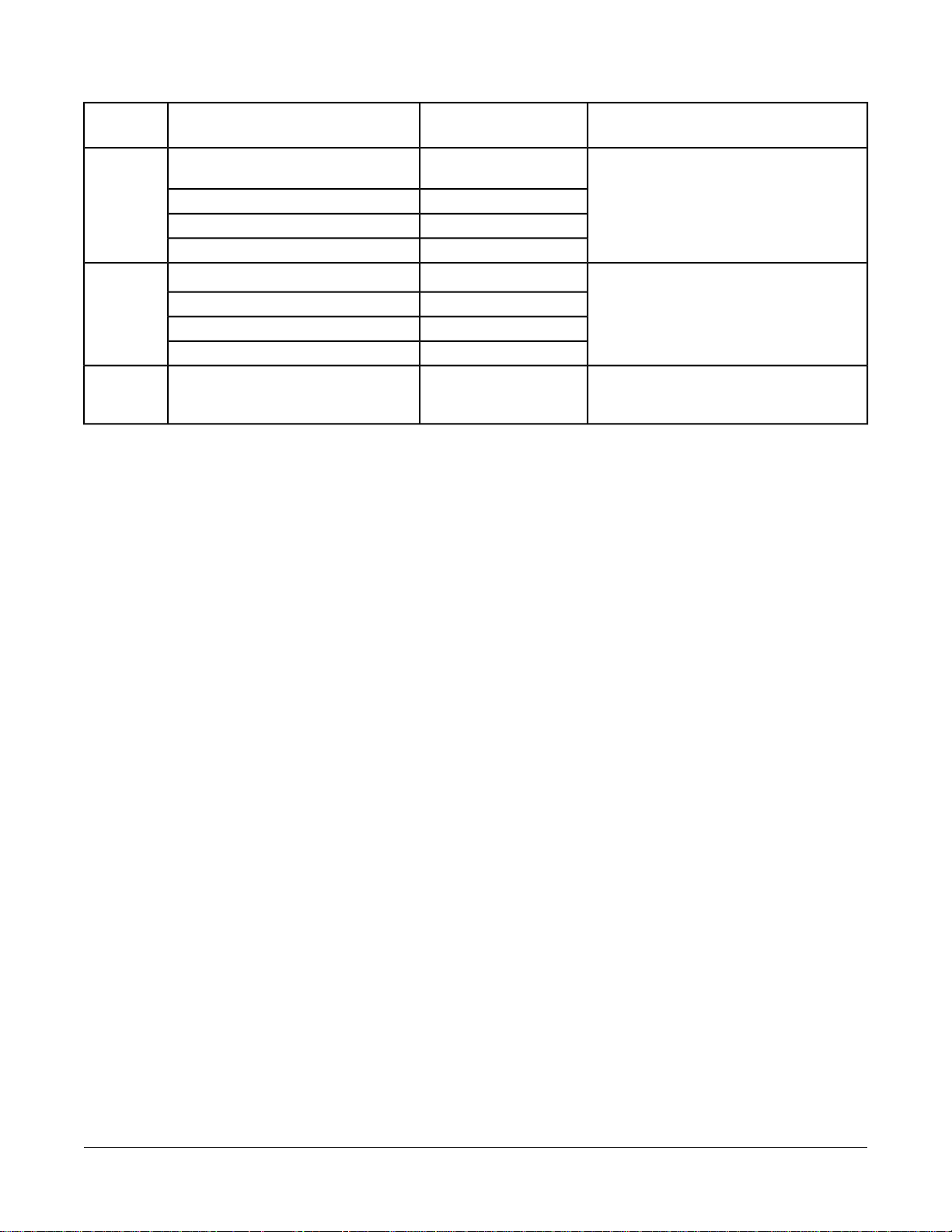

Table 3: FX-PCX3731 Terminal Blocks, Functions, Ratings, Requirements, and Cables

Terminal Block

Label

BINARY INPUT

BINARY

OUPUT(External

Power Source Only)

BINARY

OUPUT(Internal

Power Source Only)

Label

IN n

ICOM n

OUTn

OCOMn

OUTn

OCOMn

Function, Ratings, RequirementsTerminal

Binary Input - Dry Contact Maintained Mode

0.01 second minimum pulse width Internal 18 V, 3k ohm

pull up

Binary Input - Pulse Counter/Accumulator Mode

0.01 second minimum pulse width

(50 Hz at 50% duty cycle)

Internal 18 V, 3k ohm pull up

Binary Input Common for all Binary Input (IN) terminals

Note: All Binary ICOMn terminals share a common, which

is isolated from all other commons, except the

Configurable Output (CO) common (OCOMn) when

the CO is defined as an Analog Output.

Binary Output - 24 VAC Triac (External Power)

Connects OUTn to OCOMn when activated.

External Power Source Requirements:

30 VAC maximum output voltage

0.5 A maximum output current

1.3 A at 25% duty cycle

40 mA minimum load current

Binary Output Common (for OUTn terminal)

Note: Each Binary Output common terminal (OCOMn) is

isolated from all other commons, including other

Binary Output commons.

Binary Output - 24 VAC Triac (Internal Power)

Sources internal 24 VAC power (24~ HOT)

Binary Output - 24 VAC Triac (Internal Power)

Connects OCOMn to 24~ COM when activated.

Internal Power Source:

30 VAC maximum voltage to load

0.5 A maximum output current

1.3 A at 25% duty cycle

40 mA minimum load current

Determine Wire Size and

Maximum Cable Length

See Guideline A in Table 4

See Guideline C in Table 4

See Guideline C in Table 4

1

1

See Table 4 to determine wire size and cable lengths for cables.

Cable and Wire Length Guidelines

Table 4 defines cable length guidelines for the various

wire sizes that may be used for wiring low-voltage (<30V)

input and outputs.

8FX-PCX3731 Input/Output Module Installation Instructions

Page 9

Table 4: Cable Length Guidelines for Recommended Wire Sizes for Low-Voltage (<30V) Inputs and Outputs

Wire Size/Gauge and TypeGuideline

AssumptionsMaximum Cable

Length and Type

A

B

C

1.5 mm2(18 AWG) stranded copper

1.5 mm2(18 AWG) stranded copper

See Figure 8 to select wire size/gauge.

Use stranded copper wire

457 m (1,500 ft) twisted

wire

297 m (975 ft) twisted wire0.8 mm (20 AWG) stranded copper

183 m (600 ft) twisted wire0.6 mm (22 AWG) stranded copper

107 m (350 ft) twisted wireN/A (24 AWG) stranded copper

229 m (750 ft) twisted wire

137 m (450 ft) twisted wire0.8 mm (20 AWG) stranded copper

91 m (300 ft) twisted wire0.6 mm (22 AWG) stranded copper

61 m (200 ft) twisted wireN/A (24 AWG) stranded copper

See Figure 8 to determine

cable length. Use twisted

wire cable.

100 mV maximum voltage drop

Depending on cable and the connected input

or output device, you may have to define an

offset in the setup software for the input or

output point.

100 mV maximum voltage drop

Depending on cable and the connected input

or output device, you may have to define an

offset in the setup software for the input or

output point.

N/A

9FX-PCX3731 Input/Output Module Installation Instructions

Page 10

Maximum Cable Length versus Load Current

Figure 8: Maximum Wire Length for Low-Voltage (<30V) Inputs and Outputs by Current and Wire Size

Use Figure 8 to estimate the maximum cable length

relative to the wire size and the load current (in mA) when

wiring inputs and outputs.

Note: Figure 8 applies to low-voltage (<30V) inputs and

outputs only.

SA/FC Bus and Supply Power Wiring Guidelines

Table 5 provides information about the functions, ratings,

and requirements for the controller communication bus

and supply power terminals; and guidelines for wire sizes,

cable types, and cable lengths when wiring the controller

communication buses and supply power.

In addition to the guidelines in Table 5, observe these

guidelines when wiring an SA or FC bus and the 24 VAC

supply power:

• Run all low-voltage wiring and cables separate from

high-voltage wiring.

• All SA and FC bus cables, regardless of wire size,

should be twisted, insulated, stranded copper wire.

• Shielded cable is strongly recommended for all SA

and FC bus cables.

•

Refer to the FX-PC Series Controller MS/TP

Communication Bus Technical Bulletin

(LIT-12011670) for detailed information regarding

wire size and cable length requirements for the SA

and FC buses.

10FX-PCX3731 Input/Output Module Installation Instructions

Page 11

Table 5: Communications Bus and Supply Power Terminal Blocks, Functions, Ratings, Requirements, and

Cables

Terminal

Block/Port Label

FCBUS

or

SABUS

SA/FC BUS

(Port)

2

2

2

Labels

-

COM

SHLD

or

SAPWR

HOT24~

COM

Function, Electrical Ratings/RequirementsTerminal

FC or SA Bus Communications+

Signal Reference (Common) for FC or SA Bus

communications

SHLD on FC Bus: Isolated terminal (optional shield drain

connection

SAP WR on SA Bus: 15 VDC power lead connection

RJ-12 6-Position Modular Connector provides:

FC or SA Bus Communications

FC or SA Bus Signal Reference and 15 VDC Common

Commissioning Converter or an FX-ZFR 1811 Wireless

Router

(Maximum total current draw for SA Bus is 240 mA.)

24 VAC Power Supply - Hot

Supplies 20-30 VAC (Nominal 24 VAC)

24 VAC Power Supply - Common

(Isolated from all other Common terminals on controller.)

Recommended Cable Type

FC Bus: 0.6 mm (22 AWG)

stranded, 3-wire twisted, shielded

cable recommended.

SA Bus: 0.6 mm (22 AWG)

stranded, 4-wire (2 twisted-pairs),

shielded cable recommended.

Note: On the SA Bus, the + and -

wire are one twisted pair,

and the COM and SA PWR

are the second twisted pair

of wires.

Bluetooth Commissioning Converter

retractable cable or 24 AWG 3-pair

CAT 3 Cable <30.5 m (100 ft)

0.8 mm to 1.5 mm

(18 AWG) 2-wire

2

1

1

See Table 4 to determine wire size and cable lengths for cables.

2 The SA Bus and FC Bus wiring recommendations in this table are for MS/TP bus communications at 38,400 baud. For more

information, refer to the FX-PC Series Controller MS/TP Communications Bus Technical Bulletin (LIT-12011670).

Setup and Adjustments

Figure 9: Device Address DIP Switch Block Set to

Address 21

Setting the Device Addresses

FX-PCX controllers are master devices on MS/TP (SA

or FC) buses. Before operating controllers on a bus, you

must set a valid and unique device address for each

controller on the bus. You set a controller's device

address by setting the positions of the switches on the

DIP switch block at the top of the controller (Figure 3).

Device addresses 4 through 127 are the valid addresses

for these controllers.

The DIP switch block has eight switches numbered 128,

64, 32, 16, 8, 4, 2, and 1. Switches 64 through 1 are

device address switches. Switch 128 is a mode switch

that enables a controller to operate on an FX-ZFR Series

Wireless Field Bus. Switch 128 must be set to off for all

hard-wired SA and FC bus applications. Set switch 128

to ON for wireless FC bus applications only.

Note: All FX-PC series devices ship with switch 128 ON

and the remaining address switches off rendering

the controllers wired slave devices, which do not

operate on MS/TP buses, but will not interfere

with bus operation. Set a valid and unique device

address on the controller before applying power

to the controller on the bus.

To set the device addresses on FX-PCX controllers:

11FX-PCX3731 Input/Output Module Installation Instructions

Page 12

1. Set all of the switches on the address DIP switch

block (128 through 1) to off.

2. Set one or more of the seven address switches (64

though 1) to ON, so that the sum of the switch

numbers set to ON equals the intended device

address. See Table 6 for valid device addresses.

Set the highest number switch that is less than or

equal to the intended device address to ON. Then

continue setting lower numbered switches until the

total equals the intended address. For example, if the

intended device address is 21, set switch 16 to ON

first, then set switch 4 ON, followed by switch 1

(16+4+1= 21).

3. Set switch 128 to ON only for controllers on an

FX-ZFR Series Wireless Field Bus application. For

all hard-wired SA and FC bus applications, ensure

that switch 128 is set to off.

Note: Do not connect a controller with switch 128

set to ON to an active (hard-wired) SA or FC

bus. When a controller with switch 128 set to

ON and a device address from 4 to 127 is

connected to a wired field bus, the entire field

bus is rendered inoperable until the controller

is disconnected or switch 128 is set to off.

Refer to the FX-ZFR Series Wireless Bus System

Technical Bulletin (LIT-12011660) for more

information on device addresses in wireless

applications.

4. Set a unique and sequential device address for each

of the controllers connected on the SA or FC bus

starting with device address 4.

Table 6: SA/FC Bus Device Address Descriptions

Use on DescriptionDevice

Address

0

(Switch

128 Off)

1 to 3

(Switch

128 Off)

4 to 127

(Switch

128 Off)

0 to 3

(Switch

128 ON)

4 to 127

(Switch

128 ON)

Reserved for FC Bus Supervisory Controller

(not for use on controllers).

Reserved for peripheral devices (not for use

on controllers).

Used for MS/TP master devices (controllers)

that are hardwired to an SA Bus or FC Bus.

Reserved addresses for wired slave devices

(not for use on controllers).

Note: FX-PCX controllers ship with switch

128 ON and the remaining address

switches off rendering the controllers

wired slave devices, which do not

operate on MS/TP buses.

Valid for MS/TP Master controllers on wireless

FC Buses only.

Note: Do not connect a controller with

switch 128 ON to an active

(hard-wired) SA or FC bus. When a

controller with switch 128 ON and a

device address from 4 to 127 is

connected to a wired field bus, the

entire field bus is rendered inoperable

until the controller is disconnected or

switch 128 is set to off.

To ensure the best bus performance, set sequential

device addresses with no gaps in the device address

range (4, 5, 6, 7, 8, 9, and so on). The controllers do

not need to be physically connected on the bus in

their numerical device address order.

5. Write each controller's device address on the white

label below the DIP switch block on the controller's

cover.

Refer to the FX-PC Series Controllers MS/TP

Communications Bus Technical Bulletin

(LIT-12011670) for more information on controller

device addresses and how to set them on MS/TP

buses.

Removing the Controller Cover

Important: Electrostatic discharge can damage

controller components. Use proper

electrostatic discharge precautions during

installation, setup, and servicing to avoid

damaging the controller.

Important: Disconnect all the power sources to the

controller before removing cover and

changing the position of any jumper or the

EOL switch on the controller. Failure to

disconnect power before changing a jumper

or EOL switch position can result in damage

to the controller and void any warranties.

The controller cover is held in place by four plastic latches

that extend from the base and snap into slots on the

inside of the housing cover.

To remove the controller cover:

12FX-PCX3731 Input/Output Module Installation Instructions

Page 13

1. Place your fingernails under the two cover lift tabs

(Figure 3) on the sides of the housing cover and

gently pry the top of the cover away from the base to

release the cover from the two upper latches.

2. Pivot the top of the cover further to release it from the

lower two latches.

3. Replace the cover by placing it squarely over the

base, and then gently and evenly push the cover on

to the latches until they snap into the latched position.

Figure 10: FX-PCX3731 with Cover Removed Showing

EOL Switch Location

The BO source power selection jumpers determine

whether a BO provides internal power (sourced from the

controller) to the output load (INT position) or requires

an external power source (EXT position) for the output

load. Figure 11 shows an example of a controller BOs

and the associated power selection jumpers to the right

of the BOs terminal block.

Figure 11: Example Binary Outputs and the

Associated Source Power Jumper Positions

Binary Output (BO) Source Power Selection Jumpers

Risk of Electric Shock: Disconnect supply power to

the controller before attempting to adjust the Binary

Output Source Power Selection Jumpers. Failure to

disconnect the supply power may result in electric shock.

Mise En Garde: Risque de décharge électrique:

Débrancher l'alimentation de l'controller avant tout

réglage du Binary Output Source Power Selection

Jumpers. Le non-respect de cette précaution risque de

provoquer une décharge électrique.

Important: Do not connect an external power source

to a BO when the BO power source jumper

is in the internal power (INT) position.

Connecting external power to a BO that

sources internal power can damage the

controller and void any warranties.

Setting the End-of-Line (EOL) Switch

Each controller has an EOL switch, which, when set to

ON, sets the controller as a terminating device on the

bus. See Figure 10 for the EOL switch location. The

default EOL switch position is Off.

Figure 12: End-of-Line Switch Positions

To set the EOL switch on a controller:

1. Determine the physical location of the controller on

the SA or FC bus.

2. Determine if the controller must be set as a

terminating device on the bus.

13FX-PCX3731 Input/Output Module Installation Instructions

Page 14

Note: The EOL termination rules for SA buses and

FC buses are different. Refer to the FX-PC

Series Controllers MS/TP Communications

Bus Technical Bulletin (LIT-12011670) for

detailed information regarding EOL termination

rules and EOL switch settings on SA and FC

buses.

3. If the controller is a terminating device on the FC bus,

set the EOL switch to ON. If the controller is not a

terminating device on the bus, set the EOL switch to

Off.

When a controller is connected to power with its EOL

switch set to ON, the amber EOL LED on the

controller cover is lit.

Table 7: Status LEDs and Descriptions of LED States

LED ColorLED Label

Description of LED StatesNormal LED

State

On SteadyGreenPOWER

Off SteadyRedFAULT

Blink - 2 HzGreenSA/FC BUS

AmberEOL

Off (Except on

terminating

devices)

Off Steady = No Supply Power or the controller’s polyswitch/resettable fuse

is open. Check Output wiring for short circuits and cycle power to controller.

On Steady = Power Connected

Off Steady = No Faults

On Steady = Device Fault; no application loaded; Main Code download

required, if controller is in Boot mode, or a firmware mismatch exists between

the controller and the FX-ZFR1811 Wireless Field Bus Router.

Blink - 2 Hz = Download or Startup in progress, not ready for normal operation

Blink - 2 Hz = Data Transmission (normal communication)

Off Steady = No Data Transmission (N/A - auto baud not supported)

On Steady = Communication lost, waiting to join communication ring

On Steady = EOL switch in ON position

Off Steady = EOL switch in Off position

Commissioning the Controllers

You commission controllers with the FX-PCT software,

either via a Bluetooth Commissioning Converter, a

ZigBee™ wireless dongle, or in BACnet® router mode

when connected to an FX Supervisory Controller. Refer

to the Controller Tool Help (LIT-12011147) for detailed

information on commissioning controllers.

Troubleshooting the Controllers

Observe the Status LEDs on the front of the controller

and see Table 7 to troubleshoot the controller.

Repair Information

If a controller fails to operate within its specifications,

replace the controller. For a replacement controller,

contact your Johnson Controls® representative.

Table 8: Accessories Ordering Information

DescriptionProduct Code Number

Bluetooth Commissioning ConverterFX-BTCVT-1

Local Controller DisplayFX-DIS1710-0

Wireless Field Bus RouterFX-ZFR1811-0

Transformer, 120 VAC Primary to 24 VAC secondary, 20 VA, Wall PlugTP-2420

Y65T31-0

Transformer, 120/208/240 VAC Primary to 24 VAC Secondary, 40 VA, Foot Mount, 8 in. Primary

Leads and Secondary Screw Terminals, Class 2

Note: Additional Y6x-x Series transformers are also available. Refer to the Series Y63, Y64, Y65,

Y66, and Y69 Transformers Product Bulletin (LIT-125755) for more information.

Accessories

See Table 8 for controller accessories ordering

information.

14FX-PCX3731 Input/Output Module Installation Instructions

Page 15

Table 8: Accessories Ordering Information

DescriptionProduct Code Number

Power transformer (Class 2, 24 VAC, 50 VA maximum output), no enclosureAS-XFR050-0

Replacement SA Bus Terminal Blocks, 4-Position, Brown, Bulk PackAP-TBK4SA-0

Replacement FC Bus Terminal Blocks, 4-Position, Blue, Bulk PackAP-TBK4FC-0

Replacement Power Terminal Blocks, 3-Position, Gray, Bulk PackAP-TBK3PW-0

ZFR-USBHA-0

USB Dongle with ZigBee™ Driver provides a wireless connection through FX-PCT to allow wireless

commissioning of the wirelessly enabled FX-PCG, FX-PCA, FX-PCX, and FX-PCV field controllers.

Also allows use of the FX-ZFR Checkout Tool (FX-ZCT) in FX-PCT.

Note: The ZFR-USBHA-0 replaces the IA OEM DAUBI_2400 ZigBee USB dongle. For additional

information on the ZFR-USBHA-0 ZigBee dongle, refer to the FX-ZFR Series Wireless Field

Bus System Technical Bulletin (LIT-12011660) or FX-ZFR Series Wireless Field Bus System

Quick Reference Guide (LIT-12011696).

Technical Specifications

Table 9: FX-PCX3731 Technical Specifications

FX-PCX3731 Expansion Input/Output ModuleProduct Code Number

Supply Voltage

Ambient Conditions

Addressing

Communications Bus

Input and Output Capabilities

Terminations

Mounting

Housing

Dimensions(Height x Width x Depth)

24 VAC (nominal, 20 VAC minimum/30 VAC maximum), 50/60 Hz, power supply

Class 2 (North America), Safety Extra-Low Voltage (SELV) (Europe)

14 VA maximum for FX-PCX3731-0A onlyPower Consumption

Operating: 0 to 50°C (32 to 122°F); 10 to 90% RH noncondensing

Storage: -40 to 80°C (-40 to 176°F); 5 to 95% RH noncondensing

DIP switch set; valid controller device addresses 4–127 (Device addresses 0–3 and

128–255 are reserved and not valid addresses.)

BACnet® MS/TP, RS-485:

3-wire FC bus between the supervisory controller and other controllers

4-wire SA bus between controller, network sensors and other sensor/actuator devices,

includes a lead to source 15 VDC supply power (from controller) to bus devices.

H8SX/166xR Renesas® 32-bit microcontrollerProcessor

640 KB Flash Memory and 128 KB Random Access Memory (RAM)Memory

8 - Binary Inputs: Defined as Dry Contact Maintained or Pulse Counter/Accumulator

Mode

8 - Binary Outputs: Defined as 24 VAC Triac (external source power only)

Input/Output: Fixed Screw Terminal Blocks

SA/FC Bus and Supply Power: 4-Wire and 3-Wire Pluggable Screw Terminal

Blocks

SA/FC Bus Port: RJ-12 6-Pin Modular Jacks

Horizontal on single 35 mm DIN rail mount (preferred), or screw mount on flat surface

with three integral mounting clips on controller

Enclosure material: ABS and polycarbonate UL94 5VB; Self-extinguishing, Plenum

Rated

Protection Class: IP20 (IEC529)

150 x 164 x 53 mm (5-7/8 x 6-1/2 x 2-1/8 in.) including terminals and mounting clips

Note: Mounting space requires an additional 50 mm (2 in.) space on top, bottom

and front face of controller for easy cover removal, ventilation and wire

terminations.

0.5 kg (1.1 lb)Weight

15FX-PCX3731 Input/Output Module Installation Instructions

Page 16

Table 9: FX-PCX3731 Technical Specifications

Compliance

United States: UL Listed, File E107041, CCN PAZX, UL 916, Energy Management

Equipment

FCC Compliant to CFR47, Part 15, Subpart B, Class A

Canada: UL Listed, File E107041, CCN PAZX7 CAN/CSA C22.2 No.205, Signal

Equipment

Industry Canada Compliant, ICES-003

Europe: Johnson Controls, Inc. declares that this product is in compliance with the

essential requirements and other relevant provisions of the EMC Directive

2004/108/EC.

Australia and New Zealand: C-Tick Mark, Australia/NZ Emissions Compliant

BACnet International: BACnet Testing Laboratories (BTL) Protocol Revision 4

Listed BACnet Application Specific Controller (B-ASC)

The performance specifications are nominal and conform to acceptable industry standard. For application at conditions

beyond these specifications, consult the local Johnson Controls® office. Johnson Controls, Inc. shall not be liable

for damages resulting from misapplication or misuse of its products.

507 E. Michigan Street, Milwaukee, WI 53202

Metasys® and Johnson Controls® are registered trademarks of Johnson Controls, Inc.

All other marks herein are the marks of their respective owners.© 2014 Johnson Controls, Inc.

Building Efficiency

www.johnsoncontrols.comPublished in U.S.A.

16FX-PCX3731 Input/Output Module Installation Instructions

Loading...

Loading...